Novel LiAlO2 Material for Scalable and Facile Lithium Recovery Using Electrochemical Ion Pumping

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. LiAlO2 Preparation

2.3. Electrode Preparation

2.4. Material Characterization

2.5. Electrochemical Characterization

2.6. ESIX Li Capture–Release Cycling Tests

2.7. Stability Tests

3. Results and Discussion

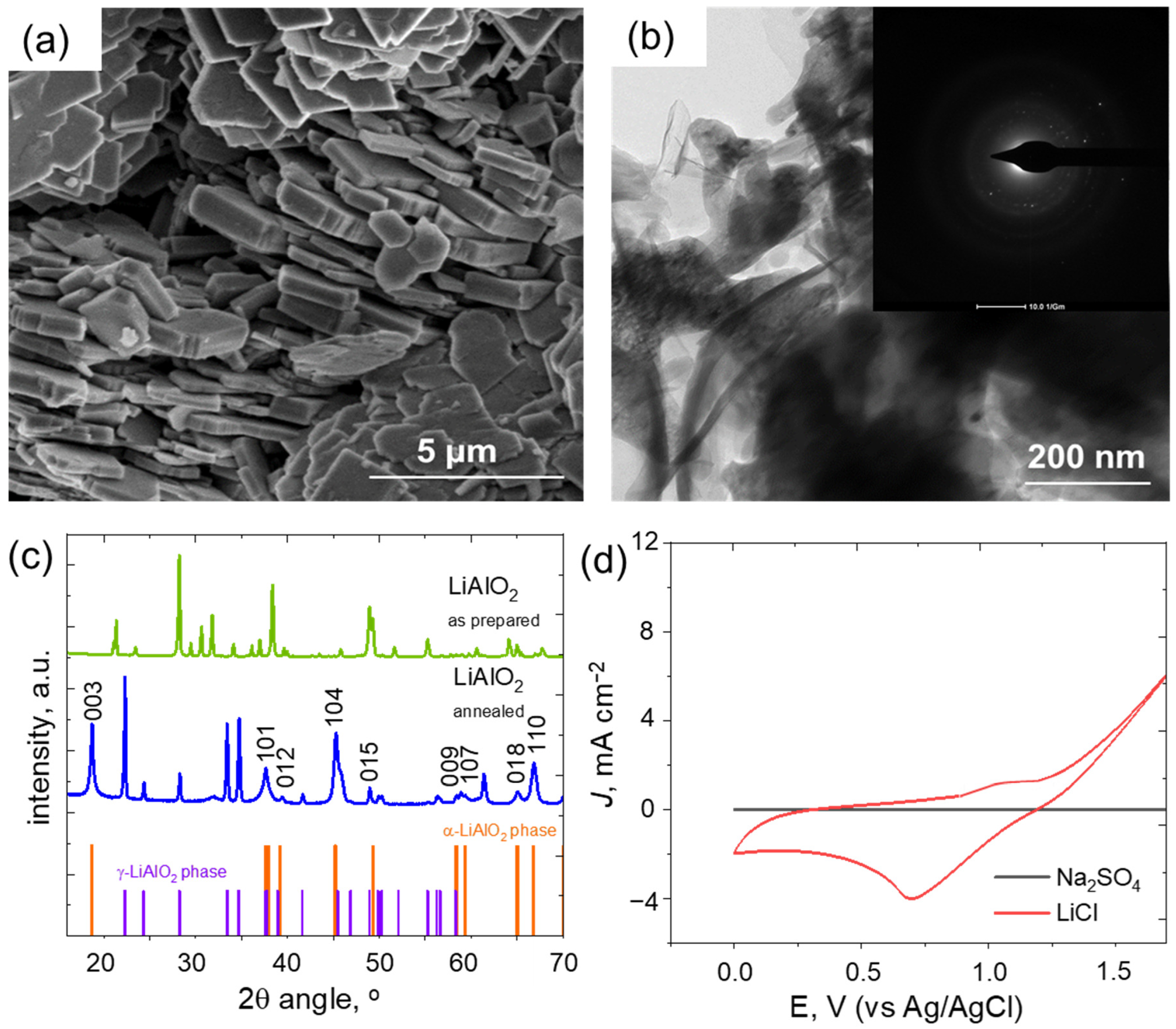

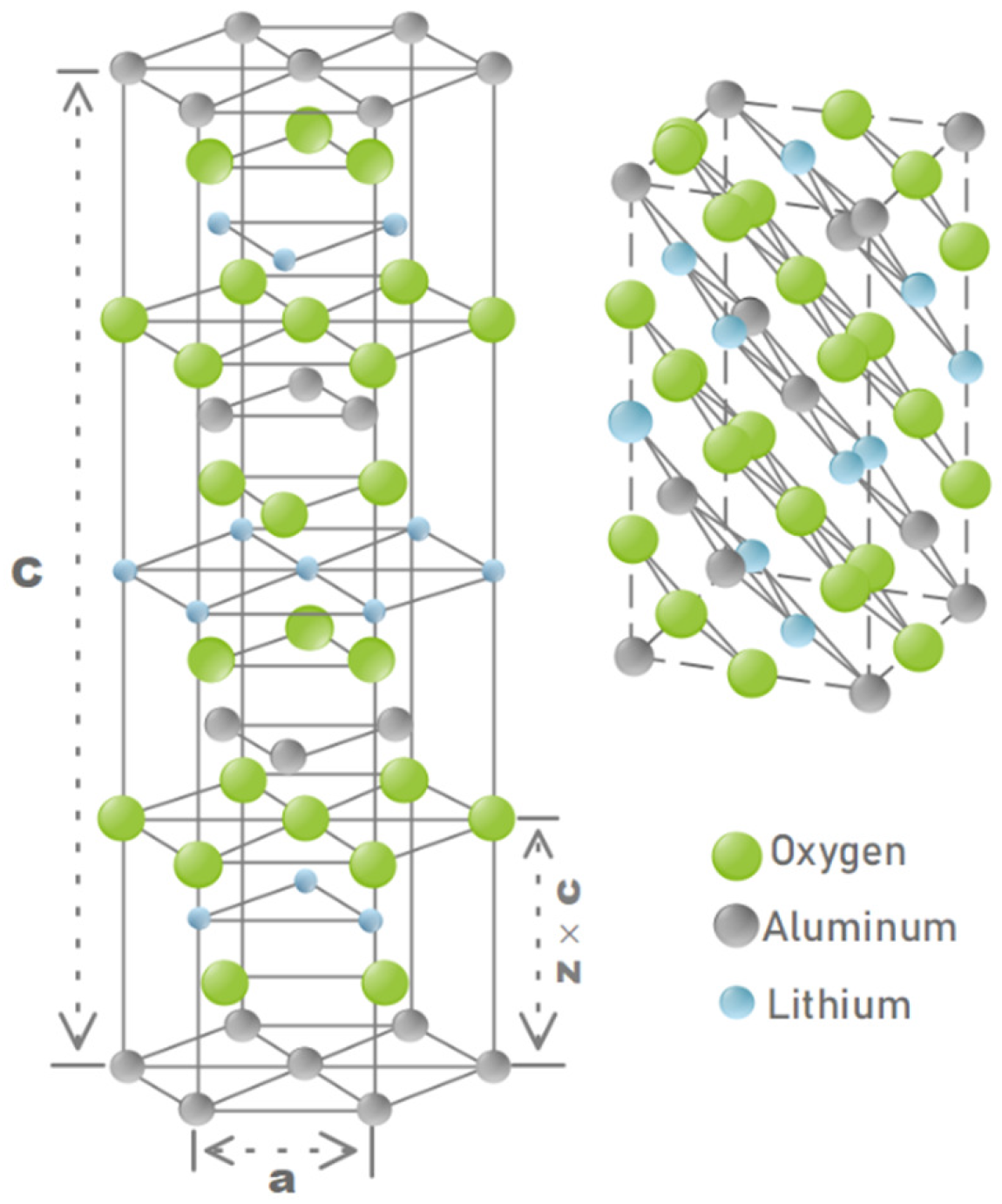

3.1. α-LiAlO2 Material Characterization

3.2. Li Recovery Cycle of LiAlO2 and AC Electrode Pair

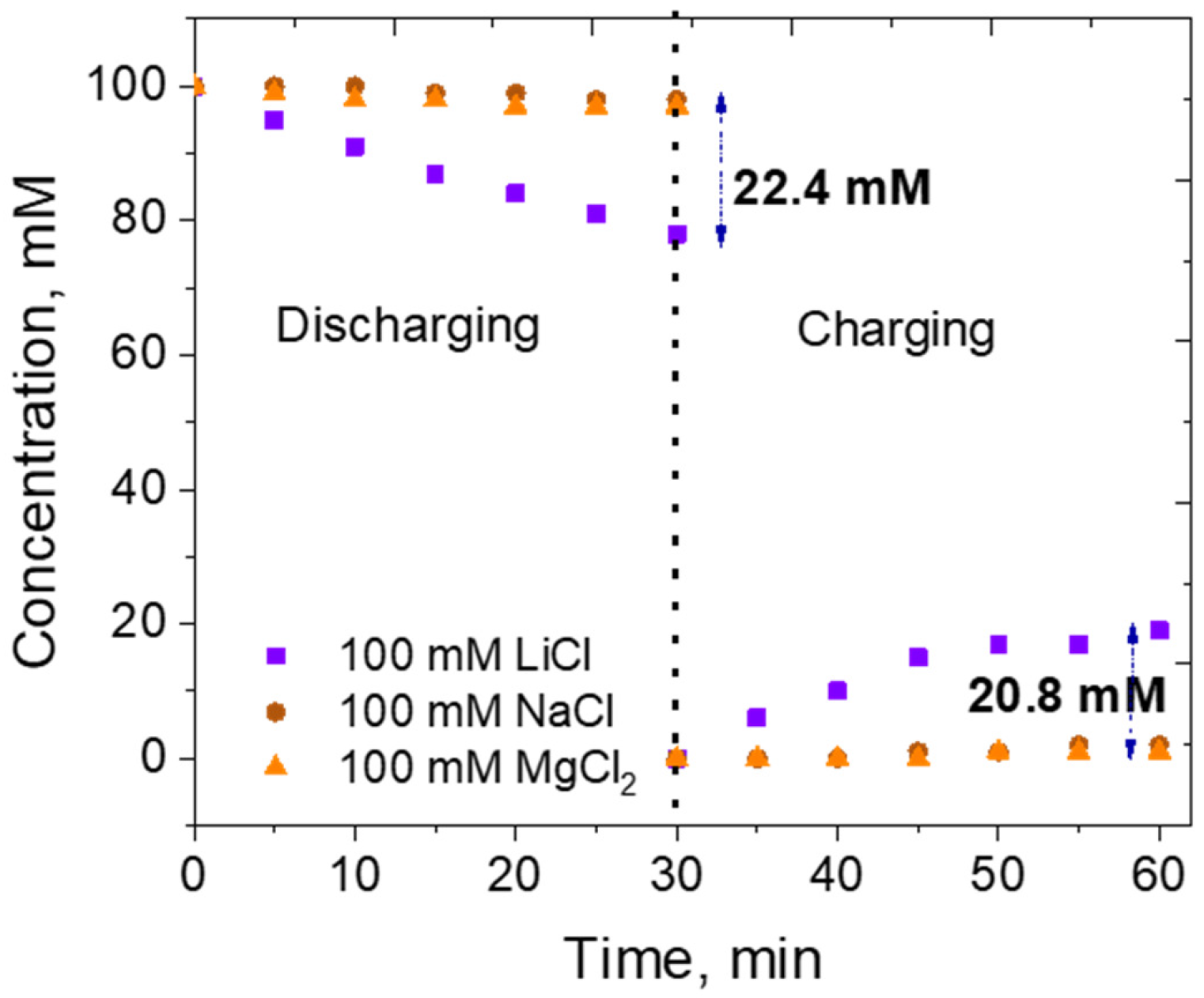

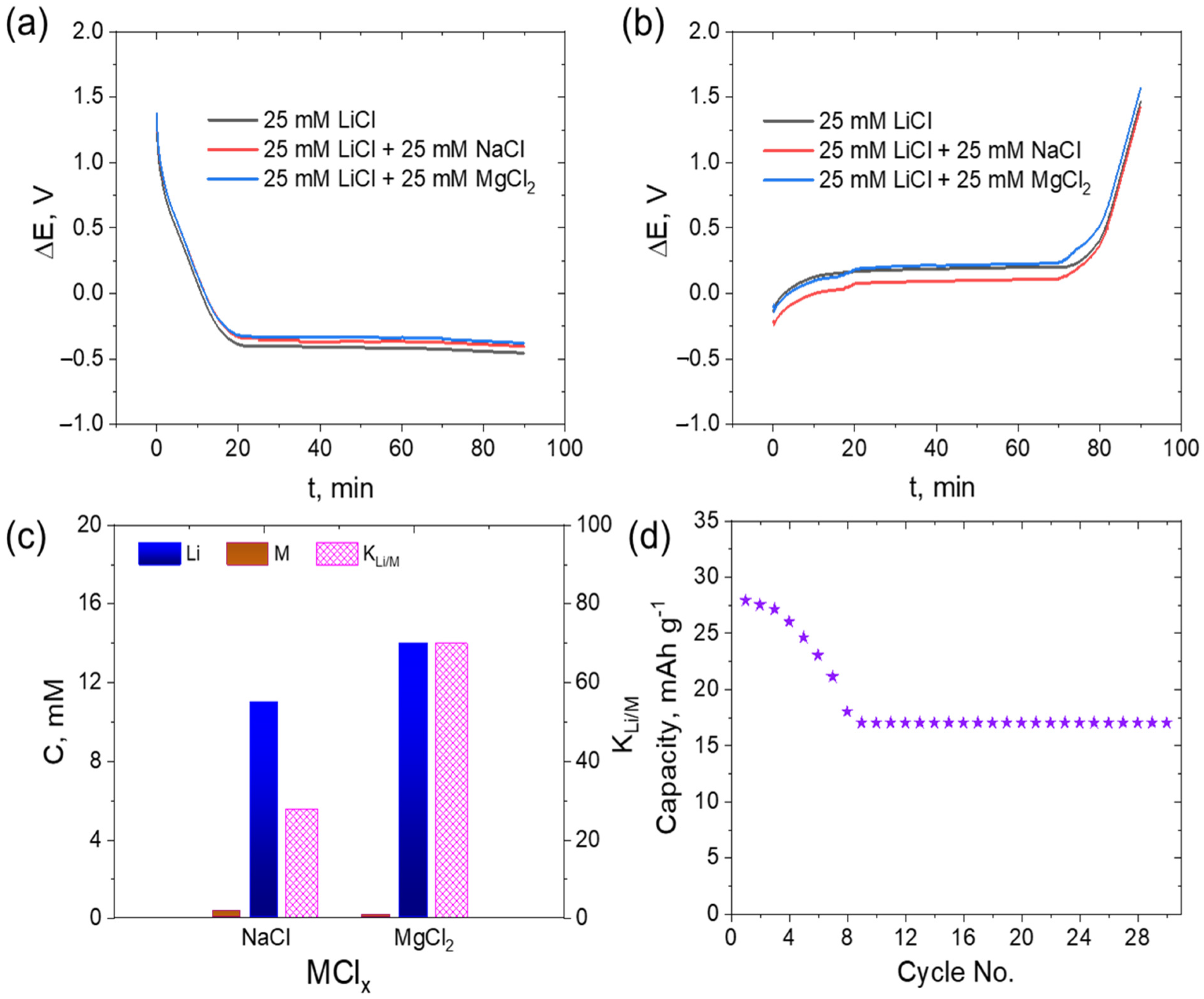

3.3. Selectivity Testing towards Competing Ions

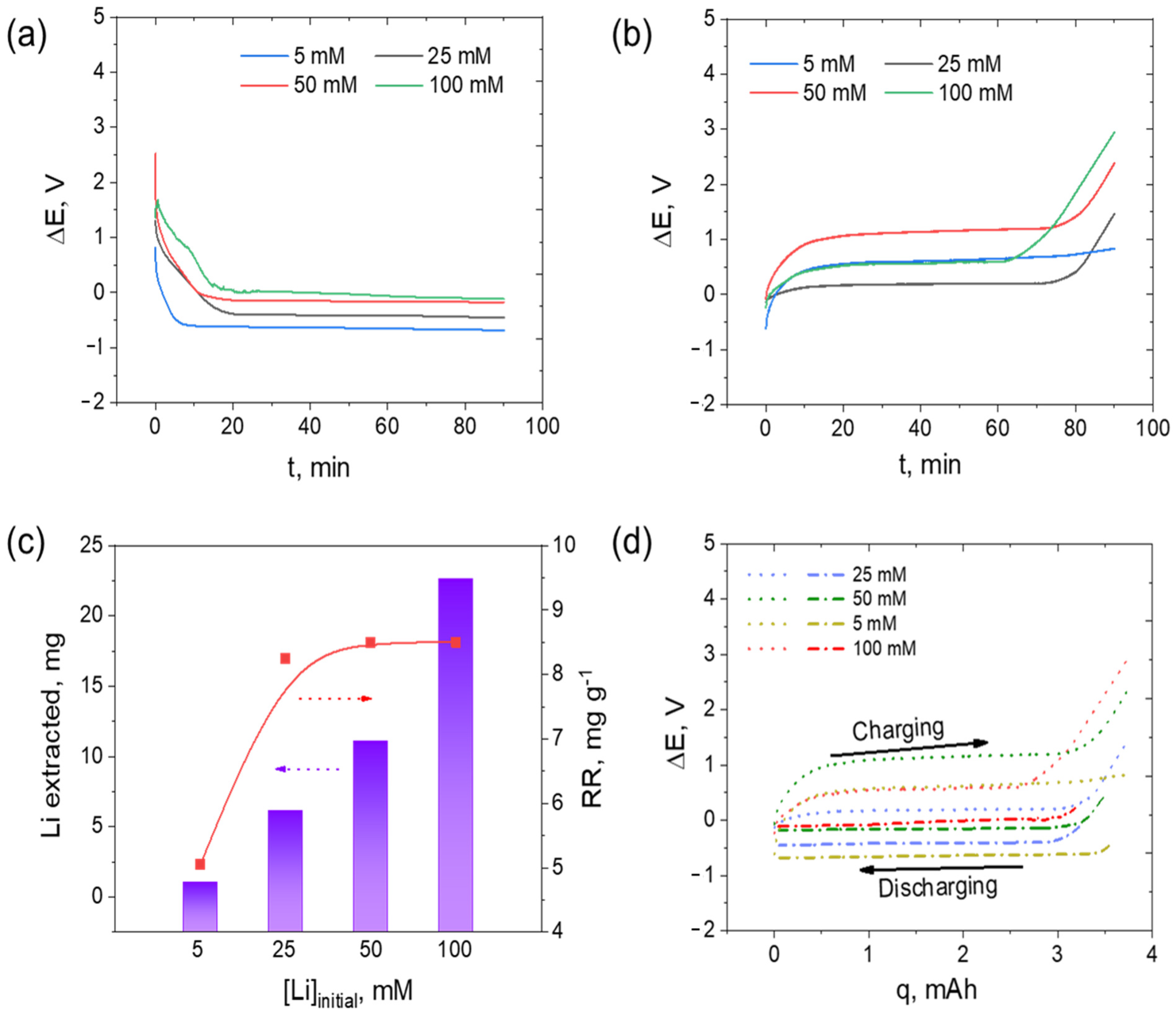

3.4. Li Recovery Cycles with Different Initial Li Concentrations

3.5. Li Recovery Cycles with Coexisting Multi-Ions

3.6. Stability Testing

3.7. Li Capture from Complex Solution

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Broussely, M.; Archdale, G. Li-ion batteries and portable power source prospects for the next 5–10 years. J. Power Sources 2004, 136, 386–394. [Google Scholar] [CrossRef]

- Sieg, J.; Bandlow, J.; Mitsch, T.; Dragicevic, D.; Materna, T.; Spier, B.; Witzenhausen, H.; Ecker, M.; Sauer, D.U. Fast charging of an electric vehicle lithium-ion battery at the limit of the lithium deposition process. J. Power Sources 2019, 427, 260–270. [Google Scholar] [CrossRef]

- Andaloro, L.; Arista, A.; Agnello, G.; Napoli, G.; Sergi, F.; Antonucci, V. Study and design of a hybrid electric vehicle (Lithium Batteries-PEM FC). Int. J. Hydrog. Energy 2017, 42, 3166–3184. [Google Scholar] [CrossRef]

- Baudino, L.; Santos, C.; Pirri, C.F.; La Mantia, F.; Lamberti, A. Recent advances in the lithium recovery from water resources: From passive to electrochemical methods. Adv. Sci. 2022, 9, 2201380. [Google Scholar] [CrossRef] [PubMed]

- Vigario, P.; Vide, R.; Mota, P.; Batista, S. Lithium feldspars for the ceramic industry: Characteristics and advantages. Ceram. Forum Int. 2012, 89, E27–E28. [Google Scholar]

- Nair, S.K.; Rocke, B.N.; Sutton, S. Lithium, magnesium, and copper: Contemporary applications of organometallic chemistry in the pharmaceutical industry. In Synthetic Methods in Drug Discovery: Volume 2; Blakemore, D.C., Doyle, P.M., Fobian, Y.M., Eds.; The Royal Society of Chemistry: London, UK, 2016; pp. 1–74. [Google Scholar]

- Licht, R.W. Lithium: Still a major option in the management of bipolar disorder. CNS Neurosci. Ther. 2012, 18, 219–226. [Google Scholar] [CrossRef] [PubMed]

- Westwood, A. New materials for aerospace industry. Mater. Sci. Technol. 1990, 6, 958–961. [Google Scholar] [CrossRef]

- Qin, H.; Zhang, H.; Wu, H. The evolution of precipitation and microstructure in friction stir welded 2195-T8 Al–Li alloy. Mater. Sci. Eng. A 2015, 626, 322–329. [Google Scholar] [CrossRef]

- Wang, D.; Li, K.; Teo, W. Porous PVDF asymmetric hollow fiber membranes prepared with the use of small molecular additives. J. Membr. Sci. 2000, 178, 13–23. [Google Scholar] [CrossRef]

- National Minerals Information Center. Mineral Commodity Summaries 2022. Available online: https://www.usgs.gov/publications/mineral-commodity-summaries-2022 (accessed on 15 December 2022).

- Gruber, P.W.; Medina, P.A.; Keoleian, G.A.; Kesler, S.E.; Everson, M.P.; Wallington, T.J. Global lithium availability: A constraint for electric vehicles? J. Ind. Ecol. 2011, 15, 760–775. [Google Scholar] [CrossRef]

- Swain, B. Recovery and recycling of lithium: A review. Sep. Purif. Technol. 2017, 172, 388–403. [Google Scholar] [CrossRef]

- Flexer, V.; Baspineiro, C.F.; Galli, C.I. Lithium recovery from brines: A vital raw material for green energies with a potential environmental impact in its mining and processing. Sci. Total Environ. 2018, 639, 1188–1204. [Google Scholar] [CrossRef] [PubMed]

- Zavahir, S.; Elmakki, T.; Gulied, M.; Ahmad, Z.; Al-Sulaiti, L.; Shon, H.K.; Chen, Y.; Park, H.; Batchelor, B.; Han, D.S. A review on lithium recovery using electrochemical capturing systems. Desalination 2021, 500, 114883. [Google Scholar] [CrossRef]

- Battistel, A.; Palagonia, M.S.; Brogioli, D.; La Mantia, F.; Trócoli, R. Electrochemical methods for lithium recovery: A comprehensive and critical review. Adv. Mater. 2020, 32, 1905440. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Chen, Y.; Wan, P.; Gasem, K.; Wang, K.; He, T.; Adidharma, H.; Fan, M. Extraction of lithium with functionalized lithium ion-sieves. Prog. Mater. Sci. 2016, 84, 276–313. [Google Scholar] [CrossRef]

- Orooji, Y.; Nezafat, Z.; Nasrollahzadeh, M.; Shafiei, N.; Afsari, M.; Pakzad, K.; Razmjou, A. Recent advances in nanomaterial development for lithium ion-sieving technologies. Desalination 2022, 529, 115624. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, Y.; Miao, Y.; Yang, Y.; Li, P. Alkaline resins enhancing Li+/H+ Ion exchange for lithium recovery from brines using granular titanium-type lithium ion-sieves. Ind. Eng. Chem. Res. 2021, 60, 16457–16468. [Google Scholar] [CrossRef]

- Ryu, T.; Shin, J.; Ryu, J.; Park, I.; Hong, H.; Kim, B.-G.; Chung, K.-S. Preparation and characterization of a cylinder-type adsorbent for the recovery of lithium from seawater. Mater. Trans. 2013, 54, 1029–1033. [Google Scholar] [CrossRef]

- Umeno, A.; Miyai, Y.; Takagi, N.; Chitrakar, R.; Sakane, K.; Ooi, K. Preparation and adsorptive properties of membrane-type adsorbents for lithium recovery from seawater. Ind. Eng. Chem. Res. 2002, 41, 4281–4287. [Google Scholar] [CrossRef]

- Kim, S.; Joo, H.; Moon, T.; Kim, S.-H.; Yoon, J. Rapid and selective lithium recovery from desalination brine using an electrochemical system. Environ. Sci. Process. Impacts 2019, 21, 667–676. [Google Scholar] [CrossRef]

- Lee, J.; Yu, S.-H.; Kim, C.; Sung, Y.-E.; Yoon, J. Highly selective lithium recovery from brine using a λ-MnO2–Ag battery. Phys. Chem. Chem. Phys. 2013, 15, 7690–7695. [Google Scholar] [CrossRef] [PubMed]

- Pasta, M.; Battistel, A.; La Mantia, F. Batteries for lithium recovery from brines. Energy Environ. Sci. 2012, 5, 9487–9491. [Google Scholar] [CrossRef]

- Kim, B.; Seo, J.Y.; Chung, C.-H. Electrochemical desalination and recovery of lithium from saline water upon operation of a capacitive deionization cell combined with a redox flow battery. ACS EST Water 2021, 1, 1047–1054. [Google Scholar] [CrossRef]

- Kim, S.; Lee, J.; Kang, J.S.; Jo, K.; Kim, S.; Sung, Y.-E.; Yoon, J. Lithium recovery from brine using a λ-MnO2/activated carbon hybrid supercapacitor system. Chemosphere 2015, 125, 50–56. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Yue, X.; Wang, P.; Yu, T.; Du, X.; Hao, X.; Abudula, A.; Guan, G. Electrochemical technologies for lithium recovery from liquid resources: A review. Renew. Sustain. Energy Rev. 2022, 154, 111813. [Google Scholar] [CrossRef]

- Niu, J.; Yan, W.; Du, J.; Hao, X.; Wang, F.; Wang, Z.; Guan, G. An electrically switched ion exchange film with molecular coupling synergistically-driven ability for recovery of Ag+ ions from wastewater. Chem. Eng. J. 2020, 389, 124498. [Google Scholar] [CrossRef]

- Johanes, H.; Sakamoto, J.; Rassat, S.; Josephson, G.; Lawrence, W.; Mendoza, D.; Viswanathan, V.; Hallen, R.; Orth, R.; Edwards, L. Electrically switched ion exchange for removal of potassium to enhance water recycling opportunities. Tappi J. 2000, 83, 53. [Google Scholar]

- Su, J.-Y.; Jin, G.-P.; Chen, T.; Liu, X.-D.; Chen, C.-N.; Tian, J.-J. The characterization and application of prussian blue at graphene coated carbon fibers in a separated adsorption and electrically switched ion exchange desorption processes of cesium. Electrochim. Acta 2017, 230, 399–406. [Google Scholar] [CrossRef]

- Kanoh, H.; Ooi, K.; Miyai, Y.; Katoh, S. Electrochemical recovery of lithium ions in the aqueous phase. Sep. Sci. Technol. 1993, 28, 643–651. [Google Scholar] [CrossRef]

- Li, X.; Wang, X.; Ma, L.; Huang, W. Solvation structures in aqueous metal-ion batteries. Adv. Energy Mater. 2022, 12, 2202068. [Google Scholar] [CrossRef]

- Wang, X.; Li, X.; Fan, H.; Ma, L. Solid electrolyte interface in zn-based battery systems. Nano-Micro Lett. 2022, 14, 205. [Google Scholar] [CrossRef] [PubMed]

- Trócoli, R.; Erinmwingbovo, C.; La Mantia, F. Optimized lithium recovery from brines by using an electrochemical ion-pumping process based on λ-MnO2 and nickel hexacyanoferrate. ChemElectroChem 2017, 4, 143–149. [Google Scholar] [CrossRef]

- Missoni, L.L.; Marchini, F.; del Pozo, M.; Calvo, E.J. A LiMn2O4-polypyrrole system for the extraction of LiCl from natural brine. J. Electrochem. Soc. 2016, 163, A1898. [Google Scholar] [CrossRef]

- Xu, X.; Zhou, Y.; Feng, Z.; Kahn, N.U.; Haq Khan, Z.U.; Tang, Y.; Sun, Y.; Wan, P.; Chen, Y.; Fan, M. A self-supported λ-MnO2 film electrode used for electrochemical lithium recovery from brines. ChemPlusChem 2018, 83, 521–528. [Google Scholar] [CrossRef]

- Du, X.; Guan, G.; Li, X.; Jagadale, A.D.; Ma, X.; Wang, Z.; Hao, X.; Abudula, A. A novel electroactive λ-MnO2/PPy/PSS core–shell nanorod coated electrode for selective recovery of lithium ions at low concentration. J. Mater. Chem. A 2016, 4, 13989–13996. [Google Scholar] [CrossRef]

- Gaines, L.L.; Dunn, J.B. Lithium-ion battery environmental impacts. In Lithium-Ion Batteries; Elsevier: Amsterdam, The Netherlands, 2014; pp. 483–508. [Google Scholar]

- Chen, C.; Yao, W.; He, Q.; Ashuri, M.; Kaduk, J.; Liu, Y.; Shaw, L. Tunable LiAlO2/Al2O3 coating through a wet-chemical method to improve cycle stability of nano-LiCoO2. ACS Appl. Energy Mater. 2019, 2, 3098–3113. [Google Scholar] [CrossRef]

- Srur-Lavi, O.; Miikkulainen, V.; Markovsky, B.; Grinblat, J.; Talianker, M.; Fleger, Y.; Cohen-Taguri, G.; Mor, A.; Tal-Yosef, Y.; Aurbach, D. Studies of the electrochemical behavior of LiNi0.80Co0.15Al0.05O2 electrodes coated with LiAlO2. J. Electrochem. Soc. 2017, 164, A3266. [Google Scholar] [CrossRef]

- Temeche, E.; Indris, S.; Laine, R.M. LiAlO2/LiAl5O8 membranes derived from flame-synthesized nanopowders as a potential electrolyte and coating material for all-solid-state batteries. ACS Appl. Mater. Interfaces 2020, 12, 46119–46131. [Google Scholar] [CrossRef]

- Liu, Y.; Fan, X.; Zhang, Z.; Wu, H.-H.; Liu, D.; Dou, A.; Su, M.; Zhang, Q.; Chu, D. Enhanced electrochemical performance of Li-rich layered cathode materials by combined Cr doping and LiAlO2 coating. ACS Sustain. Chem. Eng. 2018, 7, 2225–2235. [Google Scholar] [CrossRef]

- Aydinol, M.; Kohan, A.; Ceder, G.; Cho, K.; Joannopoulos, J. Ab initio study of lithium intercalation in metal oxides and metal dichalcogenides. Phys. Rev. B 1997, 56, 1354. [Google Scholar] [CrossRef]

- Wang, P.; Du, X.; Chen, T.; Hao, X.; Abudula, A.; Tang, K.; Guan, G. A novel electroactive PPy/HKUST-1 composite film-coated electrode for the selective recovery of lithium ions with low concentrations in aqueous solutions. Electrochim. Acta 2019, 306, 35–44. [Google Scholar] [CrossRef]

- Rao, M.; Hussain, O. Spectroscopic investigations on tetravalent doped LiCoO2 thin film cathodes. Eur. Phys. J. Appl. Phys. 2009, 48, 20503. [Google Scholar] [CrossRef]

- Amatucci, G.; Tarascon, J.; Klein, L. CoO2, the end member of the LixCoO2 solid solution. J. Electrochem. Soc. 1996, 143, 1114. [Google Scholar] [CrossRef]

- Vikström, H.; Davidsson, S.; Höök, M. Lithium availability and future production outlooks. Appl. Energy 2013, 110, 252–266. [Google Scholar] [CrossRef]

- Moradabadi, A.; Kaghazchi, P. Mechanism of Li intercalation/deintercalation into/from the surface of LiCoO2. Phys. Chem. Chem. Phys. 2015, 17, 22917–22922. [Google Scholar] [CrossRef] [PubMed]

- Zhao, R.; Biesheuvel, P.; Van der Wal, A. Energy consumption and constant current operation in membrane capacitive deionization. Energy Environ. Sci. 2012, 5, 9520–9527. [Google Scholar] [CrossRef]

- Kim, S.; Kim, J.; Kim, S.; Lee, J.; Yoon, J. Electrochemical lithium recovery and organic pollutant removal from industrial wastewater of a battery recycling plant. Environ. Sci. Water Res. Technol. 2018, 4, 175–182. [Google Scholar] [CrossRef]

| Ion | Concentration | (M)/(Li) | ||

|---|---|---|---|---|

| mg L−1 | mol L−1 | wt. Ratio | mol Ratio | |

| Li+ | 0.34 | 0.049 | 1 | 1 |

| Na+ | 24,840 | 1080 | 73,058.8 | 22,040.8 |

| Mg2+ | 540 | 22.5 | 1588.2 | 459.2 |

| K+ | 900 | 23.1 | 2647.1 | 471.4 |

| Ca2+ | 250 | 6.25 | 735.3 | 127.6 |

| Cl- | 40,720 | 1147.04 | 119,764.7 | 23,409 |

| SO42- | 580 | 6.04 | 1705.9 | 123.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elmakki, T.; Zavahir, S.; Hafsa, U.; Al-Sulaiti, L.; Ahmad, Z.; Chen, Y.; Park, H.; Shon, H.K.; Ho, Y.-C.; Han, D.S. Novel LiAlO2 Material for Scalable and Facile Lithium Recovery Using Electrochemical Ion Pumping. Nanomaterials 2023, 13, 895. https://doi.org/10.3390/nano13050895

Elmakki T, Zavahir S, Hafsa U, Al-Sulaiti L, Ahmad Z, Chen Y, Park H, Shon HK, Ho Y-C, Han DS. Novel LiAlO2 Material for Scalable and Facile Lithium Recovery Using Electrochemical Ion Pumping. Nanomaterials. 2023; 13(5):895. https://doi.org/10.3390/nano13050895

Chicago/Turabian StyleElmakki, Tasneem, Sifani Zavahir, Umme Hafsa, Leena Al-Sulaiti, Zubair Ahmad, Yuan Chen, Hyunwoong Park, Ho Kyong Shon, Yeek-Chia Ho, and Dong Suk Han. 2023. "Novel LiAlO2 Material for Scalable and Facile Lithium Recovery Using Electrochemical Ion Pumping" Nanomaterials 13, no. 5: 895. https://doi.org/10.3390/nano13050895

APA StyleElmakki, T., Zavahir, S., Hafsa, U., Al-Sulaiti, L., Ahmad, Z., Chen, Y., Park, H., Shon, H. K., Ho, Y.-C., & Han, D. S. (2023). Novel LiAlO2 Material for Scalable and Facile Lithium Recovery Using Electrochemical Ion Pumping. Nanomaterials, 13(5), 895. https://doi.org/10.3390/nano13050895