Synthesis of Platinum Nanoparticles Supported on Fused Nanosized Carbon Spheres Derived from Sustainable Source for Application in a Hydrogen Generation Reaction

Abstract

1. Introduction

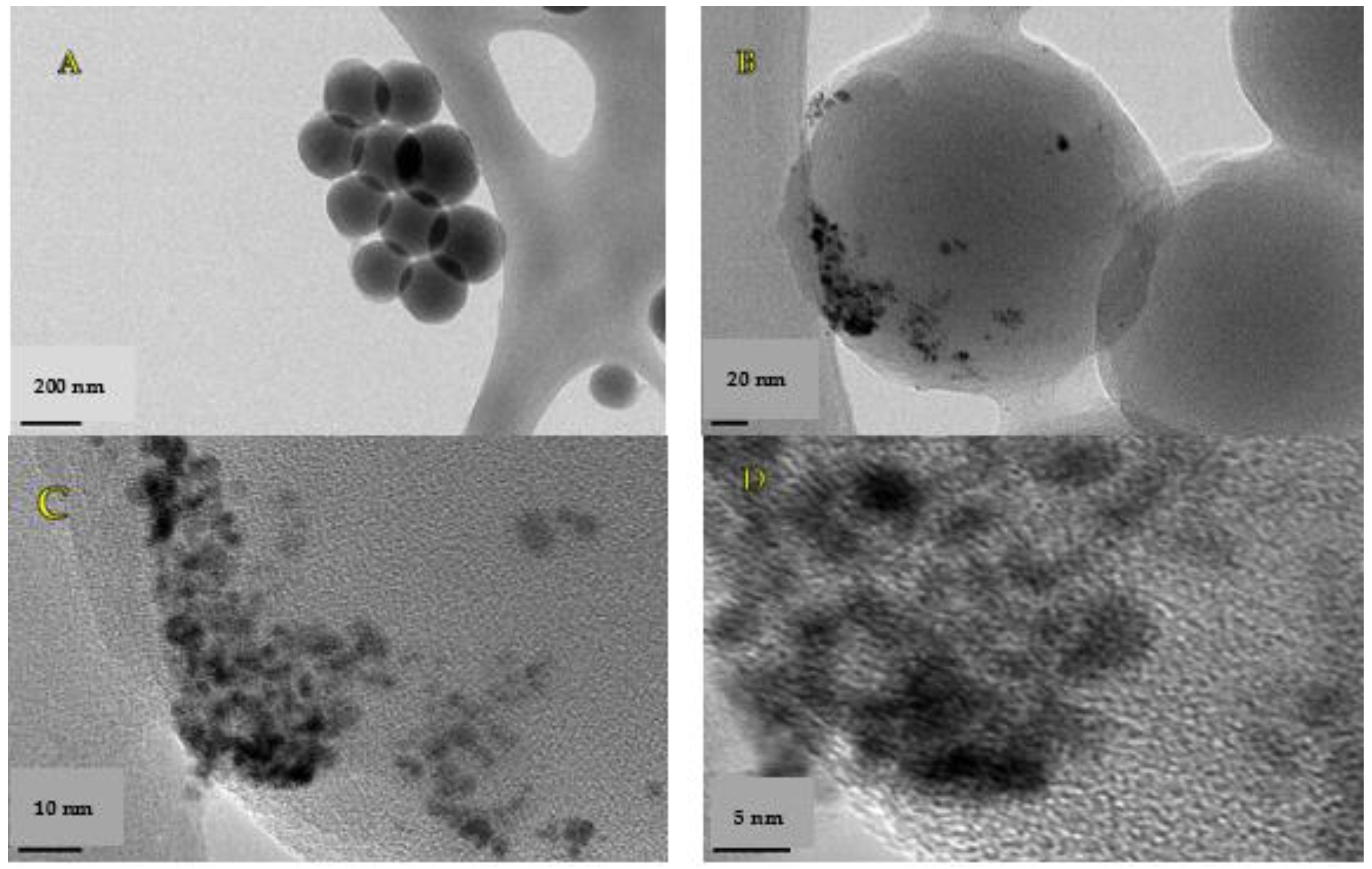

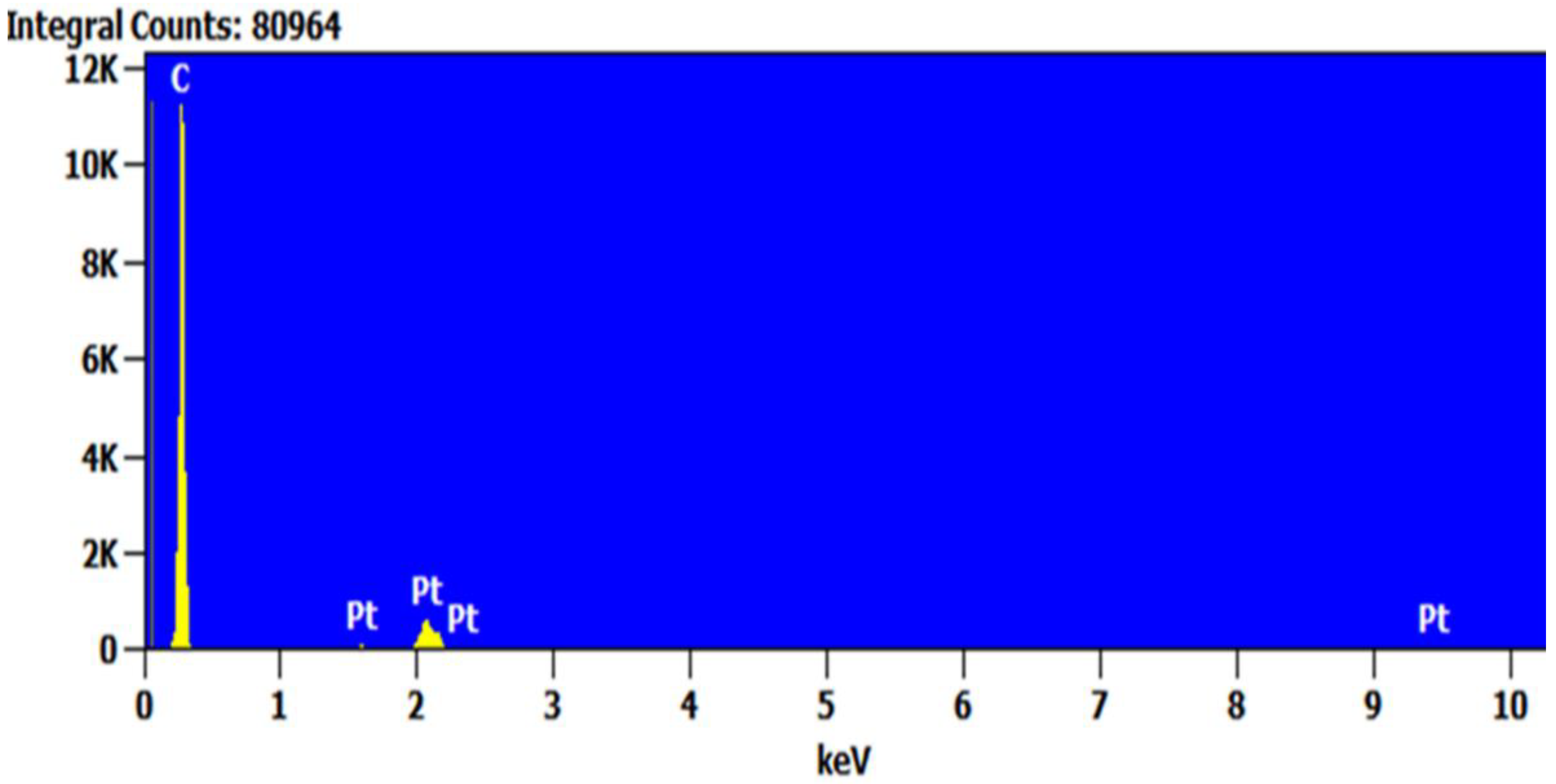

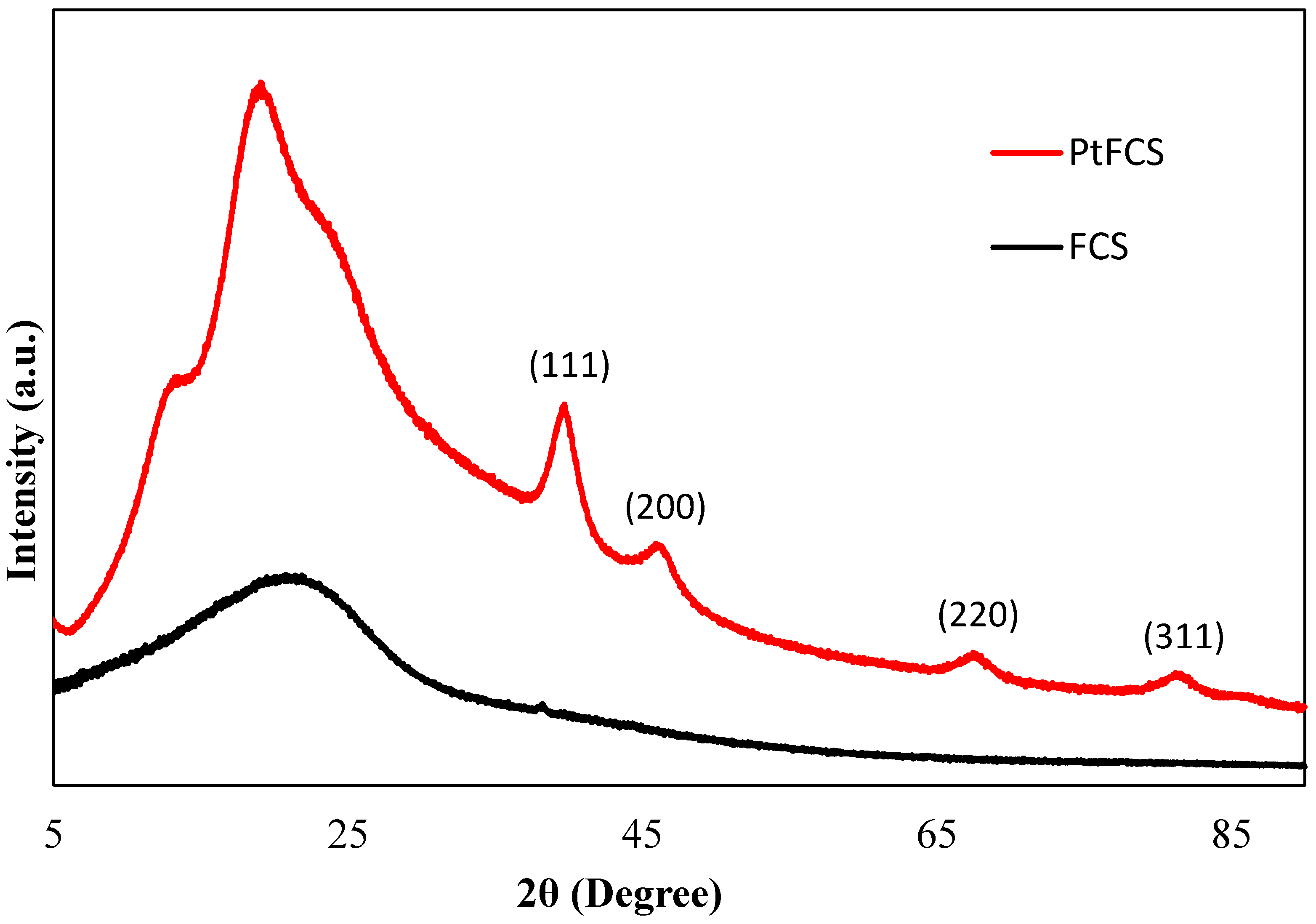

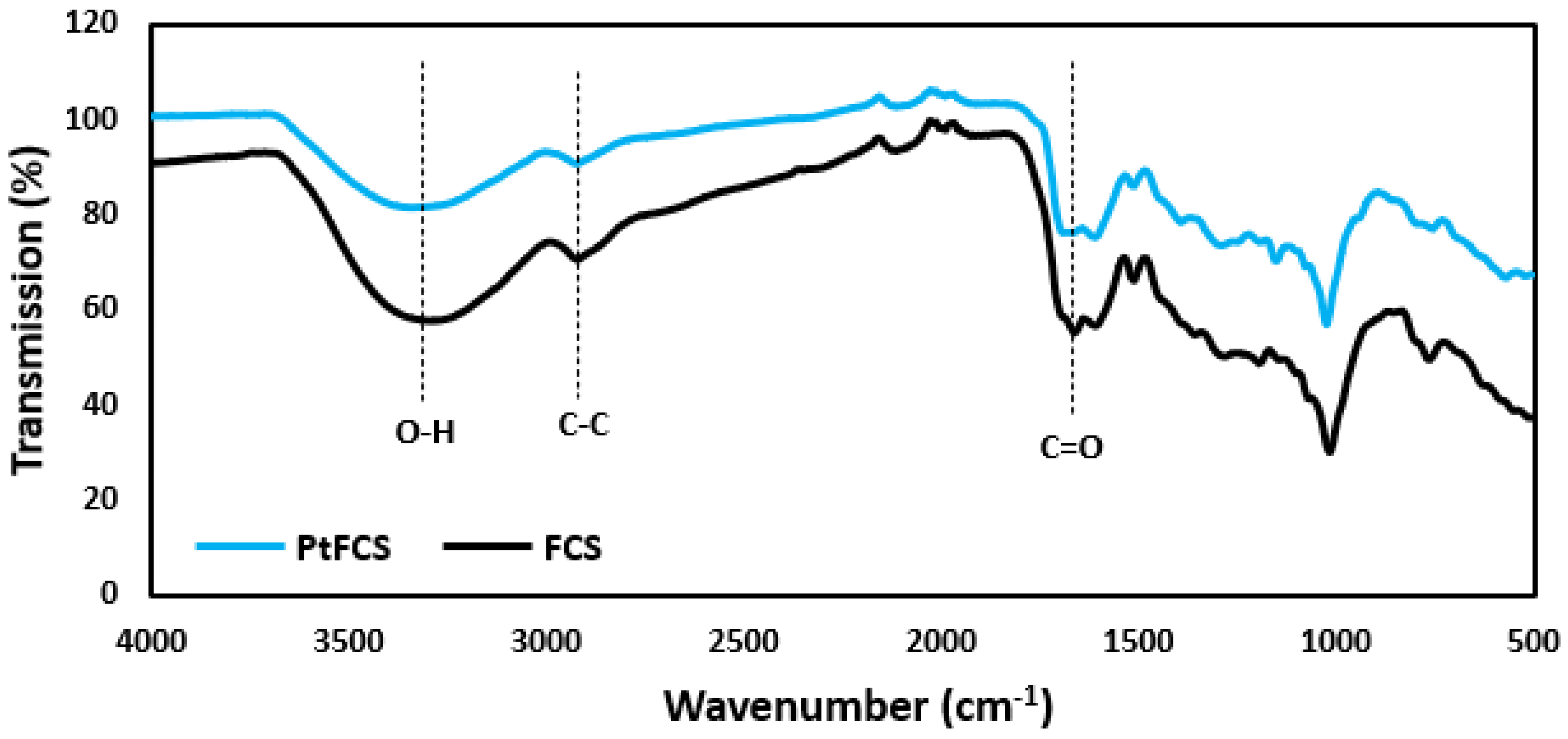

2. Experimental

2.1. Synthesis of Platinum Nanoparticles

2.2. Synthesis of Fused Carbon Spheres and Nanocomposite Catalyst

2.3. Characterization

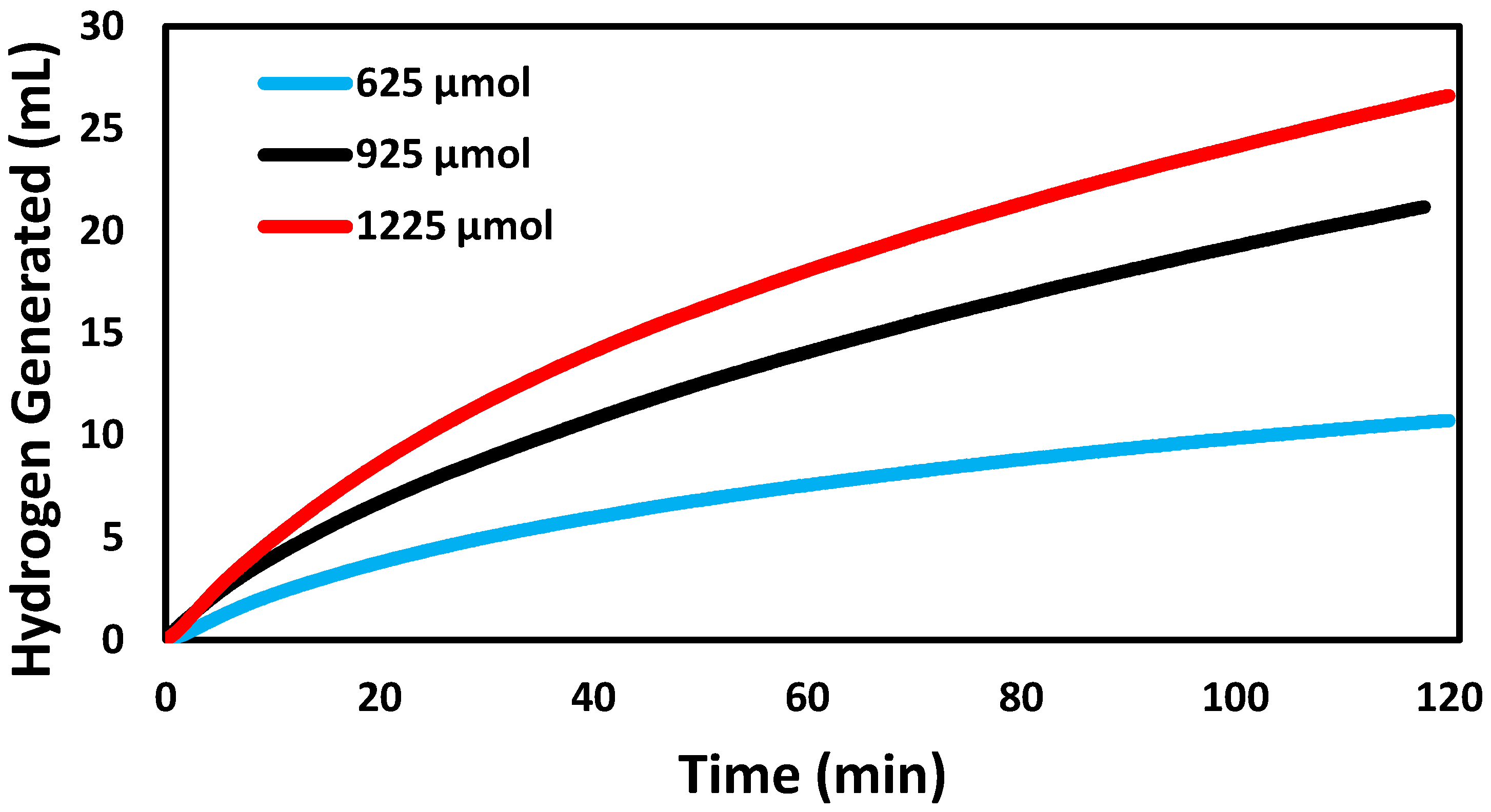

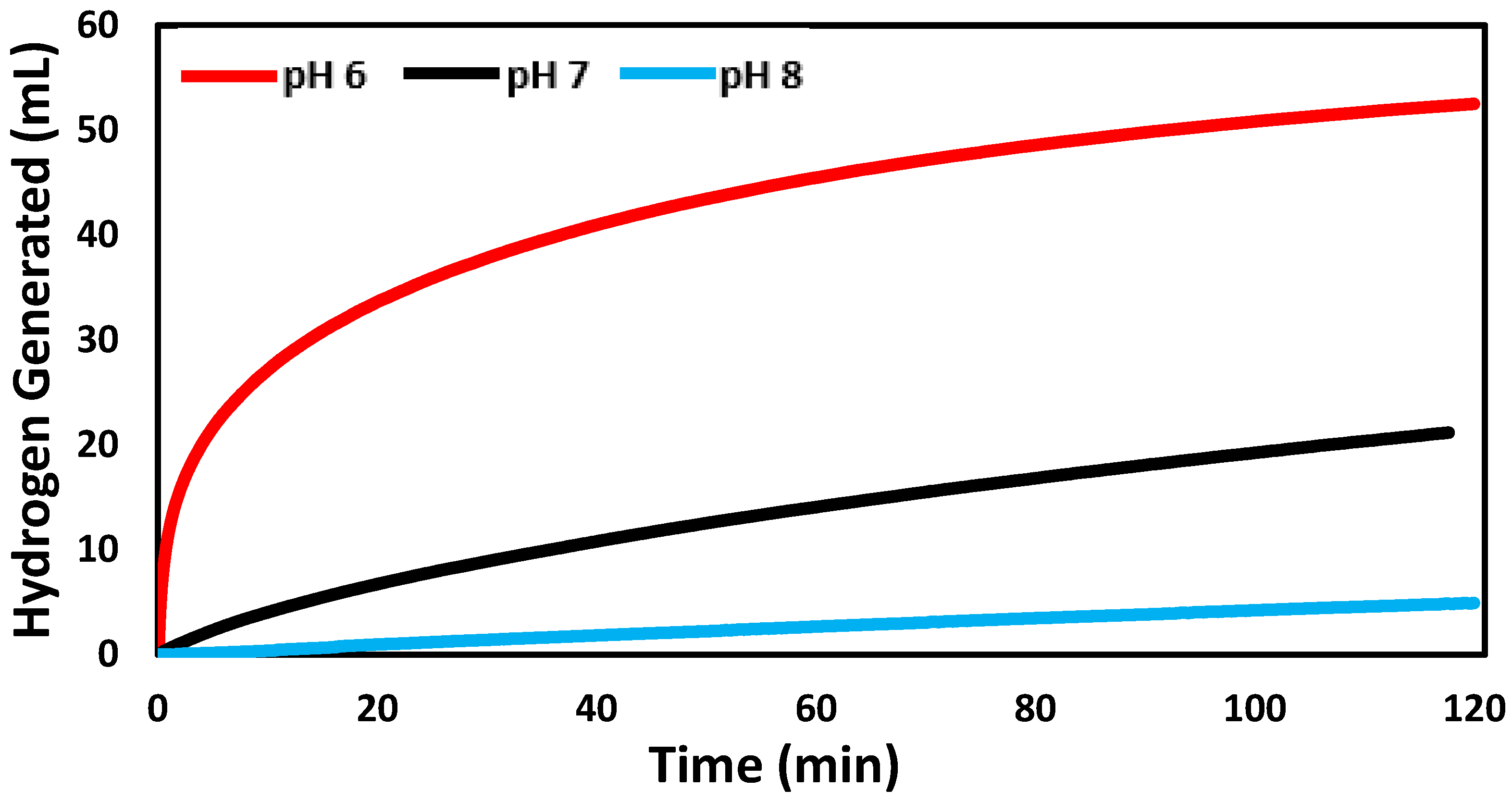

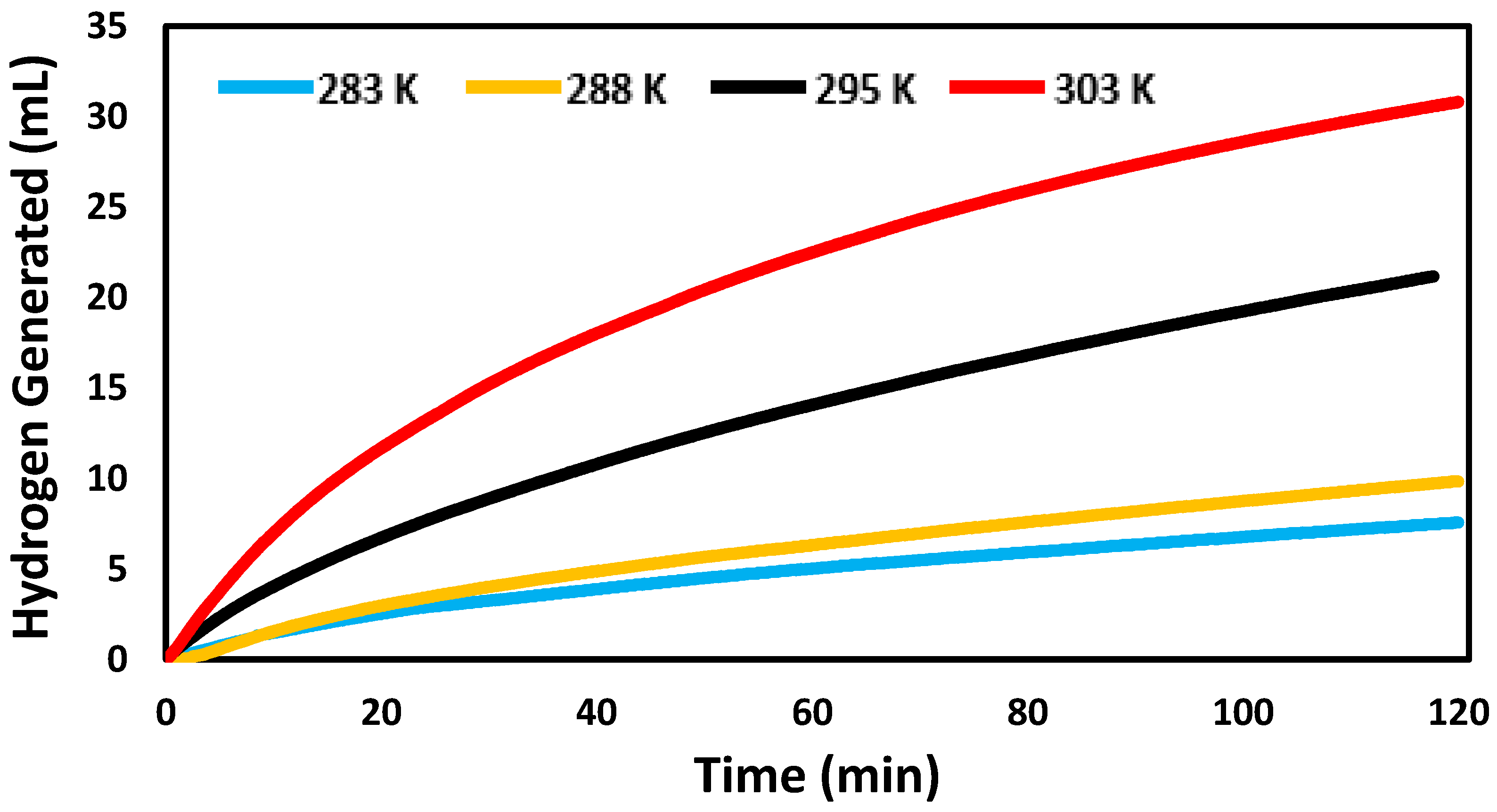

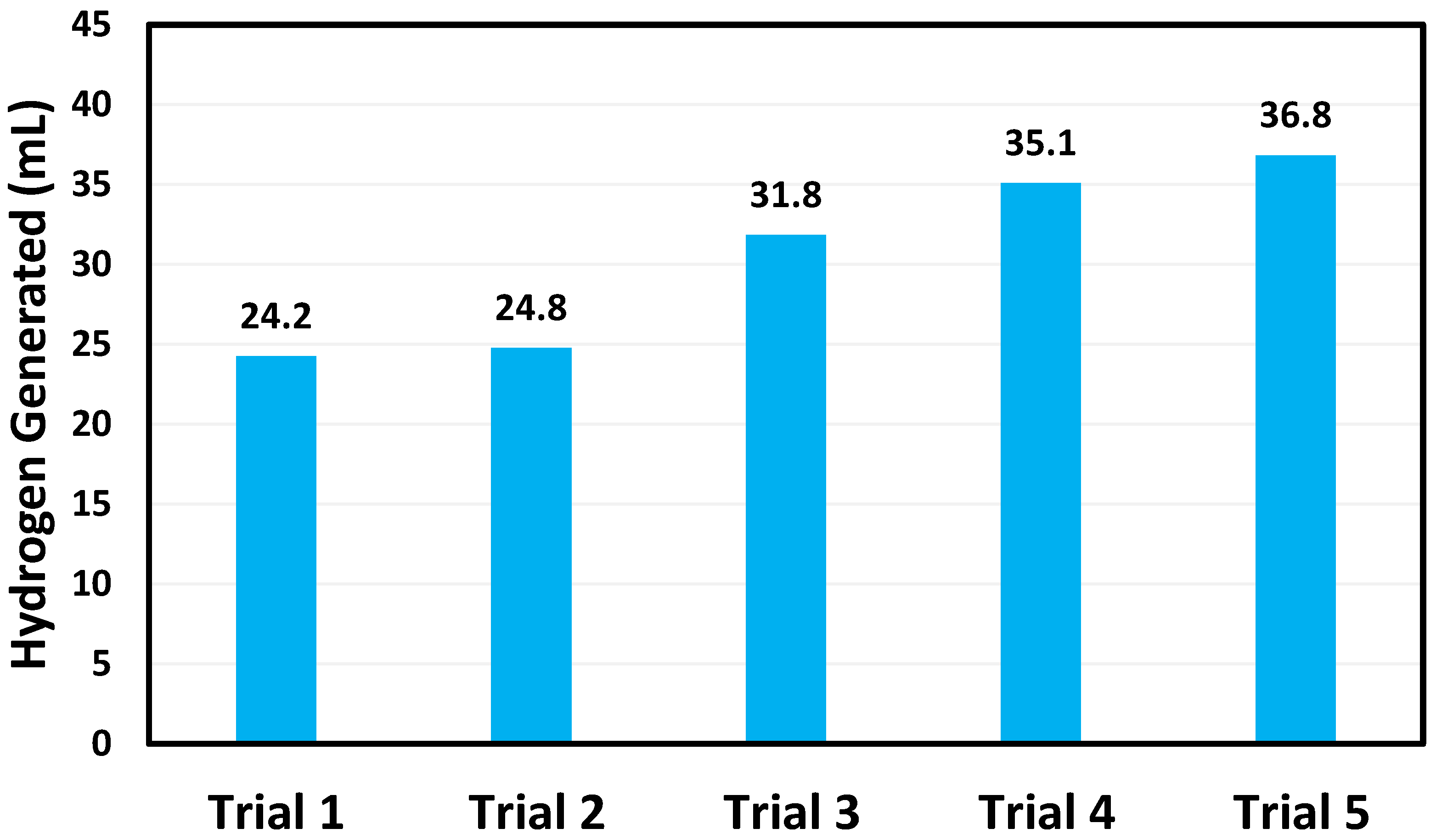

2.4. Catalysis

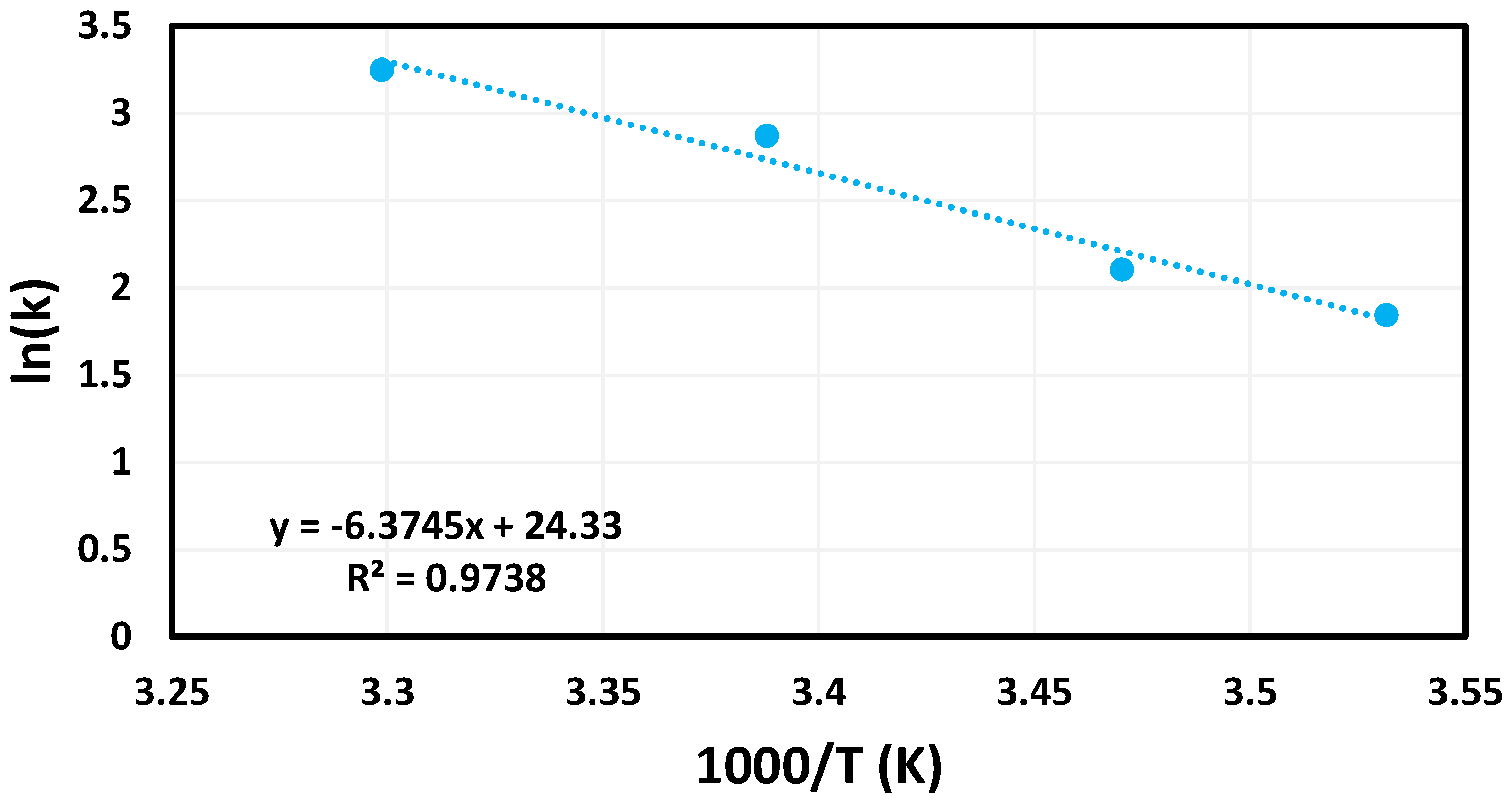

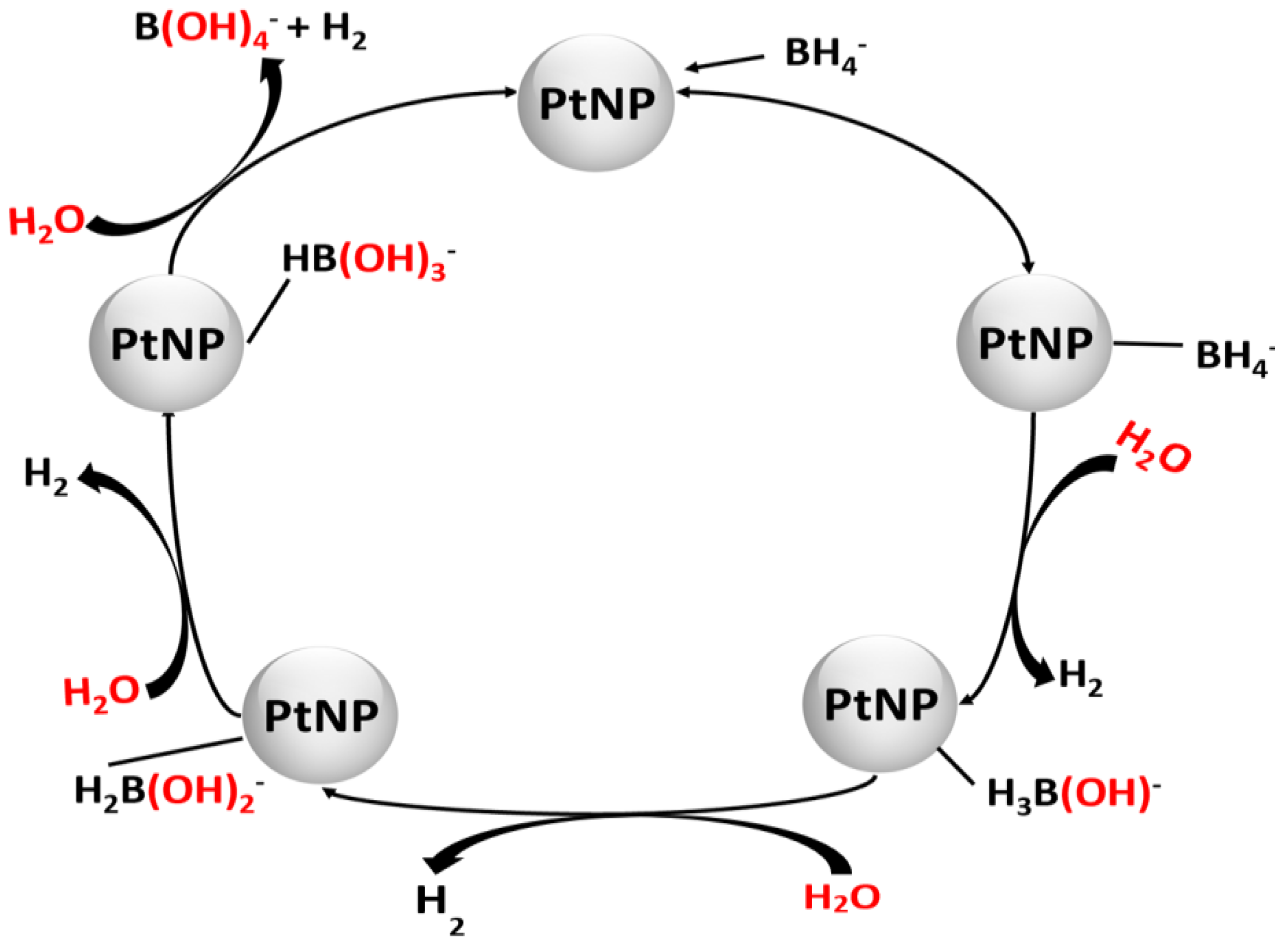

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ritchie, H.; Roser, M. Energy-Our World in Data. 2014. Available online: https://ourworldindata.org/energy (accessed on 14 November 2022).

- Rodhe, H.A. Comparison of the Contribution of Various Gases to the Greenhouse Effect. Science 1990, 248, 1217–1219. [Google Scholar] [CrossRef] [PubMed]

- Shafiee, S.; Topal, E. When Will Fossil Fuel Reserves Be Diminished? Energy Policy 2009, 37, 181–189. [Google Scholar] [CrossRef]

- Panwar, N.L.; Kaushik, S.C.; Kothari, S. Role of renewable energy sources in environmental protection: A review. Renew. Sustain. Energy Rev. 2011, 15, 1513–1524. [Google Scholar] [CrossRef]

- Tucker, M. Can solar cooking save the forests? Ecol. Econ. 1999, 31, 77–89. [Google Scholar] [CrossRef]

- Adamson, A.W.; Namnath, J.; Shastry, V.J.; Slawson, V. Thermodynamic inefficiency of conversion of solar energy to work. J. Chem. Educ. 1984, 61, 221. [Google Scholar] [CrossRef]

- Ottinger, R.L. Experience with promotion of renewable energy: Successes and lessons learned. In Proceedings of the Parliamentarian Forum on Energy Legislation and Sustainable Development, Cape Town, South Africa, 5–7 October 2005. [Google Scholar]

- US Government Accountability Office (GOA). Wind Power: Impacts on Wildlife and Government Responsibilities for Regulating Development and Protecting Wildlife; US Government Accountability Office: Washington, DC, USA, 2005. [Google Scholar]

- O’Doherty, T.; O’Doherty, D.M.; Mason-Jones, A. Tidal Energy Technology. In Wave Tidal Energy; John Wiley & Sons Ltd.: New York, NY, USA, 2018; pp. 105–150. [Google Scholar]

- Anderson, A.; Rezaie, B. Geothermal technology: Trends and potential role in a sustainable future. Appl. Energy 2019, 248, 18–34. [Google Scholar] [CrossRef]

- Li, K.; Bian, H.; Liu, C.; Zhang, D.; Yang, Y. Comparison of geothermal with solar and wind power generation systems. Renew. Sustain. Energy Rev. 2015, 42, 1464–1474. [Google Scholar] [CrossRef]

- Daut, I.; Razliana, A.R.N.; Irwan, Y.M.; Farhana, Z. A Study on the Wind as Renewable Energy in Perlis, Northern Malaysia. Energy Procedia 2012, 18, 1428–1433. [Google Scholar] [CrossRef]

- Kabir, E.; Kumar, P.; Kumar, S.; Adelodun, A.A.; Kim, K.-K. Solar energy: Potential and future prospects. Renew. Sustain. Energy Rev. 2018, 82, 894–900. [Google Scholar] [CrossRef]

- Bosnjakovic, M.; Sinaga, N. The Perspective of Large-Scale Production of Algae Biodiesel. Appl. Sci. 2020, 10, 8181. [Google Scholar] [CrossRef]

- Schlesinger, H.I.; Brown, H.C.; Finholt, E.; Gilbreath, J.R.; Hoekstra, H.R.; Hyde, E.K. Sodium Borohydride, Its Hydrolysis and its Use as a Reducing Agent and in the Generation of Hydrogen. J. Am. Chem. Soc. 1953, 75, 215–219. [Google Scholar] [CrossRef]

- Quach, Q.; Biehler, E.; Elzamzami, A.; Huff, C.; Long, J.M.; Abdel-Fattah, T.M. Catalytic Activity of Beta-Cyclodextrin-Gold Nanoparticles Network in Hydrogen Evolution Reaction. Catalysts 2021, 11, 118. [Google Scholar] [CrossRef]

- Huff, C.; Long, J.M.; Aboulatta, A.; Heyman, A.; Abdel-Fattah, T.M. Silver Nanoparticle/Multi-Walled Carbon Nanotube Composite as Catalyst for Hydrogen Production. ECS J. Solid State Sci. Technol. 2017, 6, M115–M118. [Google Scholar] [CrossRef]

- Huff, C.; Biehler, E.; Quach, Q.; Long, J.M.; Abdel-Fattah, T.M. Synthesis of Highly Dispersive Platinum Nanoparticles and their Application in a Hydrogen Generation Reaction. Colloids Surf. A Physicochem. Eng. Asp. 2021, 610, 125734. [Google Scholar] [CrossRef]

- Huff, C.; Long, J.M.; Heyman, A.; Abdel-Fattah, T.M. Palladium Nanoparticle Multiwalled Carbon Nanotube Composite as Catalyst for Hydrogen Production by the Hydrolysis of Sodium Borohydride. ACS Appl. Energy Mater. 2018, 1, 4635–4640. [Google Scholar] [CrossRef]

- Wittstock, A.; Neumann, B.; Schaefer, A.; Dumbuya, K.; Kübel, C.; Biener, M.M.; Zielasek, V.; Steinrück, H.P.; Gottfried, J.P.; Biener, J.; et al. Nanoporous Au: An Unsupported Pure Gold Catalyst? J. Phys. Chem. C 2009, 113, 5593–5600. [Google Scholar] [CrossRef]

- Li, Z.; Fu, J.-Y.; Feng, Y.; Dong, C.-K.; Liu, H.; Du, X.-W. A silver catalyst activated by stacking faults for the hydrogen evolution reaction. Nat. Catal. 2019, 2, 1107–1114. [Google Scholar] [CrossRef]

- Periana, R.A.; Taube, D.J.; Gamble, S.; Taube, H.; Satoh, T.; Fujii, H. Platinum Catalysts for the High-Yield Oxidation of Methane to a Methanol Derivative. Science 1998, 280, 560–564. [Google Scholar] [CrossRef]

- Xia, R.; Zhang, S.; Ma, X.; Jiao, F. Surface-Functionalized Palladium Catalysts for Electrochemical CO2 Reduction. J. Mater. Chem. A 2020, 8, 15884–15890. [Google Scholar] [CrossRef]

- Dushatinski, T.; Huff, C.; Abdel-Fattah, T.M. Characterization of electrochemically deposited films from aqueous and ionic liquid cobalt precursors toward hydrogen evolution reactions. Appl. Surf. Sci. 2016, 385, 282–288. [Google Scholar] [CrossRef]

- Osborne, J.; Horton, M.R.; Abdel-Fattah, T.M. Gold Nanoparticles Supported Over Low-Cost Supports for Hydrogen Generation from a Hydrogen Feedstock Material. ECS J. Solid State Sci. Technol. 2020, 9, 071004. [Google Scholar] [CrossRef]

- Huff, C.; Dushatinski, T.; Barzanjii, A.; Abdel-Fattah, N.; Barzanjii, K.; Abdel-Fattah, T.M. Pretreatment of gold nanoparticle multi-walled carbon nanotube composites for catalytic activity toward hydrogen generation reaction. ECS J. Solid State Sci. Technol. 2017, 6, M69–M71. [Google Scholar] [CrossRef]

- Nandanapalli, K.R.; Mudusu, D.; Lee, S. Defects-free single-crystalline zinc oxide nanostructures for efficient photoelectrochemical solar hydrogen generation. Int. J. Hydrogen Energy 2020, 45, 27279–27290. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, A.; Kumar, A.; Krishnan, V. Nanoscale zinc oxide based heterojunctions as visible light active photocatalysts for hydrogen energy and environmental remediation. Catal. Rev.-Sci. Eng. 2019, 62, 346–405. [Google Scholar] [CrossRef]

- Gao, Z.; Chen, K.; Wang, L.; Bai, B.; Liu, H.; Wang, Q. Aminated flower-like ZnIn2S4 coupled with benzoic acid modified g-C3N4 nanosheets via covalent bonds for ameliorated photocatalytic hydrogen generation. Appl. Catal. B 2020, 268, 118462. [Google Scholar] [CrossRef]

- Quach, Q.; Abdel-Fattah, T.M. Silver Nanoparticles functionalized Nanoporous Silica Nanoparticle grown over Graphene Oxide for enhancing Antibacterial effect. Nanomaterials 2022, 12, 3341. [Google Scholar] [CrossRef]

- Biehler, E.; Whiteman, R.; Lin, P.; Zhang, K.; Baumgart, H.; Abdel-Fattah, T.M. Controlled Synthesis of ZnO Nanorods Using Different Seed Layers. ECS J. Solid State Sci. Technol. 2020, 9, 121008. [Google Scholar] [CrossRef]

- Dushatinski, T.; Abdel-Fattah, T.M. Carbon Nanotube Composite Mesh Film with Tunable Optoelectronic Performance. ECS J. Solid State Sci. Technol. 2015, 4, M1–M5. [Google Scholar] [CrossRef]

- Abdel-Fattah, T.M.; Wixtrom, A.; Zhang, K.; Baumgart, H. Highly Uniform Self-Assembled Gold Nanoparticles over High Surface Area Dense ZnO Nanorod Arrays as Novel Surface Catalysts ECS J. Solid State Sci. Technol. 2014, 3, M61–M64. [Google Scholar] [CrossRef]

- Abdel-Fattah, T.M.; Wixtrom, A. Catalytic Reduction of 4-Nitrophenol Using Gold Nanoparticles Supported On Carbon Nanotubes. ECS J. Solid State Sci. Technol. 2014, 3, M18–M20. [Google Scholar] [CrossRef]

- Sabourault, N.; Mignani, G.; Wagner, A.; Mioskowski, C. Platinum Oxide (PtO2): A Potent Hydrosilylation Catalyst. Org. Lett. 2002, 4, 2117–2119. [Google Scholar] [CrossRef]

- Ely, J.C.; Neal, C.R.; Kulpa, C.F.; Schneegurt, M.A.; Seidler, J.A.; Jain, J.C. Implications of Platinum-Group Element Accumulation along U.S. Roads from Catalytic-Converter Attrition. Envir. Sci. Technol. 2001, 35, 3816–3822. [Google Scholar] [CrossRef] [PubMed]

- Abu-Reziq, R.; Wang, D.; Post, M.; Alper, H. Platinum Nanoparticles Supported on Ionic Liquid-Modified Magnetic Nanoparticles: Selective Hydrogenation Catalysts. Adv. Synth. Catal. 2007, 349, 2145–2150. [Google Scholar] [CrossRef]

- Fang, B.; Chaudhari, N.K.; Kim, M.-S.; Kim, J.H.; Yu, J.-S. Homogeneous Deposition of Platinum Nanoparticles on Carbon Black for Proton Exchange Membrane Fuel Cell. J. Am. Chem. Soc. 2009, 131, 15330–15338. [Google Scholar] [CrossRef] [PubMed]

- Huff, C.; Quach, Q.; Long, J.M.; Abdel-Fattah, T.M. Nanocomposite Catalyst Derived from Ultrafine Platinum Nanoparticles and Carbon Nanotubes for Hydrogen Generation. ECS J. Solid State Sci. Technol. 2020, 9, 101008. [Google Scholar] [CrossRef]

- Liu, J.; Zhou, Z.; Zhao, X.; Xin, Q.; Sun, G.; Yi, B. Studies on Performance Degradation of a Direct Methanol Fuel Cell (DMFC) in Life Test. Phys. Chem. Chem. Phys. 2004, 6, 134–137. [Google Scholar] [CrossRef]

- Zhu, Y.; Murali, S.; Cai, W.; Li, X.; Suk, J.W.; Potts, J.R.; Ruoff, R.S. Graphene and Graphene Oxide: Synthesis, Properties, and Applications. Adv. Mater. 2010, 22, 3906–3924. [Google Scholar] [CrossRef]

- Li, K.; Liu, Q.; Cheng, H.; Hu, M.; Zhang, S. Classification and carbon structural transformation from anthracite to natural coaly graphite by XRD, Raman spectroscopy, and HRTEM. Spectrochim. Acta A 2020, 249, 119286. [Google Scholar] [CrossRef]

- Kaufman, C.M.; Sen, B. Hydrogen generation by hydrolysis of sodium tetrahydroborate: Effects of acids and transition metals and their salts. J. Chem. Soc. Dalton Trans. 1985, 2, 307–313. [Google Scholar] [CrossRef]

- Narasimharao, K.; Abu-Zied, B.M.; Alfaifi, S.Y. Cobalt oxide supported multi wall carbon nanotube catalysts for hydrogen production via sodium borohydride hydrolysis. Int. J. Hydrogen Energy 2020, 46, 6404–6418. [Google Scholar] [CrossRef]

- Saka, C.; Salih Eygi, M.; Balbay, A. CoB doped acid modified zeolite catalyst for enhanced hydrogen release from sodium borohydride hydrolysis. Int. J. Hydrogen Energy 2020, 45, 15086–15099. [Google Scholar] [CrossRef]

- Lin, K.-Y.A.; Chang, H.-A. Efficient hydrogen production from NaBH4 hydrolysis catalyzed by a magnetic cobalt/carbon composite derived from a zeolitic imidazolate framework. Chem. Eng. J. 2016, 296, 243–251. [Google Scholar] [CrossRef]

- Peña-Alonso, R.; Sicurelli, A.; Callone, E.; Carturan, G.; Raj, R. A picoscale catalyst for hydrogen generation from NaBH4 for fuel cells. J. Power Sources 2007, 165, 315–323. [Google Scholar] [CrossRef]

- Huff, C.; Dushatinski, T.; Abdel-Fattah, T.M. Gold Nanoparticle/Multi-Walled Carbon Nanotube Composite as Novel Catalyst for Hydrogen Evolution Reactions. Int. J. Hydrogen Energy 2017, 42, 18985–18990. [Google Scholar] [CrossRef]

- Biehler, E.; Quach, Q.; Huff, C.; Abdel-Fattah, T.M. Organo-Nanocups Assist the Formation of Ultra-Small Palladium Nanoparticle Catalysts for Hydrogen Evolution Reaction. Materials 2022, 15, 2692. [Google Scholar] [CrossRef] [PubMed]

- Huff, C.; Long, J.M.; Abdel-Fattah, T.M. Beta-Cyclodextrin Assisted Synthesis of Silver Nanoparticle Network and its Application in a Hydrogen Generation Reaction. Catalysts 2020, 10, 1014. [Google Scholar] [CrossRef]

- Biehler, E.; Quach, Q.; Abdel-Fattah, T.M. Silver Nanoparticle-Decorated Fused Carbon Sphere Composite as a Catalyst for Hydrogen Generation. Energies 2023, 16, 5053. [Google Scholar] [CrossRef]

- Guella, G.; Patton, B.; Miotello, A. Kinetic Features of the Platinum Catalyzed Hydrolysis of Sodium Borohydride from 11B NMR Measurements. J. Phys. Chem. C 2007, 111, 18744–18750. [Google Scholar] [CrossRef]

- Zhang, H.; Feng, X.; Cheng, L.; Hou, X.; Li, Y.; Han, S. Non-noble Co anchored on nanoporous graphene oxide, as an efficient and long-life catalyst for hydrogen generation from sodium borohydride. Colloids Surf. 2018, 563, 112–119. [Google Scholar] [CrossRef]

- Deraedt, C.; Salmon, L.; Gatard, S.; Ciganda, R.; Hernandez, E.; Ruiz, J.; Astruc, D. Sodium borohydride stabilizes very active gold nanoparticle catalysts. Chem. Commun. 2014, 50, 14194–14196. [Google Scholar] [CrossRef]

- Fang, Y.; Zhang, J.; Hua, M.Y.; Zhou, D.W. Modifying effects and mechanisms of graphene on dehydrogenation properties of sodium borohydride. J. Mater. Sci. 2020, 55, 1959–1972. [Google Scholar] [CrossRef]

| Catalyst | Ea (kJ mol−1) | Temperature (K) | Reference |

|---|---|---|---|

| Ni | 71 | 273–308 | [43] |

| Raney-Nickel | 63 | 273–308 | [43] |

| Co | 75 | 273–308 | [43] |

| Co/MWCNTs | 63.8 | 303–318 | [44] |

| CoB-zeolite-HCl | 42.5 | 293–323 | [45] |

| MCCC | 64.3 | 303 | [46] |

| Pt–Pd/CNTs | 19 | 302–332 | [47] |

| Au/MWCNTs | 21.1 | 273–303 | [48] |

| Ag/MWCNTs | 44.5 | 273–303 | [17] |

| Pd/MWCNTs | 62.7 | 273–303 | [19] |

| BCD-AuNP | 54.7 | 283–303 | [16] |

| PtNPs | 39.2 | 283–303 | [18] |

| Pd Nanocup | 58.9 | 283–303 | [49] |

| AgNPs | 50.3 | 273–303 | [50] |

| AgNP-FCS | 37.0 | 273–303 | [51] |

| Pt/C | 45 | 298–313 | [52] |

| PGO | N/A | 298 | [53] |

| PtFCS | 53.0 | 283–303 | This Work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Biehler, E.; Quach, Q.; Abdel-Fattah, T.M. Synthesis of Platinum Nanoparticles Supported on Fused Nanosized Carbon Spheres Derived from Sustainable Source for Application in a Hydrogen Generation Reaction. Nanomaterials 2023, 13, 1994. https://doi.org/10.3390/nano13131994

Biehler E, Quach Q, Abdel-Fattah TM. Synthesis of Platinum Nanoparticles Supported on Fused Nanosized Carbon Spheres Derived from Sustainable Source for Application in a Hydrogen Generation Reaction. Nanomaterials. 2023; 13(13):1994. https://doi.org/10.3390/nano13131994

Chicago/Turabian StyleBiehler, Erik, Qui Quach, and Tarek M. Abdel-Fattah. 2023. "Synthesis of Platinum Nanoparticles Supported on Fused Nanosized Carbon Spheres Derived from Sustainable Source for Application in a Hydrogen Generation Reaction" Nanomaterials 13, no. 13: 1994. https://doi.org/10.3390/nano13131994

APA StyleBiehler, E., Quach, Q., & Abdel-Fattah, T. M. (2023). Synthesis of Platinum Nanoparticles Supported on Fused Nanosized Carbon Spheres Derived from Sustainable Source for Application in a Hydrogen Generation Reaction. Nanomaterials, 13(13), 1994. https://doi.org/10.3390/nano13131994