Recent Progress of Energy-Storage-Device-Integrated Sensing Systems

Abstract

:1. Introduction

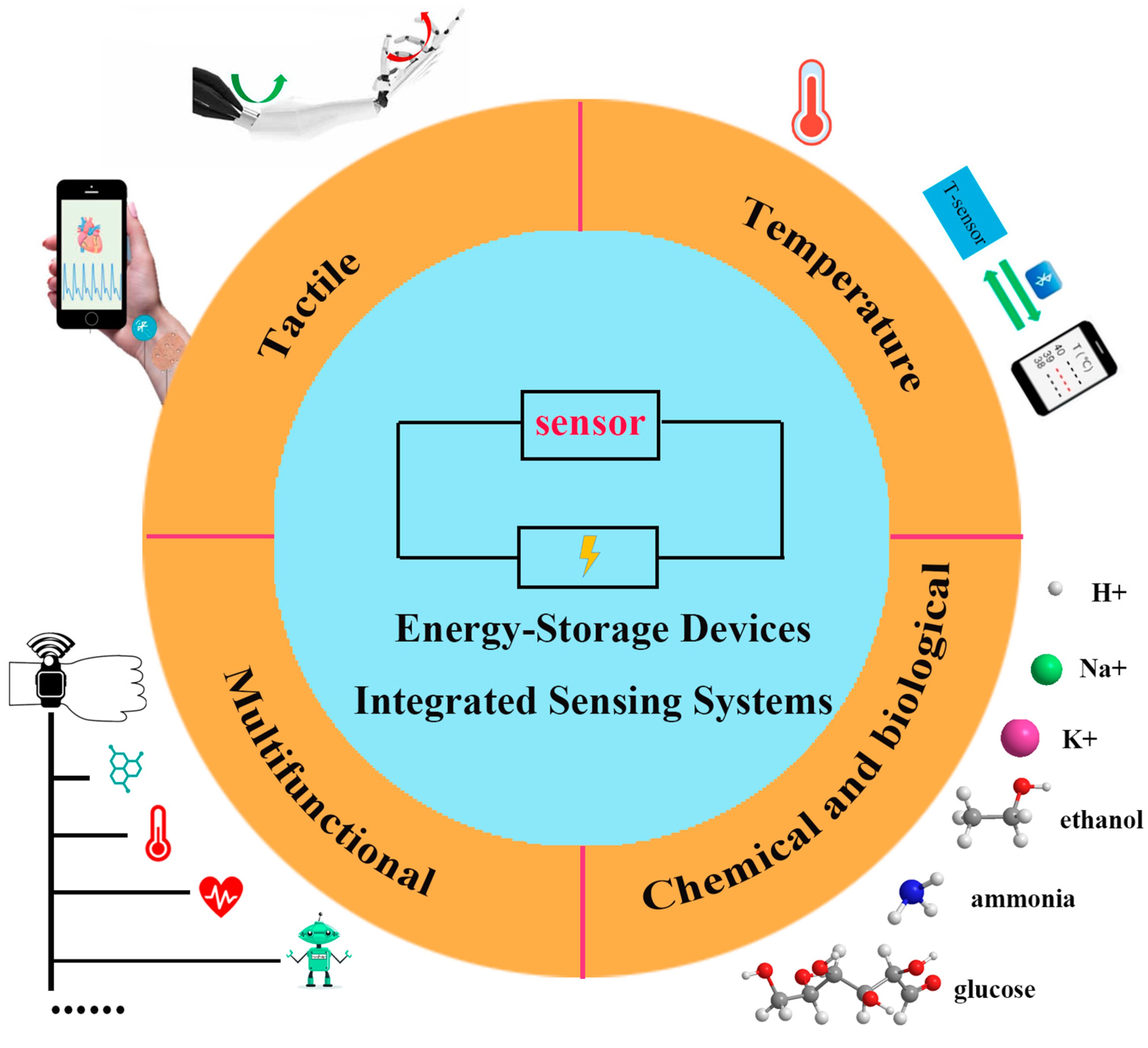

2. Energy-Storage-Device-Integrated Sensing Systems

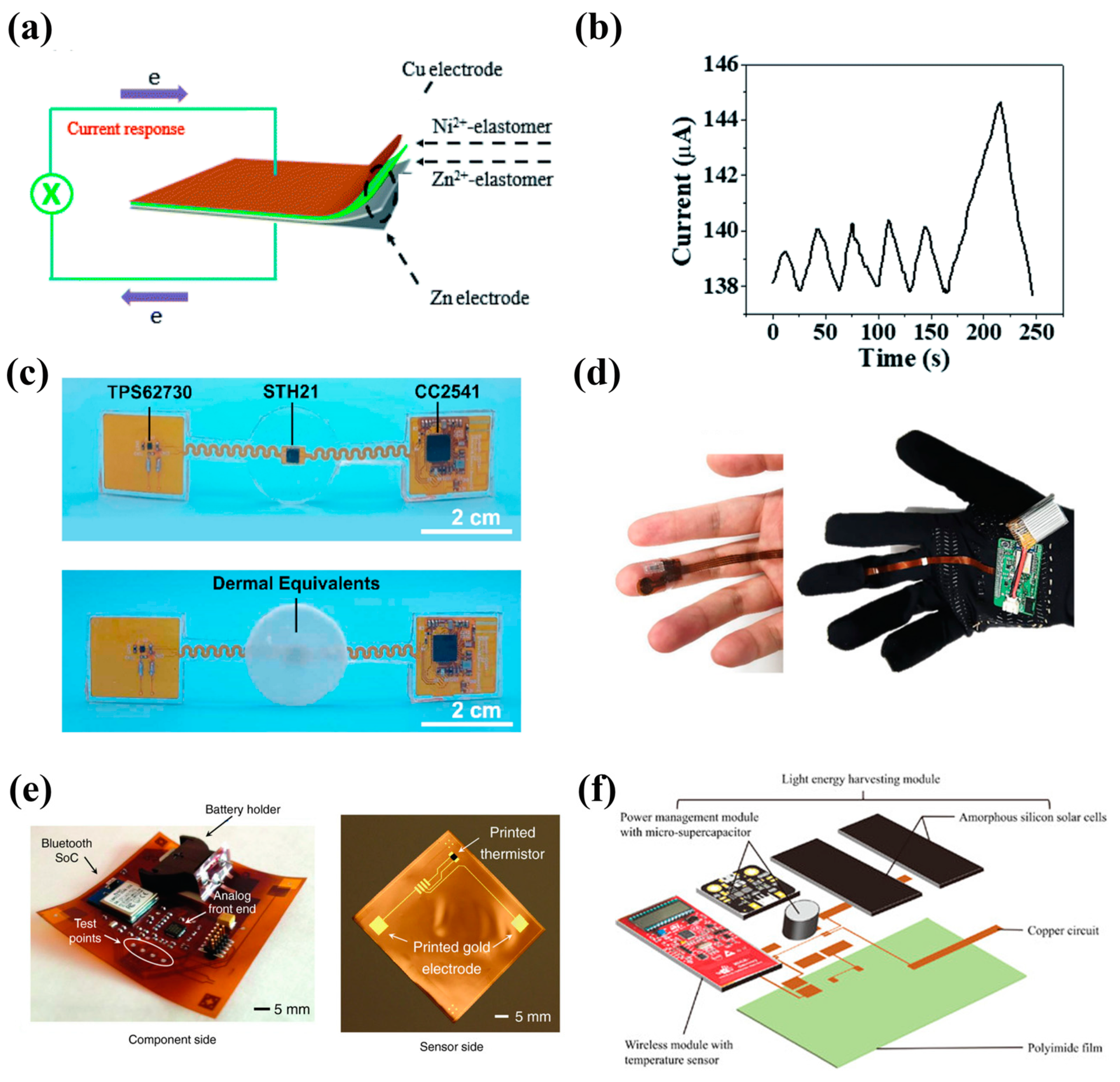

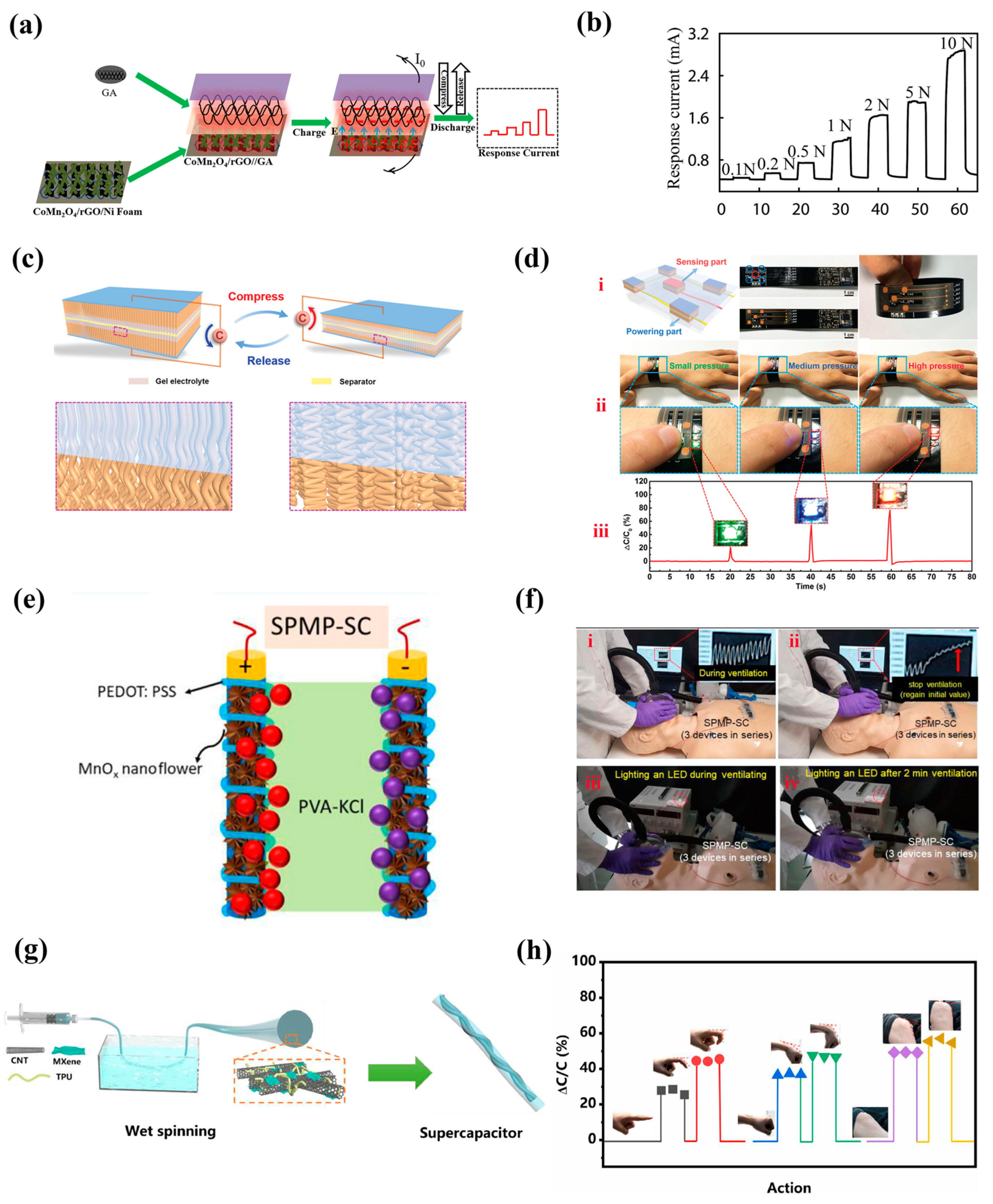

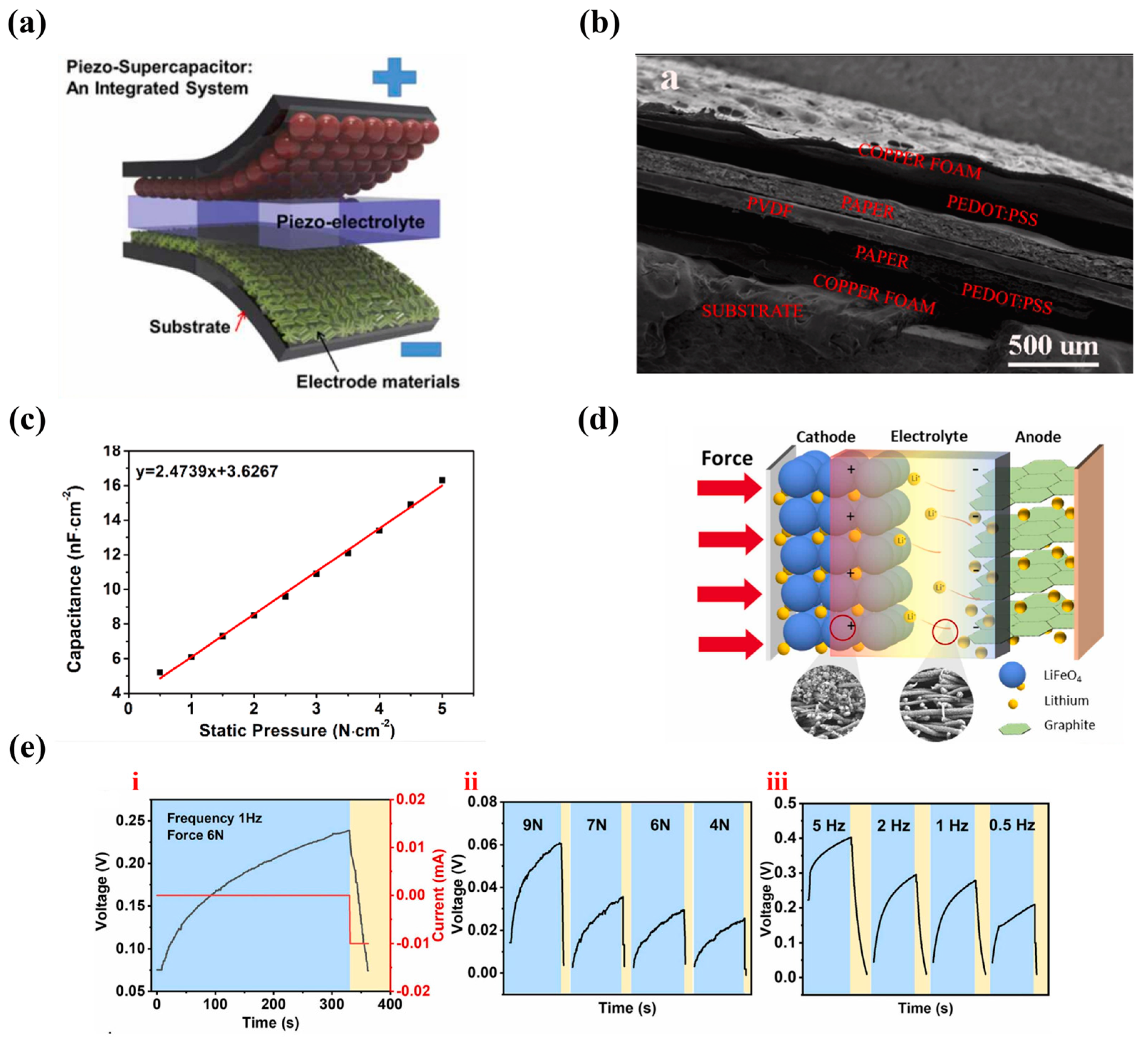

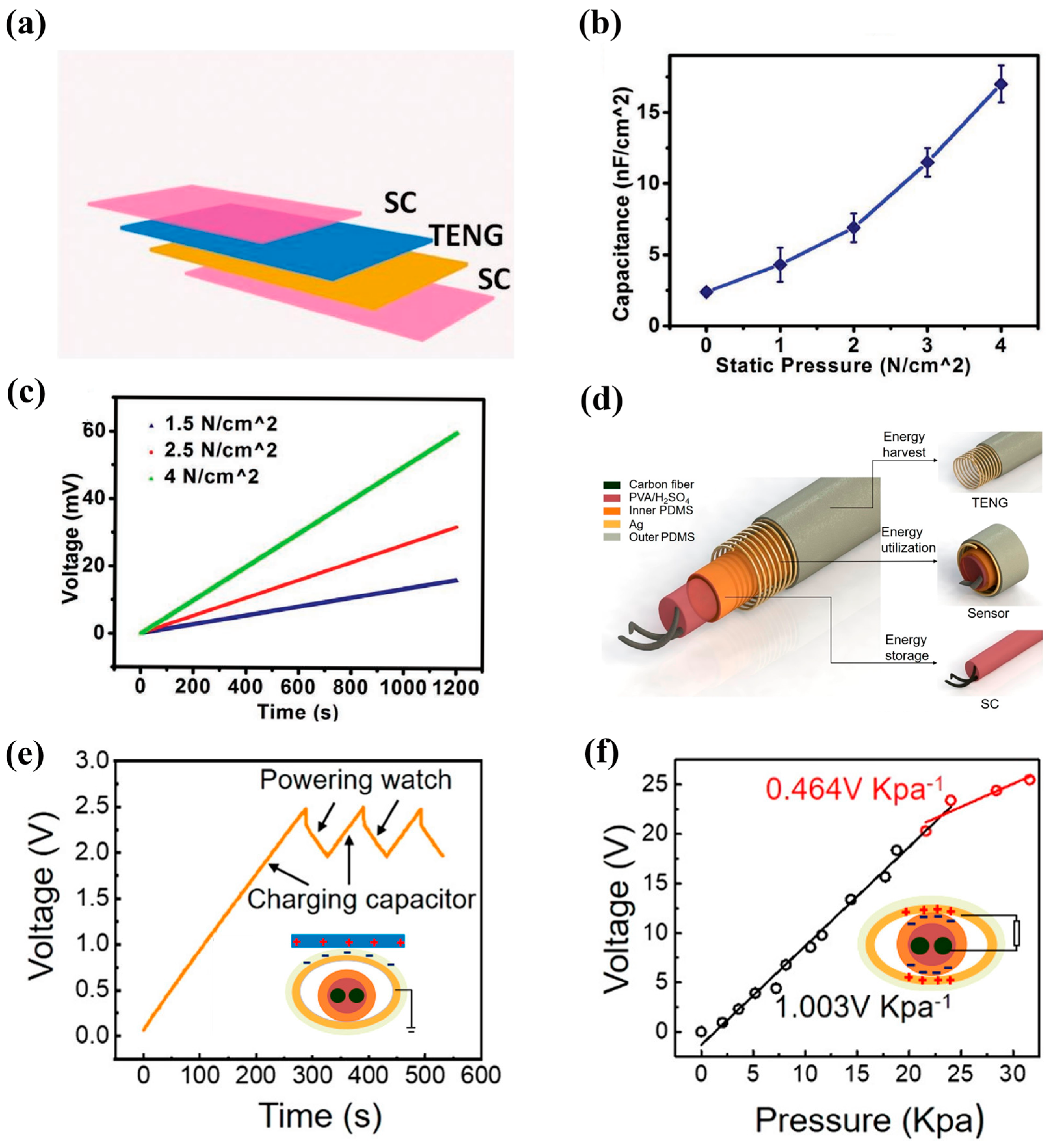

2.1. Tactile Type

2.2. Temperature Type

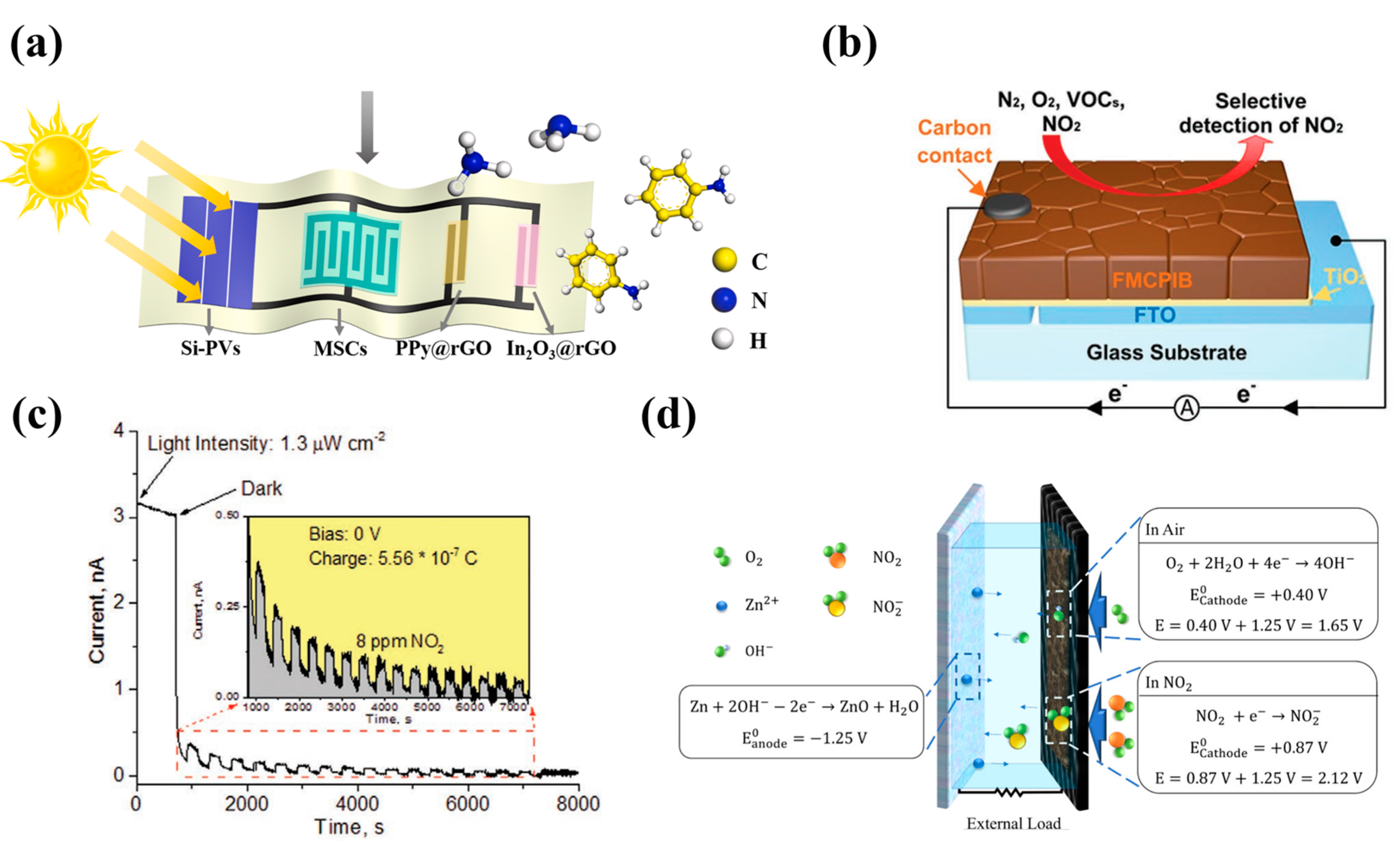

2.3. Chemical and Biological Type

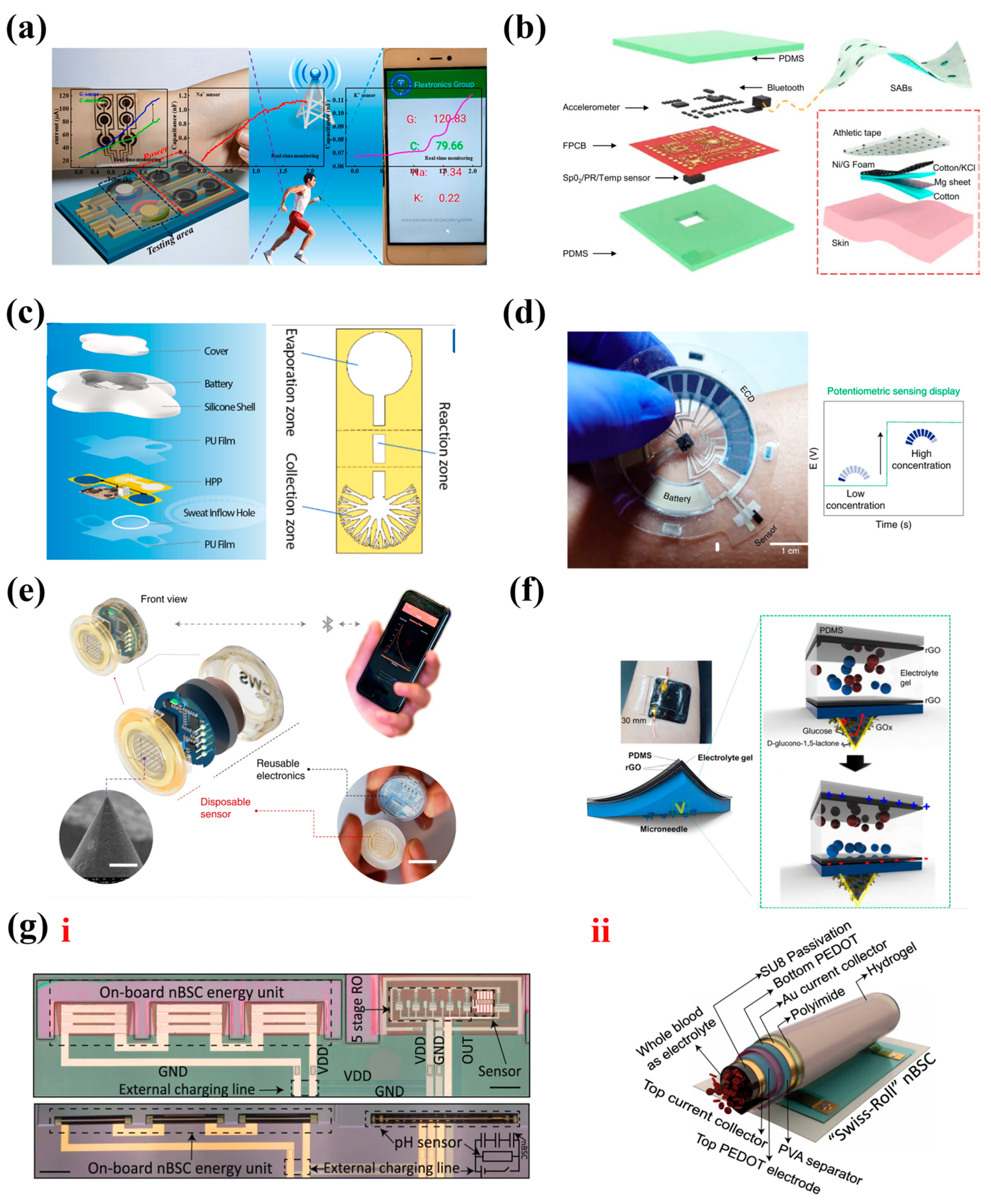

2.4. Multifunctional Integrated Type

3. Conclusions and Prospect

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dunn, J.; Kidzinski, L.; Runge, R.; Witt, D.; Hicks, J.L.; Rose, S.M.S.-F.; Li, X.; Bahmani, A.; Delp, S.L.; Hastie, T.; et al. Wearable sensors enable personalized predictions of clinical laboratory measurements. Nat. Med. 2021, 27, 1105–1112. [Google Scholar] [CrossRef]

- Lu, Y.; Lou, Z.; Jiang, K.; Chen, D.; Shen, G. Recent progress of self-powered sensing systems for wearable electronics. Mater. Today Nano 2017, 8, 100050. [Google Scholar] [CrossRef]

- Gao, W.; Emaminejad, S.; Nyein, H.Y.Y.; Challa, S.; Chen, K.; Peck, A.; Fahad, H.M.; Ota, H.; Shiraki, H.; Kiriya, D.; et al. Fully integrated wearable sensor arrays for multiplexed in situ perspiration analysis. Nature 2016, 529, 509–514. [Google Scholar] [CrossRef] [PubMed]

- Yin, L.; Kim, K.N.; Trifonov, A.; Podhajny, T.; Wang, J. Designing wearable microgrids: Towards autonomous sustainable on-body energy management. Energy Environ. Sci. 2021, 15, 82–101. [Google Scholar] [CrossRef]

- Wang, C.; Wang, C.; Huang, Z.; Xu, S. Materials and Structures toward Soft Electronics. Adv. Mater. 2018, 30, e1801368. [Google Scholar] [CrossRef] [PubMed]

- Pang, K.; Song, X.; Xu, Z.; Liu, X.; Liu, Y.; Zhong, L.; Peng, Y.; Wang, J.; Zhou, J.; Meng, F.; et al. Hydroplastic foaming of graphene aerogels and artificially intelligent tactile sensors. Sci. Adv. 2020, 6, eabd4045. [Google Scholar] [CrossRef]

- Dagdeviren, C.; Su, Y.; Joe, P.; Yona, R.; Liu, Y.; Kim, Y.-S.; Huang, Y.Y.; Damadoran, A.R.; Xia, J.; Martin, L.W.; et al. Conformable amplified lead zirconate titanate sensors with enhanced piezoelectric response for cutaneous pressure monitoring. Nat. Commun. 2014, 5, 4496. [Google Scholar] [CrossRef]

- Choong, C.-L.; Shim, M.-B.; Lee, B.-S.; Jeon, S.; Ko, D.-S.; Kang, T.-H.; Bae, J.; Lee, S.H.; Byun, K.-E.; Im, J.; et al. Highly Stretchable Resistive Pressure Sensors Using a Conductive Elastomeric Composite on a Micropyramid Array. Adv. Mater. 2014, 26, 3451–3458. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.; Lee, J.; Kim, G.; Kim, Y.; Kang, S.; Cho, S.; Kim, S.; Kim, J.-K.; Lee, W.; Kim, D.-E.; et al. Rough-Surface-Enabled Capacitive Pressure Sensors with 3D Touch Capability. Small 2017, 13, 1700368. [Google Scholar] [CrossRef]

- Shin, J.; Jeong, B.; Kim, J.; Nam, V.B.; Yoon, Y.; Jung, J.; Hong, S.; Lee, H.; Eom, H.; Yeo, J.; et al. Sensitive Wearable Temperature Sensor with Seamless Monolithic Integration. Adv. Mater. 2019, 32, e1905527. [Google Scholar] [CrossRef]

- Salvatore, G.A.; Sülzle, J.; Valle, F.D.; Cantarella, G.; Robotti, F.; Jokic, P.; Knobelspies, S.; Daus, A.; Büthe, L.; Petti, L.; et al. Biodegradable and Highly Deformable Temperature Sensors for the Internet of Things. Adv. Funct. Mater. 2017, 27, 1702390. [Google Scholar] [CrossRef]

- Chen, R.; Luo, T.; Geng, D.; Shen, Z.; Zhou, W. Facile fabrication of a fast-response flexible temperature sensor via laser reduced graphene oxide for contactless human-machine interface. Carbon 2021, 187, 35–46. [Google Scholar] [CrossRef]

- Rao, X.; Zhao, L.; Xu, L.; Wang, Y.; Liu, K.; Wang, Y.; Chen, G.Y.; Liu, T.; Wang, Y. Review of Optical Humidity Sensors. Sensors 2021, 21, 8049. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Mao, Y.; Xiao, C.; Xu, X.; Li, X. Flexible pH sensor based on a conductive PANI membrane for pH monitoring. RSC Adv. 2019, 10, 21–28. [Google Scholar] [CrossRef] [PubMed]

- Zhao, W.-W.; Xu, J.-J.; Chen, H.-Y. Photoelectrochemical DNA Biosensors. Chem. Rev. 2014, 114, 7421–7441. [Google Scholar] [CrossRef]

- Dai, J.; Ogbeide, O.; Macadam, N.; Sun, Q.; Yu, W.; Li, Y.; Su, B.-L.; Hasan, T.; Huang, X.; Huang, W. Printed gas sensors. Chem. Soc. Rev. 2020, 49, 1756–1789. [Google Scholar] [CrossRef]

- Wu, J.; Zheng, Y.; Li, X. Recent Progress in Self-Powered Sensors Based on Triboelectric Nanogenerators. Sensors 2021, 21, 7129. [Google Scholar] [CrossRef]

- Park, D.Y.; Joe, D.J.; Kim, D.H.; Park, H.; Han, J.H.; Jeong, C.K.; Park, H.; Park, J.G.; Joung, B.; Lee, K.J. Self-Powered Real-Time Arterial Pulse Monitoring Using Ultrathin Epidermal Piezoelectric Sensors. Adv. Mater. 2017, 29, 1702308. [Google Scholar] [CrossRef]

- Freitag, M.; Teuscher, J.; Saygili, Y.; Zhang, X.; Giordano, F.; Liska, P.; Hua, J.; Zakeeruddin, S.M.; Moser, J.-E.; Grätzel, M.; et al. Dye-sensitized solar cells for efficient power generation under ambient lighting. Nat. Photon. 2017, 11, 372–378. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, E.; Li, X.; Zhang, Y.; Qu, J.; Yu, Z.-Z. Cellulose/graphene aerogel supported phase change composites with high thermal conductivity and good shape stability for thermal energy storage. Carbon 2016, 98, 50–57. [Google Scholar] [CrossRef]

- Li, M.; Lu, J.; Chen, Z.; Amine, K. 30 Years of Lithium-Ion Batteries. Adv. Mater. 2018, 30, 1800561. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.W.; Aurbach, D. Promise and reality of post-lithium-ion batteries with high energy densities. Nat. Rev. Mater. 2016, 1, 16013. [Google Scholar] [CrossRef]

- Chang, J.; Huang, Q.; Gao, Y.; Zheng, Z. Pathways of Developing High-Energy-Density Flexible Lithium Batteries. Adv. Mater. 2021, 33, 2004419. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Sun, L.; Fan, Q.; Zhang, F.; Wang, Z.; Zou, J.; Zhao, S.; Mao, J.; Guo, Z. Challenges and prospects of lithium–CO2 batteries. Nano Res. Energy 2022, 1, e9120001. [Google Scholar] [CrossRef]

- Yu, P.; Zeng, Y.; Zhang, H.; Yu, M.; Tong, Y.; Lu, X. Flexible Zn-Ion Batteries: Recent Progresses and Challenges. Small 2019, 15, e1804760. [Google Scholar] [CrossRef]

- Ge, H.; Feng, X.; Liu, D.; Zhang, Y. Recent advances and perspectives for Zn-based batteries: Zn anode and electrolyte. Nano Res. Energy 2023, 2, e9120039. [Google Scholar] [CrossRef]

- Liu, R.; Wang, Z.L.; Fukuda, K.; Someya, T. Flexible self-charging power sources. Nat. Rev. Mater. 2022, 7, 870–886. [Google Scholar] [CrossRef]

- Gao, C.; Chen, K.; Wang, Y.; Zhao, Y.; Qu, L. 2D Graphene-Based Macroscopic Assemblies for Micro-Supercapacitors. Chemsuschem 2020, 13, 1255–1274. [Google Scholar] [CrossRef]

- Zhao, Z.; Xia, K.; Hou, Y.; Zhang, Q.; Ye, Z.; Lu, J. Designing flexible, smart and self-sustainable supercapacitors for portable/wearable electronics: From conductive polymers. Chem. Soc. Rev. 2021, 50, 12702–12743. [Google Scholar] [CrossRef]

- Wang, S.; Ma, J.; Shi, X.; Zhu, Y.; Wu, Z.-S. Recent status and future perspectives of ultracompact and customizable micro-supercapacitors. Nano Res. Energy 2022, 1, e9120018. [Google Scholar] [CrossRef]

- Simon, P.; Gogotsi, Y.; Dunn, B. Where Do Batteries End and Supercapacitors Begin? Science 2014, 343, 1210–1211. [Google Scholar] [CrossRef]

- Dubal, D.P.; Ayyad, O.; Ruiz, V.; Gómez-Romero, P. Hybrid energy storage: The merging of battery and supercapacitor chemistries. Chem. Soc. Rev. 2015, 44, 1777–1790. [Google Scholar] [CrossRef]

- Fang, Y.; Zou, Y.; Xu, J.; Chen, G.; Zhou, Y.; Deng, W.; Zhao, X.; Roustaei, M.; Hsiai, T.K.; Chen, J. Ambulatory Cardiovascular Monitoring Via a Machine-Learning-Assisted Textile Triboelectric Sensor. Adv. Mater. 2021, 33, 2104178. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.; Nassar, J.; Xu, C.; Min, J.; Yang, Y.; Dai, A.; Doshi, R.; Huang, A.; Song, Y.; Gehlhar, R.; et al. Biofuel-powered soft electronic skin with multiplexed and wireless sensing for human-machine interfaces. Sci. Robot. 2020, 5, eaaz7946. [Google Scholar] [CrossRef]

- Lou, D.; Pang, Q.; Pei, X.; Dong, S.; Li, S.; Tan, W.-Q.; Ma, L. Flexible wound healing system for pro-regeneration, temperature monitoring and infection early warning. Biosens. Bioelectron. 2020, 162, 112275. [Google Scholar] [CrossRef] [PubMed]

- Pyo, S.; Lee, J.; Bae, K.; Sim, S.; Kim, J. Recent Progress in Flexible Tactile Sensors for Human-Interactive Systems: From Sensors to Advanced Applications. Adv. Mater. 2021, 33, e2005902. [Google Scholar] [CrossRef]

- Meng, K.; Xiao, X.; Wei, W.; Chen, G.; Nashalian, A.; Shen, S.; Chen, J. Wearable Pressure Sensors for Pulse Wave Monitoring. Adv. Mater. 2022, 34, 2109357. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Fan, X.; Chen, S.; Zhao, N. Emerging Technologies of Flexible Pressure Sensors: Materials, Modeling, Devices, and Manufacturing. Adv. Funct. Mater. 2019, 29, 1808509. [Google Scholar] [CrossRef]

- Liu, Y.; Bao, R.; Tao, J.; Li, J.; Dong, M.; Pan, C. Recent progress in tactile sensors and their applications in intelligent systems. Sci. Bull. 2019, 65, 70–88. [Google Scholar] [CrossRef]

- Amjadi, M.; Kyung, K.-U.; Park, I.; Sitti, M. Stretchable, Skin-Mountable, and Wearable Strain Sensors and Their Potential Applications: A Review. Adv. Funct. Mater. 2015, 26, 1678–1698. [Google Scholar] [CrossRef]

- Liu, M.-Y.; Hang, C.-Z.; Zhao, X.-F.; Zhu, L.-Y.; Ma, R.-G.; Wang, J.-C.; Lu, H.-L.; Zhang, D.W. Advance on flexible pressure sensors based on metal and carbonaceous nanomaterial. Nano Energy 2021, 87, 106181. [Google Scholar] [CrossRef]

- Zhou, H.; Lai, J.; Zheng, B.; Jin, X.; Zhao, G.; Liu, H.; Chen, W.; Ma, A.; Li, X.; Wu, Y. From Glutinous-Rice-Inspired Adhesive Organohydrogels to Flexible Electronic Devices Toward Wearable Sensing, Power Supply, and Energy Storage. Adv. Funct. Mater. 2021, 32, 2108423. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, D.; He, X.; Zhou, J.; Zhou, Y.; Wang, X.; Wang, Z.; Liu, S.; Zheng, S.Y.; Yang, J. Anti-Swelling Zwitterionic Hydrogels as Multi-Modal Underwater Sensors and All-in-One Supercapacitors. ACS Appl. Polym. Mater. 2022, 4, 7498–7507. [Google Scholar] [CrossRef]

- Wang, B.; Peng, J.; Yang, K.; Cheng, H.; Yin, Y.; Wang, C. Multifunctional Textile Electronic with Sensing, Energy Storing, and Electrothermal Heating Capabilities. ACS Appl. Mater. Interfaces 2022, 14, 22497–22509. [Google Scholar] [CrossRef] [PubMed]

- Huang, S.; Li, J.; Zhang, X.; Yang, X.; Wang, L.; Li, X.; Lü, W. Reduced graphene oxide/polyaniline wrapped carbonized sponge with elasticity for energy storage and pressure sensing. New J. Chem. 2021, 45, 7860–7866. [Google Scholar] [CrossRef]

- Zahed, A.; Barman, S.C.; Sharifuzzaman; Zhang, S.; Yoon, H.; Park, C.; Yoon, S.H.; Park, J.Y. Polyaziridine-Encapsulated Phosphorene-Incorporated Flexible 3D Porous Graphene for Multimodal Sensing and Energy Storage Applications. Adv. Funct. Mater. 2021, 31, 2009018. [Google Scholar] [CrossRef]

- Yun, J.; Song, C.; Lee, H.; Park, H.; Jeong, Y.R.; Kim, J.W.; Jin, S.W.; Oh, S.Y.; Sun, L.; Zi, G.; et al. Stretchable array of high-performance micro-supercapacitors charged with solar cells for wireless powering of an integrated strain sensor. Nano Energy 2018, 49, 644–654. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, L.; Zhao, L.; Wang, K.; Zheng, Y.; Yuan, Z.; Wang, D.; Fu, X.; Shen, G.; Han, W. Flexible Self-Powered Integrated Sensing System with 3D Periodic Ordered Black Phosphorus@MXene Thin-Films. Adv. Mater. 2021, 33, e2007890. [Google Scholar] [CrossRef]

- Zhang, Y.-Z.; Wang, Y.; Cheng, T.; Yao, L.-Q.; Li, X.; Lai, W.-Y.; Huang, W. Printed supercapacitors: Materials, printing and applications. Chem. Soc. Rev. 2019, 48, 3229–3264. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, H.; Han, W.; Lin, H.; Li, R.; Zhu, J.; Huang, W. 3D Printed Flexible Strain Sensors: From Printing to Devices and Signals. Adv. Mater. 2021, 33, e2004782. [Google Scholar] [CrossRef]

- Lyu, Z.; Lim, G.J.; Koh, J.J.; Li, Y.; Ma, Y.; Ding, J.; Wang, J.; Hu, Z.; Wang, J.; Chen, W.; et al. Design and Manufacture of 3D-Printed Batteries. Joule 2020, 5, 89–114. [Google Scholar] [CrossRef]

- Sreenilayam, S.P.; Ahad, I.U.; Nicolosi, V.; Brabazon, D. MXene materials based printed flexible devices for healthcare, biomedical and energy storage applications. Mater. Today 2021, 43, 99–131. [Google Scholar] [CrossRef]

- Zheng, S.; Wang, H.; Das, P.; Zhang, Y.; Cao, Y.; Ma, J.; Liu, S.; Wu, Z. Multitasking MXene Inks Enable High-Performance Printable Microelectrochemical Energy Storage Devices for All-Flexible Self-Powered Integrated Systems. Adv. Mater. 2021, 33, e2005449. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.-C.; Karmakar, R.S.; Lu, Y.-J.; Huang, C.-Y.; Wei, K.-C. Characterization of Piezoresistive PEDOT:PSS Pressure Sensors with Inter-Digitated and Cross-Point Electrode Structures. Sensors 2015, 15, 818–831. [Google Scholar] [CrossRef]

- Zhao, Y.; Hou, N.; Wang, Y.; Fu, C.; Li, X.; Li, L.; Zhang, W. All-fiber structure covered with two-dimensional conductive MOF materials to construct a comfortable, breathable and high-quality self-powered wearable sensor system. J. Mater. Chem. A 2021, 10, 1248–1256. [Google Scholar] [CrossRef]

- Li, D.; Yang, S.; Chen, X.; Lai, W.; Huang, W. 3D Wearable Fabric-Based Micro-Supercapacitors with Ultra-High Areal Capacitance. Adv. Funct. Mater. 2021, 31, 2107484. [Google Scholar] [CrossRef]

- Yang, Y.; Huang, Q.; Niu, L.; Wang, D.; Yan, C.; She, Y.; Zheng, Z. Waterproof, Ultrahigh Areal-Capacitance, Wearable Supercapacitor Fabrics. Adv. Mater. 2017, 29, 1606679. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Li, M.; Fan, Q.; Qi, X.; Qu, L.; Tian, M. Smart-Fabric-Based Supercapacitor with Long-Term Durability and Waterproof Properties toward Wearable Applications. ACS Appl. Mater. Interfaces 2021, 13, 14778–14785. [Google Scholar] [CrossRef]

- Kim, T.; Park, C.; Samuel, E.P.; Kim, Y.-I.; An, S.; Yoon, S.S. Wearable sensors and supercapacitors using electroplated-Ni/ZnO antibacterial fabric. J. Mater. Sci. Technol. 2021, 100, 254–264. [Google Scholar] [CrossRef]

- Wei, Y.; Li, X.; Wang, Y.; Hirtz, T.; Guo, Z.; Qiao, Y.; Cui, T.; Tian, H.; Yang, Y.; Ren, T.-L. Graphene-Based Multifunctional Textile for Sensing and Actuating. ACS Nano 2021, 15, 17738–17747. [Google Scholar] [CrossRef]

- Zhou, Y.; Myant, C.; Stewart, R. Multifunctional and stretchable graphene/textile composite sensor for human motion monitoring. J. Appl. Polym. Sci. 2022, 139, e52755. [Google Scholar] [CrossRef]

- Wu, R.; Ma, L.; Patil, A.; Meng, Z.; Liu, S.; Hou, C.; Zhang, Y.; Yu, W.; Guo, W.; Liu, X.Y. Graphene decorated carbonized cellulose fabric for physiological signal monitoring and energy harvesting. J. Mater. Chem. A 2020, 8, 12665–12673. [Google Scholar] [CrossRef]

- Park, H.; Kim, J.W.; Hong, S.Y.; Lee, G.; Lee, H.; Song, C.; Keum, K.; Jeong, Y.R.; Jin, S.W.; Kim, D.S.; et al. Dynamically Stretchable Supercapacitor for Powering an Integrated Biosensor in an All-in-One Textile System. ACS Nano 2019, 13, 10469–10480. [Google Scholar] [CrossRef]

- Amit, M.; Chukoskie, L.; Skalsky, A.J.; Garudadri, H.; Ng, T.N. Flexible Pressure Sensors for Objective Assessment of Motor Disorders. Adv. Funct. Mater. 2019, 30, 1905241. [Google Scholar] [CrossRef]

- Ha, K.-H.; Huh, H.; Li, Z.; Lu, N. Soft Capacitive Pressure Sensors: Trends, Challenges, and Perspectives. ACS Nano 2022, 16, 3442–3448. [Google Scholar] [CrossRef] [PubMed]

- Zang, Y.; Zhang, F.; Huang, D.; Gao, X.; Di, C.-A.; Zhu, D. Flexible suspended gate organic thin-film transistors for ultra-sensitive pressure detection. Nat. Commun. 2015, 6, 6269. [Google Scholar] [CrossRef]

- Wu, Z.-S.; Winter, A.; Chen, L.; Sun, Y.; Turchanin, A.; Feng, X.; Müllen, K. Three-Dimensional Nitrogen and Boron Co-doped Graphene for High-Performance All-Solid-State Supercapacitors. Adv. Mater. 2012, 24, 5130–5135. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Zhang, Y.; Luo, Y.; Zhang, Y.; Li, X.; Yu, X.; Ding, H.; Chu, P.; Sun, L. High-performance asymmetrical supercapacitor composed of rGO-enveloped nickel phosphite hollow spheres and N/S co-doped rGO aerogel. Nano Res. 2017, 11, 1651–1663. [Google Scholar] [CrossRef]

- Bora, A.; Mohan, K.; Doley, S.; Dolui, S.K. Flexible Asymmetric Supercapacitor Based on Functionalized Reduced Graphene Oxide Aerogels with Wide Working Potential Window. ACS Appl. Mater. Interfaces 2018, 10, 7996–8009. [Google Scholar] [CrossRef] [PubMed]

- Wei, N.; Wang, Q.; Ma, Y.; Ruan, L.; Zeng, W.; Liang, D.; Xu, C.; Huang, L.; Zhao, J. Asymmetric supercapacitor for sensitive elastic-electrochemical stress sensor. J. Power Sources 2018, 402, 353–362. [Google Scholar] [CrossRef]

- Huang, L.; Guo, H.; Long, C.; Fu, J.; Zeng, W.; Xiong, Y.; Wei, N.; Guo, X.; Xu, C.; Fang, P. Regenerated Silk Fibroin-Modified Soft Graphene Aerogels for Supercapacitive Stress Sensors. J. Electrochem. Soc. 2021, 168, 117511. [Google Scholar] [CrossRef]

- Komatsubara, K.; Suzuki, H.; Inoue, H.; Kishibuchi, M.; Takahashi, S.; Marui, T.; Umezawa, S.; Nakagawa, T.; Nasu, K.; Maetani, M.; et al. Highly Oriented Carbon Nanotube Supercapacitors. ACS Appl. Nano Mater. 2022, 5, 1521–1532. [Google Scholar] [CrossRef]

- Cao, J.; Zhao, Y.; Xu, Y.; Zhang, Y.; Zhang, B.; Peng, H. Sticky-note supercapacitors. J. Mater. Chem. A 2018, 6, 3355–3360. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhao, Y.; Cao, J.; Cao, J.; Zhang, Y.; Zhang, Y.; Peng, H.; Peng, H. Gradually Crosslinking Carbon Nanotube Array in Mimicking the Beak of Giant Squid for Compression-Sensing Supercapacitor. Adv. Funct. Mater. 2019, 30, 1902971. [Google Scholar] [CrossRef]

- Pullanchiyodan, A.; Manjakkal, L.; Ntagios, M.; Dahiya, R. MnOx-Electrodeposited Fabric-Based Stretchable Supercapacitors with Intrinsic Strain Sensing. ACS Appl. Mater. Interfaces 2021, 13, 47581–47592. [Google Scholar] [CrossRef]

- Wu, G.; Yang, Z.; Zhang, Z.; Ji, B.; Hou, C.; Li, Y.; Jia, W.; Zhang, Q.; Wang, H. High performance stretchable fibrous supercapacitors and flexible strain sensors based on CNTs/MXene-TPU hybrid fibers. Electrochim. Acta 2021, 395, 139141. [Google Scholar] [CrossRef]

- Niu, H.; Chen, Y.; Kim, E.-S.; Zhou, W.; Li, Y.; Kim, N.-Y. Ultrasensitive capacitive tactile sensor with heterostructured active layers for tiny signal perception. Chem. Eng. J. 2022, 450, 138258. [Google Scholar] [CrossRef]

- Lee, S.; Franklin, S.; Hassani, F.A.; Yokota, T.; Nayeem, O.G.; Wang, Y.; Leib, R.; Cheng, G.; Franklin, D.W.; Someya, T. Nanomesh pressure sensor for monitoring finger manipulation without sensory interference. Science 2020, 370, 966–970. [Google Scholar] [CrossRef]

- Yang, X.; Chen, S.; Shi, Y.; Fu, Z.; Zhou, B. A flexible highly sensitive capacitive pressure sensor. Sens. Actuators A Phys. 2021, 324, 112629. [Google Scholar] [CrossRef]

- Yuan, H.; Lei, T.; Qin, Y.; Yang, R. Flexible electronic skins based on piezoelectric nanogenerators and piezotronics. Nano Energy 2019, 59, 84–90. [Google Scholar] [CrossRef]

- Yang, T.; Pan, H.; Tian, G.; Zhang, B.; Xiong, D.; Gao, Y.; Yan, C.; Chu, X.; Chen, N.; Zhong, S.; et al. Hierarchically structured PVDF/ZnO core-shell nanofibers for self-powered physiological monitoring electronics. Nano Energy 2020, 72, 104706. [Google Scholar] [CrossRef]

- Kim, M.-O.; Pyo, S.; Oh, Y.; Kang, Y.; Cho, K.-H.; Choi, J.; Kim, J. Flexible and multi-directional piezoelectric energy harvester for self-powered human motion sensor. Smart Mater. Struct. 2018, 27, 035001. [Google Scholar] [CrossRef]

- Chodankar, N.; Padwal, C.; Pham, H.D.; Ostrikov, K.; Jadhav, S.; Mahale, K.; Yarlagadda, P.K.; Huh, Y.S.; Han, Y.-K.; Dubal, D. Piezo-supercapacitors: A new paradigm of self-powered wellbeing and biomedical devices. Nano Energy 2021, 90, 106607. [Google Scholar] [CrossRef]

- Wang, N.; Dou, W.; Hao, S.; Cheng, Y.; Zhou, D.; Huang, X.; Jiang, C.; Cao, X. Tactile sensor from self-chargeable piezoelectric supercapacitor. Nano Energy 2018, 56, 868–874. [Google Scholar] [CrossRef]

- Yu, S.; Ling, Y.; Sun, S.; Wang, Y.; Yu, Z.; Zheng, J.; Liu, G.; Chen, D.; Fu, Y.; Liu, Y.; et al. Flexible self-charging lithium battery for storing low-frequency mechanical energy. Nano Energy 2022, 94, 106911. [Google Scholar] [CrossRef]

- Fan, F.-R.; Lin, L.; Zhu, G.; Wu, W.; Zhang, R.; Wang, Z.L. Transparent Triboelectric Nanogenerators and Self-Powered Pressure Sensors Based on Micropatterned Plastic Films. Nano Lett. 2012, 12, 3109–3114. [Google Scholar] [CrossRef]

- Jiang, M.; Lu, Y.; Zhu, Z.; Jia, W. Advances in Smart Sensing and Medical Electronics by Self-Powered Sensors Based on Triboelectric Nanogenerators. Micromachines 2021, 12, 698. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Dong, K.; Li, X.; An, J.; Wu, D.; Peng, X.; Yi, J.; Ning, C.; Cheng, R.; Yu, P.; et al. Stretchable, Washable, and Ultrathin Triboelectric Nanogenerators as Skin-Like Highly Sensitive Self-Powered Haptic Sensors. Adv. Funct. Mater. 2020, 31, 2005584. [Google Scholar] [CrossRef]

- Ning, C.; Cheng, R.; Jiang, Y.; Sheng, F.; Yi, J.; Shen, S.; Zhang, Y.; Peng, X.; Dong, K.; Wang, Z.L. Helical Fiber Strain Sensors Based on Triboelectric Nanogenerators for Self-Powered Human Respiratory Monitoring. ACS Nano 2022, 16, 2811–2821. [Google Scholar] [CrossRef] [PubMed]

- Su, L.; Jiang, Z.; Tian, Z.; Wang, H.; Wang, H.; Zi, Y. Self-powered, ultrasensitive, and high-resolution visualized flexible pressure sensor based on color-tunable triboelectrification-induced electroluminescence. Nano Energy 2020, 79, 105431. [Google Scholar] [CrossRef]

- Wen, F.; Zhang, Z.; He, T.; Lee, C. AI enabled sign language recognition and VR space bidirectional communication using triboelectric smart glove. Nat. Commun. 2021, 12, 5378. [Google Scholar] [CrossRef] [PubMed]

- Zou, J.; Zhang, M.; Huang, J.; Bian, J.; Jie, Y.; Willander, M.; Cao, X.; Wang, N.; Wang, Z.L. Coupled Supercapacitor and Triboelectric Nanogenerator Boost Biomimetic Pressure Sensor. Adv. Energy Mater. 2018, 8, 1702671. [Google Scholar] [CrossRef]

- Han, J.; Xu, C.; Zhang, J.; Xu, N.; Xiong, Y.; Cao, X.; Liang, Y.; Zheng, L.; Sun, J.; Zhai, J.; et al. Multifunctional Coaxial Energy Fiber toward Energy Harvesting, Storage, and Utilization. ACS Nano 2021, 15, 1597–1607. [Google Scholar] [CrossRef] [PubMed]

- Kuzubasoglu, B.A.; Bahadir, S.K. Flexible temperature sensors: A review. Sens. Actuators A Phys. 2020, 315, 112282. [Google Scholar] [CrossRef]

- Chen, J.; Zhu, Y.; Chang, X.; Pan, D.; Song, G.; Guo, Z.; Naik, N. Recent Progress in Essential Functions of Soft Electronic Skin. Adv. Funct. Mater. 2021, 31, 2104686. [Google Scholar] [CrossRef]

- Liu, R.; He, L.; Cao, M.; Sun, Z.; Zhu, R.; Li, Y. Flexible Temperature Sensors. Front. Chem. 2021, 9, 539678. [Google Scholar] [CrossRef]

- Li, M.; Chen, J.; Zhong, W.; Luo, M.; Wang, W.; Qing, X.; Lu, Y.; Liu, Q.; Liu, K.; Wang, Y.; et al. A Large-Area, Wearable, Self-Powered Pressure-Temperature Sensor Based on the 3D Thermoelectric Spacer Fabric. ACS Sens. 2020, 5, 2545–2554. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.; Ji, Y.; Ouyang, B.; Li, Z.; Yang, Y. Self-Powered Light-Temperature Dual-Parameter Sensor Using Nb-Doped SrTiO3 Materials Via Thermo-Phototronic Effect. Adv. Funct. Mater. 2021, 31, 2010439. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, W.; Deng, Y.; Zhu, P.; Yu, Y.; Hu, S.; Zhang, R. High-sensitivity self-powered temperature/pressure sensor based on flexible Bi-Te thermoelectric film and porous microconed elastomer. J. Mater. Sci. Technol. 2021, 103, 1–7. [Google Scholar] [CrossRef]

- Wan, K.; Liu, Y.; Santagiuliana, G.; Barandun, G.; Junior, P.T.; Güder, F.; Bastiaansen, C.W.; Baxendale, M.; Fenwick, O.; Papageorgiou, D.G.; et al. Self-powered ultrasensitive and highly stretchable temperature–strain sensing composite yarns. Mater. Horiz. 2021, 8, 2513–2519. [Google Scholar] [CrossRef]

- Zhao, J.; Zhang, Y.; Huang, Y.; Zhao, X.; Shi, Y.; Qu, J.; Yang, C.; Xie, J.; Wang, J.; Li, L.; et al. Duplex printing of all-in-one integrated electronic devices for temperature monitoring. J. Mater. Chem. A 2018, 7, 972–978. [Google Scholar] [CrossRef]

- Liu, D.; Ma, J.; Zheng, S.; Shao, W.; Zhang, T.; Liu, S.; Jian, X.; Wu, Z.; Hu, F. High-Performance and Flexible Co-Planar Integrated Microsystem of Carbon-Based All-Solid-State Micro-Supercapacitor and Real-Time Temperature Sensor. Energy Environ. Mater. 2022, 3, e12445. [Google Scholar] [CrossRef]

- Chen, X.; Ren, Z.; Guo, H.; Cheng, X.; Zhang, H. Self-powered flexible and transparent smart patch for temperature sensing. Appl. Phys. Lett. 2020, 116, 043902. [Google Scholar] [CrossRef]

- Ma, J.; Zheng, S.; Cao, Y.; Zhu, Y.; Das, P.; Wang, H.; Liu, Y.; Wang, J.; Chi, L.; Liu, S.; et al. Aqueous MXene/PH1000 Hybrid Inks for Inkjet-Printing Micro-Supercapacitors with Unprecedented Volumetric Capacitance and Modular Self-Powered Microelectronics. Adv. Energy Mater. 2021, 11, 2100746. [Google Scholar] [CrossRef]

- Zhang, D.; Liu, Y.; Liu, Y.; Peng, Y.; Tang, Y.; Xiong, L.; Gong, X.; Zheng, J. A General Crosslinker Strategy to Realize Intrinsic Frozen Resistance of Hydrogels. Adv. Mater. 2021, 33, 2104006. [Google Scholar] [CrossRef] [PubMed]

- Dai, C.; Chen, H.; Wang, L.; Liu, Y.; Yin, Q.; Jiang, J.; Zhou, Q.; Weng, G. A highly temperature- and pressure-sensitive soft sensor self-powered by a galvanic cell design. J. Mater. Chem. A 2022, 10, 4408–4417. [Google Scholar] [CrossRef]

- Lu, Y.; Fujita, Y.; Honda, S.; Yang, S.; Xuan, Y.; Xu, K.; Arie, T.; Akita, S.; Takei, K. Wireless and Flexible Skin Moisture and Temperature Sensor Sheets toward the Study of Thermoregulator Center. Adv. Health Mater. 2021, 10, 2100103. [Google Scholar] [CrossRef] [PubMed]

- Khan, Y.; Garg, M.; Gui, Q.; Schadt, M.; Gaikwad, A.; Han, D.; Yamamoto, N.A.D.; Hart, P.; Welte, R.; Wilson, W.; et al. Flexible Hybrid Electronics: Direct Interfacing of Soft and Hard Electronics for Wearable Health Monitoring. Adv. Funct. Mater. 2016, 26, 8764–8775. [Google Scholar] [CrossRef]

- Xiao, X.; Mu, B.; Cao, G. Light-Energy-Harvested Flexible Wireless Temperature-Sensing Patch for Food Cold Storage. ACS Appl. Electron. Mater. 2021, 3, 3015–3022. [Google Scholar] [CrossRef]

- Kim, J.; Campbell, A.S.; De Ávila, B.E.-F.; Wang, J. Wearable biosensors for healthcare monitoring. Nat. Biotechnol. 2019, 37, 389–406. [Google Scholar] [CrossRef]

- Iqbal, S.M.A.; Mahgoub, I.; Du, E.; Leavitt, M.A.; Asghar, W. Advances in healthcare wearable devices. NPJ Flex. Electron. 2021, 5, 9. [Google Scholar] [CrossRef]

- Reid, R.C.; Mahbub, I. Wearable self-powered biosensors. Curr. Opin. Electrochem. 2019, 19, 55–62. [Google Scholar] [CrossRef]

- Wu, G.; Heck, I.; Zhang, N.; Phaup, G.; Zhang, X.; Wu, Y.; Stalla, D.E.; Weng, Z.; Sun, H.; Li, H.; et al. Wireless, battery-free push-pull microsystem for membrane-free neurochemical sampling in freely moving animals. Sci. Adv. 2022, 8, eabn2277. [Google Scholar] [CrossRef]

- Baik, S.; Lee, J.; Jeon, E.J.; Park, B.-Y.; Kim, D.W.; Song, J.H.; Lee, H.J.; Han, S.Y.; Cho, S.-W.; Pang, C. Diving beetle–like miniaturized plungers with reversible, rapid biofluid capturing for machine learning–based care of skin disease. Sci. Adv. 2021, 7, eabf5695. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.; Lillehoj, P.B. Microneedle-based skin patch for blood-free rapid diagnostic testing. Microsyst. Nanoeng. 2020, 6, 96. [Google Scholar] [CrossRef]

- Jung, H.-T. The Present and Future of Gas Sensors. ACS Sens. 2022, 7, 912–913. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Ning, J.; Wang, B.; Guo, H.; Feng, X.; Shen, X.; Jia, Y.; Dong, J.; Wang, D.; Zhang, J.; et al. Hybridized 1T/2H-MoS2/graphene fishnet tube for high-performance on-chip integrated micro-systems comprising supercapacitors and gas sensors. Nano Res. 2020, 14, 114–121. [Google Scholar] [CrossRef]

- Lin, Y.; Chen, J.; Tavakoli, M.M.; Gao, Y.; Zhu, Y.; Zhang, D.; Kam, M.; He, Z.; Fan, Z. Printable Fabrication of a Fully Integrated and Self-Powered Sensor System on Plastic Substrates. Adv. Mater. 2018, 31, e1804285. [Google Scholar] [CrossRef] [PubMed]

- Shi, X.; Chang, J.; Qin, J.; Liu, H.; Zhang, X.; Ma, Y.; He, J.; Chou, X.; Feng, L.; Wu, Z.-S.; et al. Scalable fabrication of in-plane microscale self-powered integrated systems for fast-response and highly selective dual-channel gas detection. Nano Energy 2021, 88, 106253. [Google Scholar] [CrossRef]

- Guo, R.; Chen, J.; Yang, B.; Liu, L.; Su, L.; Shen, B.; Yan, X. In-Plane Micro-Supercapacitors for an Integrated Device on One Piece of Paper. Adv. Funct. Mater. 2017, 27, 1702394. [Google Scholar] [CrossRef]

- Song, C.; Yun, J.; Lee, H.; Park, H.; Jeong, Y.R.; Lee, G.; Kim, M.S.; Ha, J.S. A Shape Memory High-Voltage Supercapacitor with Asymmetric Organic Electrolytes for Driving an Integrated NO2 Gas Sensor. Adv. Funct. Mater. 2019, 29, 1901996. [Google Scholar] [CrossRef]

- Li, L.; Fu, C.; Lou, Z.; Chen, S.; Han, W.; Jiang, K.; Chen, D.; Shen, G. Flexible planar concentric circular micro-supercapacitor arrays for wearable gas sensing application. Nano Energy 2017, 41, 261–268. [Google Scholar] [CrossRef]

- Ma, H.; Lv, F.; Shen, L.; Yang, K.; Jiang, Y.; Ma, J.; Geng, X.; Sun, T.; Pan, Y.; Xie, Z.; et al. Self-Healing All-in-One Energy Storage for Flexible Self-Powering Ammonia Smartsensors. Energy Environ. Mater. 2021, 5, 986–995. [Google Scholar] [CrossRef]

- Liu, X.-L.; Zhao, Y.; Wang, W.-J.; Ma, S.-X.; Ning, X.-J.; Zhao, L.; Zhuang, J. Photovoltaic Self-Powered Gas Sensing: A Review. IEEE Sens. J. 2020, 21, 5628–5644. [Google Scholar] [CrossRef]

- Espid, E.; Taghipour, F. UV-LED Photo-activated Chemical Gas Sensors: A Review. Crit. Rev. Solid State Mater. Sci. 2016, 42, 416–432. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, M.; Xing, B.; Fu, X.; Bo, R.; Mulmudi, H.K.; Huang, S.; Ho-Baillie, A.W.Y.; Catchpole, K.R.; Tricoli, A. Superior Self-Charged and -Powered Chemical Sensing with High Performance for NO2 Detection at Room Temperature. Adv. Opt. Mater. 2020, 8, 1901863. [Google Scholar] [CrossRef]

- Yan, W.; Ma, L.; Xu, J.; Guo, Y.; Hu, H.; Zhi, C.; Ho, D. Battery-Sensor Hybrid: A New Gas Sensing Paradigm with Complete Energy Self-Sufficiency. ACS Appl. Mater. Interfaces 2021, 13, 46507–46517. [Google Scholar] [CrossRef]

- Zeng, X.; Peng, R.; Fan, Z.; Lin, Y. Self-powered and wearable biosensors for healthcare. Mater. Today Energy 2021, 23, 100900. [Google Scholar] [CrossRef]

- Lu, Y.; Jiang, K.; Chen, D.; Shen, G. Wearable sweat monitoring system with integrated micro-supercapacitors. Nano Energy 2019, 58, 624–632. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, X.; Zhou, J.; Li, J.; Nejad, S.K.; Yiu, C.K.; Li, H.; Wong, T.H.; Park, W.; Yao, K.; et al. Bandage based energy generators activated by sweat in wireless skin electronics for continuous physiological monitoring. Nano Energy 2021, 92, 106755. [Google Scholar] [CrossRef]

- Li, T.; Liang, B.; Ye, Z.; Zhang, L.; Xu, S.; Tu, T.; Zhang, Y.; Cai, Y.; Zhang, B.; Fang, L.; et al. An integrated and conductive hydrogel-paper patch for simultaneous sensing of Chemical–Electrophysiological signals. Biosens. Bioelectron. 2022, 198, 113855. [Google Scholar] [CrossRef] [PubMed]

- Yin, L.; Cao, M.; Kim, K.N.; Lin, M.; Moon, J.-M.; Sempionatto, J.R.; Yu, J.; Liu, R.; Wicker, C.; Trifonov, A.; et al. A stretchable epidermal sweat sensing platform with an integrated printed battery and electrochromic display. Nat. Electron. 2022, 5, 694–705. [Google Scholar] [CrossRef]

- Tran, B.Q.; Miller, P.R.; Taylor, R.M.; Boyd, G.; Mach, P.M.; Rosenzweig, C.N.; Baca, J.T.; Polsky, R.; Glaros, T. Proteomic Characterization of Dermal Interstitial Fluid Extracted Using a Novel Microneedle-Assisted Technique. J. Proteome Res. 2017, 17, 479–485. [Google Scholar] [CrossRef] [PubMed]

- Teymourian, H.; Tehrani, F.; Mahato, K.; Wang, J. Lab under the Skin: Microneedle Based Wearable Devices. Adv. Health Mater. 2021, 10, e2002255. [Google Scholar] [CrossRef]

- Samant, P.P.; Niedzwiecki, M.M.; Raviele, N.; Tran, V.; Mena-Lapaix, J.; Walker, D.I.; Felner, E.I.; Jones, D.P.; Miller, G.W.; Prausnitz, M.R. Sampling interstitial fluid from human skin using a microneedle patch. Sci. Transl. Med. 2020, 12, eaaw0285. [Google Scholar] [CrossRef]

- Tehrani, F.; Teymourian, H.; Wuerstle, B.; Kavner, J.; Patel, R.; Furmidge, A.; Aghavali, R.; Hosseini-Toudeshki, H.; Brown, C.; Zhang, F.; et al. An integrated wearable microneedle array for the continuous monitoring of multiple biomarkers in interstitial fluid. Nat. Biomed. Eng. 2022, 6, 1214–1224. [Google Scholar] [CrossRef]

- Kil, H.-J.; Kim, S.-R.; Park, J.-W. A Self-Charging Supercapacitor for a Patch-Type Glucose Sensor. ACS Appl. Mater. Interfaces 2022, 14, 3838–3848. [Google Scholar] [CrossRef]

- Chen, J.C.; Kan, P.; Yu, Z.; Alrashdan, F.; Garcia, R.; Singer, A.; Lai, C.S.E.; Ben Avants, B.; Crosby, S.; Li, Z.; et al. A wireless millimetric magnetoelectric implant for the endovascular stimulation of peripheral nerves. Nat. Biomed. Eng. 2022, 6, 706–716. [Google Scholar] [CrossRef]

- Opie, N.L.; John, S.E.; Rind, G.S.; Ronayne, S.M.; Wong, Y.T.; Gerboni, G.; Yoo, P.E.; Lovell, T.J.H.; Scordas, T.C.M.; Wilson, S.L.; et al. Focal stimulation of the sheep motor cortex with a chronically implanted minimally invasive electrode array mounted on an endovascular stent. Nat. Biomed. Eng. 2018, 2, 907–914. [Google Scholar] [CrossRef]

- Oxley, T.; Opie, N.; John, S.; Rind, G.S.; Ronayne, S.M.; Wheeler, T.L.; Judy, J.W.; McDonald, A.J.; Dornom, A.; Lovell, T.J.H.; et al. Minimally invasive endovascular stent-electrode array for high-fidelity, chronic recordings of cortical neural activity. Nat. Biotechnol. 2016, 34, 320–327. [Google Scholar] [CrossRef]

- Lee, Y.; Bandari, V.K.; Li, Z.; Medina-Sánchez, M.; Maitz, M.F.; Karnaushenko, D.; Tsurkan, M.V.; Karnaushenko, D.D.; Schmidt, O.G. Nano-biosupercapacitors enable autarkic sensor operation in blood. Nat. Commun. 2021, 12, 4967. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Sun, G.; Li, Y.; Yang, R. Wearable Wireless Physiological Monitoring System Based on Multi-Sensor. Electronics 2021, 10, 986. [Google Scholar] [CrossRef]

- Wei, J.; Teng, Y.; Meng, T.; Bu, X.; Du, H.; Li, D. A multicomponent interconnected composite paper for triple-mode sensors and flexible micro-supercapacitors. J. Mater. Chem. A 2020, 8, 24620–24634. [Google Scholar] [CrossRef]

- Huang, Y.; Kershaw, S.V.; Wang, Z.; Pei, Z.; Liu, J.; Li, H.; Zhu, M.; Rogach, A.L.; Zhi, C. Highly Integrated Supercapacitor-Sensor Systems via Material and Geometry Design. Small 2016, 12, 3393–3399. [Google Scholar] [CrossRef]

- Park, H.; Kim, J.W.; Hong, S.Y.; Lee, G.; Kim, D.S.; Oh, J.H.; Jin, S.W.; Jeong, Y.R.; Oh, S.Y.; Yun, J.Y.; et al. Microporous Polypyrrole-Coated Graphene Foam for High-Performance Multifunctional Sensors and Flexible Supercapacitors. Adv. Funct. Mater. 2018, 28, 1707013. [Google Scholar] [CrossRef]

- Liang, B.; Huang, B.; He, J.; Yang, R.; Zhao, C.; Yang, B.-R.; Cao, A.; Tang, Z.; Gui, X. Direct stamping multifunctional tactile sensor for pressure and temperature sensing. Nano Res. 2021, 15, 3614–3620. [Google Scholar] [CrossRef]

- Sun, J.; Lu, G.; Zhou, J.; Yuan, Y.; Zhu, X.; Nie, J. Robust Physically Linked Double-Network Ionogel as a Flexible Bimodal Sensor. ACS Appl. Mater. Interfaces 2020, 12, 14272–14279. [Google Scholar] [CrossRef]

- Li, L.; Chen, Z.; Hao, M.; Wang, S.; Sun, F.; Zhao, Z.; Zhang, T. Moisture-Driven Power Generation for Multifunctional Flexible Sensing Systems. Nano Lett. 2019, 19, 5544–5552. [Google Scholar] [CrossRef]

- Liu, H.; Xiang, H.; Wang, Y.; Li, Z.; Qian, L.; Li, P.; Ma, Y.; Zhou, H.; Huang, W. A Flexible Multimodal Sensor That Detects Strain, Humidity, Temperature, and Pressure with Carbon Black and Reduced Graphene Oxide Hierarchical Composite on Paper. ACS Appl. Mater. Interfaces 2019, 11, 40613–40619. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Lou, Z.; Shen, G. An integrated flexible multifunctional sensing system for simultaneous monitoring of environment signals. Sci. China Mater. 2020, 63, 2560–2569. [Google Scholar] [CrossRef]

- Ai, Y.; Lou, Z.; Chen, S.; Chen, D.; Wang, Z.M.; Jiang, K.; Shen, G. All rGO-on-PVDF-nanofibers based self-powered electronic skins. Nano Energy 2017, 35, 121–127. [Google Scholar] [CrossRef]

- Righini, G.C.; Krzak, J.; Lukowiak, A.; Macrelli, G.; Varas, S.; Ferrari, M. From flexible electronics to flexible photonics: A brief overview. Opt. Mater. 2021, 115, 111011. [Google Scholar] [CrossRef]

- Song, H.; Luo, G.; Ji, Z.; Bo, R.; Xue, Z.; Yan, D.; Zhang, F.; Bai, K.; Liu, J.; Cheng, X.; et al. Highly-integrated, miniaturized, stretchable electronic systems based on stacked multilayer network materials. Sci. Adv. 2022, 8, eabm3785. [Google Scholar] [CrossRef] [PubMed]

| Characteristics | Integration Mode | Devices | Mechanism | Characteristics | |||

|---|---|---|---|---|---|---|---|

| Positives | Negatives | Positives | Negatives | ||||

| Excellent sensing and energy-storage performance | Low integration degree | Component integration | Energy-storage devices for sensing systems | Supercapacitor | Electric double-layer capacitance or pseudocapacitance | High power, long cycle life | Low energy density |

| Battery | Electrochemical redox reaction | High energy | Low power density | ||||

| High integration degree | Sacrifice sensing and energy-storage performance | Function integration | Hybrid energy-storage device | Hybrid charge–storage mechanism | High energy density and high-power density | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, M.; Zhang, X.; Wang, J.; Zhao, Y. Recent Progress of Energy-Storage-Device-Integrated Sensing Systems. Nanomaterials 2023, 13, 645. https://doi.org/10.3390/nano13040645

Yuan M, Zhang X, Wang J, Zhao Y. Recent Progress of Energy-Storage-Device-Integrated Sensing Systems. Nanomaterials. 2023; 13(4):645. https://doi.org/10.3390/nano13040645

Chicago/Turabian StyleYuan, Man, Xinqun Zhang, Jiaqi Wang, and Yang Zhao. 2023. "Recent Progress of Energy-Storage-Device-Integrated Sensing Systems" Nanomaterials 13, no. 4: 645. https://doi.org/10.3390/nano13040645

APA StyleYuan, M., Zhang, X., Wang, J., & Zhao, Y. (2023). Recent Progress of Energy-Storage-Device-Integrated Sensing Systems. Nanomaterials, 13(4), 645. https://doi.org/10.3390/nano13040645