An Approach for the Optimization of Thermal Conductivity and Viscosity of Hybrid (Graphene Nanoplatelets, GNPs: Cellulose Nanocrystal, CNC) Nanofluids Using Response Surface Methodology (RSM)

Abstract

1. Introduction

2. Methodology

2.1. Nanofluid Preparation and Evaluation of Thermal Characteristics

2.2. Thermal Conductivity and Viscosity Measurements

2.3. Uncertainity Analysis

2.4. Response Surface Methodology

2.5. Design of Experiment

3. Results and Interpretation

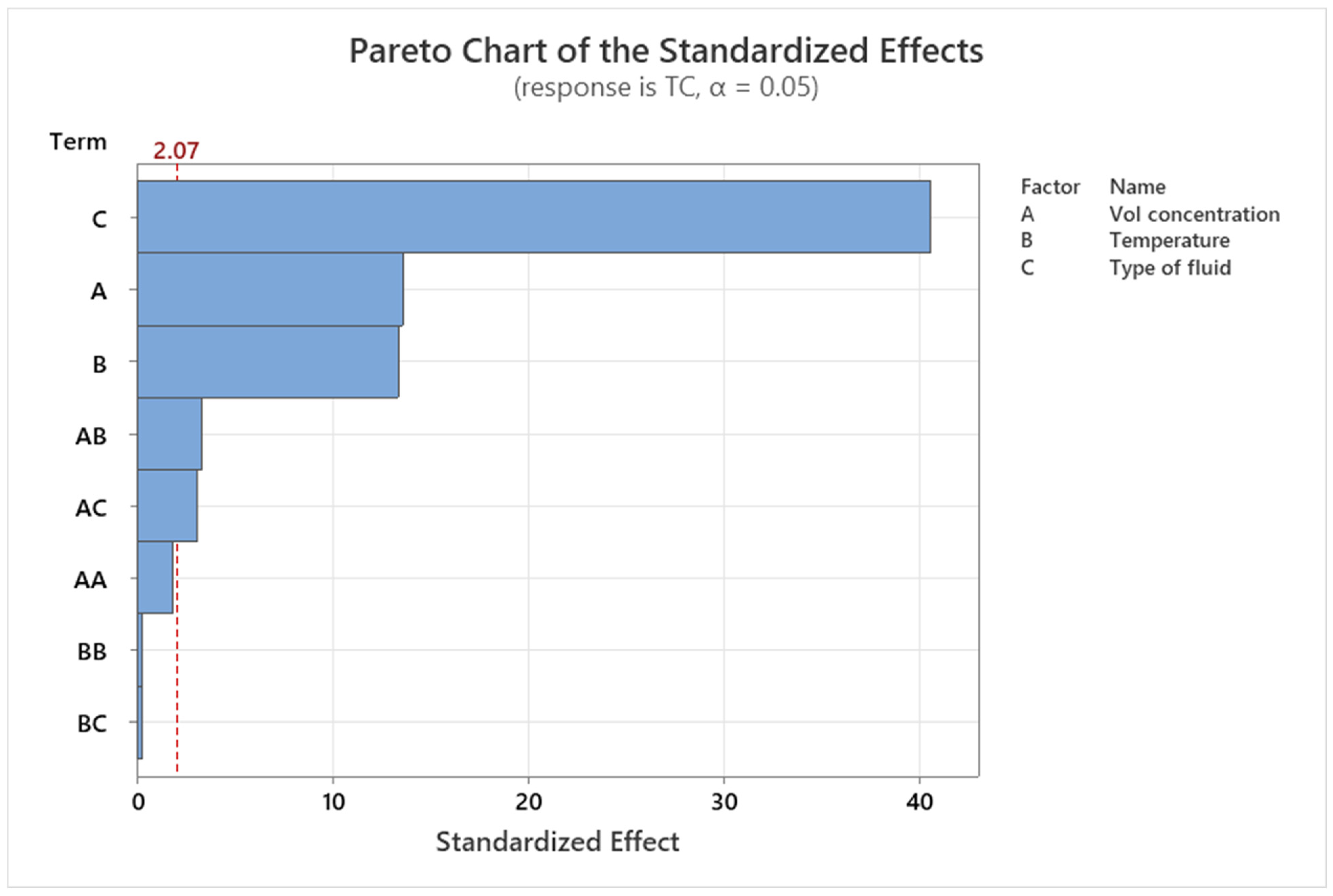

3.1. Anova Analysis

3.2. The Effect of Independent Variables on Responses

3.3. The Development of an Empirical Model

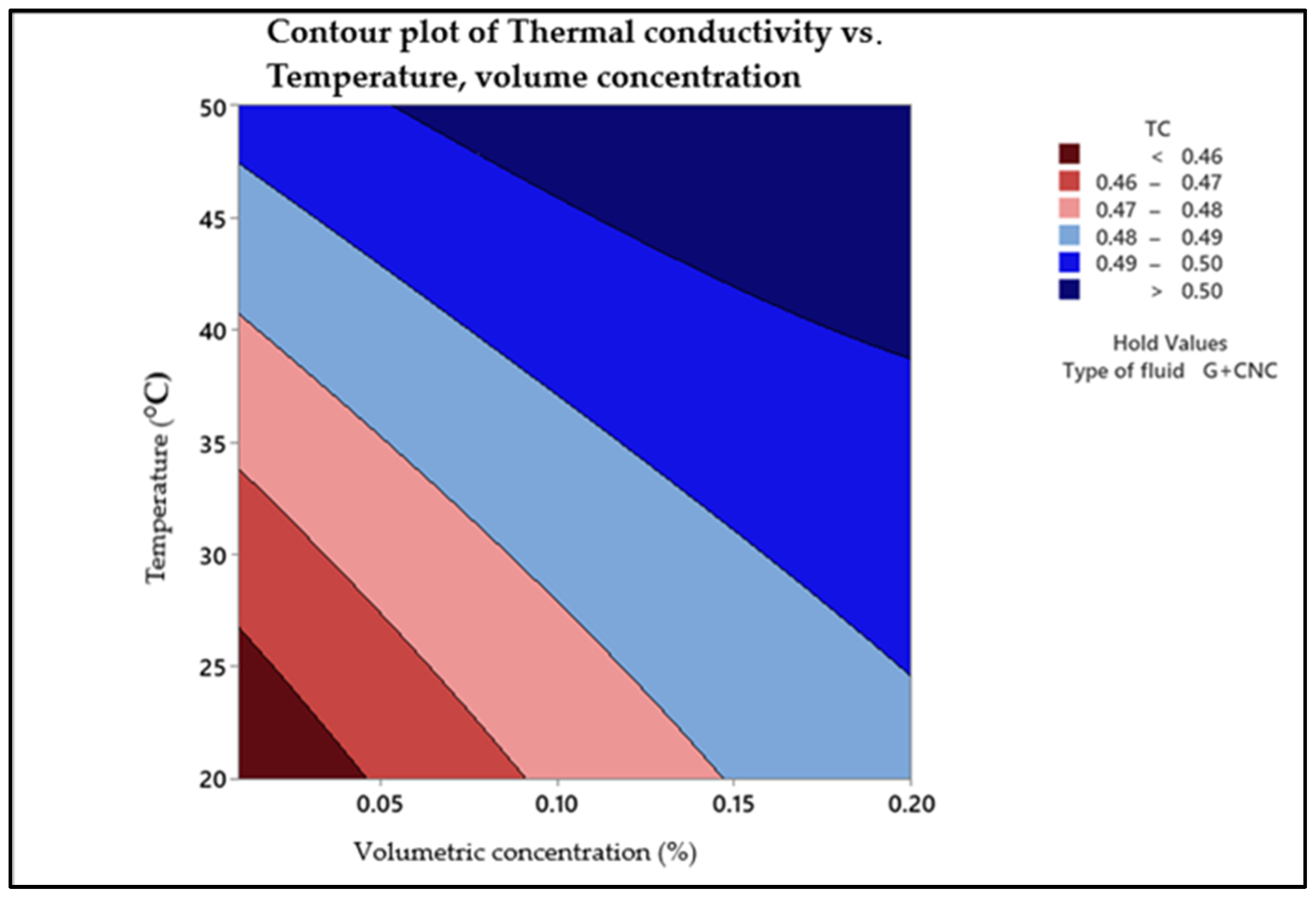

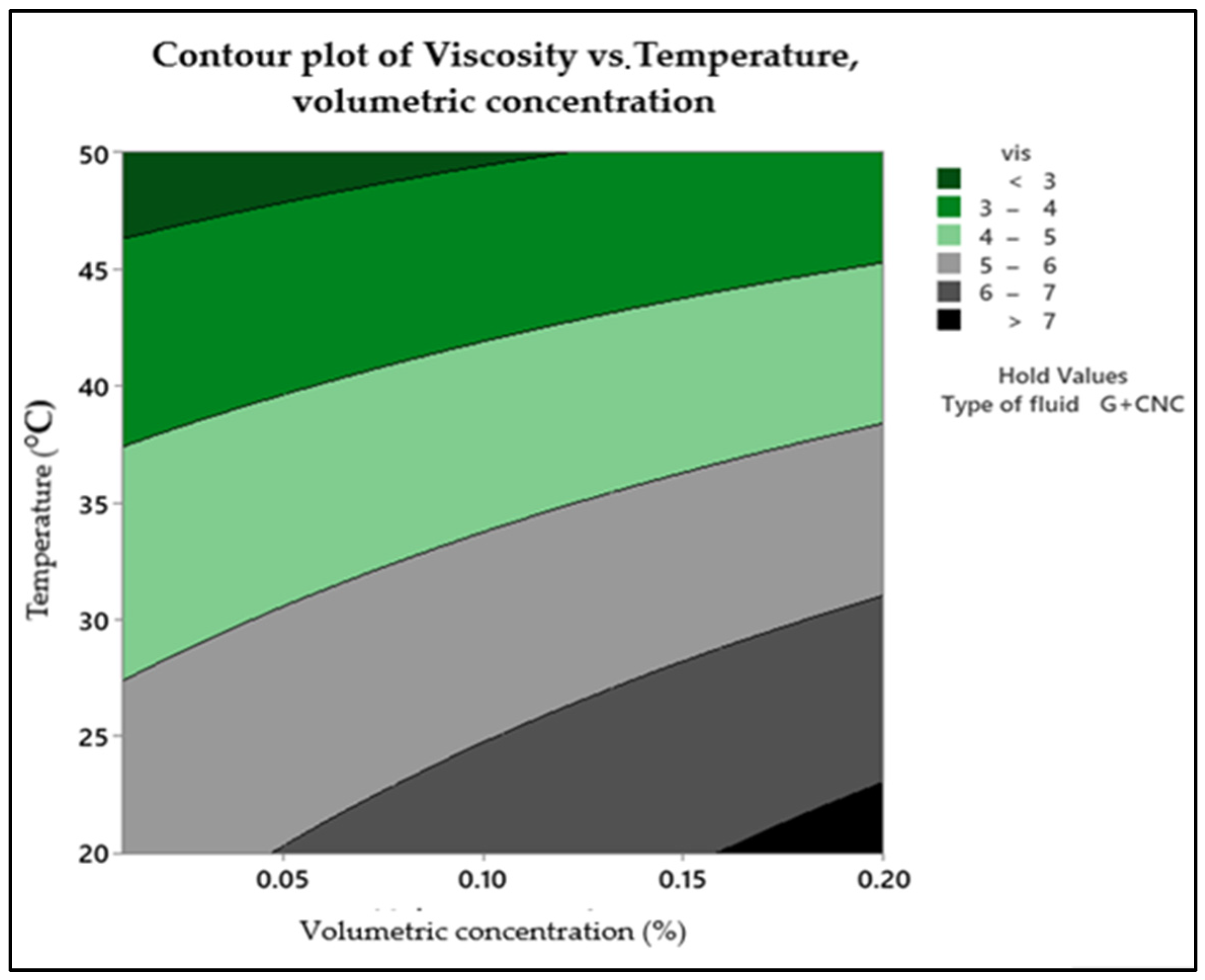

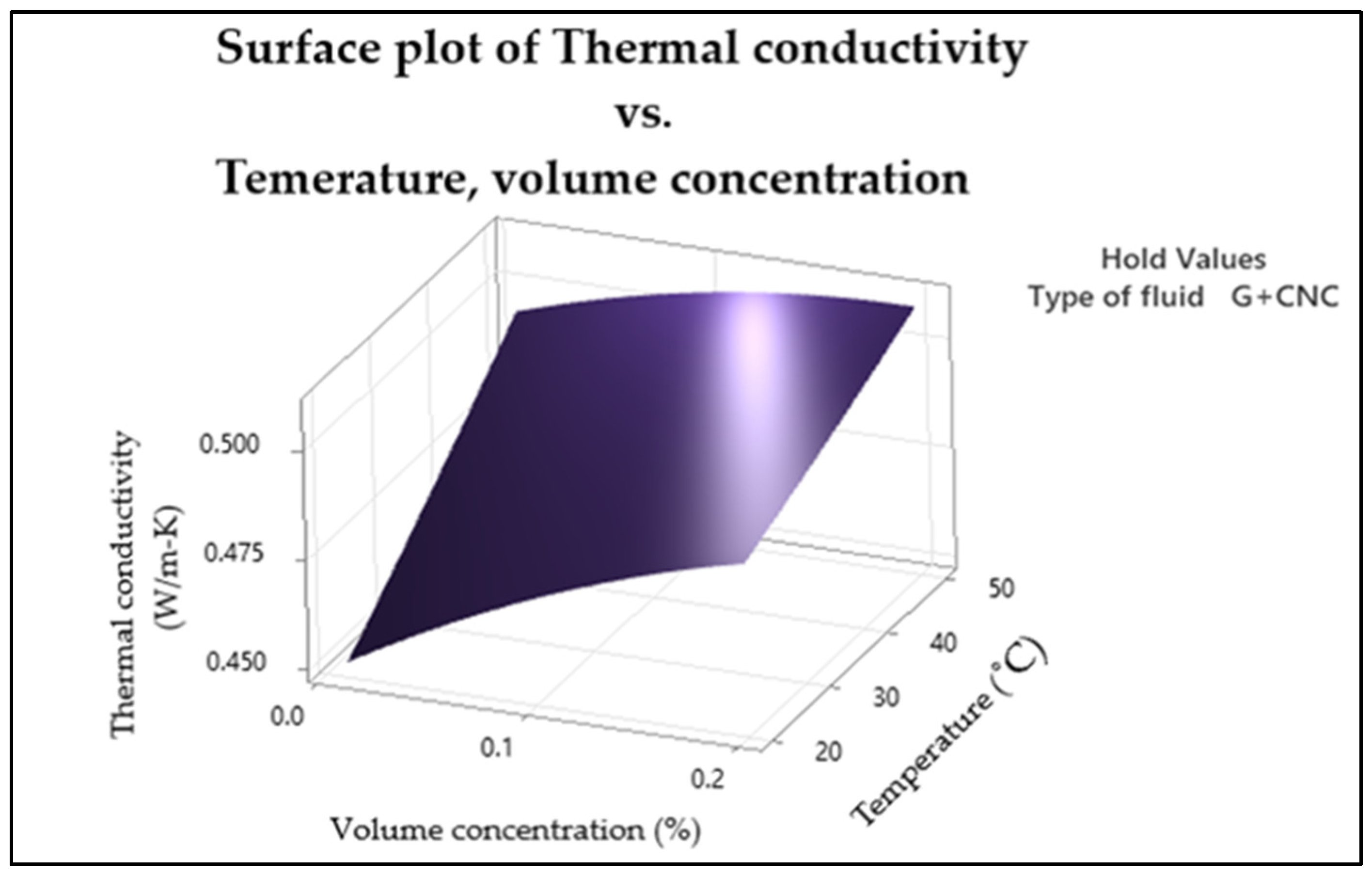

3.4. Contour and Surface Plots for Thermal Conductivity and Viscosity

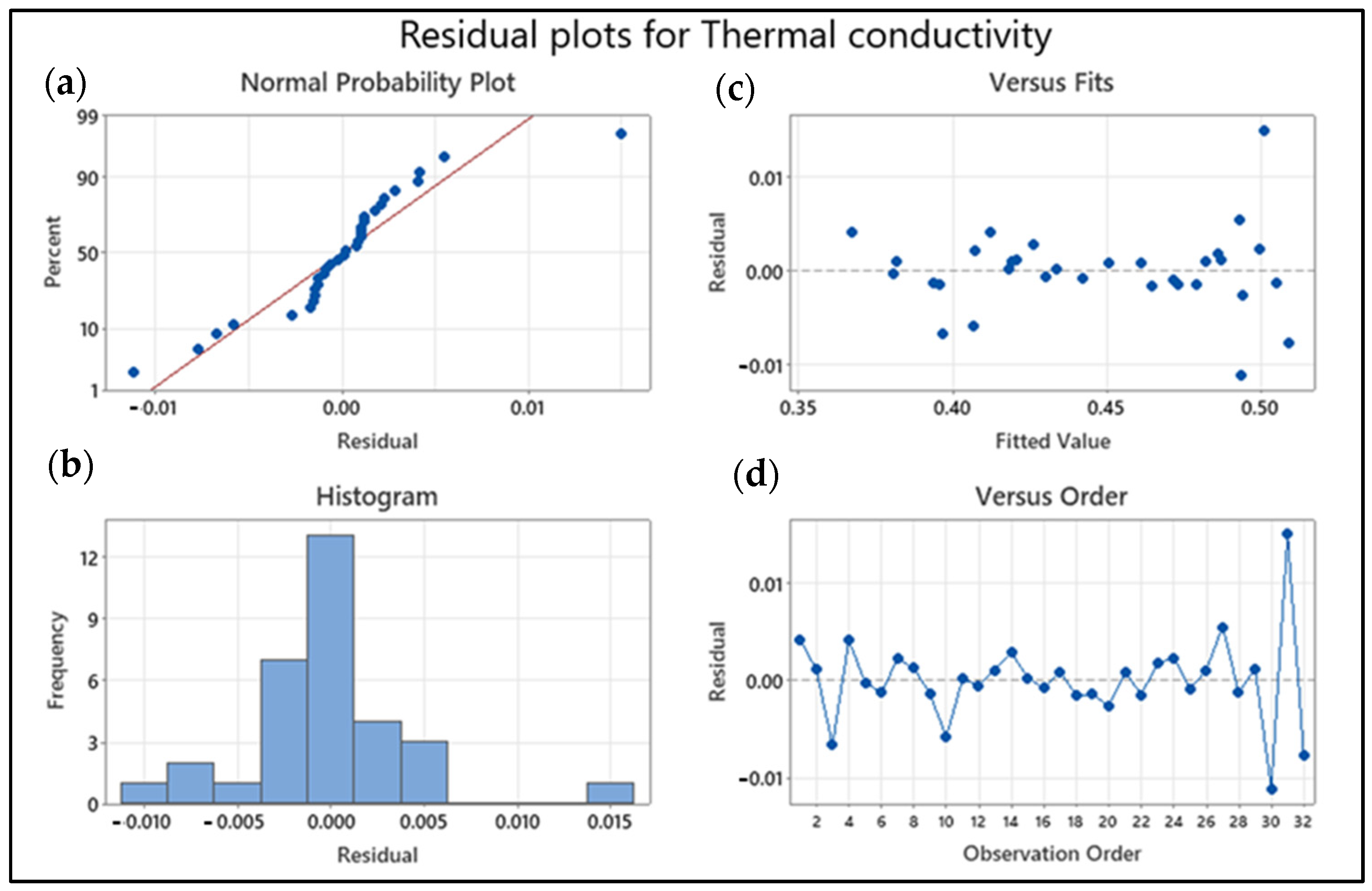

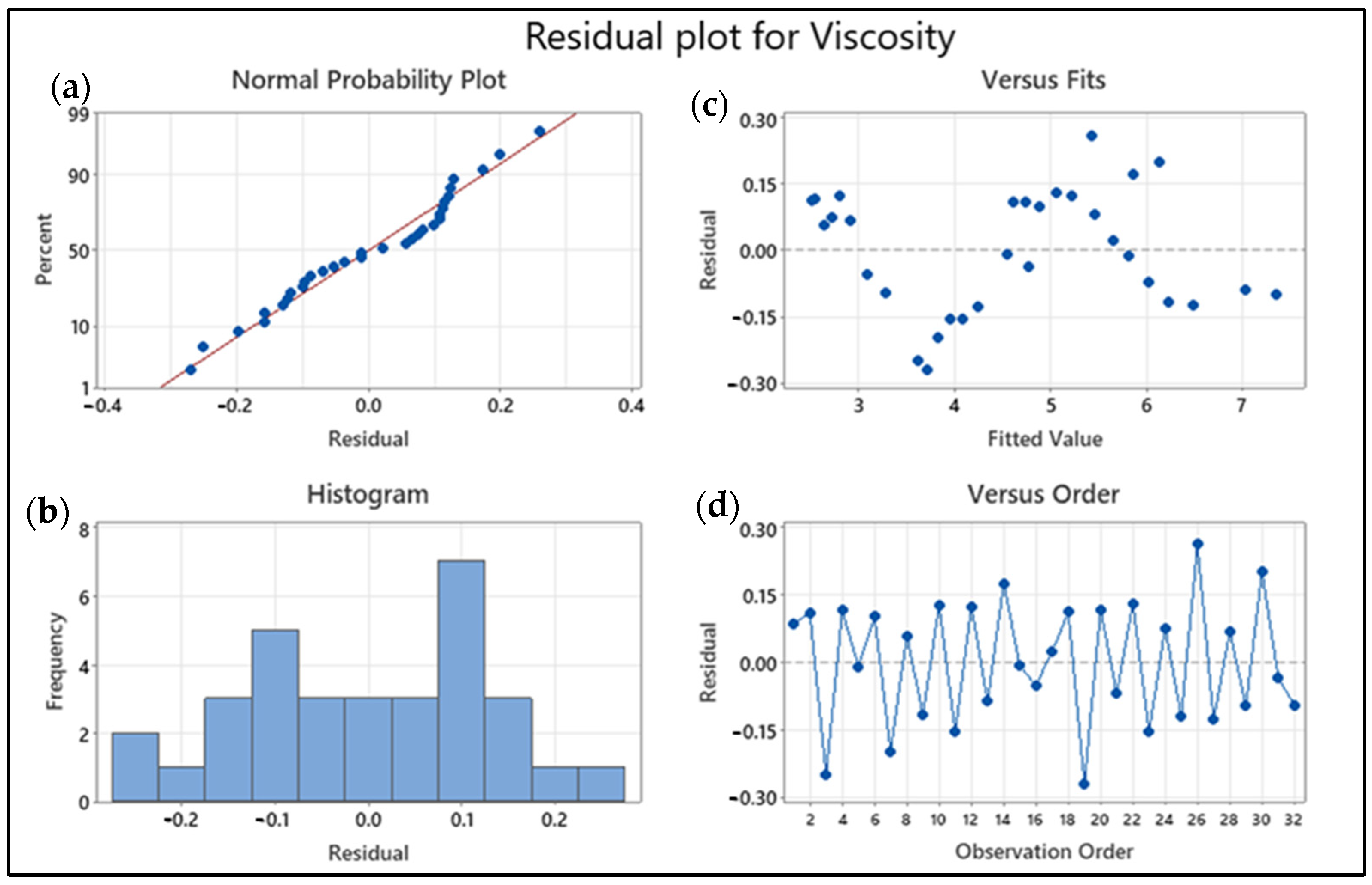

3.5. Pareto and Residual Plots for Thermal Conductivity and Viscosity

3.6. Multi-Objective Optimization

3.7. Applications of Hybrid Nanofluids

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Barma, M.; Saidur, R.; Rahman, S.M.A.; Allouhi, A.; Akash, B.A.; Sait, S.M. A review on boilers energy use, energy savings, and emissions reductions. Renew. Sustain. Energy Rev. 2017, 79, 970–983. [Google Scholar] [CrossRef]

- Bahiraei, M.; Rahmani, R.; Yaghoobi, A.; Khodabandeh, E.; Mashayekhi, R.; Amani, M. Recent research contributions concerning use of nanofluids in heat exchangers: A critical review. Appl. Therm. Eng. 2018, 133, 137–159. [Google Scholar] [CrossRef]

- Sandhya, M.; Ramasamy, D.; Sudhakar, K.; Kadirgama, K.; Samykano, M.; Harun, W.S.W.; Najafi, G.; Mofijur, M.; Mazlan, M. A systematic review on graphene-based nanofluids application in renewable energy systems: Preparation, characterization, and thermophysical properties. Sustain. Energy Technol. Assess. 2021, 44, 101058. [Google Scholar] [CrossRef]

- Maxwell, J.C. A Treatise on Electricity and Magnetism; Clarendon Press: Oxfrod, UK, 1873; Volume 1. [Google Scholar]

- Mousa, M.H.; Miljkovic, N.; Nawaz, K. Review of heat transfer enhancement techniques for single phase flows. Renew. Sustain. Energy Rev. 2021, 137, 110566. [Google Scholar] [CrossRef]

- Esfe, M.H.; Saedodoin, S.; Bahiraei, M.; Toghraie, D.; Mahian, O.; Wongwises, S. Thermal conductivity modeling of MgO/EG nanofluids using experimental data and artificial neural network. J. Therm. Anal. Calorim. 2014, 118, 287–294. [Google Scholar] [CrossRef]

- Esfe, M.H.; Saedodoin, S.; Biglari, M.; Rostamian, H. Experimental investigation of thermal conductivity of CNTs-Al2O3/water: A statistical approach. Int. Commun. Heat Mass Transf. 2015, 69, 29–33. [Google Scholar] [CrossRef]

- Esfe, M.H.; Saedodoin, S.; Asadi, A.; Karimipour, A. Thermal conductivity and viscosity of Mg(OH)2-ethylene glycol nanofluids. J. Therm. Anal. Calorim. 2015, 120, 1145–1149. [Google Scholar] [CrossRef]

- Putra, N.; Roetzel, W.; Das, S.K. Natural convection of nano-fluids. Heat Mass Transf. 2003, 39, 775–784. [Google Scholar] [CrossRef]

- Ahmadi, H.; Ettefaghi, E.; Rashidi, A.M.; Mohtasebi, S.S.; Nouralishahi, A. Surveying and comparing thermal conductivity and physical properties of oil base nanofluids containing carbon and metal oxide nanotubes. J. Nanostruct. 2012, 2, 405–412. [Google Scholar]

- Asadi, M.; Asadi, A. Dynamic viscosity of MWCNT/ZnO–engine oil hybrid nanofluid: An experimental investigation and new correlation in different temperatures and solid concentrations. Int. Commun. Heat Mass Transf. 2016, 76, 41–45. [Google Scholar] [CrossRef]

- Toghraie, D.; Chaharsoghi, V.A.; Afrand, M. Measurement of thermal conductivity of ZnO–TiO2/EG hybrid nanofluid. J. Therm. Anal. Calorim. 2016, 125, 527–535. [Google Scholar] [CrossRef]

- Keshtkar, M.; Mehdipour, N.; Eslami, H. Thermal conductivity of polyamide-6, 6/carbon nanotube composites: Effects of tube diameter and polymer linkage between tubes. Polymers 2019, 11, 1465. [Google Scholar] [CrossRef] [PubMed]

- Konermann, L.; Kim, S. Grotthuss Molecular Dynamics Simulations for Modeling Proton Hopping in Electrosprayed Water Droplets. J. Chem. Theory Comput. 2022, 18, 3781–3794. [Google Scholar] [CrossRef]

- Aybar, H.Ş.; Sharifpur, M.; Azizian, M.R.; Mehrabi, M.; Meyer, J.P. A review of thermal conductivity models for nanofluids. Heat Transf. Eng. 2015, 36, 1085–1110. [Google Scholar] [CrossRef]

- Minea, A.A.; Murshed, S.S. A review on development of ionic liquid based nanofluids and their heat transfer behavior. Renew. Sustain. Energy Rev. 2018, 91, 584–599. [Google Scholar] [CrossRef]

- Paul, T.C.; Tikadar, A.; Mahamud, R.; Salman, A.S.; Morshed, A.M.; Khan, J.A. A critical review on the development of ionic liquids-based nanofluids as heat transfer fluids for solar thermal energy. Processes 2021, 9, 858. [Google Scholar] [CrossRef]

- Murshed, S.S.; De Castro, C.N. Superior thermal features of carbon nanotubes-based nanofluids–A review. Renew. Sustain. Energy Rev. 2014, 37, 155–167. [Google Scholar] [CrossRef]

- Murshed, S.M.S.; Leong, K.C.; Yang, C. Investigations of thermal conductivity and viscosity of nanofluids. Int. J. Therm. Sci. 2008, 47, 560–568. [Google Scholar] [CrossRef]

- Ali, N.; Teixeira, J.A.; Addali, A. A review on nanofluids: Fabrication, stability, and thermophysical properties. J. Nanomater. 2018, 2018, 6978130. [Google Scholar] [CrossRef]

- Wang, X.Q.; Mujumdar, A.S. Heat transfer characteristics of nanofluids: A review. Int. J. Therm. Sci. 2007, 46, 1–19. [Google Scholar] [CrossRef]

- Pordanjani, A.H.; Aghakhani, S.; Afrand, M.; Sharifpur, M.; Meyer, J.P.; Xu, H.; Ali, H.M.; Karimi, N.; Cheraghian, G. Nanofluids: Physical phenomena, applications in thermal systems and the environment effects-a critical review. J. Clean. Prod. 2021, 320, 128573. [Google Scholar] [CrossRef]

- Sanmamed, Y.A.; Navia, P.; González-Salgado, D.; Troncoso, J.; Romani, L. Pressure and temperature dependence of isobaric heat capacity for [Emim][BF4], [Bmim][BF4], [Hmim][BF4], and [Omim][BF4]. J. Chem. Eng. Data 2010, 55, 600–604. [Google Scholar] [CrossRef]

- Waliszewski, D.; Stępniak, I.; Piekarski, H.; Lewandowski, A. Heat capacities of ionic liquids and their heats of solution in molecular liquids. Thermochim. Acta 2005, 433, 149–152. [Google Scholar] [CrossRef]

- Salam, S.; Choudhary, T.; Pugazhendhi, A.; Verma, T.V.; Sharma, A. A review on recent progress in computational and empirical studies of compression ignition internal combustion engine. Fuel 2020, 279, 118469. [Google Scholar] [CrossRef]

- Anderson, M.J.; Whitcomb, P.J. RSM Simplified: Optimizing Processes Using Response Surface Methods for Design of Experiments; Productivity Press: New York, NY, USA, 2016. [Google Scholar]

- Vajjha, R.S.; Das, D.K. A review and analysis on influence of temperature and concentration of nanofluids on thermophysical properties, heat transfer and pumping power. Int. J. Heat Mass Transf. 2012, 55, 4063–4078. [Google Scholar] [CrossRef]

- Sandhya, M.; Ramasamy, D.; Sudhakar, K.; Kadirgama, K.; Harun, W.S.W. Ultrasonication an intensifying tool for preparation of stable nanofluids and study the time influence on distinct properties of graphene nanofluids—A systematic overview. Ultrason. Sonochem. 2021, 73, 105479. [Google Scholar] [CrossRef]

- Sandhya, M.; Ramasamy, D.; Kadirgama, K.; Harun, W.S.W.; Saidur, R. Experimental study on properties of hybrid stable & surfactant-free nanofluids GNPs/CNCs (Graphene nanoplatelets/cellulose nanocrystal) in water/ethylene glycol mixture for heat transfer application. J. Mol. Liq. 2021, 348, 118019. [Google Scholar]

- Sandhya, M.; Ramasamy, D.; Sudhakar, K.; Kadirgama, K.; Harun, W.S.W. Enhancement of the heat transfer in radiator with louvered fin by using Graphene-based hybrid nanofluids. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1062, 012014. [Google Scholar] [CrossRef]

- Amiri, A.; Arzani, H.K.; Kazi, S.N.; Chew, B.T.; Badarudin, A. Backward-facing step heat transfer of the turbulent regime for functionalized graphene nanoplatelets based water–ethylene glycol nanofluids. Int. J. Heat Mass Transf. 2016, 97, 538–546. [Google Scholar] [CrossRef]

- Ganeshkumar, J.; Kathirkaman, D.; Raja, K.; Kumaresan, V.; Velraj, R. Experimental study on density, thermal conductivity, specific heat, and viscosity of water-ethylene glycol mixture dispersed with carbon nanotubes. Therm. Sci. 2017, 21, 255–265. [Google Scholar] [CrossRef]

- Wu, S.; Tahri, O. State-of-art carbon and graphene family nanomaterials for asphalt modification. Road Mater. Pavement Des. 2021, 22, 735–756. [Google Scholar] [CrossRef]

- Kulkarni, D.P.; Das, D.K.; Chukwu, G.A. Temperature dependent rheological property of copper oxide nanoparticles suspension (nanofluid). J. Nanosci. Nanotechnol. 2006, 6, 1150–1154. [Google Scholar] [CrossRef]

- Sandhya, M.; Ramasamy, D.; Kadirgama, K.; Harun, W.S.W.; Saidur, R. Assessment of Thermophysical Properties of Hybrid Nanoparticles [Graphene Nanoplatelets (GNPs) and Cellulose Nanocrystal (CNC)] in a Base Fluid for Heat Transfer Applications. Int. J. Thermophys. 2023, 44, 55. [Google Scholar] [CrossRef]

- Myers, R.H.; Montgomery, D.C.; Vining, G.; Borror, C.M.; Kowalski, S.C. Response surface methodology: A retrospective and literature survey. J. Qual. Technol. 2004, 36, 53–77. [Google Scholar] [CrossRef]

- Khuri, A.I.; Mukhopadhyay, S. Response surface methodology. Wiley Interdiscip. Rev. Comput. Stat. 2010, 2, 128–149. [Google Scholar] [CrossRef]

- Esfe, M.H.; Hajmohammad, M.H. Thermal conductivity and viscosity optimization of nanodiamond-Co3O4/EG (40:60) aqueous nanofluid using NSGA-II coupled with RSM. J. Mol. Liq. 2017, 238, 545–552. [Google Scholar] [CrossRef]

- Myers, R.H.; Montgomery, D.C.; Anderson-Cook, C.M. Response Surface Methodology: Process and Product Optimization Using Designed Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Esfe, M.H.; Arani, A.A.A.; Esfandeh, S. Improving engine oil lubrication in light-duty vehicles by using of dispersing MWCNT and ZnO nanoparticles in 5W50 as viscosity index improvers (VII). Appl. Therm. Eng. 2018, 143, 493–506. [Google Scholar] [CrossRef]

| Type of Factors | Factors | −1 | +1 |

|---|---|---|---|

| Continuous factors | Temperature (°C) | 20 | 50 |

| Volume Concentration (%) | 0.01 | 0.2 | |

| Categorical factors | Type of Nanolubricant | GNP | GNP/CNC |

| Std Order | Temperature °C (T) | Volume Concentration % (Ø) | Type of Nanofluid | Thermal Conductivity (k) W/m-K | Viscosity (cP) |

|---|---|---|---|---|---|

| 1 | 20 | 0.01 | Graphene | 0.371 | 5.54 |

| 2 | 30 | 0.01 | Graphene | 0.382 | 4.72 |

| 3 | 40 | 0.01 | Graphene | 0.390 | 3.37 |

| 4 | 50 | 0.01 | Graphene | 0.416 | 2.62 |

| 5 | 20 | 0.05 | Graphene | 0.380 | 5.79 |

| 6 | 30 | 0.05 | Graphene | 0.392 | 4.98 |

| 7 | 40 | 0.05 | Graphene | 0.409 | 3.63 |

| 8 | 50 | 0.05 | Graphene | 0.422 | 2.70 |

| 9 | 20 | 0.10 | Graphene | 0.394 | 6.11 |

| 10 | 30 | 0.10 | Graphene | 0.400 | 5.34 |

| 11 | 40 | 0.10 | Graphene | 0.418 | 3.92 |

| 12 | 50 | 0.10 | Graphene | 0.429 | 2.93 |

| 13 | 20 | 0.20 | Graphene | 0.420 | 6.94 |

| 14 | 30 | 0.20 | Graphene | 0.428 | 6.02 |

| 15 | 40 | 0.20 | Graphene | 0.434 | 4.53 |

| 16 | 50 | 0.20 | Graphene | 0.441 | 3.04 |

| 17 | 20 | 0.01 | G+CNC | 0.451 | 5.67 |

| 18 | 30 | 0.01 | G+CNC | 0.462 | 4.85 |

| 19 | 40 | 0.01 | G+CNC | 0.477 | 3.44 |

| 20 | 50 | 0.01 | G+CNC | 0.491 | 2.66 |

| 21 | 20 | 0.05 | G+CNC | 0.461 | 5.95 |

| 22 | 30 | 0.05 | G+CNC | 0.471 | 5.18 |

| 23 | 40 | 0.05 | G+CNC | 0.487 | 3.79 |

| 24 | 50 | 0.05 | G+CNC | 0.501 | 2.79 |

| 25 | 20 | 0.10 | G+CNC | 0.470 | 6.35 |

| 26 | 30 | 0.10 | G+CNC | 0.483 | 5.68 |

| 27 | 40 | 0.10 | G+CNC | 0.498 | 4.11 |

| 28 | 50 | 0.10 | G+CNC | 0.503 | 2.98 |

| 29 | 20 | 0.20 | G+CNC | 0.488 | 7.26 |

| 30 | 30 | 0.20 | G+CNC | 0.482 | 6.33 |

| 31 | 40 | 0.20 | G+CNC | 0.515 | 4.73 |

| 32 | 50 | 0.20 | G+CNC | 0.501 | 3.18 |

| Source | DF | Seq SS | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|---|

| Model | 8 | 0.057066 | 0.057066 | 0.007133 | 273.23 | 0.000 |

| Linear | 3 | 0.056434 | 0.052458 | 0.017486 | 669.78 | 0.000 |

| Vol concentration | 1 | 0.004741 | 0.004831 | 0.004831 | 185.03 | 0.000 |

| Temperature | 1 | 0.005377 | 0.004658 | 0.004658 | 178.42 | 0.000 |

| Type of fluid | 1 | 0.046315 | 0.042970 | 0.042970 | 1645.91 | 0.000 |

| Square | 2 | 0.000092 | 0.000092 | 0.000046 | 1.75 | 0.196 |

| Vol concentrationVol concentration | 1 | 0.000089 | 0.000089 | 0.000089 | 3.42 | 0.077 |

| Temperature*Temperature | 1 | 0.000002 | 0.000002 | 0.000002 | 0.09 | 0.773 |

| 2-Way Interaction | 3 | 0.000541 | 0.000541 | 0.000180 | 6.91 | 0.002 |

| Vol concentration*Temperature | 1 | 0.000287 | 0.000287 | 0.000287 | 11.00 | 0.003 |

| Vol concentration*Type of fluid | 1 | 0.000252 | 0.000252 | 0.000252 | 9.65 | 0.005 |

| Temperature*Type of fluid | 1 | 0.000002 | 0.000002 | 0.000002 | 0.07 | 0.794 |

| Error | 23 | 0.000600 | 0.000600 | 0.000026 | ||

| Total | 31 | 0.057667 |

| Source | DF | Seq SS | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|---|

| Model | 8 | 59.4256 | 59.4256 | 7.4282 | 299.63 | 0.000 |

| Linear | 3 | 58.6352 | 58.6423 | 19.5474 | 788.49 | 0.000 |

| Vol concentration | 1 | 5.8737 | 5.8025 | 5.8025 | 234.06 | 0.000 |

| Temperature | 1 | 52.5252 | 52.5840 | 52.5840 | 2121.09 | 0.000 |

| Type of fluid | 1 | 0.2363 | 0.2559 | 0.2559 | 10.32 | 0.004 |

| Square | 2 | 0.1440 | 0.1440 | 0.0720 | 2.90 | 0.075 |

| Vol concentration*Vol concentration | 1 | 0.0031 | 0.0031 | 0.0031 | 0.13 | 0.725 |

| Temperature*Temperature | 1 | 0.1409 | 0.1409 | 0.1409 | 5.68 | 0.026 |

| 2-Way Interaction | 3 | 0.6464 | 0.6464 | 0.2155 | 8.69 | 0.000 |

| Vol concentration*Temperature | 1 | 0.6025 | 0.6025 | 0.6025 | 24.30 | 0.000 |

| Vol concentration*Type of fluid | 1 | 0.0214 | 0.0214 | 0.0214 | 0.86 | 0.363 |

| Temperature*Type of fluid | 1 | 0.0226 | 0.0226 | 0.0226 | 0.91 | 0.350 |

| Error | 23 | 0.5702 | 0.5702 | 0.0248 | ||

| Total | 31 | 59.9958 |

| Model | S | R-Square | R-Square (Adjacent) | PRESS | R-Square (Prediction) | AICc | BIC |

|---|---|---|---|---|---|---|---|

| Thermal conductivity | 0.0051095 | 98.96% | 98.60% | 0.0012977 | 97.75% | −226.99 | −222.80 |

| Viscosity | 0.157452 | 99.05% | 98.72% | 1.04063 | 98.27% | −7.59 | −3.41 |

| Optimum Results | Temperature (°C) | Concentration (%) | Type of Nanofluid | Experimental Value | Predicted Value | ARE% |

|---|---|---|---|---|---|---|

| Thermal conductivity (W/m-K) | 50 | 0.0254 | GNP/CNC | 0.495443 | 0.4962 | 0.16148 |

| Viscosity (cP) | 50 | 0.0254 | GNP/CNC | 2.7134 | 2.6191 | 3.4753 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yaw, C.T.; Koh, S.P.; Sandhya, M.; Ramasamy, D.; Kadirgama, K.; Benedict, F.; Ali, K.; Tiong, S.K.; Abdalla, A.N.; Chong, K.H. An Approach for the Optimization of Thermal Conductivity and Viscosity of Hybrid (Graphene Nanoplatelets, GNPs: Cellulose Nanocrystal, CNC) Nanofluids Using Response Surface Methodology (RSM). Nanomaterials 2023, 13, 1596. https://doi.org/10.3390/nano13101596

Yaw CT, Koh SP, Sandhya M, Ramasamy D, Kadirgama K, Benedict F, Ali K, Tiong SK, Abdalla AN, Chong KH. An Approach for the Optimization of Thermal Conductivity and Viscosity of Hybrid (Graphene Nanoplatelets, GNPs: Cellulose Nanocrystal, CNC) Nanofluids Using Response Surface Methodology (RSM). Nanomaterials. 2023; 13(10):1596. https://doi.org/10.3390/nano13101596

Chicago/Turabian StyleYaw, Chong Tak, Siaw Paw Koh, Madderla Sandhya, Devarajan Ramasamy, Kumaran Kadirgama, Foo Benedict, Kharuddin Ali, Sieh Kiong Tiong, Ahmed N. Abdalla, and Kok Hen Chong. 2023. "An Approach for the Optimization of Thermal Conductivity and Viscosity of Hybrid (Graphene Nanoplatelets, GNPs: Cellulose Nanocrystal, CNC) Nanofluids Using Response Surface Methodology (RSM)" Nanomaterials 13, no. 10: 1596. https://doi.org/10.3390/nano13101596

APA StyleYaw, C. T., Koh, S. P., Sandhya, M., Ramasamy, D., Kadirgama, K., Benedict, F., Ali, K., Tiong, S. K., Abdalla, A. N., & Chong, K. H. (2023). An Approach for the Optimization of Thermal Conductivity and Viscosity of Hybrid (Graphene Nanoplatelets, GNPs: Cellulose Nanocrystal, CNC) Nanofluids Using Response Surface Methodology (RSM). Nanomaterials, 13(10), 1596. https://doi.org/10.3390/nano13101596