Efficient Semitransparent Organic Solar Cells Enabled by Ag Grid Electrodes and Optical Coupling Layers

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

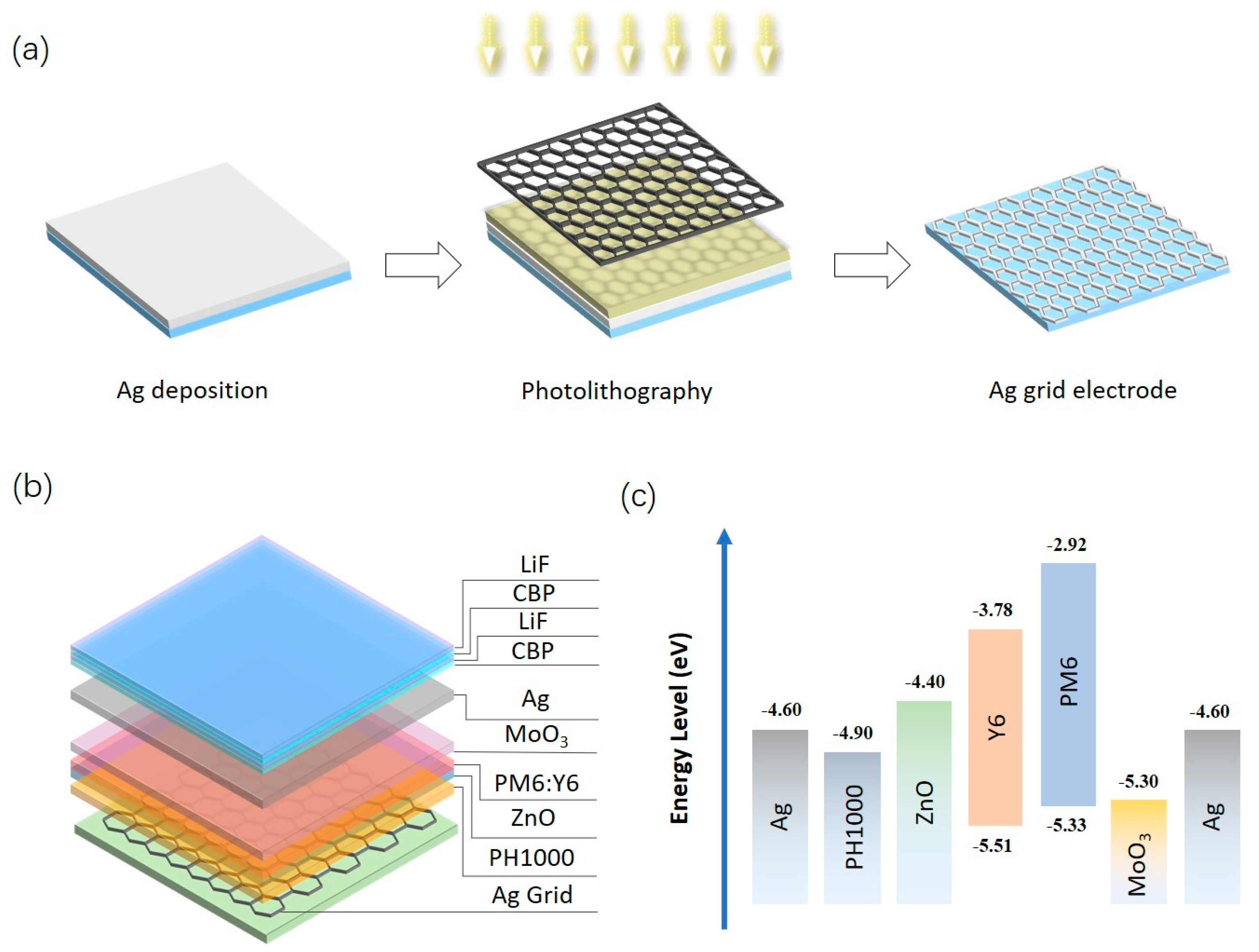

2.2. Fabrication of Ag Grid Electrodes

2.3. Fabrication of OSC Devices

2.4. Device Characterization

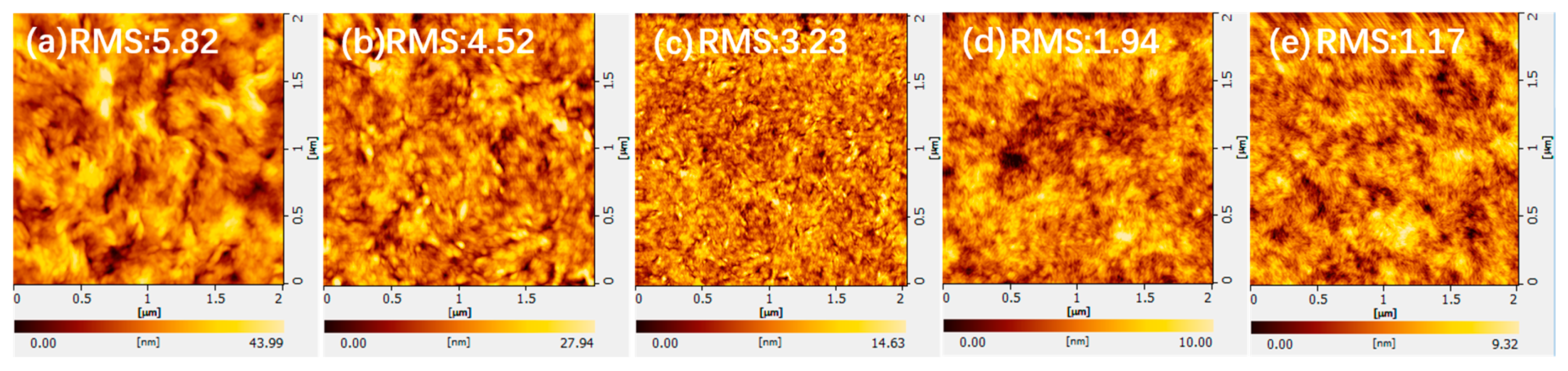

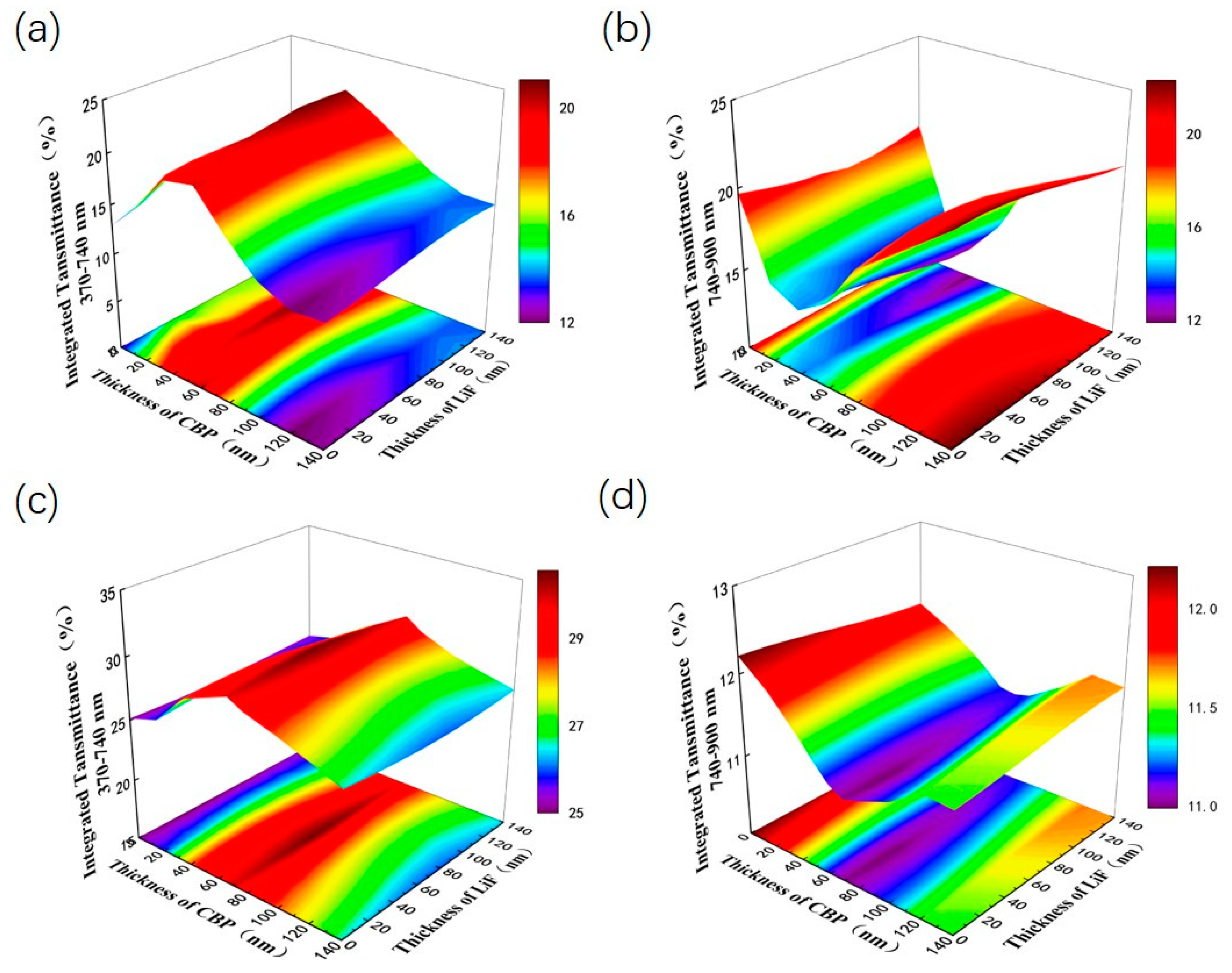

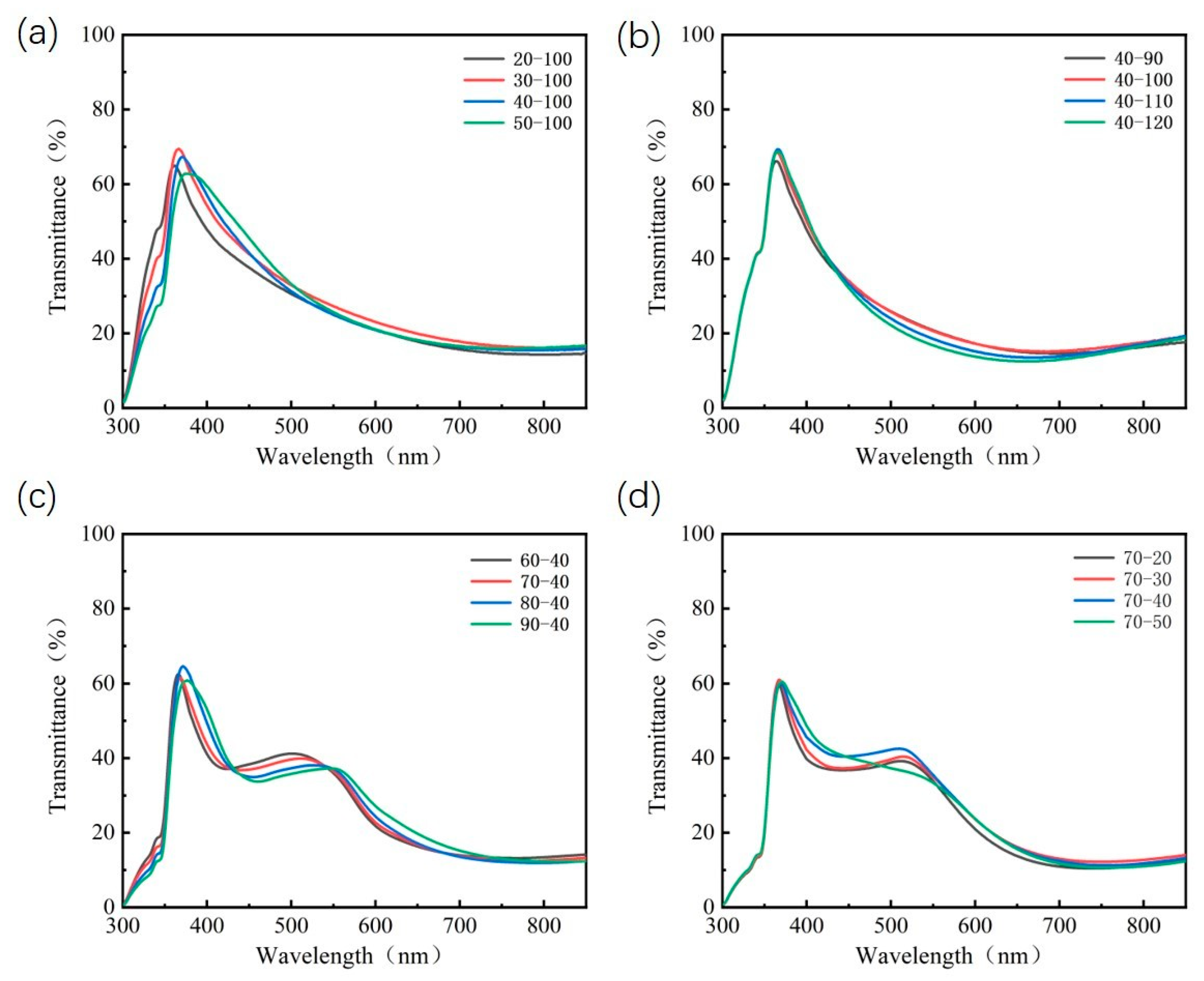

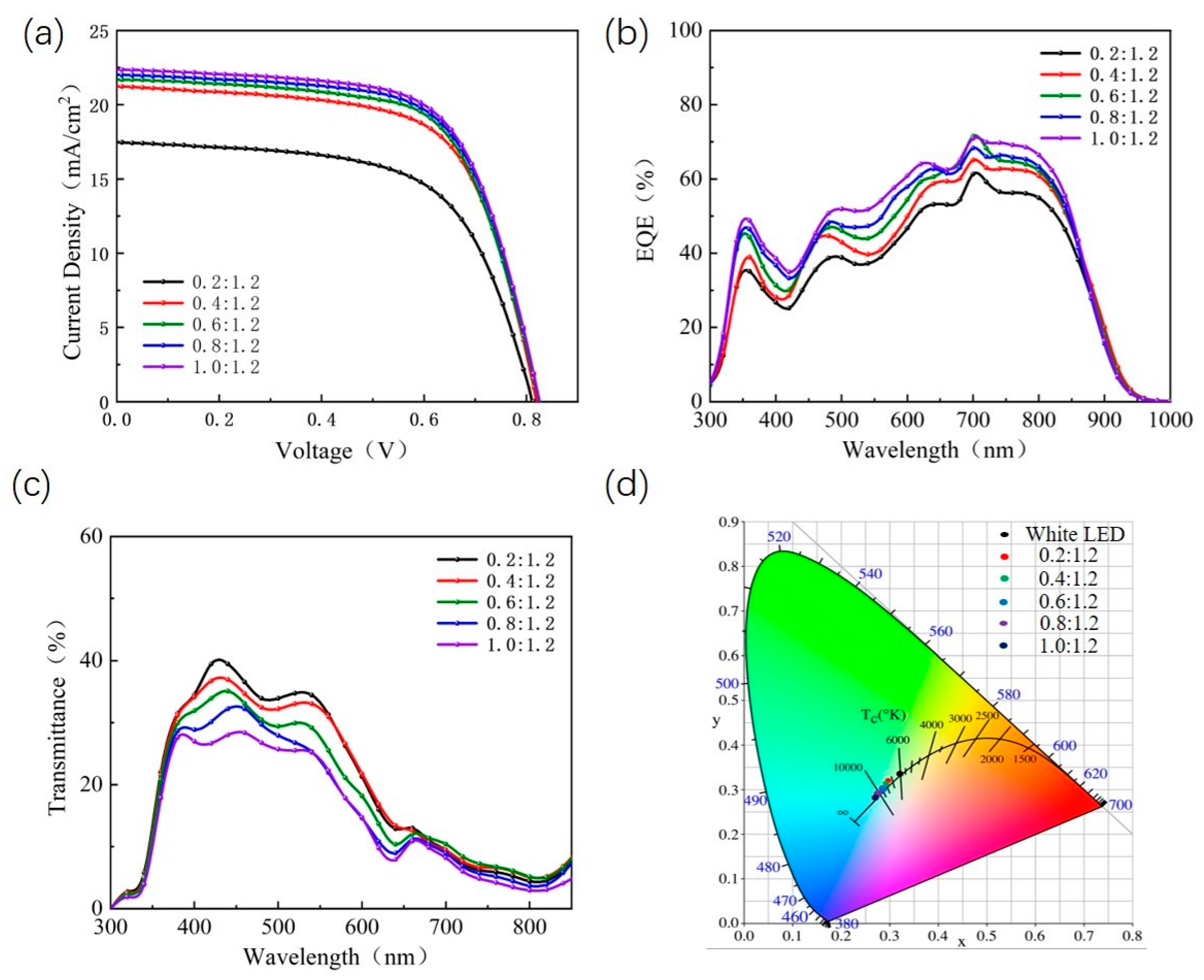

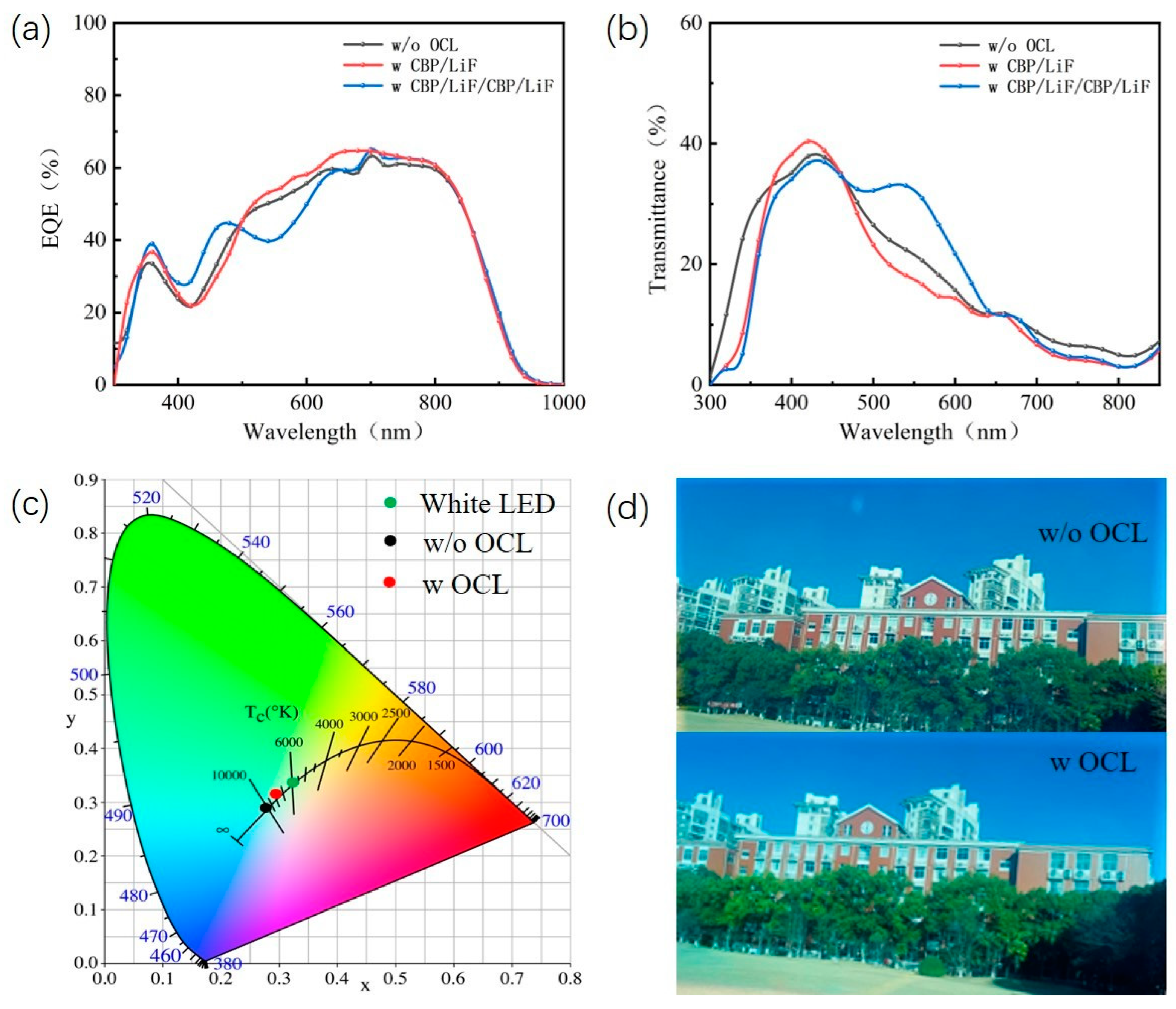

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fan, X.; Nie, W.; Tsai, H.; Wang, N.; Huang, H.; Cheng, Y.; Wen, R.; Ma, L.; Yan, F.; Xia, Y. PEDOT:PSS for Flexible and Stretchable Electronics: Modifications, Strategies, and Applications. Adv. Sci. 2019, 6, 1900813. [Google Scholar] [CrossRef] [PubMed]

- Fan, X. Doping and Design of Flexible Transparent Electrodes for High-Performance Flexible Organic Solar Cells: Recent Advances and Perspectives. Adv. Funct. Mater. 2021, 31, 2102717. [Google Scholar] [CrossRef]

- Yao, J.; Qiu, B.; Zhang, Z.G.; Xue, L.; Wang, R.; Zhang, C.; Chen, S.; Zhou, Q.; Sun, C.; Yang, C.; et al. Cathode engineering with perylene-diimide interlayer enabling over 17% efficiency single-junction organic solar cells. Nat. Commun. 2020, 11, 2726. [Google Scholar] [CrossRef] [PubMed]

- He, C.; Pan, Y.; Ouyang, Y.; Shen, Q.; Gao, Y.; Yan, K.; Fang, J.; Chen, Y.; Ma, C.-Q.; Min, J.; et al. Manipulating the D:A interfacial energetics and intermolecular packing for 19.2% efficiency organic photovoltaics. Energy Environ. Sci. 2022, 15, 2537–2544. [Google Scholar] [CrossRef]

- Chong, K.; Xu, X.; Meng, H.; Xue, J.; Yu, L.; Ma, W.; Peng, Q. Realizing 19.05% Efficiency Polymer Solar Cells by Progressively Improving Charge Extraction and Suppressing Charge Recombination. Adv. Mater. 2022, 34, e2109516. [Google Scholar] [CrossRef] [PubMed]

- Cui, Y.; Xu, Y.; Yao, H.; Bi, P.; Hong, L.; Zhang, J.; Zu, Y.; Zhang, T.; Qin, J.; Ren, J.; et al. Single-Junction Organic Photovoltaic Cell with 19% Efficiency. Adv. Mater. 2021, 33, e2102420. [Google Scholar] [CrossRef]

- Traverse, C.J.; Pandey, R.; Barr, M.C.; Lunt, R.R. Emergence of highly transparent photovoltaics for distributed applications. Nat. Energy 2017, 2, 849–860. [Google Scholar] [CrossRef]

- Qin, J.; Lan, L.; Chen, S.; Huang, F.; Shi, H.; Chen, W.; Xia, H.; Sun, K.; Yang, C. Recent Progress in Flexible and Stretchable Organic Solar Cells. Adv. Funct. Mater. 2020, 30, 2002529. [Google Scholar] [CrossRef]

- Xia, R.; Brabec, C.J.; Yip, H.-L.; Cao, Y. High-Throughput Optical Screening for Efficient Semitransparent Organic Solar Cells. Joule 2019, 3, 2241–2254. [Google Scholar] [CrossRef]

- Kini, G.P.; Jeon, S.J.; Moon, D.K. Latest Progress on Photoabsorbent Materials for Multifunctional Semitransparent Organic Solar Cells. Adv. Funct. Mater. 2021, 31, 2007931. [Google Scholar] [CrossRef]

- Xie, Y.; Cai, Y.; Zhu, L.; Xia, R.; Ye, L.; Feng, X.; Yip, H.L.; Liu, F.; Lu, G.; Tan, S.; et al. Fibril Network Strategy Enables High-Performance Semitransparent Organic Solar Cells. Adv. Funct. Mater. 2020, 30, 2002181. [Google Scholar] [CrossRef]

- Yao, M.; Li, T.; Long, Y.; Shen, P.; Wang, G.; Li, C.; Liu, J.; Guo, W.; Wang, Y.; Shen, L.; et al. Color and transparency-switchable semitransparent polymer solar cells towards smart windows. Sci. Bull. 2020, 65, 217–224. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Ji, C.; Qu, Y.; Huang, X.; Hou, S.; Li, C.Z.; Liao, L.S.; Guo, L.J.; Forrest, S.R. Enhanced Light Utilization in Semitransparent Organic Photovoltaics Using an Optical Outcoupling Architecture. Adv. Mater. 2019, 31, e1903173. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Zhang, L.; Cheng, Y.; Oh, J.; Li, C.; Huang, B.; Zhao, L.; Deng, J.; Zhang, Y.; Liu, Z.; et al. Novel Narrow Bandgap Terpolymer Donors Enables Record Performance for Semitransparent Organic Solar Cells Based on All-Narrow Bandgap Semiconductors. Adv. Funct. Mater. 2021, 32, 2108634. [Google Scholar] [CrossRef]

- Cheng, P.; Wang, H.C.; Zhu, Y.; Zheng, R.; Li, T.; Chen, C.H.; Huang, T.; Zhao, Y.; Wang, R.; Meng, D.; et al. Transparent Hole-Transporting Frameworks: A Unique Strategy to Design High-Performance Semitransparent Organic Photovoltaics. Adv. Mater. 2020, 32, e2003891. [Google Scholar] [CrossRef]

- Xue, P.; Xin, J.; Lu, G.; Jia, B.; Lu, H.; Lu, G.; Ma, W.; Han, R.P.S.; Zhan, X. High-performance semitransparent organic solar cells based on sequentially processed heterojunction. J. Mater. Chem. C 2023. [Google Scholar] [CrossRef]

- Hu, Z.; Wang, Z.; An, Q.; Zhang, F. Semitransparent polymer solar cells with 12.37% efficiency and 18.6% average visible transmittance. Sci. Bull. 2020, 65, 131–137. [Google Scholar] [CrossRef]

- Hu, Z.; Wang, Z.; Zhang, F. Semitransparent polymer solar cells with 9.06% efficiency and 27.1% average visible transmittance obtained by employing a smart strategy. J. Mater. Chem. A 2019, 7, 7025–7032. [Google Scholar] [CrossRef]

- Chueh, C.-C.; Chien, S.-C.; Yip, H.-L.; Salinas, J.F.; Li, C.-Z.; Chen, K.-S.; Chen, F.-C.; Chen, W.-C.; Jen, A.K.Y. Toward High-Performance Semi-Transparent Polymer Solar Cells: Optimization of Ultra-Thin Light Absorbing Layer and Transparent Cathode Architecture. Adv. Energy Mater. 2013, 3, 417–423. [Google Scholar] [CrossRef]

- Min, J.; Bronnbauer, C.; Zhang, Z.-G.; Cui, C.; Luponosov, Y.N.; Ata, I.; Schweizer, P.; Przybilla, T.; Guo, F.; Ameri, T.; et al. Fully Solution-Processed Small Molecule Semitransparent Solar Cells: Optimization of Transparent Cathode Architecture and Four Absorbing Layers. Adv. Funct. Mater. 2016, 26, 4543–4550. [Google Scholar] [CrossRef]

- Song, Y.; Chang, S.; Gradecak, S.; Kong, J. Visibly-Transparent Organic Solar Cells on Flexible Substrates with All-Graphene Electrodes. Adv. Energy Mater. 2016, 6, 1600847. [Google Scholar] [CrossRef]

- Czolk, J.; Puetz, A.; Kutsarov, D.; Reinhard, M.; Lemmer, U.; Colsmann, A. Inverted Semi-transparent Polymer Solar Cells with Transparency Color Rendering Indices approaching 100. Adv. Energy Mater. 2013, 3, 386–390. [Google Scholar] [CrossRef]

- Xu, G.; Shen, L.; Cui, C.; Wen, S.; Xue, R.; Chen, W.; Chen, H.; Zhang, J.; Li, H.; Li, Y.; et al. High-Performance Colorful Semitransparent Polymer Solar Cells with Ultrathin Hybrid-Metal Electrodes and Fine-Tuned Dielectric Mirrors. Adv. Funct. Mater. 2017, 27, 1605908. [Google Scholar] [CrossRef]

- Yu, W.; Shen, L.; Long, Y.; Shen, P.; Guo, W.; Chen, W.; Ruan, S. Highly efficient and high transmittance semitransparent polymer solar cells with one-dimensional photonic crystals as distributed Bragg reflectors. Org. Electron. 2014, 15, 470–477. [Google Scholar] [CrossRef]

- Yeom, H.R.; Song, S.; Park, S.Y.; Ryu, H.S.; Kim, J.W.; Heo, J.; Cho, H.W.; Walker, B.; Ko, S.-J.; Woo, H.Y.; et al. Aesthetic and colorful: Dichroic polymer solar cells using high-performance Fabry-Pérot etalon electrodes with a unique Sb2O3 cavity. Nano Energy 2020, 77, 105146. [Google Scholar] [CrossRef]

- Xu, T.; Luo, Y.; Wu, S.; Deng, B.; Chen, S.; Zhong, Y.; Wang, S.; Leveque, G.; Bachelot, R.; Zhu, F. High-Performance Semitransparent Organic Solar Cells: From Competing Indexes of Transparency and Efficiency Perspectives. Adv. Sci. 2022, 9, e2202150. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Zhong, Z.; Zhu, R.; Yu, J.; Li, G. Aperiodic band-pass electrode enables record-performance transparent organic photovoltaics. Joule 2022, 6, 1918–1930. [Google Scholar] [CrossRef]

- Lim, J.W.; Lee, Y.T.; Pandey, R.; Yoo, T.H.; Sang, B.I.; Ju, B.K.; Hwang, D.K.; Choi, W.K. Effect of geometric lattice design on optical/electrical properties of transparent silver grid for organic solar cells. Opt. Express 2014, 22, 26891–26899. [Google Scholar] [CrossRef]

- Raman, V.; Cho, Y.-H.; Park, J.-H.; Chinnadurai, D.; Kim, H.-K. Impact of low temperature plasma annealing for flexible, transparent and conductive ITO/PEDOT:PSS composite electrode. J. Ind. Eng. Chem. 2021, 93, 423–429. [Google Scholar] [CrossRef]

- Wu, S.; Li, Y.; Lian, H.; Leveque, G.; Grandidier, B.; Adam, P.M.; Gerard, D.; Bachelot, R.; Xu, T.; Wei, B. Hybrid nanostructured plasmonic electrodes for flexible organic light-emitting diodes. Nanotechnology 2020, 31, 375203. [Google Scholar] [CrossRef]

- Jeong, G.; Jung, S.; Choi, Y.; Lee, J.; Seo, J.; Kim, D.S.; Park, H. A highly robust and stable graphene-encapsulated Cu-grid hybrid transparent electrode demonstrating superior performance in organic solar cells. J. Mater. Chem. A 2018, 6, 24805–24813. [Google Scholar] [CrossRef]

- Seo, K.W.; Lee, J.; Jo, J.; Cho, C.; Lee, J.Y. Highly Efficient (>10%) Flexible Organic Solar Cells on PEDOT-Free and ITO-Free Transparent Electrodes. Adv. Mater. 2019, 31, e1902447. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.; Zhang, M.; Tan, J.; Zhang, S.; Huo, L.; Hu, W.; Li, Y.; Hou, J. Influence of D/A ratio on photovoltaic performance of a highly efficient polymer solar cell system. Adv. Mater. 2012, 24, 6536–6541. [Google Scholar] [CrossRef] [PubMed]

- Hu, Z.; Wang, J.; Ma, X.; Gao, J.; Xu, C.; Yang, K.; Wang, Z.; Zhang, J.; Zhang, F. A critical review on semitransparent organic solar cells. Nano Energy 2020, 78, 105376. [Google Scholar] [CrossRef]

- Xiao, L.; Huang, G.; Zhang, H.; Zhang, X.; Li, Y.; Li, S.; Jiang, T.; Han, B.; Zhang, Y.; Zhou, H. Light Managements and Transparent Electrodes for Semitransparent Organic and Perovskite Solar Cells. Sol. RRL 2022, 6, 2100818. [Google Scholar] [CrossRef]

- Huang, X.; Cheng, Y.; Fang, Y.; Zhang, L.; Hu, X.; Jeong, S.Y.; Zhang, H.; Woo, H.Y.; Wu, F.; Chen, L. A molecular weight-regulated sequential deposition strategy enabling semitransparent organic solar cells with the light utilization efficiency of over 5%. Energy Environ. Sci. 2022, 15, 4776–4788. [Google Scholar] [CrossRef]

- Sun, J.; Ma, X.; Zhang, Z.; Yu, J.; Zhou, J.; Yin, X.; Yang, L.; Geng, R.; Zhu, R.; Zhang, F.; et al. Dithieno[3,2-b:2′,3′-d]pyrrol Fused Nonfullerene Acceptors Enabling Over 13% Efficiency for Organic Solar Cells. Adv. Mater. 2018, 30, e1707150. [Google Scholar] [CrossRef]

- Guan, S.; Li, Y.; Yan, K.; Fu, W.; Zuo, L.; Chen, H. Balancing the Selective Absorption and Photon-to-Electron Conversion for Semitransparent Organic Photovoltaics with 5.0% Light-Utilization Efficiency. Adv. Mater. 2022, 34, e2205844. [Google Scholar] [CrossRef]

- Huo, Y.; Gong, X.-T.; Lau, T.-K.; Xiao, T.; Yan, C.; Lu, X.; Lu, G.; Zhan, X.; Zhang, H.-L. Dual-Accepting-Unit Design of Donor Material for All-Small-Molecule Organic Solar Cells with Efficiency Approaching 11%. Chem. Mater. 2018, 30, 8661–8668. [Google Scholar] [CrossRef]

| Pitch (μm) | Sheet Resistance (Ω/sq) | Transmittance (@550 nm%) | FOM |

|---|---|---|---|

| 100 | 14.3 | 91 | 273 |

| 200 | 22.9 | 94.6 | 292.46 |

| 300 | 36.6 | 96.3 | 270.64 |

| 400 | 66.4 | 97.6 | 233.7 |

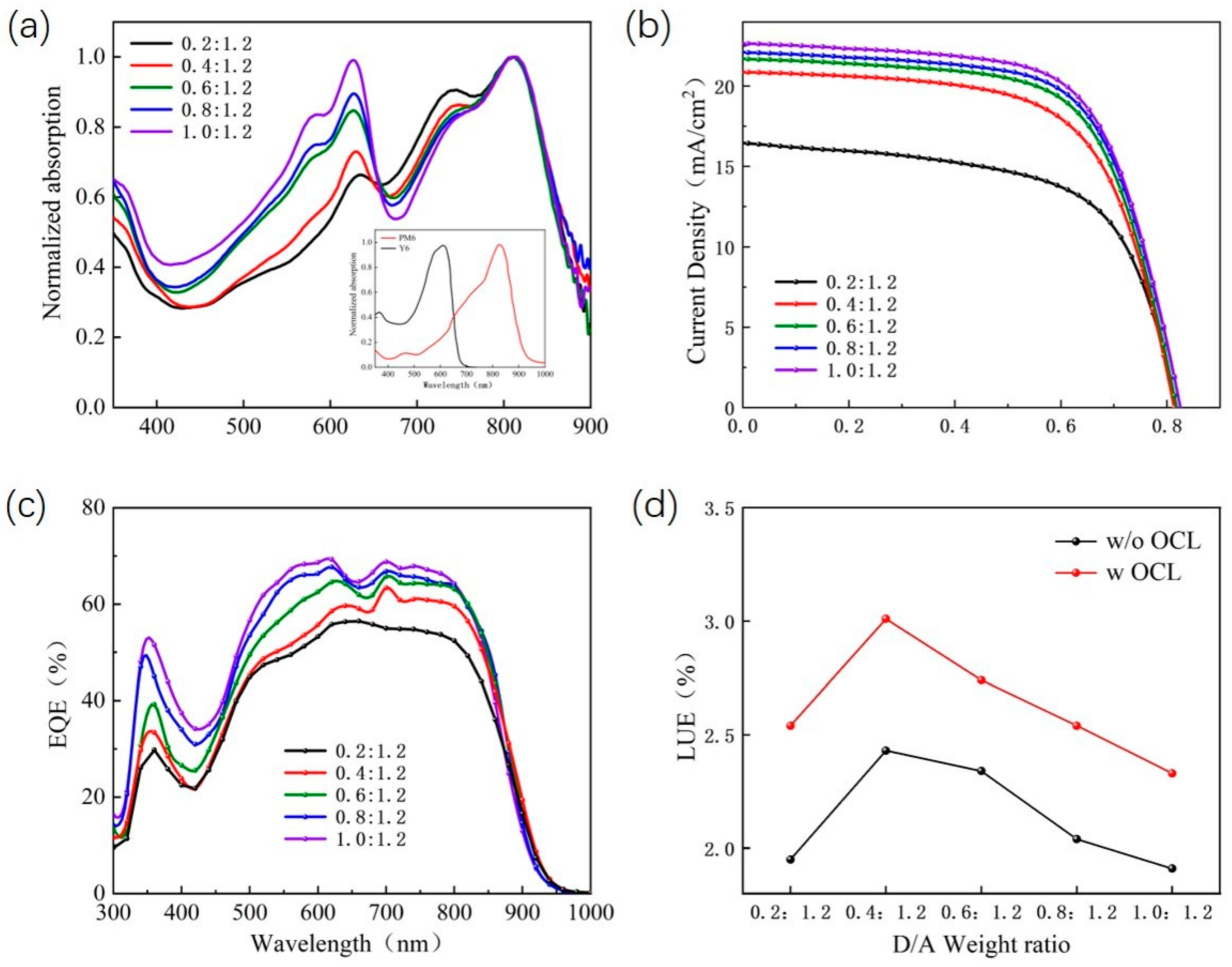

| D:A Ratio | JSC [mA/cm2] | VOC [V] | FF [%] | PCE [%] | AVT [%] | LUE [%] | |

|---|---|---|---|---|---|---|---|

| ST-OSCs without OCL | 0.2:1.2 | 16.46 ± 0.24 | 0.817 ± 0.02 | 62.10 ± 0.32 | 8.36 ± 0.21 | 23.43 | 1.95 |

| 0.4:1.2 | 20.65 ± 0.22 | 0.816 ± 0.03 | 63.12 ± 0.43 | 10.65 ± 0.24 | 22.78 | 2.43 | |

| 0.6:1.2 | 21.64 ± 0.19 | 0.818 ± 0.02 | 65.15 ± 0.25 | 11.52 ± 0.17 | 20.37 | 2.34 | |

| 0.8:1.2 | 22.09 ± 0.29 | 0.821 ± 0.02 | 65.23 ± 0.36 | 11.83 ± 0.07 | 17.30 | 2.04 | |

| 1.0:1.2 | 22.65 ± 0.34 | 0.823 ± 0.01 | 65.31 ± 0.18 | 12.17 ± 0.19 | 15.78 | 1.91 | |

| ST-OSCs with OCL | 0.2:1.2 | 17.45 ± 0.42 | 0.817 ± 0.02 | 62.23 ± 0.37 | 8.7 ± 0.12 | 28.94 | 2.54 |

| 0.4:1.2 | 21.23 ± 0.43 | 0.816 ± 0.03 | 63.59 ± 0.34 | 10.87 ± 0.18 | 27.61 | 3.01 | |

| 0.6:1.2 | 21.67 ± 0.32 | 0.818 ± 0.01 | 65.17 ± 0.25 | 11.55 ± 0.22 | 23.72 | 2.74 | |

| 0.8:1.2 | 22.01 ± 0.26 | 0.821 ± 0.02 | 65.22 ± 0.34 | 11.76 ± 0.21 | 21.29 | 2.54 | |

| 1.0:1.2 | 22.36 ± 0.31 | 0.823 ± 0.02 | 65.24 ± 0.36 | 12.00 ± 0.26 | 19.43 | 2.33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, N.; Zhen, T.; Wu, Y.; Wei, B.; Liao, Y.; Liu, Y. Efficient Semitransparent Organic Solar Cells Enabled by Ag Grid Electrodes and Optical Coupling Layers. Nanomaterials 2023, 13, 1308. https://doi.org/10.3390/nano13081308

Zhao N, Zhen T, Wu Y, Wei B, Liao Y, Liu Y. Efficient Semitransparent Organic Solar Cells Enabled by Ag Grid Electrodes and Optical Coupling Layers. Nanomaterials. 2023; 13(8):1308. https://doi.org/10.3390/nano13081308

Chicago/Turabian StyleZhao, Ning, Tao Zhen, Yizhou Wu, Bin Wei, Yingjie Liao, and Yuanyuan Liu. 2023. "Efficient Semitransparent Organic Solar Cells Enabled by Ag Grid Electrodes and Optical Coupling Layers" Nanomaterials 13, no. 8: 1308. https://doi.org/10.3390/nano13081308

APA StyleZhao, N., Zhen, T., Wu, Y., Wei, B., Liao, Y., & Liu, Y. (2023). Efficient Semitransparent Organic Solar Cells Enabled by Ag Grid Electrodes and Optical Coupling Layers. Nanomaterials, 13(8), 1308. https://doi.org/10.3390/nano13081308