Great Potential of Si-Te Ovonic Threshold Selector in Electrical Performance and Scalability

Abstract

1. Introduction

2. Materials and Methods

2.1. Film Preparation and Testing

2.2. Device Fabrication

3. Results

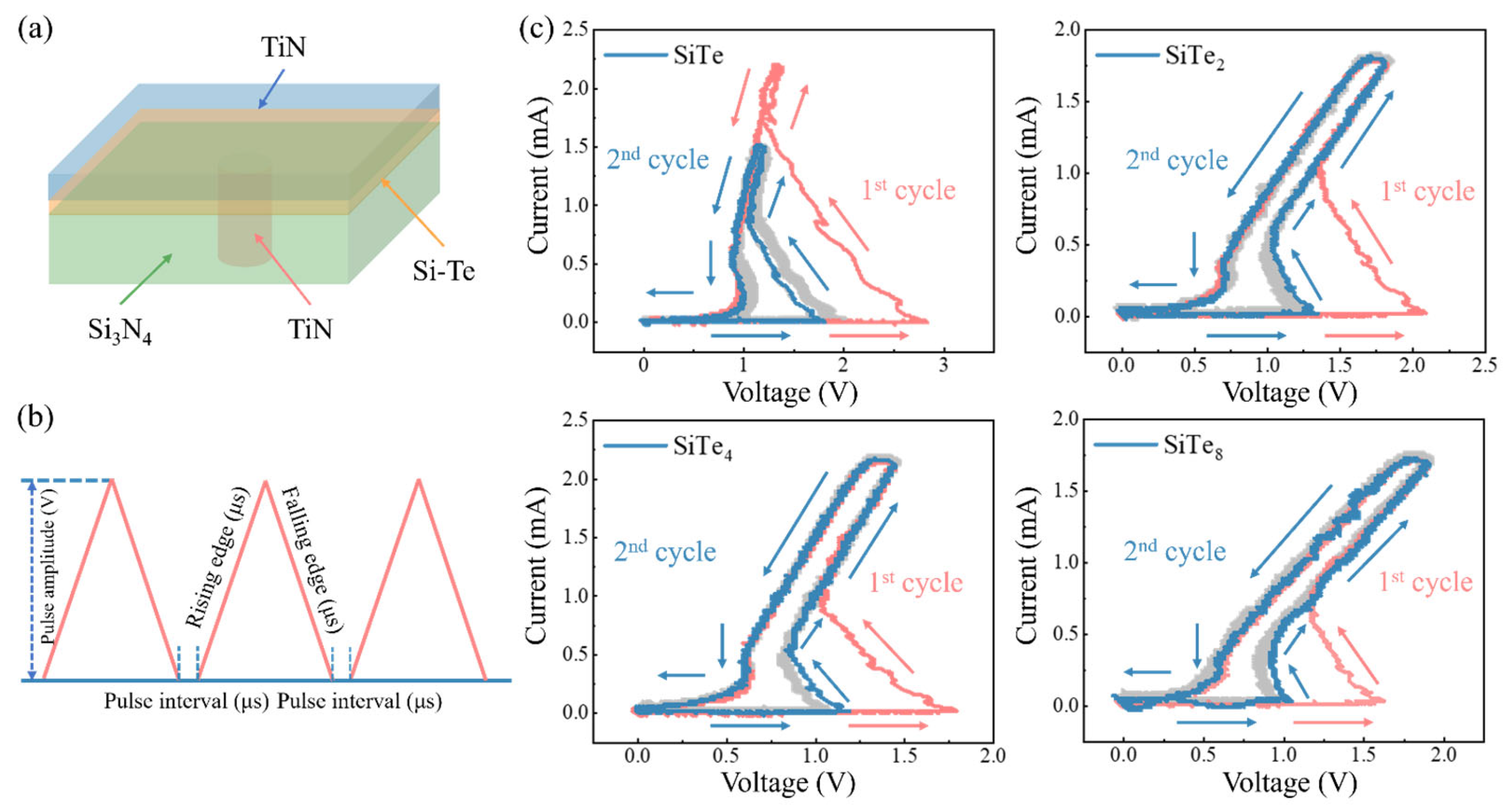

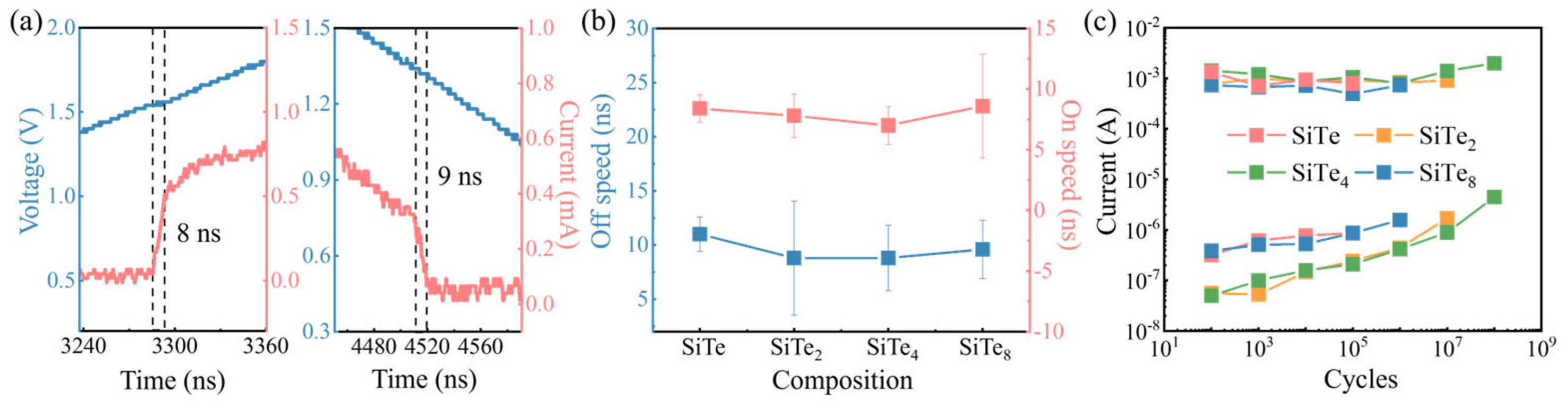

3.1. Variations of Electrical Performance with Different Si Concentrations

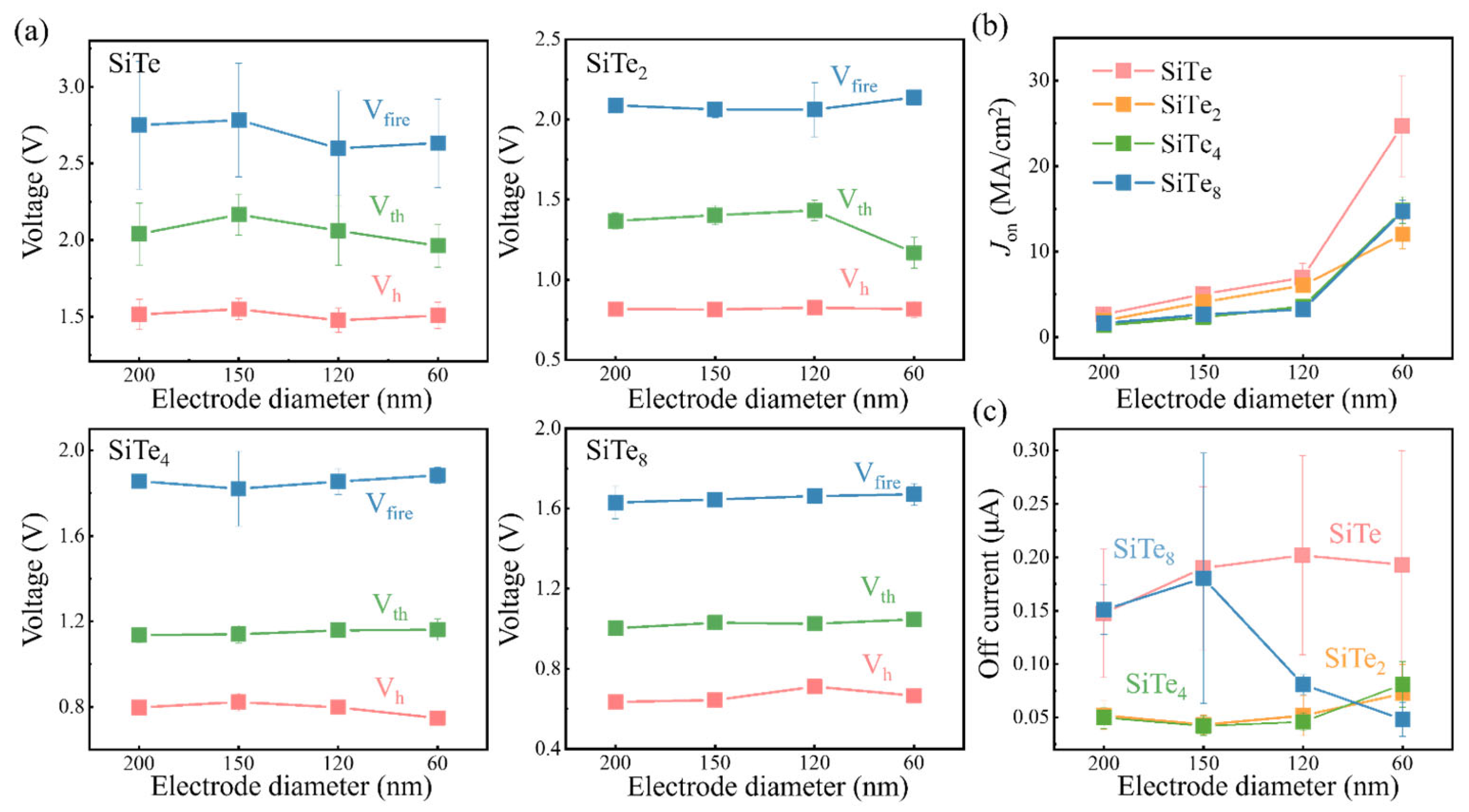

3.2. Effect of Device Size on Electrical Performance

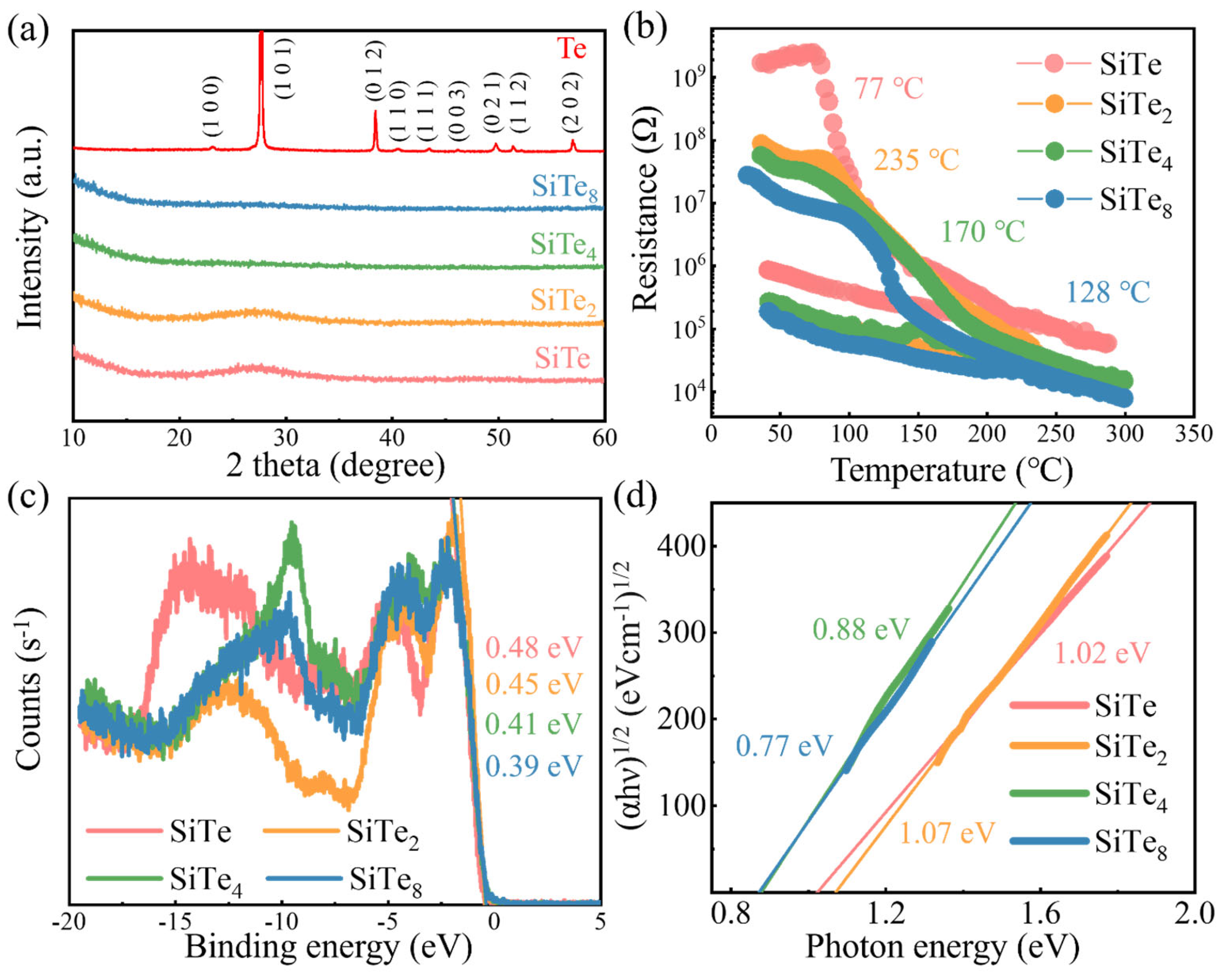

3.3. Characterization of Si-Te Films

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shen, J.; Jia, S.; Shi, N.; Ge, Q.; Gotoh, T.; Lv, S.; Liu, Q.; Dronskowski, R.; Elliott, S.R.; Song, Z.; et al. Elemental Electrical Switch Enabling Phase Segregation–Free Operation. Science 2021, 374, 1390–1394. [Google Scholar] [CrossRef] [PubMed]

- Calarco, R.; Arciprete, F. Keep It Simple and Switch to Pure Tellurium. Science 2021, 374, 1321–1322. [Google Scholar] [CrossRef] [PubMed]

- Wuttig, M.; Yamada, N. Phase-Change Materials for Rewriteable Data Storage. Nat. Mater. 2007, 6, 824–832. [Google Scholar] [CrossRef] [PubMed]

- Zhu, M.; Song, W.; Konze, P.M.; Li, T.; Gault, B.; Chen, X.; Shen, J.; Lv, S.; Song, Z.; Wuttig, M.; et al. Direct Atomic Insight into the Role of Dopants in Phase-Change Materials. Nat. Commun. 2019, 10, 3525. [Google Scholar] [CrossRef] [PubMed]

- Lai, S.; Lowrey, T. OUM—A 180 nm Nonvolatile Memory Cell Element Technology for Stand Alone and Embedded Applications. In Proceedings of the International Electron Devices Meeting. Technical Digest, Washington, DC, USA, 2–5 December 2001; IEEE: Piscataway, NJ, USA, 2001; pp. 36.5.1–36.5.4. [Google Scholar] [CrossRef]

- Choe, J. Memory Technology 2021: Trends & Challenges. In Proceedings of the 2021 International Conference on Simulation of Semiconductor Processes and Devices (SISPAD), Dallas, TX, USA, 27–29 September 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 111–115. [Google Scholar] [CrossRef]

- Kau, D.; Tang, S.; Karpov, I.V.; Dodge, R.; Klehn, B.; Kalb, J.A.; Strand, J.; Diaz, A.; Leung, N.; Wu, J.; et al. A Stackable Cross Point Phase Change Memory. In Proceedings of the Technical Digest—International Electron Devices Meeting, IEDM, Baltimore, MD, USA, 7–9 December 2009; IEEE: Piscataway, NJ, USA, 2009; pp. 1–4. [Google Scholar] [CrossRef]

- Jia, S.; Li, H.; Gotoh, T.; Longeaud, C.; Zhang, B.; Lyu, J.; Lv, S.; Zhu, M.; Song, Z.; Liu, Q.; et al. Ultrahigh Drive Current and Large Selectivity in GeS Selector. Nat. Commun. 2020, 11, 4636. [Google Scholar] [CrossRef] [PubMed]

- Wu, R.; Jia, S.; Gotoh, T.; Luo, Q.; Song, Z.; Zhu, M. Screening Switching Materials with Low Leakage Current and High Thermal Stability for Neuromorphic Computing. Adv. Electron. Mater. 2022, 8, 2200150. [Google Scholar] [CrossRef]

- Jia, S.; Li, H.; Liu, Q.; Song, Z.; Zhu, M. Scalability of Sulfur-Based Ovonic Threshold Selectors for 3D Stackable Memory Applications. Phys. Status Solidi Rapid Res. Lett. 2021, 15, 2100084. [Google Scholar] [CrossRef]

- Yuan, Z.; Li, X.; Song, S.; Song, Z.; Zha, J.; Han, G.; Yang, B.; Jimbo, T.; Suu, K. The Enhanced Performance of a Si–As–Se Ovonic Threshold Switching Selector. J. Mater. Chem. C 2021, 9, 13376–13383. [Google Scholar] [CrossRef]

- Yuan, Z.; Li, X.; Wang, H.; Xue, Y.; Song, S.; Song, Z.; Zhu, S.; Han, G.; Yang, B.; Jimbo, T.; et al. Characteristic of As3Se4-Based Ovonic Threshold Switching Device. J. Mater. Sci. Mater. Electron. 2021, 32, 7209–7214. [Google Scholar] [CrossRef]

- Cheng, H.Y.; Chien, W.C.; Kuo, I.T.; Lai, E.K.; Zhu, Y.; Jordan-Sweet, J.L.; Ray, A.; Carta, F.; Lee, F.M.; Tseng, P.H.; et al. An Ultra High Endurance and Thermally Stable Selector Based on TeAsGeSiSe Chalcogenides Compatible with BEOL IC Integration for Cross-Point PCM. In Proceedings of the 2017 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 2–6 December 2017; IEEE: Piscataway, NJ, USA, 2017; Volume 1, pp. 2.2.1–2.2.4. [Google Scholar] [CrossRef]

- Garbin, D.; Devulder, W.; Degraeve, R.; Donadio, G.L.; Clima, S.; Opsomer, K.; Fantini, A.; Cellier, D.; Kim, W.G.; Pakala, M.; et al. Composition Optimization and Device Understanding of Si-Ge-As-Te Ovonic Threshold Switch Selector with Excellent Endurance. In Proceedings of the 2019 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 7–11 December 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 35.1.1–35.1.4. [Google Scholar] [CrossRef]

- Zhu, M.; Ren, K.; Song, Z. Ovonic Threshold Switching Selectors for Three-Dimensional Stackable Phase-Change Memory. MRS Bull. 2019, 44, 715–720. [Google Scholar] [CrossRef]

- Keukelier, J.; Opsomer, K.; Devulder, W.; Clima, S.; Goux, L.; Sankar Kar, G.; Detavernier, C. Tuning of the Thermal Stability and Ovonic Threshold Switching Properties of GeSe with Metallic and Non-Metallic Alloying Elements. J. Appl. Phys. 2021, 130, 165103. [Google Scholar] [CrossRef]

- Anbarasu, M.; Wimmer, M.; Bruns, G.; Salinga, M.; Wuttig, M. Nanosecond Threshold Switching of GeTe6 Cells and Their Potential as Selector Devices. Appl. Phys. Lett. 2012, 100, 143505. [Google Scholar] [CrossRef]

- Li, X.; Yuan, Z.; Lv, S.; Song, S.; Song, Z. Extended Endurance Performance and Reduced Threshold Voltage by Doping Si in GeSe-Based Ovonic Threshold Switching Selectors. Thin Solid Films 2021, 734, 1–9. [Google Scholar] [CrossRef]

- Koo, Y.; Lee, S.; Park, S.; Yang, M.; Hwang, H. Simple Binary Ovonic Threshold Switching Material SiTe and Its Excellent Selector Performance for High-Density Memory Array Application. IEEE Electron Device Lett. 2017, 38, 568–571. [Google Scholar] [CrossRef]

- Velea, A.; Opsomer, K.; Devulder, W.; Dumortier, J.; Fan, J.; Detavernier, C.; Jurczak, M.; Govoreanu, B. Te-Based Chalcogenide Materials for Selector Applications. Sci. Rep. 2017, 7, 8103. [Google Scholar] [CrossRef] [PubMed]

- Yoo, J.; Lee, D.; Park, J.; Song, J.; Hwang, H. Steep Slope Field-Effect Transistors with B-Te-Based Ovonic Threshold Switch Device. IEEE J. Electron Devices Soc. 2018, 6, 821–824. [Google Scholar] [CrossRef]

- Cheng, H.Y.; Chien, W.C.; Kuo, I.T.; Yeh, C.W.; Gignac, L.; Kim, W.; Lai, E.K.; Lin, Y.F.; Bruce, R.L.; Lavoie, C.; et al. Ultra-High Endurance and Low IOFF Selector Based on AsSeGe Chalcogenides for Wide Memory Window 3D Stackable Crosspoint Memory. In Proceedings of the 2018 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 1–5 December 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 37.3.1–37.3.4. [Google Scholar] [CrossRef]

- Chen, M.; Rubin, K.A.; Barton, R.W. Compound Materials for Reversible, Phase-change Optical Data Storage. Appl. Phys. Lett. 1986, 49, 502–504. [Google Scholar] [CrossRef]

- Ielmini, D.; Zhang, Y. Analytical Model for Subthreshold Conduction and Threshold Switching in Chalcogenide-Based Memory Devices. J. Appl. Phys. 2007, 102, 054517. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, R.; Sun, Y.; Zhang, S.; Zhao, Z.; Song, Z. Great Potential of Si-Te Ovonic Threshold Selector in Electrical Performance and Scalability. Nanomaterials 2023, 13, 1114. https://doi.org/10.3390/nano13061114

Wu R, Sun Y, Zhang S, Zhao Z, Song Z. Great Potential of Si-Te Ovonic Threshold Selector in Electrical Performance and Scalability. Nanomaterials. 2023; 13(6):1114. https://doi.org/10.3390/nano13061114

Chicago/Turabian StyleWu, Renjie, Yuting Sun, Shuhao Zhang, Zihao Zhao, and Zhitang Song. 2023. "Great Potential of Si-Te Ovonic Threshold Selector in Electrical Performance and Scalability" Nanomaterials 13, no. 6: 1114. https://doi.org/10.3390/nano13061114

APA StyleWu, R., Sun, Y., Zhang, S., Zhao, Z., & Song, Z. (2023). Great Potential of Si-Te Ovonic Threshold Selector in Electrical Performance and Scalability. Nanomaterials, 13(6), 1114. https://doi.org/10.3390/nano13061114