Towards Efficient Electrically-Driven Deep UVC Lasing: Challenges and Opportunities

Abstract

1. Introduction

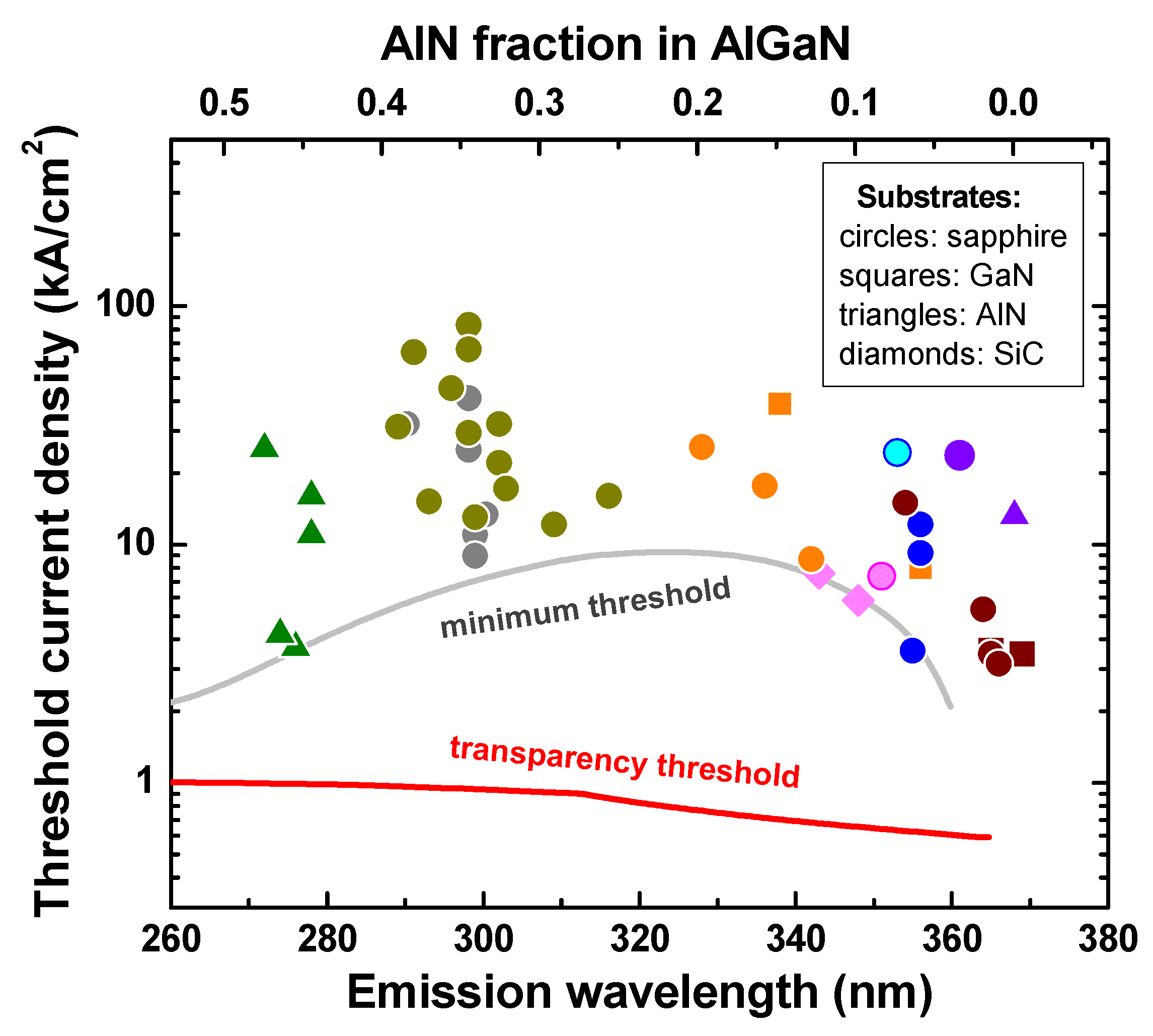

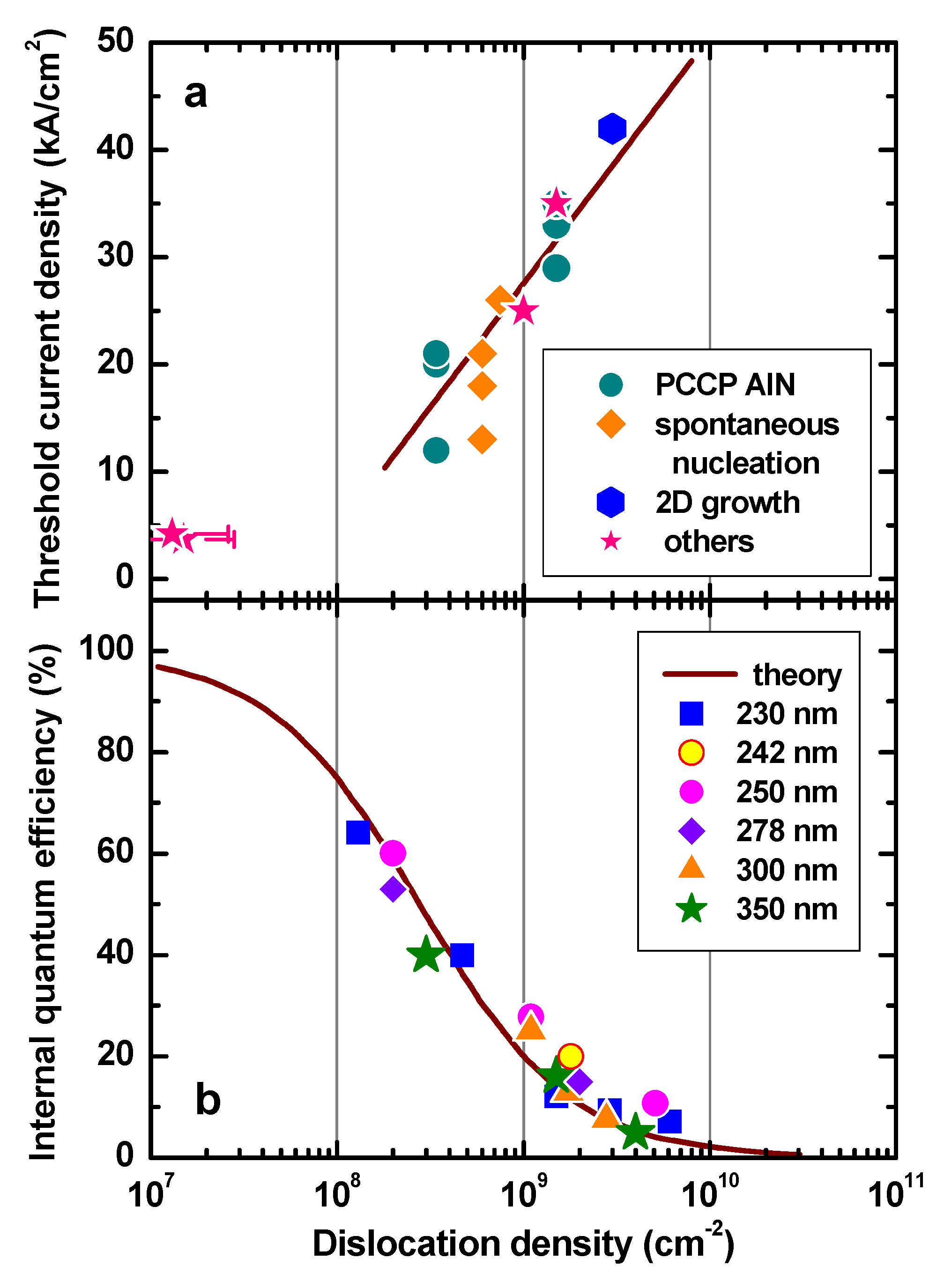

2. Material Quality and Its Impact on Internal Quantum Efficiency and Threshold Current Density of UVC Laser Diodes

3. Low-Resistive AlGaN Layers and Doping Problems

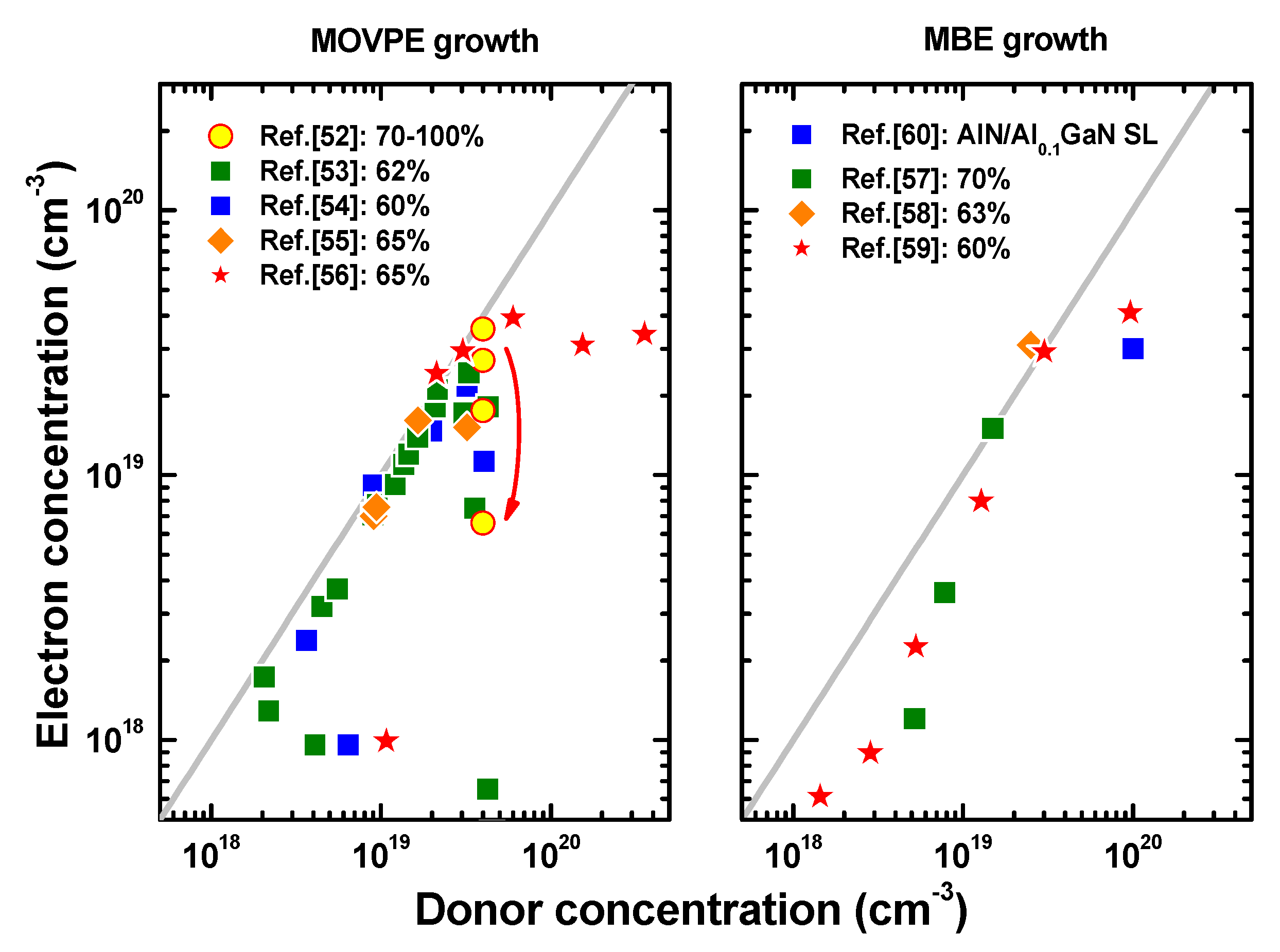

3.1. N-Type Doping of AlGaN

3.2. P-type doping of AlGaN

4. Laser Structure Design

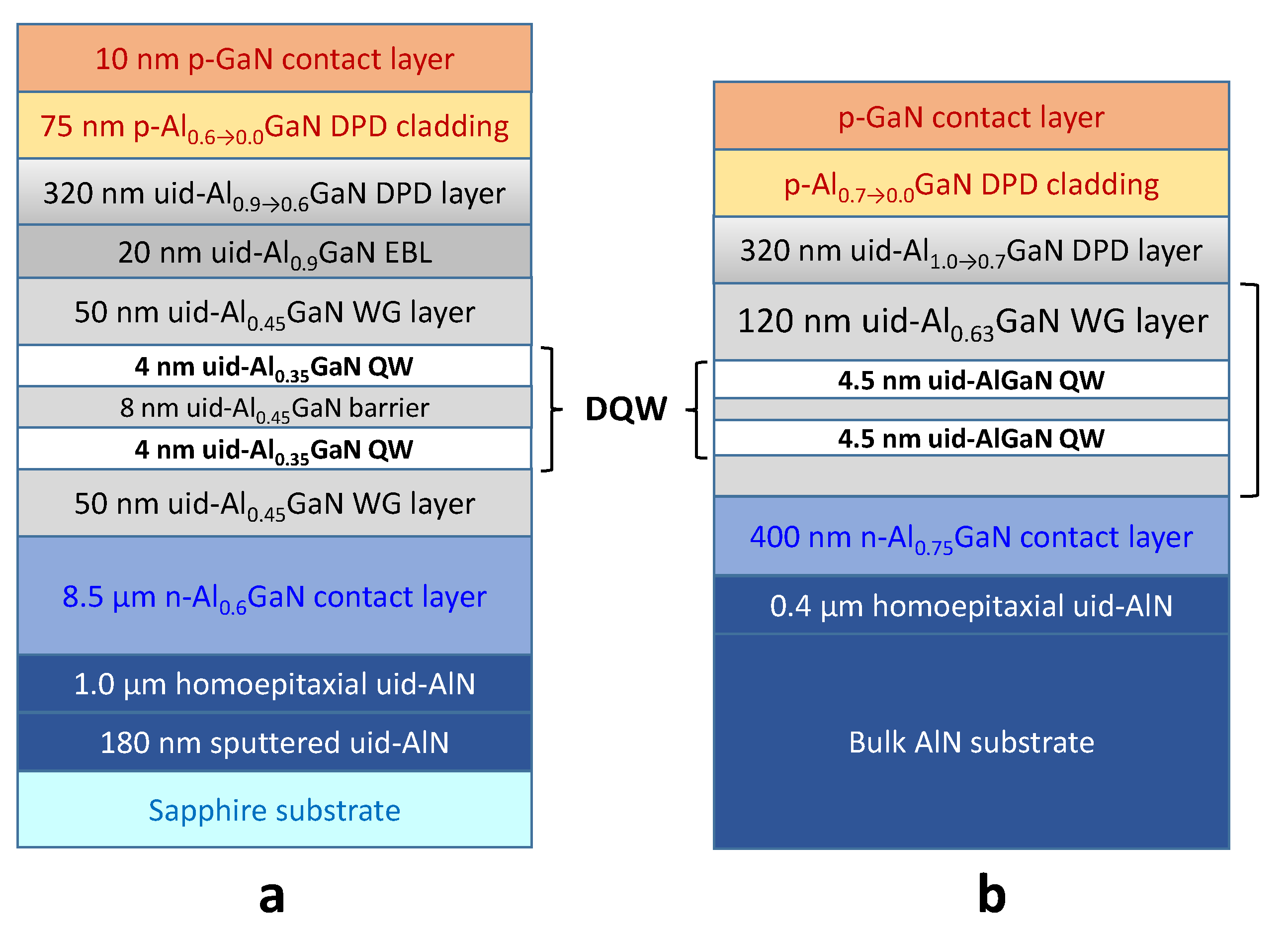

4.1. Typical UVC Laser Diode Structures

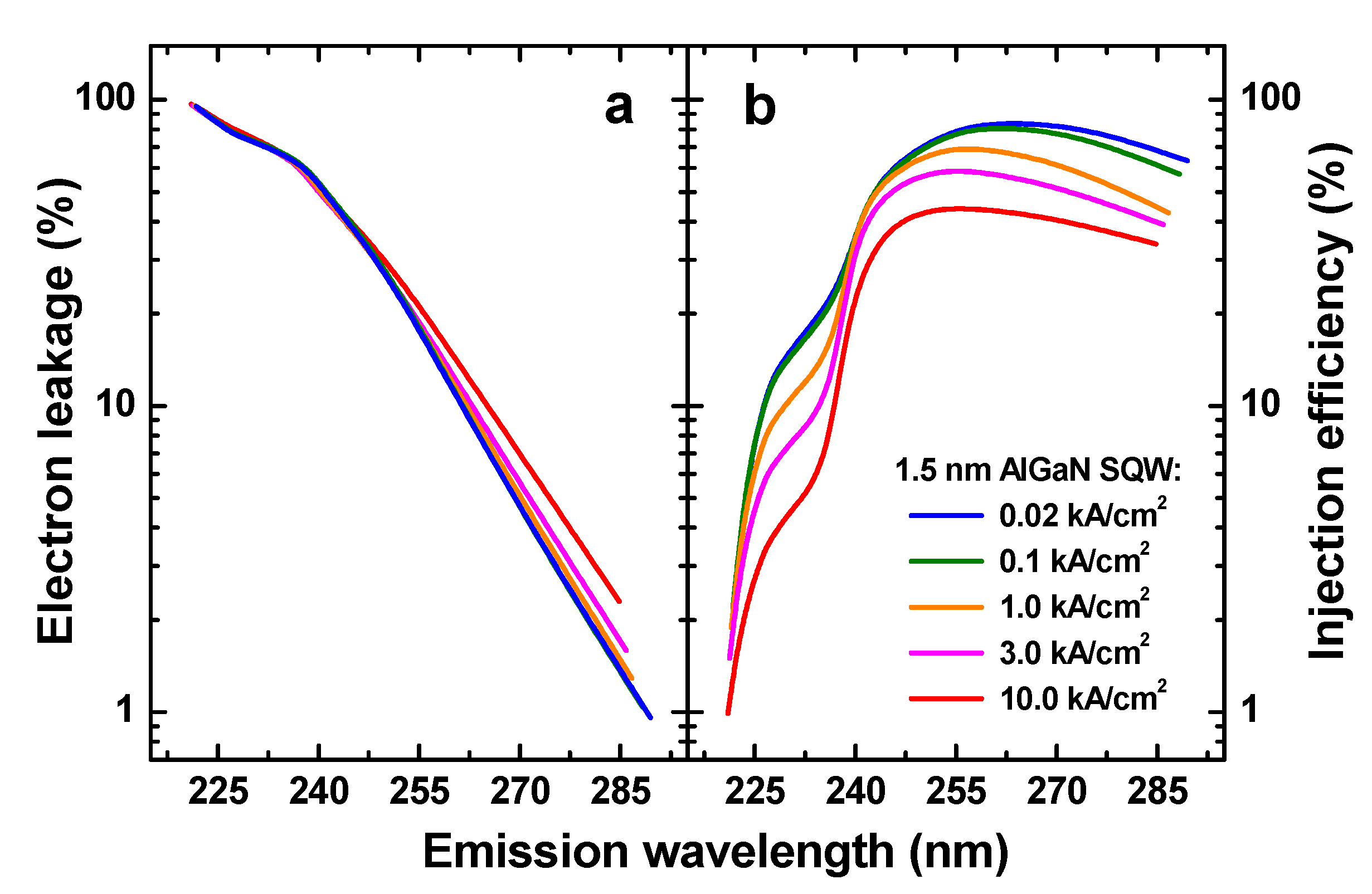

4.2. Electron Leakage into P-Layers of Device Structures

4.3. Active Region Design and P-Type Ohmic Contacts

4.4. Tunnel Junctions in the Laser Diode Structures

5. Summary

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hayashi, T.; Oguma, K.; Fujimura, Y.; Furuta, R.A.; Tanaka, M.; Masaki, M.; Sninbata, Y.; Kimura, T.; Tani, Y.; Hirayama, F.; et al. UV light-emitting diode (UV-LED) at 265 nm as a potential light source for disinfecting human platelet concentrates. PLoS ONE 2021, 16, e0251650. [Google Scholar] [CrossRef] [PubMed]

- Sharma, V.K.; Demir, H.V. Bright Future of Deep-Ultraviolet Photonics: Emerging UVC Chip-Scale Light-Source Technology Platforms, Benchmarking, Challenges, and Outlook for UV Disinfection. ACS Photonics 2022, 9, 1513–1521. [Google Scholar] [CrossRef]

- Yuan, J.; Ma, J. Review of ultraviolet non-line-of-light communication. China Commun. 2016, 13, 63–75. [Google Scholar] [CrossRef]

- Bentancourt, W.Q.; Rose, J.B. Drinking Water Treatment Processes for Removal of Cryptosporidium and Giardia. Vet. Parasitolog. 2004, 126, 219–234. [Google Scholar]

- Glaab, J.; Lobo-Ploch, N.; Cho, H.K.; Filler, T.; Gundlach, H.; Guttmann, M.; Hagedorn, S.; Lohan, S.B.; Mehnke, F.; Schleusener, J.; et al. Skin tolerant inactivation of multiresistant pathogens using far-UVC LEDs. Sci. Rep. 2021, 11, 14647. [Google Scholar] [CrossRef] [PubMed]

- Hirayama, H.; Fujikawa, S.; Noguchi, N.; Norimatsu, J.; Takano, T.; Tsubaki, K.; Kamata, N. 222–282 nm AlGaN and InAlGaN-based deep-UV LEDs fabricated on high-quality AlN on sapphire. Phys. Status Solidi 2009, 206, 1176–1182. [Google Scholar] [CrossRef]

- Zhao, S.; Liu, X.; Wu, Y.; Mi, Z. An electrically pumped 239 nm AlGaN nanowire laser operating at room temperature. Appl. Phys. Lett. 2016, 109, 191106. [Google Scholar] [CrossRef]

- Yoshida, H.; Yamashita, Y.; Kuwabara, M.; Kan, H. Demonstration of an ultraviolet 336 nm AlGaN multiple-quantum-well laser diode. Appl. Phys. Lett. 2008, 93, 241106. [Google Scholar] [CrossRef]

- Jmerik, V.N.; Mizerov, A.M.; Sitnikova, A.A.; Kop’ev, P.S.; Ivanov, S.V.; Lutsenko, E.V.; Tarasuk, N.P.; Rzheutskii, N.V.; Yablonskii, G.P. Low-threshold 303 nm lasing in AlGaN-based multiple-quantum well structures with an asymmetric waveguide grown by plasma-assisted molecular beam epitaxy on c-sapphire. Appl. Phys. Lett. 2010, 96, 141112. [Google Scholar] [CrossRef]

- Lachab, M.; Sun, W.; Jain, R.; Dobrinsky, A.; Gaevski, M.; Rumyantsev, S.; Shur, M.; Shatalov, M. Optical polarization control of photo-pumped stimulated emissions at 238 nm from AlGaN multiple-quantum-well laser structures on AlN substrates. Appl. Phys. Express 2017, 10, 012702. [Google Scholar] [CrossRef]

- Taketomi, H.; Aoki, Y.; Takagi, Y.; Sugiyama, A.; Kuwabara, M.; Yoshida, H. Over 1 W record-peak-power operation of a 338 nm AlGaN multiple-quantum-well laser diode on a GaN substrate. Jpn. J. Appl. Phys. 2016, 55, 05FJ05. [Google Scholar] [CrossRef]

- Jmerik, V.N.; Lutsenko, E.V.; Ivanov, S.V. Plasma-assisted molecular beam epitaxy of AlGaN heterostructures for deep-ultraviolet optically pumped lasers. Phys. Status Solidi A 2013, 210, 439–450. [Google Scholar] [CrossRef]

- Takano, T.; Narita, Y.; Horiuchi, A.; Kawanishi, H. Room-temperature deep-ultraviolet lasing at 241.5 nm of AlGaN multiple-quantum-well laser. Appl. Phys. Lett. 2004, 84, 3567–3569. [Google Scholar] [CrossRef]

- Ivanov, S.V.; Nechaev, D.V.; Sitnikova, A.A.; Ratnikov, V.V.; Yagovkina, M.A.; Rzheutskii, N.V.; Lutsenko, E.V.; Jmerik, V.N. Plasma-assisted molecular beam epitaxy of Al(Ga)N layers and quantum well structures for optically pumped mid-UV lasers on c-Al2O3. Semicond. Sci. Technol. 2014, 29, 084008. [Google Scholar] [CrossRef]

- Li, D.; Jiang, K.; Sun, X.; Guo, C. AlGaN photonics: Recent advances in materials and ultraviolet devices. Adv. Opt. Photonics 2018, 10, 43–110. [Google Scholar] [CrossRef]

- Kirste, R.; Guo, Q.; Dycus, H.J.; Franke, A.; Mita, S.; Sarkar, B.; Reddy, P.; LeBeau, J.M.; Collazo, R.; Sitar, Z. 6 kW/cm2 UVC laser threshold in optically pumped lasers achieved by controlling point defect formation. Appl. Phys. Express 2018, 11, 082101. [Google Scholar] [CrossRef]

- Ni, R.; Chen, X.; Yan, J.; Zhang, L.; Guo, Y.; Wang, J.; Li, J.; Zhang, Y. Reducing stimulated emission threshold power density of AlGaN/AlN multiple quantum wells by nano-trench-patterned AlN template. J. Alloy Compd. 2019, 777, 344–349. [Google Scholar] [CrossRef]

- Sato, K.; Yasue, S.; Ogino, Y.; Tanaka, S.; Iwaya, M.; Takeuchi, T.; Kamiyama, S.; Akasaki, I. Light confinement and high current density in UVB laser diode structure using Al composition-graded p-AlGaN cladding layer. Appl. Phys. Lett. 2019, 114, 191103-1–191103-5. [Google Scholar] [CrossRef]

- Arafin, S.; Hasan, S.M.N.; Jamal-Eddine, Z.; Wickramaratne, D.; Paul, B.; Rajan, S. Design of AlGaN-based lasers with a buried tunnel junction for sub-300 nm emission. Semicond. Sci. Technol. 2019, 34, 074002. [Google Scholar] [CrossRef]

- Liu, Y.-S.; Lochner, Z.; Kao, T.-T.; Satter, M.; Li, X.-H.; Ryou, J.-H.; Shen, S.-C.; Yoder, P.D.; Detchprohm, T.; Dupuis, R.D.; et al. Optically pumped AlGaN quantum-well lasers at sub-250 nm grown by MOCVD on AlN substrates. Phys. Status Solidi C 2014, 11, 258–260. [Google Scholar] [CrossRef]

- Hayashi, T.; Kawase, Y.; Nagata, N.; Senga, T.; Iwayama, S.; Iwaya, M.; Takeuchi, T.; Kamiyama, S.; Akasaki, I.; Matsumoto, T. Demonstration of electron beam laser excitation in the UV range using a GaN/AlGaN multiquantum well active layer. Sci. Rep. 2017, 7, 2944. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Yin, X.; Zhao, S. Recent Progress on Aluminum Gallium Nitride Deep Ultraviolet Lasers by Molecular Beam Epitaxy. Phys. Status Solidi RRL 2021, 15, 2100090. [Google Scholar] [CrossRef]

- Jmerik, V.; Nechaev, D.; Orekhova, K.; Prasolov, N.; Kozlovsky, V.; Sviridov, D.; Zverev, M.; Gamov, N.; Grieger, L.; Wang, Y.; et al. Monolayer-Scale GaN/AlN Multiple Quantum Wells for High Power e-Beam Pumped UV-Emitters in the 240–270 nm Spectral Range. Nanomaterials 2021, 11, 2553. [Google Scholar] [CrossRef] [PubMed]

- Iwaya, M.; Tanaka, S.; Omori, T.; Yamada, K.; Hasegawa, R.; Shimokawa, M.; Yabutani, A.; Iwayama, S.; Sato, K.; Takeuchi, T.; et al. Recent development of UV-B laser diodes. Jpn. J. Appl. Phys. 2022, 61, 040501. [Google Scholar] [CrossRef]

- Zhang, Z.; Kushimoto, M.; Yoshikawa, A.; Aoto, K.; Schowalter, L.J.; Sasaoka, C.; Amano, H. Continuous-wave lasing of AlGaN-based ultraviolet laser diode at 274.8 nm by current injection. Appl. Phys. Express 2022, 15, 041007. [Google Scholar] [CrossRef]

- Zhang, Z.; Kushimoto, M.; Yoshikawa, A.; Aoto, K.; Sasaoka, C.; Schowalter, L.J.; Amano, H. Key temperature-dependent characteristics of AlGaN-based UV-C laser diode and demonstration of room-temperature continuous-wave lasing. Appl. Phys. Lett. 2022, 121, 222103. [Google Scholar] [CrossRef]

- Nippert, F.; Mazraehno, M.T.; Davies, M.J.; Hoffmann, M.P.; Lugauer, H.-J.; Kure, T.; Kneissl, M.; Hoffmann, A.; Wagner, M.R. Auger recombination in AlGaN quantum wells for UV light-emitting diodes. Appl. Phys. Lett. 2018, 113, 071107. [Google Scholar] [CrossRef]

- Omori, T.; Ishizuka, S.; Tanaka, S.; Yasue, S.; Sato, K.; Ogino, Y.; Teramura, S.; Yamada, K.; Iwayama, S.; Miyake, H.; et al. Internal loss of AlGaN-based ultraviolet-B band laser diodes with p-type AlGaNcladding layer using polarization doping. Appl. Phys. Express 2020, 13, 071008. [Google Scholar] [CrossRef]

- Tanaka, S.; Teramura, S.; Shimokawa, M.; Yamada, K.; Omori, T.; Iwayama, S.; Sato, K.; Miyake, H.; Iwaya, M.; Takeuchi, T.; et al. AlGaN-based UV-B laser diode with a wavelength of 290 nm on 1 μm periodic concavo-convex pattern AlN on a sapphire substrate. Appl. Phys. Express 2021, 14, 055505. [Google Scholar] [CrossRef]

- Omori, T.; Yabutani, A.; Tanaka, S.; Yamada, K.; Shimokawa, M.; Hasegawa, R.; Iwayama, S.; Miyake, H.; Takeuchi, T.; Kamiyama, S.; et al. Reduction of dislocation density in lattice-relaxed Al0.68Ga0.32N film grown on periodical 1 μm spacing AlN pillar concave-convex patterns and its effect on the performance of UV-B laser diodes. Appl. Phys. Express 2022, 15, 031004. [Google Scholar] [CrossRef]

- Amano, H.; Sawaki, N.; Akasaki, I. Metalorganic vapor phase epitaxial growth of high quality GaN film using an AlN buffer layer. Appl. Phys. Lett. 1986, 48, 353–355. [Google Scholar] [CrossRef]

- Ban, K.; Yamamoto, J.-I.; Takeda, K.; Ide, K.; Iwaya, M.; Takeuchi, T.; Kamiyama, S.; Akasaki, I.; Amano, H. Internal Quantum Efficiency of Whole-Composition-Range AlGaN Multiquantum Wells. Appl. Phys. Express 2011, 4, 052101. [Google Scholar] [CrossRef]

- Shatalov, M.; Sun, W.; Lunev, A.; Hu, X.; Dobrinsky, A.; Bilenko, Y.; Yang, J.; Shur, M.; Gaska, R.; Moe, G.; et al. AlGaN Deep-Ultraviolet Light-Emitting Diodes with External Quantum Efficiency above 10%. Appl. Phys. Express 2012, 5, 082101. [Google Scholar] [CrossRef]

- Karpov, S.Y.; Makarov, Y.N. Dislocation effect on light emission efficiency in gallium nitride. Appl. Phys. Lett. 2002, 81, 4721–4723. [Google Scholar] [CrossRef]

- Karpov, S.Y. Light-emitting diodes for solid-state lighting: Searching room for improvements. Proc. SPIE 2016, 9768, 19–35. [Google Scholar]

- Shatalov, M.; Sun, W.; Jain, R.; Lunev, A.; Hu, X.; Dobrinsky, A.; Bilenko, Y.; Yang, J.; Garrett, G.A.; Rodak, L.E.; et al. High power AlGaN ultraviolet light emitters. Semicond. Sci. Technol. 2014, 29, 084007. [Google Scholar] [CrossRef]

- Hirayama, H.; Noguchi, N.; Yatabe, T.; Kamata, N. 227nm AlGaN Light-Emitting Diode with 0.15 mW Output Power Realized using a Thin Quantum Well and AlN Buffer with Reduced Threading Dislocation Density. Appl. Phys. Express 2008, 1, 051101. [Google Scholar] [CrossRef]

- Hirayama, H.; Maeda, N.; Fujikawa, S.; Toyoda, S.; Kamata, N. Recent progress and future prospects of AlGaN-based high-efficiency deep-ultraviolet light-emitting diodes. Jpn J. Appl. Phys. 2014, 53, 100209. [Google Scholar] [CrossRef]

- Imura, M.; Nakano, K.; Fujimoto, N.; Okada, N.; Balakrishnan, K.; Iwaya, M.; Kamiyama, S.; Amano, H.; Akasaki, I.; Noro, T.; et al. High-Temperature Metal-Organic Vapor Phase Epitaxial Growth of AlN on Sapphire by Multi Transition Growth Mode Method Varying V/III Ratio. Jpn J. Appl. Phys. 2006, 45, 8639–8643. [Google Scholar] [CrossRef]

- Imura, M.; Nakano, K.; Narita, G.; Fujimoto, N.; Okada, N.; Balakrishnan, K.; Iwaya, M.; Kamiyama, S.; Amano, H.; Akasaki, I.; et al. Epitaxial lateral overgrowth of AlN on trench-patterned AlN layers. J. Cryst. Growth 2007, 298, 257–260. [Google Scholar] [CrossRef]

- Hirayama, H.; Fujikawa, S.; Norimatsu, J.; Takano, T.; Tsubaki, K.; Kamata, N. Fabrication of a low threading dislocation density ELO-AlN template for application to deep-UV LEDs. Phys. Status Solidi C 2009, 6, S356–S359. [Google Scholar] [CrossRef]

- Nechaev, D.V.; Aseev, P.A.; Jmerik, V.N.; Brunkov, P.N.; Kuznetsova, Y.V.; Sitnikova, A.A.; Ratnikov, V.V.; Ivanov, S.V. Control of threading dislocation density at the initial growth stage of AlN on c-sapphire in plasma-assisted MBE. J. Cryst. Growth 2013, 378, 319–322. [Google Scholar] [CrossRef]

- Jmerik, V.N.; Nechaev, D.V.; Rouvimov, S.; Ratnikov, V.V.; Kop’ev, P.S.; Rzheutski, M.V.; Lutsenko, E.V.; Yablonskii, G.P.; Aljohenii, M.; Aljerwii, A.; et al. Structural and optical properties of PA MBE AlGaN quantum well heterostructures grown on c-Al2O3 by using flux- and temperature-modulated techniques. J. Mater. Res. 2015, 30, 2871–2880. [Google Scholar] [CrossRef]

- Nikishin, S.A.; Borisov, B.A.; Chandolu, A.; Kuryatkov, V.V.; Temkin, H.; Holtz, M.; Mokhov, E.N.; Makarov, Y.; Helava, H. Short-period superlattices of AlN/Al0.08Ga0.92N grown on AlN substrates. Appl. Phys. Lett. 2004, 85, 4355–4357. [Google Scholar] [CrossRef]

- Miyake, H.; Lin, C.-H.; Tokoro, K.; Hiramatsu, K. Preparation of high-quality AlN on sapphire by high-temperature face-to-face annealing. J. Cryst. Growth 2016, 456, 155–159. [Google Scholar] [CrossRef]

- Uesugi, K.; Miyake, H. Fabrication of AlN templates by high-temperature face-to-face annealing for deep UV LEDs. Jpn. J. Appl. Phys. 2021, 60, 120502. [Google Scholar] [CrossRef]

- Xiao, S.; Suzuki, R.; Miyake, H.; Harada, S.; Ujihara, T. Improvement mechanism of sputtered AlN films by high-temperature annealing. J. Cryst. Growth 2018, 502, 41–44. [Google Scholar] [CrossRef]

- Hagedorn, S.; Walde, S.; Knauer, A.; Susilo, N.; Pacak, D.; Cancellara, L.; Netzel, C.; Mogilatenko, A.; Hartmann, C.; Wernicke, T.; et al. Status and Prospects of AlN Templates on Sapphire for Ultraviolet Light-Emitting Diodes. Phys. Status Solidi A 2020, 217, 1901022. [Google Scholar] [CrossRef]

- Grandusky, J.R.; Smart, J.A.; Mendrick, M.C.; Schowalter, L.J.; Chen, K.X.; Schubert, E.F. Pseudomorphicgrowthofthickn-typeAlxGa1−xN layers on low-defect-density bulk AlN substrates for UV LED applications. J. Cryst. Growth 2009, 311, 2864–2866. [Google Scholar] [CrossRef]

- Rathkanthiwar, S.; Houston Dycus, J.; Mita, S.; Kirste, R.; Tweedie, J.; Collazo, R.; Sitar, Z. Pseudomorphic growth of thick Al0.6Ga0.4N epilayers on AlN substrates. Appl. Phys. Lett. 2022, 120, 202105. [Google Scholar] [CrossRef]

- Huang, X.-Y.; Walde, S.; Tsai, C.-L.; Netzel, C.; Liu, H.-H.; Hagedorn, S.; Wu, Y.-R.; Fu, Y.-K.; Weyers, M. Overcoming the excessive compressive strain in AlGaN epitaxy by introducing high Si-doping in AlN templates. Jpn. J. Appl. Phys. 2020, 59, 070904. [Google Scholar] [CrossRef]

- Nakarmi, M.L.; Kim, K.H.; Zhu, K.; Lin, J.Y.; Jiang, H.X. Transport properties of highly conductive n-type Al-rich AlxGa1−xN (x ≥ 0.7). Appl. Phys. Lett. 2004, 85, 3769–3771. [Google Scholar] [CrossRef]

- Nagata, K.; Makino, H.; Yamamoto, T.; Kataoka, K.; Narita, T.; Saito, Y. Low resistivity of highly Si-doped n-type Al0.62Ga0.38N layer by suppressing self-compensation. Appl. Phys. Express 2020, 13, 025504. [Google Scholar] [CrossRef]

- Kataoka, K.; Narita, T.; Nagata, K.; Makino, H.; Saito, Y. Electronic degeneracy conduction in highly Si-doped Al0.6Ga0.4N layers based on the carrier compensation effect. Appl. Phys. Lett. 2020, 117, 262103. [Google Scholar] [CrossRef]

- Almogbel, A.S.; Zollner, C.J.; Saifaddin, B.K.; Iza, M.; Wang, J.; Yao, Y.; Wang, M.; Foronda, H.; Prozheev, I.; Tuomisto, F.; et al. Growth of highly conductive Al-rich AlGaN: Si with low group-III vacancy concentration. AIP Adv. 2021, 11, 095119. [Google Scholar] [CrossRef]

- Zollner, C.J.; Yao, Y.; Wang, M.; Wu, F.; Iza, M.; Speck, J.S.; DenBaars, S.P.; Nakamura, S. Highly Conductive n-Al0.65Ga0.35N Grown by MOCVD Using Low V/III Ratio. Crystals 2021, 11, 1006. [Google Scholar]

- Bharadwaj, S.; Islam, S.M.; Nomoto, K.; Protasenko, V.; Chaney, A.; Xing, H.; Jena, D. Bandgap narrowing and Mott transition in Si-doped Al0.7Ga0.3N. Appl. Phys. Lett. 2019, 114, 113501. [Google Scholar] [CrossRef]

- Lee, K.; Page, R.; Protasenko, V.; Schowalter, L.J.; Toita, M.; Xing, H.; Jena, D. MBE growth and donor doping of coherent ultrawide bandgap AlGaN alloy layers on single-crystal AlN substrates. Appl. Phys. Lett. 2021, 118, 092101. [Google Scholar] [CrossRef]

- Wang, J.; Saifaddin, B.K.; Zollner, C.J.; Bonef, B.; Almogbel, A.S.; Yao, Y.; Iza, M.; Zhang, Y.; Fireman, M.N.; Young, E.C.; et al. High conductivity n-Al0.6Ga0.4N by ammonia-assisted molecular beam epitaxy for buried tunnel junctions in UV emitters. Opt. Express 2021, 29, 40781–40794. [Google Scholar] [CrossRef]

- Kipshidze, G.; Kuryatkov, V.; Zhu, K.; Borisov, B.; Holtz, M.; Nikishin, S.; Temkin, H. AlN/AlGaInN superlattice light-emitting diodes at 280 nm. J. Appl. Phys. 2003, 92, 1363–1366. [Google Scholar] [CrossRef]

- Washiyama, S.; Mirrielees, K.J.; Bagheri, P.; Baker, J.N.; Kim, J.-H.; Guo, Q.; Kirste, R.; Guan, Y.; Breckenridge, M.H.; Klump, A.J.; et al. Self-compensation in heavily Ge doped AlGaN: A comparison to Si doping. Appl. Phys. Lett. 2021, 118, 0421026. [Google Scholar] [CrossRef]

- Borisov, B.; Kuryatkov, V.; Kudryavtsev, Y.; Asomoza, R.; Nikishin, S.; Song, D.Y.; Holtz, M.; Temkin, H. Si-doped AlxGa1−xN (0.56 ≤ x ≤ 1) layers grown by molecular beam epitaxy with ammonia. Appl. Phys. Lett. 2005, 87, 132106. [Google Scholar] [CrossRef]

- Park, C.H.; Chadi, D.J. Stability of deep donor and acceptor centers in GaN, AlN, and BN. Phys. Rev B 1997, 55, 12995–13001. [Google Scholar] [CrossRef]

- Gordon, L.; Lyons, J.L.; Janotti, A.; Van de Walle, C.G. Hybrid functional calculations of DX centers in AlN and GaN. Phys. Rev. B 2014, 89, 085204. [Google Scholar] [CrossRef]

- Noh, S.K.; Lee, H.J. Doping Characteristics of Si-doped n-GaN Epilayers Grown by Low-Pressure Metal-Organic Chemical-Vapor Deposition. J. Korean Phys. Soc. 1998, 32, 851–856. [Google Scholar]

- Taniyasu, Y.; Kasu, M.; Kobayashi, N. Intentional control of n-type conduction for Si-doped AlN and AlxGa1−xN (0.42 ≤ x < 1). Appl. Phys. Lett. 2002, 81, 1255–1257. [Google Scholar]

- Zhu, K.; Nakarmi, M.L.; Kim, K.H.; Lin, J.Y.; Jiang, H.X. Silicon doping dependence of highly conductive n-type Al0.7Ga0.3N. Appl. Phys. Lett. 2004, 85, 4669–4671. [Google Scholar] [CrossRef]

- Forghani, K.; Gharavipour, M.; Scholz, F.; Thonke, K. Investigations on Si-doped AlGaN: Below and above the Mott density. Phys. Status Solidi C 2012, 9, 492–495. [Google Scholar] [CrossRef]

- Son, N.T.; Bickermann, M.; Janzén, E. Shallow donor and DX states of Si in AlN. Appl. Phys. Lett. 2011, 98, 092104. [Google Scholar] [CrossRef]

- Breckenridge, M.H.; Guo, Q.; Klump, A.; Sarkar, B.; Guan, Y.; Tweedie, J.; Kirste, R.; Mita, S.; Reddy, P.; Collazo, R.; et al. Shallow Si donor in ion-implanted homoepitaxial AlN. Appl. Phys. Lett. 2020, 116, 172103. [Google Scholar] [CrossRef]

- Bagheri, P.; Kirste, R.; Reddy, P.; Washiyama, S.; Mita, S.; Sarkar, B.; Collazo, R.; Sitar, Z. The nature of the DX state in Ge-doped AlGaN. Appl. Phys. Lett. 2020, 116, 222102. [Google Scholar] [CrossRef]

- Fedorova, O.A.; Karpov, S.Y. Silicon in AlGaN and AlN: Shallow donor or deep DX-center? In Proceedings of the 5th International Workshop on Ultraviolet Materials and Devices, Jeju, Korea, 23–26 May 2022. [Google Scholar]

- Tanaka, T.; Watanabe, A.; Amano, H.; Kobayashi, Y.; Akasaki, I.; Yamazaki, S.; Koike, M. p-type conduction in Mg-doped GaN and A0.08Ga0.92N grown by metalorganic vapor phase epitaxy. Appl. Phys. Lett. 1994, 65, 593–594. [Google Scholar] [CrossRef]

- Suzuki, M.; Nishio, J.; Onomura, M.; Hongo, C. Doping characteristics and electrical properties of Mg-dope AlGaN grown by atmospheric-pressure MOCVD. J. Cryst. Growth 1998, 189–190, 511–515. [Google Scholar] [CrossRef]

- Li, J.; Oder, T.N.; Nakarmi, M.L.; Lin, J.Y.; Jiang, H.X. Optical and electrical properties of Mg-doped p-type AlxGa1−xN. Appl. Phys. Lett. 2002, 80, 1210–1212. [Google Scholar] [CrossRef]

- Nam, K.B.; Nakarmi, M.L.; Li, J.; Lin, J.Y.; Jiang, H.X. Mg acceptor level in AlN probed by deep ultraviolet photoluminescence. Appl. Phys. Lett. 2003, 83, 878–880. [Google Scholar] [CrossRef]

- Nakarmi, M.L.; Kim, K.H.; Khizar, M.; Fan, Z.Y.; Lin, J.Y.; Jiang, H.X. Electrical and optical properties of Mg-doped Al0.7Ga0.3N alloys. Appl. Phys. Lett. 2005, 86, 092108. [Google Scholar] [CrossRef]

- Nikishin, S.A. III-Nitride Short Period Superlattices for Deep UV Light Emitters. Appl. Sci. 2018, 8, 2362. [Google Scholar] [CrossRef]

- Qiu, X.; Jiang, H. Highly Conductive and 260 nm Transparent p-Type Al0.6Ga0.4N Achieved Utilizing Interface Doping Effects. Cryst. Growth Des. 2021, 21, 2389–2397. [Google Scholar] [CrossRef]

- Bagheri, P.; Klump, A.; Washiyama, S.; Breckenridge, M.H.; Kim, J.H.; Guan, Y.; Khachariya, D.; Quiñones-Garcia, C.; Sarkar, B.; Rathkanthiwar, S.; et al. Doping and compensation in heavily Mg doped Al-rich AlGaN films. Appl. Phys. Lett. 2022, 120, 082102. [Google Scholar] [CrossRef]

- Kinoshita, T.; Obata, T.; Yanagi, H.; Inoue, S.-I. High p-type conduction in high-Al content Mg-doped AlGaN. Appl. Phys. Lett. 2013, 102, 012105. [Google Scholar] [CrossRef]

- Qiu, X.; Chen, Y.; Han, E.; Lv, Z.; Song, Z.; Jiang, H. High doping efficiency in p-type Al-rich AlGaN by modifying the Mg doping planes. Mater. Adv. 2020, 1, 77–85. [Google Scholar] [CrossRef]

- Kipshidze, G.; Kuryatkov, V.; Borisov, B.; Nikishin, S.; Holtz, M.; Chu, S.N.G.; Temkin, H. Deep Ultraviolet AlGaInN-Based Light-Emitting Diodes on Si(111) and Sapphire. Phys. Stat. Sol. 2002, 192, 286–291. [Google Scholar] [CrossRef]

- Nikishin, S.A.; Holtz, M.; Temkin, H. Digital alloys AlN/AlGaN for deep UV light emitting diodes. Jpn. J. Appl. Phys. 2005, 44, 7221–7226. [Google Scholar] [CrossRef]

- Nikishin, S.A.; Kuryatkov, V.V.; Chandolu, A.; Borisov, B.A.; Kipshidze, G.D.; Ahmad, I.; Holtz, M.; Temkin, H. Deep ultraviolet light emitting diodes based on short period superlattices of AlN/AlGa(In)N. Jpn. J. Appl. Phys. 2003, 42, L1362–L1365. [Google Scholar] [CrossRef]

- Lopatiuk-Tirpak, O.; Chernyak, L.; Borisov, B.A.; Kuryatkov, V.V.; Nikishin, S.A.; Gartsman, K. Electron irradiation-induced increase of minority carrier diffusion length, mobility, and lifetime in Mg-doped AlN/AlGaN short period superlattice. Appl. Phys. Lett. 2007, 91, 182103. [Google Scholar] [CrossRef]

- Wang, X.; Wang, W.; Wang, J.; Wu, H.; Liu, C. Experimental evidences for reducing Mg activation energy in high Al-content AlGaN alloy by MgGa δ doping in (AlN)m/(GaN)n superlattice. Sci. Rep. 2017, 7, 44223. [Google Scholar] [CrossRef]

- Nikishin, S.; Borisov, B.; Mansurov, V.; Pandikunta, M.; Chary, I.; Rajanna, G.; Bernussi, A.; Kudryavtsev, Y.; Asomoza, R.; Bulashevich, K.A.; et al. Short period p-type AlN/AlGaN superlattices for deep UV light emitters. Mater. Res. Soc. Symp. Proc. 2010, 1202, 1202-I10-03. [Google Scholar] [CrossRef]

- Ebata, K.; Nishinaka, J.; Taniyasu, Y.; Kumakura, K. High hole concentration in Mg-doped AlN/AlGaN superlattices with high Al content. Jpn. J. Appl. Phys. 2018, 57, 04FH09. [Google Scholar] [CrossRef]

- Allerman, A.A.; Crawford, M.H.; Miller, M.A.; Lee, S.R. Growth and characterization of Mg-doped AlGaN-AlN short-period superlattices for deep-UV optoelectronic devices. J. Cryst. Growth 2010, 312, 756–761. [Google Scholar] [CrossRef]

- Shatalov, M.; Gaska, R.; Yang, J.; Shur, M. Method of Doping and Semiconductor Devices. U.S. Patent 8,426,225, 23 April 2013. [Google Scholar]

- Martens, M.; Kuhn, C.; Ziffer, E.; Simoneit, T.; Kueller, V.; Knauer, A.; Rass, J.; Wernicke, T.; Einfeldt, S.; Weyers, M.; et al. Low absorption loss p-AlGaN superlattice cladding layer for current-injection deep ultraviolet laser diodes. Appl. Phys. Lett. 2016, 108, 151108. [Google Scholar] [CrossRef]

- Kozodoy, P.; Xing, H.; DenBaars, S.P.; Mishra, U.K.; Saxler, A.; Perrin, R.; Elhamri, S.; Mitchel, W.C. Heavy doping effects in Mg-doped GaN. J. Appl. Phys. 2000, 87, 1832–1835. [Google Scholar] [CrossRef]

- Taniyasu, Y.; Kasu, M.; Makimoto, T. An aluminium nitride light-emitting diode with a wavelength of 210 nanometres. Nature 2006, 441, 325–328. [Google Scholar] [CrossRef] [PubMed]

- Dussaigne, A.; Damilano, B.; Brault, J.; Massies, J.; Feltin, E.; Grandjean, N. High doping level in Mg-doped GaN layers grown at low temperature. J. Appl. Phys. 2008, 103, 013110. [Google Scholar] [CrossRef]

- Nikishin, S.; Chary, I.; Borisov, B.; Kuryatkov, V.; Kudryavtsev, Y.; Asomoza, R.; Karpov, S.Y.; Holtz, M. Mechanism of curriers injection in (Ni/Au)/p-AlxGa1−xN:Mg (0 ≤ x < 0.1) ohmic contacts. Appl. Phys. Lett. 2009, 95, 163502. [Google Scholar]

- Yamamoto, T.; Katayama-Yoshida, H. Materials design for the fabrication of low-resistivity p-type GaN using cooping method. Jpn. J. Appl. Phys. 1997, 36, L180–L183. [Google Scholar] [CrossRef]

- Katayama-Yoshida, H.; Nishimatsu, T.; Yamamoto, T.; Orita, N. Codoping method for the fabrication of low-resistivity wide band-gap semiconductors in p-type GaN, p-type AlN and n-type diamond: Prediction versus experiment. J. Phys. Condens. Matter. 2001, 13, 8901–8914. [Google Scholar] [CrossRef]

- Wu, R.Q.; Shen, L.; Yang, M.; Sha, Z.D.; Cai, Y.Q.; Feng, Y.P.; Huang, Z.G.; Wu, Q.Y. Enhancing hole concentration in AlN by Mg:O codoping: Ab initio study. Phys. Rev. B 2008, 77, 073203. [Google Scholar] [CrossRef]

- Kipshidze, G.; Kuryatkov, V.; Borisov, B.; Kudryavtsev, Y.; Asomoza, R.; Nikishin, S.; Temkin, H. Mg and O codoping in p-type GaN and AlxGa1−xN (0 < x < 0.08). Appl. Phys. Lett. 2002, 80, 2910–2912. [Google Scholar]

- Korotkov, R.Y.; Gregie, J.M.; Wessels, B.W. Electrical properties of p-type GaN:Mg codoped with oxygen. Appl. Phys. Lett. 2001, 78, 222–224. [Google Scholar] [CrossRef]

- Bulashevich, K.A.; Mymrin, V.F.; Karpov, S.Y. Control of electron leakage in III-nitride laser diodes by blocking layer design, using distributed polarization doping. In Proceedings of the 3rd Asia-Pacific Workshop on Widegap Semiconductors, Jeonju, Korea, 11–14 March 2007. [Google Scholar]

- Simon, J.; Protasenko, V.; Jena, D. Polarization-induced hole doping in wide-band-gap uniaxial semiconductor heterostructures. Science 2010, 327, 60–64. [Google Scholar] [CrossRef]

- Zhang, Z.; Kushimoto, M.; Sakai, T.; Sugiyama, N.; Schowalter, L.J.; Sasaoka, C.; Amano, H. A 271.8 nm deep-ultraviolet laser diode for room temperature operation. Appl. Phys. Express 2019, 12, 124003. [Google Scholar] [CrossRef]

- Sato, K.; Yasue, S.; Yamada, K.; Tanaka, S.; Omori, T.; Ishizuka, S.; Teramura, S.; Ogino, Y.; Iwayama, S.; Miyake, H.; et al. Room-temperature operation of AlGaN ultraviolet-B laser diode at 298 nm on lattice-relaxed Al0.6Ga0.4N/AlN/sapphire. Appl. Phys. Express 2020, 13, 031004. [Google Scholar] [CrossRef]

- Tanaka, S.; Ogino, Y.; Yamada, K.; Omori, T.; Ogura, R.; Teramura, S.; Shimokawa, M.; Ishizuka, S.; Yabutani, A.; Iwayama, S.; et al. AlGaN-based UV-B laser diode with a high optical confinement factor. Appl. Phys. Lett. 2021, 118, 163504. [Google Scholar] [CrossRef]

- Hirayama, H.; Tsukada, Y.; Maeda, T.; Kamata, N. Marked Enhancement in the Efficiency of Deep-Ultraviolet AlGaN Light-Emitting Diodes by Using a Multiquantum-Barrier Electron Blocking Layer. Appl. Phys. Express 2010, 3, 031002. [Google Scholar] [CrossRef]

- Karpov, S.Y.; Bulashevich, K.A.; Zhmakin, I.A.; Nestoklon, M.O.; Mymrin, V.F.; Makarov, Y.N. Carrier injection and light emission in visible and UV nitride LEDs by modeling. Phys. Stat. Solidi B 2004, 241, 2668–2671. [Google Scholar] [CrossRef]

- Wong, M.H.; Keller, S.; Dasgupta, N.S.; Denninghoff, D.J.; Kolluri, S.; Brown, D.F.; Lu, J.; Fichtenbaum, N.A.; Ahmadi, E.; Singisetti, U.; et al. N-polar GaN epitaxy and high electron mobility transistors. Semicond. Sci. Technol. 2013, 28, 074009. [Google Scholar] [CrossRef]

- Li, C.; Zhang, K.; Zeng, Q.; Yin, X.; Ge, X.; Wang, J.; Wang, Q.; He, C.; Zhao, W.; Chen, Z. High quality N-polar GaN films grown with varied V/III ratios by metal-organic vapor phase epitaxy. RSC Adv. 2020, 10, 43187–43192. [Google Scholar] [CrossRef]

- David, A.; Grundmann, M.J.; Kaeding, J.F.; Gardner, N.F.; Mihopoulos, T.G.; Krames, M.R. Carrier distribution in (0001)InGaN/GaN multiple quantum well light-emitting diodes. Appl. Phys. Lett. 2008, 92, 053502. [Google Scholar] [CrossRef]

- Zakheim, D.A.; Pavluchenko, A.S.; Bauman, D.A.; Bulashevich, K.A.; Khokhlev, O.V.; Karpov, S.Y. Efficiency droop suppression in InGaN-based blue LEDs: Experiment and numerical modelling. Phys. Stat. Solidi A 2012, 209, 456–460. [Google Scholar] [CrossRef]

- Rajan, S.; Takeuchi, T. III-nitride tunnel junctions and their applications. In III-Nitride Based Light Emitting Diodes and Applications; Seong, T.-Y., Han, J., Amano, H., Morkoc, H., Eds.; Springer: Dordrecht, The Netherlands, 2017; pp. 209–238. [Google Scholar]

- Neugebauer, S.; Hoffmann, M.P.; Witte, H.; Bläsing, J.; Dadgar, A.; Strittmatter, A.; Niermann, T.; Narodovitch, M.; Lehmann, M. All metalorganic chemical vapor phase epitaxy of p/n-GaN tunnel junction for blue light emitting diode applications. Appl. Phys. Lett. 2017, 110, 102104. [Google Scholar] [CrossRef]

- Zhang, Y.; Krishnamoorthy, S.; Johnson, J.M.; Akyol, F.; Allerman, A.; Moseley, M.W.; Armstrong, A.; Hwang, J.; Rajan, S. Interband tunneling for hole injection in III-nitride ultraviolet emitters. Appl. Phys. Lett. 2015, 106, 141103. [Google Scholar] [CrossRef]

- Zhang, Y.; Jamal-Eddine, Z.; Akyol, F.; Bajaj, S.; Johnson, J.M.; Calderon, G.; Allerman, A.A.; Moseley, M.W.; Armstrong, A.M.; Hwang, J.; et al. Tunnel-injected sub 290 nm ultra-violet light emitting diodes with 2.8% external quantum efficiency. Appl. Phys. Lett. 2018, 112, 071107. [Google Scholar] [CrossRef]

- Kuhn, C.; Sulmoni, L.; Guttmann, M.; Glaab, J.; Susilo, N.; Wernike, T.; Weyers, M.; Kneissl, M. MOVPE-grown AlGaN-based tunnel heterojunctions enabling fully transparent UVC LEDs. Photonics Res. 2019, 7, B7–B11. [Google Scholar] [CrossRef]

- Zhang, Y.; Krishnamoorthy, S.; Akyol, F.; Allerman, A.A.; Moseley, M.W.; Armstrong, A.M.; Rajan, S. Design and demonstration of ultra-wide bandgap AlGaN tunnel junctions. Appl. Phys. Lett. 2016, 109, 121102. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nikishin, S.; Bernussi, A.; Karpov, S. Towards Efficient Electrically-Driven Deep UVC Lasing: Challenges and Opportunities. Nanomaterials 2023, 13, 185. https://doi.org/10.3390/nano13010185

Nikishin S, Bernussi A, Karpov S. Towards Efficient Electrically-Driven Deep UVC Lasing: Challenges and Opportunities. Nanomaterials. 2023; 13(1):185. https://doi.org/10.3390/nano13010185

Chicago/Turabian StyleNikishin, Sergey, Ayrton Bernussi, and Sergey Karpov. 2023. "Towards Efficient Electrically-Driven Deep UVC Lasing: Challenges and Opportunities" Nanomaterials 13, no. 1: 185. https://doi.org/10.3390/nano13010185

APA StyleNikishin, S., Bernussi, A., & Karpov, S. (2023). Towards Efficient Electrically-Driven Deep UVC Lasing: Challenges and Opportunities. Nanomaterials, 13(1), 185. https://doi.org/10.3390/nano13010185