Electrochemical Performance of Metal-Free Carbon-Based Catalysts from Different Hydrothermal Carbonization Treatments for Oxygen Reduction Reaction

Abstract

1. Introduction

2. Materials and Methods

2.1. Reagents

2.2. Experimental

2.2.1. T-HTC

2.2.2. MW-HTC

2.2.3. Characterization

- Pure glucose (D-(+)-glucose);

- Carbonaceous nanostructures obtained from 1 M glucose solution using hydrothermal carbonization (T-HTC);

- Carbon nanospheres acquired from 1 M glucose solution by microwave-assisted hydrothermal carbonization (MW-HTC).

3. Results and Discussion

3.1. Synthesis Processes

- Initiation: D-(+)-glucose undergoes hydrolysis in hydrothermal conditions (elevated solvent temperatures at the vessel’s high pressures), driven by hydronium ions from the autoionization of water.

- Production of Soluble Derivatives: The advancing hydrolysis yields different soluble derivatives and various acids. Among these products are fructose, furfurals (such as 5-hydroxymethylfurfural (5 HMF)), carboxylic acids (formic, acetic, levulinic, etc.), and aldehydes (formic, acetic, etc.), while H2, CO2, CO, and various light hydrocarbons (methane, ethane, propane, etc.) can be distinguished in the gaseous phase. The resulting acids, especially those deriving from monosaccharide degradation, serve dual purposes, as they catalyze further reactions and become foundational elements during the latter microstructures’ growth.

- Polymerization: The soluble derivatives enter polymerization reactions through mechanisms like intermolecular dehydration and aldol condensation. Concurrently, there is potential for these polymers to undergo aromatization, resulting in aromatic clusters. When these clusters attain a saturation threshold, they trigger a nucleation event.

- Progressive Growth and Settling: The originating nuclei undergo growth driven by the dehydration of aromatic products. As they grow, their solubility diminishes, making them increasingly hydrophobic and leading them to precipitate.

- Particle Clustering: These hydrophobic particles tend to cluster together, pushing to minimize surface energy. During this phase, carbon-rich spheres separate from the hydrothermal water. The latter development is accentuated by high-temperature processes and alkaline catalysts, while being inhibited by the high concentration of glucose. Once their growth reaches a plateau, the outer surfaces of these microstructures exhibit reactive functional groups, while the inner core is composed of more stable carbon-rich groups.

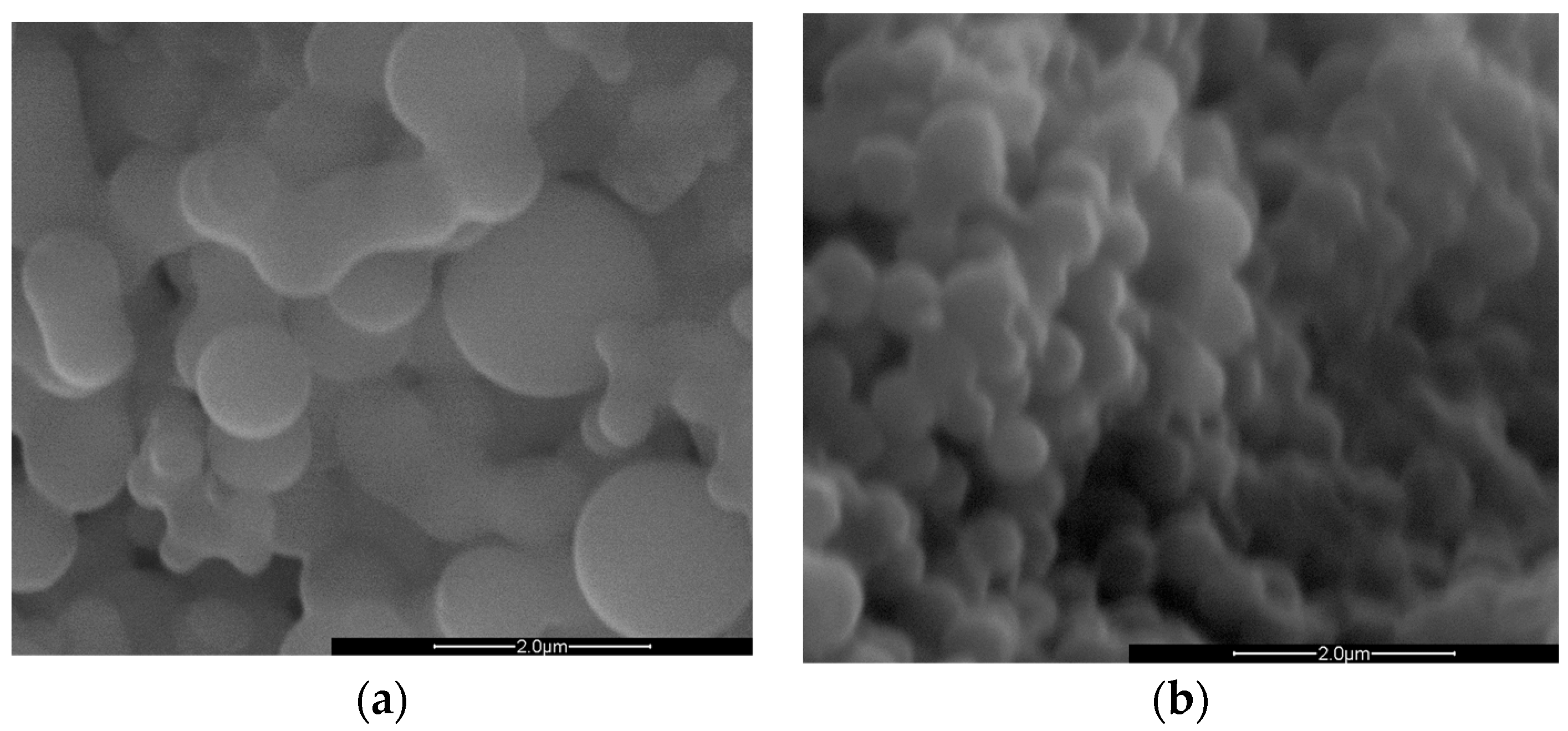

3.2. Physical Characterization

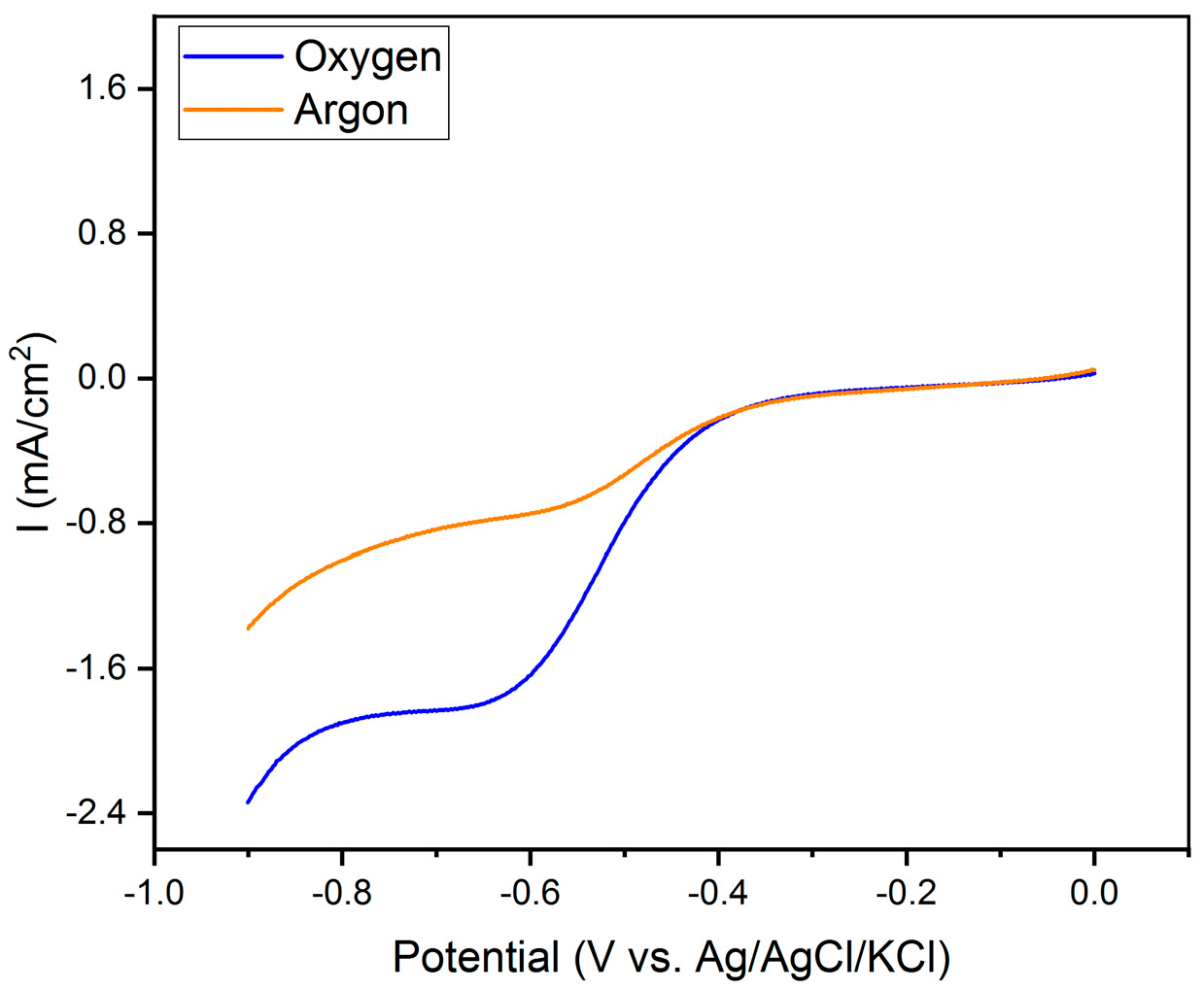

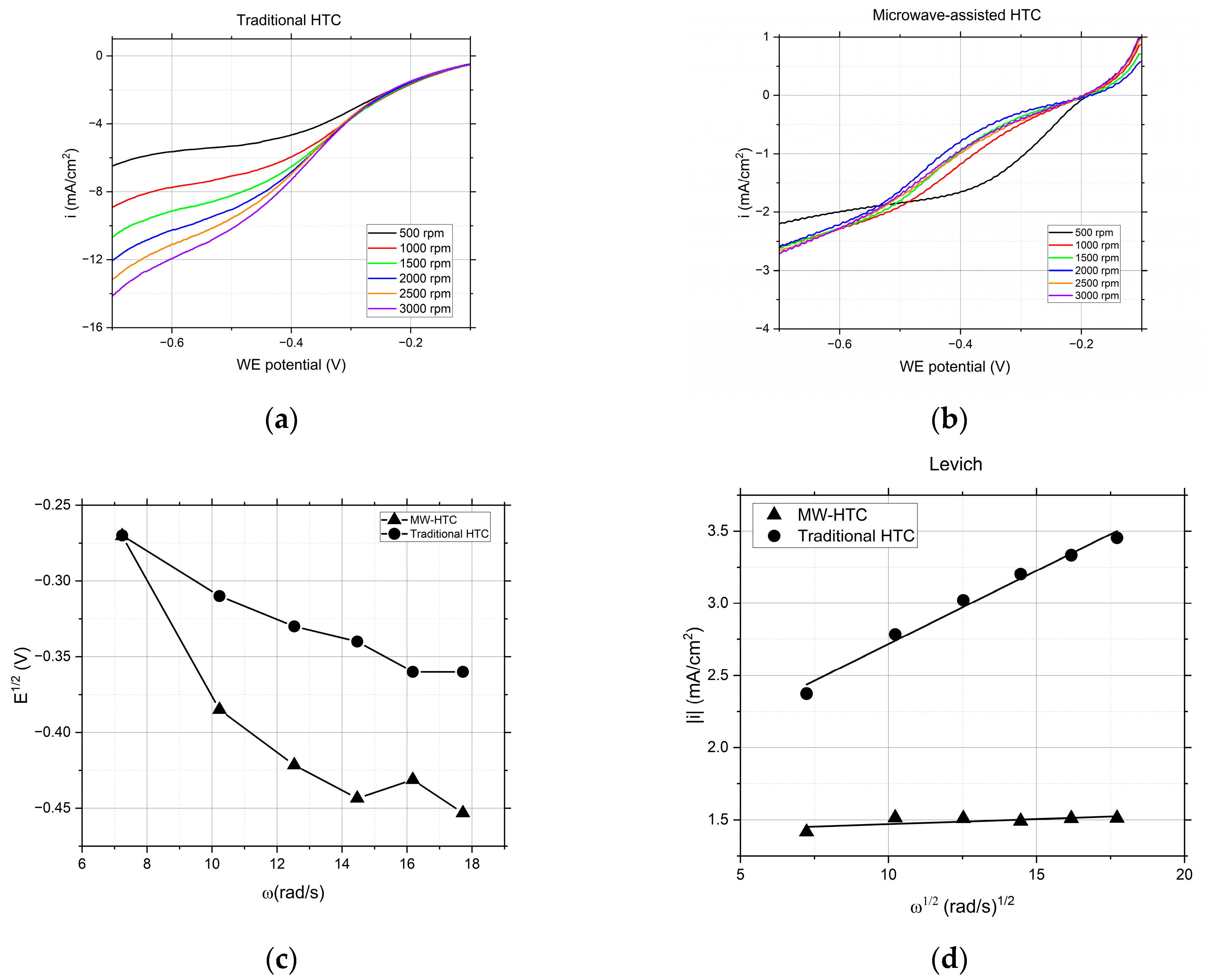

3.3. Electrochemical Characterization

3.4. Infrared Spectroscopic Analysis

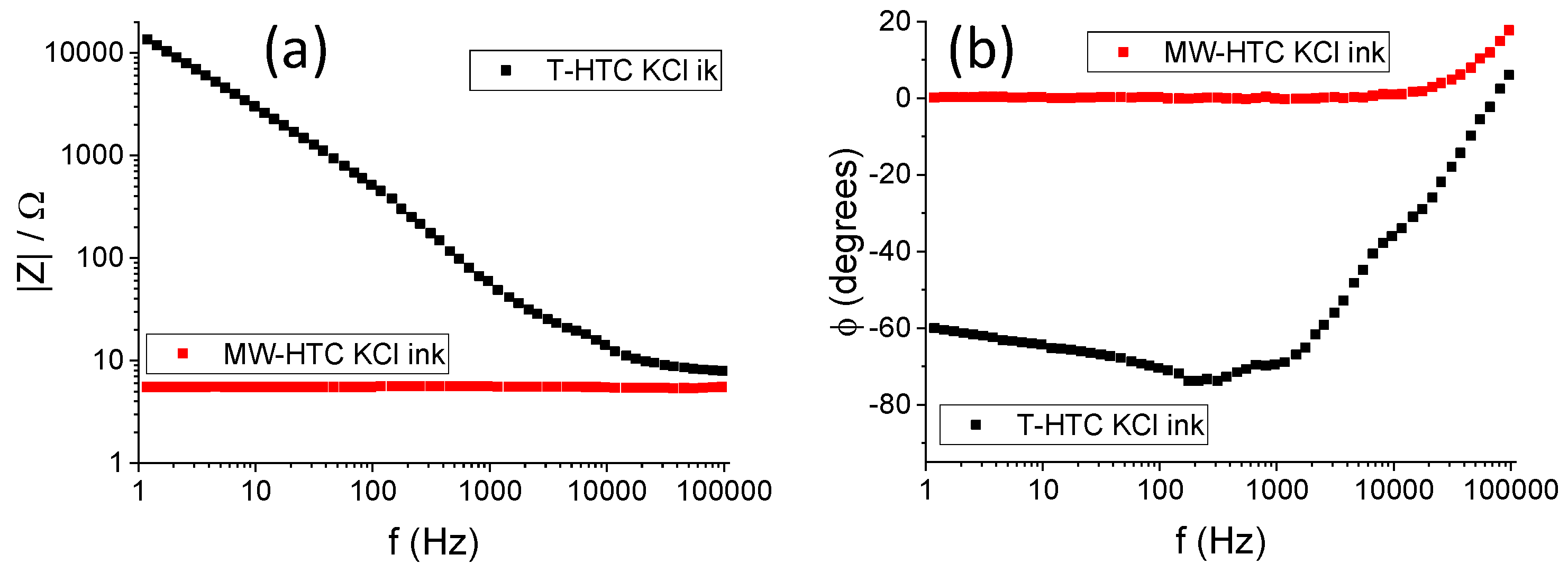

3.5. Electrochemical Impedance Spectra

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Schmidt, T.J.; Stamenkovic, V.; Ross, J.P.N.; Markovic, N.M. Temperature dependent surface electrochemistry on Pt single crystals in alkaline electrolyte. Phys. Chem. Chem. Phys. 2003, 5, 400–406. [Google Scholar] [CrossRef]

- Ramaswamy, N.; Mukerjee, S. Influence of Inner- and Outer-Sphere Electron Transfer Mechanisms during Electrocatalysis of Oxygen Reduction in Alkaline Media. J. Phys. Chem. C 2011, 115, 18015–18026. [Google Scholar] [CrossRef]

- Zhang, L.; Li, H.; Zhang, J. Kinetics of oxygen reduction reaction on three different Pt surfaces of Pt/C catalyst analyzed by rotating ring-disk electrode in acidic solution. J. Power Sources 2014, 255, 242–250. [Google Scholar] [CrossRef]

- Pegis, M.L.; Wise, C.F.; Martin, D.J.; Mayer, J.M. Oxygen Reduction by Homogeneous Molecular Catalysts and Electrocatalysts. Chem. Rev. 2018, 118, 2340–2391. [Google Scholar] [CrossRef] [PubMed]

- Yu-Wu, Q.M.; Weiss-Hortala, E.; Barna, R. Hydrothermal conversion of glucose in multiscale batch processes. Analysis of the gas, liquid and solid residues. J. Supercrit. Fluids 2013, 79, 76–83. [Google Scholar] [CrossRef][Green Version]

- Tovar-Martinez, E.; Sanchez-Rodriguez, C.E.; Sanchez-Vasquez, J.D.; Reyes-Reyes, M.; López-Sandoval, R. Synthesis of carbon spheres from glucose using the hydrothermal carbonization method for the fabrication of EDLCs. Diam. Relat. Mater. 2023, 136, 110010. [Google Scholar] [CrossRef]

- Zhang, W.; Li, J.; Wei, Z. Carbon-based catalysts of the oxygen reduction reaction: Mechanistic understanding and porous structures. Chin. J. Catal. 2023, 48, 15–31. [Google Scholar] [CrossRef]

- Guo, S.; Xiao, W.; Zhao, D.; Liu, Z.; Liu, L.; Xu, D.; Li, X.; Li, G. Water-catalyzed conversion of glucose to small molecules during hydrothermal carbonization: A density functional theory study. Sustain. Energy Fuels 2023, 7, 1322–1332. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, C.; Meng, T.; Pu, Z.; Jin, H.; He, D.; Zhang, J.; Mu, S. Iron oxide and phosphide encapsulated within N,P-doped microporous carbon nanofibers as advanced tri-functional electrocatalyst toward oxygen reduction/evolution and hydrogen evolution reactions and zinc-air batteries. J. Power Sources 2019, 413, 367–375. [Google Scholar] [CrossRef]

- Yang, W.; Dong, Y.; Li, J.; Fu, Q.; Zhang, L. Templating synthesis of hierarchically meso/macroporous N-doped microalgae derived biocarbon as oxygen reduction reaction catalyst for microbial fuel cells. Int. J. Hydrog. Energy 2021, 46, 2530–2542. [Google Scholar] [CrossRef]

- He, Q.; Li, J.; Qiao, Y.; Zhan, S.; Zhou, F. Investigation of two-electron ORR pathway of non-metallic carbon-based catalysts with P-C bond structure in Cl—Bearing electrolytes. Appl. Catal. B Environ. 2023, 339, 123087. [Google Scholar] [CrossRef]

- Morvillo, P.; Diana, R.; Fontanesi, C.; Ricciardi, R.; Lanzi, M.; Mucci, A.; Tassinari, F.; Schenetti, L.; Minarini, C.; Parenti, F. Low band gap polymers for application in solar cells: Synthesis and characterization of thienothiophene-thiophene copolymers. Polym. Chem. 2013, 5, 2391–2400. [Google Scholar] [CrossRef]

- Bruno, C.; Paolucci, F.; Marcaccio, M.; Benassi, R.; Fontanesi, C.; Mucci, A.; Parenti, F.; Preti, L.; Schenetti, L.; Vanossi, D. Experimental and Theoretical Study of the p- and n-Doped States of Alkylsulfanyl Octithiophenes. J. Phys. Chem. B 2010, 114, 8585–8592. [Google Scholar] [CrossRef] [PubMed]

- Marcaccio, M.; Paolucci, F.; Fontanesi, C.; Fioravanti, G.; Zanarini, S. Electrochemistry and spectroelectrochemistry of polypyridine ligands: A theoretical approach. Inorganica Chim. Acta 2007, 360, 1154–1162. [Google Scholar] [CrossRef]

- Fontanesi, C.; Capua, E.; Paltiel, Y.; Waldeck, D.H.; Naaman, R. Spin-Dependent Processes Measured without a Permanent Magnet. Adv. Mater. 2018, 30, 1707390. [Google Scholar] [CrossRef] [PubMed]

- Mtangi, W.; Kiran, V.; Fontanesi, C.; Naaman, R. Role of the Electron Spin Polarization in Water Splitting. J. Phys. Chem. Lett. 2015, 6, 4916–4922. [Google Scholar] [CrossRef] [PubMed]

- Sang, Y.; Tassinari, F.; Santra, K.; Zhang, W.; Fontanesi, C.; Bloom, B.P.; Waldeck, D.H.; Fransson, J.; Naaman, R. Chirality enhances oxygen reduction. Proc. Natl. Acad. Sci. USA 2022, 119, e2202650119. [Google Scholar] [CrossRef]

- Gupta, A.; Sang, Y.; Fontanesi, C.; Turin, L.; Naaman, R. Effect of Anesthesia Gases on the Oxygen Reduction Reaction. J. Phys. Chem. Lett. 2023, 14, 1756–1761. [Google Scholar] [CrossRef]

- Ischia, G.; Cutillo, M.; Guella, G.; Bazzanella, N.; Cazzanelli, M.; Orlandi, M.; Miotello, A.; Fiori, L. Hydrothermal carbonization of glucose: Secondary char properties, reaction pathways, and kinetics. Chem. Eng. J. 2022, 449, 137827. [Google Scholar] [CrossRef]

- Ischia, G.; Fiori, L. Hydrothermal Carbonization of Organic Waste and Biomass: A Review on Process, Reactor, and Plant Modeling. Waste Biomass Valorizat. 2021, 12, 2797–2824. [Google Scholar] [CrossRef]

- Kumar, A.; Saini, K.; Bhaskar, T. Hydochar and biochar: Production, physicochemical properties and techno-economic analysis. Bioresour. Technol. 2020, 310, 123442. [Google Scholar] [CrossRef] [PubMed]

- Elaigwu, S.E.; Greenway, G.M. Chemical, structural and energy properties of hydrochars from microwave-assisted hydrothermal carbonization of glucose. Int. J. Ind. Chem. 2016, 7, 449–456. [Google Scholar] [CrossRef]

- Abdulwali, N.; Van Der Zalm, J.; Thiruppathi, A.R.; Khaleel, A.; Chen, A. Microwave-assisted green synthesis of monodispersed carbon micro-spheres and their antibacterial activity. Appl. Surf. Sci. 2024, 642, 158579. [Google Scholar] [CrossRef]

- Seven, E.S.; Kirbas Cilingir, E.; Bartoli, M.; Zhou, Y.; Sampson, R.; Shi, W.; Peng, Z.; Ram Pandey, R.; Chusuei, C.C.; Tagliaferro, A.; et al. Hydrothermal vs microwave nanoarchitechtonics of carbon dots significantly affects the structure, physicochemical properties, and anti-cancer activity against a specific neuroblastoma cell line. J. Colloid Interface Sci. 2023, 630, 306–321. [Google Scholar] [CrossRef] [PubMed]

- Poerschmann, J.; Weiner, B.; Koehler, R.; Kopinke, F.-D. Hydrothermal Carbonization of Glucose, Fructose, and Xylose—Identification of Organic Products with Medium Molecular Masses. ACS Sustain. Chem. Eng. 2017, 5, 6420–6428. [Google Scholar] [CrossRef]

- Peng, J.; Kang, X.; Zhao, S.; Zhao, P.; Ragauskas, A.J.; Si, C.; Xu, T.; Song, X. Growth mechanism of glucose-based hydrochar under the effects of acid and temperature regulation. J. Colloid Interface Sci. 2023, 630, 654–665. [Google Scholar] [CrossRef] [PubMed]

- Smith, B.C. An IR Spectral Interpretation Potpourri: Carbohydrates and Alkynes. Spectroscopy 2017, 32, 18–24. [Google Scholar]

- Bilba, K.; Ouensanga, A. Fourier transform infrared spectroscopic study of thermal degradation of sugar cane bagasse. J. Anal. Appl. Pyrolysis 1996, 38, 61–73. [Google Scholar] [CrossRef]

- Ibrahim, M.; Alaam, M.; El-Haes, H.; Jalbout, A.F.; de Leon, A. Analysis of the structure and vibrational spectra of glucose and fructose. Eclética Quím. 2006, 31, 15–21. [Google Scholar] [CrossRef]

- Nafar, A. Rapid Green Biosynthesis and Characterization of Silver Nanoparticles Using Glucose as a Green Route. Rev. Roum. Chim. 2019, 64, 409–413. [Google Scholar]

- Fang, Z.; Smith, R.L.; Kozinski, J.A.; Minowa, T.; Arai, K. Reaction of d-glucose in water at high temperatures (410 °C) and pressures (180 MPa) for the production of dyes and nano-particles. J. Supercrit. Fluids 2011, 56, 41–47. [Google Scholar] [CrossRef]

- Li, M.; Li, W.; Liu, S. Hydrothermal synthesis, characterization, and KOH activation of carbon spheres from glucose. Carbohydr. Res. 2011, 346, 999–1004. [Google Scholar] [CrossRef] [PubMed]

| Traditional HTC | MW-HTC | |

|---|---|---|

| Surface average (μm2) | 4.46 | 1.57 |

| Sigma surface (μm2) | 3.70 | 0.40 |

| Form factor average | 1.05 | 1.06 |

| Sigma Form factor | 0.09 | 0.05 |

| Effective Area [mm2] | |||

|---|---|---|---|

| T-HTC at −0.55 V | T-HTC At −0.7 V | MW-HTC at −0.55 V | MW-HTC at −0.7 V |

| 3.32 × 104 | 4.58 × 104 | 2.63 × 102 | 2.54 × 103 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Girimonte, A.; Stefani, A.; Mucci, C.; Giovanardi, R.; Marchetti, A.; Innocenti, M.; Fontanesi, C. Electrochemical Performance of Metal-Free Carbon-Based Catalysts from Different Hydrothermal Carbonization Treatments for Oxygen Reduction Reaction. Nanomaterials 2024, 14, 173. https://doi.org/10.3390/nano14020173

Girimonte A, Stefani A, Mucci C, Giovanardi R, Marchetti A, Innocenti M, Fontanesi C. Electrochemical Performance of Metal-Free Carbon-Based Catalysts from Different Hydrothermal Carbonization Treatments for Oxygen Reduction Reaction. Nanomaterials. 2024; 14(2):173. https://doi.org/10.3390/nano14020173

Chicago/Turabian StyleGirimonte, Aldo, Andrea Stefani, Clara Mucci, Roberto Giovanardi, Andrea Marchetti, Massimo Innocenti, and Claudio Fontanesi. 2024. "Electrochemical Performance of Metal-Free Carbon-Based Catalysts from Different Hydrothermal Carbonization Treatments for Oxygen Reduction Reaction" Nanomaterials 14, no. 2: 173. https://doi.org/10.3390/nano14020173

APA StyleGirimonte, A., Stefani, A., Mucci, C., Giovanardi, R., Marchetti, A., Innocenti, M., & Fontanesi, C. (2024). Electrochemical Performance of Metal-Free Carbon-Based Catalysts from Different Hydrothermal Carbonization Treatments for Oxygen Reduction Reaction. Nanomaterials, 14(2), 173. https://doi.org/10.3390/nano14020173