Further Improvement Based on Traditional Nanocapsule Preparation Methods: A Review

Abstract

:1. Introduction

2. Chemical Methods

2.1. Emulsion Polymerization

2.1.1. Miniemulsion Polymerization

2.1.2. Microemulsion Polymerization

2.2. Interfacial Polymerization

3. Physicochemical Methods

3.1. Layer-by-Layer (LBL) Self-Assembly

- (1)

- The electrostatic assembly driving force is the most classic and mature type in the LBL self-assembly method. However, the nanocapsules prepared based on static electricity have a weak stability and are easily destroyed under extreme conditions, such as high temperatures, strong acids, strong alkalis, and high ionic strengths [82]. Fan et al. [83] used PLGA as the core and alternately wrapped poly-L-ornithine (PLO) and the sulfated polysaccharide rockweed polysaccharide complex in the outer layer to form a shell, successfully encapsulating the drug dispersed within the PLGA core and allowing a controlled release.

- (2)

- The preparation of nanocapsules based on hydrogen bonding interactions is similar to electrostatic interactions, which are all weak interactions. The hydrogen-bonding self-assembly generally needs to suppress the ionization of assembled molecules, so the wall of the prepared nanocapsules is sensitive to pH. Hwangbo et al. [84] used polyethyleneimine and siloxane coupling agents as the wall material, silica as the core material, and hydrogen-bonding self-assembly to successfully prepare nanocapsules with antibacterial functions and good hydrophilicity.

- (3)

- Through the LBL self-assembly of covalent bond interactions, a stable covalent bond is formed that connects the layers, and a firm self-assembly structure can be obtained. This is due to the chemical reaction of the functional groups of the assembly material. The prepared nanocapsules have a good stability and are not easy to degrade under strong acids, strong bases, high salinity, high temperatures, and so on [85]. Zhang et al. [86] successfully used covalent LBL self-assembly (CSA) to synthesize hollow capsules with N-Methyl-2-nitro-diphenylamine-4-diazoresin (NDR) and m Methylphenol-formaldehyde resin (MPR) in latex core LBL assembly to form nanocapsules with an average diameter of 260 nm.

- (4)

- The host–guest interaction is a common assembly technique in supramolecular chemistry. The LBL microcapsules based on the host–guest effect usually have excellent environmental responsiveness [87]. Li et al. [88] assembled bis-aminated poly(glycerol methacrylate)s and cucurbit [7] uril on mesoporous silica nanoparticles. As a molecular bridge, cucurbit [7] uril connected two different diamino polymer molecular layers through the interaction between the host and guest. The prepared nanocapsules could release the encapsulated anticancer drug (doxorubicin hydrochloride) under specific acidic conditions. (See Table 3).

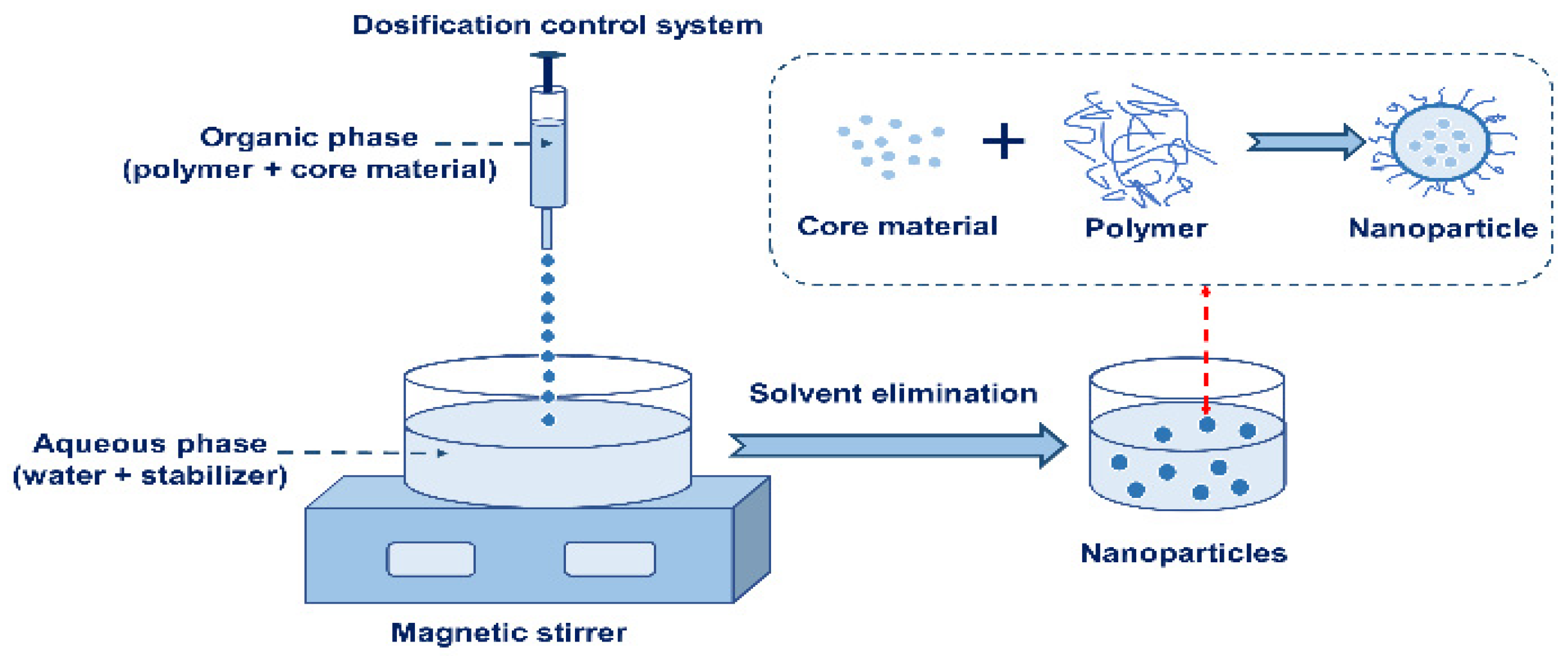

3.2. Nanoprecipitation

4. Physical Methods

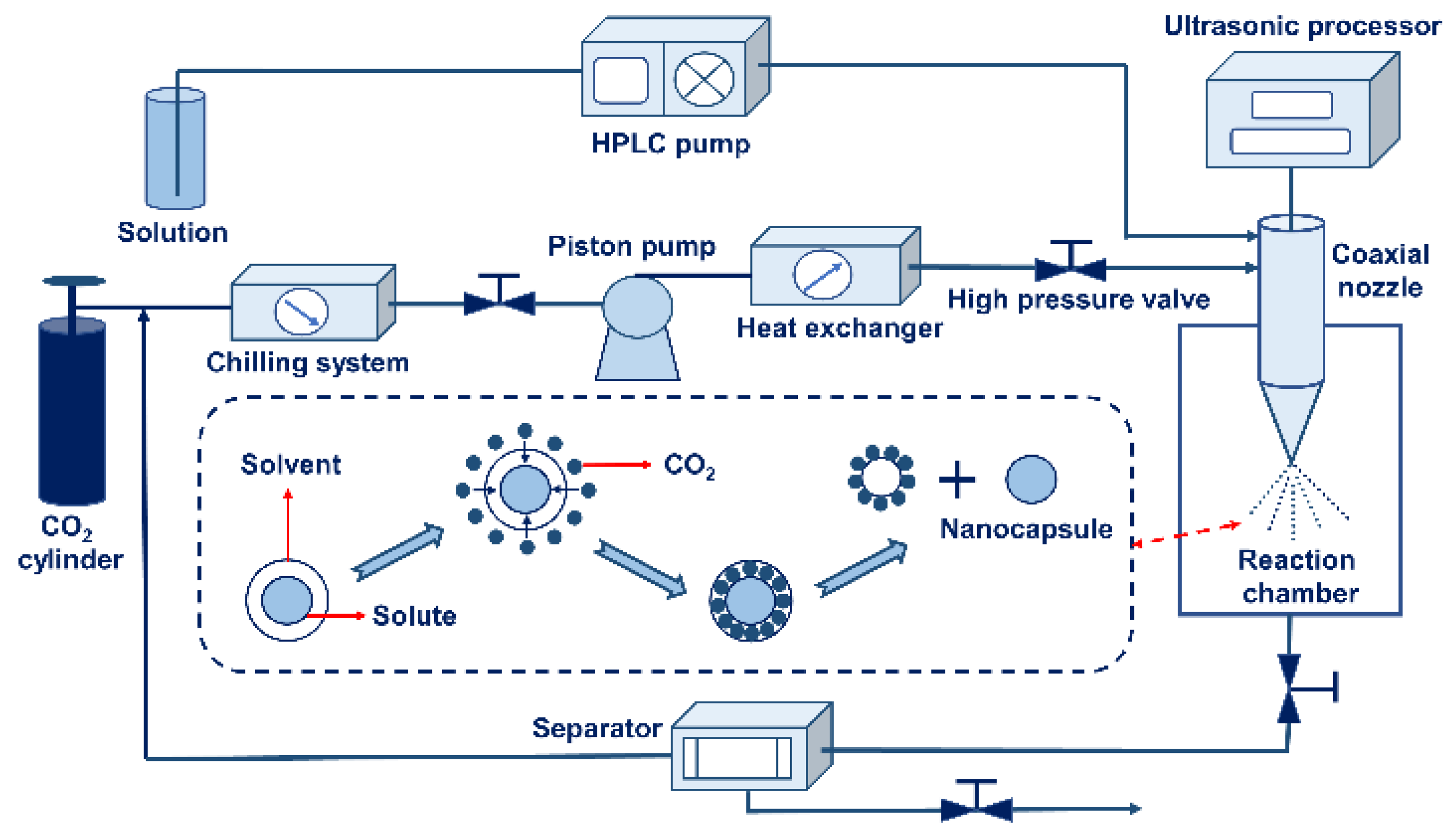

4.1. Supercritical Fluid (SCF)

4.1.1. Rapid Expansion of the Supercritical Fluid

4.1.2. Supercritical Antisolvent (SAS)

- Gas antisolvent (GAS)

- Aerosol solvent extraction (ASE)

- Solution-enhanced dispersion (SED)

- Solution-enhanced dispersion via ultrasound (SED-U)

4.1.3. Supercritical Fluid Extraction of Emulsions (SFEE)

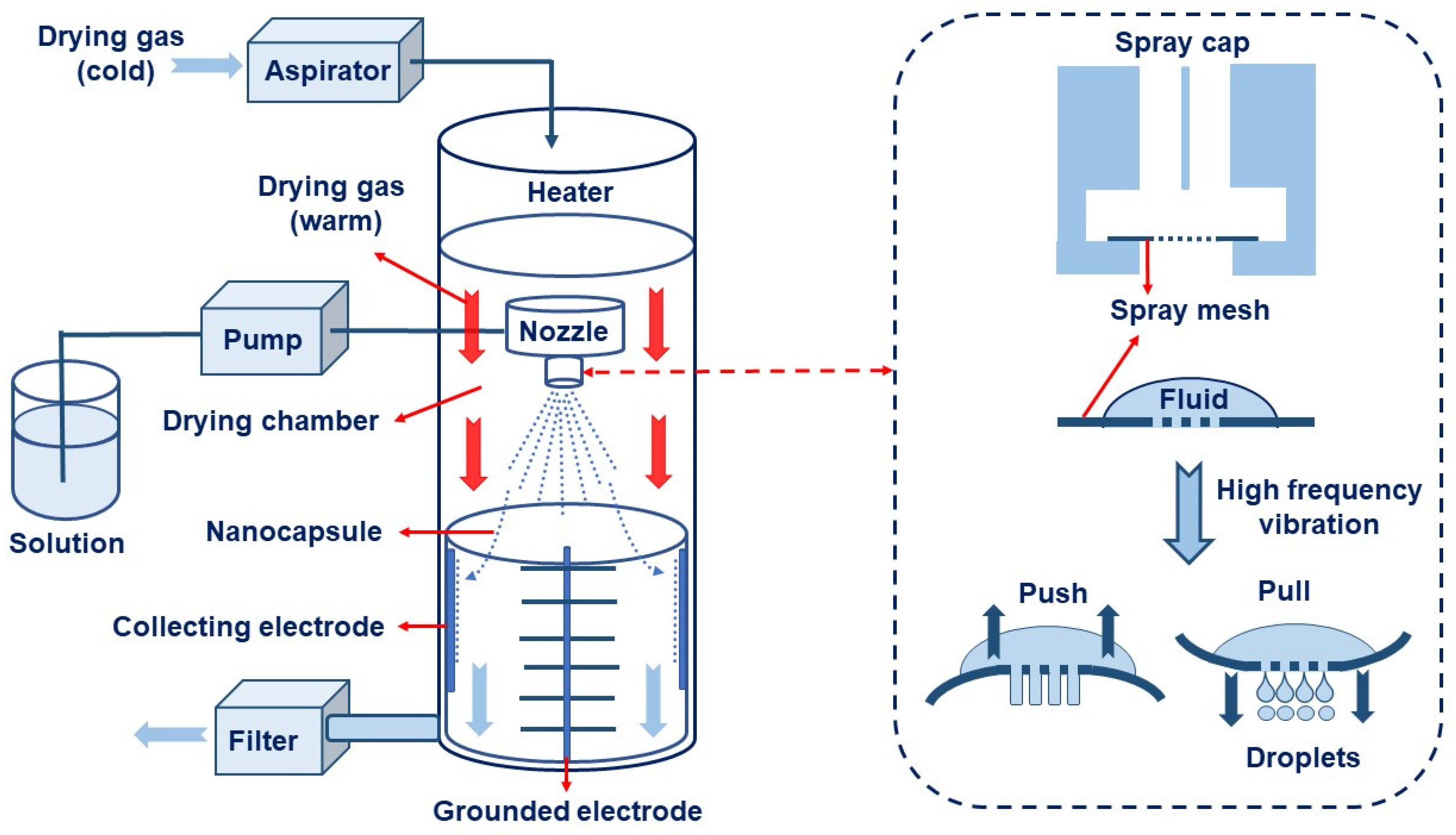

4.2. Nano Spray Drying

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Holgate, S.T. Exposure, uptake, distribution and toxicity of nanomaterials in humans. J. Biomed. Nanotechnol. 2010, 6, 1–19. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez, J.; Martín, M.J.; Ruiz, M.A.; Clares, B. Current encapsulation strategies for bioactive oils: From alimentary to pharmaceutical perspectives. Food Res. Int. 2016, 83, 41–59. [Google Scholar] [CrossRef]

- Hu, J.; Zhang, Y.; Xiao, Z.; Wang, X. Preparation and properties of cinnamon-thyme-ginger composite essential oil nanocapsules. Ind. Crops Prod. 2018, 122, 85–92. [Google Scholar] [CrossRef]

- Arpagaus, C.; John, P.; Collenberg, A.; Rütti, D. 10—Nanocapsules formation by nano spray drying. In Nanoencapsulation Technologies for the Food and Nutraceutical Industries; Jafari, S.M., Ed.; Academic Press: Cambridge, MA, USA, 2017; pp. 346–401. [Google Scholar]

- Katouzian, I.; Jafari, S.M. Nano-encapsulation as a promising approach for targeted delivery and controlled release of vitamins. Trends Food Sci. Technol. 2016, 53, 34–48. [Google Scholar] [CrossRef]

- Esmaeili, A.; Niknam, S. Preparation of polyamide nanocapsules of Elaeagnus angustifolia L. delivery with in vivo studies. Ind. Crops Prod. 2014, 55, 49–55. [Google Scholar] [CrossRef]

- Shishir, M.R.I.; Xie, L.; Sun, C.; Zheng, X.; Chen, W. Advances in micro and nano-encapsulation of bioactive compounds using biopolymer and lipid-based transporters. Trends Food Sci. Technol. 2018, 78, 34–60. [Google Scholar] [CrossRef]

- Zhao, M.; Zhang, X.; Kong, X. Preparation and characterization of a novel composite phase change material with double phase change points based on nanocapsules. Renew. Energy 2020, 147, 374–383. [Google Scholar] [CrossRef]

- Yamashina, M.; Akita, M.; Hasegawa, T.; Hayashi, S.; Yoshizawa, M. A polyaromatic nanocapsule as a sucrose receptor in water. Sci. Adv. 2017, 3, e1701126. [Google Scholar] [CrossRef]

- Zheng, Y.-N.; Liang, W.-B.; Xiong, C.-Y.; Yuan, Y.-L.; Chai, Y.-Q.; Yuan, R. Self-enhanced ultrasensitive photoelectrochemical biosensor based on nanocapsule packaging both donor–acceptor-type photoactive material and its sensitizer. Anal. Chem. 2016, 88, 8698–8705. [Google Scholar] [CrossRef]

- de Souza, Z.C.; Júnior, F.H.X.; Pinheiro, I.O.; de Souza Rebouças, J.; de Abreu, B.O.; Mesquita, P.R.R.; de Medeiros Rodrigues, F.; Quadros, H.C.; Mendes, T.M.F.; Nguewa, P.; et al. Ameliorating the antiparasitic activity of the multifaceted drug ivermectin through a polymer nanocapsule formulation. Int. J. Pharm. 2023, 639, 122965. [Google Scholar] [CrossRef]

- Shimanovich, U.; Bernardes, G.J.; Knowles, T.; Cavaco-Paulo, A. Protein micro-and nano-capsules for biomedical applications. Chem. Soc. Rev. 2014, 43, 1361–1371. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Y.; Xia, T.; Zhao, W.; Yang, W. Effects of fabricated technology on particle size distribution and thermal properties of stearic–eicosanoic acid/polymethylmethacrylate nanocapsules. Sol. Energy Mater. Sol. Cells 2014, 120, 481–490. [Google Scholar] [CrossRef]

- Bazzano, M.; Pisano, R.; Brelstaff, J.; Spillantini, M.G.; Sidoryk-Wegrzynowicz, M.; Rizza, G.; Sangermano, M. Synthesis of polymeric nanocapsules by radical UV-activated interface-emulsion polymerization. J. Polym. Sci. Part A Polym. Chem. 2016, 54, 3357–3369. [Google Scholar] [CrossRef]

- Rusli, W.; Jackson, A.W.; Van Herk, A. A roadmap towards successful nanocapsule synthesis via vesicle templated RAFT-based emulsion polymerization. Polymers 2018, 10, 774. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Liu, T.-Y.; Hou, G.-H.; Guan, R.-F.; Zhang, J.-H. Preparation of paraffin@ poly (styrene-co-acrylic acid) phase change nanocapsules via combined miniemulsion/emulsion polymerization. J. Nanosci. Nanotechnol. 2018, 18, 4413–4417. [Google Scholar] [CrossRef] [PubMed]

- Feuser, P.E.; Bubniak, L.d.S.; Bodack, C.d.N.; Valério, A.; Silva, M.C.d.S.; Ricci-Júnior, E.; Sayer, C.; Araújo, P.H.H.d. In vitro cytotoxicity of poly (methyl methacrylate) nanoparticles and nanocapsules obtained by miniemulsion polymerization for drug delivery application. J. Nanosci. Nanotechnol. 2016, 16, 7669–7676. [Google Scholar] [CrossRef]

- Ramirez, L.M.F.; Babin, J.; Boudier, A.; Gaucher, C.; Schmutz, M.; Er-Rafik, M.; Durand, A.; Six, J.-L.; Nouvel, C. First multi-reactive polysaccharide-based transurf to produce potentially biocompatible dextran-covered nanocapsules. Carbohydr. Polym. 2019, 224, 115153. [Google Scholar] [CrossRef] [PubMed]

- Ramirez, L.M.F.; Boudier, A.; Gaucher, C.; Babin, J.; Durand, A.; Six, J.-L.; Nouvel, C. Dextran-covered pH-sensitive oily core nanocapsules produced by interfacial Reversible Addition-Fragmentation chain transfer miniemulsion polymerization. J. Colloid Interface Sci. 2020, 569, 57–67. [Google Scholar] [CrossRef]

- Katta, K.; Busko, D.; Landfester, K.; Baluschev, S.; Muñoz-Espí, R. Inorganic Protection of Polymer Nanocapsules: A Strategy to Improve the Efficiency of Encapsulated Optically Active Molecules. Isr. J. Chem. 2018, 58, 1356–1362. [Google Scholar] [CrossRef]

- Villegas, M.R.; Baeza, A.; Usategui, A.; Ortiz-Romero, P.L.; Pablos, J.L.; Vallet-Regí, M. Collagenase nanocapsules: An approach to fibrosis treatment. Acta Biomater. 2018, 74, 430–438. [Google Scholar] [CrossRef]

- Cao, Z.; Li, Q.; Wang, G. Photodegradable polymer nanocapsules fabricated from dimethyldiethoxysilane emulsion templates for controlled release. Polym. Chem. 2017, 8, 6817–6823. [Google Scholar] [CrossRef]

- Dergunov, S.A.; Khabiyev, A.T.; Shmakov, S.N.; Kim, M.D.; Ehterami, N.; Weiss, M.C.; Birman, V.B.; Pinkhassik, E. Encapsulation of homogeneous catalysts in porous polymer nanocapsules produces fast-acting selective nanoreactors. ACS Nano 2016, 10, 11397–11406. [Google Scholar] [CrossRef] [PubMed]

- Crociani, L.; Ruggiero, L. Methods for synthesis of nanocontainers. In Smart Nanocontainers; Elsevier: Amsterdam, The Netherlands, 2020; pp. 19–48. [Google Scholar]

- Dong, Y.; Matson, J.B.; Edgar, K.J. Olefin cross-metathesis in polymer and polysaccharide chemistry: A review. Biomacromolecules 2017, 18, 1661–1676. [Google Scholar] [CrossRef]

- Zhou, J.; Cui, Y.; Yao, H.; Ma, J.; Ren, H. Nanocapsules containing binary phase change material obtained via miniemulsion polymerization with reactive emulsifier: Synthesis, characterization, and application in fabric finishing. Polym. Eng. Sci. 2019, 59, E42–E51. [Google Scholar] [CrossRef]

- Gharieh, A.; Khoee, S.; Mahdavian, A.R. Emulsion and miniemulsion techniques in preparation of polymer nanoparticles with versatile characteristics. Adv. Colloid Interface Sci. 2019, 269, 152–186. [Google Scholar] [CrossRef] [PubMed]

- Hecht, L.L.; Merkel, T.; Schoth, A.; Wagner, C.; Köhler, K.; Muñoz-Espí, R.; Landfester, K.; Schuchmann, H.P. Emulsification of particle loaded droplets with regard to miniemulsion polymerization. Chem. Eng. J. 2013, 229, 206–216. [Google Scholar] [CrossRef]

- Shirin-Abadi, A.R.; Khoee, S.; Rahim-Abadi, M.M.; Mahdavian, A.R. Kinetic and thermodynamic correlation for prediction of morphology of nanocapsules with hydrophobic core via miniemulsion polymerization. Colloids Surf. A Physicochem. Eng. Asp. 2014, 462, 18–26. [Google Scholar] [CrossRef]

- Sarı, A.; Alkan, C.; Altıntaş, A. Preparation, characterization and latent heat thermal energy storage properties of micro-nanoencapsulated fatty acids by polystyrene shell. Appl. Therm. Eng. 2014, 73, 1160–1168. [Google Scholar] [CrossRef]

- Chen, Z.-H.; Yu, F.; Zeng, X.-R.; Zhang, Z.-G. Preparation, characterization and thermal properties of nanocapsules containing phase change material n-dodecanol by miniemulsion polymerization with polymerizable emulsifier. Appl. Energy 2012, 91, 7–12. [Google Scholar] [CrossRef]

- Yan, X.; Alcouffe, P.; Sudre, G.; David, L.; Bernard, J.; Ganachaud, F. Modular construction of single-component polymer nanocapsules through a one-step surfactant-free microemulsion templated synthesis. Chem. Commun. 2017, 53, 1401–1404. [Google Scholar] [CrossRef]

- Wang, W.; Hao, X.; Chen, S.; Yang, Z.; Wang, C.; Yan, R.; Zhang, X.; Liu, H.; Shao, Q.; Guo, Z. pH-responsive Capsaicin@ chitosan nanocapsules for antibiofouling in marine applications. Polymer 2018, 158, 223–230. [Google Scholar] [CrossRef]

- Calderó, G.; Rodríguez-Abreu, C.; González, A.; Monge, M.; García-Celma, M.J.; Solans, C. Biomedical perfluorohexane-loaded nanocapsules prepared by low-energy emulsification and selective solvent diffusion. Mater. Sci. Eng. C 2020, 111, 110838. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Corona, P.T.; Ruocco, N.; Alvarez, D.; Malo de Molina, P.; Mitragotri, S.; Helgeson, M.E. Controlling complex nanoemulsion morphology using asymmetric cosurfactants for the preparation of polymer nanocapsules. Langmuir 2018, 34, 978–990. [Google Scholar] [CrossRef] [PubMed]

- Calderó, G.; Rodríguez-Abreu, C.; González, A.; Monge, M.; García-Celma, M.; Solans, C. Low Energy Emulsification as a Novel Approach for Microbubble Preparation from Perfluorocarbon Nanoemulsions. 2018. Available online: https://digital.csic.es/bitstream/10261/206487/1/732088.pdf (accessed on 10 November 2023).

- Cui, G.; Wang, J.; Wang, X.; Li, W.; Zhang, X. Preparation and Properties of Narrowly Dispersed Polyurethane Nanocapsules Containing Essential Oil via Phase Inversion Emulsification. J. Agric. Food Chem. 2018, 66, 10799–10807. [Google Scholar] [CrossRef]

- Assadpour, E.; Jafari, S.-M.; Maghsoudlou, Y. Evaluation of folic acid release from spray dried powder particles of pectin-whey protein nano-capsules. Int. J. Biol. Macromol. 2017, 95, 238–247. [Google Scholar] [CrossRef] [PubMed]

- Kopeć, M.; Szczepanowicz, K.; Warszyński, P.; Nowak, P. Liquid-core polyelectrolyte nanocapsules produced by membrane emulsification as carriers for corrosion inhibitors. Colloids Surf. A Physicochem. Eng. Asp. 2016, 510, 2–10. [Google Scholar] [CrossRef]

- He, W.; Lu, Y.; Qi, J.; Chen, L.; Hu, F.; Wu, W. Nanoemulsion-templated shell-crosslinked nanocapsules as drug delivery systems. Int. J. Pharm. 2013, 445, 69–78. [Google Scholar] [CrossRef]

- Carbone, C.; Musumeci, T.; Lauro, M.; Puglisi, G. Eco-friendly aqueous core surface-modified nanocapsules. Colloids Surf. B Biointerfaces 2015, 125, 190–196. [Google Scholar] [CrossRef]

- Ghayempour, S.; Montazer, M. Tragacanth nanocapsules containing Chamomile extract prepared through sono-assisted W/O/W microemulsion and UV cured on cotton fabric. Carbohydr. Polym. 2017, 170, 234–240. [Google Scholar] [CrossRef]

- Khoshakhlagh, K.; Mohebbi, M.; Koocheki, A.; Allafchian, A. Encapsulation of D-limonene in Alyssum homolocarpum seed gum nanocapsules by emulsion electrospraying: Morphology characterization and stability assessment. Bioact. Carbohydr. Diet. Fibre 2018, 16, 43–52. [Google Scholar] [CrossRef]

- Yuan, L.; Wang, Y.; Pan, M.; Rempel, G.L.; Pan, Q. Synthesis of poly (methyl methacrylate) nanoparticles via differential microemulsion polymerization. Eur. Polym. J. 2013, 49, 41–48. [Google Scholar] [CrossRef]

- Marin, E.; Briceno, M.; George, C. Method to produce curcumin oil-in-water nano-emulsion as templates for drug carries. J. Biotechnol. Biomater. 2016, 6, 1–8. [Google Scholar]

- Gazme, B.; Madadlou, A. Fabrication of whey protein–pectin conjugate particles through laccase-induced gelation of microemulsified nanodroplets. Food Hydrocoll. 2014, 40, 189–195. [Google Scholar] [CrossRef]

- Daşkın, D.; Erdoğar, N.; İskit, A.B.; Bilensoy, E. Oral docetaxel delivery with cationic polymeric core-shell nanocapsules: In vitro and in vivo evaluation. J. Drug Deliv. Sci. Technol. 2023, 80, 104163. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, Y.; Zhang, Y.; Liu, D.; Li, M.; Cao, Y. Surface encapsulating UV filters based on self-assembly of an amphiphilic random copolymer by miniemulsion polymerization. Colloids Surf. A Physicochem. Eng. Asp. 2023, 668, 131414. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Q.; Zhang, A.; Pan, S.; Cheng, J.; Zhi, X.; Ding, X.; Hong, L.; Zi, M.; Cui, D. Multifunctional co-loaded magnetic nanocapsules for enhancing targeted MR imaging and in vivo photodynamic therapy. Nanomed. Nanotechnol. Biol. Med. 2019, 21, 102047. [Google Scholar] [CrossRef] [PubMed]

- Salabat, A.; Mirhoseini, F.; Arjomandzadegan, M.; Jiryaei, E. A novel methodology for fabrication of Ag–polypyrrole core–shell nanosphere using microemulsion system and evaluation of its antibacterial application. New J. Chem. 2017, 41, 12892–12900. [Google Scholar] [CrossRef]

- Ishizuka, F.; Chapman, R.; Kuchel, R.P.; Coureault, M.; Zetterlund, P.B.; Stenzel, M.H. Polymeric Nanocapsules for Enzyme Stabilization in Organic Solvents. Macromolecules 2018, 51, 438–446. [Google Scholar] [CrossRef]

- Qi, D.; Cao, Z.; Ziener, U. Recent advances in the preparation of hybrid nanoparticles in miniemulsions. Adv. Colloid Interface Sci. 2014, 211, 47–62. [Google Scholar] [CrossRef]

- Sarkar, J.; Xiao, L.; Jackson, A.W.; van Herk, A.M.; Goto, A. Synthesis of transition-metal-free and sulfur-free nanoparticles and nanocapsules via reversible complexation mediated polymerization (RCMP) and polymerization induced self-assembly (PISA). Polym. Chem. 2018, 9, 4900–4907. [Google Scholar] [CrossRef]

- Ghayempour, S.; Montazer, M.; Rad, M.M. Tragacanth gum as a natural polymeric wall for producing antimicrobial nanocapsules loaded with plant extract. Int. J. Biol. Macromol. 2015, 81, 514–520. [Google Scholar] [CrossRef] [PubMed]

- Adjonu, R.; Doran, G.; Torley, P.; Agboola, S. Whey protein peptides as components of nanoemulsions: A review of emulsifying and biological functionalities. J. Food Eng. 2014, 122, 15–27. [Google Scholar] [CrossRef]

- Liang, J.; Qian, Y.; Yuan, X.; Leng, L.; Zeng, G.; Jiang, L.; Shao, J.; Luo, Y.; Ding, X.; Yang, Z.; et al. Span80/Tween80 stabilized bio-oil-in-diesel microemulsion: Formation and combustion. Renew. Energy 2018, 126, 774–782. [Google Scholar] [CrossRef]

- Zhou, J.; Zhao, J.; Cui, Y.; Cheng, W. Synthesis of bifunctional nanoencapsulated phase change materials with nano-TiO2 modified polyacrylate shell for thermal energy storage and ultraviolet absorption. Polym. Int. 2020, 69, 140–148. [Google Scholar] [CrossRef]

- Zaragoza-Contreras, E.A.; Hernández-Escobar, C.A.; Estrada-Monje, A.; Kobayashi, T. Synthesis of diphenylamine-co-aniline copolymers in emulsified systems using a reactive surfactant as the emulsifying agent and aniline monomer. Synth. Met. 2016, 214, 5–13. [Google Scholar] [CrossRef]

- Asgari, S.; Saberi, A.H.; McClements, D.J.; Lin, M. Microemulsions as nanoreactors for synthesis of biopolymer nanoparticles. Trends Food Sci. Technol. 2019, 86, 118–130. [Google Scholar] [CrossRef]

- Tian, K.; Zeng, J.; Zhao, X.; Liu, L.; Jia, X.; Liu, P. Synthesis of multi-functional nanocapsules via interfacial AGET ATRP in miniemulsion for tumor micro-environment responsive drug delivery. Colloids Surf. B Biointerfaces 2015, 134, 188–195. [Google Scholar] [CrossRef] [PubMed]

- Marturano, V.; Cerruti, P.; Carfagna, C.; Giamberini, M.; Tylkowski, B.; Ambrogi, V. Photo-responsive polymer nanocapsules. Polymer 2015, 70, 222–230. [Google Scholar] [CrossRef]

- Malzahn, K.; Marsico, F.; Koynov, K.; Landfester, K.; Weiss, C.K.; Wurm, F.R. Selective interfacial olefin cross metathesis for the preparation of hollow nanocapsules. ACS Macro Lett. 2014, 3, 40–43. [Google Scholar] [CrossRef]

- Park, S.; Lee, Y.; Kim, Y.S.; Lee, H.M.; Kim, J.H.; Cheong, I.W.; Koh, W.-G. Magnetic nanoparticle-embedded PCM nanocapsules based on paraffin core and polyurea shell. Colloids Surf. A Physicochem. Eng. Asp. 2014, 450, 46–51. [Google Scholar] [CrossRef]

- Shi, J.; Wu, X.; Sun, R.; Ban, B.; Li, J.; Chen, J. Nano-encapsulated phase change materials prepared by one-step interfacial polymerization for thermal energy storage. Mater. Chem. Phys. 2019, 231, 244–251. [Google Scholar] [CrossRef]

- Song, X.-Q.; Tao, C.; Li, W.; Wang, J.-X.; Le, Y.; Zhang, J.-J. Preparation of reduction-responsive camptothecin nanocapsules by combining nanoprecipitation and in situ polymerization for anticancer therapy. Pharmaceutics 2018, 10, 173. [Google Scholar] [CrossRef] [PubMed]

- Qiu, X.; Li, W.; Song, G.; Chu, X.; Tang, G. Fabrication and characterization of microencapsulated n-octadecane with different crosslinked methylmethacrylate-based polymer shells. Sol. Energy Mater. Sol. Cells 2012, 98, 283–293. [Google Scholar] [CrossRef]

- Ashraf, M.A.; Khan, A.M.; Sarfraz, M.; Ahmad, M. Effectiveness of silica based sol-gel microencapsulation method for odorants and flavors leading to sustainable environment. Front. Chem. 2015, 3, 42. [Google Scholar] [CrossRef] [PubMed]

- Barker, M.T. Review of Synthetic Methods to Form Hollow Polymer Nanocapsules; Los Alamos National Lab. (LANL): Los Alamos, NM, USA, 2014. [Google Scholar]

- Ni, Y.-Z.; Jiang, W.-F.; Tong, G.-S.; Chen, J.-X.; Wang, J.; Li, H.-M.; Yu, C.-Y.; Huang, X.-h.; Zhou, Y.-F. Preparation of polydopamine nanocapsules in a miscible tetrahydrofuran–buffer mixture. Org. Biomol. Chem. 2015, 13, 686–690. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Liu, P.; Ju, L.; Wang, L.; Zhao, S. Polypyrrole nanocapsules via interfacial polymerization. Macromol. Res. 2010, 18, 648–652. [Google Scholar] [CrossRef]

- Alyami, H.S.; Ali, D.K.; Jarrar, Q.; Jaradat, A.; Aburass, H.; Mohammed, A.A.; Alyami, M.H.; Aodah, A.H.; Dahmash, E.Z. Taste Masking of Promethazine Hydrochloride Using l-Arginine Polyamide-Based Nanocapsules. Molecules 2023, 28, 748. [Google Scholar] [CrossRef]

- Dellali, K.Z.; Dellali, M.; Raţă, D.M.; Cadinoiu, A.N.; Atanase, L.I.; Popa, M.; Spataru, M.-C.; Solcan, C. Assessment of Physicochemical and In Vivo Biological Properties of Polymeric Nanocapsules Based on Chitosan and Poly(N-vinyl pyrrolidone-alt-itaconic anhydride). Polymers 2022, 14, 1811. [Google Scholar] [CrossRef]

- Lin, G.; Chen, H.; Zhou, H.; Zhou, X.; Xu, H. Preparation of tea tree oil/Poly (styrene-butyl methacrylate) microspheres with sustained release and anti-bacterial properties. Materials 2018, 11, 710. [Google Scholar] [CrossRef]

- Latibari, S.T.; Mehrali, M.; Mehrali, M.; Afifi, A.; Mahlia, T.; Akhiani, A.R.; Metselaar, H. Facile synthesis and thermal performances of stearic acid/titania core/shell nanocapsules by sol–gel method. Energy 2015, 85, 635–644. [Google Scholar] [CrossRef]

- Meng, H.; Xu, K.; Xu, Y.; Luo, P.; Du, F.; Huang, J.; Lu, W.; Yu, J.; Liu, S.; Muir, B. Nanocapsules based on mPEGylated artesunate prodrug and its cytotoxicity. Colloids Surf. B: Biointerfaces 2014, 115, 164–169. [Google Scholar] [CrossRef]

- Badri, W.; Miladi, K.; Nazari, Q.A.; Fessi, H.; Elaissari, A. Effect of process and formulation parameters on polycaprolactone nanoparticles prepared by solvent displacement. Colloids Surf. A Physicochem. Eng. Asp. 2017, 516, 238–244. [Google Scholar] [CrossRef]

- Guo, H.; Guo, Q.; Chu, T.; Zhang, X.; Wu, Z.; Yu, D. Glucose-sensitive polyelectrolyte nanocapsules based on layer-by-layer technique for protein drug delivery. J. Mater. Sci. Mater. Med. 2014, 25, 121–129. [Google Scholar] [CrossRef] [PubMed]

- Kittitheeranun, P.; Sajomsang, W.; Phanpee, S.; Treetong, A.; Wutikhun, T.; Suktham, K.; Puttipipatkhachorn, S.; Ruktanonchai, U.R. Layer-by-layer engineered nanocapsules of curcumin with improved cell activity. Int. J. Pharm. 2015, 492, 92–102. [Google Scholar] [CrossRef] [PubMed]

- Elizarova, I.S.; Luckham, P.F. Layer-by-layer encapsulated nano-emulsion of ionic liquid loaded with functional material for extraction of Cd2+ ions from aqueous solutions. J Colloid Interface Sci. 2017, 491, 286–293. [Google Scholar] [CrossRef] [PubMed]

- Abbas, S.; Karangwa, E.; Bashari, M.; Hayat, K.; Hong, X.; Sharif, H.R.; Zhang, X. Fabrication of polymeric nanocapsules from curcumin-loaded nanoemulsion templates by self-assembly. Ultrason. Sonochem. 2015, 23, 81–92. [Google Scholar] [CrossRef]

- Biedermann, F.; Nau, W.M.; Schneider, H.J. The Hydrophobic Effect Revisited—Studies with Supramolecular Complexes Imply High-Energy Water as a Noncovalent Driving Force. Angew. Chem. Int. Ed. 2014, 53, 11158–11171. [Google Scholar] [CrossRef] [PubMed]

- Pandey, A.P.; Singh, S.S.; Patil, G.B.; Patil, P.O.; Bhavsar, C.J.; Deshmukh, P.K. Sonication-assisted drug encapsulation in layer-by-layer self-assembled gelatin-poly (styrenesulfonate) polyelectrolyte nanocapsules: Process optimization. Artif. Cells Nanomed. Biotechnol. 2015, 43, 413–424. [Google Scholar] [CrossRef]

- Fan, J.; Liu, Y.; Wang, S.; Liu, Y.; Li, S.; Long, R.; Zhang, R.; Kankala, R.K. Synthesis and characterization of innovative poly(lactide-co-glycolide)-(poly-L-ornithine/fucoidan) core–shell nanocarriers by layer-by-layer self-assembly. RSC Adv. 2017, 7, 32786. [Google Scholar] [CrossRef]

- Hwangbo, S.; Jeong, H.; Heo, J.; Lin, X.; Kim, Y.; Chang, M.; Hong, J. Antibacterial nanofilm coatings based on organosilicate and nanoparticles. React. Funct. Polym. 2016, 102, 27–32. [Google Scholar] [CrossRef]

- Zhang, C.; Patil, R.S.; Li, T.; Barnes, C.L.; Atwood, J.L. Self-assembly of magnesium-seamed hexameric pyrogallol{4}arene nanocapsules. Chem. Commun. 2017, 53, 4312–4314. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, S.; Ying, G.; Cao, W.; Jian, X. Fabrication of Stable Hollow Capsules by Covalent Layer-by-Layer Self-Assembly. Macromolecules 2003, 36, 4238–4240. [Google Scholar] [CrossRef]

- Goehry, C.; Besora, M.; Maseras, F. Computational description of a huisgen cycloaddition inside a self-assembled nanocapsule. Eur. J. Org. Chem. 2018, 2018, 2103–2109. [Google Scholar] [CrossRef]

- Li, Q.-L.; Sun, Y.; Sun, Y.-L.; Wen, J.; Zhou, Y.; Bing, Q.-M.; Isaacs, L.D.; Jin, Y.; Gao, H.; Yang, Y.-W. Mesoporous silica nanoparticles coated by layer-by-layer self-assembly using cucurbit{7}uril for in vitro and in vivo anticancer drug release. Chem. Mater. 2014, 26, 6418–6431. [Google Scholar] [CrossRef]

- Santos, A.C.; Sequeira, J.; Pereira, I.; Cabral, C.; Veiga, F. Sonication-assisted Layer-by-Layer self-assembly nanoparticles for resveratrol delivery. Mater. Sci. Eng. C 2019, 105, 110022. [Google Scholar] [CrossRef] [PubMed]

- Xu, C.; Zeng, X.; Yang, Z.; Ji, H. Enhanced Sunscreen Effects via Layer-By-Layer Self-Assembly of Chitosan/Sodium Alginate/Calcium Chloride/EHA. Molecules 2022, 27, 1148. [Google Scholar] [CrossRef]

- Di Cicco, C.; Vecchione, R.; Quagliariello, V.; Busato, A.; Tufano, I.; Bedini, E.; Gerosa, M.; Sbarbati, A.; Boschi, F.; Marzola, P.; et al. Biocompatible, photo-responsive layer-by-layer polymer nanocapsules with an oil core: In vitro and in vivo study. J. R. Soc. Interface 2022, 19, 20210800. [Google Scholar] [CrossRef]

- He, J.; Meng, X.; Meng, C.; Zhao, J.; Chen, Y.; Zhang, Z.; Zhang, Y. Layer-by-Layer Pirfenidone/Cerium Oxide Nanocapsule Dressing Promotes Wound Repair and Prevents Scar Formation. Molecules 2022, 27, 1830. [Google Scholar] [CrossRef] [PubMed]

- Qin, X.; Engwer, C.; Desai, S.; Vila-Sanjurjo, C.; Goycoolea, F.M. An investigation of the interactions between an E. coli bacterial quorum sensing biosensor and chitosan-based nanocapsules. Colloids Surf. B: Biointerfaces 2017, 149, 358–368. [Google Scholar] [CrossRef]

- Milosavljevic, V.; Jamroz, E.; Gagic, M.; Haddad, Y.; Michalkova, H.; Balkova, R.; Tesarova, B.; Moulick, A.; Heger, Z.; Richtera, L. Encapsulation of Doxorubicin in Furcellaran/Chitosan Nanocapsules by Layer-by-Layer Technique for Selectively Controlled Drug Delivery. Biomacromolecules 2019, 21, 418–434. [Google Scholar] [CrossRef]

- Jafari, A.; Sun, H.; Sun, B.; Mohamed, M.A.; Cui, H.; Cheng, C. Layer-by-layer preparation of polyelectrolyte multilayer nanocapsules via crystallized miniemulsions. Chem. Commun. 2019, 55, 1267–1270. [Google Scholar] [CrossRef]

- Fan, Q.; Ma, J.; Xu, Q.; Wang, J.; Ma, Y. Facile Synthesis of Chitosan-Coated Silica Nanocapsules via Interfacial Condensation Approach for Sustained Release of Vanillin. Ind. Eng. Chem. Res. 2018, 57, 6171–6179. [Google Scholar] [CrossRef]

- Ibragimova, A.R.; Mirgorodskaya, A.B.; Vasilieva, E.A.; Khairutdinova, E.I.; Meleshko, T.K.; Ivanov, I.V.; Yakimansky, A.V.; Nizameev, I.R.; Kadirov, M.K.; Zakharova, L.Y. Polyelectrolyte nanocapsules with controlled properties fabricated by layer-by-layer deposition of polyethyleneimine and graft-copolyimide with polymethacrylic acid side chains. Colloids Surf. A Physicochem. Eng. Asp. 2017, 526, 20–28. [Google Scholar] [CrossRef]

- Reisch, A.; Runser, A.; Arntz, Y.; Mely, Y.; Klymchenko, A.S. Charge-controlled nanoprecipitation as a modular approach to ultrasmall polymer nanocarriers: Making bright and stable nanoparticles. ACS Nano 2015, 9, 5104–5116. [Google Scholar] [CrossRef]

- Martínez Rivas, C.J.; Tarhini, M.; Badri, W.; Miladi, K.; Greige-Gerges, H.; Nazari, Q.A.; Galindo Rodríguez, S.A.; Román, R.Á.; Fessi, H.; Elaissari, A. Nanoprecipitation process: From encapsulation to drug delivery. Int. J. Pharm. 2017, 532, 66–81. [Google Scholar] [CrossRef]

- Tang, C.; Amin, D.; Messersmith, P.B.; Anthony, J.E.; Prud’homme, R.K. Polymer directed self-assembly of pH-responsive antioxidant nanoparticles. Langmuir 2015, 31, 3612–3620. [Google Scholar] [CrossRef]

- Miladi, K.; Sfar, S.; Fessi, H.; Elaissari, A. Nanoprecipitation process: From particle preparation to in vivo applications. In Polymer Nanoparticles for Nanomedicines; Springer: Berlin/Heidelberg, Germany, 2016; pp. 17–53. [Google Scholar]

- Pustulka, K.M.; Wohl, A.R.; Lee, H.S.; Michel, A.R.; Han, J.; Hoye, T.R.; McCormick, A.V.; Panyam, J.; Macosko, C.W. Flash nanoprecipitation: Particle structure and stability. Mol. Pharm. 2013, 10, 4367–4377. [Google Scholar] [CrossRef]

- Perevyazko, I.Y.; Delaney, J.T.; Vollrath, A.; Pavlov, G.M.; Schubert, S.; Schubert, U.S. Examination and optimization of the self-assembly of biocompatible, polymeric nanoparticles by high-throughput nanoprecipitation. Soft Matter 2011, 7, 5030–5035. [Google Scholar] [CrossRef]

- Wang, M.; Yang, N.; Guo, Z.; Gu, K.; Shao, A.; Zhu, W.; Xu, Y.; Wang, J.; Prud’homme, R.K.; Guo, X. Facile preparation of AIE-active fluorescent nanoparticles through flash nanoprecipitation. Ind. Eng. Chem. Res. 2015, 54, 4683–4688. [Google Scholar] [CrossRef]

- Liu, Y.; Wei, Y.; Zong, C. Synthesis of nonionic polyurethanes with hydroxyl-terminated polybutadiene hydrophobic segments and their application in octadecane nanocapsules. Colloid Polym. Sci. 2014, 292, 873–884. [Google Scholar] [CrossRef]

- Silva, M.F.; Ciciliatti, M.A.; Hechenleitner, A.A.W.; Peñalva, R.; Agüeros, M.; Irache, J.M.; de Oliveira, A.J.; Farooqi, A.A.; Pineda, E.A. Superparamagnetic maghemite loaded poly (ε-caprolactone) nanocapsules: Characterization and synthesis optimization. Matéria Rio Jan. 2014, 19, 40–52. [Google Scholar] [CrossRef]

- Penteado, L.; Lopes, V.F.; Karam, T.K.; Nakamura, C.V.; Khalil, N.M.; Mainardes, R.M. Chitosan-coated poly(є-caprolactone) nanocapsules for mucoadhesive applications of perillyl alcohol. Soft Mater. 2021, 20, 1–11. [Google Scholar] [CrossRef]

- Mahmoud, K.Y.; Elhesaisy, N.A.; Rashed, A.R.; Mikhael, E.S.; Fadl, M.I.; Elsadek, M.S.; Mohamed, M.A.; Mostafa, M.A.; Hassan, M.A.; Halema, O.M.; et al. Exploring the potential of intranasally administered naturally occurring quercetin loaded into polymeric nanocapsules as a novel platform for the treatment of anxiety. Sci. Rep. 2023, 13, 510. [Google Scholar] [CrossRef]

- de Andrade, L.R.M.; Guilger-Casagrande, M.; Germano-Costa, T.; de Lima, R. Polymeric Nanorepellent Systems Containing Geraniol and Icaridin Aimed at Repelling Aedes aegypti. Int. J. Mol. Sci. 2022, 23, 8317. [Google Scholar] [CrossRef]

- Granata, G.; Riccobene, C.; Napoli, E.; Geraci, C. Polymeric Nanocapsules Containing Fennel Essential Oil: Their Preparation, Physicochemical Characterization, Stability over Time and in Simulated Gastrointestinal Conditions. Pharmaceutics 2022, 14, 873. [Google Scholar] [CrossRef]

- Liu, Y.; Budhlall, B.M. Self-healing nanocomposites comprised of poly (urea formaldehyde) nanocapsules in a thermosetting polyurea. Eur. Polym. J. 2020, 126, 109545. [Google Scholar] [CrossRef]

- Yadav, S.C.; Kumari, A.; Yadav, R. Development of peptide and protein nanotherapeutics by nanoencapsulation and nanobioconjugation. Peptides 2011, 32, 173–187. [Google Scholar] [CrossRef]

- Abbaspoor, S.; Ashrafi, A.; Salehi, M. Synthesis and characterization of ethyl cellulose micro/nanocapsules using solvent evaporation method. Colloid Polym. Sci. 2018, 296, 1509–1514. [Google Scholar] [CrossRef]

- Wibowo, D.; Hui, Y.; Middelberg, A.P.; Zhao, C.-X. Interfacial engineering for silica nanocapsules. Adv. Colloid Interface Sci. 2016, 236, 83–100. [Google Scholar] [CrossRef]

- Prieto, C.; Calvo, L.; Duarte, C.M. Continuous supercritical fluid extraction of emulsions to produce nanocapsules of vitamin E in polycaprolactone. J. Supercrit. Fluids 2017, 124, 72–79. [Google Scholar] [CrossRef]

- Nagavarma, B.; Yadav, H.K.; Ayaz, A.; Vasudha, L.; Shivakumar, H. Different techniques for preparation of polymeric nanoparticles-a review. Asian J. Pharm. Clin. Res. 2012, 5, 16–23. [Google Scholar]

- Zabihi, F.; Xin, N.; Li, S.; Jia, J.; Cheng, T.; Zhao, Y. Polymeric coating of fluidizing nano-curcumin via anti-solvent supercritical method for sustained release. J. Supercrit. Fluids 2014, 89, 99–105. [Google Scholar] [CrossRef]

- Prieto, C.; Calvo, L. Supercritical fluid extraction of emulsions to nanoencapsulate vitamin E in polycaprolactone. J. Supercrit. Fluids 2017, 119, 274–282. [Google Scholar] [CrossRef]

- Anandharamakrishnan, C. Liquid-Based Nanoencapsulation Techniques. In Techniques for Nanoencapsulation of Food Ingredients; Springer: Berlin/Heidelberg, Germany, 2014; pp. 29–41. [Google Scholar]

- Ladawan, S.; Mark, C.T.; Amporn, S. Effect of rapid expansion of subcritical solutions processing conditions on loading capacity of tetrahydrocurcumin encapsulated in poly(l-lactide) particles. J. Supercrit. Fluids 2016, 113, 119–127. [Google Scholar]

- Xiao, Z.B.; Li, W.; Zhu, G.Y.; Zhou, R.J.; Niu, Y.W. The nanocapsulation research progress in food industry. Proc. Appl. Mech. Mater. 2013, 395, 144–148. [Google Scholar] [CrossRef]

- Prieto, C.; Duarte, C.M.; Calvo, L. Performance comparison of different supercritical fluid extraction equipments for the production of vitamin E in polycaprolactone nanocapsules by supercritical fluid extraction of emulsionsc. J. Supercrit. Fluids 2017, 122, 70–78. [Google Scholar] [CrossRef]

- Li, H.; Shen, Q.; Zhou, W.; Mo, H.; Pan, D.; Hu, L. Nanocapsular dispersion of cinnamaldehyde for enhanced inhibitory activity against aflatoxin production by Aspergillus flavus. Molecules 2015, 20, 6022–6032. [Google Scholar] [CrossRef]

- Shakeri-Zadeh, A.; Khoei, S.; Khoee, S.; Sharifi, A.M.; Shiran, M.-B. Combination of ultrasound and newly synthesized magnetic nanocapsules affects the temperature profile of CT26 tumors in BALB/c mice. J. Med. Ultrason. 2015, 42, 9–16. [Google Scholar] [CrossRef]

- Campardelli, R.; Reverchon, E. Instantaneous coprecipitation of polymer/drug microparticles using the supercritical assisted injection in a liquid antisolvent. J. Supercrit. Fluids 2017, 120, 151–160. [Google Scholar] [CrossRef]

- Dong, C.; Li, Z.; Liu, F.; Wei, W.; Wang, X.; Liu, Z. Effects of supercritical fluid parameters and emulsion formulation on the production of quercetin nanocapsules by supercritical fluid extraction of emulsion. Chem. Eng. Sci. 2019, 205, 190–200. [Google Scholar] [CrossRef]

- Prieto, C.; Calvo, L. The encapsulation of low viscosity omega-3 rich fish oil in polycaprolactone by supercritical fluid extraction of emulsions. J. Supercrit. Fluids 2017, 128, 227–234. [Google Scholar] [CrossRef]

- Lévai, G.; Martín, Á.; Rojo, S.R.; Cocero, M.J.; Fieback, T.M. Measurement and modelling of mass transport properties during the supercritical fluid extraction of emulsions. J. Supercrit. Fluids 2017, 129, 36–47. [Google Scholar] [CrossRef]

- Jin, H.; Xia, F.; Jiang, C.; Zhao, Y.; He, L. Nanoencapsulation of Lutein with Hydroxypropylmethyl Cellulose Phthalate by Supercritical Antisolvent. Chin. J. Chem. Eng. 2009, 17, 672–677. [Google Scholar] [CrossRef]

- Dong, S.; Spicer, P.T.; Lucien, F.P.; Zetterlund, P.B. Synthesis of crosslinked polymeric nanocapsules using catanionic vesicle templates stabilized by compressed CO2. Soft Matter 2015, 11, 8613–8620. [Google Scholar] [CrossRef]

- Arpagaus, C.; Collenberg, A.; Rütti, D.; Assadpour, E.; Jafari, S.M. Nano spray drying for encapsulation of pharmaceuticals. Int. J. Pharm. 2018, 546, 194–214. [Google Scholar] [CrossRef]

- Arpagaus, C. Chapter Four—Production of food bioactive-loaded nanoparticles by nano spray drying. In Nanoencapsulation of Food Ingredients by Specialized Equipment; Jafari, S.M., Ed.; Academic Press: Cambridge, MA, USA, 2019; Volume 3, pp. 151–211. [Google Scholar]

- Assadpour, E.; Jafari, S.M. Advances in spray-drying encapsulation of food bioactive ingredients: From microcapsules to nanocapsules. Annu. Rev. Food Sci. Technol. 2019, 10, 103–131. [Google Scholar] [CrossRef]

- Nguyen, T.V.; Nguyen, T.T.H.; Wang, S.-L.; Vo, T.P.K.; Nguyen, A.D. Preparation of chitosan nanoparticles by TPP ionic gelation combined with spray drying, and the antibacterial activity of chitosan nanoparticles and a chitosan nanoparticle–amoxicillin complex. Res. Chem. Intermed. 2017, 43, 3527–3537. [Google Scholar] [CrossRef]

- Öztürk, A.A.; Yenilmez, E.; Arslan, R.; Şenel, B.; Yazan, Y. Dexketoprofen trometamol-loaded Kollidon® SR and Eudragit® RS 100 polymeric nanoparticles: Formulation and in vitro-in vivo evaluation. Lat. Am. J. Pharm. 2017, 36, 2153–2165. [Google Scholar]

- Amsalem, O.; Nassar, T.; Benhamron, S.; Lazarovici, P.; Benita, S.; Yavin, E. Solid nano-in-nanoparticles for potential delivery of siRNA. J. Control. Release 2017, 257, 144–155. [Google Scholar] [CrossRef]

- Sithole, M.N.; Choonara, Y.E.; du Toit, L.C.; Kumar, P.; Marimuthu, T.; Kondiah, P.P.; Pillay, V. Development of a novel polymeric nanocomposite complex for drugs with low bioavailability. AAPS PharmSciTech 2018, 19, 303–314. [Google Scholar] [CrossRef]

- Prasad Reddy, M.; Padma Ishwarya, S.; Anandharamakrishnan, C. Nanoencapsulation of roasted coffee bean oil in whey protein wall system through nanospray drying. J. Food Process. Preserv. 2019, 43, e13893. [Google Scholar] [CrossRef]

- Hu, Q.; Gerhard, H.; Upadhyaya, I.; Venkitanarayanan, K.; Luo, Y. Antimicrobial eugenol nanoemulsion prepared by gum arabic and lecithin and evaluation of drying technologies. Int. J. Biol. Macromol. 2016, 87, 130–140. [Google Scholar] [CrossRef] [PubMed]

- Malapert, A.; Reboul, E.; Tourbin, M.; Dangles, O.; Thiéry, A.; Ziarelli, F.; Tomao, V. Characterization of hydroxytyrosol-β-cyclodextrin complexes in solution and in the solid state, a potential bioactive ingredient. LWT 2019, 102, 317–323. [Google Scholar] [CrossRef]

- Yaman, D.M.; Koçak Yanık, D.; Elik Demir, A.; Uzun Karka, H.; Güçlü, G.; Selli, S.; Kelebek, H.; Göğüş, F. Effect of Encapsulation Techniques on Aroma Retention of Pistacia terebinthus L. Fruit Oil: Spray Drying, Spray Freeze Drying, and Freeze Drying. Foods 2023, 12, 3244. [Google Scholar] [CrossRef] [PubMed]

- Plati, F.; Papi, R.; Paraskevopoulou, A. Characterization of Oregano Essential Oil (Origanum vulgare L. subsp. hirtum) Particles Produced by the Novel Nano Spray Drying Technique. Foods 2021, 10, 2923. [Google Scholar] [CrossRef]

| Core | Monomer | Emulsifier | Encapsulation Efficiency (%) | Particle Size (nm) | References |

|---|---|---|---|---|---|

| Caffeine | Whey protein, sugar beet pectin | Sorbitan monooleate (Span-80) | 83 | 200 | Gazme et al. [46] |

| Develop Docetaxel | Polycaprolactone | Tween 80, Span 80 | 65 | 180~210 | Daşkın et al. [47] |

| UV filters | Methyl methacrylate | Styrene-co-methacrylic acid | 69.85 | 50-500 | Chen et al. [48] |

| Ivermectin | Poly(ε-caprolactone) (PCL) | Span 80 and Tween 20 | 98~100 | 400 | Souza et al. [11] |

| Wall Material | Solvent | Core Material | Reaction Temperature (°C) | Particle Size (nm) | TSM or SEM | References |

|---|---|---|---|---|---|---|

| Polymethyl methacrylate | Water | Paraffin | 80 | 200~400 |  | Shi et al. [64] |

| Polypyrrole | Water | 0 | 200~500 |  | Zhang et al. [70] | |

| Arginine polyamide | Water and acetone | Promethazine hydrochloride | 0~5 | 193.63 |  | Alyami et al. [71] |

| Chitosan and poly(N-vinyl pyrrolidone-alt-itaconic anhydride) | Water and acetone | Span 80 and Tween 20 | 65 | 107~250 |  | Dellali et al. [72] |

| Core Material or Template | Monomer 1 | Monomer 2 | Particle Size (nm) | TSM or SEM | Refs. |

|---|---|---|---|---|---|

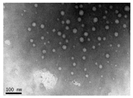

| Curcumin-enriched MCT oil nanoemulsion | Chitosan | Allylamine hydrochloride | 159.85 |  | Shabbar et al. [80] |

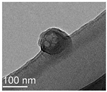

| Silica nanoparticles | Branched polyethyleneimine | Silsesquioxane | Approximately 58.83 |  | Hwangbo et al. [84] |

| Resveratrol nanoparticles | Allylamine hydrochloride | Anionic dextran sulfate | 116~220 |  | Santos. Et al. [89] |

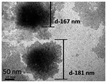

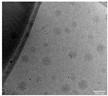

| Poly(lactide-coglycolide) (PLGA) | L-ornithine | Sulfated polysaccharide fucoidan | 170 |  | Fan et al. [83] |

| 2-Ethylhexyl-4-dimethylaminobenzoate | Chitosan | Sodium alginate and calcium | 155~205 |  | Xu et al. [90] |

| Soybean oil | Egg lecithin | Glycol chitosan | 106~130 |  | Vecchione et al. [91] |

| Cerium oxide nanoparticles and pirfenidone | Poly-1-arginine (parg) | Dextrose sulfate (DS) | 111.1 |  | He et al. [92] |

| Wall Material | Core Material | Organic Solvent | Surfactant | Particle Size (nm) | Encapsulation Efficiency (%) | Refs. |

|---|---|---|---|---|---|---|

| PCL | Perillyl alcohol and chitosan | Acetone | Sorbitan monoestearate | 330 | 56 | Penteado et al. [107] |

| Polycaprolactone | Quercetin | Acetone | Tween 80 and Span 80 | 227.8 | 92.5 | Mahmoud et al. [108] |

| Pcl | Icaridin | Acetone | Tween 80 | 314 | 98.7 | Andrade et al. [109] |

| PLC and sorbitan monostearate | Essential oil | Acetone | Tween 80 | 210 | 93 | Granata et al. [110] |

| Wall Material | Core Material | Pressure | Reaction Temperature (°C) | Particle Size (nm) | Encapsulation Efficiency | Method | TSM or SEM | Refs. |

|---|---|---|---|---|---|---|---|---|

| Polycaprolactone | Vitamin E | 8.0 | 40 | 9 | Above 70% | SFEE |  | Prieto et al. [115] |

| Hydroxypropylmethyl cellulose phthalate | Lutein | 11 | 40 | 163 ~ 219 | 88.41% | SAS |  | Jin et al. [129] |

| Multiple polymer monomers | The dye (Nile Blue) | 5 | 25 | 40~100 | RESS |  | Dong et al. [130] | |

| Polycaprolactone | Quercetin | 9 | 40 | 25~35 | 82.4% | SFEE |  | Dong et al. [126] |

| Wall Materials | Core Materials | Solvent | Inlet Temperature (°C) | Drying Gas (L/min) | Particle Size (nm) | Encapsulation Efficiency (%) | Product Yield (%) | SEM | References |

|---|---|---|---|---|---|---|---|---|---|

| Chitosan, tripolyphosphate | Amoxicillin trihydrate | 0.35% (w/v) acetic acid solution | 120 | 120 | 156~376 | —— | 90 |  | Nguyen et al. [134] |

| Hyaluronic acid, poly(acrylic acid) | Acyclovir | Water | 85 | —— | 258 | 85 | 75 |  | Sithole et al. [137] |

| Kollidon® SR, Eudragit® RS | Dexketoprofen trometamol | Methanol | 119~121 | —— | 108~691 | 35~51 | —— |  | Öztürk et al. [135] |

| Poly (D,L-lactide-co-glycolide acid) | Human serum albumin primary nanoparticles loaded with sirna | Acetonitrile | 50 | 118~121 (N2/CO2) | 270~990 | 20~25 | 60 |  | Amsalem et al. [136] |

| Whey protein isolate | Roasted coffee bean oil | Water | 90 | 90~110 | 206~404 | —— | —— |  | Prasad Reddy et al. [138] |

| Gum Arabic, lecithin | Eugenol | Water, Ethanol | 100 | 100~110 | 317~491 | —— | —— |  | Hu et al. [139] |

| β-cyclodextrin | Hydroxytyrosol | Water | 100 | 100 | 400~3400 | 81~88 | 53 |  | Malapert et al. [140] |

| Gum arabic and maltodextrin | Pistacia terebinthus fruit oil | Water | 135 | 500 | 93.33 | 45.27 |  | Yaman et al. [141] | |

| Protein isolate-maltodextrin mixtures | Oregano essential oil | Water | 100 | 130 | 77.9 | 54.9 |  | Plati et al. [142] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Y.; Wang, P.; Wan, F.; Zhu, L.; Wang, Z.; Fan, G.; Wang, P.; Luo, H.; Liao, S.; Yang, Y.; et al. Further Improvement Based on Traditional Nanocapsule Preparation Methods: A Review. Nanomaterials 2023, 13, 3125. https://doi.org/10.3390/nano13243125

Zhou Y, Wang P, Wan F, Zhu L, Wang Z, Fan G, Wang P, Luo H, Liao S, Yang Y, et al. Further Improvement Based on Traditional Nanocapsule Preparation Methods: A Review. Nanomaterials. 2023; 13(24):3125. https://doi.org/10.3390/nano13243125

Chicago/Turabian StyleZhou, Yihong, Peng Wang, Faling Wan, Lifang Zhu, Zongde Wang, Guorong Fan, Peng Wang, Hai Luo, Shengliang Liao, Yuling Yang, and et al. 2023. "Further Improvement Based on Traditional Nanocapsule Preparation Methods: A Review" Nanomaterials 13, no. 24: 3125. https://doi.org/10.3390/nano13243125

APA StyleZhou, Y., Wang, P., Wan, F., Zhu, L., Wang, Z., Fan, G., Wang, P., Luo, H., Liao, S., Yang, Y., Chen, S., & Zhang, J. (2023). Further Improvement Based on Traditional Nanocapsule Preparation Methods: A Review. Nanomaterials, 13(24), 3125. https://doi.org/10.3390/nano13243125