Measurement of the Dzyaloshinskii–Moriya Interaction in Mn4N Films That Host Skyrmions

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

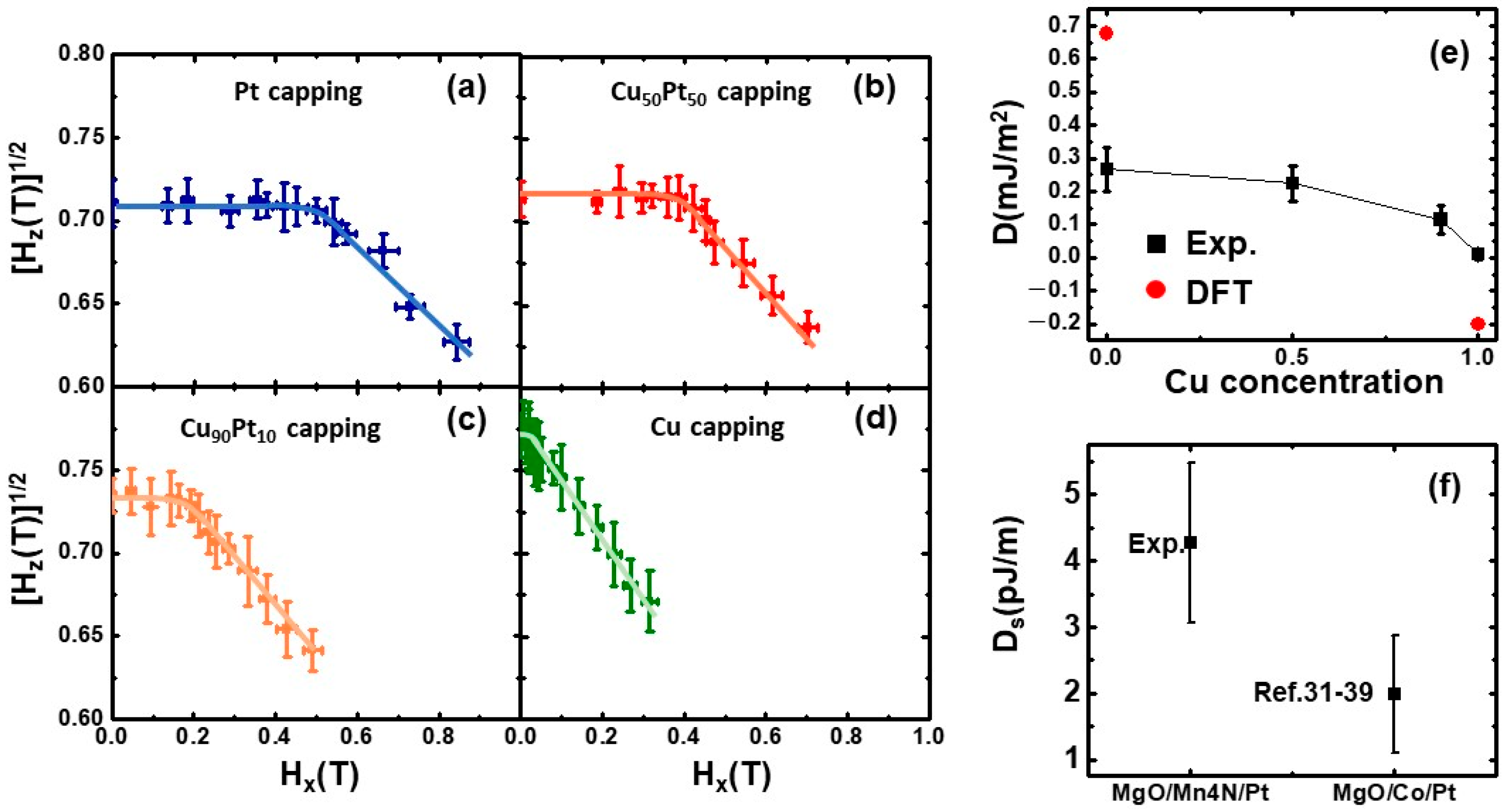

3.1. DMI Measurement

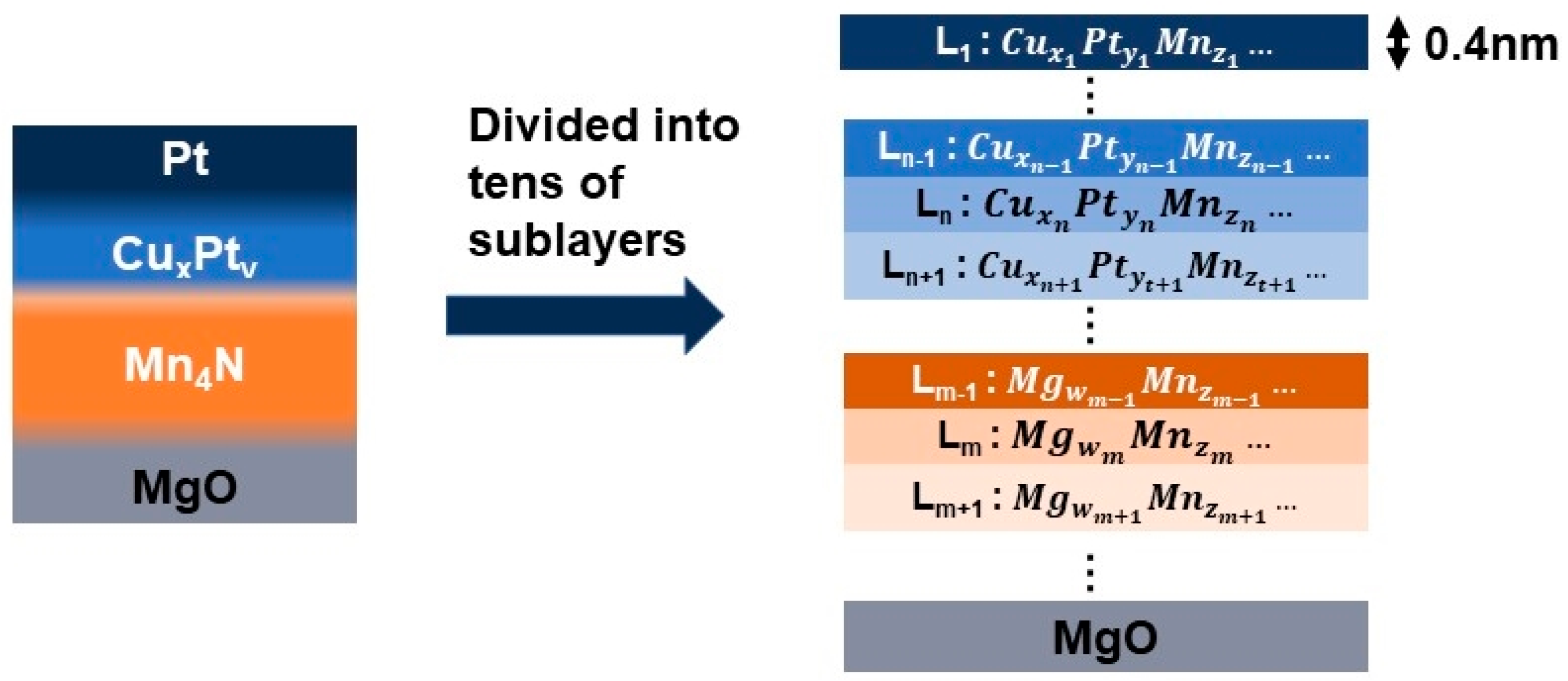

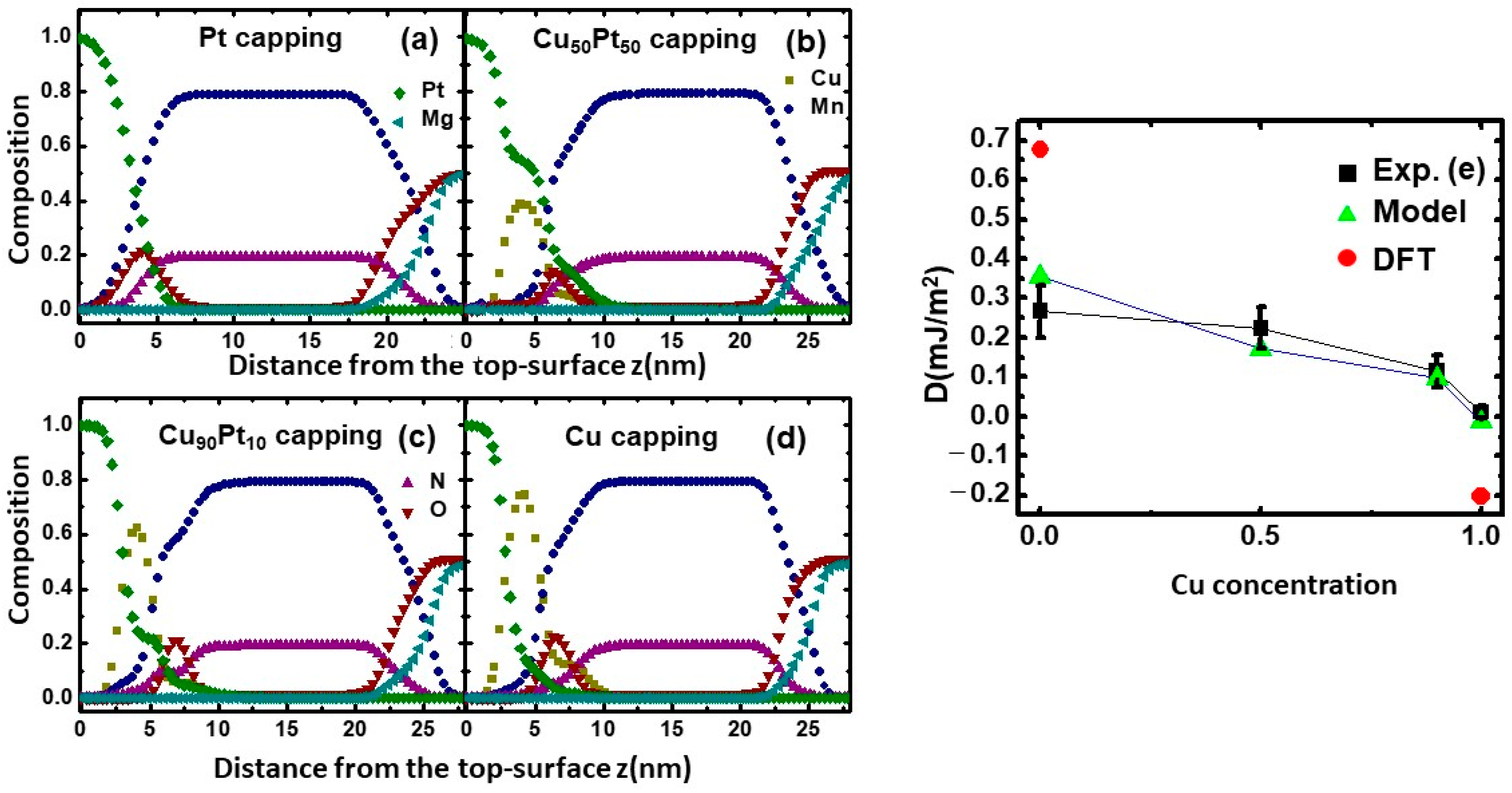

3.2. Mixing Layer Effect on the DMI

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dieny, B.; Prejbeanu, I.L.; Garello, K.; Gambardella, P.; Freitas, P.; Lehndorff, R.; Raberg, W.; Ebels, U.; Demokritov, S.O.; Akerman, J.; et al. Opportunities and challenges for spintronics in the microelectronics industry. Nat. Electron. 2020, 3, 446–459. [Google Scholar] [CrossRef]

- Jungwirth, T.; Marti, X.; Wadley, P.; Wunderlich, J. Antiferromagnetic spintronics. Nat. Nanotechnol. 2016, 11, 231–241. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Feng, X.; Vallobra, P.; He, Y.; Wang, Z.; Chen, L.; Zhang, K.; Zhao, W. Ferrimagnets for spintronic devices: From materials to applications. Appl. Phys. Lett. 2023, 10, 011301. [Google Scholar] [CrossRef]

- Žutić, I.; Fabian, J.; Sarma, S.D. Spintronics: Fundamentals and applications. Rev. Mod. Phys. 2004, 76, 323. [Google Scholar] [CrossRef]

- Barla, P.; Joshi, V.K.; Bhat, S. Spintronic devices: A promising alternative to CMOS devices. J. Comput. Electron. 2021, 20, 805–837. [Google Scholar] [CrossRef]

- Amal, E.G.; Jon, G.; Richard, B.W.; Akshay, P.; Jeffrey, B. Progress towards ultrafast spintronics applications. J. Magn. Magn. Mater. 2020, 502, 166478. [Google Scholar] [CrossRef]

- Stanciu, C.D.; Tsukamoto, A.; Kimel, A.V.; Hansteen, F.; Kirilyuk, A.; Itoh, A.; Rasing, T. Subpicosecond Magnetization Reversal across Ferrimagnetic Compensation Point. Phys. Rev. Lett. 2007, 99, 217204. [Google Scholar] [CrossRef]

- Siddiqui, S.A.; Han, J.; Finley, J.T.; Hansteen, F.; Kirilyuk, A.; Itoh, A.; Rasing, T. Current-Induced Domain Wall Motion in a Compensated Ferrimagnet. Phys. Rev. Lett. 2018, 121, 057701. [Google Scholar] [CrossRef]

- Caretta, L.; Mann, M.; Büttner, F.; Ueda, K.; Pfau, B.; Günther, C.M.; Hessing, P.; Churikova, A.; Klose, C.; Schneider, M.; et al. Fast current-driven domain walls and small skyrmions in a compensated ferrimagnet. Nat. Nanotechnol. 2018, 13, 1154–1160. [Google Scholar] [CrossRef]

- Gushi, T.; Klug, M.J.; Garcia, J.P.; Ghosh, S.; Attané, J.P.; Okuno, H.; Fruchart, O.; Vogel, J.; Suemasu, T.; Pizzini, S.; et al. Large Current Driven Domain Wall Mobility and Gate Tuning of Coercivity in Ferrimagnetic Mn4N Thin Films. Nano Lett. 2019, 19, 8716–8723. [Google Scholar] [CrossRef]

- Zhang, Z.; Mi, W. Progress in ferrimagnetic Mn4N films and its heterostructures for spintronics applications. J. Phys. D Appl. Phys. 2022, 55, 013001. [Google Scholar] [CrossRef]

- Suemasu, T.; Vila, L.; Attané, J.P. Present Status of Rare-earth Free Ferrimagnet Mn4N and Future Prospects of Mn4N-based Compensated Ferrimagnets. J. Phys. Soc. Jpn. 2021, 90, 081010. [Google Scholar] [CrossRef]

- Zhou, W.; Ma, C.T.; Hartnett, T.Q.; Balachandran, P.V.; Poon, S.J. Rare-earth-free ferrimagnetic mn4n sub-20 nm thin films as potential high-temperature spintronic material. AIP Adv. 2021, 11, 015334. [Google Scholar] [CrossRef]

- Shen, X.; Chikamatsu, A.; Shigematsu, K.; Hirose, Y.; Fukumura, T.; Hasegawa, T. Metallic transport and large anomalous hall effect at room temperature in ferrimagnetic Mn4N epitaxial thin film. Appl. Phys. Lett. 2014, 105, 072410. [Google Scholar] [CrossRef]

- Yasutomi, Y.; Ito, K.; Sanai, T.; Toko, K.; Suemasu, T. Perpendicular magnetic anisotropy of Mn4N films on MgO(001) and SrTiO3(001) substrates. J. Appl. Phys. 2014, 115, 17A935. [Google Scholar] [CrossRef]

- Kabara, K.; Tsunoda, M. Perpendicular magnetic anisotropy of Mn4N films fabricated by reactive sputtering method. J. Appl. Phys. 2015, 117, 17B512. [Google Scholar] [CrossRef]

- Foley, A.; Corbett, J.; Khan, A.; Richard, A.L.; Ingram, D.C.; Smith, A.R.; Zhao, L.; Gallagher, J.C.; Yang, F. Contribution from ising domains overlapping out-of-plane to perpendicular magnetic anisotropy in Mn4N thin films on MgO(001). J. Magn. Magn. Mater. 2017, 439, 236. [Google Scholar] [CrossRef]

- Hirose, T.; Komori, T.; Gushi, T.; Anzai, A.; Toko, K.; Suemasu, T. Strong correlation between uniaxial magnetic anisotropic constant and in-plane tensile strain in Mn4N epitaxial films. AIP Adv. 2020, 10, 025117. [Google Scholar] [CrossRef]

- Isogami, S.; Masuda, K.; Miura, Y. Contributions of magnetic structure and nitrogen to perpendicular magnetocrystalline anisotropy in antiperovskite ε− Mn4N. Phys. Rev. Mater. 2020, 4, 014406. [Google Scholar] [CrossRef]

- Komori, T.; Gushi, T.; Anzai, A.; Vila, L.; Attané, J.P.; Pizzini, S.; Vogel, J.; Isogami, S.; Toko, K.; Suemasu, T. Magnetic and magneto-transport properties of Mn4N thin films by Ni substitution and their possibility of magnetic compensation. J. Appl. Phys. 2019, 125, 213902. [Google Scholar] [CrossRef]

- Mitarai, H.; Komori, T.; Hirose, T.; Ito, K.; Ghosh, S.; Honda, S.; Toko, K.; Vila, L.; Attané, J.P.; Amemiya, K.; et al. Magnetic compensation at two different composition ratios in rare-earth-free Mn4-xCoxN ferrimagnetic films. Phys. Rev. Mater. 2020, 4, 094401. [Google Scholar] [CrossRef]

- Ghosh, S.; Komori, T.; Hallal, A.; Garcia, J.P.; Gushi Hirose, T.; Mitarai, H.; Okuno, H.; Vogel, J.; Chshiev, M.; Attané, J.P.; et al. Current-Driven Domain Wall Dynamics in Ferrimagnetic Nickel-Doped Mn4N Films: Very Large Domain Wall Velocities and Reversal of Motion Direction across the Magnetic Compensation Point. Nano Lett. 2021, 6, 2580–2587. [Google Scholar] [CrossRef]

- Ma, C.T.; Zhou, W.; Hartnett, T.Q.; Balachandran, P.V.; Poon, S.J. Tunable magnetic skyrmions in ferrimagnetic Mn4N. Appl. Phys. Lett. 2021, 119, 192406. [Google Scholar] [CrossRef]

- Fert, A.; Reyren, N.; Cros, V. Magnetic skyrmions: Advances in physics and potential applications. Nat. Rev. Mater. 2017, 2, 17031. [Google Scholar] [CrossRef]

- Everschor-Sitte, K.; Masell, J.; Reeve, R.M.; Kläui, M. Perspective: Magnetic skyrmions—Overview of recent progress in an active research field. J. Appl. Phys. 2018, 124, 240901. [Google Scholar] [CrossRef]

- Jiang, W.J.; Chen, G.; Liu, K.; Zang, J.; Velthuis, S.G.E.; Hoffmann, A. Skyrmions in magnetic multilayers. Phys. Rep. 2017, 704, 1–49. [Google Scholar] [CrossRef]

- Kuepferling, M.; Casiraghi, A.; Soares, G.; Durin, G. Measuring interfacial Dzyaloshinskii-Moriya interaction in ultrathin magnetic films. Rev. Mod. Phys. 2023, 95, 015003. [Google Scholar] [CrossRef]

- He, W.; Wan, C.; Zheng, C.; Wang, Y.; Wang, X.; Ma, T.; Wang, Y.; Guo, C.; Luo, X.; Stebliy, M.E.; et al. Field-Free Spin–Orbit Torque Switching Enabled by the Interlayer Dzyaloshinskii–Moriya Interaction. Nano Lett. 2022, 22, 6857–6865. [Google Scholar] [CrossRef]

- Zheng, Z.; Zhang, Y.; Lopez-Dominguez, V.; Sánchez-Tejerina, L.; Shi, J.; Feng, X.; Chen, L.; Wang, Z.; Zhang, Z.; Zhang, K.; et al. Field-free spin-orbit torque-induced switching of perpendicular magnetization in a ferrimagnetic layer with a vertical composition gradient. Nat. Commun. 2021, 12, 4555. [Google Scholar] [CrossRef]

- Belabbes, A.; Bihlmayer, G.; Bechstedt, F.; Blügel, S.; Manchon, A. Hund’s Rule-Driven Dzyaloshinskii-Moriya Interaction at 3d−5dInterfaces. Phys. Rev. Lett. 2016, 117, 247202. [Google Scholar] [CrossRef]

- Boulle, O.; Vogel, J.; Yang, H.; Pizzini, S.; Chaves, D.S.; Locatelli, A.; Menteş, T.O.; Sala, A.; Buda-Prejbeanu, L.D.; Klein, O.; et al. Room-temperature chiral magnetic skyrmions in ultrathin magnetic nanostructures. Nat. Nanotech. 2016, 11, 449–454. [Google Scholar] [CrossRef] [PubMed]

- Cao, A.; Zhang, X.; Koopmans, B.; Peng, S.; Zhang, Y.; Wang, Z.; Yan, S.; Yang, H.; Zhao, W. Tuning the Dzyaloshinskii–Moriya interaction in Pt/Co/MgO heterostructures through the MgO thickness. Nanoscale 2018, 10, 12062–12067. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Ueda, K.; Go, G.; Jang, P.H.; Lee, K.J.; Belabbes, A.; Manchon, A.; Suzuki, M.; Kotani, Y.; Nakamura, T.; et al. Correlation of the Dzyaloshinskii–Moriya interaction with Heisenberg exchange and orbital asphericity. Nat. Commun. 2018, 9, 1648. [Google Scholar] [CrossRef] [PubMed]

- Ma, X.; Yu, G.; Tang, C.; Li, X.; He, C.; Shi, J.; Wang, K.L.; Li, X. Interfacial Dzyaloshinskii-Moriya Interaction: Effect of 5d Band Filling and Correlation with Spin Mixing Conductance. Phys. Rev. Lett. 2018, 120, 157204. [Google Scholar] [CrossRef] [PubMed]

- Kasukawa, S.; Shiota, Y.; Moriyama, T.; Ono, T. Evaluation of electric field effect on interface magnetic properties by propagating spin wave in Pt/Co/MgO structures. Jpn. J. Appl. Phys. 2018, 57, 080309. [Google Scholar] [CrossRef]

- Kim, D.Y.; Kim, N.H.; Park, T.K.; Park, M.H.; Kim, J.S.; Nam, Y.S.; Jung, J.; Cho, J.; Kim, D.H.; Kim, J.S.; et al. Quantitative accordance of Dzyaloshinskii-Moriya interaction between domain-wall and spin-wave dynamics. Phys. Rev. B 2019, 100, 224419. [Google Scholar] [CrossRef]

- Mokhtari, B.E.; Ourdani, D.; Roussigne, Y.; Mos, R.B.; Nasui, M.; Kail, F.; Chahed, L.; Chérif, S.M.; Stashkevich, A.; Gabor, M. Perpendicular magnetic anisotropy and interfacial Dzyaloshinskii–Moriya interaction in as grown and annealed X/Co/Y ultrathin systems. J. Phys. Condens. Matter. 2020, 32, 495802. [Google Scholar] [CrossRef]

- Pai, C.F.; Mann, M.; Tan, A.J.; Geoffrey, S.D. Beach, Determination of spin torque efficiencies in heterostructures with perpendicular magnetic anisotropy. Phys. Rev. B 2016, 93, 144409. [Google Scholar] [CrossRef]

- Lee, J.M.; Jang, C.; Min, B.C.; Lee, S.W.; Lee, K.J.; Chang, J. All-Electrical Measurement of Interfacial Dzyaloshinskii-Moriya Interaction Using Collective Spin-Wave Dynamics. Nano Lett. 2016, 1, 62–67. [Google Scholar] [CrossRef]

- Kim, S.; Jang, P.H.; Kim, D.H.; Ishibashi, M.; Taniguchi, T.; Moriyama, T.; Kim, K.J.; Lee, K.J.; Ono, T. Magnetic droplet nucleation with a homochiral Néel domain wall. Phys. Rev. B 2017, 95, 220402. [Google Scholar] [CrossRef]

- Ma, C.T.; Zhou, W.; Kirby, B.J.; Poon, S.J. Interfacial mixing effect in a promising skyrmionic material: Ferrimagnetic Mn4N. AIP Adv. 2022, 12, 085023. [Google Scholar] [CrossRef]

- Huyen, N.T.V.; Suzuki, M.; Yamauchi, K.; Oguchi, T. Topology analysis for anomalous Hall effect in the noncollinear antiferromagnetic states of Mn3AN (A= Ni, Cy, Zn, Ga, Ge, Pd, In, Sn, Ir, Pt). Phys. Rev. B 2019, 100, 094426. [Google Scholar] [CrossRef]

- Quessab, Y.; Xu, J.W.; Ma, C.T.; Zhou, W.; Riley, G.A.; Shaw, J.M.; Nembach, H.T.; Poon, S.J.; Kent, A.D. Tuning interfacial Dzyaloshinskii-Moriya interactions in thin amorphous ferrimagnetic alloys. Sci. Rep. 2020, 10, 7447. [Google Scholar] [CrossRef] [PubMed]

- Ma, C.T.; Xie, Y.; Sheng, H.; Ghosh, A.W.; Poon, S.J. Robust Formation of Ultrasmall Room-Temperature Neél Skyrmions in Amorphous Ferrimagnets from Atomistic Simulations. Sci. Rep. 2019, 9, 9964. [Google Scholar] [CrossRef]

| MgO/Mn4N (001) | Pt/Mn4N (001) | Cu/Mn4N (001) |

|---|---|---|

| −1.017 mJ/m2 | 6.969 mJ/m2 | −2.633 mJ/m2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, W.; Ma, C.T.; Poon, S.J. Measurement of the Dzyaloshinskii–Moriya Interaction in Mn4N Films That Host Skyrmions. Nanomaterials 2023, 13, 1672. https://doi.org/10.3390/nano13101672

Zhou W, Ma CT, Poon SJ. Measurement of the Dzyaloshinskii–Moriya Interaction in Mn4N Films That Host Skyrmions. Nanomaterials. 2023; 13(10):1672. https://doi.org/10.3390/nano13101672

Chicago/Turabian StyleZhou, Wei, Chung Ting Ma, and S. Joseph Poon. 2023. "Measurement of the Dzyaloshinskii–Moriya Interaction in Mn4N Films That Host Skyrmions" Nanomaterials 13, no. 10: 1672. https://doi.org/10.3390/nano13101672

APA StyleZhou, W., Ma, C. T., & Poon, S. J. (2023). Measurement of the Dzyaloshinskii–Moriya Interaction in Mn4N Films That Host Skyrmions. Nanomaterials, 13(10), 1672. https://doi.org/10.3390/nano13101672