Co-Influence of Nanofiller Content and 3D Printing Parameters on Mechanical Properties of Thermoplastic Polyurethane (TPU)/Halloysite Nanotube (HNT) Nanocomposites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

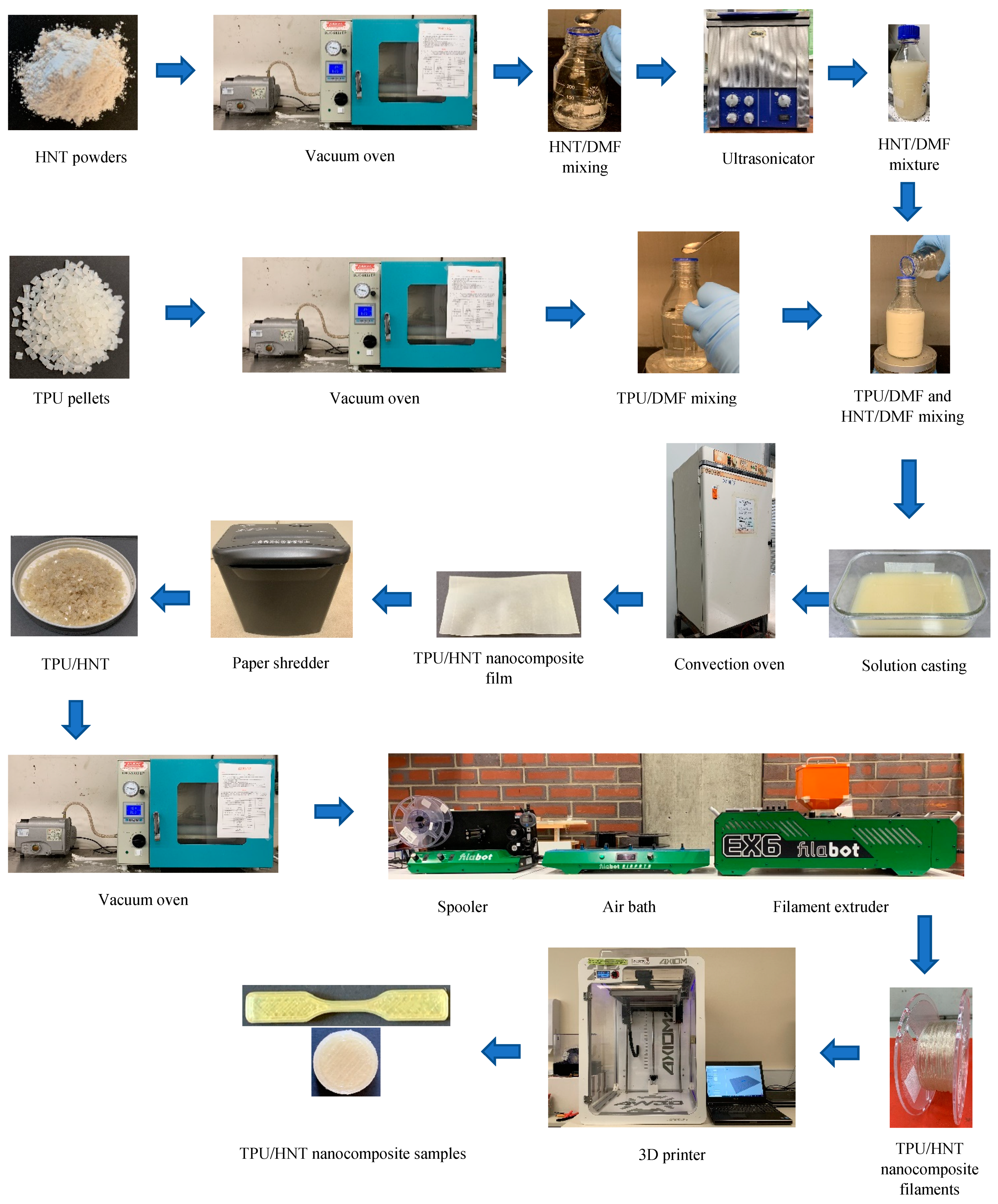

2.2. Preparation of TPU/HNT Nanocomposites

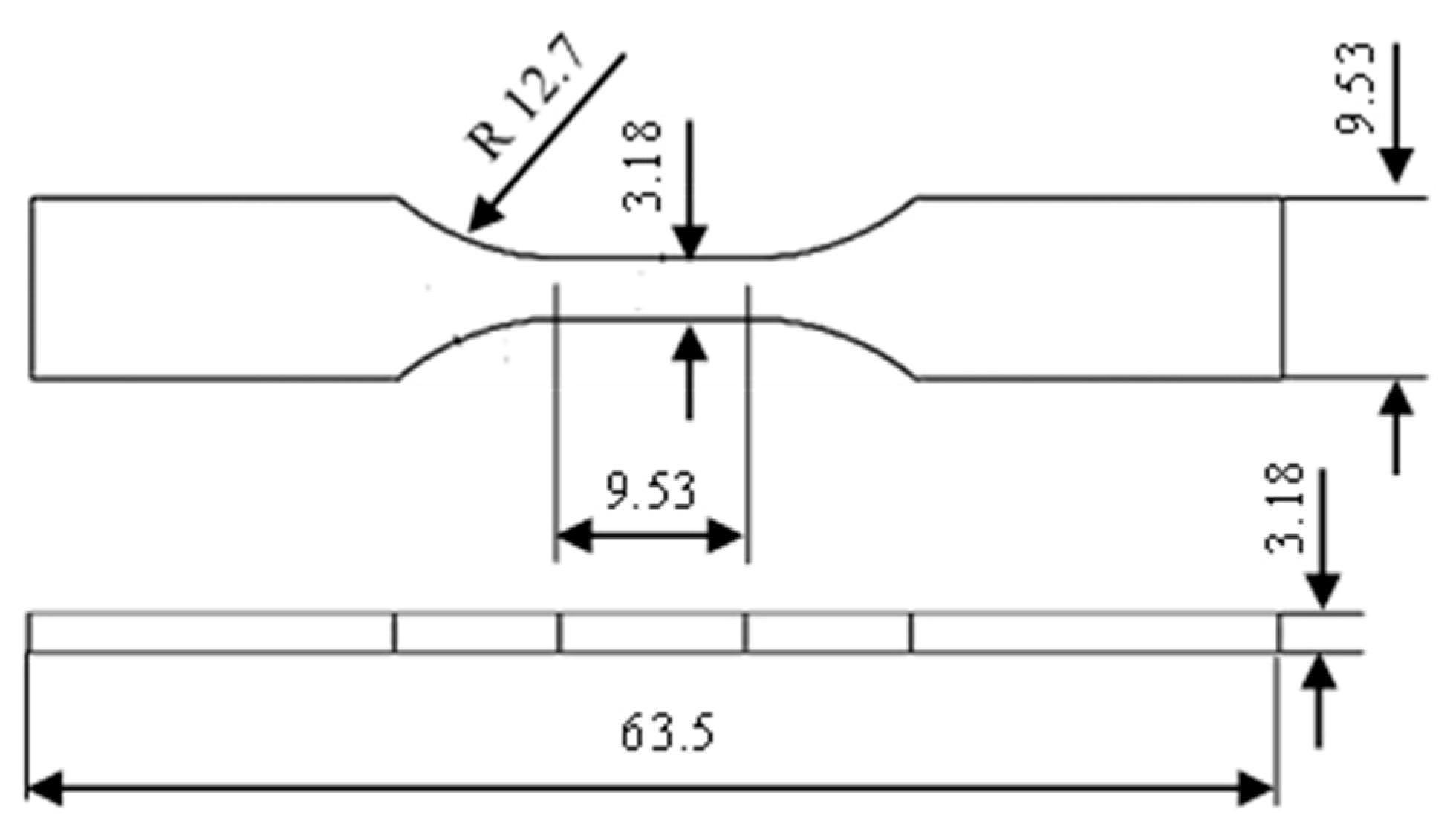

2.3. Mechanical Testing

2.4. Material Characterisation

3. Statistical Analysis

4. Results and Discussion

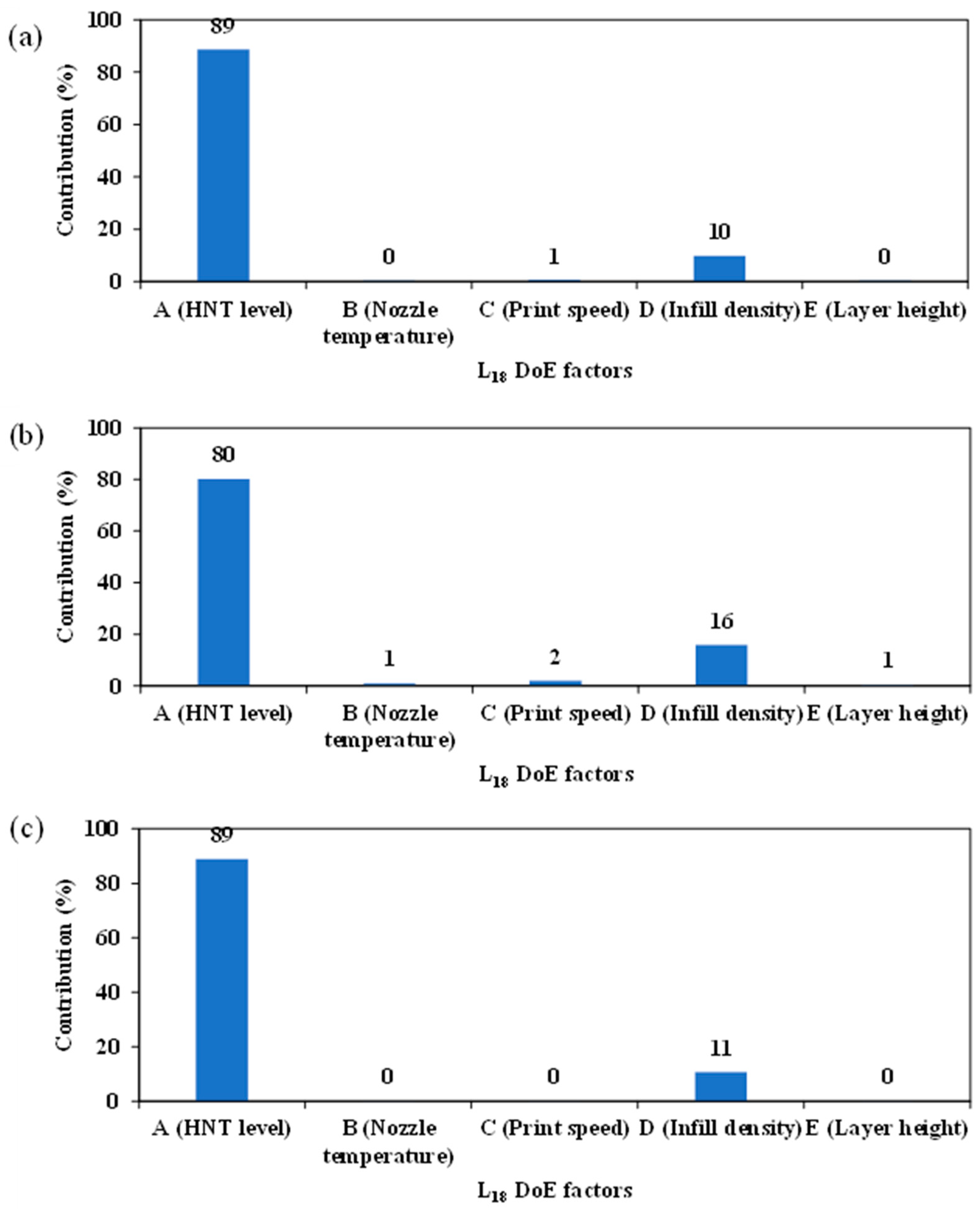

4.1. Tensile Properties

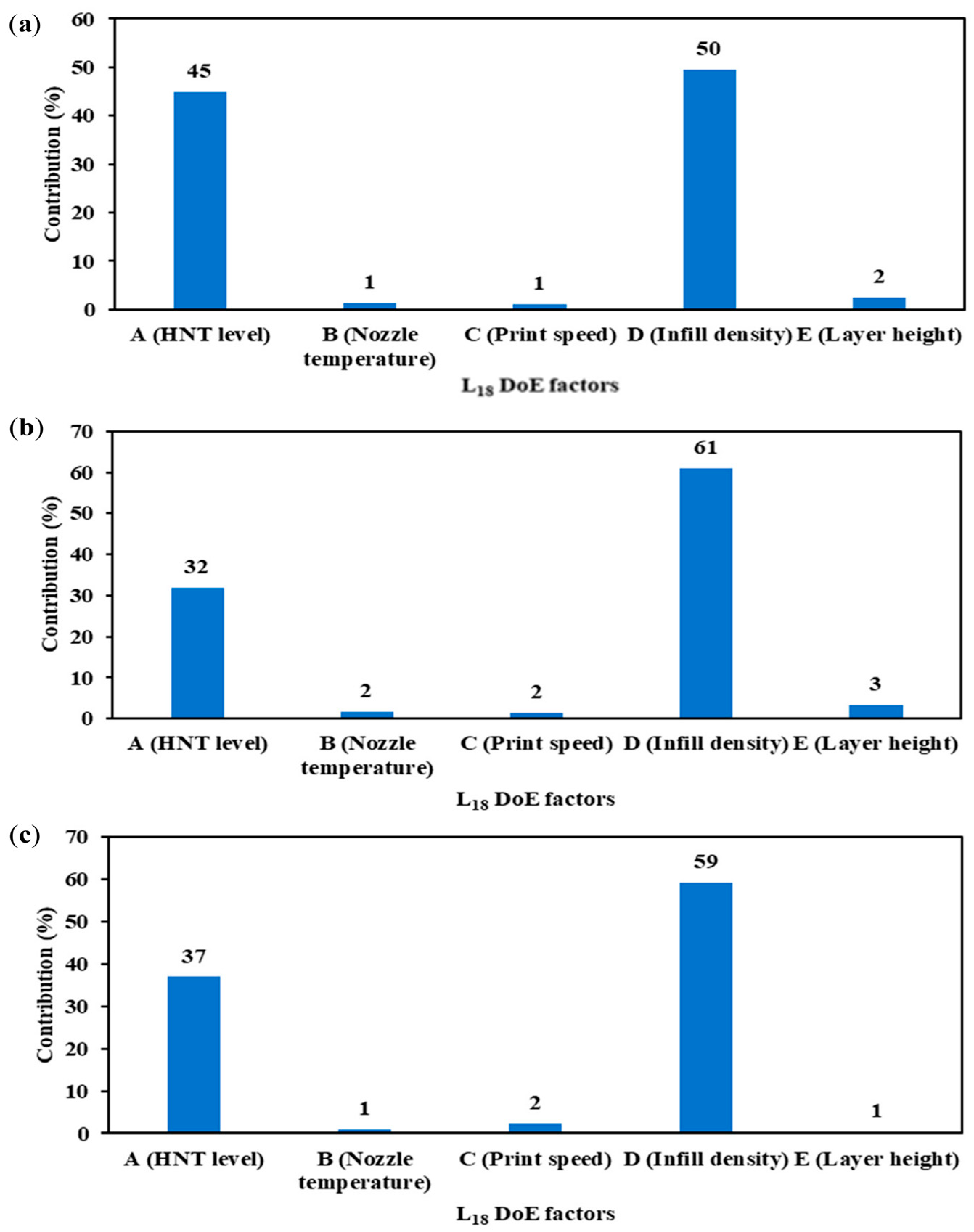

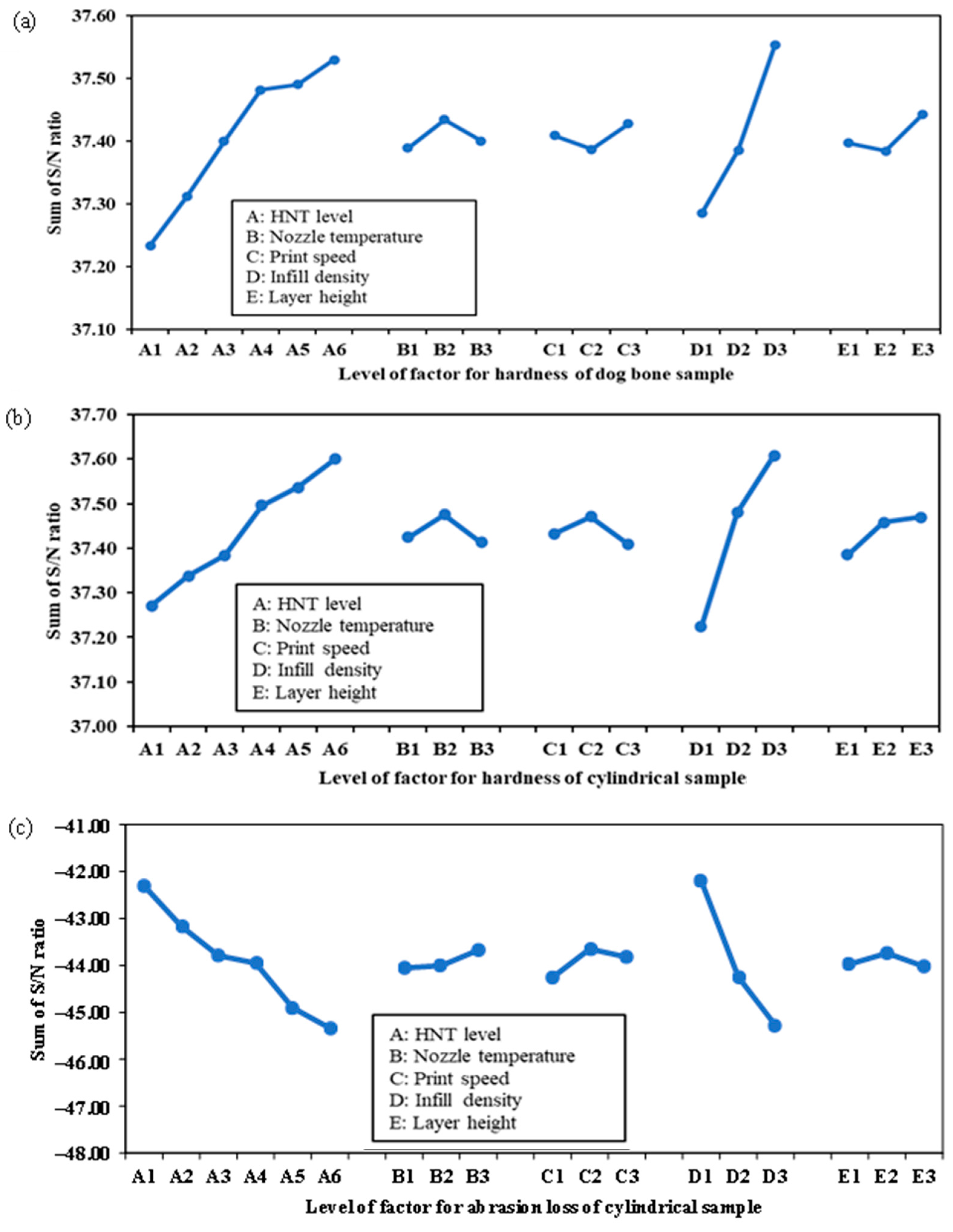

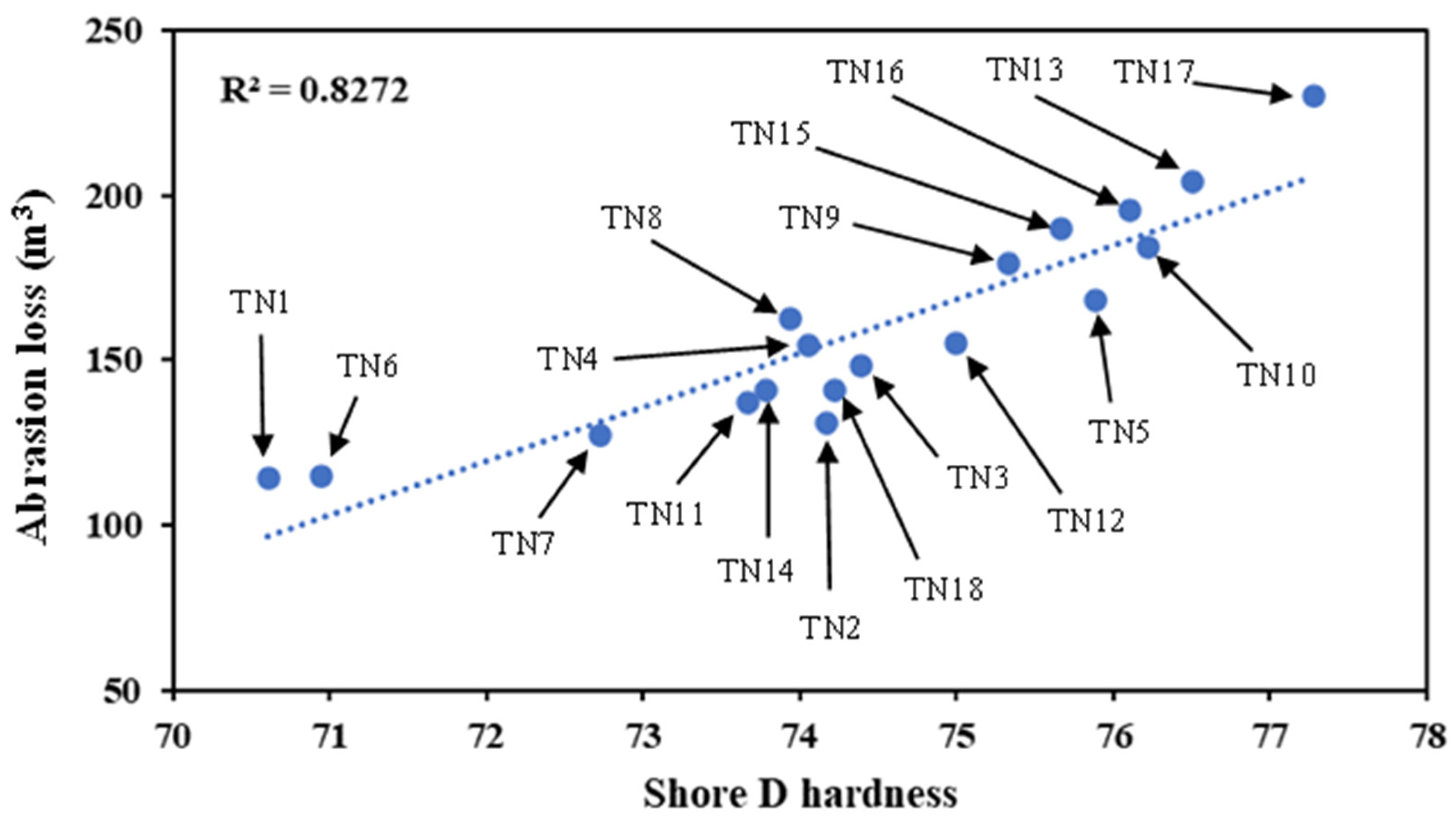

4.2. Hardness and Abrasion Resistance

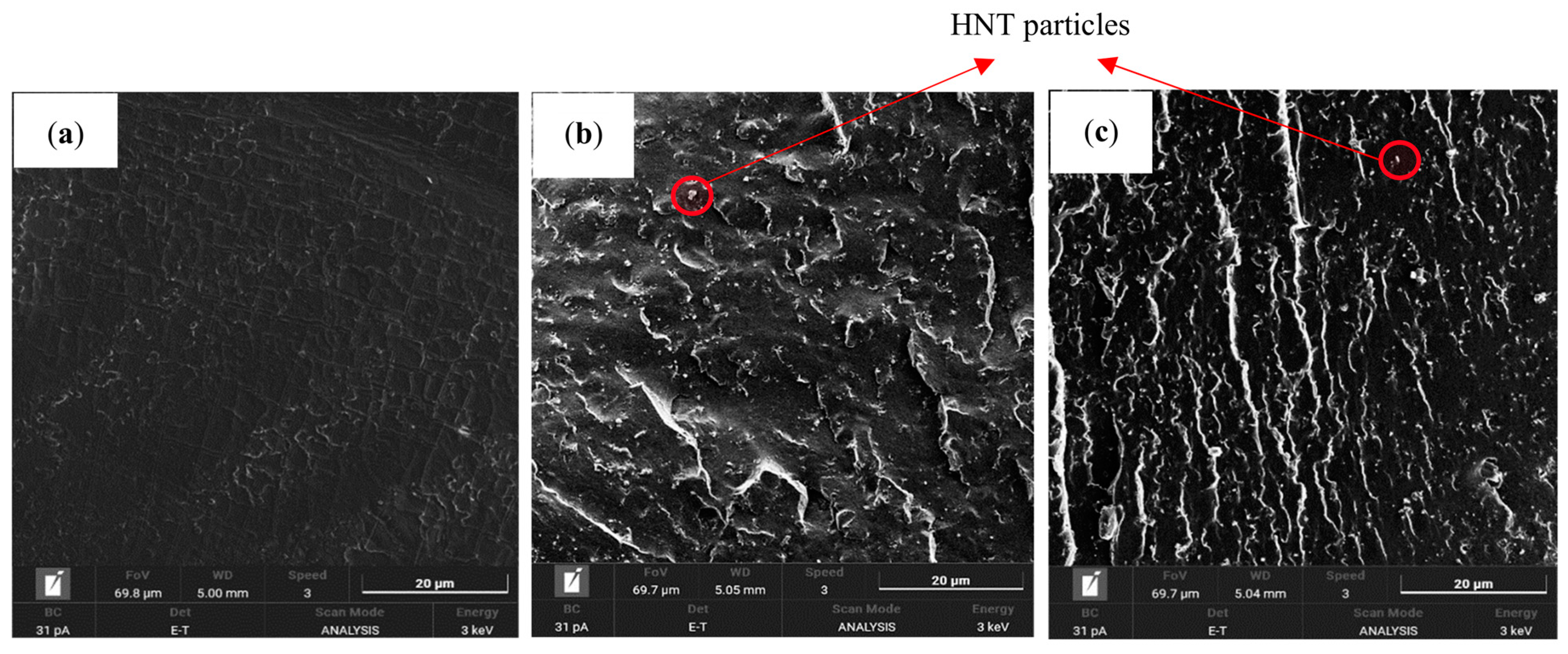

4.3. Morphology of TPU/HNT Nanocomposites

4.4. FTIR Analysis

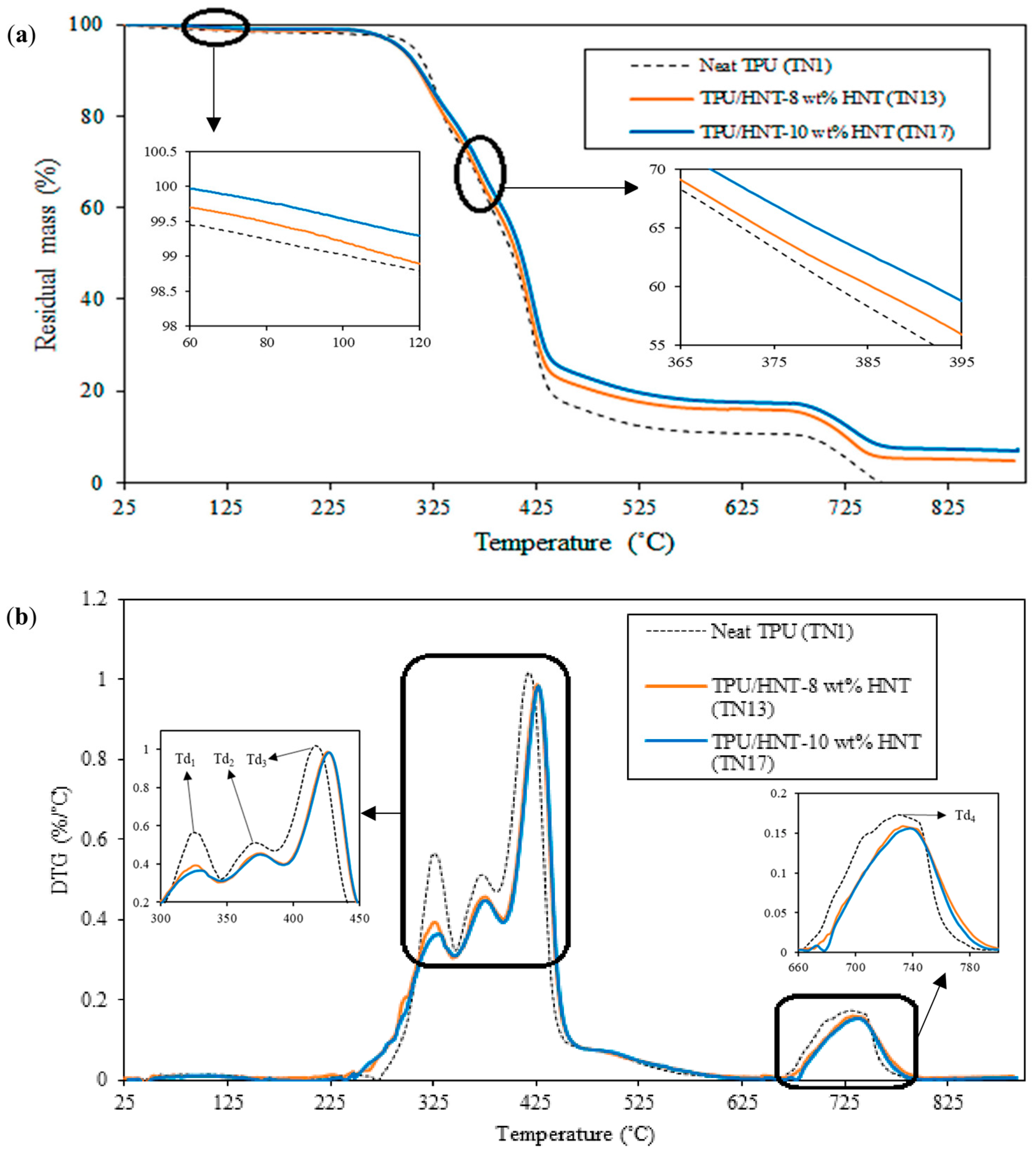

4.5. Thermal Stability

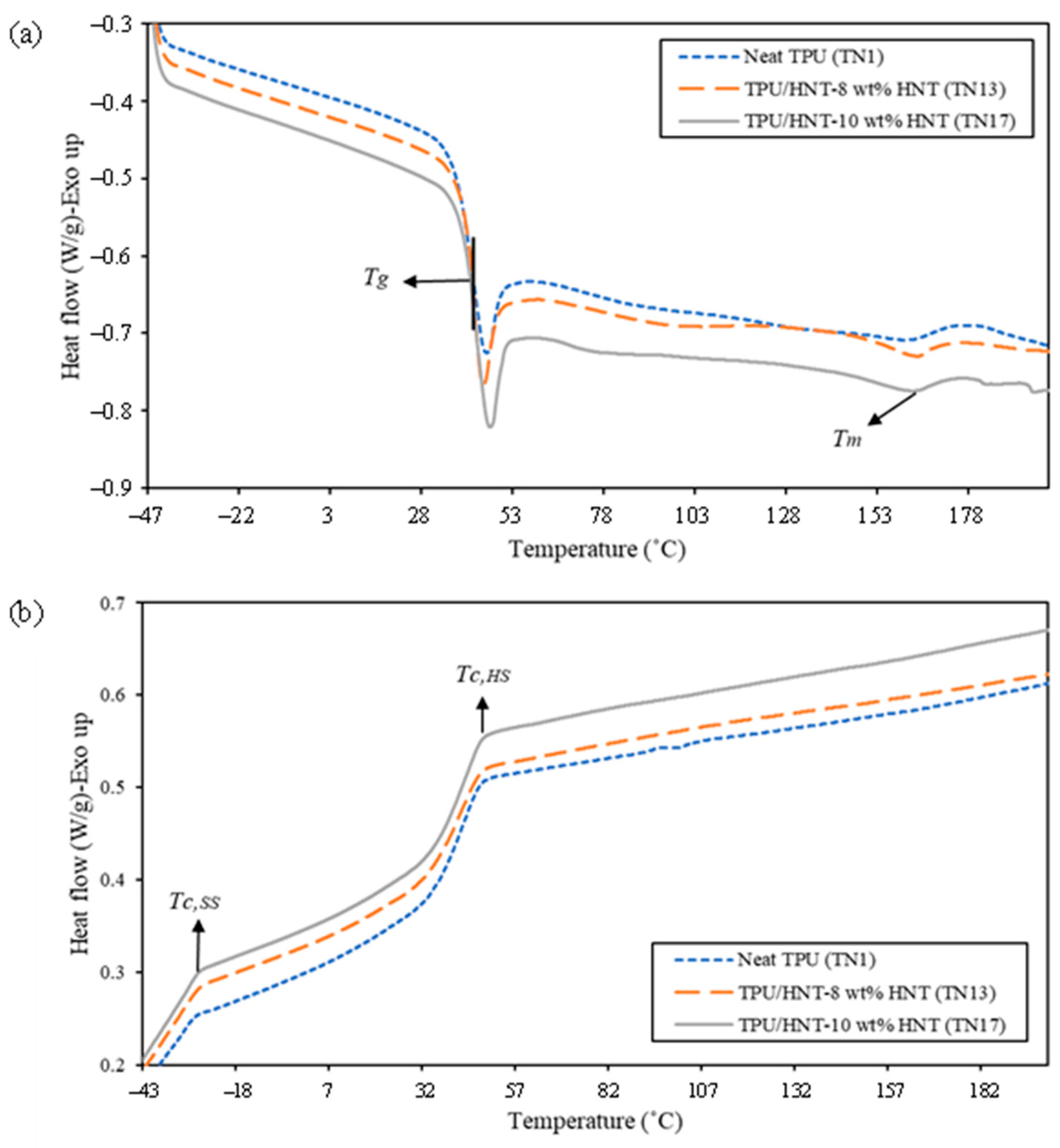

4.6. DSC Measurements

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- He, Y.; Xie, D.; Zhang, X. The structure, microphase-separated morphology, and property of polyurethanes and polyureas. J. Mater. Sci. 2014, 49, 7339–7352. [Google Scholar] [CrossRef]

- Driffield, M.; Bradley, E.L.; Castle, L. A method of test for residual isophorone diisocyanate trimer in new polyester–polyurethane coatings on light metal packaging using liquid chromatography with tandem mass spectrometric detection. J. Chromatogr. A 2007, 1141, 61–66. [Google Scholar] [CrossRef] [PubMed]

- Hernandez, R.; Weksler, J.; Padsalgikar, A.; Runt, J. In vitro oxidation of high polydimethylsiloxane content biomedical polyurethanes: Correlation with the microstructure. J. Biomedl. Mater. Rese A 2008, 87, 546–556. [Google Scholar] [CrossRef] [PubMed]

- Aneja, A.; Wilkes, G.L.; Rightor, E.G. Study of slabstock flexible polyurethane foams based on varied toluene diisocyanate isomer ratios. J. Polym. Sci. Part B Polym. Phys. 2003, 41, 258–268. [Google Scholar] [CrossRef]

- Chen, Q.; Mangadlao, J.D.; Wallat, J.; De Leon, A.; Pokorski, J.K.; Advincula, R.C. 3D printing biocompatible polyurethane/poly(lactic acid)/graphene oxide nanocomposites: Anisotropic properties. ACS Appl. Mater. Interfaces 2017, 9, 4015–4023. [Google Scholar] [CrossRef] [PubMed]

- Tao, Y.; Shao, J.; Li, P.; Shi, S.Q. Application of a thermoplastic polyurethane/polylactic acid composite filament for 3D-printed personalized orthosis. Mater. Teh. 2019, 53, 71–76. [Google Scholar] [CrossRef]

- Joo, H.; Cho, S. Comparative studies on polyurethane composites filled with polyaniline and graphene for DLP-type 3D printing. Polymers 2020, 12, 67. [Google Scholar] [CrossRef] [Green Version]

- Lathers, S.; La Belle, J. Additive manufactured biomimicking actuator with shape memory polymer composite for prosthetic actuators. 3D Print. Addit. Manuf. 2017, 4, 201–213. [Google Scholar] [CrossRef]

- Christ, J.F.; Hohimer, C.J.; Aliheidari, N.; Ameli, A.; Mo, C.; Potschke, P. 3D printing of highly elastic strain sensors using polyurethane/multiwall carbon nonotube composites. Proceeding SPIE 2017, 10168, 70–76. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Z.; Gan, X.; Fu, D.; Fei, G.; Xia, H. Selective laser sintering 3D printing: A way to Construct 3D electrically conductive segregated network in polymer matrix. Macromol. Mater. Eng. 2017, 302, 1700211. [Google Scholar] [CrossRef]

- Tzounis, L.; Petousis, M.; Grammatikos, S.; Vidakis, N. 3D printed thermoelectric polyurethane/multiwalled carbon nanotube nanocomposites: A novel approach towards the fabrication of flexible and stretchable organic thermoelectrics. Materials 2020, 13, 2879. [Google Scholar] [CrossRef] [PubMed]

- Petrovic, Z.S.; Ferguson, J. Polyurethane elastomers. Prog. Polym. Sci. 1991, 16, 695–836. [Google Scholar] [CrossRef]

- Xiang, D.; Zhang, X.; Li, Y.; Harkin-Jones, E.; Zheng, Y.; Wang, L.; Zhao, C.; Wang, P. Enhanced performance of 3D printed highly elastic strain sensors of carbon nanotube/thermoplastic polyurethane nanocomposites via non-covalent interactions. Compos. B Eng. 2019, 176, 107250. [Google Scholar] [CrossRef]

- Kandiyil, J.; Vasudevan, S.; Athiyanathil, S. Efficient selective methylene blue adsorption by polyurethane/montmorillonite-based antifouling electrospun composite membranes. J. Appl. Polym. Sci. 2022, 140, e53464. [Google Scholar] [CrossRef]

- Maamoun, A.; El-Wakil, A.; El-Basheer, T.M. Enhancement of the mechanical and acoustical properties of flexible polyurethane foam/waste seashell composites for industrial applications. J. Cell. Plast. 2022, 58, 645–672. [Google Scholar] [CrossRef]

- Nugroho, W.T.; Dong, Y.; Pramanik, A. 3D printing composite materials: A comprehensive review. In Composite Materials: Manufacturing, Properties and Applications; Low, I.-M., Dong, Y., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 65–115. ISBN 9780128205129. [Google Scholar] [CrossRef]

- Murali, A.; Vakkattil, M.A.; Parameswaran, R. Investigating the effect of processing on mechanical behavior of 3D fused deposition modelling printed polylactic acid. J. Mater. Eng. Perform. 2023, 32, 1089–1102. [Google Scholar] [CrossRef]

- Airwolf3D. Download APEX 3D-Printing Software. 2019. Available online: https://airwolf3d.com/3d-printing-software/ (accessed on 25 June 2023).

- Makerbot Industries. The All-New Makerbot Print. 2021. Available online: www.makerbot.com/3d-printers/apps/makerbot-print/ (accessed on 25 June 2023).

- Ultimaker, B.V. Ultimaker Cura. 2021. Available online: https://ultimaker.com/software/ultimaker-cura/ (accessed on 25 June 2023).

- Kokcu, I.; Eryildiz, M.; Altan, M.; Ertugrul, M.I.; Odabas, S. Scaffold fabrication from drug loaded HNT reinforced polylactic acid by FDM for biomedical applications. Polym. Compos. 2022, 44, 2138–2152. [Google Scholar] [CrossRef]

- Lv, Q.; Peng, Z.; Meng, Y.; Pei, H.; Chen, Y.; Ivanaov, E.; Kotsilkova, R. Three-dimensional printing to fabricate graphene-modified polyolefin elastomer flexible composites with tailorable porous structures for Electromagnetic interference shielding and thermal management application. Ind. Eng. Chem. Res. 2022, 61, 16733–16746. [Google Scholar] [CrossRef]

- Ghaziof, S.; Shojaei, S.; Mehdikhani, M.; Khodaei, M.; Jafari Nodoushan, M. Electro-conductive 3D printed polycaprolactone/gold nanoparticles nanocomposite scaffolds for myocardial tissue engineering. J. Mech. Behav. Biomed. Mater. 2022, 132, 105271. [Google Scholar] [CrossRef]

- Mrowka, M.; Szymiczek, M.; Machoczek, T.; Pawlyta, M. Influence of the halloysite nanotube (HNT) addition on selected mechanical and biological properties of thermoplastic polyurethane. Materials 2021, 14, 3625. [Google Scholar] [CrossRef]

- Mahunaki, M.P.; Asl, V.H.; Mamaqani, H.R.; Koosha, M.; Yazdi, M. Halloysite-reinforced thermoplastic polyurethane nanocomposites: Physico-mechanical, rheological, and thermal investigations. Polym. Compos. 2020, 41, 3260–3270. [Google Scholar] [CrossRef]

- Prasanthi, I.; Bora, B.R.; Raidongia, K.; Datta, K.K.R. Fluorinated graphene nanosheet supported halloysite nanoarchitectonics: Super-wetting coatings for efficient and recyclable oil sorption. Sep. Purif. Technol. 2021, 301, 122049. [Google Scholar] [CrossRef]

- SMP Technologies. Shape Memory Polymer. 2021. Available online: http://www2.smptechno.com/en/smp/ (accessed on 25 June 2023).

- Imerys. Halloysite. 2021. Available online: https://www.imerys.com/minerals/halloysite (accessed on 25 June 2023).

- Du, M.; Guo, B.; Jia, D. Newly emerging applications of halloysite nanotubes: A review. Polym. Int. 2010, 59, 574–582. [Google Scholar] [CrossRef]

- Nugroho, W.T.; Dong, Y.; Pramanik, A.; Leng, J.; Ramakrishna, S. Smart polyurethane composites for 3D or 4D printing: General-purpose use, sustainability and shape memory effect. Compos Part B Eng. 2021, 223, 109104. [Google Scholar] [CrossRef]

- Bouaziz, R.; Prashantha, K.; Roger, F. Thermomechanical modeling of halloysite nanotube-filled shape memory polymer nanocomposites. Mech. Adv. Mater. Struct. 2019, 26, 1209–1217. [Google Scholar] [CrossRef]

- Rosales, C.A.G.; Duarte, M.F.G.; Kim, H.; Chavez, L.; Hodges, D.; Mandal, P.; Lin, Y.; Tseng, T.-L. 3D printing of Shape Memory Polymer (SMP)/Carbon Black (CB) nanocomposites with electro-responsive toughness enhancement. Mater. Res. Express 2018, 5, 065704. Available online: https://iopscience.iop.org/article/10.1088/2053-1591/aacd53 (accessed on 25 June 2023). [CrossRef]

- Salam, H. Synthesis and Characterisation of Bio-Based Epoxy/Clay Nanocomposites. Ph.D. Thesis, Curtin University, Perth, Australia, 2017. Available online: http://hdl.handle.net/20.500.11937/66689 (accessed on 25 June 2023).

- Adak, B.; Butola, B.S.; Joshi, M. Effect of organoclay-type and clay-polyurethane interaction chemistry for tuning the morphology, gas barrier and mechanical properties of clay/polyurethane nanocomposites. Appl. Clay Sci. 2018, 161, 343–353. [Google Scholar] [CrossRef]

- Massaro, M.; Piana, S.; Colletti, C.G.; Noto, R.; Riela, S.; Baiamonte, C.; Giordano, C.; Pizzolanti, G.; Cavallaro, G.; Milioto, S.; et al. Multicavity halloysite–amphiphilic cyclodextrin hybrids for co-delivery of natural drugs into thyroid cancer cells. J. Mater. Chem. B 2015, 3, 4074–4081. [Google Scholar] [CrossRef] [Green Version]

- ASTM D638; Standard Test Method for Tensile Properties of Plastics. ASTM: West Conshohocken, PA, USA, 2022.

- ASTM D5963; Standard Test Method for Rubber Property—Abrasion Resistance (Rotary Drum Abrader). ASTM: West Conshohocken, PA, USA, 2022.

- Nugroho, W.T.; Dong, Y.; Pramanik, A. Dimensional accuracy and surface finish of 3D printed polyurethane (PU) dog-bone samples optimally manufactured by fused deposition modelling (FDM). Rapid Prototyp. J. 2022, 28, 1779–1795. [Google Scholar] [CrossRef]

- ASTM D2240; Standard Test Method for Rubber Property—Durometer Hardness. ASTM: West Conshohocken, PA, USA, 2021.

- Pressbooks. Archimedes’s Principle. Douglas College Physics 1104 Custom Textbook—Winter and Summer. 2020. Available online: https://pressbooks.bccampus.ca/practicalphysicsphys1104/chapter/11-7-archimedes-principle/ (accessed on 12 April 2023).

- Deng, S.; Zhang, J.; Ye, L.; Wu, J. Toughening epoxies with halloysite nanotubes. Polymer 2008, 49, 5119–5127. [Google Scholar] [CrossRef]

- Cao, H.; Qi, F.; Liu, R.; Wang, F.; Zhang, C.; Zhang, X.; Chai, Y.; Zhai, L. The influence of hydrogen bonding on N-methyldiethanolamine-extended polyurethane solid–solid phase change materials for energy storage. RSC Adv. 2017, 17, 11244–11252. [Google Scholar] [CrossRef] [Green Version]

- Park, S.H. Robust Design and Analysis for Quality Engineering; Springer: New York, NY, USA, 1996; ISBN 978-0-412-55620-3. Available online: https://link.springer.com/book/9780412556203 (accessed on 25 June 2023).

- Ross, P.J. Taguchi Techniques for Quality Engineering, Loss Function, Orthogonal Experiments, Parameter and Tolerance Design; McGraw-Hill: New York, NY, USA, 1988; ISBN 0070539588, 9780070539587. [Google Scholar]

- Mahunaki, M.P.; Asl, V.H.; Mamaqani, H.R.; Koosha, M.; Yazdi, M. Preparation of polyurethane composites reinforced with halloysite and carbon nanotubes. Polym. Compos. 2021, 42, 450–461. [Google Scholar] [CrossRef]

- Sulong, A.B.; Gaaz, T.S.; Sahari, J. Mechanical and physical properties of injection molded halloysite nanotubes-thermoplastic polyurethane nanocomposites. Procedia-Soc. Behav. Sci. 2015, 195, 2748–2752. [Google Scholar] [CrossRef] [Green Version]

- Chie, S.C.; Mansor, N.S.S.; Keat, Y.C.; Ai, T.M.; Leng, T.P.; Wei, K.K. Effect of printing parameters on characteristic and properties PLA/Fe2O3 and CPLA/Fe2O3 composites using FDM techniques. AIP Conf. Proc. 2022, 2541, 050005. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Korlos, A.; Velidakis, E.; Mountakis, N.; Charou, C.; Myftari, A. Strain rate sensitivity of polycarbonate and thermoplastic polyurethane for various 3D printing temperatures and layer heights. Polymers 2021, 13, 2752. [Google Scholar] [CrossRef]

- Kandi, R.; Pandey, P.M. Statistical modelling and optimization of print quality and mechanical properties of customized tubular scaffolds fabricated using solvent-based extrusion 3D printing process. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2021, 235, 1421–1438. [Google Scholar] [CrossRef]

- Wang, J.; Yang, B.; Lin, X.; Gao, L.; Liu, T.; Lu, Y.; Wang, R. Research of TPU materials for 3D printing aiming at non-pneumatic tires by FDM method. Polymers 2020, 12, 2492. [Google Scholar] [CrossRef]

- Le, D.; Nguyen, C.H.; Pham, T.H.N.; Nguyen, V.T.; Pham, S.M.; Le, M.T.; Nguyen, T.T. Optimizing 3D printing process parameters for the tensile strength of thermoplastic polyurethane plastic. J. Mater. Eng. Perform. 2023. [Google Scholar] [CrossRef]

- Mohamed, S.T.; Tirkes, S.; Akar, S.O.; Tayfun, U. Hybrid nanocomposites of elastomeric polyurethane containing halloysite nanotubes and POSS nanoparticles: Tensile, hardness, damping and abrasion performance. Clay Miner. 2020, 55, 281–292. [Google Scholar] [CrossRef]

- Kwiatkowski, K.; Nachman, M. The abrasive wear resistance of the segmented linear polyurethane elastomers based on a variety of polyols as soft segments. Polymers 2017, 9, 705. [Google Scholar] [CrossRef] [Green Version]

- Bogrekci, I.; Demircioglu, P.; Sucuoglu, H.S.; Turhanlar, O. The effect of the infill type and density on hardness of 3D printed parts. Int. J. 3D Print. Technol. Digit. Ind. 2019, 3, 212–219. [Google Scholar]

- Ozdil, N.; Kayseri, G.O.; Menguc, G.S. Chapter 7-Analysis of abrasion characteristics in textiles. In Abrasion Resistance of Materials; Adamiak, M., Ed.; InTech: Rijeka, Croatia, 2012. [Google Scholar]

- Mohammadzadeh, F.; Haddadi-Asl, V.; Siavoshani, A.Y.; Salami-Kalajahi, M. Preparation of intelligent magnetic halloysite nanotubes/polyurethane nanocomposites: The role of nanotube modification on the shape recovery rate. Mater. Res. Bull. 2022, 147, 111653. [Google Scholar] [CrossRef]

- Li, X.; Nikiforow, I.; Pohl, K.; Adams, J.; Johannsmann, D. Polyurethane coatings reinforced by halloysite nanotubes. Coatings 2013, 3, 16–25. [Google Scholar] [CrossRef] [Green Version]

- Luo, P.; Zhao, Y.; Zhang, B.; Liu, J.; Yang, Y.; Liu, J. Study on the adsorption of Neutral Red from aqueous solution onto halloysite nanotubes. Water Res. 2010, 44, 1489–1497. [Google Scholar] [CrossRef] [PubMed]

- Maamoun, A.A.; Elkhateeb, A.; Zulfiqar, S. Halloysite-decorated mechanically robust polyurethane nanocomposite foams for acoustic relevance. Ind. Eng. Chem. Res. 2022, 61, 17937–17949. [Google Scholar] [CrossRef]

- Carriço, C.S.; Fraga, T.; Carvalho, V.E.; Pasa, V.M.D. Polyurethane foams for thermal insulation uses produced from castor oil and crude glycerol biopolyols. Molecules 2017, 22, 1091. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, C.-J.; Tsai, M.-H.; Tseng, I.-H.; Hsu, A.-W.; Liu, T.-C.; Huang, S.-L. Composition, thermal and tensile properties of polyurethane-urea-silica hybrids. RSC Adv. 2013, 3, 9729–9738. [Google Scholar] [CrossRef]

- Delebecq, E.; Pascault, J.P.; Boutevin, B.; Ganachaud, F. On the versatility of urethane/urea bonds: Reversibility, blocked isocyanate, and non-isocyanate polyurethane. Chem. Rev. 2012, 113, 80–118. [Google Scholar] [CrossRef]

- Lee, D.W.; Kim, H.N.; Lee, D.S. Introduction of reversible urethane bonds based on vanillyl alcohol for efficient self-healing of polyurethane elastomers. Molecules 2019, 24, 2201. [Google Scholar] [CrossRef] [Green Version]

- Wu, W.; Zhao, W.; Gong, X.; Sun, Q.; Cao, X.; Su, Y.; Yu, B.; Li, R.K.Y.; Vellaisamy, R.A.L. Surface decoration of halloysite nanotubes with POSS for fire-safe thermoplastic polyurethane nanocomposites. J. Mater. Sci. Technol. 2022, 101, 107–117. [Google Scholar] [CrossRef]

- Jouibari, I.S.; Asl, V.H.; Ahmadi, H.; Mirhosseini, M.M. Micro-phase separation kinetics of polyurethane nanocomposites with neural network. Polym. Compos. 2019, 40, 3904–3913. [Google Scholar] [CrossRef]

- Mohammadzadeh, F.; Haddadi-Asl, V.; Balzade, Z.; Jouibari, I.S. Switch segment and halloysite nanotube role in the phase separation behavior of shape-memory thermoplastic polyurethane. Polym. Compos. 2020, 41, 2625–2633. [Google Scholar] [CrossRef]

- Razzaq, M.Y.; Anhalt, M.; Frormann, L.; Weidenfeller, B. Mechanical spectroscopy of magnetite fillet polyurethane shape memory polymers. Mater. Sci. Eng. A 2007, 471, 57–62. [Google Scholar] [CrossRef]

- Mamaqani, H.R.; Asl, V.H.; Kalajahi, M.S. In situ controlled radical polymerization: A review on synthesis of well-defied nanocomposites. Polym. Rev. 2012, 52, 142–188. [Google Scholar] [CrossRef]

| Factor | Level | |||||

|---|---|---|---|---|---|---|

| HNT level (wt%) | 0 | 2 | 4 | 6 | 8 | 10 |

| Nozzle temperature (°C) | 210 | 220 | 230 | |||

| Print speed (mm/s) | 10 | 20 | 30 | |||

| Infill density (%) | 40 | 70 | 100 | |||

| Layer height (mm) | 0.2 | 0.3 | 0.4 | |||

| Parameter | Specific Parameter | Setting |

|---|---|---|

| Quality | Shell thickness (mm) | 1.6 |

| Initial layer thickness (mm) | 0.5 | |

| Initial layer line width (%) | 120 | |

| Top surface quality | precise | |

| Fill | Bottom/top thickness (mm) | 1.2 |

| Infill interface density | dense | |

| Infill type | triangle | |

| Infill overlap (%) | 15 | |

| Temperature | Bed temperature (°C) | 55 |

| Speed | Travel speed (mm·s−1) | 150 |

| Bottom layer speed (mm·s−1) | 15 | |

| Infill speed (mm/s) | 30 | |

| Filament | Flow (%) | 115 |

| Retraction | Speed (mm/s) | 30 |

| Distance (mm) | 5 | |

| Minimum travel (mm) | 1.5 | |

| Minimal extrusion before retracting (mm) | 0.005 |

| Exp. | Symbol | Factor | ||||

|---|---|---|---|---|---|---|

| A (HNT Level wt%) | B (Nozzle Temperature °C) | C (Print Speed mm·s−1) | D (Infill Density %) | E (Layer Height mm) | ||

| 1 | TN1 | 0 | 210 | 10 | 40 | 0.2 |

| 2 | TN2 | 0 | 220 | 20 | 70 | 0.3 |

| 3 | TN3 | 0 | 230 | 30 | 100 | 0.4 |

| 4 | TN4 | 2 | 210 | 10 | 70 | 0.3 |

| 5 | TN5 | 2 | 220 | 20 | 100 | 0.4 |

| 6 | TN6 | 2 | 230 | 30 | 40 | 0.2 |

| 7 | TN7 | 4 | 210 | 20 | 40 | 0.4 |

| 8 | TN8 | 4 | 220 | 30 | 70 | 0.2 |

| 9 | TN9 | 4 | 230 | 10 | 100 | 0.3 |

| 10 | TN10 | 6 | 210 | 30 | 100 | 0.3 |

| 11 | TN11 | 6 | 220 | 10 | 40 | 0.4 |

| 12 | TN12 | 6 | 230 | 20 | 70 | 0.2 |

| 13 | TN13 | 8 | 210 | 20 | 100 | 0.2 |

| 14 | TN14 | 8 | 220 | 30 | 40 | 0.3 |

| 15 | TN15 | 8 | 230 | 10 | 70 | 0.4 |

| 16 | TN16 | 10 | 210 | 30 | 70 | 0.4 |

| 17 | TN17 | 10 | 220 | 10 | 100 | 0.2 |

| 18 | TN18 | 10 | 230 | 20 | 40 | 0.3 |

| Larger-the-Better L18 DoE Response | Significant Factor | Optimum Combination | Factor-Level Combination | Confirmation Test |

|---|---|---|---|---|

| Tensile strength at yield (MPa) |

| A5B1C1D3E3 |

| 57.293 |

| Tensile modulus (MPa) |

| A6B3C3D3E2 |

| 5.003 |

| Elongation at break (%) |

| A1B3C2D3E2 |

| 668.68 |

| Shore D hardness (dog-bone samples) |

| A6B2C3D3E3 |

| 76.867 |

| Shore D hardness (cylindrical samples) |

| A6B2C2D3E3 |

| 77.880 |

| Smaller-the-better L18 DoE response | Significant factor | Optimum combination | Factor-level combination | Confirmation test |

| Abrasion loss (mm3) |

| A1B3C2D1E2 |

| 112.813 |

| Sample Code | Td1 (°C) | DTG (%/°C) | Td2 (°C) | DTG (%/°C) | Td3 (°C) | DTG (%/°C) | Td4 (°C) | DTG (%/°C) |

|---|---|---|---|---|---|---|---|---|

| TN1 | 325.29 | 0.5659 | 371.16 | 0.5116 | 416.82 | 1.019 | 730.06 | 0.1729 |

| TN13 | 326.1 | 0.393 | 376.11 | 0.4568 | 426.36 | 0.9878 | 732.88 | 0.1586 |

| TN17 | 330.18 | 0.3655 | 375.4 | 0.4496 | 427.3 | 0.9843 | 737.5 | 0.1563 |

| Sample Code | Tg (°C) | Tc,SS (°C) | Tc,HS (°C) | Tm (°C) | ∆Hm (J/g) | ∆Hc (J/g) | Χc (%) |

|---|---|---|---|---|---|---|---|

| TN1 | 40.97 | −31.18 | 47.65 | 161.31 | 4.37 | 0.39 | 2.84 |

| TN13 | 41.56 | −29.94 | 48.42 | 164.01 | 6.41 | 0.46 | 4.62 |

| TN17 | 42.36 | −27.87 | 49.43 | 163.03 | 6.54 | 0.44 | 4.84 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nugroho, W.T.; Dong, Y.; Pramanik, A.; Zhang, Z.; Ramakrishna, S. Co-Influence of Nanofiller Content and 3D Printing Parameters on Mechanical Properties of Thermoplastic Polyurethane (TPU)/Halloysite Nanotube (HNT) Nanocomposites. Nanomaterials 2023, 13, 1975. https://doi.org/10.3390/nano13131975

Nugroho WT, Dong Y, Pramanik A, Zhang Z, Ramakrishna S. Co-Influence of Nanofiller Content and 3D Printing Parameters on Mechanical Properties of Thermoplastic Polyurethane (TPU)/Halloysite Nanotube (HNT) Nanocomposites. Nanomaterials. 2023; 13(13):1975. https://doi.org/10.3390/nano13131975

Chicago/Turabian StyleNugroho, Wendy Triadji, Yu Dong, Alokesh Pramanik, Zhixiao Zhang, and Seeram Ramakrishna. 2023. "Co-Influence of Nanofiller Content and 3D Printing Parameters on Mechanical Properties of Thermoplastic Polyurethane (TPU)/Halloysite Nanotube (HNT) Nanocomposites" Nanomaterials 13, no. 13: 1975. https://doi.org/10.3390/nano13131975

APA StyleNugroho, W. T., Dong, Y., Pramanik, A., Zhang, Z., & Ramakrishna, S. (2023). Co-Influence of Nanofiller Content and 3D Printing Parameters on Mechanical Properties of Thermoplastic Polyurethane (TPU)/Halloysite Nanotube (HNT) Nanocomposites. Nanomaterials, 13(13), 1975. https://doi.org/10.3390/nano13131975