Efficient Anti-Fog and Anti-Reflection Functions of the Bio-Inspired, Hierarchically-Architectured Surfaces of Multiscale Columnar Structures

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Morphological Characterization, Chemical Composition Analysis, and Performance Testing

2.3. Preparation of Multiscale Hierarchical Honeycomb Structures (MHCS)

3. Results

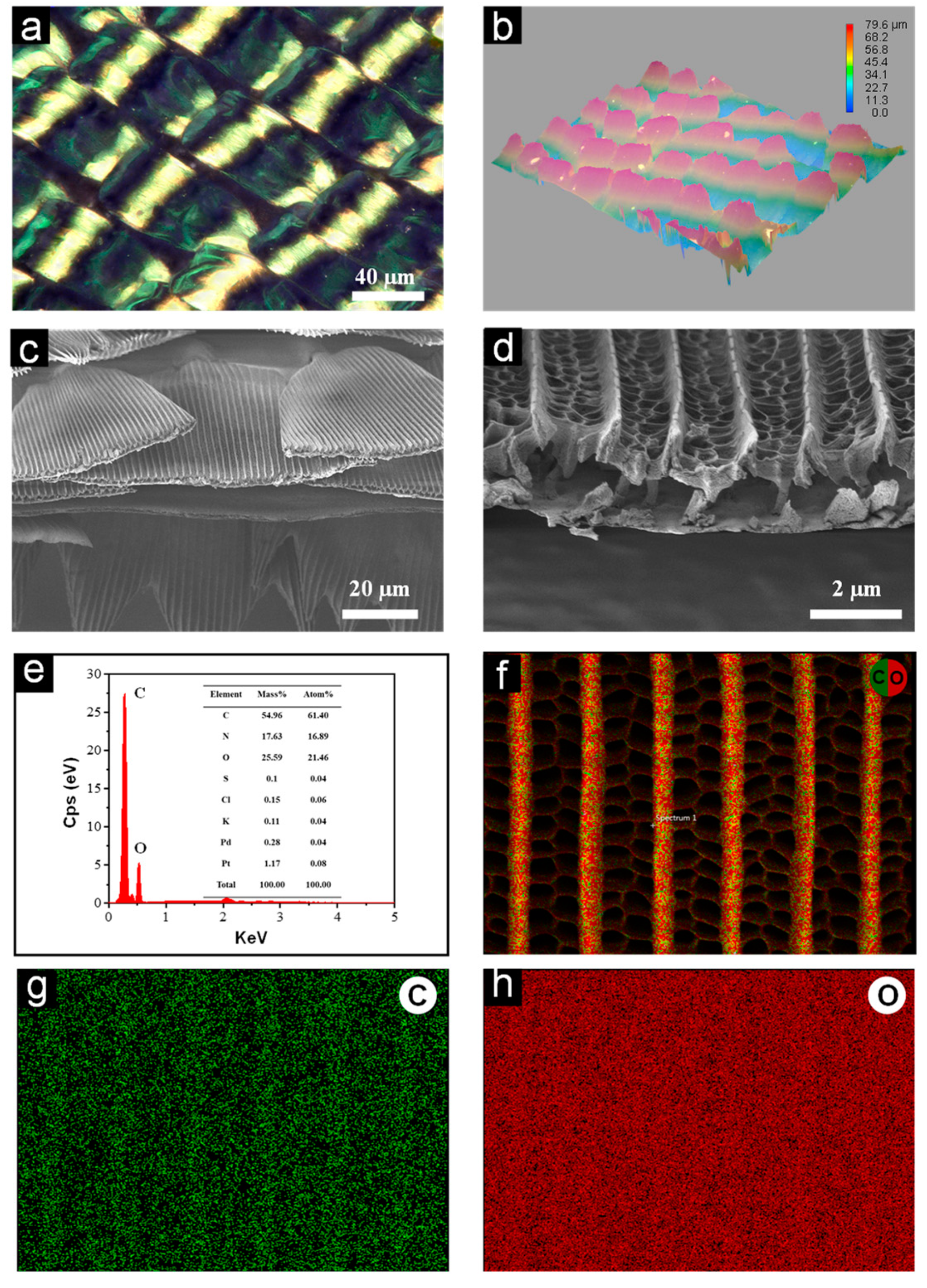

3.1. Biological Templates and General Characteristics of Butterfly Wing Scales

3.2. Microscopic Morphology Observations and Chemical Composition Analysis of Butterfly Wing Scales

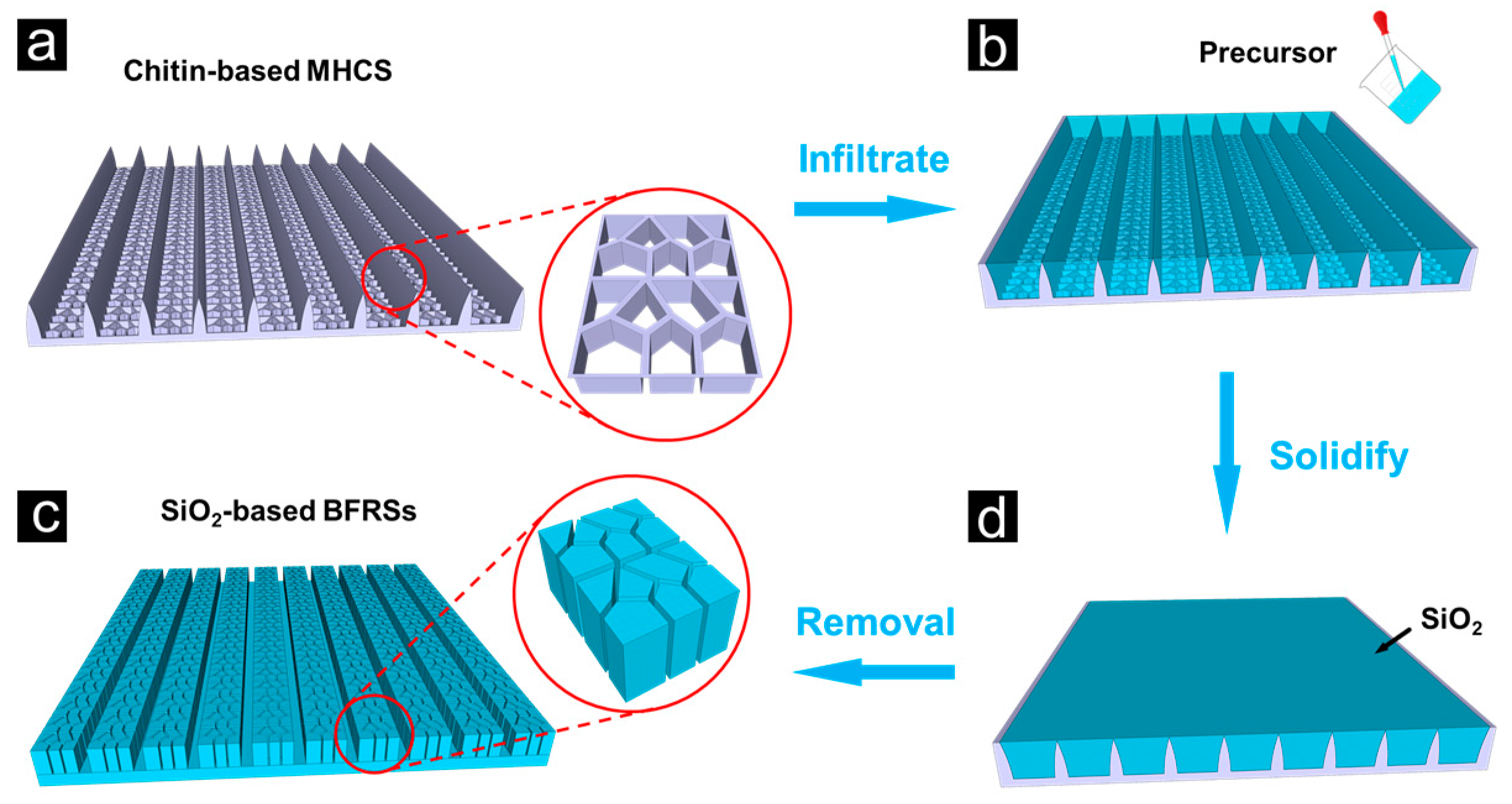

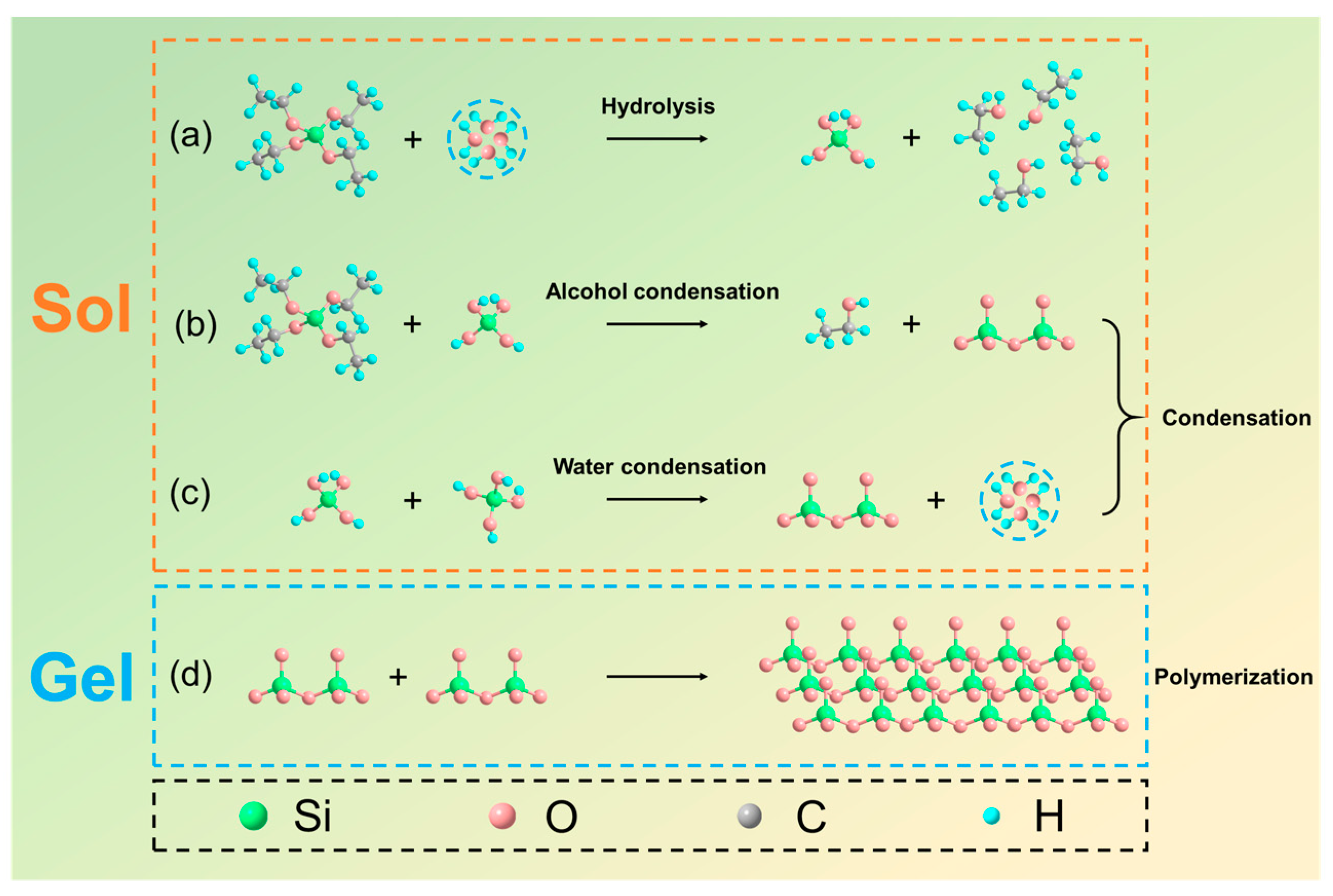

3.3. The Preparation Process of the BFRSs

3.4. The Preparation Process of the BFRSs

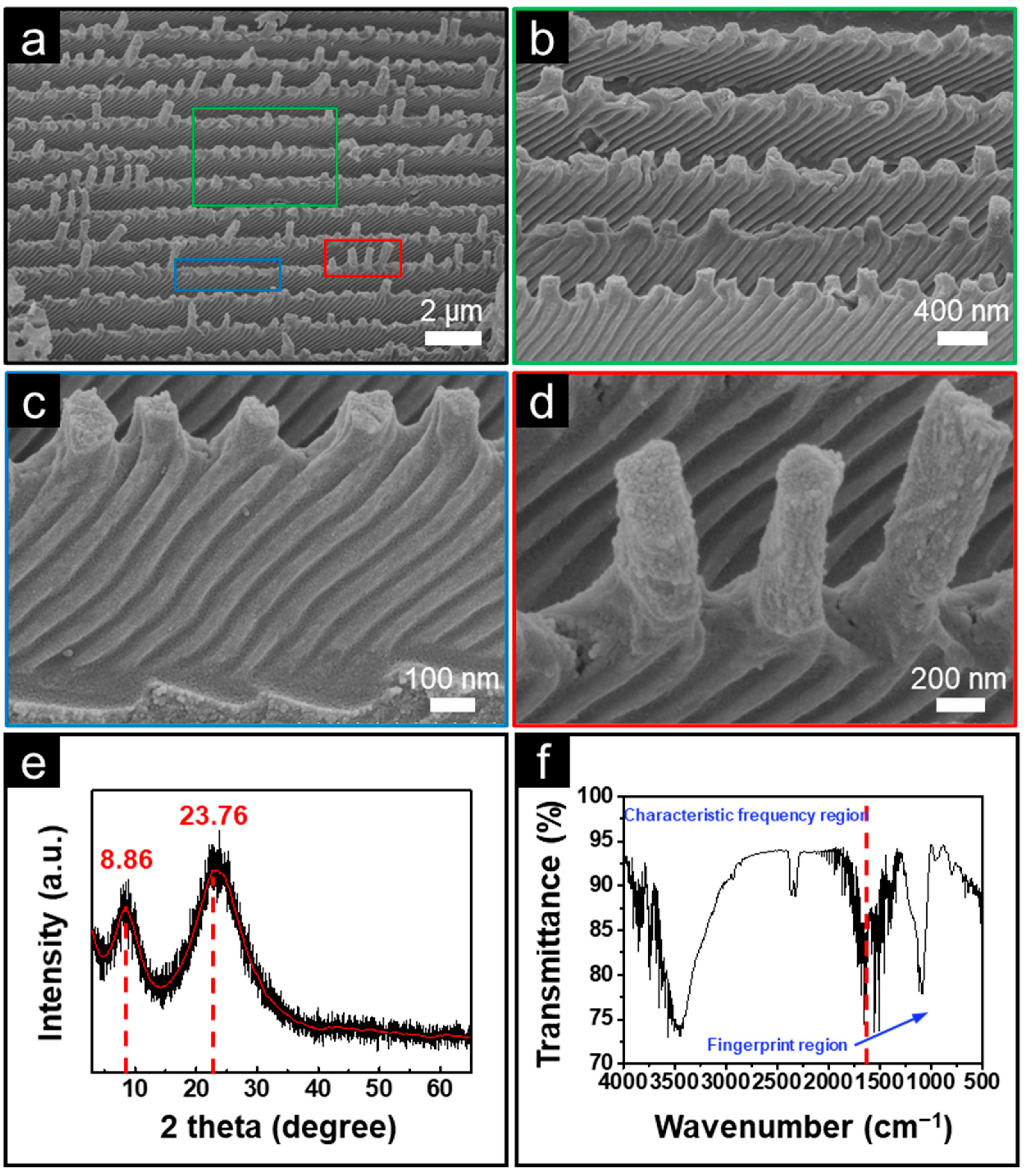

3.5. Microscopic Morphology Observations and Chemical Composition Analysis of the BFRSs

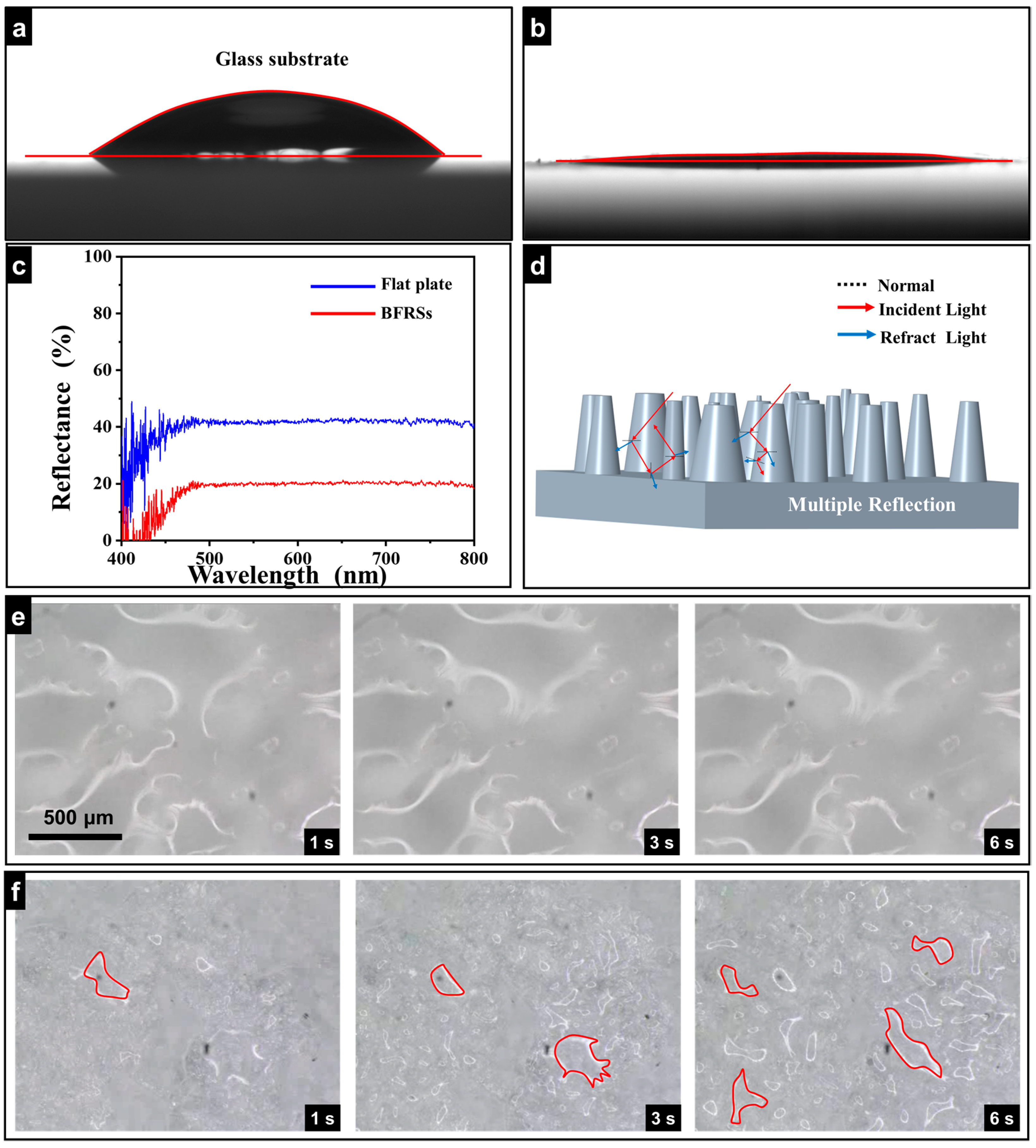

3.6. Anti-Reflection and Anti-Fog Capability of BFRSs

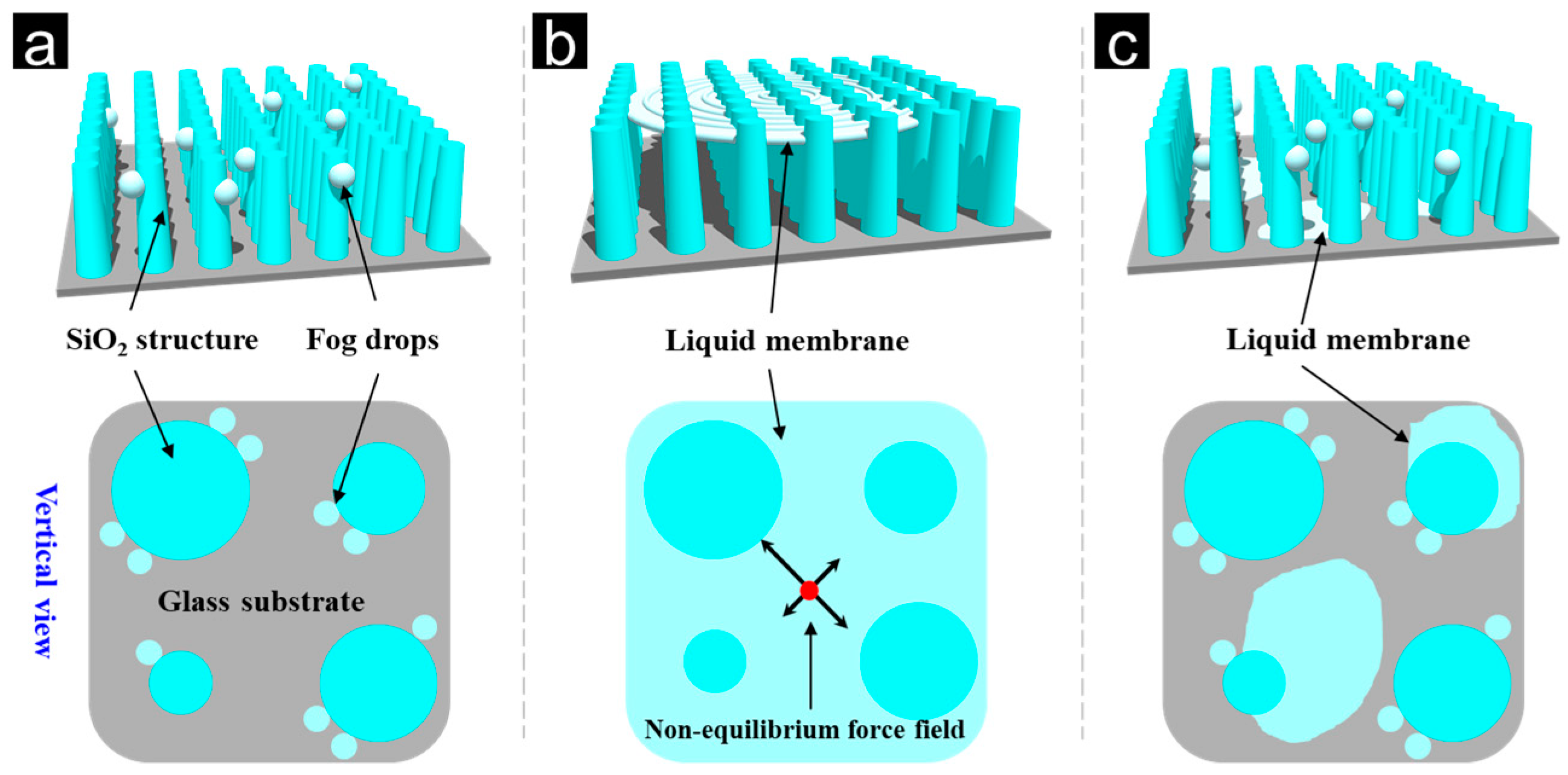

3.7. Autonomous Fog-Collecting Mechanism of BFRSs

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kyaw, S.; Johns, M.; Lim, R.; Stewart, W.C.; Rojas, N.; Thambiraj, S.R.; Shehabi, Y.; Arora, S. Prediction of N95 respirator fit from fogging of eyeglasses: A pilot study. Indian J. Crit. Care Med. 2021, 25, 976–980. [Google Scholar] [CrossRef] [PubMed]

- Durán, I.R.; Laroche, G. Current trends, challenges, and perspectives of anti-fogging technology: Surface and material design, fabrication strategies, and beyond. Prog. Mater. Sci. 2019, 99, 106–186. [Google Scholar] [CrossRef]

- Dankert, J.F.; Virk, M.S. Mask-Related Glasses Fogging: A Predisposing Mechanism of Falls during the COVID-19 Pandemic. Case Rep. Orthop. 2021, 2021, 1–5. [Google Scholar] [CrossRef] [PubMed]

- Huang, W.; Chen, Y.; Yang, C.; Situ, Y.; Huang, H. PH-driven phase separation: Simple routes for fabricating porous TiO2 film with superhydrophilic and anti-fog properties. Ceram. Int. 2015, 41, 7573–7581. [Google Scholar] [CrossRef]

- Ye, L.; Zhang, Y.; Song, C.; Li, Y.; Jiang, B. A simple sol-gel method to prepare superhydrophilic silica coatings. Mater. Lett. 2017, 188, 316–318. [Google Scholar] [CrossRef]

- Ogawa, T.; Murata, N.; Yamazaki, S. Development of Anti-Fogging Mirror Coated with SiO2-ZrO2-Colloidal SiO2 Film by the Sol-Gel Process. J. Sol-Gel Sci. Technol. 2003, 27, 237–238. [Google Scholar] [CrossRef]

- Park, C.; Kim, T.; Kim, Y.I.; Lee, M.W.; An, S.; Yoon, S.S. Supersonically sprayed transparent flexible multifunctional composites for self-cleaning, anti-icing, anti-fogging, and anti-bacterial applications. Compos. Part B Eng. 2021, 222, 109070. [Google Scholar] [CrossRef]

- Kashem, M.N.H.; Liu, X.; Ding, Z.; Li, W. Spin-spray-assisted layer-by-layer assembly of thick polymer films with self-healing, UV-protection, and anti-fog properties. J. Polym. Sci. 2022. [Google Scholar] [CrossRef]

- Mansoor, B.; Iqbal, O.; Habumugisha, J.C.; Xia, Z.; Jiang, R.; Chen, W. Polyvinyl alcohol (PVA) based super-hydrophilic anti-fogging layer assisted by plasma spraying for low density polyethylene (LDPE) greenhouse films. Prog. Org. Coat. 2021, 159, 106412. [Google Scholar] [CrossRef]

- Varshney, P.; Mohapatra, S.S. Durable and regenerable superhydrophobic coatings for brass surfaces with excellent self-cleaning and anti-fogging properties prepared by immersion technique. Tribol. Int. 2018, 123, 17–25. [Google Scholar] [CrossRef]

- Lomga, J.; Varshney, P.; Nanda, D.; Satapathy, M.; Mohapatra, S.S.; Kumar, A. Fabrication of durable and regenerable superhydrophobic coatings with excellent self-cleaning and anti-fogging properties for aluminium surfaces. J. Alloys Compd. 2017, 702, 161–170. [Google Scholar] [CrossRef]

- Varshney, P.; Lomga, J.; Gupta, P.K.; Mohapatra, S.S.; Kumar, A. Durable and regenerable superhydrophobic coatings for aluminium surfaces with excellent self-cleaning and anti-fogging properties. Tribol. Int. 2018, 119, 38–44. [Google Scholar] [CrossRef]

- Varshney, P.; Mohapatra, S.; Kumar, A. Fabrication of Mechanically Stable Superhydrophobic Aluminium Surface with Excellent Self-Cleaning and Anti-Fogging Properties. Biomimetics 2017, 2, 2. [Google Scholar] [CrossRef] [PubMed]

- Yoon, S.M.; Lee, H.; Lee, H.; Nahm, S.; Moon, M.W. Nanostructured polycarbonate for robust transparency and anti-fogging by control of self-masking metallic clusters. Res. Chem. Intermed. 2018, 44, 4697–4706. [Google Scholar] [CrossRef]

- Huang, L.; Wang, T.; Li, X.; Wang, X.; Zhang, W.; Yang, Y.; Tang, Y. UV-to-IR highly transparent ultrathin diamond nanofilms with intriguing performances: Anti-fogging, self-cleaning and self-lubricating. Appl. Surf. Sci. 2020, 527, 146733. [Google Scholar] [CrossRef]

- Cao, R.; Zhou, Z.; Haghanifar, S.; Wu, J.; Li, M.J.; Tan, S.; Leu, P.W.; Chen, K.P. Surface nanostructuring of alkali-aluminosilicate Gorilla display glass substrates using a maskless process. Nanotechnology 2022, 33, 245301. [Google Scholar] [CrossRef]

- Lu, K.W.; Lin, Y.T.; Wei, H.S.; Kuo, C.C. Superhydrophilic Modification of Polycarbonate Substrate Surface by Organic Plasma Polymerization Film. Materials 2022, 15, 4411. [Google Scholar] [CrossRef]

- Tong, F.; Gong, J.; Yu, L.; Li, M.; Zhang, L. Transparent and anti-fogging AlPO4-5 films constructed by oblique oriented nano-flake crystals. Chin. J. Chem. Eng. 2022, 44, 332–340. [Google Scholar] [CrossRef]

- Chevallier, P.; Turgeon, S.; Sarra-Bournet, C.; Turcotte, R.; Laroche, G. Characterization of multilayer anti-fog coatings. ACS Appl. Mater. Interfaces 2011, 3, 750–758. [Google Scholar] [CrossRef]

- Boutamart, M.; Briche, S.; Nouneh, K.; Rafqah, S.; Agzenai, Y. Transparent and Self-Cleaning Surfaces Based on Nanocomposite Sol-Gel Coatings. ChemistrySelect 2020, 5, 8522–8531. [Google Scholar] [CrossRef]

- Kryuchkov, M.; Adamcik, J.; Katanaev, V.L. Bactericidal and Antiviral Bionic Metalized Nanocoatings. Nanomaterials 2022, 12, 1868. [Google Scholar] [CrossRef] [PubMed]

- Heitz, J. Nanopatterning of Bionic Materials. Nanomaterials 2023, 13, 233. [Google Scholar] [CrossRef] [PubMed]

- Du, J.; Hao, P. Investigation on microstructure of beetle elytra and energy absorption properties of bio-inspired honeycomb thin-walled structure under axial dynamic crushing. Nanomaterials 2018, 8, 667. [Google Scholar] [CrossRef] [PubMed]

- Wang, L. Bionic design elements in the application of modern product design. Appl. Mech. Mater. 2012, 201–202, 838–841. [Google Scholar]

- Ren, L. Progress in the bionic study on anti-adhesion and resistance reduction of terrain machines. Sci. China Ser. E Technol. Sci. 2009, 52, 273–284. [Google Scholar] [CrossRef]

- Ge-Zhang, S.; Cai, T.; Yang, H.; Ding, Y.; Song, M. Biology and nature: Bionic superhydrophobic surface and principle. Front. Bioeng. Biotechnol. 2022, 10, 1–19. [Google Scholar] [CrossRef]

- Liu, C.; Zhu, L.; Li, J.; Liang, Y. Fabrication of superhydrophobic bionic surface integrating with VOF simulation studies of liquid drop impacting. Microsc. Res. Tech. 2019, 82, 615–623. [Google Scholar] [CrossRef]

- Xing, D.; Wang, R.; Wu, F.; Gao, X. Confined Growth and Controlled Coalescence/Self-Removal of Condensate Microdrops on a Spatially Heterogeneously Patterned Superhydrophilic-Superhydrophobic Surface. ACS Appl. Mater. Interfaces 2020, 12, 29946–29952. [Google Scholar] [CrossRef]

- Yuan, L.; Wen, T.; Jiang, L.; Liu, Z.; Tian, C.; Yu, J. Modified superhydrophilic/underwater superoleophobic mullite fiber-based porous ceramic for oil-water separation. Mater. Res. Bull. 2021, 143, 111454. [Google Scholar] [CrossRef]

- Yan, D.; Yu, Z.; Zou, T.; Lin, Y.; Kong, W.; Yang, J. Long-Time Persisting Superhydrophilicity on Sapphire Surface via Femtosecond Laser Processing with the Varnish of TiO2. Nanomaterials 2022, 12, 3403. [Google Scholar] [CrossRef]

- Vázquez-Velázquez, A.R.; Velasco-Soto, M.A.; Pérez-García, S.A.; Licea-Jiménez, L. Functionalization effect on polymer nanocomposite coatings based on TiO2–SiO2 nanoparticles with superhydrophilic properties. Nanomaterials 2018, 8, 369. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Luo, X.; Chang, W.; Tian, Y.; Wang, Z.; Gao, J.; Cai, Y.; Qin, Y.; Duxbury, M. Manufacturing of anti-fogging super-hydrophilic microstructures on glass by nanosecond laser. J. Manuf. Process. 2020, 59, 557–565. [Google Scholar] [CrossRef]

- Feng, C.; Gou, T.; Li, J.; Cai, Y.; He, P.; Huang, J.; Wen, Y.; Ma, Y.; Zhang, Z. A highly transparent polymer coating on the glass with broadband antireflection, antifogging and antifouling properties. Mater. Res. Express 2019, 6, 075319. [Google Scholar] [CrossRef]

- Han, Z.; Mu, Z.; Li, B.; Wang, Z.; Zhang, J.; Niu, S.; Ren, L. Active Antifogging Property of Monolayer SiO2 Film with Bioinspired Multiscale Hierarchical Pagoda Structures. ACS Nano 2016, 10, 8591–8602. [Google Scholar] [CrossRef]

- Wang, Z.; Ding, H.; Liu, D.; Xu, C.; Li, B.; Niu, S.; Li, J.; Liu, L.; Zhao, J.; Zhang, J.; et al. Large-Scale Bio-Inspired Flexible Antireflective Film with Scale-Insensitivity Arrays. ACS Appl. Mater. Interfaces 2021, 13, 23103–23112. [Google Scholar] [CrossRef] [PubMed]

- Sun, H.; Xing, Y.; Wu, Q.; Yang, P. Highly luminescent hybrid SiO2-coated CdTe quantum dots retained initial photoluminescence efficiency in sol-gel SiO2 film. J. Nanosci. Nanotechnol. 2015, 15, 1562–1566. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Chen, Y.; Jiao, Z. Efficient Anti-Fog and Anti-Reflection Functions of the Bio-Inspired, Hierarchically-Architectured Surfaces of Multiscale Columnar Structures. Nanomaterials 2023, 13, 1570. https://doi.org/10.3390/nano13091570

Li W, Chen Y, Jiao Z. Efficient Anti-Fog and Anti-Reflection Functions of the Bio-Inspired, Hierarchically-Architectured Surfaces of Multiscale Columnar Structures. Nanomaterials. 2023; 13(9):1570. https://doi.org/10.3390/nano13091570

Chicago/Turabian StyleLi, Weixuan, You Chen, and Zhibin Jiao. 2023. "Efficient Anti-Fog and Anti-Reflection Functions of the Bio-Inspired, Hierarchically-Architectured Surfaces of Multiscale Columnar Structures" Nanomaterials 13, no. 9: 1570. https://doi.org/10.3390/nano13091570

APA StyleLi, W., Chen, Y., & Jiao, Z. (2023). Efficient Anti-Fog and Anti-Reflection Functions of the Bio-Inspired, Hierarchically-Architectured Surfaces of Multiscale Columnar Structures. Nanomaterials, 13(9), 1570. https://doi.org/10.3390/nano13091570