Effect of Void Defects on the Indentation Behavior of Ni/Ni3Al Crystal

Abstract

:1. Introduction

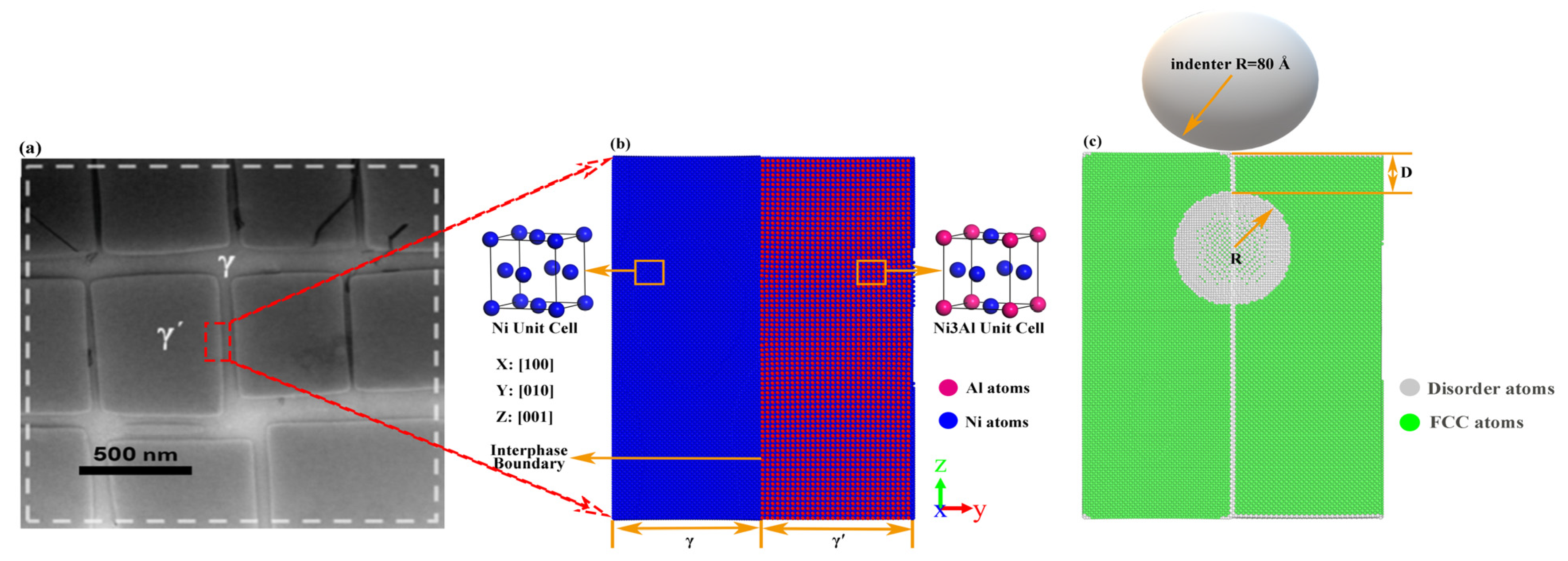

2. Calculation Methods

3. Results and Discussions

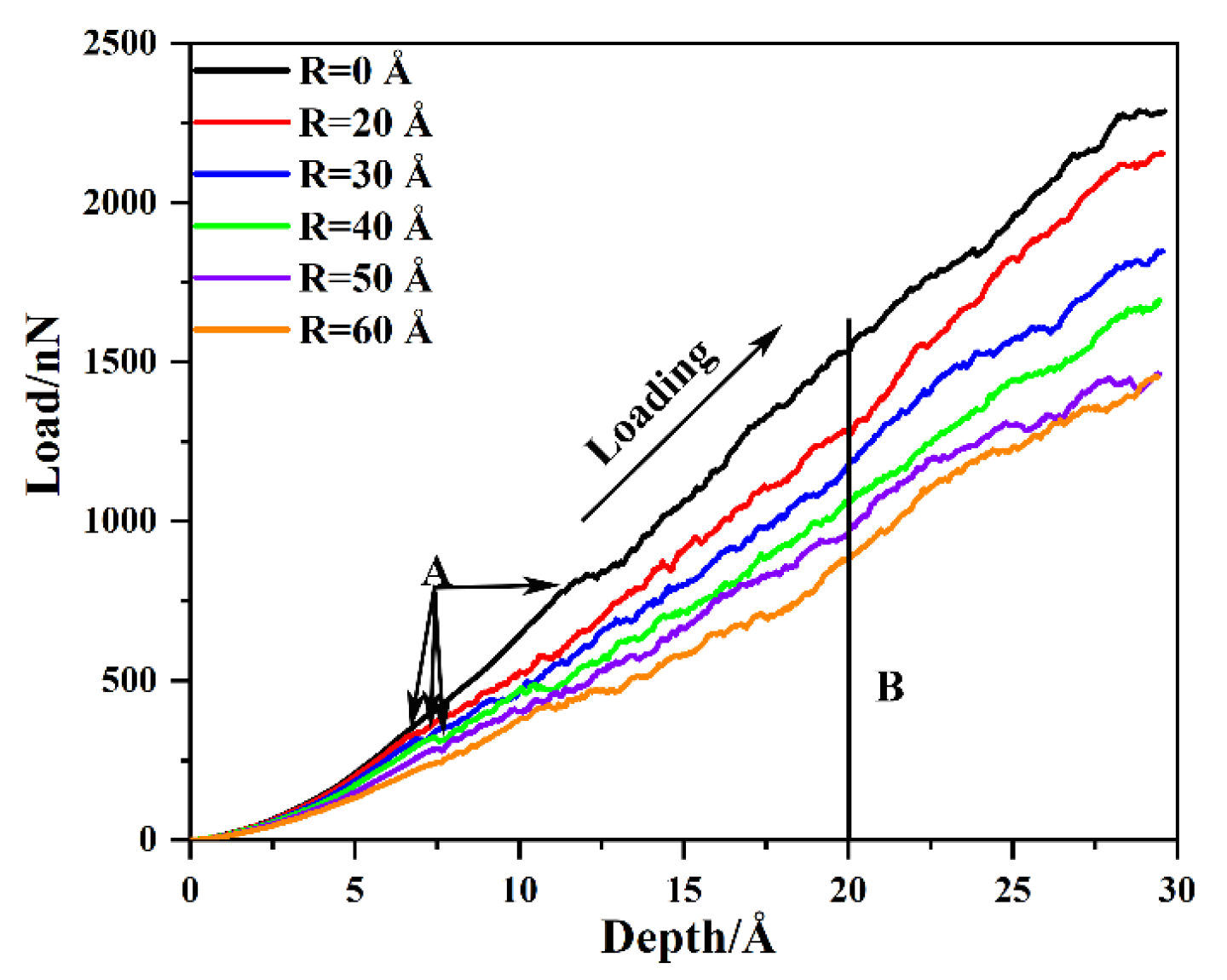

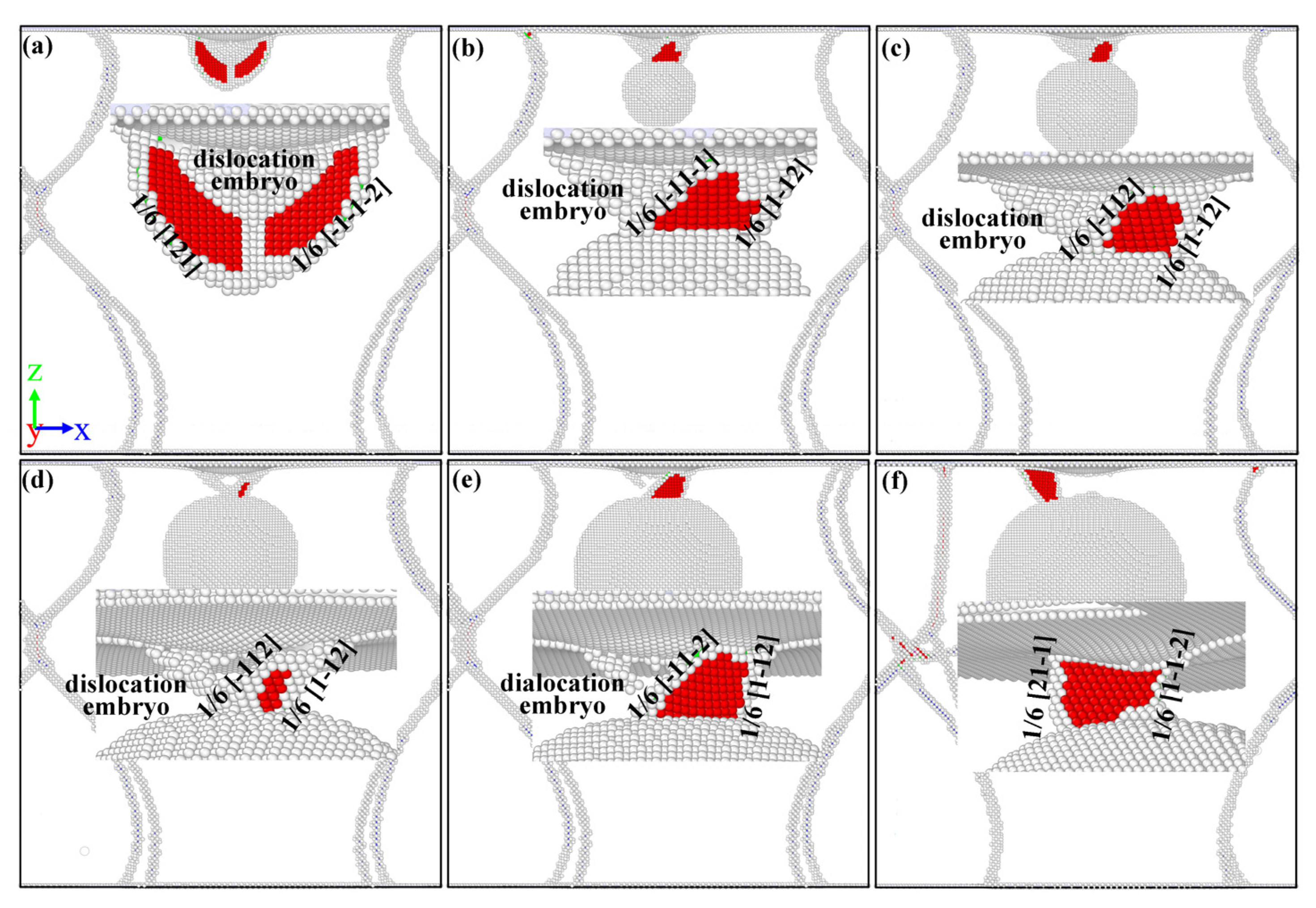

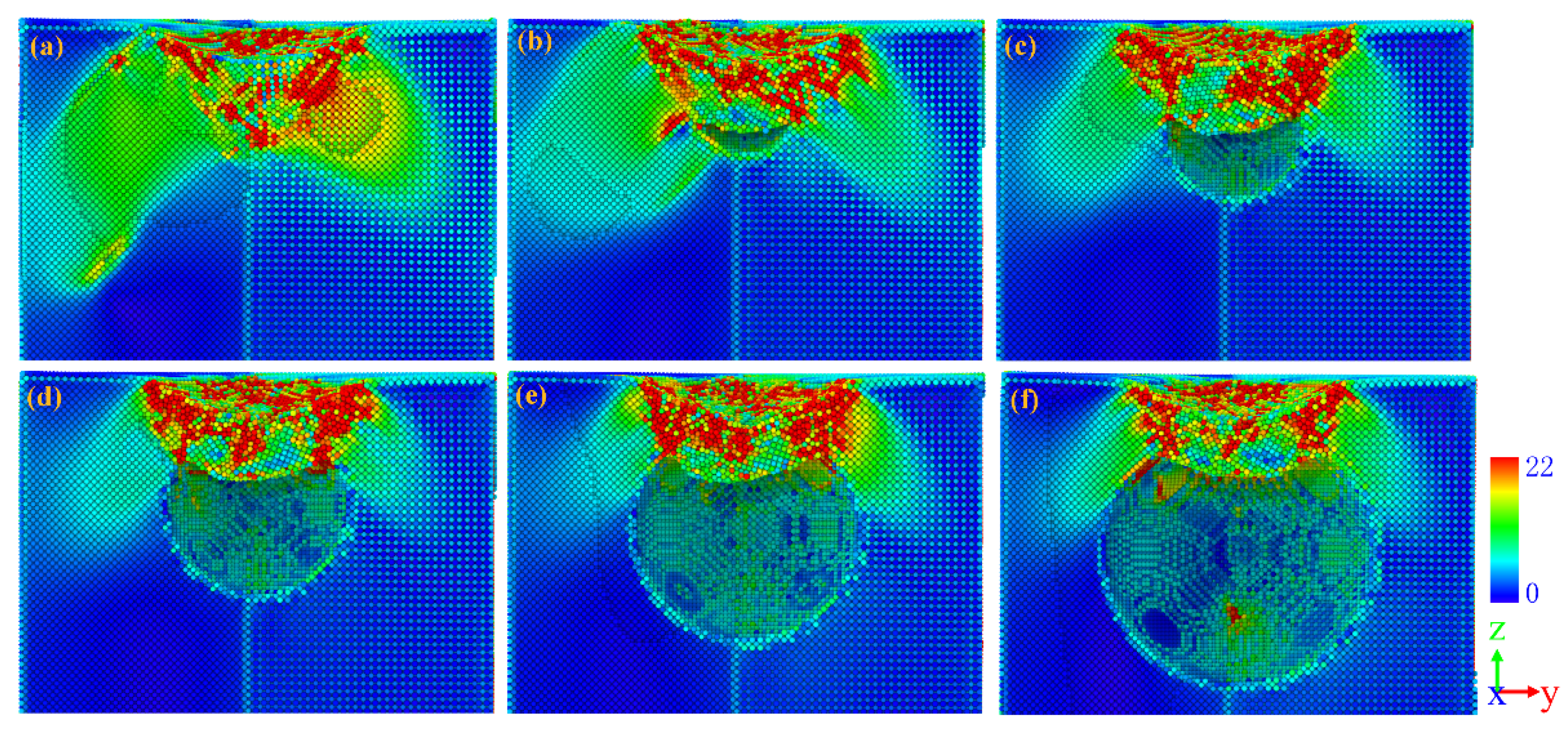

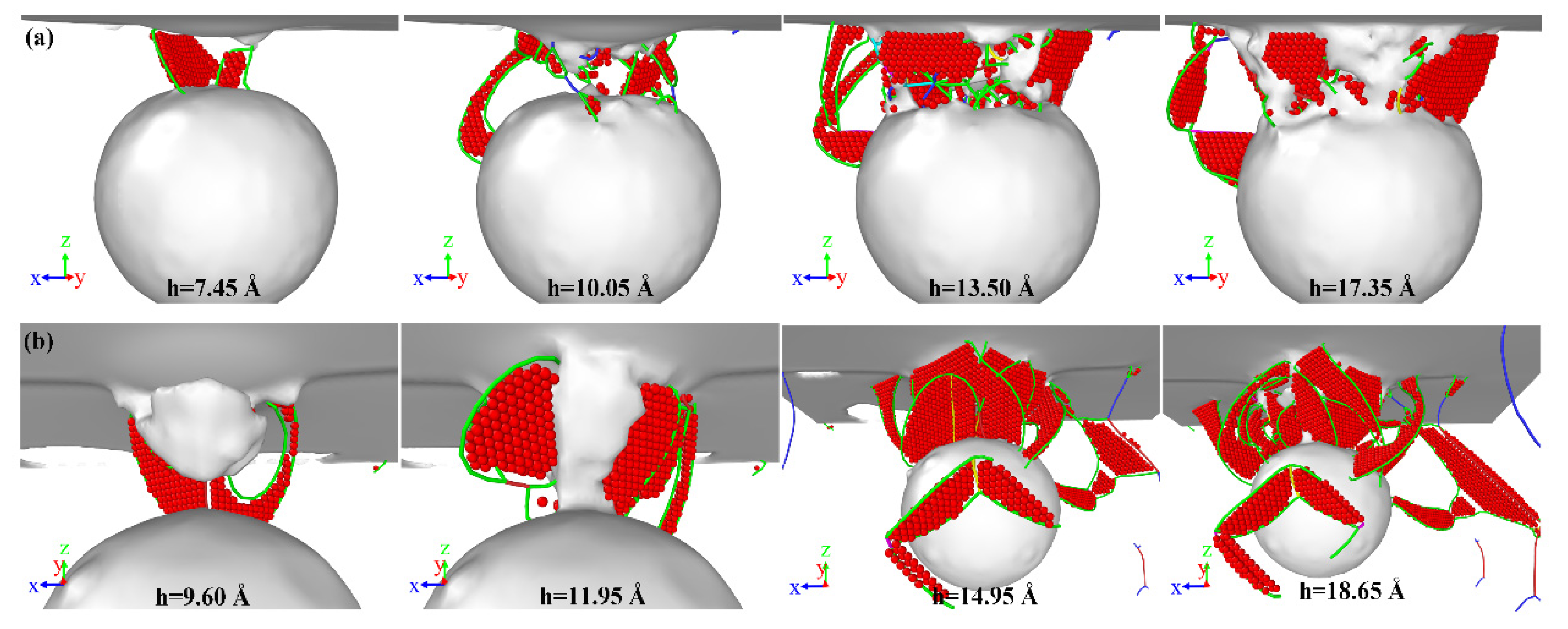

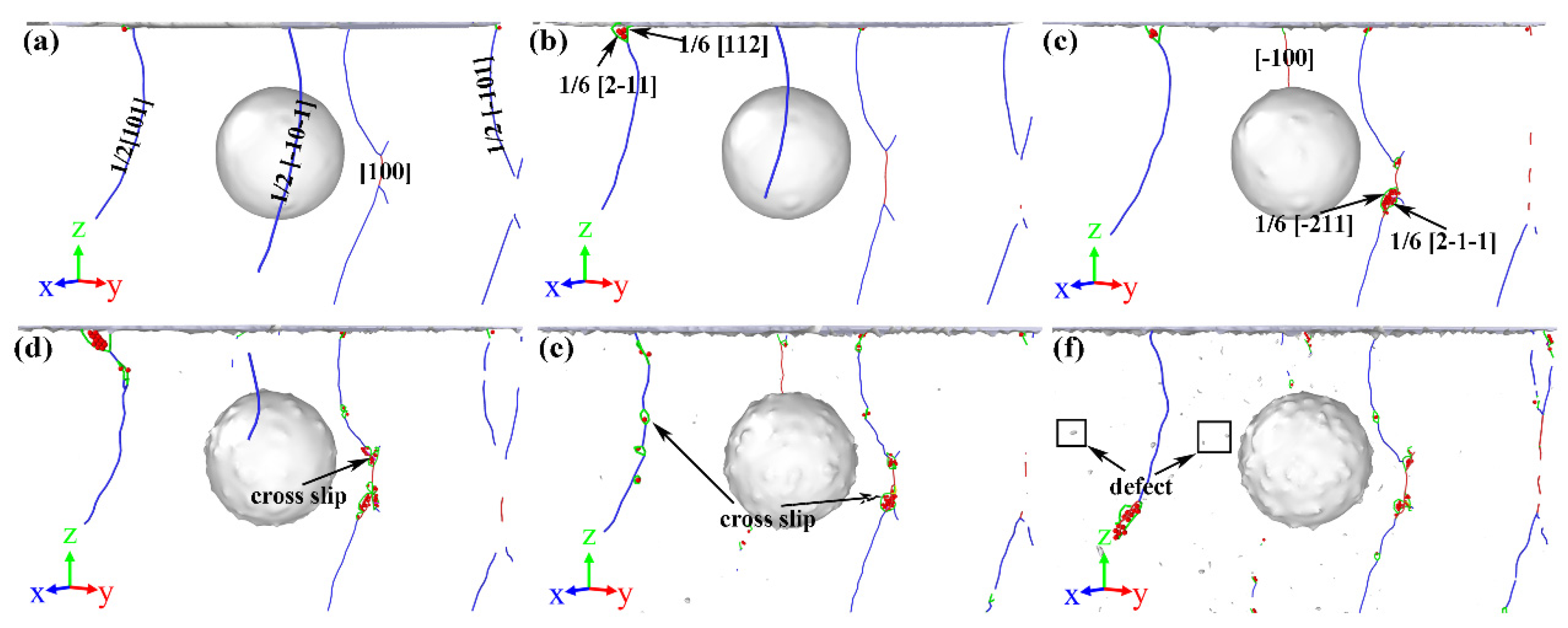

3.1. Influence of the Void Radius

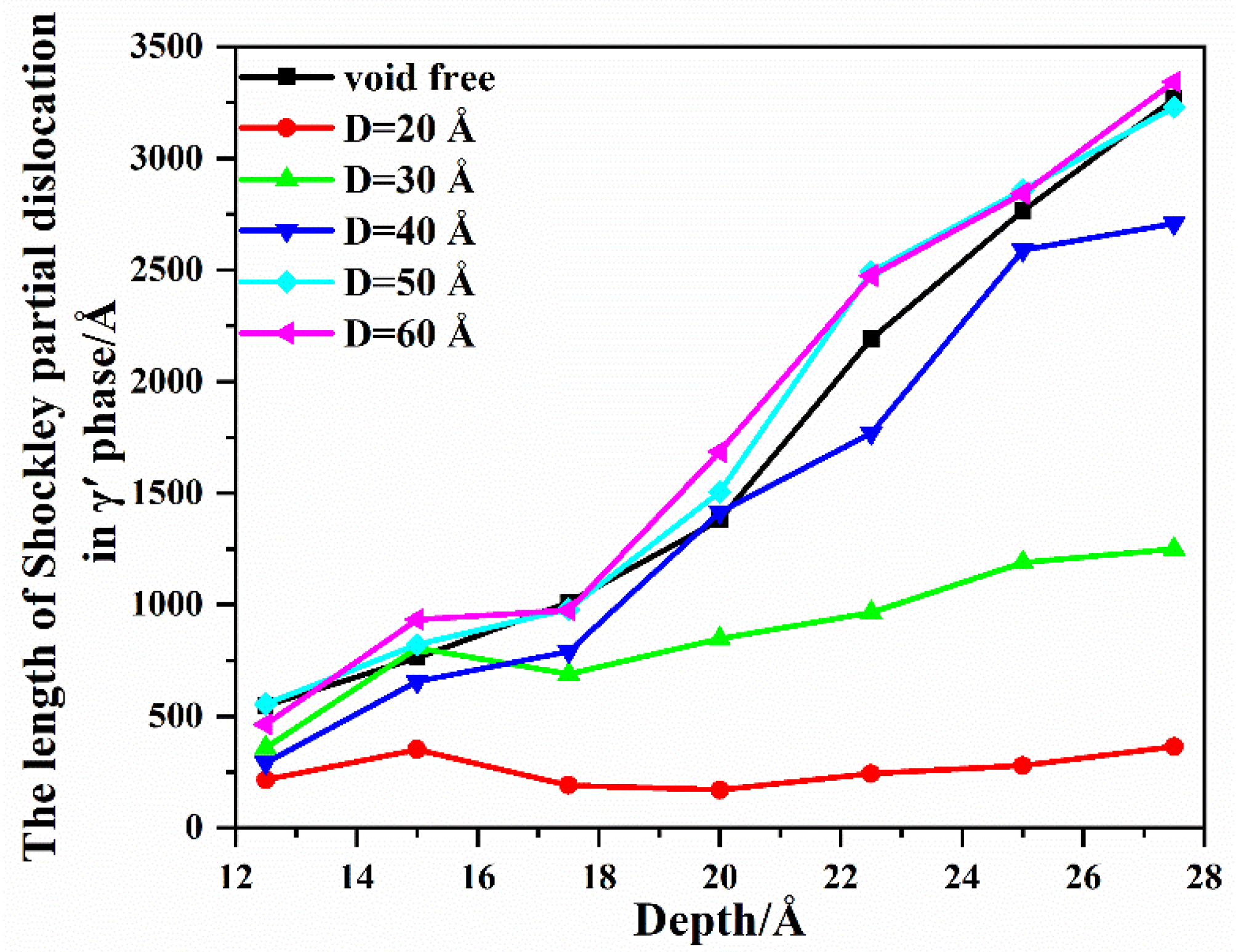

3.2. Influence of the Void Distance

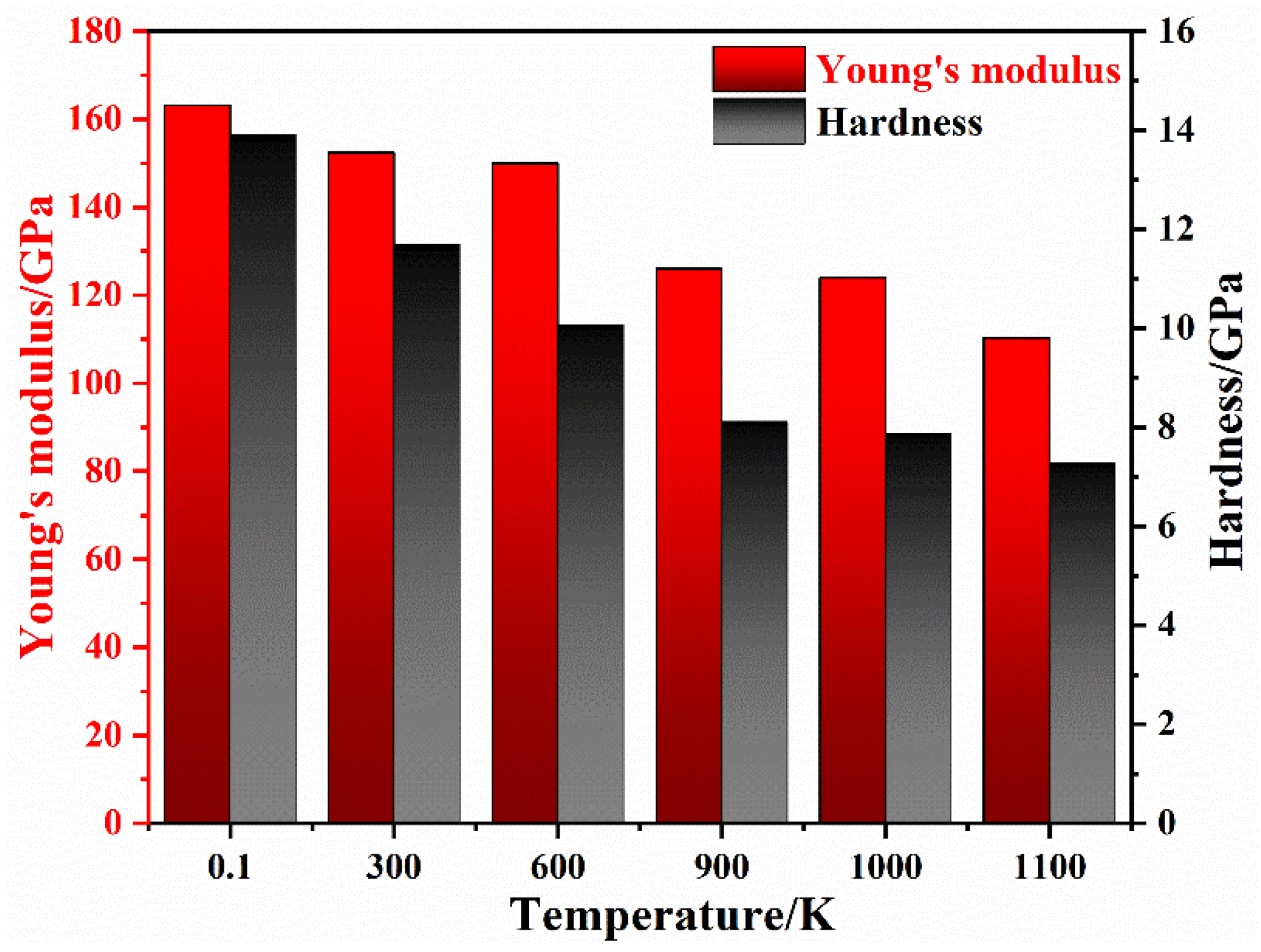

3.3. Influence of the Void Temperature

4. Conclusions

- (1)

- With the increase in the void radius, Young’s modulus, hardness, and flow stress decrease significantly. For dislocation nucleation, the larger the void radius is, the more conducive the Shockley dislocation and dislocation embryo are. For dislocation slip, voids act as a defect, which anchors the expansion of the dislocation in the substrate, effectively alleviating the stress.

- (2)

- With the increase in the void distance, mechanical properties increase, and when the void distance D = 40 Å, the mechanical properties of all models are similar. The void distance affects the dislocation shape and type, and then affects the slip of the glissile dislocation in the γ′ phase.

- (3)

- With the increase in the temperature, the mechanical properties decrease significantly, but still maintain a high level. The interphase boundary becomes irregular and the number of disordered atoms increase in the substrate. These defects increase the dislocation nucleation rate and leads to the decrease in mechanical properties.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Huda, Z.; Edi, P. Materials selection in design of structures and engines of supersonic aircrafts: A review. Mater. Des. 2013, 46, 552–560. [Google Scholar] [CrossRef]

- Du, J.H.; Lu, X.D.; Deng, Q.; Bi, Z.B. Progress in the Research and Manufacture of GH4169 Alloy. J. Iron Steel Res. Int. 2015, 22, 657–663. [Google Scholar] [CrossRef]

- Ding, W.; Miao, Q.; Li, B.; Xu, J. Review on Grinding Technology of Nickel-based Superalloys Used for Aero-engine. J. Mech. Eng. 2019, 55, 180–215. [Google Scholar] [CrossRef]

- Pollock, T.M.; Tin, S. Nickel-based superalloys for advanced turbine engines: Chemistry, microstructure, and properties. J. Propul. Power 2006, 22, 361–374. [Google Scholar] [CrossRef]

- Xiang, S.; Long, H.; Mao, S.; Liu, Y.; Wei, H.; Zhang, J.; Shen, Z.; Zhang, H.; Wang, X.; Zhang, Z.; et al. Response to ldquoComments on Selective evolution of secondary gamma precipitation in a Ni-based single crystal superalloy both in the gamma matrix and at the dislocation nodes’rdquo. Scr. Mater. 2017, 129, 104–106. [Google Scholar] [CrossRef]

- Mukherji, D.; Rosler, J.; Strunz, P.; Gilles, R.; Schumacher, G.; Piegert, S. Beyond Ni-based superalloys: Development of CoRe-based alloys for gas turbine applications at very high temperatures. Int. J. Mater. Res. 2011, 102, 1125–1132. [Google Scholar] [CrossRef]

- Detor, A.J.; DiDomizio, R.; Sharghi-Moshtaghin, R.; Zhou, N.; Shi, R.P.; Wang, Y.Z.; McAllister, D.P.; Mills, M.J. Enabling Large Superalloy Parts Using Compact Coprecipitation of gamma and gamma. Metall. Mater. Trans. A-Phys. Metall. Mater. Sci. 2018, 49A, 708–717. [Google Scholar] [CrossRef]

- Antolovich, S.D. Microstructural aspects of fatigue in Ni-base superalloys. Philos. Trans. R. Soc. A-Math. Phys. Eng. Sci. 2015, 373, 36. [Google Scholar] [CrossRef] [Green Version]

- Selvaraj, S.K.; Sundaramali, G.; Dev, S.J.; Swathish, R.S.; Karthikeyan, R.; Vishaal, K.E.V.; Paramasivam, V. Recent Advancements in the Field of Ni-Based Superalloys. Adv. Mater. Sci. Eng. 2021, 2021, 60. [Google Scholar] [CrossRef]

- Zhang, G.H.; Guo, S.Q.; Huang, S.; Zhou, B.; Yan, T.Q.; Chen, B.Q.; Zhang, X.J. Relative Density of GH4169 Superalloy Prepared by Selective Laser Melting. Laser Optoelectron. Prog. 2020, 57, 7. [Google Scholar] [CrossRef]

- Das, D.K. Microstructure and high temperature oxidation behavior of Pt-modified aluminide bond coats on Ni-base superalloys. Prog. Mater. Sci. 2013, 58, 151–182. [Google Scholar] [CrossRef]

- Long, H.B.; Mao, S.C.; Liu, Y.N.; Zhang, Z.; Han, X.D. Microstructural and compositional design of Ni-based single crystalline superalloysd—A review. J. Alloys Compd. 2018, 743, 203–220. [Google Scholar] [CrossRef]

- Huang, M.; Zhu, J. An overview of rhenium effect in single-crystal superalloys. Rare Met. 2016, 35, 127–139. [Google Scholar] [CrossRef]

- Naragani, D.P.; Park, J.S.; Kenesei, P.; Sangid, M.D. Void coalescence and ductile failure in IN718 investigated via high-energy synchrotron X-ray tomography and diffraction. J. Mech. Phys. Solids 2020, 145, 23. [Google Scholar] [CrossRef]

- Liu, C.P.; Zhang, X.N.; Ge, L.; Liu, S.H.; Wang, C.Y.; Yu, T.; Zhang, Y.F.; Zhang, Z. Effect of rhenium and ruthenium on the deformation and fracture mechanism in nickel-based model single crystal superalloys during the in-situ tensile at room temperature. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2017, 682, 90–97. [Google Scholar] [CrossRef]

- Yu, Z.Y.; Wang, X.Z.; Yue, Z.F.; Wang, X.M. Investigation on microstructure evolution and fracture morphology of single crystal nickel-base superalloys under creep-fatigue interaction loading. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2017, 697, 126–131. [Google Scholar] [CrossRef]

- Wu, R.H.; Yin, Q.; Wang, J.P.; Mao, Q.Z.; Zhang, X.; Wen, Z.X. Effect of Re on mechanical properties of single crystal Ni-based superalloys: Insights from first-principle and molecular dynamics. J. Alloys Compd. 2021, 862, 8. [Google Scholar] [CrossRef]

- Wu, R.H.; Zhao, Y.S.; Yin, Q.; Wang, J.P.; Ai, X.; Wen, Z.X. Atomistic simulation studies of Ni-based superalloys. J. Alloys Compd. 2021, 855, 11. [Google Scholar] [CrossRef]

- Li, N.L.; Wu, W.P.; Nie, K. Molecular dynamics study on the evolution of interfacial dislocation network and mechanical properties of Ni-based single crystal superalloys. Phys. Lett. A 2018, 382, 1361–1367. [Google Scholar] [CrossRef]

- Qin, Z.J.; Wang, Z.; Wang, Y.Q.; Zhang, L.N.; Li, W.F.; Liu, J.; Wang, Z.X.; Li, Z.H.; Pan, J.; Zhao, L.; et al. Phase prediction of Ni-base superalloys via high-throughput experiments and machine learning. Mater. Res. Lett. 2021, 9, 32–40. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, L.; Li, W.F.; Qin, Z.J.; Wang, Z.X.; Li, Z.H.; Tan, L.M.; Zhu, L.L.; Liu, F.; Han, H.; et al. High throughput experiment assisted discovery of new Ni-base superalloys. Scr. Mater. 2020, 178, 134–138. [Google Scholar] [CrossRef]

- Khoei, A.R.; Eshlaghi, G.T.; Shahoveisi, S. Atomistic simulation of creep deformation mechanisms in nickel-based single crystal superalloys. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2021, 809, 22. [Google Scholar] [CrossRef]

- Zhou, J.J.; He, Y.L.; Shen, J.C.; Essa, F.A.; Yu, J.G. Ni/Ni3Al interface-dominated nanoindentation deformation and pop-in events. Nanotechnology 2022, 33, 10. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.P.; Liang, J.W.; Wen, Z.X.; Yue, Z.F. Atomic simulation of void location effect on the void growth in nickel-based single crystal. Comput. Mater. Sci. 2019, 160, 245–255. [Google Scholar] [CrossRef]

- Shang, J.; Yang, F.; Li, C.; Wei, N.; Tan, X. Size effect on the plastic deformation of pre-void Ni/Ni3Al interface under uniaxial tension: A molecular dynamics simulation. Comput. Mater. Sci. 2018, 148, 200–206. [Google Scholar] [CrossRef]

- Cui, C.; Gong, X.G.; Chen, L.J.; Xu, W.W.; Chen, L.J. Atomic-scale investigations on dislocation-precipitate interactions influenced by voids in Ni-based superalloys. Int. J. Mech. Sci. 2022, 216, 10. [Google Scholar] [CrossRef]

- Li, Y.L.; Wu, W.P.; Ruan, Z.G. Molecular Dynamics Simulation of the Evolution of Interfacial Dislocation Network and Stress Distribution of a Ni-Based Single-Crystal Superalloy. Acta Metall. Sin.-Engl. Lett. 2016, 29, 689–696. [Google Scholar] [CrossRef] [Green Version]

- Mishin, Y. Atomistic modeling of the gamma and gamma ’-phases of the Ni-Al system. Acta Mater. 2004, 52, 1451–1467. [Google Scholar] [CrossRef]

- Hirel, P. Atomsk: A tool for manipulating and converting atomic data files. Comput. Phys. Commun. 2015, 197, 212–219. [Google Scholar] [CrossRef]

- Pollock, T.M.; Argon, A.S. Directional coarsening in nickel-base single-crystals with high-volume fractions of coherent precipitates. Acta Metall. Mater. 1994, 42, 1859–1874. [Google Scholar] [CrossRef]

- Liu, X.L.; Shang, S.L.; Hu, Y.J.; Wang, Y.; Du, Y.; Liu, Z.K. Insight into gamma-Ni/gamma ’-Ni3Al interfacial energy affected by alloying elements. Mater. Des. 2017, 133, 39–46. [Google Scholar] [CrossRef]

- Luu, H.T.; Dang, S.L.; Hoang, T.V.; Gunkelmann, N. Molecular dynamics simulation of nanoindentation in Al and Fe: On the influence of system characteristics. Appl. Surf. Sci. 2021, 551, 13. [Google Scholar] [CrossRef]

- Ziegenhain, G.; Urbassek, H.M.; Hartmaier, A. Influence of crystal anisotropy on elastic deformation and onset of plasticity in nanoindentation: A simulational study. J. Appl. Phys. 2010, 107, 6. [Google Scholar] [CrossRef] [Green Version]

- Ding, Q.Q.; Li, S.Z.; Chen, L.Q.; Han, X.D.; Zhang, Z.; Yu, Q.; Li, J.X. Re segregation at interfacial dislocation network in a nickel-based superalloy. Acta Mater. 2018, 154, 137–146. [Google Scholar] [CrossRef]

- Plimpton, S. Fast parallel algorithms for short-range molecular-dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Xiong, J.; Zhu, Y.X.; Li, Z.H.; Huang, M.S. Quantitative study on interactions between interfacial misfit dislocation networks and matrix dislocations in Ni-based single crystal superalloys. Acta Mech. Solida Sin. 2017, 30, 345–353. [Google Scholar] [CrossRef]

- Seymour, R.; Hemeryck, A.; Nomura, K.; Wang, W.Q.; Kalia, R.K.; Nakano, A.; Vashishta, P. Nanoindentation of NiAl and Ni3Al crystals on (100), (110), and (111) surfaces: A molecular dynamics study. Appl. Phys. Lett. 2014, 104, 4. [Google Scholar] [CrossRef] [Green Version]

- Toxvaerd, S. Molecular-dynamics at constant temperature and pressure. Phys. Rev. E 1993, 47, 343–350. [Google Scholar] [CrossRef]

- Melchionna, S.; Ciccotti, G.; Holian, B.L. Hoover npt dynamics for systems varying in shape and size. Mol. Phys. 1993, 78, 533–544. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO-the Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2010, 18, 7. [Google Scholar] [CrossRef]

- Stukowski, A.; Bulatov, V.V.; Arsenlis, A. Automated identification and indexing of dislocations in crystal interfaces. Model. Simul. Mater. Sci. Eng. 2012, 20, 16. [Google Scholar] [CrossRef]

- Machado, M.; Moreira, P.; Flores, P.; Lankarani, H.M. Compliant contact force models in multibody dynamics: Evolution of the Hertz contact theory. Mech. Mach. Theory 2012, 53, 99–121. [Google Scholar] [CrossRef]

- Xiong, K.; Lu, H.M.; Gu, J.F. Atomistic simulations of the nanoindentation-induced incipient plasticity in Ni3Al crystal. Comput. Mater. Sci. 2016, 115, 214–226. [Google Scholar] [CrossRef]

- Talaei, M.S.; Nouri, N.; Ziaei-Rad, S. Grain boundary effects on nanoindentation of Fe bicrystal using molecular dynamic. Mech. Mater. 2016, 102, 97–107. [Google Scholar] [CrossRef]

- Chang, H.J.; Fivel, M.; Rodney, D.; Verdier, M. Multiscale modelling of indentation in FCC metals: From atomic to continuum. Comptes Rendus Phys. 2010, 11, 285–292. [Google Scholar] [CrossRef]

- Remington, T.P.; Ruestes, C.J.; Bringa, E.M.; Remington, B.A.; Lu, C.H.; Kad, B.; Meyers, M.A. Plastic deformation in nanoindentation of tantalum: A new mechanism for prismatic loop formation. Acta Mater. 2014, 78, 378–393. [Google Scholar] [CrossRef] [Green Version]

- Voyiadjis, G.Z.; Yaghoobi, M. Large scale atomistic simulation of size effects during nanoindentation: Dislocation length and hardness. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2015, 634, 20–31. [Google Scholar] [CrossRef]

- Egami, T. Atomic level stresses. Prog. Mater. Sci. 2011, 56, 637–653. [Google Scholar] [CrossRef]

| Parameter | Radius of Void/Å | |||||

|---|---|---|---|---|---|---|

| 0 | 20 | 30 | 40 | 50 | 60 | |

| Depth of the pop-in/Å | 11.2 | 6.4 | 6.8 | 7.5 | 7.2 | 7.4 |

| Load of the pop-in/nN | 770.97 | 306.82 | 312.01 | 321.39 | 273.49 | 226.47 |

| Young’s modulus/GPa | 168.39 | 150.57 | 140.80 | 132.09 | 115.48 | 100.85 |

| Hardness/GPa | 14.73 | 10.13 | 9.53 | 9.07 | 7.98 | 6.82 |

| Parameter | Distance of Void/Å | ||||

|---|---|---|---|---|---|

| 20 | 30 | 40 | 50 | 60 | |

| Depth of pop-in/Å | 7.5 | 8.8 | 10.9 | 11.0 | 11.1 |

| Load of pop-in/nN | 321.39 | 489.56 | 711.44 | 736.80 | 740.31 |

| Young’s modulus/GPa | 132.09 | 155.84 | 163.13 | 166.95 | 167.96 |

| Hardness/GPa | 9.07 | 11.77 | 13.91 | 14.31 | 14.45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, L.; Sun, K.; Wu, H. Effect of Void Defects on the Indentation Behavior of Ni/Ni3Al Crystal. Nanomaterials 2023, 13, 1969. https://doi.org/10.3390/nano13131969

Yang L, Sun K, Wu H. Effect of Void Defects on the Indentation Behavior of Ni/Ni3Al Crystal. Nanomaterials. 2023; 13(13):1969. https://doi.org/10.3390/nano13131969

Chicago/Turabian StyleYang, Longlong, Kun Sun, and Huaying Wu. 2023. "Effect of Void Defects on the Indentation Behavior of Ni/Ni3Al Crystal" Nanomaterials 13, no. 13: 1969. https://doi.org/10.3390/nano13131969

APA StyleYang, L., Sun, K., & Wu, H. (2023). Effect of Void Defects on the Indentation Behavior of Ni/Ni3Al Crystal. Nanomaterials, 13(13), 1969. https://doi.org/10.3390/nano13131969