Simultaneous Effect of Diameter and Concentration of Multi-Walled Carbon Nanotubes on Mechanical and Electrical Properties of Cement Mortars: With and without Biosilica

Abstract

1. Introduction

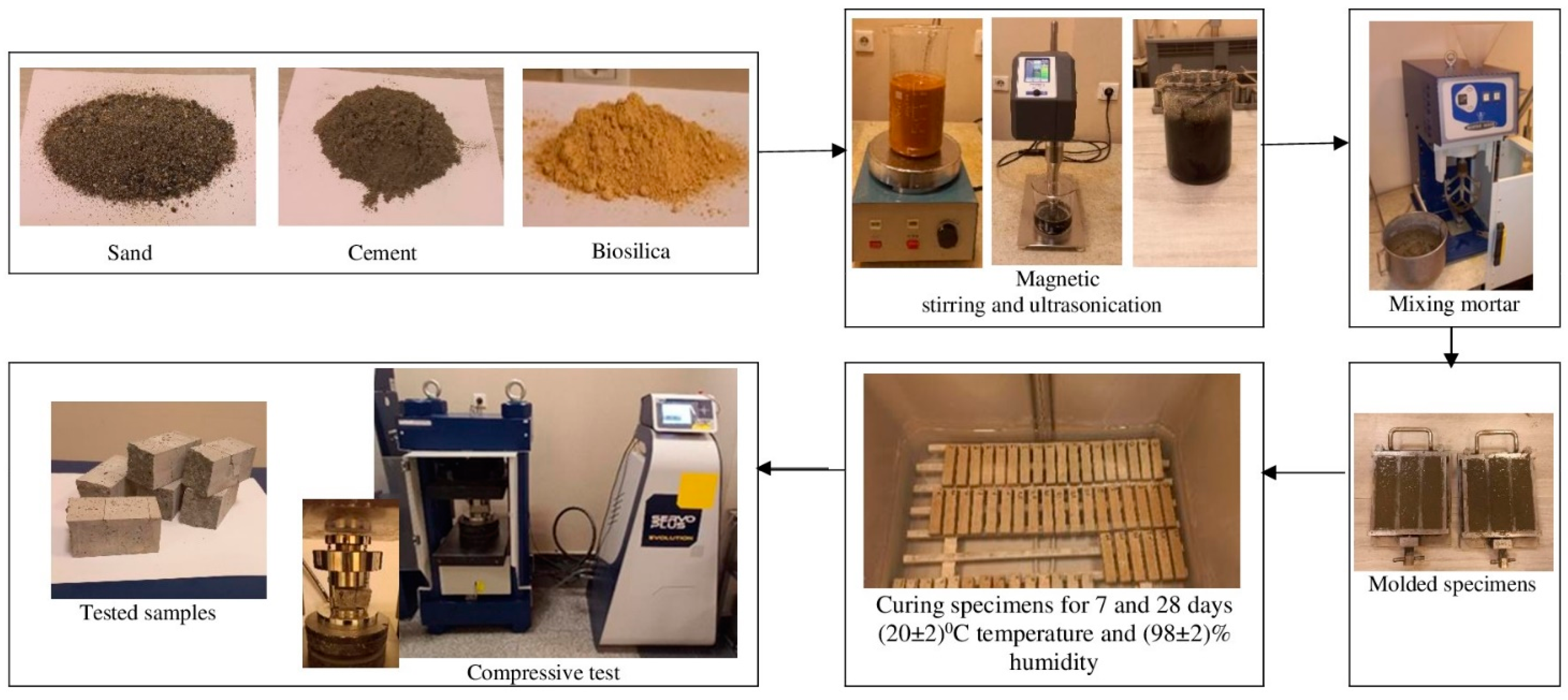

2. Materials and Methods

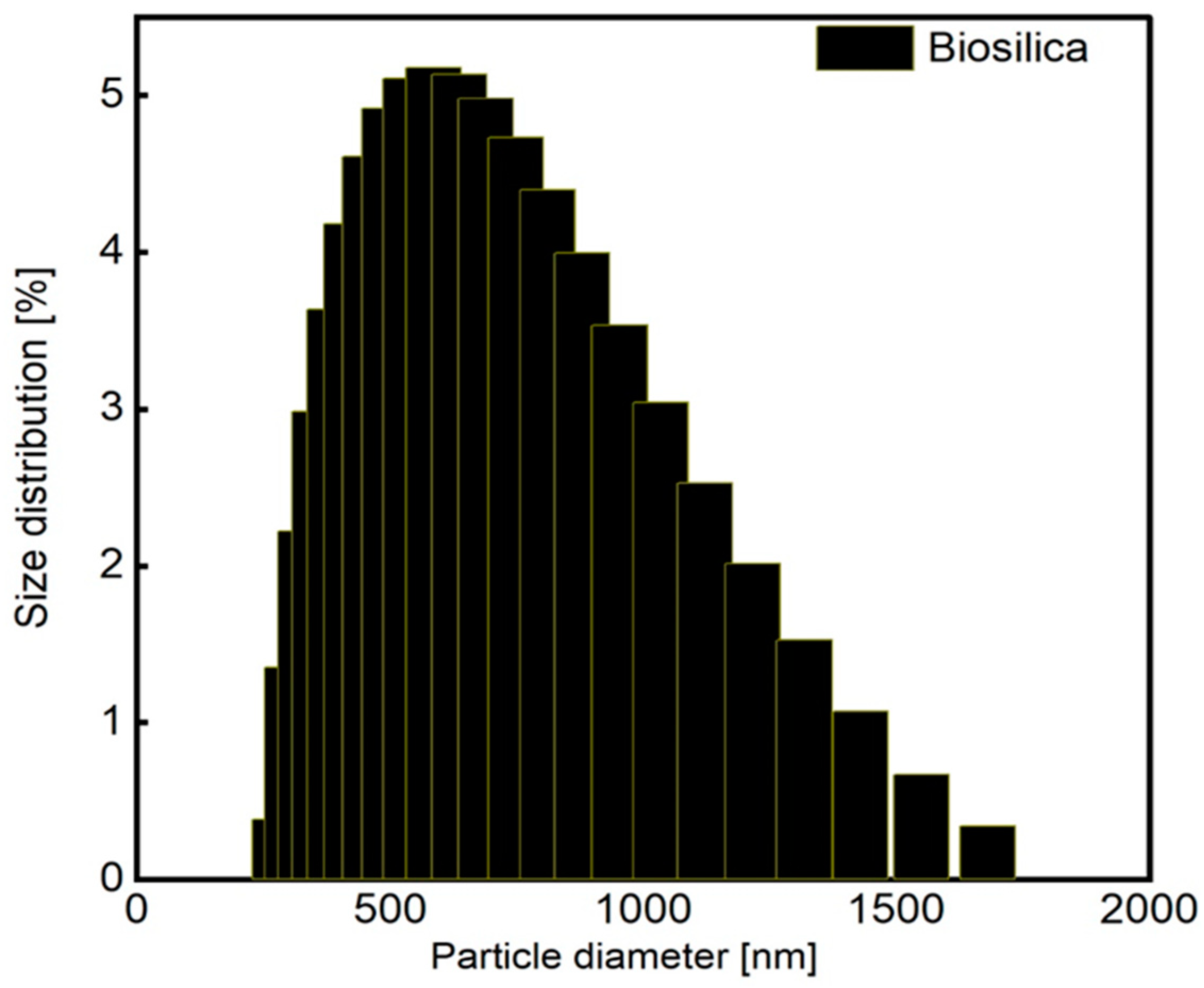

2.1. Materials

2.2. Mixing and Sample Preparation

2.3. Compressive Strength

- where—Rc is the compressive strength, N/mm2;

- Fc—maximum load, N;

- 1600 = (40 mm × 40 mm)—area of slabs, mm2.

2.4. Water Absorbtion

- where—Ww = Weight of the wet cement sample after immersion, g,

- Wd = Weight of the dry cement sample before immersion, g.

2.5. Electrical Properties

3. Results and Discussion

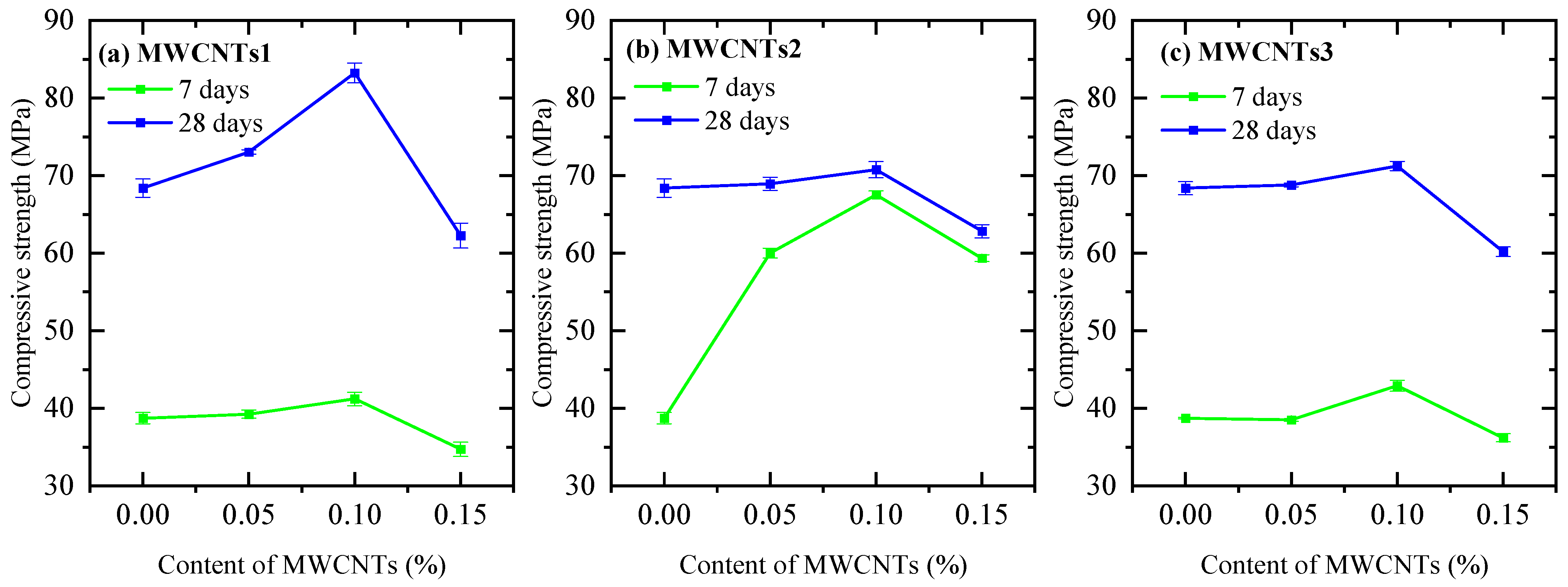

3.1. Mechanical and Physical Properties

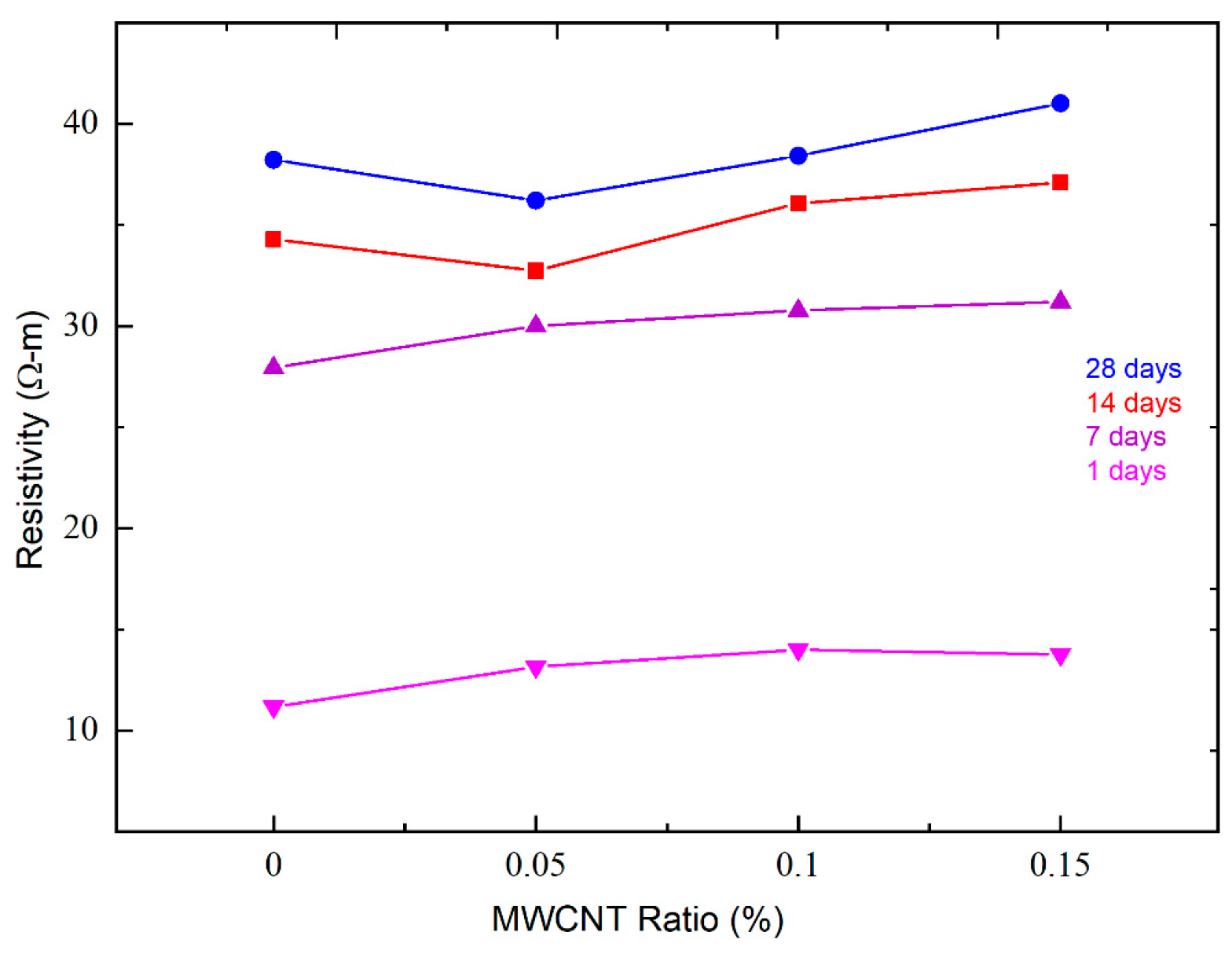

3.2. Bulk Electrical Resistivity

3.3. Cyclic Compressive Tests Results

4. Conclusions

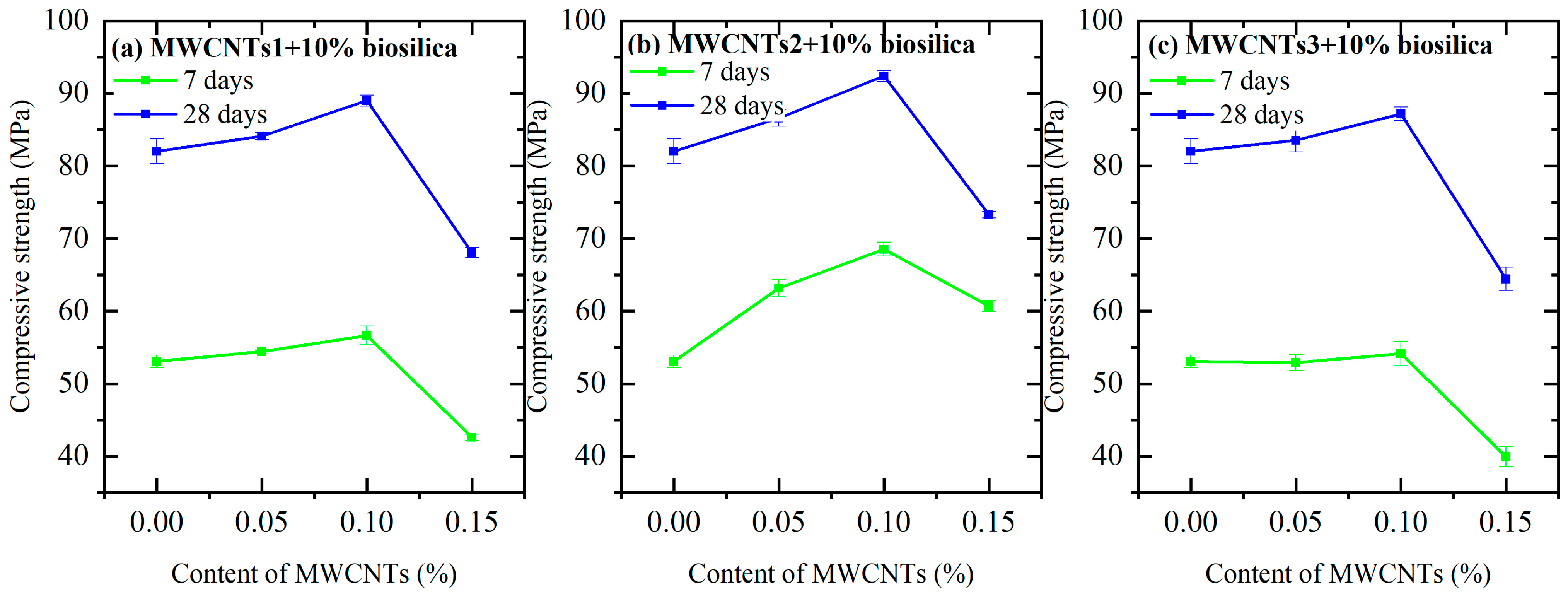

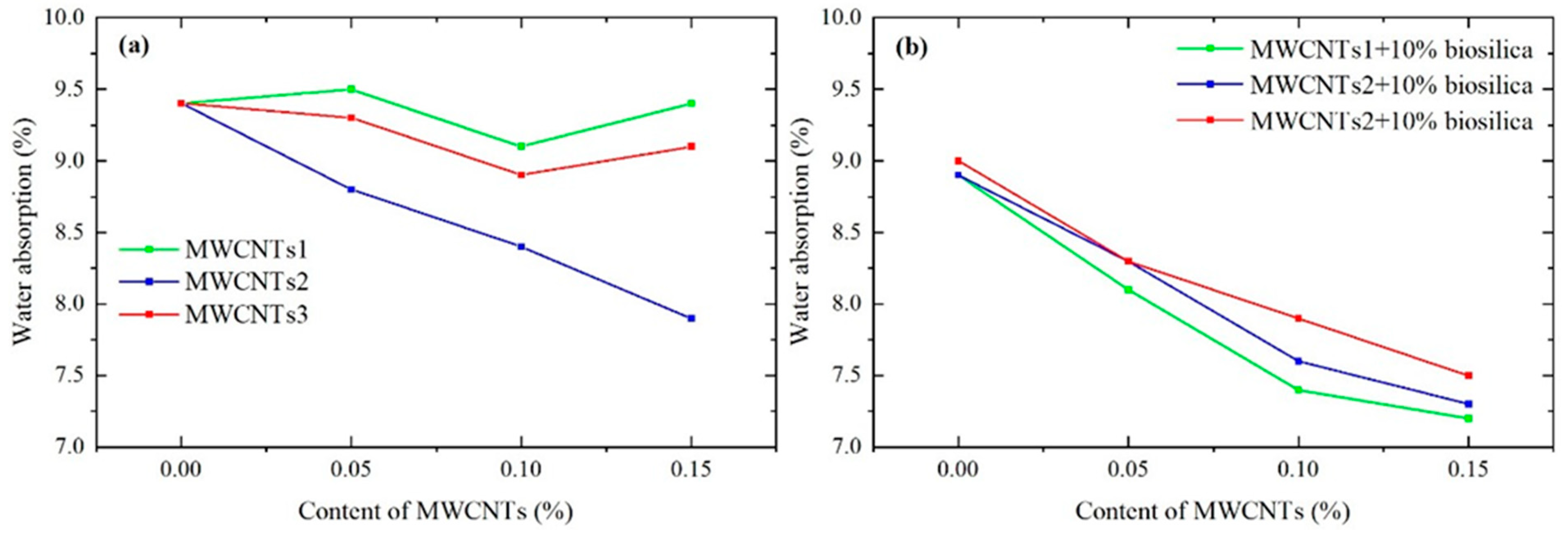

- The 7-day compressive strength of samples prepared without biosilica was as follows: MWCNT1 was 34.7–39.2 MPa, MWCNT2 was 59.3–67.5 MPa, and MWCNT3 was 36.2–42.9 MPa, while the compressive strength of the reference sample was 38.7 MPa. When 10% biosilica was used in the cement mortar formulations, the 7-day compressive strength of the test specimens was as follows: MWCNT1 was 42.6–56.6 MPa, MWCNT2 was 60.7–68.5 MPa, and MWCNT3 was 39.9–54.2 MPa, while the strength of the reference sample was 53.0 MPa.In the results of the 28-day compressive strength test, the following data were obtained:

- -

- Prototypes prepared from MWCNT1 exhibited a strength of 62.2–83.2 MPa.

- -

- Prototypes prepared from MWCNT2 exhibited a strength of 62.8–68.9 MPa.

- -

- Prototypes prepared from MWCNT3 exhibited a strength of 60.1–71.2 MPa.

The compressive strength of the reference sample was 68.3 MPa. These results were obtained for compositions without biosilica. For compositions with biosilica, the following surface strengths were observed—MWCNT1: 68.0–89.0 MPa; MWCNT2: 73.3–92.4 MPa; MWCNT3: 64.6–87.1 MPa The strength of the reference sample was 82.0 MPa. The highest compressive strength was observed in the case of composites processed with a 0.1% concentration of MWCNTs2, while the strengths for 0.05% and 0.15% concentrations were relatively low. At 28 days, the strength of samples without biosilica increased by 29.2%, and in the case of biosilica, it increased by 12.6%. - At a concentration of 0.05%, the electrical resistivity reached its lowest value, possibly due to the agglomeration of nanoparticles. The curves show that all specimens exhibited piezoresistive properties, and the measurements indicated a continuous increase in initial resistivity with cyclic loading, except for the batch of specimens with a concentration of 0.15% (3rd batch). Specifically, the third sample in this batch showed a change in the curve structure. For the first and second batches, all samples had almost the same curve structure and better piezoresistive response with a deviation in FCR. At a concentration of 0.05%, the electrical resistivity reached its lowest value, possibly due to the agglomeration of nanoparticles. The graphs demonstrate that all samples showed piezoresistive properties, and the measurements indicated a consistent increase in initial resistivity with cyclic loading, except for the specimens with a concentration of 0.15% (third batch). Particularly, the third sample in this batch exhibited a change in the curve structure. For the first and second batches, all samples had nearly identical curve structures and displayed better piezoresistive responses with a variation in FCR.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, Z.; Xu, J.; Bai, E.; Nie, L. Dielectric Model of Carbon Nanofiber Reinforced Concrete. Materials 2020, 13, 4869. [Google Scholar] [CrossRef]

- Shi, T.; Li, Z.; Guo, J.; Gong, H.; Gu, C. Research progress CNTs/CNFs—Modified cement-based composites—A review. Constr. Build. Mater. 2019, 202, 290–307. [Google Scholar] [CrossRef]

- Sonebi, M.; Garcia-Taengua, E.; Hassain, K.; Khatib, J.; Lachemi, M. Effect of nanosilica addition on the fresh properties and shrinkage of mortars with fly ash and superplasticizer. Constr. Build. Mater. 2015, 84, 269–276. [Google Scholar] [CrossRef]

- De Sensale, G.R. Effect of rice-husk ash on durability of cementitious materials. Cem. Concr. Compos. 2010, 32, 718–725. [Google Scholar] [CrossRef]

- Szeląg, M. Mechano-Physical Properties and Microstructure of Carbon Nanotube Reinforced Cement Paste after Thermal Load. Nanomaterials 2017, 7, 267. [Google Scholar] [CrossRef]

- Zhang, P.; Su, J.; Guo, J.; Hu, S. Influence of carbon nanotube on properties of concrete: A review. Constr. Build. Mater. 2023, 369, 130388. [Google Scholar] [CrossRef]

- Zhen, X.; Chao, G. Graphene fiber: A new trend in carbon fibers. Mater. Today 2015, 18, 480–492. [Google Scholar] [CrossRef]

- Metaxa, Z.S.; Boutsioukou, S.; Amenta, M.; Favvas, E.P.; Kourkoulis, S.K.; Alexopoulos, N.D. Dispersion of Multi-Walled Carbon Nanotubes into White Cement Mortars: The Effect of Concentration and Surfactants. Nanomaterials 2022, 12, 1031. [Google Scholar] [CrossRef]

- Muradyan, N.G.; Gyulasaryan, H.; Arzumanyan, A.A.; Badalyan, M.M.; Kalantaryan, M.A.; Vardanyan, Y.V.; Laroze, D.; Manukyan, A.; Barseghyan, M.G. The Effect of Multi-Walled Carbon Nanotubes on the Compressive Strength of Cement Mortars. Coatings 2022, 12, 1933. [Google Scholar] [CrossRef]

- Sarvandani, M.; Mahdikhani, M.; Aghabarati, H.; Fatmehsari, H. Effect of functionalized multi-walled carbon nanotubes on mechanical properties and durability of cement mortars. J. Build. Eng. 2021, 41, 102407. [Google Scholar] [CrossRef]

- Parveen, S.; Rana, S.; Fangueiro, R.; Paiva, M.C. Microstructure and mechanical properties of carbon nanotube reinforced cementitious composites developed using a novel dispersion technique. Cem. Concr. Res. 2015, 73, 215–227. [Google Scholar] [CrossRef]

- O’Rear, A.; Onthong, S.; Pongprayoon, T. Mechanical Strength and Conductivity of Cementitious Composites with Multiwalled Carbon Nanotubes: To Functionalize or Not? Nanomaterials 2024, 14, 80. [Google Scholar] [CrossRef]

- Stephens, C.; Brown, L.; Sanchez, F. Quantification of the re-agglomeration of carbon nanofiber aqueous dispersion in cement pastes and effect on the early age flexural response. Carbon 2016, 107, 482–500. [Google Scholar] [CrossRef]

- Peyvandi, A.; Soroushin, P.; Abdol, N.; Balachandra, A. Surface-modified graphite nanomaterials for improved reinforcement efficiency in cementitious paste. Carbon 2013, 63, 175–186. [Google Scholar] [CrossRef]

- Rashid, K.; Al-Rub, A.; Ahmad, I.; Bryan, M. On the aspect ratio effect of multi-walled carbon nanotube reinforcements on the mechanical properties of cementitious nanocomposites. Constr. Build. Mater. 2012, 35, 647–655. [Google Scholar] [CrossRef]

- Nasibulina, L.; Anoshkin, I.; Nasibulin, A.; Cwirzen, A.; Penttala, V.; Kauppinen, E. Effect of Carbon Nanotube Aqueous Dispersion Quality on Mechanical Properties of Cement Composite. J. Nanomater. 2012, 2012, 169262. [Google Scholar] [CrossRef]

- Al-Rub, R.; Tyson, B.; Yazdanbakhsh, A.; Grasley, Z. Mechanical Properties of Nanocomposite Cement Incorporating Surface-Treated and Untreated Carbon Nanotubes and Carbon Nanofibers. J. Nanomech. Micromech. 2011, 2, 1–6. [Google Scholar] [CrossRef]

- Zhang, D.; Song, W.; Lv, L.; Gao, C.; Gao, F.; Guo, H.; Diao, R.; Dai, W.; Niu, J.; Chen, X.; et al. Mono-dispersion decorated ultra-long single-walled carbon nanotube/aramid nanofiber for high-strength electromagnetic interference shielding film with Joule heating properties. Carbon 2023, 214, 118315. [Google Scholar] [CrossRef]

- Danoglidis, P.A.; Konsta-Gdoutos, M.S.; Gdoutos, E.E.; Shah, S.P. Strength, energy absorption capability and self-sensing properties of multifunctional carbon nanotube reinforced mortars. Constr. Build. Mater. 2016, 120, 265–274. [Google Scholar] [CrossRef]

- Han, B.; Ou, J. Embedded piezoresistive cement-based stress/strain sensor. Sens. Actuators A Phys. 2007, 138, 294–298. [Google Scholar] [CrossRef]

- Luo, J.; Duan, Z.; Zhao, T.; Li, Q. Effect of compressive strain on electrical resistivity of carbon nanotube cement-based composites. Key Eng. Mater. 2011, 483, 579–583. [Google Scholar] [CrossRef]

- Han, B.; Yu, X.; Kwon, E.; Ou, J. Effects of CNT concentration level and water/cement ratio on the piezoresistivity of CNT/cement composites. J. Compos. Mater. 2011, 46, 19–25. [Google Scholar] [CrossRef]

- Azhari, F.; Banthia, N. Cement-based sensors with carbon fibers and carbon nanotubes for piezoresistive sensing. Cem. Concr. Compos. 2012, 34, 866–873. [Google Scholar] [CrossRef]

- Kim, H.K.; Park, I.S.; Lee, H.K. Improved piezoresistive sensitivity and stability of CNT/cement mortar composites with low water–binder ratio. Compos. Struct. 2014, 116, 713–719. [Google Scholar] [CrossRef]

- Muradyan, N.G.; Arzumanyan, A.A.; Kalantaryan, M.A.; Vardanyan, Y.V.; Yeranosyan, M.; Ulewicz, M.; Laroze, D.; Barseghyan, M.G. The Use of Biosilica to Increase the Compressive Strength of Cement Mortar: The Effect of the Mixing Method. Materials 2023, 16, 5516. [Google Scholar] [CrossRef] [PubMed]

- Ganesan, K.; Rajagopal, K.; Thangavel, K. Rice husk ash blended cement: Assessment of optimal level of replacement for strength and permeability properties of concrete. Constr. Build. Mater. 2008, 22, 1675–1683. [Google Scholar] [CrossRef]

- Mahmood, R.A.; Kockal, N.U. Effects of Silica Fume and Micro Silica on the Properties of Mortars Containing Waste PVC Plastic Fibers. Microplastics 2022, 1, 587–609. [Google Scholar] [CrossRef]

- Lataste, J.; Sirieix, C.; Breysse, D.; Frappa, M. Electrical resistivity measurement applied to cracking assessment on reinforced concrete structures in civil engineering. NDT E Int. 2003, 36, 383–394. [Google Scholar] [CrossRef]

- Sahibulla, S.M.M.; Jaisingh, S.J. Pozzolanic biosilica, biochar, and egg shell in setting time, WVTR, and compression strength of biocement mortar: A Taguchi GRA validation. Biomass Convers. Biorefinery 2021, 13, 10475–10482. [Google Scholar] [CrossRef]

- Li, J.; Jin, Q.; Zhang, W.; Li, C.; Monteiro, P.J. Microstructure and durability performance of sustainable cementitious composites containing high-volume regenerative biosilica. Resour. Conserv. Recycl. 2022, 178, 106038. [Google Scholar] [CrossRef]

- Medeiros-Junior, R.; Lima, M. Electrical resistivity of unsaturated concrete using different types of cement. Constr. Build. Mater. 2016, 107, 11–16. [Google Scholar] [CrossRef]

- Singh, N.; Singh, S. Electrical resistivity of self consolidating concretes prepared with reused concrete aggregates and blended cements. J. Build. Eng. 2019, 25, 100780. [Google Scholar] [CrossRef]

- Lavagna, L.; Santagati, A.; Bartoli, M.; Suarez-Riera, D.; Pavese, M. Cement-Based Composites Containing Oxidized Graphene Nanoplatelets: Effects on the Mechanical and Electrical Properties. Nanomaterials 2023, 13, 901. [Google Scholar] [CrossRef]

- Mo Lim, K.; Lee, J. Electrical Conductivity and Compressive Strength of Cement Paste with Multiwalled Carbon Nanotubes and Graphene Nanoplatelets. Appl. Sci. 2022, 12, 1160. [Google Scholar] [CrossRef]

- Sevim, O.; Jiang, Z.; Ozbulut, O.E. Effects of graphene nanoplatelets type on self-sensing properties of cement mortar composites. Constr. Build. Mater. 2022, 359, 129488. [Google Scholar] [CrossRef]

- GOST 31108-2020; Common Cements. Specifications. GOST: Moscow, Russia, 2020. Available online: https://www.armstandard.am/en/standart/16253 (accessed on 5 September 2022).

- GOST EN 196-1-2002; Methods of Testing Cement. Part 1. Determination of Strength. GOST: Moscow, Russia, 2002. Available online: https://www.armstandard.am/en/standart/5556 (accessed on 31 July 2023).

- GOST EN 196-2-2002; Methods of Testing Cement. Part 2. Chemical Analysis of Cement. GOST: Moscow, Russia, 2002. Available online: https://www.armstandard.am/en/standart/5557 (accessed on 31 July 2023).

- GOST EN 196-3-2002; Methods of Testing Cement. Part 3. Determination of Setting Time and Soundness. GOST: Moscow, Russia, 2002. Available online: https://www.armstandard.am/en/standart/5558 (accessed on 31 July 2023).

- GOST 8735-88; Sand for Construction. Test Methods. GOST: Moscow, Russia, 2021. Available online: https://meganorm.ru/Index2/1/4294853/4294853080.htm (accessed on 1 January 2021).

- Wang, X.; Schröder, H.; Wiens, M.; Schloßmacher, U.; Müller, W. Chapter five—Biosilica: Molecular Biology, Biochemistry and Function in Demosponges as well as its Applied Aspects for Tissue Engineering. Adv. Mar. Biol. 2012, 62, 231–271. [Google Scholar] [CrossRef]

- Görlich, S.; Pawolski, D.; Zlotnikov, I.; Zlotnikov, I.; Kröger, N. Control of biosilica morphology and mechanical performance by the conserved diatom gene Silicanin-1. Commun. Biol. 2019, 2, 245. [Google Scholar] [CrossRef]

- Soltani, D.C.; Khataee, A.R.; Godini, H.; Safari, M.; Ghanadzadeh, M.J.; Rajaei, M.S. Response surface methodological evaluation of the adsorption of textile dye onto biosilica/alginate nanobiocomposite: Thermodynamic, kinetic, and isotherm studies. Desalination Water Treat. 2014, 56, 1389–1402. [Google Scholar] [CrossRef]

- Adams, L.A.; Essien, E.R.; Adesalu, A.T.; Julius, M.L. Bioactive glass 45S5 from diatom biosilica. J. Sci. Adv. Mater. Devices 2017, 2, 476–482. [Google Scholar] [CrossRef]

- Bansal, V.; Ahmad, A.; Sastry, M. Fungus-Mediated Biotransformation of Amorphous Silica in Rice Husk to Nanocrystalline Silica. J. Am. Chem. Soc. 2006, 128, 14059–14066. [Google Scholar] [CrossRef] [PubMed]

- Telussa, I.; Rahayu; Lilipaly, E.R.M.A.P. Isolation and characterization of biosilica as bionanomaterial from the waste of frustules diatom Navicula sp. TAD. Rasayan J. Chem. 2022, 198–203. [Google Scholar] [CrossRef]

- Mudasir, P.; Naqash, J.A. The effect of water cement ratio on the characteristics of multi-walled carbon nanotube reinforced concrete. Mater. Today Proc. 2021, 43, 3852–3855. [Google Scholar] [CrossRef]

- Badalyan, M.M.; Muradyan, N.G.; Shainova, R.S.; Arzumanyan, A.A.; Kalantaryan, M.A.; Sukiasyan, R.R.; Yeranosyan, M.; Laroze, D.; Vardanyan, Y.V.; Barseghyan, M.G. Effect of Silica Fume Concentration and Water–Cement Ratio on the Compressive Strength of Cement-Based Mortars. Buildings 2024, 14, 757. [Google Scholar] [CrossRef]

- Malumyan, S. Influence of Carbon Nanotubes Concentration on the Mechanical Properties of Cement Mortars. J. Archit. Eng. Res. 2023, 5, 47–52. [Google Scholar] [CrossRef]

- Arzumanyan, A.; Muradyan, N.; Arzumanyan, A.; Laroze, D.; Barseghyan, M. Non-Cement Building Materials from Volcanic Rock Extraction Waste. Buildings 2024, 14, 1555. [Google Scholar] [CrossRef]

- Mohammadi, B. Development of Concrete Water Absorption Testing for Quality. Doctoral Dissertation, Concordia University, Montreal, QC, Canada, 2013. Available online: https://core.ac.uk/download/pdf/211517047.pdf (accessed on 25 June 2024).

- GOST 12730.3-2020; Concretes. Method of Determination of Water Absorption. GOST: Moscow, Russia, 2020. Available online: https://www.armstandard.am/en/standart/5508 (accessed on 31 July 2023).

- Cerro-Prada, E.; Pacheco-Torres, R.; Varela, F. Effect of Multi-Walled Carbon Nanotubes on Strength and Electrical Properties of Cement Mortar. Materials 2021, 14, 79. [Google Scholar] [CrossRef]

- Monteiroa, A.O.; Cachima, P.B.; Costab, P.J. Electrical properties of cement-based composites containing carbon black particles. Mater. Today Proc. 2015, 2, 193–199. [Google Scholar] [CrossRef]

- Abdalla, J.; Thomas, B.; Hawileh, R.; Kabeer, K. Influence of nanomaterials on the water absorption and chloride penetration of cement-based concrete. Mater. Today Proc. 2022, 65, 2066–2069. [Google Scholar] [CrossRef]

- Torres, M.L.; Garcia-Ruiz, P.A. Lightweight pozzolanic materials used in mortars: Evaluation of their influence on density, mechanical strength and water absorption. Cem. Concr. Compos. 2009, 32, 114–119. [Google Scholar] [CrossRef]

- Oltulu, M.; Şahin, R. Effect of Nano-SiO2, Nano-Al2O3 and Nano-Fe2O3 Powders on Compressive Strengths and Capillary Water Absorption of Cement Mortar Containing Fly Ash: A Comparative Study. Energy Build. 2013, 58, 292–301. [Google Scholar] [CrossRef]

- Liu, Y.; Cheng, X. Effect of Carbon Nanotube Size on Electrical Properties of Cement Mortar under Different Temperatures and Water Content. Geofluids 2022, 2022, 7237049. [Google Scholar] [CrossRef]

| Characteristics | Unit | Results Obtained | ||||||

|---|---|---|---|---|---|---|---|---|

| Specific gravity | g/cm3 | 3.1 | ||||||

| Blain’s fineness | cm2/g | 3250 | ||||||

| Standard consistency | % | 30.2 | ||||||

| Setting time | Initial | min | 45 | |||||

| Final | 285 | |||||||

| Compressive strength | 3 days | MPa | 20 | |||||

| 7 days | 38 | |||||||

| 28 days | 52 | |||||||

| Chemical composition of cement (wt.%) | ||||||||

| Al2O3 | SiO2 | Fe2O3 | CaO | MgO | SO3 | Free CaO | Insol. resid. | Loss on ignition |

| 4.16 | 28.1 | 3.25 | 53.4 | 3.8 | 1.9 | 1.09 | 2.5 | 1.8 |

| Sieve Residues, % | Size Modulus, Mк | Specific Gravity, g/cm3 | Bulk Density in Compact State, kg/m3 | Bulk Density in Loose State, kg/m3 | ||||

|---|---|---|---|---|---|---|---|---|

| 2.5 | 1.25 | 0.63 | 0.315 | 0.16 | ||||

| 17.34 | 32.16 | 53.46 | 75.52 | 95.68 | 2.7 | 2.5 | 1800 | 1670 |

| Chemical Composition (wt.%) | ||||

|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | K2O | MgO |

| 88.92 | 6.1 | 2.8 | 1.34 | 0.84 |

| Physical properties | ||||

| Residue on sieve 45 µm, % | Bulk density, kg/m3 | |||

| 5.0 | 280 | |||

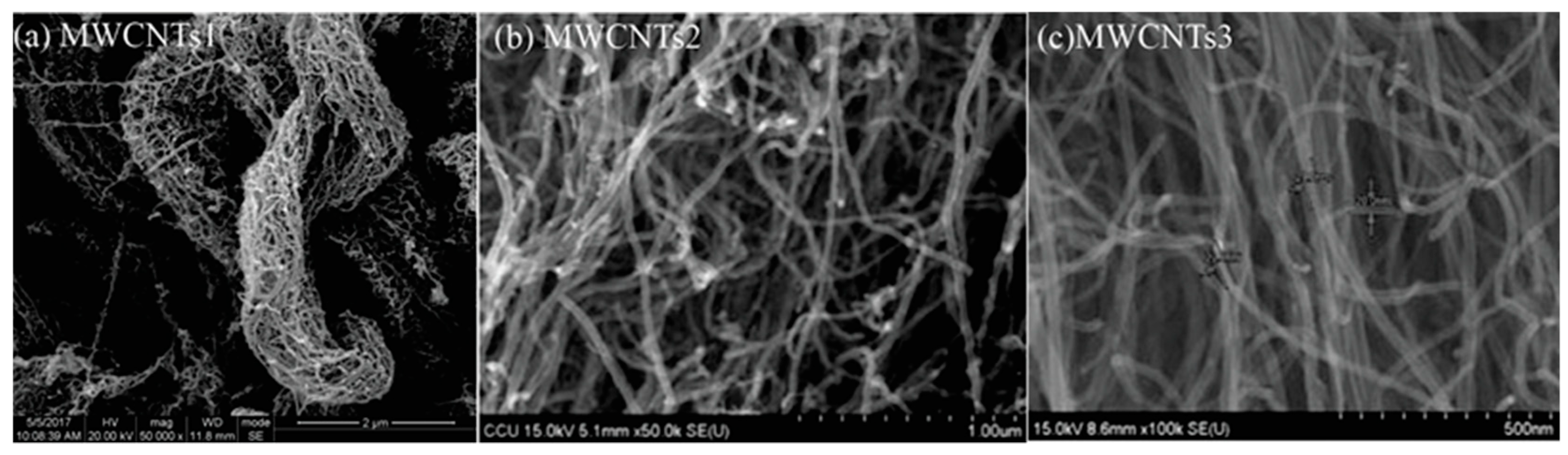

| MWCNT | Outer Diameter | Length | SSA | Purity |

|---|---|---|---|---|

| MWCNTs1 | 4–6 nm | 10–20 µm | >380 m2/g | >98% |

| MWCNTs2 | 5–15 nm | 10–30 µm | >220 m2/g | >98% |

| MWCNTs3 | 20–30 nm | 10–30 µm | >110 m2/g | >98% |

| N | Cement, g | Sand, g | W/C | Biosilica, g | MWCNTs, % | Disperbyk, g | Density, g/cm3 | Water Absorption, % | Compressive Strength, MPa | |

|---|---|---|---|---|---|---|---|---|---|---|

| 7 Days | 28 Days | |||||||||

| 0 | 880 | 2200 | 0.47 | - | - | - | 2.14 | 9.4 | 38.74 | 68.39 |

| 1 | 880 | 2200 | 0.47 | 88 | - | - | 2.19 | 8.9 | 53.06 | 82.04 |

| MWCNT1 | ||||||||||

| 2 | 880 | 2200 | 0.47 | - | 0.05 | 0.44 | 2.16 | 10.5 | 39.26 | 73.05 |

| 3 | 880 | 2200 | 0.47 | - | 0.1 | 0.88 | 2.20 | 10.8 | 41.22 | 83.24 |

| 4 | 880 | 2200 | 0.47 | - | 0.15 | 1.32 | 2.20 | 10.6 | 34.73 | 62.27 |

| 5 | 880 | 2200 | 0.47 | 88 | 0.05 | 0.44 | 2.20 | 9.05 | 54.44 | 84.13 |

| 6 | 880 | 2200 | 0.47 | 88 | 0.1 | 0.88 | 2.20 | 8.6 | 56.64 | 89.01 |

| 7 | 880 | 2200 | 0.47 | 88 | 0.15 | 1.32 | 2.19 | 8.5 | 42.62 | 68.06 |

| MWCNT2 | ||||||||||

| 8 | 880 | 2200 | 0.47 | - | 0.05 | 0.44 | 2.18 | 8.8 | 60.01 | 68.96 |

| 9 | 880 | 2200 | 0.47 | - | 0.1 | 0.88 | 2.20 | 8.4 | 67.54 | 70.77 |

| 10 | 880 | 2200 | 0.47 | - | 0.15 | 1.32 | 2.21 | 7.9 | 59.35 | 62.84 |

| 11 | 880 | 2200 | 0.47 | 88 | 0.05 | 0.44 | 2.21 | 8.3 | 63.18 | 86.62 |

| 12 | 880 | 2200 | 0.47 | 88 | 0.1 | 0.88 | 2.21 | 7.6 | 68.54 | 92.41 |

| 13 | 880 | 2200 | 0.47 | 88 | 0.15 | 1.32 | 2.20 | 7.3 | 60.70 | 73.30 |

| MWCNT3 | ||||||||||

| 14 | 880 | 2200 | 0.47 | - | 0.05 | 0.44 | 2.15 | 9.3 | 38.51 | 68.80 |

| 15 | 880 | 2200 | 0.47 | - | 0.1 | 0.88 | 2.18 | 8.9 | 42.92 | 71.24 |

| 16 | 880 | 2200 | 0.47 | - | 0.15 | 1.32 | 2.18 | 9.1 | 36.21 | 60.19 |

| 17 | 880 | 2200 | 0.47 | 88 | 0.05 | 0.44 | 2.20 | 8.3 | 52.91 | 83.54 |

| 18 | 880 | 2200 | 0.47 | 88 | 0.1 | 0.88 | 2.21 | 7.9 | 54.15 | 87.19 |

| 19 | 880 | 2200 | 0.47 | 88 | 0.15 | 1.32 | 2.20 | 7.5 | 39.94 | 64.66 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malumyan, S.A.; Muradyan, N.G.; Kalantaryan, M.A.; Arzumanyan, A.A.; Melikyan, Y.; Laroze, D.; Barseghyan, M.G. Simultaneous Effect of Diameter and Concentration of Multi-Walled Carbon Nanotubes on Mechanical and Electrical Properties of Cement Mortars: With and without Biosilica. Nanomaterials 2024, 14, 1271. https://doi.org/10.3390/nano14151271

Malumyan SA, Muradyan NG, Kalantaryan MA, Arzumanyan AA, Melikyan Y, Laroze D, Barseghyan MG. Simultaneous Effect of Diameter and Concentration of Multi-Walled Carbon Nanotubes on Mechanical and Electrical Properties of Cement Mortars: With and without Biosilica. Nanomaterials. 2024; 14(15):1271. https://doi.org/10.3390/nano14151271

Chicago/Turabian StyleMalumyan, Suren A., Nelli G. Muradyan, Marine A. Kalantaryan, Avetik A. Arzumanyan, Yeghvard Melikyan, David Laroze, and Manuk G. Barseghyan. 2024. "Simultaneous Effect of Diameter and Concentration of Multi-Walled Carbon Nanotubes on Mechanical and Electrical Properties of Cement Mortars: With and without Biosilica" Nanomaterials 14, no. 15: 1271. https://doi.org/10.3390/nano14151271

APA StyleMalumyan, S. A., Muradyan, N. G., Kalantaryan, M. A., Arzumanyan, A. A., Melikyan, Y., Laroze, D., & Barseghyan, M. G. (2024). Simultaneous Effect of Diameter and Concentration of Multi-Walled Carbon Nanotubes on Mechanical and Electrical Properties of Cement Mortars: With and without Biosilica. Nanomaterials, 14(15), 1271. https://doi.org/10.3390/nano14151271