Electronic and Optoelectronic Monolayer WSe2 Devices via Transfer-Free Fabrication Method

Abstract

1. Introduction

2. Experimental Section

2.1. Au Foil Preparation

2.2. CVD Growth Process of Monolayer WSe2

2.3. Transfer WSe2 Film to SiO2/Si Substrate

2.4. Device Fabrication

2.5. Characterization

3. Results and Discussion

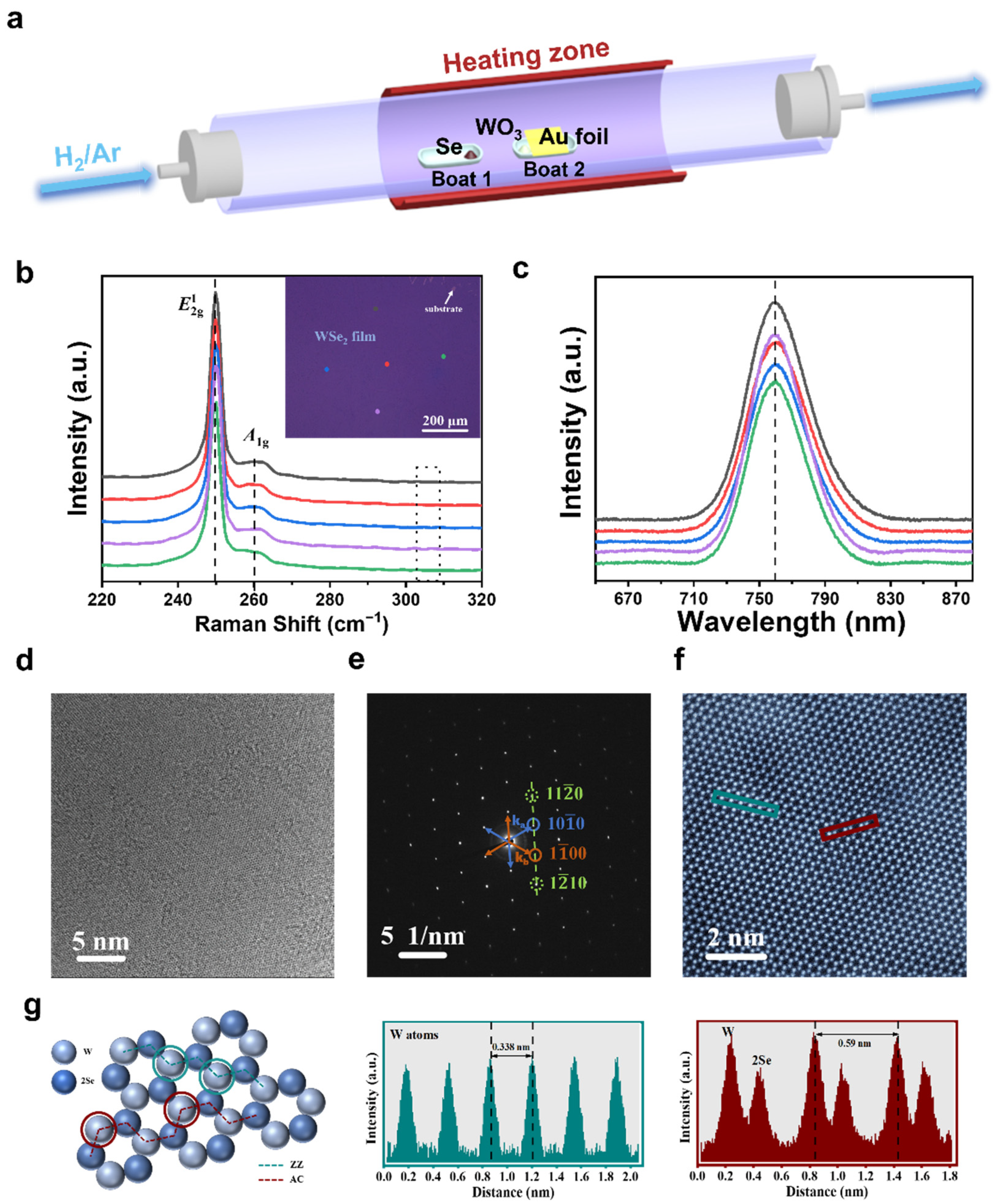

3.1. Synthesis and Characterization of Monolayer WSe2

3.2. Design of the Transfer-Free Monolayer WSe2-Based Device

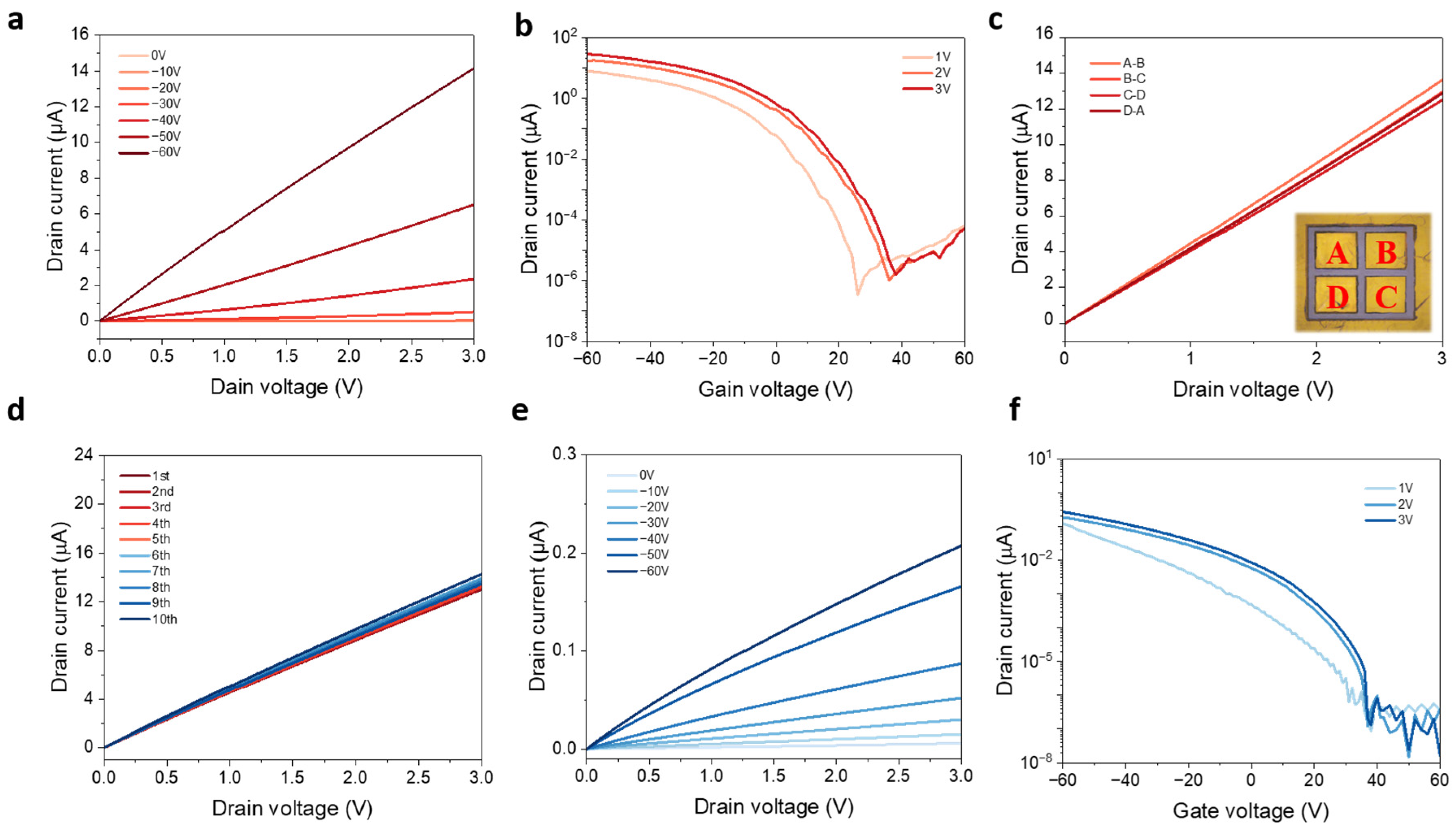

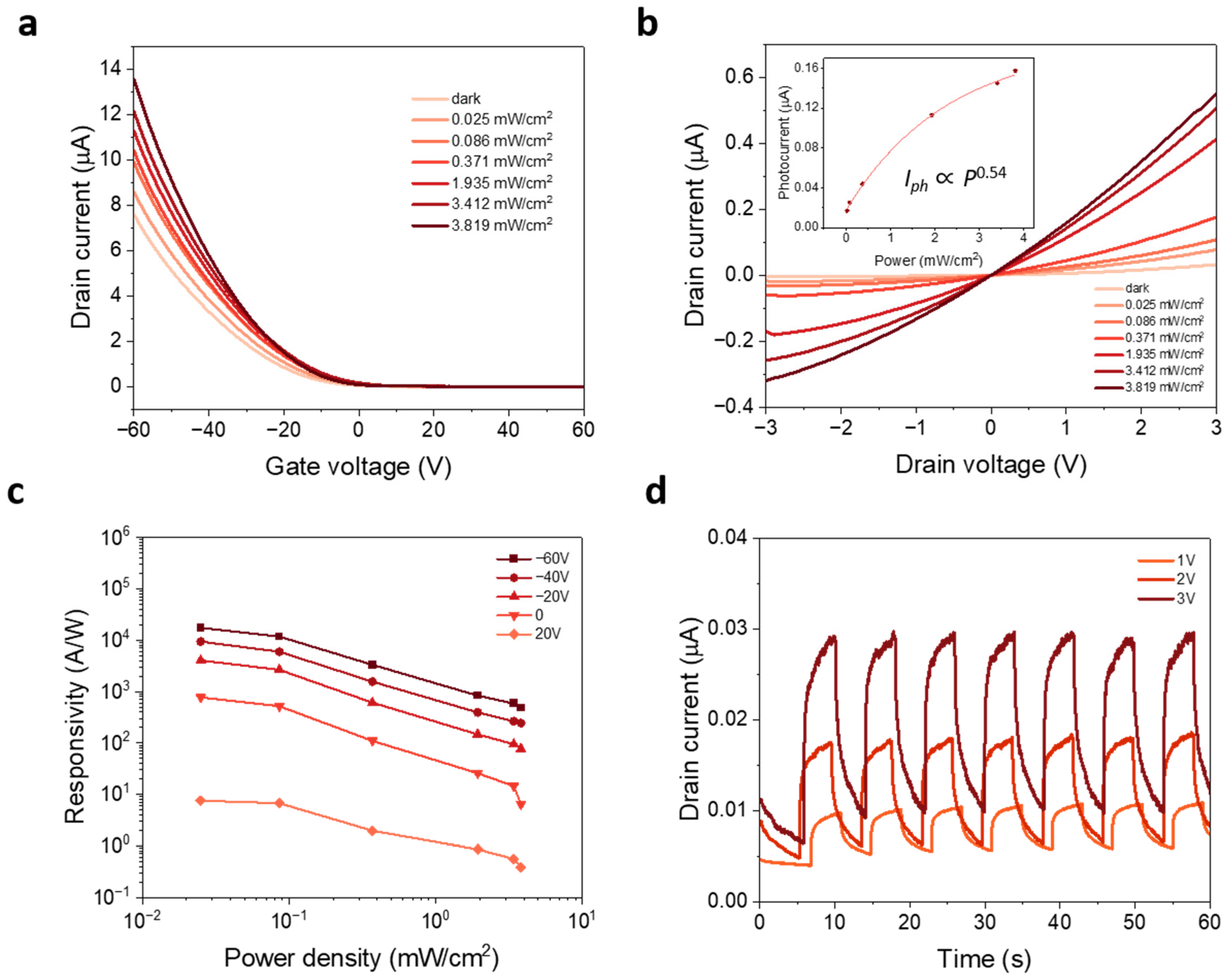

3.3. Electrical and Optoelectronic Properties of the WSe2-Based Device

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chhowalla, M.; Jena, D.; Zhang, H. Two-dimensional semiconductors for transistors. Nat. Rev. Mater. 2016, 1, 16052. [Google Scholar] [CrossRef]

- Shen, P.-C.; Su, C.; Lin, Y.; Chou, A.-S.; Cheng, C.-C.; Park, J.-H.; Chiu, M.-H.; Lu, A.-Y.; Tang, H.-L.; Tavakoli, M.M.; et al. Ultralow contact resistance between semimetal and monolayer semiconductors. Nature 2021, 593, 211–217. [Google Scholar] [CrossRef] [PubMed]

- Mak, K.F.; Shan, J. Photonics and optoelectronics of 2D semiconductor transition metal dichalcogenides. Nat. Photonics 2016, 10, 216–226. [Google Scholar] [CrossRef]

- Zhou, H.; Wang, C.; Shaw, J.C.; Cheng, R.; Chen, Y.; Huang, X.; Liu, Y.; Weiss, N.O.; Lin, Z.; Huang, Y.; et al. Large Area Growth and Electrical Properties of p-Type WSe2 Atomic Layers. Nano Lett. 2015, 15, 709–713. [Google Scholar] [CrossRef] [PubMed]

- Nipane, A.; Choi, M.S.; Sebastian, P.J.; Yao, K.; Borah, A.; Deshmukh, P.; Jung, Y.; Kim, B.; Rajendran, A.; Kwock, K.W.C.; et al. Damage-Free Atomic Layer Etch of WSe2: A Platform for Fabricating Clean Two-Dimensional Devices. ACS Appl. Mater. Interfaces 2021, 13, 1930–1942. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Zhang, Z.; Dong, J.; Yi, D.; Niu, J.; Wu, M.; Lin, L.; Yin, R.; Li, M.; Zhou, J. Ultrafast epitaxial growth of metre-sized single-crystal graphene on industrial Cu foil. Sci. Bull. 2017, 62, 1074–1080. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Xu, X.; Zhang, L.; Qiao, R.; Wu, M.; Wang, Z.; Zhang, S.; Liang, J.; Zhang, Z.; Zhang, Z. Epitaxial growth of a 100-square-centimetre single-crystal hexagonal boron nitride monolayer on copper. Nature 2019, 570, 91–95. [Google Scholar] [CrossRef]

- Gao, Y.; Hong, Y.-L.; Yin, L.-C.; Wu, Z.; Yang, Z.; Chen, M.-L.; Liu, Z.; Ma, T.; Sun, D.-M.; Ni, Z.; et al. Ultrafast Growth of High-Quality Monolayer WSe2 on Au. Adv. Mater. 2017, 29, 1700990. [Google Scholar] [CrossRef] [PubMed]

- Choi, S.H.; Kim, H.J.; Song, B.; Kim, Y.I.; Han, G.; Nguyen, H.T.T.; Ko, H.; Boandoh, S.; Choi, J.H.; Oh, C.S. Epitaxial Single-Crystal Growth of Transition Metal Dichalcogenide Monolayers via the Atomic Sawtooth Au Surface. Adv. Mater. 2021, 33, 2006601. [Google Scholar] [CrossRef]

- Shi, J.; Zhang, X.; Ma, D.; Zhu, J.; Zhang, Y.; Guo, Z.; Yao, Y.; Ji, Q.; Song, X.; Zhang, Y. Substrate facet effect on the growth of monolayer MoS2 on Au foils. ACS Nano 2015, 9, 4017–4025. [Google Scholar] [CrossRef]

- Leong, W.S.; Wang, H.; Yeo, J.; Martin-Martinez, F.J.; Zubair, A.; Shen, P.-C.; Mao, Y.; Palacios, T.; Buehler, M.J.; Hong, J.-Y. Paraffin-enabled graphene transfer. Nat. Commun. 2019, 10, 867. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Du, J.; Zhang, D.; Sun, H.; Yin, L.; Ma, L.; Chen, J.; Ma, D.; Cheng, H.-M.; Ren, W. Rosin-enabled ultraclean and damage-free transfer of graphene for large-area flexible organic light-emitting diodes. Nat. Commun. 2017, 8, 14560. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Lu, C.-C.; Yeh, C.-H.; Jin, C.; Suenaga, K.; Chiu, P.-W. Graphene annealing: How clean can it be? Nano Lett. 2012, 12, 414–419. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Xu, W.; Li, B.; Hao, Q.; Wu, D.; Qi, D.; Gan, H.; Xie, J.; Hong, G.; Zhang, W. Selective Chemical Vapor Deposition Growth of WS2/MoS2 Vertical and Lateral Heterostructures on Gold Foils. Nanomaterials 2022, 12, 1696. [Google Scholar] [CrossRef]

- Wang, Q.H.; Kalantar-Zadeh, K.; Kis, A.; Coleman, J.N.; Strano, M.S. Electronics and optoelectronics of two-dimensional transition metal dichalcogenides. Nat. Nanotechnol. 2012, 7, 699–712. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Yang, L.; Liu, D.; Chen, J.; Fu, Q.; Xiong, Y.; Lin, F.; Xiang, B. Large-area synthesis of monolayer WSe2 on a SiO2/Si substrate and its device applications. Nanoscale 2015, 7, 4193–4198. [Google Scholar] [CrossRef]

- Liu, B.; Fathi, M.; Chen, L.; Abbas, A.; Ma, Y.; Zhou, C. Chemical vapor deposition growth of monolayer WSe2 with tunable device characteristics and growth mechanism study. ACS Nano 2015, 9, 6119–6127. [Google Scholar] [CrossRef]

- Liang, J.; Xu, K.; Toncini, B.; Bersch, B.; Jariwala, B.; Lin, Y.C.; Robinson, J.; Fullerton-Shirey, S.K. Impact of Post-Lithography Polymer Residue on the Electrical Characteristics of MoS2 and WSe2 Field Effect Transistors. Adv. Mater. Interfaces 2019, 6, 1801321. [Google Scholar] [CrossRef]

- Liu, Y.; Guo, J.; Zhu, E.; Liao, L.; Lee, S.-J.; Ding, M.; Shakir, I.; Gambin, V.; Huang, Y.; Duan, X. Approaching the Schottky–Mott limit in van der Waals metal–semiconductor junctions. Nature 2018, 557, 696–700. [Google Scholar] [CrossRef]

- Jung, Y.; Choi, M.S.; Nipane, A.; Borah, A.; Kim, B.; Zangiabadi, A.; Taniguchi, T.; Watanabe, K.; Yoo, W.J.; Hone, J. Transferred via contacts as a platform for ideal two-dimensional transistors. Nat. Electron. 2019, 2, 187–194. [Google Scholar] [CrossRef]

- Yue, L.; Meng, F.; Ren, D.; Luo, S. Top-gate In–Al–Zn–O thin film transistor based on organic poly(methyl methacrylate) dielectric layer. J. Mater. Sci. Mater. Electron. 2019, 30, 11976–11983. [Google Scholar] [CrossRef]

- Zhang, W.; Chiu, M.-H.; Chen, C.-H.; Chen, W.; Li, L.-J.; Wee, A.T.S. Role of Metal Contacts in High-Performance Phototransistors Based on WSe2 Monolayers. ACS Nano 2014, 8, 8653–8661. [Google Scholar] [CrossRef] [PubMed]

- Freitag, M.; Tsang, J.C.; Bol, A.; Yuan, D.; Liu, J.; Avouris, P. Imaging of the Schottky barriers and charge depletion in carbon nanotube transistors. Nano Lett. 2007, 7, 2037–2042. [Google Scholar] [CrossRef] [PubMed]

- Bandyopadhyay, A.S.; Adhikari, N.; Kaul, A.B. Quantum Multibody Interactions in Halide-Assisted Vapor-Synthesized Monolayer WSe2 and Its Integration in a High Responsivity Photodetector with Low-Interface Trap Density. Chem. Mater. 2019, 31, 9861–9874. [Google Scholar] [CrossRef]

- Lopez-Sanchez, O.; Lembke, D.; Kayci, M.; Radenovic, A.; Kis, A. Ultrasensitive photodetectors based on monolayer MoS2. Nat. Nanotechnol. 2013, 8, 497–501. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhang, Y.; Lu, Y.; Xu, W.; Mu, H.; Chen, C.; Qiao, H.; Song, J.; Li, S.; Sun, B.; et al. Hybrid Graphene–Perovskite Phototransistors with Ultrahigh Responsivity and Gain. Adv. Opt. Mater. 2015, 3, 1389–1396. [Google Scholar] [CrossRef]

- Xie, Y.; Wu, E.; Hu, R.; Qian, S.; Feng, Z.; Chen, X.; Zhang, H.; Xu, L.; Hu, X.; Liu, J.; et al. Enhancing electronic and optoelectronic performances of tungsten diselenide by plasma treatment. Nanoscale 2018, 10, 12436–12444. [Google Scholar] [CrossRef]

- Gong, X.; Tong, M.; Xia, Y.; Cai, W.; Moon, J.S.; Cao, Y.; Yu, G.; Shieh, C.-L.; Nilsson, B.; Heeger, A.J. High-Detectivity Polymer Photodetectors with Spectral Response from 300 nm to 1450 nm. Science 2009, 325, 1665–1667. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Nie, Y.; Ou, H.; Chen, D.; Cen, Y.; Liu, J.; Wu, D.; Hong, G.; Li, B.; Xing, G.; et al. Electronic and Optoelectronic Monolayer WSe2 Devices via Transfer-Free Fabrication Method. Nanomaterials 2023, 13, 1368. https://doi.org/10.3390/nano13081368

Wang Z, Nie Y, Ou H, Chen D, Cen Y, Liu J, Wu D, Hong G, Li B, Xing G, et al. Electronic and Optoelectronic Monolayer WSe2 Devices via Transfer-Free Fabrication Method. Nanomaterials. 2023; 13(8):1368. https://doi.org/10.3390/nano13081368

Chicago/Turabian StyleWang, Zixuan, Yecheng Nie, Haohui Ou, Dao Chen, Yingqian Cen, Jidong Liu, Di Wu, Guo Hong, Benxuan Li, Guichuan Xing, and et al. 2023. "Electronic and Optoelectronic Monolayer WSe2 Devices via Transfer-Free Fabrication Method" Nanomaterials 13, no. 8: 1368. https://doi.org/10.3390/nano13081368

APA StyleWang, Z., Nie, Y., Ou, H., Chen, D., Cen, Y., Liu, J., Wu, D., Hong, G., Li, B., Xing, G., & Zhang, W. (2023). Electronic and Optoelectronic Monolayer WSe2 Devices via Transfer-Free Fabrication Method. Nanomaterials, 13(8), 1368. https://doi.org/10.3390/nano13081368