Effect of Synthesized Titanium Dioxide Nanofibers Weight Fraction on the Tribological Characteristics of Magnesium Nanocomposites Used in Biomedical Applications

Abstract

1. Introduction

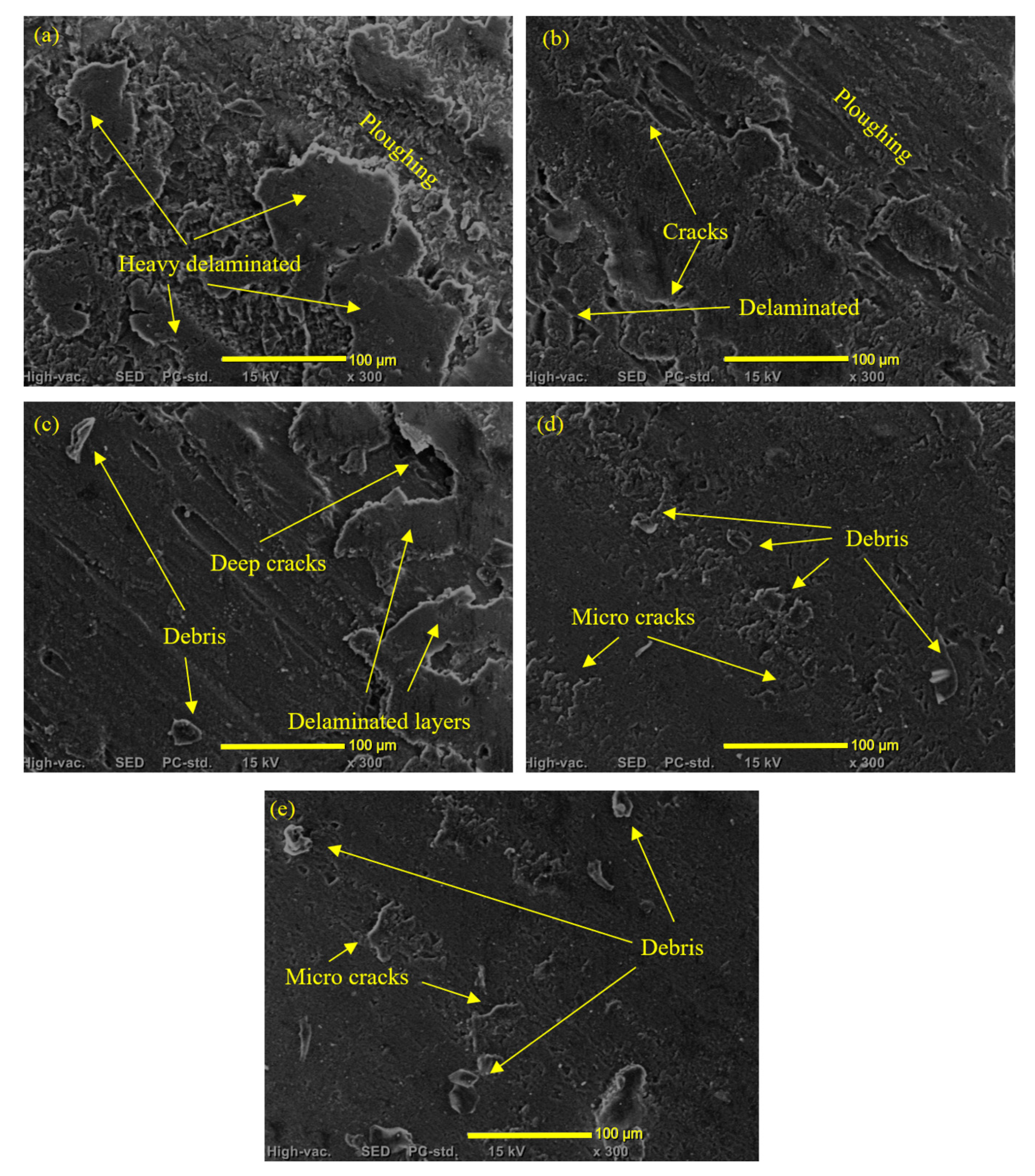

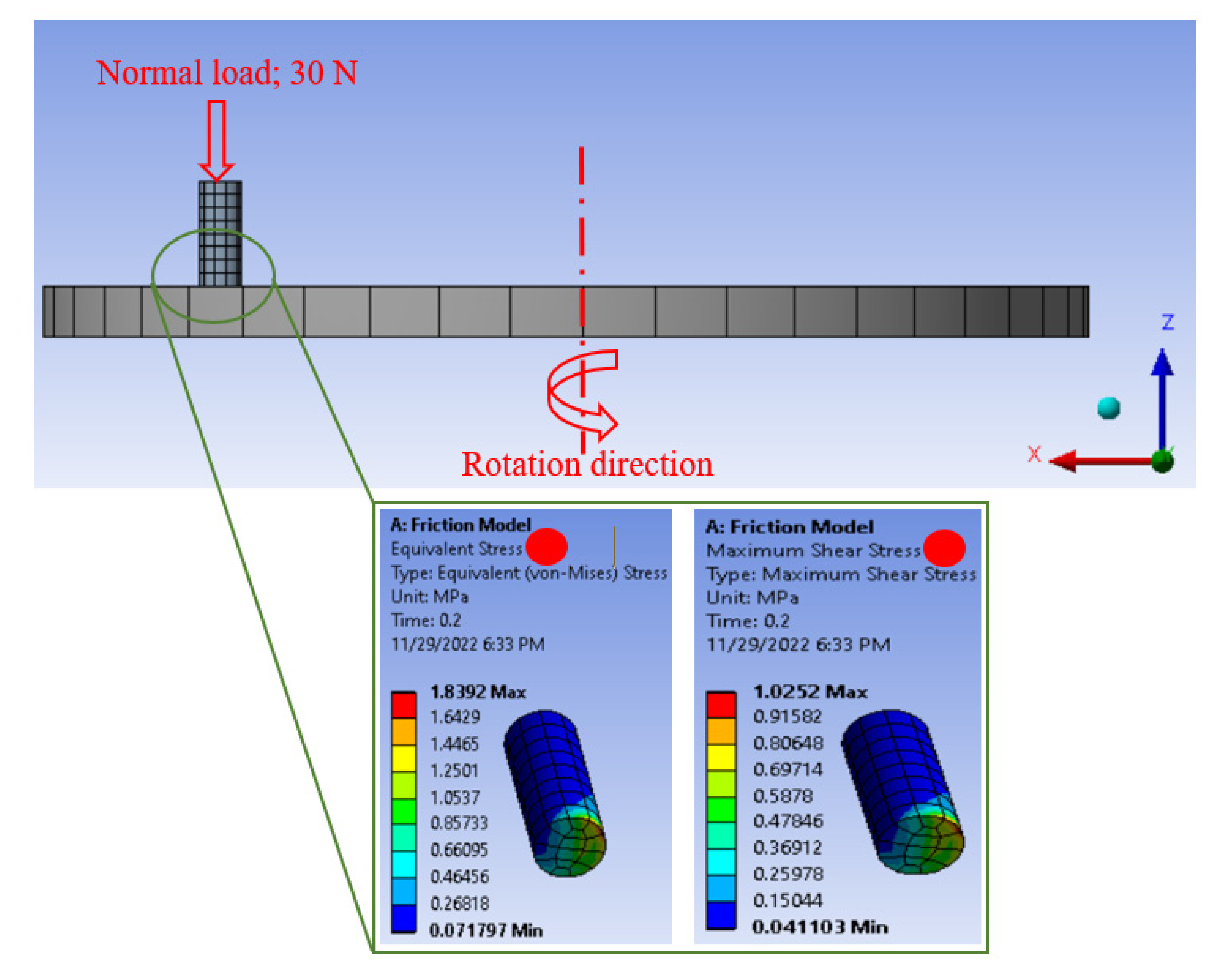

2. Materials and Experimental Work

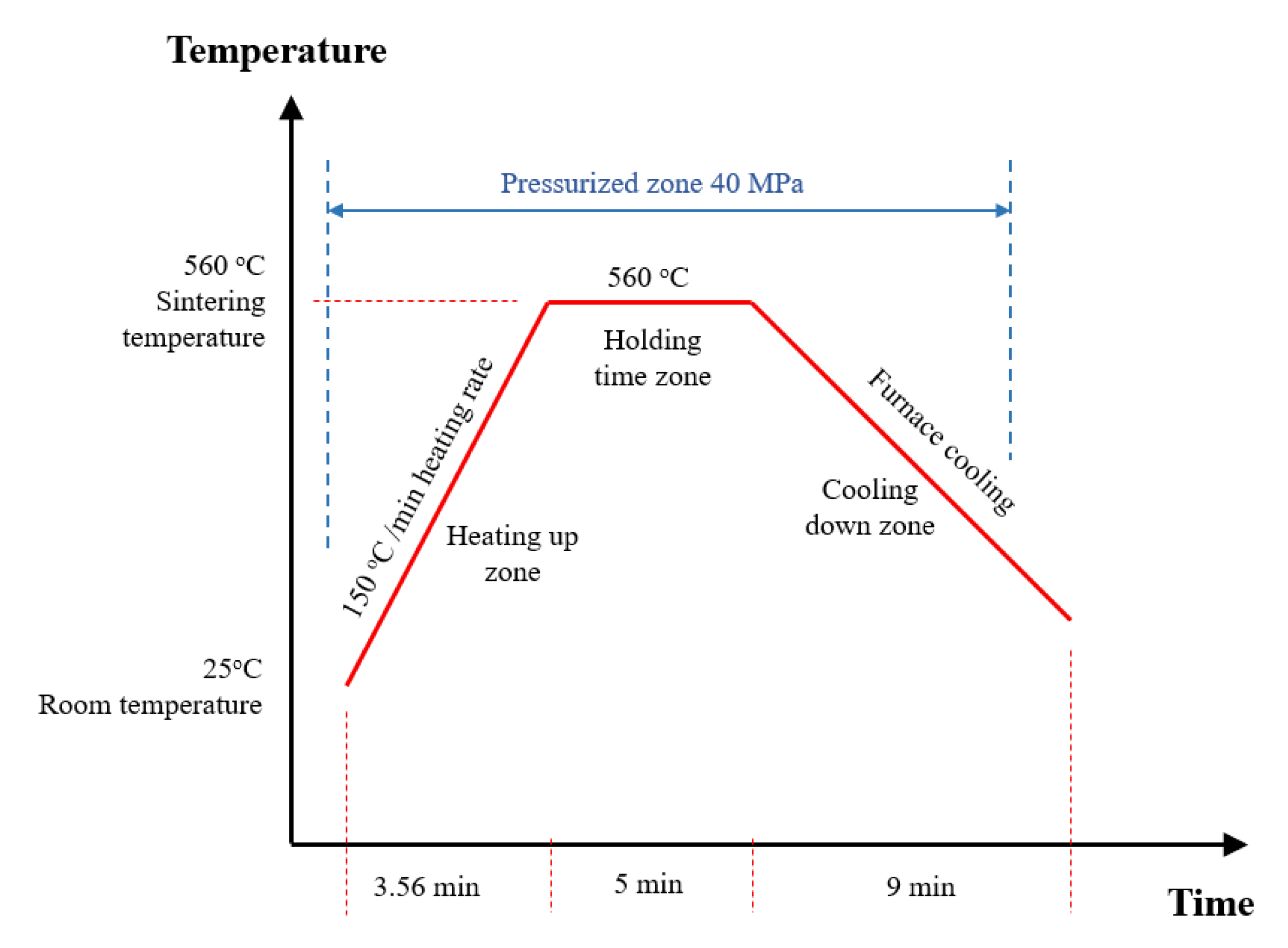

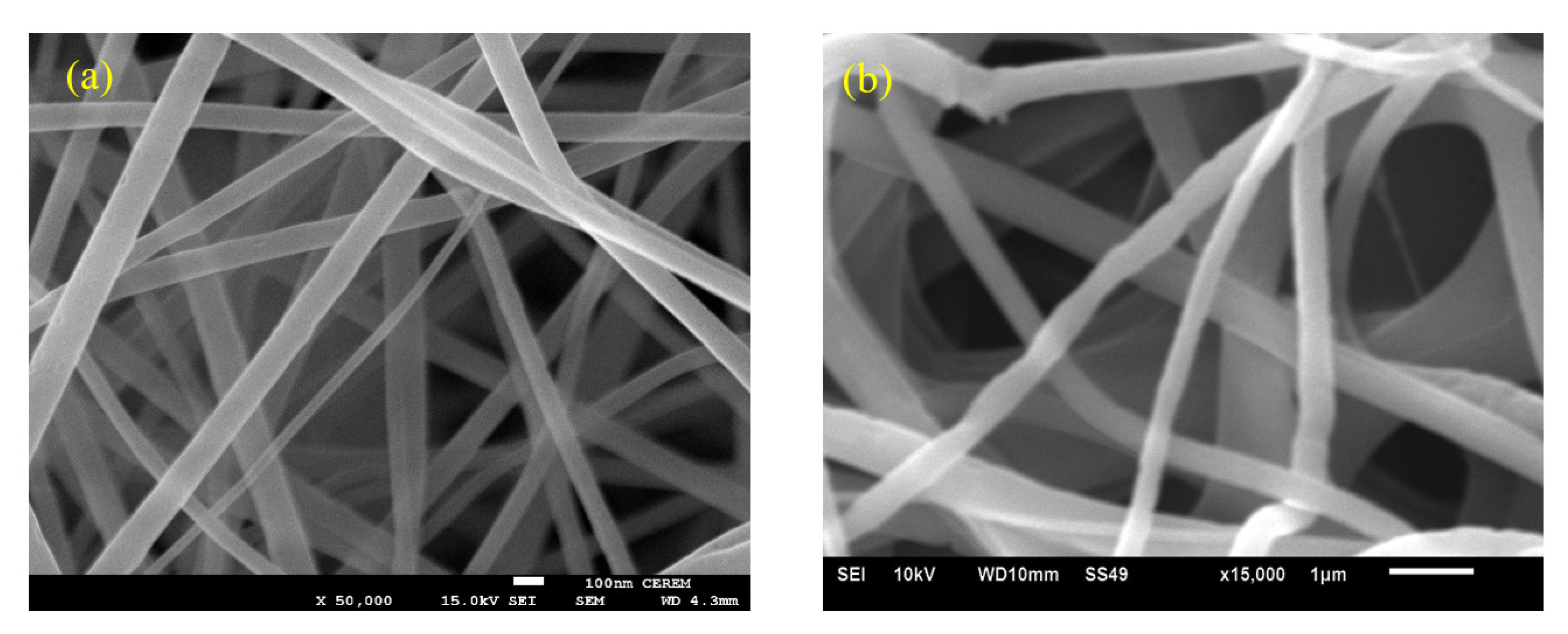

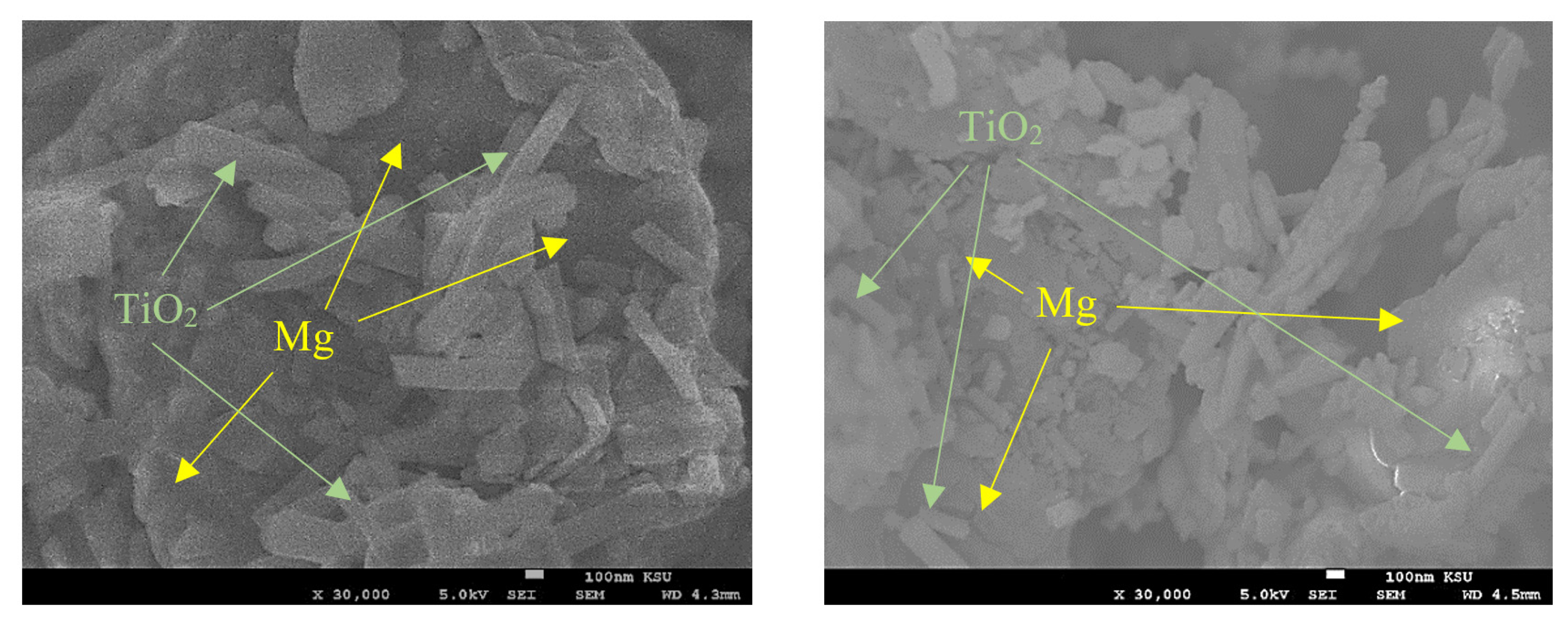

2.1. Materials and Samples Preparation

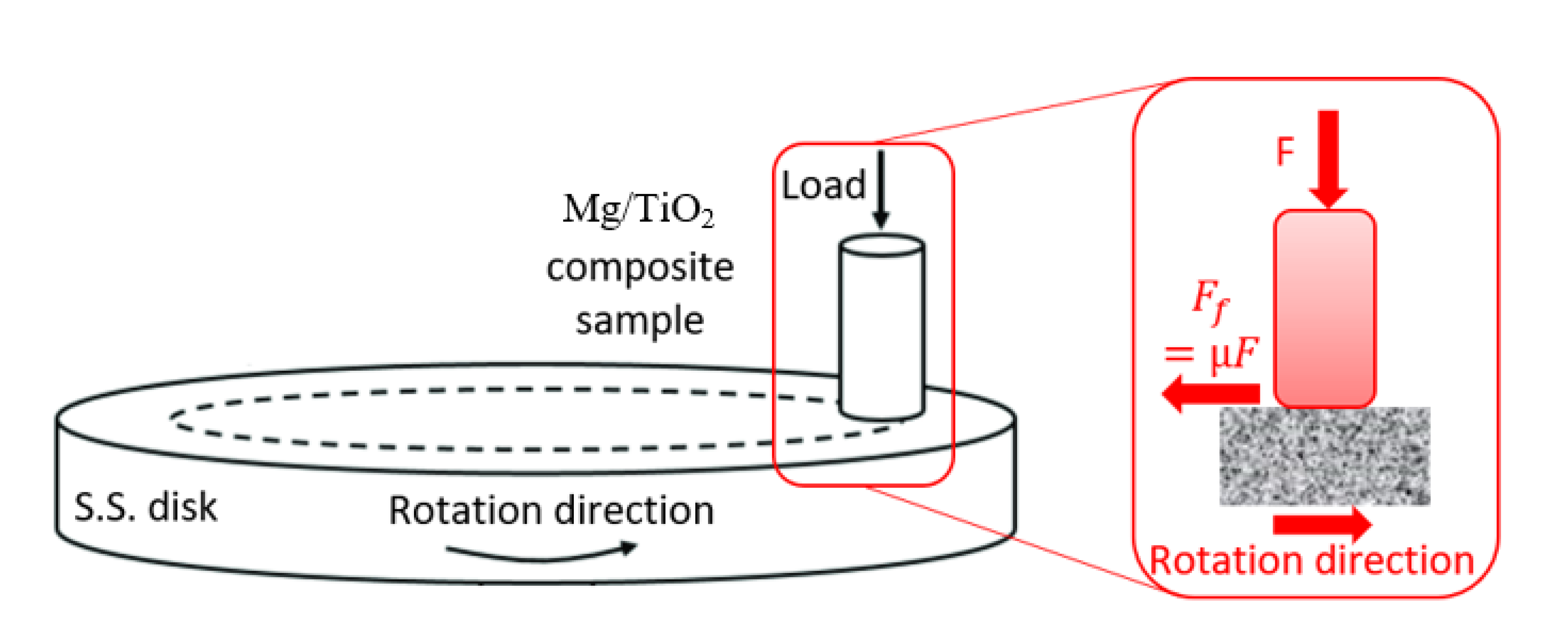

2.2. Characterization and Testing

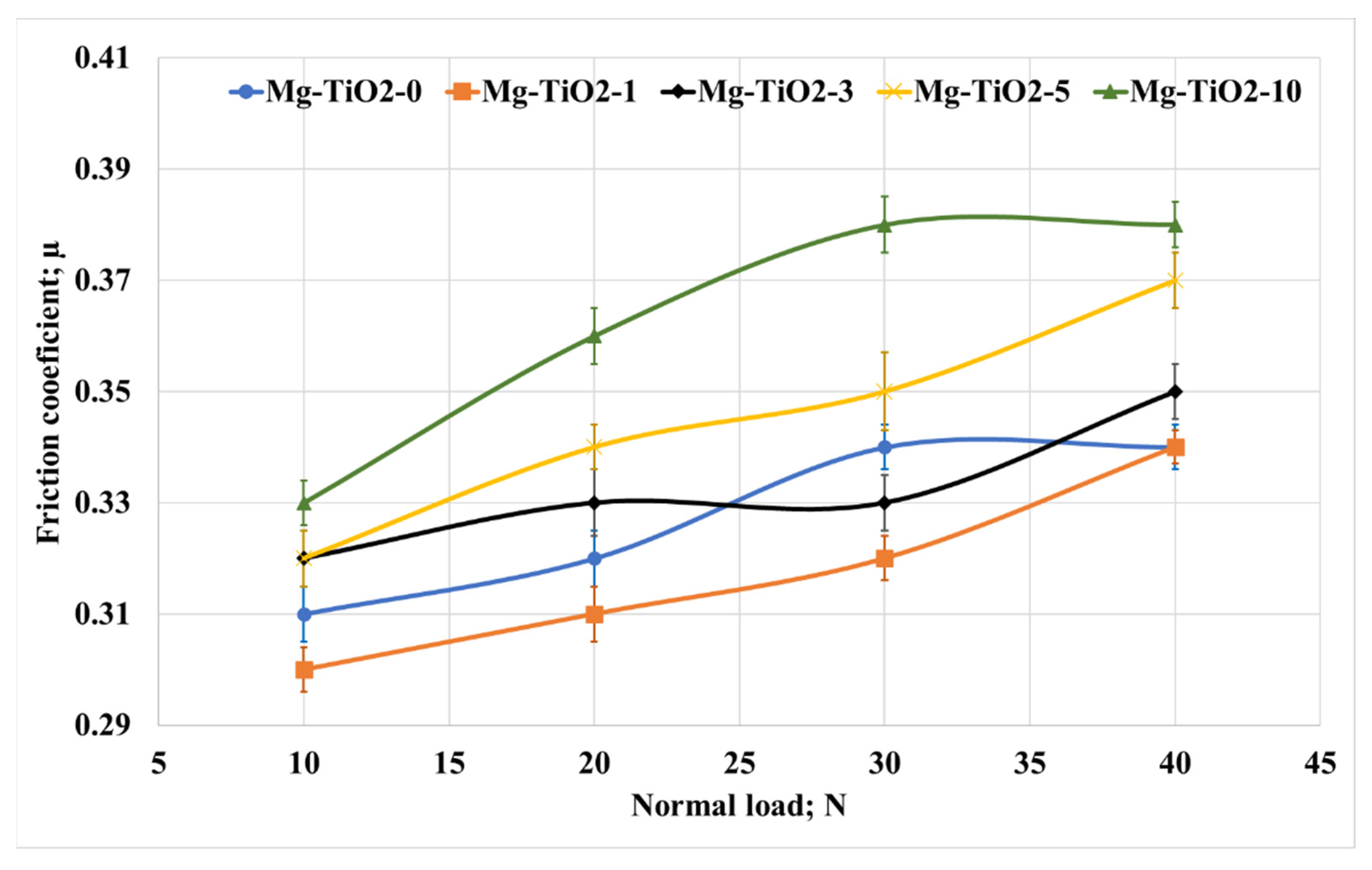

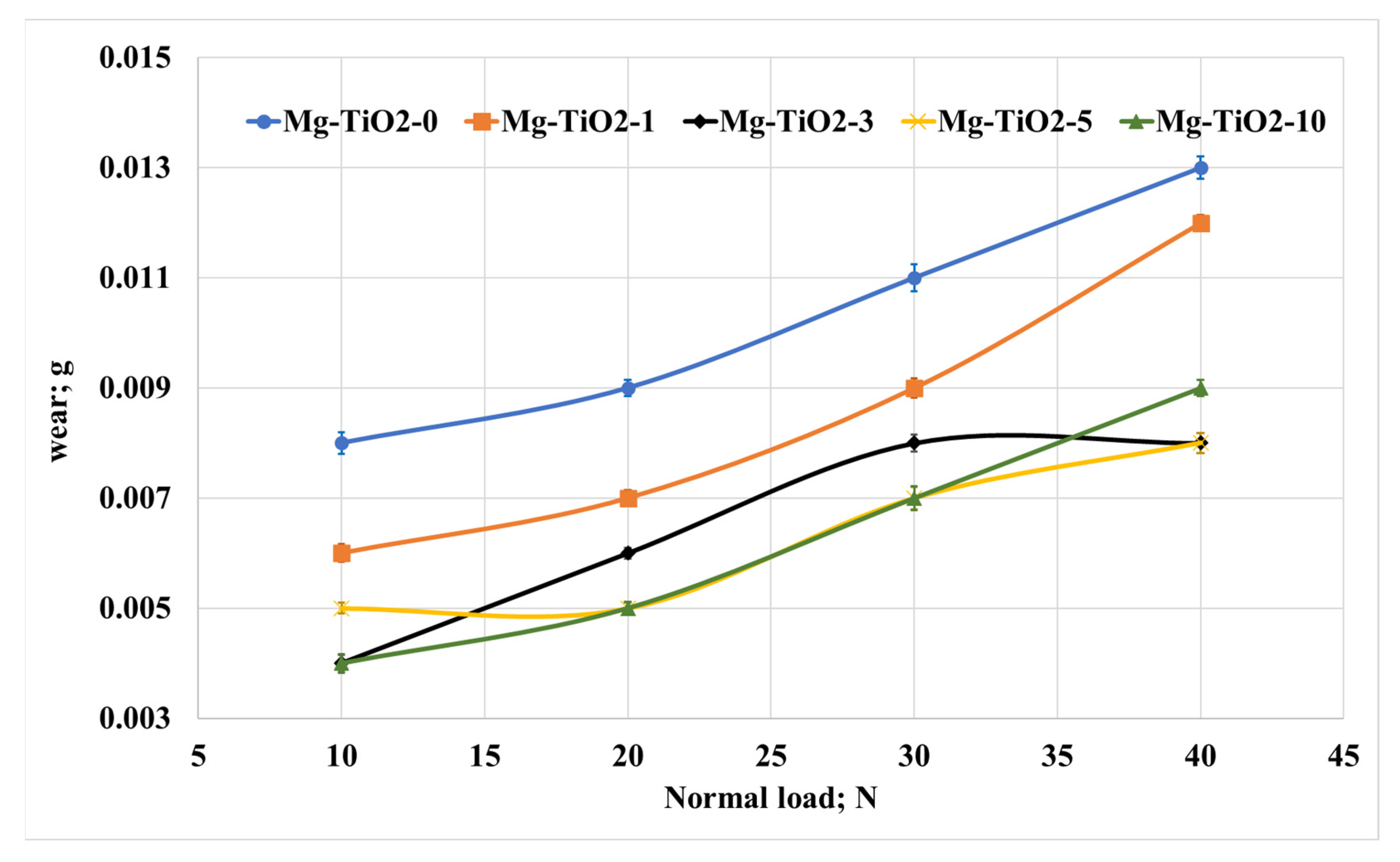

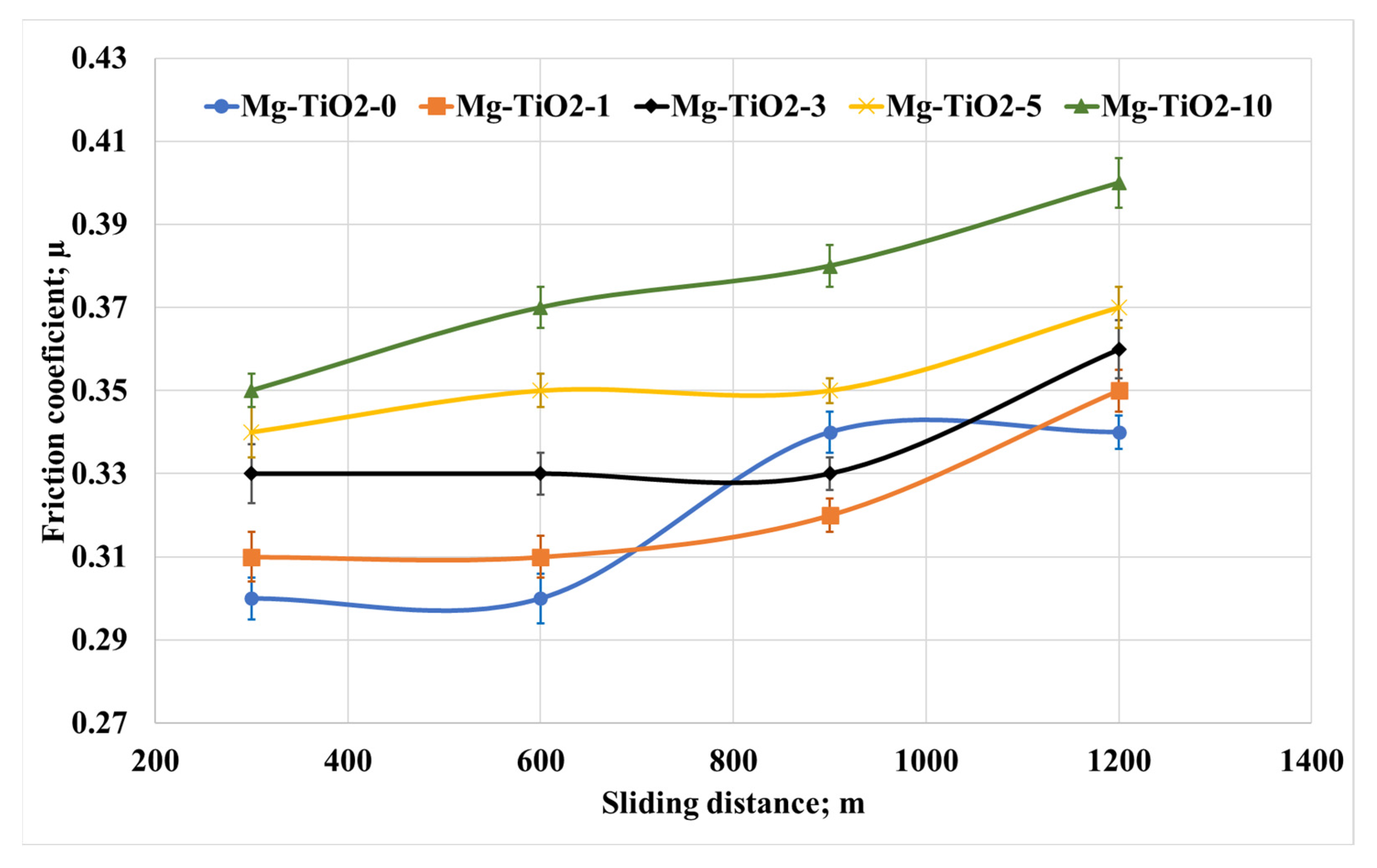

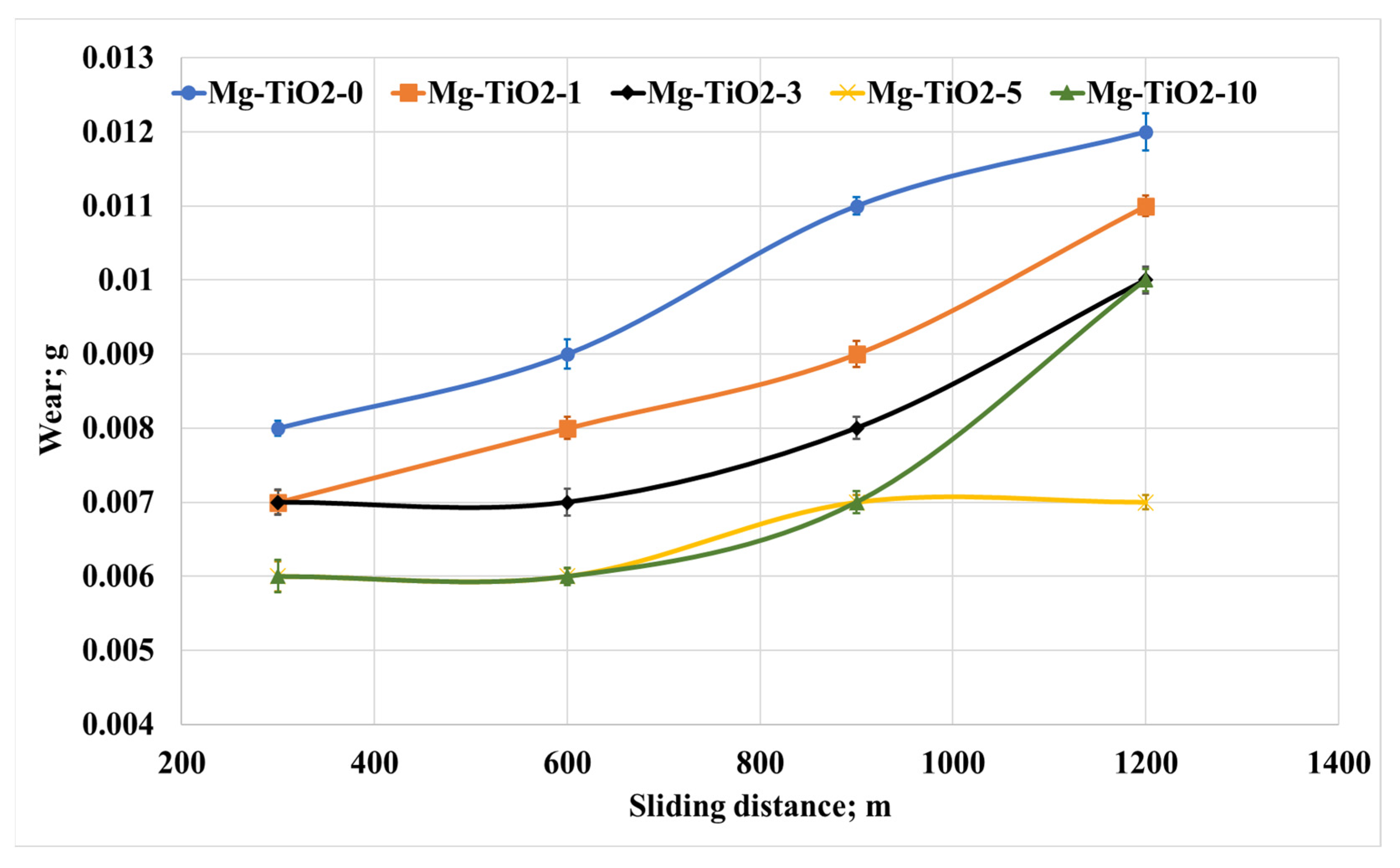

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Goswami, C.; Patnaik, A.; Bhat, I.K.; Singh, T. Mechanical physical and wear properties of some oxide ceramics for hip joint application: A short review. Mater. Today Proc. 2021, 44, 4913–4918. [Google Scholar] [CrossRef]

- Gomez, P.F.; Morcuende, J.A. Early attempts at hip arthroplasty: 1700s to 1950s. Iowa Orthop. J. 2005, 25, 25. [Google Scholar] [PubMed]

- Herberts, P.; Malchau, H. How outcome studies have changed total hip arthroplasty practices in Sweden. Clin. Orthop. 1997, 344, 44–60. [Google Scholar] [CrossRef]

- Fouly, A.; Alnaser, I.A.; Assaifan, A.K.; Abdo, H.S. Evaluating the Performance of 3D-Printed PLA Reinforced with Date Pit Particles for Its Suitability as an Acetabular Liner in Artificial Hip Joints. Polymers 2022, 14, 3321. [Google Scholar] [CrossRef] [PubMed]

- Mavrogenis, A.F.; Dimitriou, R.; Parvizi, J.; Babis, G.C. Biology of implant osseointegration. J. Musculoskelet. Neuronal Interact. 2009, 9, 61–71. [Google Scholar]

- Williams, D.F. Tissue-biomaterial interactions. J. Mater. Sci. 1987, 22, 3421–3445. [Google Scholar] [CrossRef]

- Fouly, A.; Assaifan, A.K.; Alnaser, I.A.; Hussein, O.A.; Abdo, H.S. Evaluating the Mechanical and Tribological Properties of 3D Printed Polylactic-Acid (PLA) Green-Composite for Artificial Implant: Hip Joint Case Study. Polymers 2022, 14, 5299. [Google Scholar] [CrossRef]

- Fouly, A.; Nabhan, A.; Badran, A. Mechanical and Tribological Characteristics of PMMA Reinforced by Natural Materials. Egypt. J. Chem. 2022, 65, 1–2. [Google Scholar] [CrossRef]

- Hench, L.L.; Thompson, I. Twenty-first century challenges for biomaterials. J. R. Soc. Interface 2010, 7, S379–S391. [Google Scholar] [CrossRef]

- Dumbleton, J.H.; Manley, M.T.; Edidin, A.A. A literature review of the association between wear rate and osteolysis in total hip arthroplasty. J. Arthroplast. 2002, 17, 649–661. [Google Scholar] [CrossRef]

- Schmalzried, T.P.; Shepherd, E.F.; Dorey, F.J.; Jackson, W.O.; dela Rosa, M.; McKellop, H.A.; McClung, C.D.; Martell, J.; Moreland, J.R.; Amstutz, H.C. Wear is a function of use, not time. Clin. Orthop. Relat. Res. 2000, 381, 36–46. [Google Scholar] [CrossRef]

- El-Abden, S.Z.; Abdel-Rahman, M.; Mohamed, F.A. Finishing of non-ferrous internal surfaces using ballizing technique. J. Mater. Process. Technol. 2002, 124, 144–152. [Google Scholar] [CrossRef]

- Abdo, H.S.; Seikh, A.H.; Abdus Samad, U.; Fouly, A.; Mohammed, J.A. Electrochemical Corrosion Behavior of Laser Welded 2205 Duplex Stainless-Steel in Artificial Seawater Environment under Different Acidity and Alkalinity Conditions. Crystals 2021, 11, 1025. [Google Scholar] [CrossRef]

- Yun, Y.; Dong, Z.; Yang, D.; Schulz, M.J.; Shanov, V.N.; Yarmolenko, S.; Xu, Z.; Kumta, P.; Sfeir, C. Biodegradable Mg corrosion and osteoblast cell culture studies. Mater. Sci. Eng. C 2009, 29, 1814–1821. [Google Scholar] [CrossRef]

- Brar, H.S.; Platt, M.O.; Sarntinoranont, M.; Martin, P.I.; Manuel, M.V. Magnesium as a biodegradable and bioabsorbable material for medical implants. Jom 2009, 61, 31–34. [Google Scholar] [CrossRef]

- Kuwahara, H.; Al-Abdullat, Y.; Mazaki, N.; Tsutsumi, S.; Aizawa, T. Precipitation of magnesium apatite on pure magnesium surface during immersing in Hank’s solution. Mater. Trans. 2001, 42, 1317–1321. [Google Scholar] [CrossRef]

- Ng, W.F.; Chiu, K.Y.; Cheng, F.T. Effect of pH on the in vitro corrosion rate of magnesium degradable implant material. Mater. Sci. Eng. C 2010, 30, 898–903. [Google Scholar] [CrossRef]

- Tsakiris, V.; Tardei, C.; Clicinschi, F.M. Biodegradable Mg alloys for orthopedic implants—A review. J. Magnes. Alloy. 2021, 9, 1884–1905. [Google Scholar] [CrossRef]

- Umeda, J.; Kawakami, M.; Kondoh, K.; Ayman, E.-S.; Imai, H. Microstructural and mechanical properties of titanium particulate reinforced magnesium composite materials. Mater. Chem. Phys. 2010, 123, 649–657. [Google Scholar] [CrossRef]

- Ramalingam, V.V.; Ramasamy, P.; Kovukkal, M.D.; Myilsamy, G. Research and development in magnesium alloys for industrial and biomedical applications: A review. Met. Mater. Int. 2020, 26, 409–430. [Google Scholar] [CrossRef]

- Badran, A.H.; Alamro, T.; Bazuhair, R.W.; El-Mawla, A.A.G.; El-Adben, S.Z.; Fouly, A. Investigation of the Mechanical Behavior of Synthesized Al6061/TiO2 Microcomposites Using an Innovative Stir Casting Method. Nanomaterials 2022, 12, 1646. [Google Scholar] [CrossRef] [PubMed]

- Abdo, H.S.; Seikh, A.H.; Fouly, A.; Ragab, S.A. Synergistic Strengthening Effect of Reinforcing Spark Plasma Sintered Al-Zn-TiC Nanocomposites with TiC Nanoparticles. Crystals 2021, 11, 842. [Google Scholar] [CrossRef]

- Wang, W.-N.; Lenggoro, I.W.; Terashi, Y.; Kim, T.O.; Okuyama, K. One-step synthesis of titanium oxide nanoparticles by spray pyrolysis of organic precursors. Mater. Sci. Eng. B 2005, 123, 194–202. [Google Scholar] [CrossRef]

- Li, H.; Khor, K.A.; Cheang, P. Impact formation and microstructure characterization of thermal sprayed hydroxyapatite/titania composite coatings. Biomaterials 2003, 24, 949–957. [Google Scholar] [CrossRef] [PubMed]

- Su, B.; Zhang, G.; Yu, X.; Wang, C. Sol-gel derived bioactive hydroxyapatite/titania composite films on Ti6Al4V. J. Univ. Sci. Technol. Beijing Miner. Metall. Mater. 2006, 13, 469–475. [Google Scholar] [CrossRef]

- Abdo, H.S.; Khalil, K.A.; El-Rayes, M.M.; Marzouk, W.W.; Hashem, A.M.; Abdel-Jaber, G.T. Electrospun Nanofibers Reinforced Aluminium Matrix Composites, A Trial to Improve the Mechanical Properties. Mech. Prop. Int. J. Adv. Mater. Sci. Eng. 2018, 7, 1–13. [Google Scholar]

- Najjar, I.R.; Elmahdy, M. Study of mechanical properties and wear resistance of nanostructured Al 1100/TiO2 nanocomposite processed by accumulative roll bonding. J. Compos. Mater. 2022, 56, 00219983221103636. [Google Scholar] [CrossRef]

- Sreenivasulu, G.; Mohan, C.B.; Veeresh Kumar, G.B.; Ananthaprasad, M.G. Evaluation of Mechanical and Tribological Behavior of Aluminum Alloy LM13 Reinforced with Titanium Dioxide Metal Matrix Composites. Iran. J. Mater. Sci. Eng. 2022, 19, 1–15. [Google Scholar]

- Yadav, R.; Meena, A. Comparative investigation of tribological behavior of hybrid dental restorative composite materials. Ceram. Int. 2022, 48, 6698–6706. [Google Scholar] [CrossRef]

- Meng, Z.; Wang, Y.; Liu, H.; Yan, Y.; Yan, F. Reinforced UHMWPE composites by grafting TiO2 on ATP nanofibers for improving thermal and tribological properties. Tribol. Int. 2022, 172, 107585. [Google Scholar] [CrossRef]

- Sumesh, K.R.; Saikrishnan, G.; Pandiyan, P.; Prabhu, L.; Gokulkumar, S.; Priya, A.K.; Spatenka, P.; Krishna, S. The influence of different parameters in tribological characteristics of pineapple/sisal/TiO2 filler incorporation. J. Ind. Text. 2022, 51, 8626S–8644S. [Google Scholar] [CrossRef]

- Laudenslager, M.J.; Sigmund, W.M. Developments in electrohydrodynamic forming: Fabricating nanomaterials from charged liquids via electrospinning and electrospraying. Am. Ceram. Soc. Bull. 2011, 90, 22–27. [Google Scholar]

- Anton, F. Process and Apparatus for Preparing Artificial Threads. U.S. Patent No. 1,975,504, 2 October 1934. Available online: https://patents.google.com/patent/US1975504A/en (accessed on 21 November 2022).

- Ahmad, Z.; Zhang, H.B.; Farook, U.; Edirisinghe, M.; Stride, E.; Colombo, P. Generation of multilayered structures for biomedical applications using a novel tri-needle coaxial device and electrohydrodynamic flow. J. R. Soc. Interface 2008, 5, 1255–1261. [Google Scholar] [CrossRef]

- Jia, L.; Prabhakaran, M.P.; Qin, X.; Ramakrishna, S. Stem cell differentiation on electrospun nanofibrous substrates for vascular tissue engineering. Mater. Sci. Eng. C 2013, 33, 4640–4650. [Google Scholar] [CrossRef]

- Pan, H.; Li, L.; Hu, L.; Cui, X. Continuous aligned polymer fibers produced by a modified electrospinning method. Polymer 2006, 47, 4901–4904. [Google Scholar] [CrossRef]

- Abdo, H.S.; Samad, U.A.; Abdo, M.S.; Alkhammash, H.I.; Aijaz, M.O. Electrochemical Behavior of Inductively Sintered Al/TiO2 Nanocomposites Reinforced by Electrospun Ceramic Nanofibers. Polymers 2021, 13, 4319. [Google Scholar] [CrossRef]

- Meenashisundaram, G.K.; Nai, M.H.; Almajid, A.; Khalil, K.A.; Abdo, H.S.; Gupta, M. Effects of TiO2 powder morphology on the mechanical response of pure magnesium: 1D nanofibers versus 0D nanoparticulates. J. Alloy. Compd. 2016, 664, 45–58. [Google Scholar] [CrossRef]

- Abdo Hany, S.; Monis, L.; Mohammed; Khalil, K.A. Fiber-reinforced metal-matrix composites. In Fiber Reinforced Composites; Kuruvilla, J., Oksman, K., Gejo, G., Wilson, R., Appukuttan, S., Eds.; Woodhead Publishing: Southen, UK, 2021; pp. 649–667. [Google Scholar]

- Radha, R.; Sreekanth, D. Mechanical, in vitro corrosion and bioactivity performance of Mg based composite for orthopedic implant applications: Influence of Sn and HA addition. Biomed. Eng. Adv. 2022, 3, 100033. [Google Scholar] [CrossRef]

- Methods, A.T. Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus1. Wear 2011, 5, 1–5. [Google Scholar]

- Lee, D.Y.; Lee, M.-H.; Cho, N.-I. Preparation and photocatalytic degradation of erbium doped titanium dioxide nanorods. Curr. Appl. Phys. 2012, 12, 1229–1233. [Google Scholar] [CrossRef]

- Tekmen, C.; Suslu, A.; Cocen, U. Titania nanofibers prepared by electrospinning. Mater. Lett. 2008, 62, 4470–4472. [Google Scholar] [CrossRef]

- Lee, D.Y.; Cho, J.; Lee, M.; Cho, N.; Song, Y. Insertion of a TiO2 buffer layer for the fixation of electrospun TiO2 nanofibers on glass substrates. J. Korean Phys. Soc. 2009, 55, 84–88. [Google Scholar] [CrossRef]

- Li, D.; Xia, Y. Fabrication of titania nanofibers by electrospinning. Nano Lett. 2003, 3, 555–560. [Google Scholar] [CrossRef]

- Khalil, K.A.; Sherif ES, M.; Nabawy, A.M.; Abdo, H.S.; Marzouk, W.W.; Alharbi, H.F. Titanium carbide nanofibers-reinforced aluminum compacts, a new strategy to enhance mechanical properties. Materials 2016, 9, 399. [Google Scholar] [CrossRef] [PubMed]

- Fouly, A.; Abdo, H.S.; Seikh, A.H.; Alluhydan, K.; Alkhammash, H.I.; Alnaser, I.A.; Abdo, M.S. Evaluation of Mechanical and Tribological Properties of Corn Cob-Reinforced Epoxy-Based Composites—Theoretical and Experimental Study. Polymers 2021, 13, 4407. [Google Scholar] [CrossRef]

- Guo, R.Q.; Rohatgi, P.K.; Nath, D. Preparation of aluminium-fly ash particulate composite by powder metallurgy technique. J. Mater. Sci. 1997, 32, 3971–3974. [Google Scholar] [CrossRef]

- Ibrahim, A.M.M.; Shi, X.; Radwan, A.R.; Mohamed, A.F.A.; Ezzat, M.F. Enhancing the tribological properties of NiAl based nano-composites for aerospace bearing applications. Mater. Res. Express 2019, 6, 085067. [Google Scholar] [CrossRef]

- Khun, N.W.; Zhang, H.; Lim, L.H.; Yue, C.Y.; Hu, X.; Yang, J. Tribological properties of short carbon fibers reinforced epoxy composites. Friction 2014, 2, 226–239. [Google Scholar] [CrossRef]

- Chang, L.; Zhang, Z.; Zhang, H.; Friedrich, K. Effect of nanoparticles on the tribological behaviour of short carbon fibre reinforced poly (etherimide) composites. Tribol. Int. 2005, 38, 966–973. [Google Scholar] [CrossRef]

- Fouly, A.; Almotairy, S.M.; Aijaz, M.O.; Alharbi, H.F.; Abdo, H.S. Balanced mechanical and tribological performance of high-frequency-sintered al-sic achieved via innovative milling route—Experimental and theoretical study. Crystals 2021, 11, 700. [Google Scholar] [CrossRef]

- Kuminek, T.; Aniolek, K.; Mlyńczak, J. A numerical analysis of the contact stress distribution and physical modelling of abrasive wear in the tram wheel-frog system. Wear 2015, 328, 177–185. [Google Scholar] [CrossRef]

| Sample | Composition (wt.%) | Density (gm/cm3) | Vickers Hardness | Ultimate Compressive Strength (MPa) | Yield Compressive Strength (MPa) |

|---|---|---|---|---|---|

| Mg-TiO2-0 | Mg + 0%TiO2 | 1.7 ± 0.1 | 45 ± 1.4 | 250 ± 1.3 | 100 ± 0.95 |

| Mg-TiO2-1 | Mg + 1%TiO2 | 1.71 ± 0.2 | 55.52 ± 1.1 | 259 ± 0.85 | 133 ± 0.73 |

| Mg-TiO2-3 | Mg + 3%TiO2 | 1.74 ± 0.15 | 63.95 ± 1.6 | 272 ± 1.7 | 142 ± 1.1 |

| Mg-TiO2-5 | Mg + 5%TiO2 | 1.76 ± 0.13 | 66.83 ± 0.9 | 281 ± 1.5 | 145 ± 1.22 |

| Mg-TiO2-10 | Mg + 10%TiO2 | 1.82 ± 0.1 | 74.02 ± 0.13 | 276 ± 1.4 | 136 ± 1.16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alnaser, I.A.; Abdo, H.S.; Abdo, M.S.; Alkalla, M.; Fouly, A. Effect of Synthesized Titanium Dioxide Nanofibers Weight Fraction on the Tribological Characteristics of Magnesium Nanocomposites Used in Biomedical Applications. Nanomaterials 2023, 13, 294. https://doi.org/10.3390/nano13020294

Alnaser IA, Abdo HS, Abdo MS, Alkalla M, Fouly A. Effect of Synthesized Titanium Dioxide Nanofibers Weight Fraction on the Tribological Characteristics of Magnesium Nanocomposites Used in Biomedical Applications. Nanomaterials. 2023; 13(2):294. https://doi.org/10.3390/nano13020294

Chicago/Turabian StyleAlnaser, Ibrahim A., Hany S. Abdo, Mohamed S. Abdo, Mohamed Alkalla, and Ahmed Fouly. 2023. "Effect of Synthesized Titanium Dioxide Nanofibers Weight Fraction on the Tribological Characteristics of Magnesium Nanocomposites Used in Biomedical Applications" Nanomaterials 13, no. 2: 294. https://doi.org/10.3390/nano13020294

APA StyleAlnaser, I. A., Abdo, H. S., Abdo, M. S., Alkalla, M., & Fouly, A. (2023). Effect of Synthesized Titanium Dioxide Nanofibers Weight Fraction on the Tribological Characteristics of Magnesium Nanocomposites Used in Biomedical Applications. Nanomaterials, 13(2), 294. https://doi.org/10.3390/nano13020294