Suppression of Secondary Electron Emission from Nickel Surface by Graphene Composites Based on First-Principles Method

Abstract

:1. Introduction

2. Materials and Methods

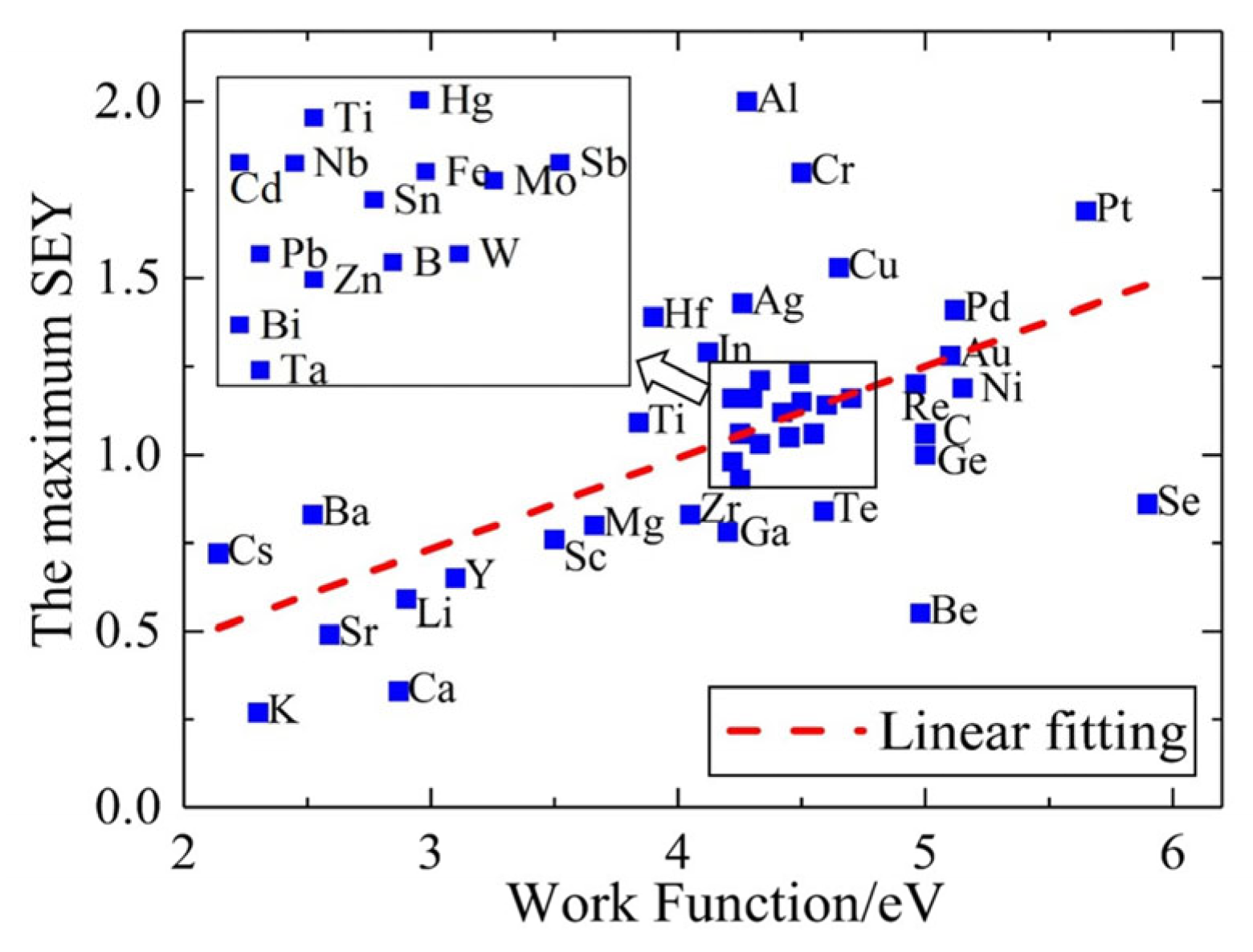

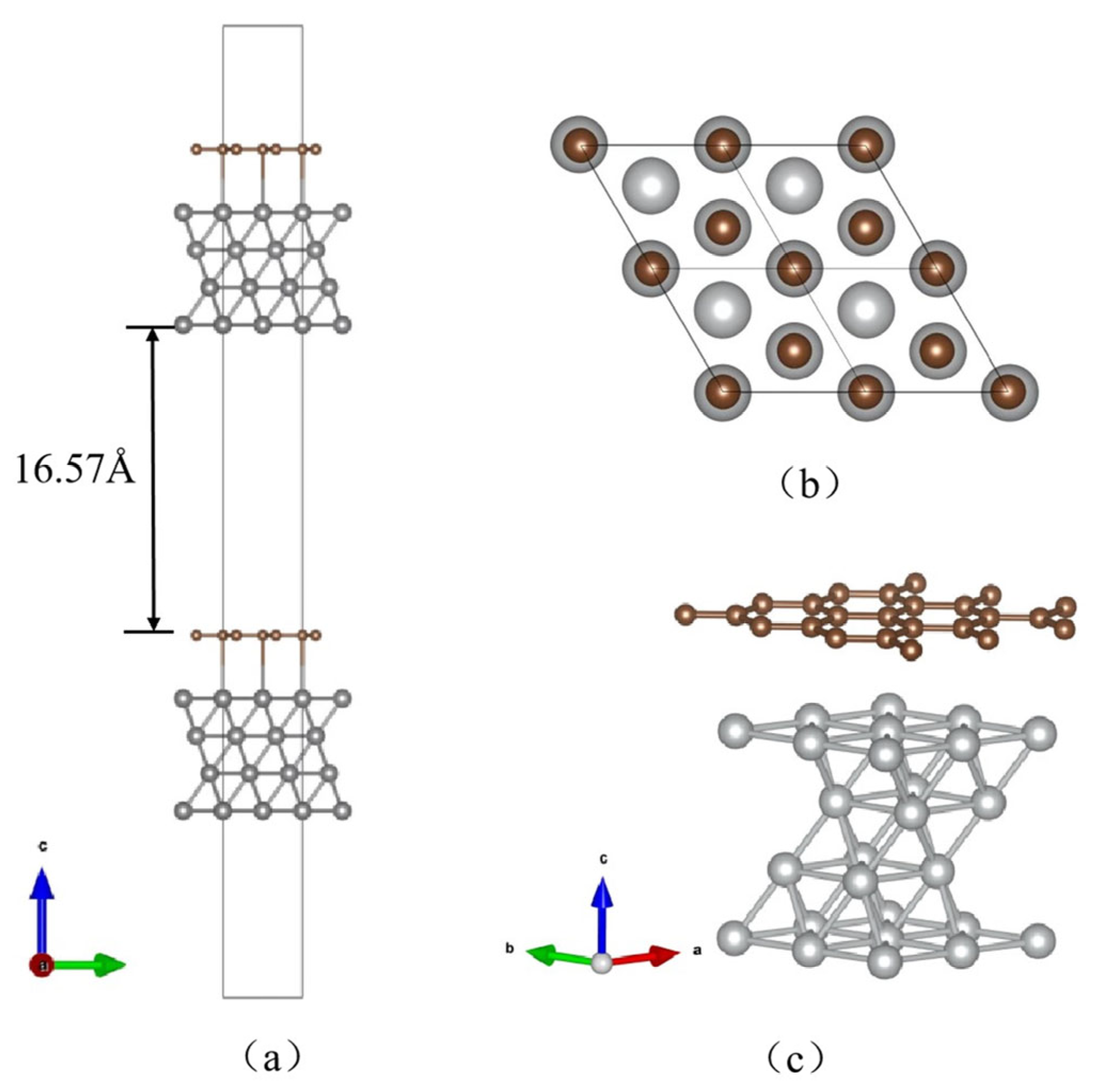

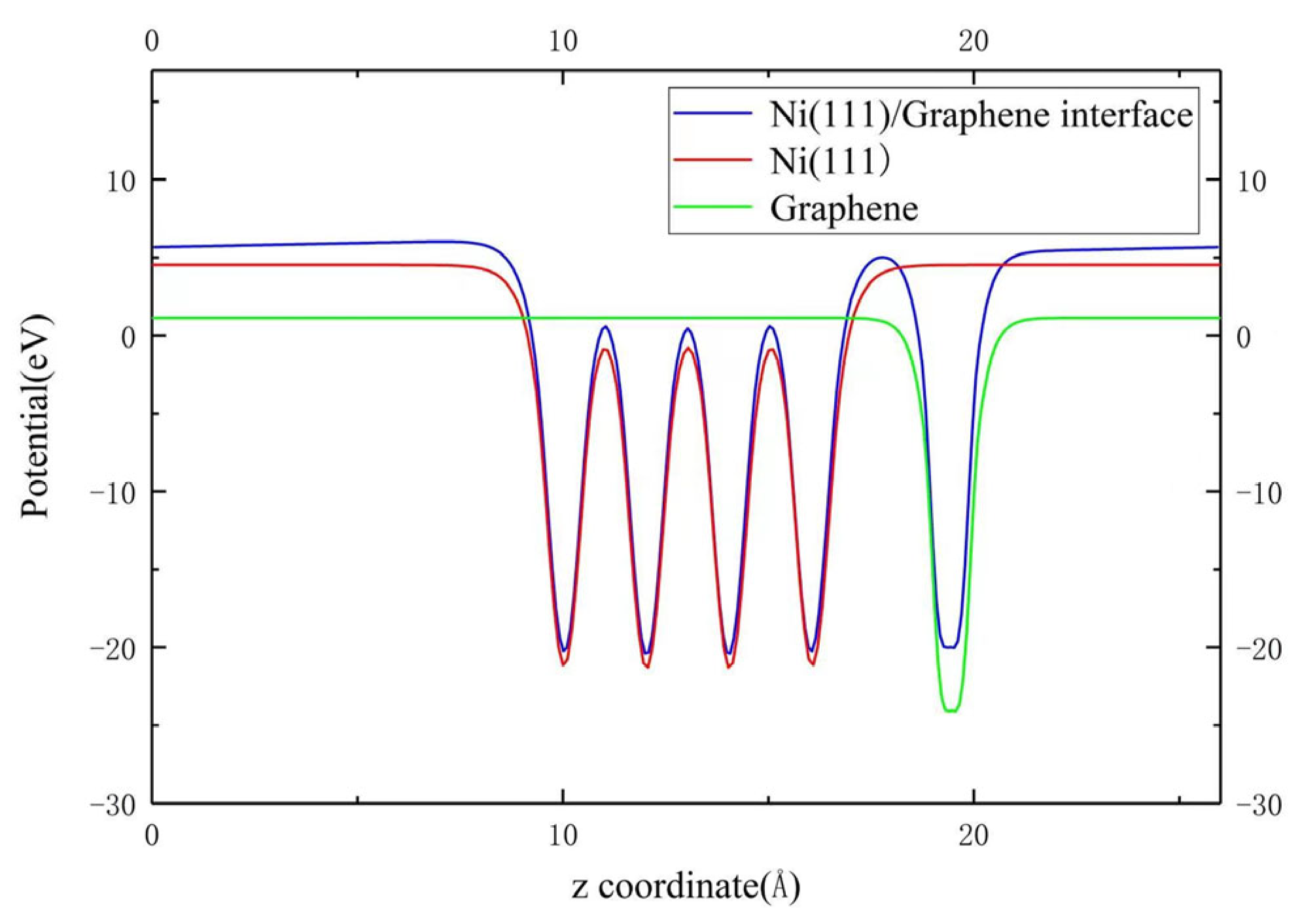

2.1. Theoretical Analysis and Design via DFT

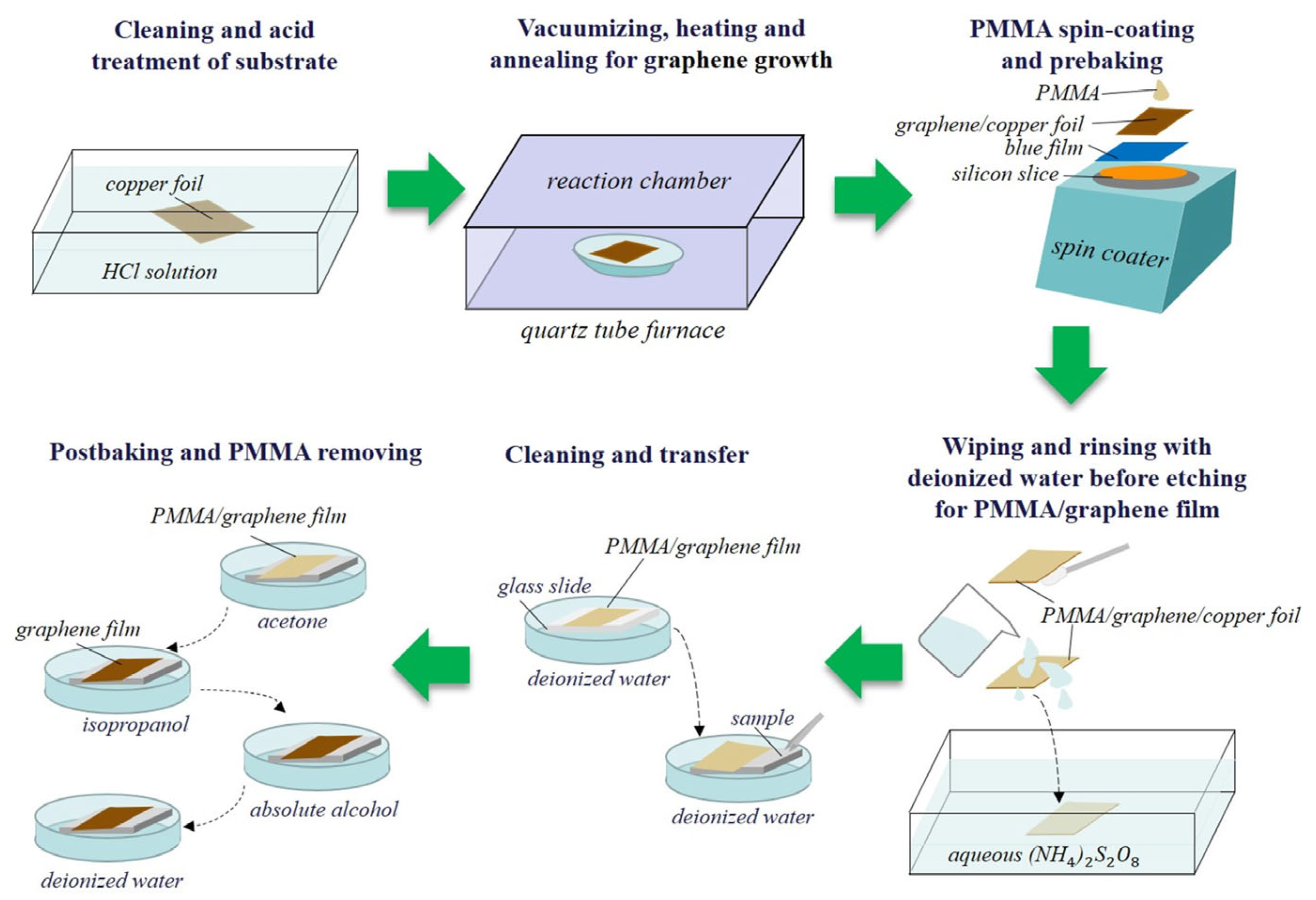

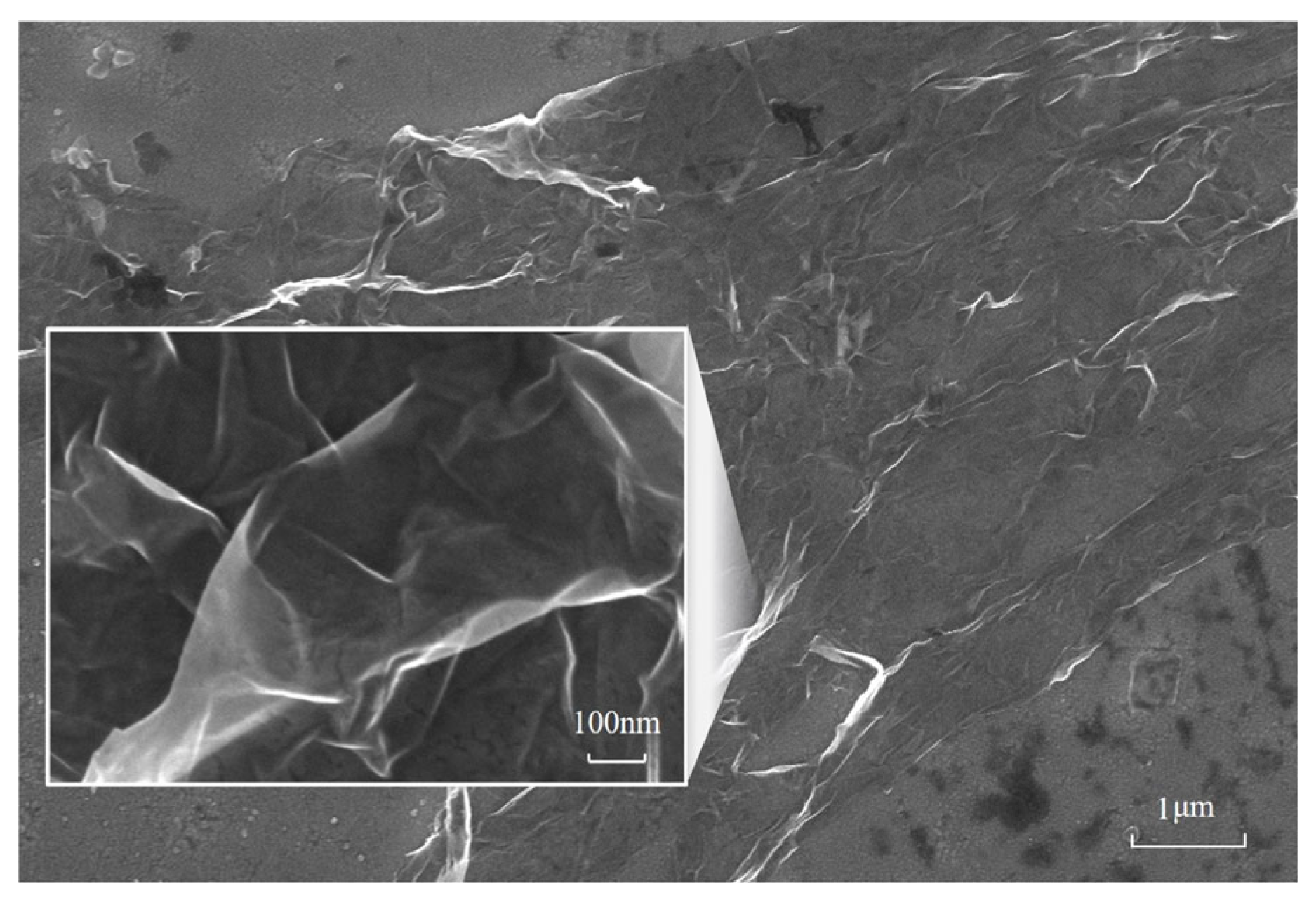

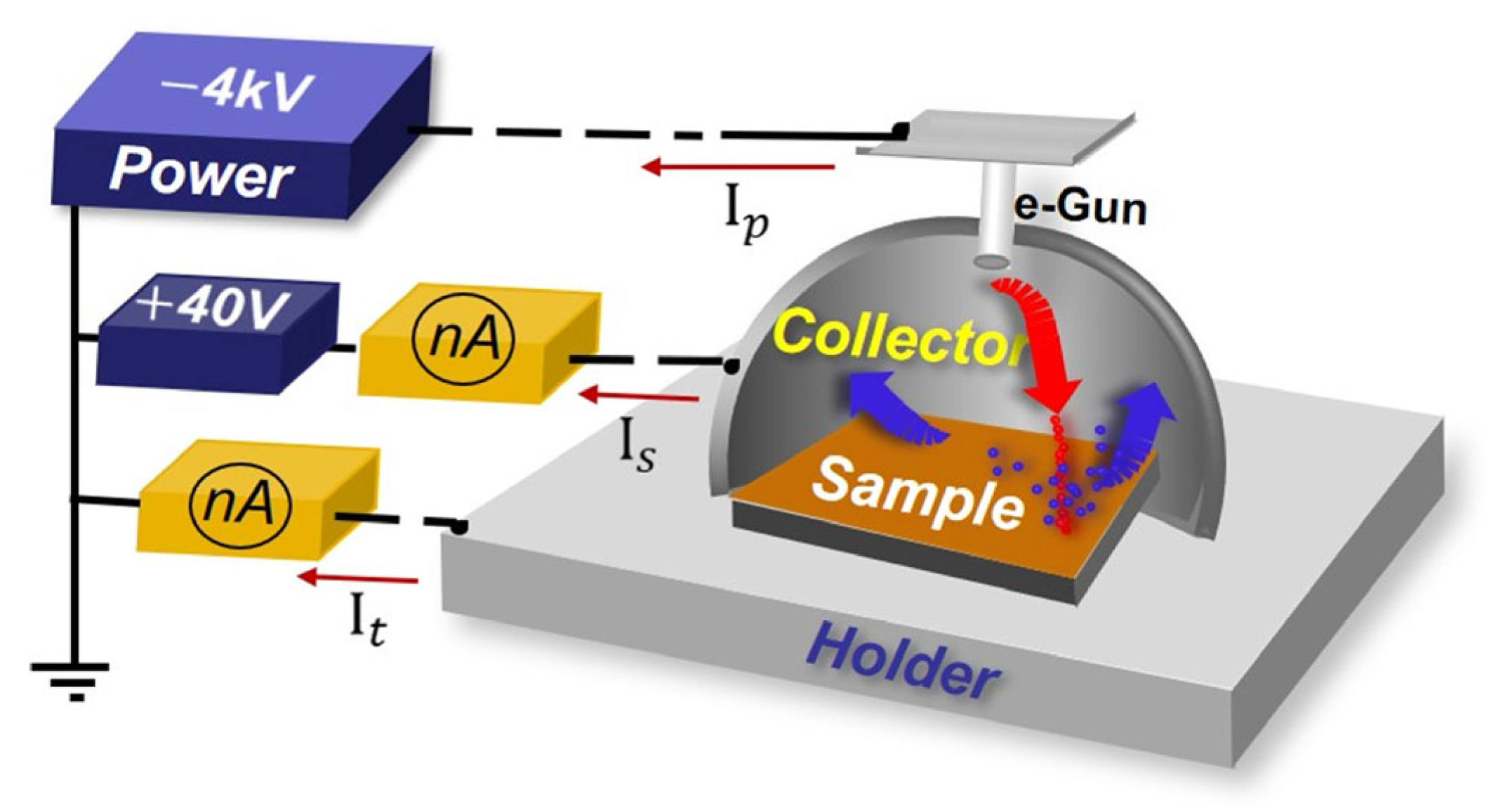

2.2. Experiments for Material Preparing and Processing

3. Theoretical and Experimental Results and Discussion

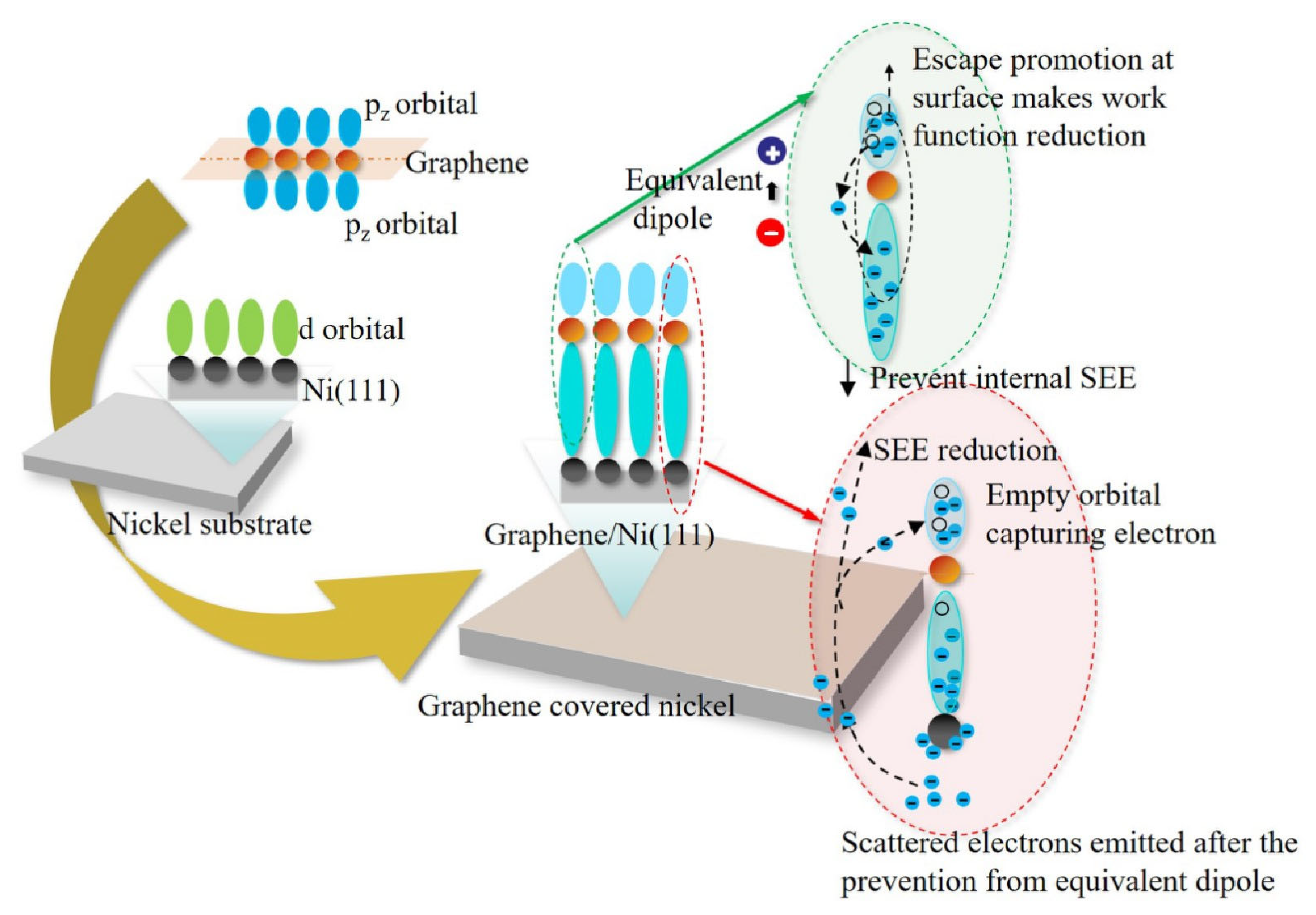

3.1. Explanation of SEE Suppression via DFT Simulation

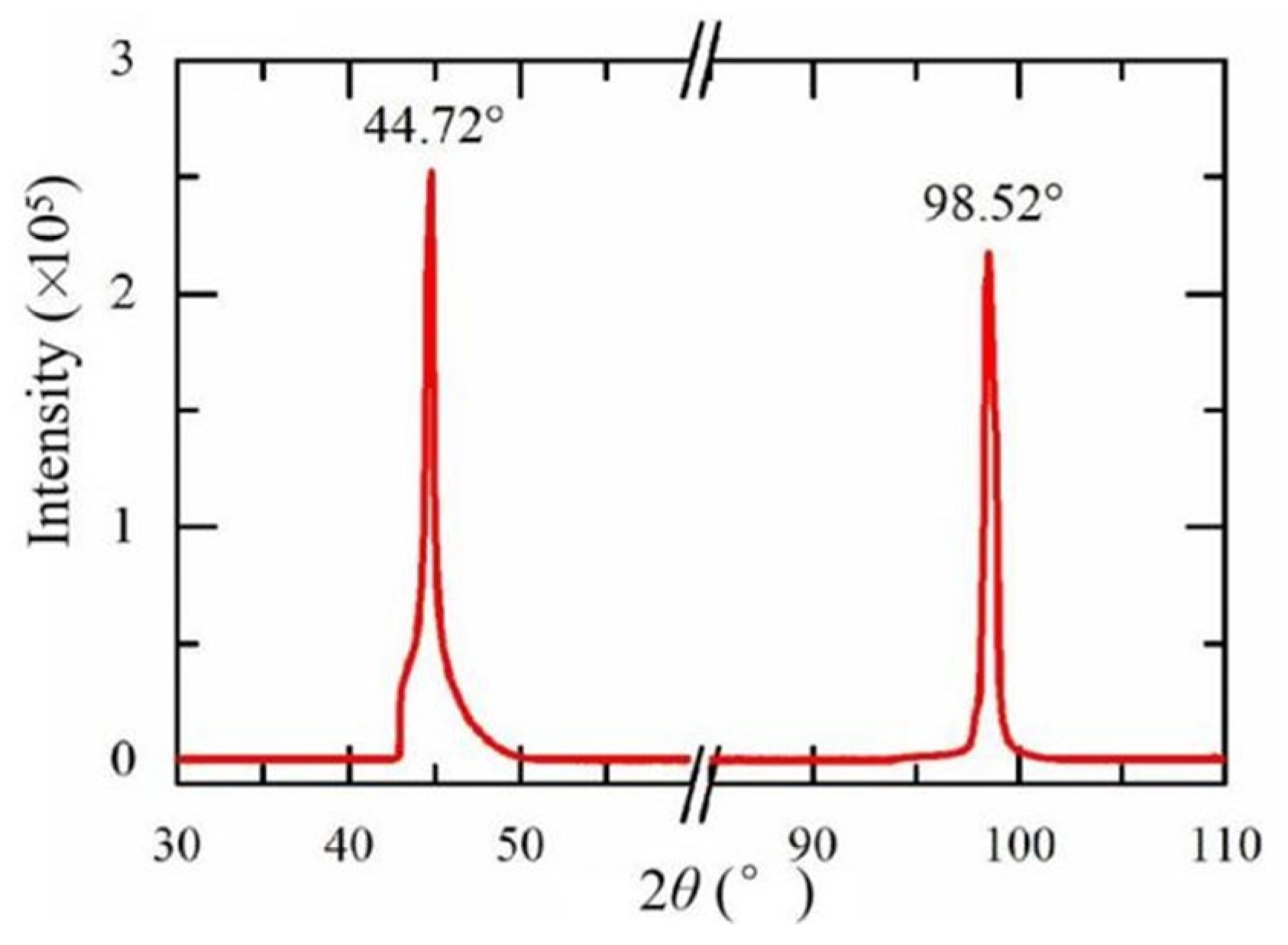

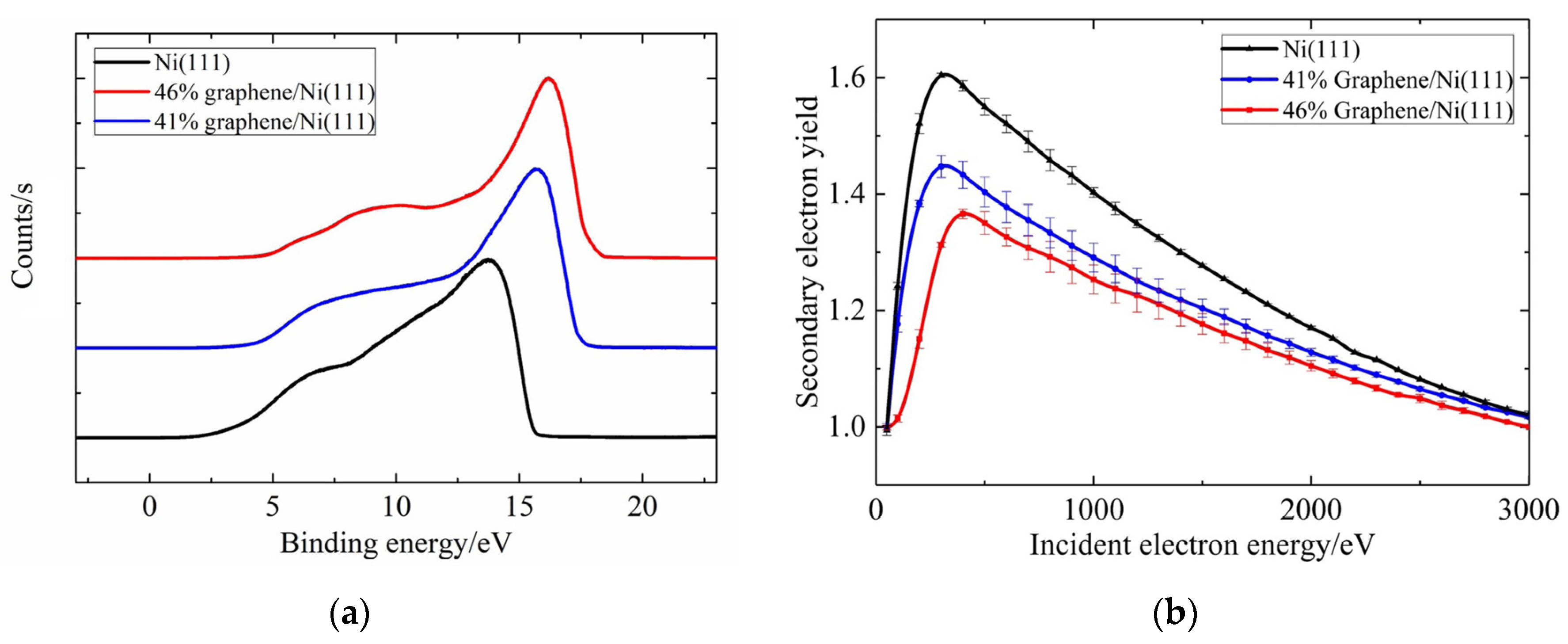

3.2. Valilation of Suppressing SEE Methods

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Marcak, A.; Corbella, C.; Arcos, T.L.; Keudell, A.V. Note: Ion-induced secondary electron emission from oxidized metal surfaces measured in a particle beam reactor. Rev. Sci. Instrum. 2015, 86, 106102. [Google Scholar] [CrossRef] [PubMed]

- Sorolla, E.; Sounas, A.; Mattes, M. Space charge effects for multipactor in coaxial lines. Phys. Plasmas 2015, 22, 033512. [Google Scholar] [CrossRef]

- Balcon, N.; Payan, D.; Belhaj, M.; Tondu, T.; Inguimbert, V. Secondary electron emission on space materials: Evaluation of the total secondary electron yield from surface potential measurements. IEEE Trans. Plasma Sci. 2012, 40, 282. [Google Scholar] [CrossRef]

- Marić, D.; Savić, M.; Sivoš, J.; Škoro, N.; Radmilović-Radjenović, M.; Malović, G.; Petrović, Z.L. Gas breakdown and secondary electron yields. Eur. Phys. J. D 2014, 68, 155. [Google Scholar] [CrossRef]

- Powell, C.; Jablonski, A. Evaluation of calculated and measured electron inelastic mean free paths near solid surfaces. J. Phys. Chem. Ref. Data 1999, 28, 19. [Google Scholar] [CrossRef]

- Belhaj, M.; Jbara, O.; Fakhfakh, S. Quantitative voltage contrast method for electron irradiated insulators in SEM. J. Phys. D Appl. Phys. 2008, 41, 175304. [Google Scholar] [CrossRef]

- Vaughan, J. Multipactor. IEEE Trans. Electron. Devices 1988, 35, 1172–1180. [Google Scholar] [CrossRef]

- Kishek, R.A.; Lau, Y.Y.; Ang, L.K.; Valfells, A.; Gilgenbach, R.M. Multipactor discharge on metals and dielectrics: Historical review and recent theories. Phys. Plasmas 1998, 5, 2120–2126. [Google Scholar] [CrossRef]

- Pivi, M.; King, F.K.; Kirby, R.E.; Raubenheimer, T.O.; Stupakov, G.; Pimpec, F.L. Sharp reduction of the secondary electron emission yield from grooved surfaces. J. Appl. Phys. 2008, 104, 104904. [Google Scholar] [CrossRef]

- Ye, M.; He, Y.N.; Hu, S.G.; Wang, R.; Hu, T.C.; Yang, J.; Cui, W.Z. Suppression of secondary electron yield by micro-porous array structure. J. Appl. Phys. 2013, 113, 074904. [Google Scholar] [CrossRef]

- Chang, C.; Liu, G.Z.; Huang, H.J.; Chen, C.H.; Fang, J.Y. Suppressing high-power microwave dielectric multipactor by the sawtooth surface. Phys. Plasmas 2009, 16, 083501. [Google Scholar] [CrossRef]

- Chang, C.; Huang, H.J.; Liu, G.Z.; Chen, C.H.; Hou, Q.; Fang, J.Y.; Zhu, X.X.; Zhang, Y.P. The effect of grooved surface on dielectric multipactor. J. Appl. Phys. 2009, 105, 123305. [Google Scholar] [CrossRef]

- Zhang, N.; Cao, M.; Cui, W.Z.; Hu, T.C. Effect of rough surface morphology on secondary electron emission from metal surface. J. Appl. Phys. 2017, 56, 075802. [Google Scholar] [CrossRef]

- Swanson, C.; Kaganovich, I.D. Modeling of reduced secondary electron emission yield from a foam or fuzz surface. J. Appl. Phys. 2018, 123, 023302. [Google Scholar] [CrossRef]

- Peng, M.; Lin, S.; Zhang, C.X.; Liang, H.F.; Liu, C.L.; Cao, M.; Hu, W.B.; Zhai, Y.G.; Li, Y.D. Effect of the Surface Morphology of Porous Coatings on Secondary Electron Yield of Metal Surface. Materials 2022, 15, 4322. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Sun, G.Y.; Zhou, R.D.; Huang, K.; Li, W.; Wang, C.; Dong, J.; Song, B.; Zhang, G. Ultralow secondary electron emission and improved vacuum surface insulation of polyimide with scalable nanocomposite coating. Appl. Surf. Sci. 2022, 592, 153221. [Google Scholar] [CrossRef]

- Suetsugu, Y.; Fukuma, H.; Shibata, K.; Tsukuba, J.; Menlo. Experimental studies on grooved surfaces to suppress secondary electron emission. In Proceedings of the IPAC 2010, Kyoto, Japan, 23–28 May 2010. [Google Scholar]

- Díaz, N.; Casrañeda, S.; Montero, I.; Galán, L.; Rueda, F. Coating to Prevent Multipactor Effect in RF High Power Components for Space; Final Report, ESA-ESTEC Contract P.O.162594(1996); ESA: Paris, France, 1998. [Google Scholar]

- Montero, I.; Mohamed, S.H.; García, M.; Galán, L.; Raboso, D. Effect of surface reactions of low-energy carbon ions on the secondary electron emission of TiN:O thin films. J. Appl. Phys. 2007, 101, 113306. [Google Scholar] [CrossRef]

- Pinto, P.C.; Calatroni, S.; Neupert, H.; Letant-Delrieux, D.; Edwards, P.; Chiggiato, P.; Taborelli, M.; Vollenberg, W.; Yin-Vallgren, C.; Colaux, J.L.; et al. Carbon coatings with low secondary electron yield. Vacuum 2013, 98, 29–36. [Google Scholar] [CrossRef]

- Lu, Q.; Yu, B.; Hu, Z.Q.; He, Y.; Hu, T.C.; Zhao, Y.N.; Wang, Z.G.; Zhou, Z.Y.; Cui, W.Z.; Liu, M. Surface roughness evolution induced low secondary electron yield in carbon coated Ag/Al substrates for space microwave devices. Appl. Surf. Sci. 2020, 501, 144236. [Google Scholar] [CrossRef]

- Jin, C.; Ottaviano, A.; Raitses, Y. Secondary electron emission yield from high aspect ratio carbon velvet surfaces. J. Appl. Phys. 2017, 122, 173301. [Google Scholar] [CrossRef]

- Riccardi, P.; Cupolillo, A.; Pisarra, M.; Sindona, A.; Caputi, L.S. Primary energy dependence of secondary electron emission from grapheme adsorbed on Ni (111). Appl. Phys. Lett. 2012, 101, 183102. [Google Scholar] [CrossRef]

- Sian, T.; Lin, Y.; Valizadeh, R.; Malyshev, O.B.; Xia, G.X.; Valles, C.; Yu, G.L.; Kinloch, I. Graphene coating for the reduction of the secondary electron yield. In Proceedings of the 7th International Particle Accelerator Conference, Busan, Republic of Korea, 8–13 May 2016. [Google Scholar]

- Xie, G.B.; Cui, W.Z.; Yang, J. A general route towards secondary electron yield suppression based on graphene. In Proceedings of the 17th International Symposium on Antenna Technology and Applied Electromagnetics, Montreal, QC, Canada, 10–13 July 2016. [Google Scholar]

- Luo, J.; Tian, P.; Pan, C.T.; Robertson, A.W.; Warner, J.H.; Hill, E.W.; Briggs, G.A.D. Ultralow secondary electron emission of graphene. ACS Nano 2011, 5, 1047–1055. [Google Scholar] [CrossRef] [PubMed]

- Aguincha, R.; Bundaleski, N.; Bundaleska, N.; Novaković, M.; Henriques, J.; Rakočević, Z.; Tatarova, E.; Teodoro, O.M.N.D. Low total electron yield graphene coatings produced by electrophoretic deposition. Appl. Surf. Sci. 2020, 504, 143870. [Google Scholar] [CrossRef]

- Cao, M.; Zhang, X.S.; Liu, W.H.; Wang, H.G.; Li, Y.D. Secondary electron emission of graphene-coated copper. Diam. Relat. Mater. 2017, 73, 199–203. [Google Scholar] [CrossRef]

- Montero, I.; Aguilera, L.; Dávila, M.E.; Nistor, V.C.; González, L.A.; Galán, L.; Raboso, D.; Ferritto, R. Secondary electron emission under electron bombardment from graphene nanoplatelets. Appl. Surf. Sci. 2014, 291, 74–77. [Google Scholar] [CrossRef]

- Wang, D.; Mao, Z.S.; Ye, Z.; Cai, Y.H.; Li, Y.; He, Y.N.; Qi, K.C.; Xu, Y.N.; Jia, Q.Q. Ultralow electron emission yield achieved on alumina ceramic surfaces and its application in multipactor suppression. J. Phys. D Appl. Phys. 2022, 55, 455301. [Google Scholar] [CrossRef]

- Bertoni, G.; Calmels, L.; Altibelli, A.; Serin, V. First-principles calculation of the electronic structure and EELS spectra at the graphene/Ni (111) interface. Phys. Rev. B 2005, 71, 075402. [Google Scholar] [CrossRef]

- Ligato, N.; Cupolillo, A.; Sindona, A.; Riccardi, P.; Pisarra, M.; Caputi, L.S. A comparative study of the plasmonic properties of graphene on lattice-matched and lattice-mismatched Ni surfaces. Surf. Sci. 2014, 626, 40–43. [Google Scholar] [CrossRef]

- Baroody, E.M. A theory of secondary electron emission from metals. Phys. Rev. 1950, 78, 780. [Google Scholar] [CrossRef]

- Ashcroft, N.W.; Mermin, N.D. Solid State Physics; Holt-Sanders International Editions: Philadelphia, PA, USA, 1976. [Google Scholar]

- Kawano, H. Effective Work Functions of the Elements: Database, most probable value, previously recommended value, polycrystalline thermionic contrast, change at critical temperature, anisotropic dependence sequence, particle size dependence. Prog. Surf. Sci. 2022, 97, 100583. [Google Scholar] [CrossRef]

- Mannstadt, W. Coverage dependence of the work function of Li adsorbed on Ru (001): Ab initio studies within DFT. Surf. Sci. 2003, 525, 119–125. [Google Scholar] [CrossRef]

- Olawole, O.C.; De, D.K.; Olawole, O.F.; Lamba, R.; Joel, E.S.; Oyedepo, S.O.; Ajayi, A.A.; Adegbite, O.A.; Ezema, F.I.; Naghdi, S.; et al. Progress in the experimental and computational methods of work function evaluation of materials: A review. Heliyon 2022, 8, e11030. [Google Scholar] [CrossRef] [PubMed]

- Perdew, J.P.; Chevary, J.A.; Vosko, S.H.; Jackson, K.A.; Pederson, M.R.; Singh, D.J.; Fiolhais, C. Atoms, Molecules, Solids, and Surfaces: Applications of the Generalized Gradient: Approximation for Exchange and Correlation. Phys. Rev. B 1993, 46, 6671–6687. [Google Scholar] [CrossRef] [PubMed]

- Perdew, J.P.; Burke, K.; Ernzerhof, M. Generalized Gradient Approximation Made Simple. Phys. Rev. Lett. 1996, 77, 3865–3868. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.; Liu, W.H.; Guo, S.X.; Zhu, S.Y.; Li, Q.F.; Li, X.; Wang, X.L.; Liu, H.Z. Synthesis of well-aligned millimeter-sized tetragon-shaped graphene domains by tuning the copper substrate orientation. Carbon 2015, 93, 945–952. [Google Scholar] [CrossRef]

- Tsukamoto, T.; Yamazaki, K.; Komurasaki, H.; Ogino, T. Effects of Surface Chemistry of Substrates on Raman Spectra in Graphene. J. Phys. Chem. C 2014, 116, 4732–4737. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Ni, Z.H.; Yu, T.; Shen, Z.X.; Wang, H.M.; Wu, Y.H.; Chen, W.; Wee, A.T.S. Raman studies of monolayer graphene: The substrate effect. J. Phys. Chem. C 2008, 112, 10637–10640. [Google Scholar] [CrossRef]

- Das, A.; Chakraborty, B.; Sood, A.K. Raman spectroscopy of graphene on different substrates and influence of defects. Bull. Mater. Sci. 2008, 31, 579–584. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Meyer, J.C.; Scardaci, V.; Casiraghi, C.; Lazzeri, M.; Mauri, F.; Piscanec, S.; Jiang, D.; Novoselov, K.S.; Roth, S.; et al. Raman spectrum of graphene and graphene layers. Phys. Rev. Lett. 2006, 97, 187401. [Google Scholar] [CrossRef]

- Wu, J.; Xu, H.; Zhang, J. Raman Spectroscopy of Graphene. Acta Chim. Sin. 2014, 72, 301. [Google Scholar] [CrossRef]

- Weng, M.; Cao, M.; Zhao, H.J.; Zhang, H.B. A simple charge neutralization method for measuring the secondary electron yield of insulators. Rev. Sci. Instrum. 2014, 85, 036108. [Google Scholar] [CrossRef] [PubMed]

- Park, Y.; Choong, V.; Gao, Y.; Hsieh, B.R.; Tang, C.W. Work function of indium tin oxide transparent conductor measured by photoelectron spectroscopy. Appl. Phys. Lett. 1996, 68, 2699–2701. [Google Scholar] [CrossRef]

- Wang, X.J.; Wang, D.W.; Li, Y.D.; Chang, Q.F.; Zhang, C.X. Secondary Electron Yield Materials for Space Microwave Devices Based on First Principles Computation. J. Mech. Eng. 2018, 54, 115–120. [Google Scholar] [CrossRef]

- Lin, Y.H.; Joy, D.C. A new examination of secondary electron yield data. Surf. Interface Anal. 2005, 37, 895–900. [Google Scholar] [CrossRef]

- Hussain, A.; Yang, L.; Zou, Y.; Mao, S.; Da, B.; Li, H.; Ding, Z. Theoretical calculations of the mean escape depth of secondary electron emission from compound semiconductor materials. J. Appl. Phys. 2020, 128, 015305. [Google Scholar] [CrossRef]

- Nguyen, H.; Sanati, M.; Joshi, R.P. Probing changes in secondary electron yield from copper electrodes due to surface defects and changes in crystal orientation. J. Appl. Phys. 2019, 126, 123301. [Google Scholar] [CrossRef]

- Brown, M.; Sanati, M.; Joshi, R.P. Combined first-principles-Monte Carlo analysis to evaluate the effect of surface hydrogen on the secondary electron yield of nickel. J. Appl. Phys. 2022, 131, 103301. [Google Scholar] [CrossRef]

| Material | Calculated Values of φ (eV) | Experimental Values of φ (eV) |

|---|---|---|

| Graphene | 4.44 | 4.60 |

| Ni (111) | 5.11 | 5.37 |

| Graphene/Ni (111) | 3.73 | 3.42 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, M.; Nan, C.; Wang, D.; Cao, M.; Zhang, L.; Liu, L.; Liu, C.; Fang, D.; Zhang, Y.; Zhai, Y.; et al. Suppression of Secondary Electron Emission from Nickel Surface by Graphene Composites Based on First-Principles Method. Nanomaterials 2023, 13, 2550. https://doi.org/10.3390/nano13182550

Peng M, Nan C, Wang D, Cao M, Zhang L, Liu L, Liu C, Fang D, Zhang Y, Zhai Y, et al. Suppression of Secondary Electron Emission from Nickel Surface by Graphene Composites Based on First-Principles Method. Nanomaterials. 2023; 13(18):2550. https://doi.org/10.3390/nano13182550

Chicago/Turabian StylePeng, Min, Chang Nan, Dawei Wang, Meng Cao, Liang Zhang, Laijun Liu, Chunliang Liu, Dangqi Fang, Yiqi Zhang, Yonggui Zhai, and et al. 2023. "Suppression of Secondary Electron Emission from Nickel Surface by Graphene Composites Based on First-Principles Method" Nanomaterials 13, no. 18: 2550. https://doi.org/10.3390/nano13182550

APA StylePeng, M., Nan, C., Wang, D., Cao, M., Zhang, L., Liu, L., Liu, C., Fang, D., Zhang, Y., Zhai, Y., & Li, Y. (2023). Suppression of Secondary Electron Emission from Nickel Surface by Graphene Composites Based on First-Principles Method. Nanomaterials, 13(18), 2550. https://doi.org/10.3390/nano13182550