Overview of the Influence of Silver, Gold, and Titanium Nanoparticles on the Physical Properties of PEDOT:PSS-Coated Cotton Fabrics

Abstract

:1. Introduction

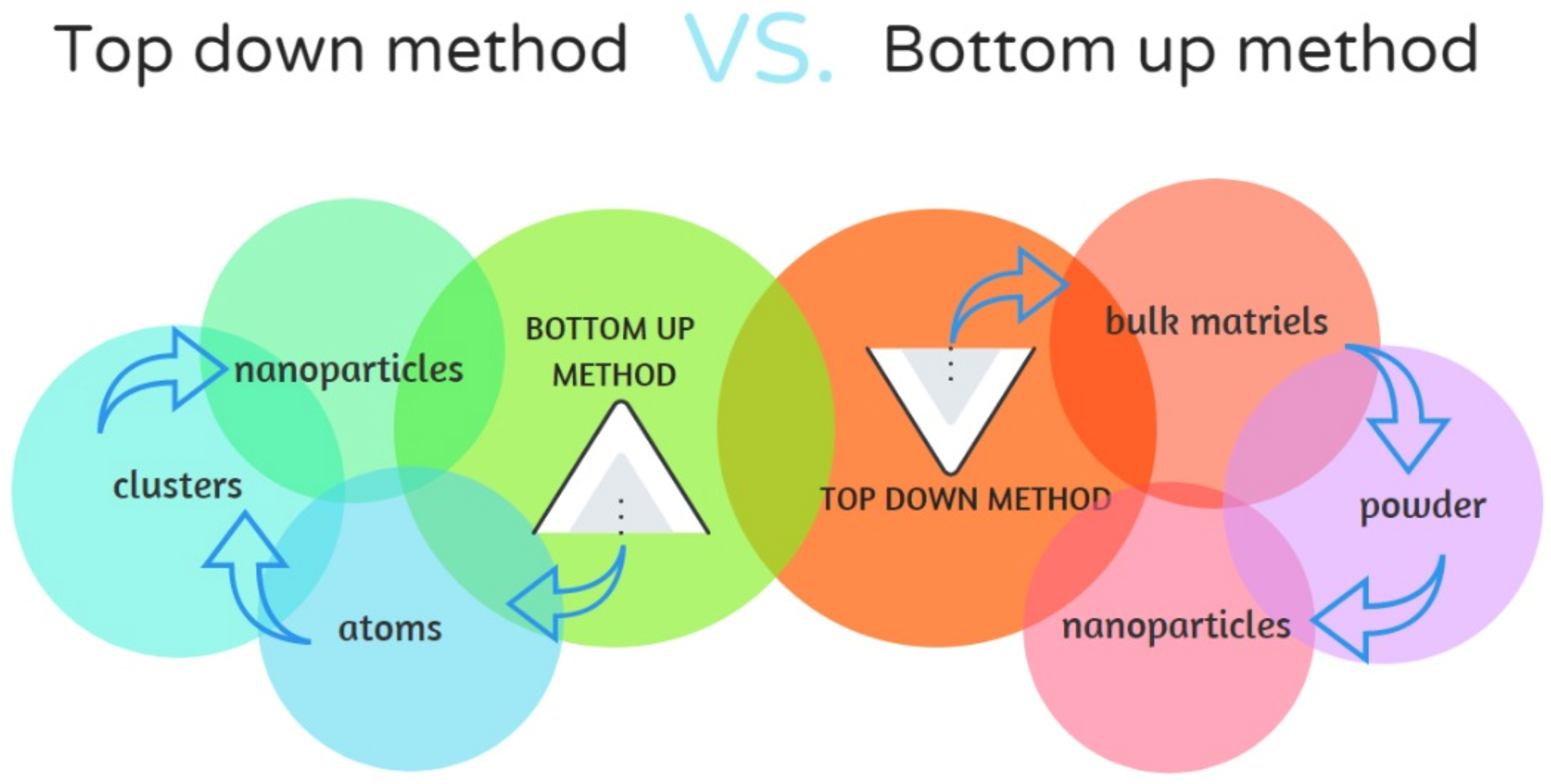

1.1. Nanoparticles

1.2. Importance of Metallic NPs

1.3. Titanium Nanoparticles

1.4. Silver Nanoparticles

1.5. Gold Nanoparticles

2. Toxicity of Metallic NPs

3. Conductive Polymers

PEDOT:PSS Nano Composite Thin Films

4. Textiles

4.1. Cotton Fabrics

4.2. Nanoparticles-Doped PEDOT:PSS Fabric

4.3. Toxicity of Metal Nanoparticles in Terms of Fabrics

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jeevanandam, J.; Barhoum, A.; Chan, Y.S.; Dufresne, A.; Danquah, M.K. Review on nanoparticles and nanostructured materials: History, sources, toxicity and regulations. Beilstein J. Nanotechnol. 2018, 9, 1050–1074. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Martinez-Gutierrez, F.; Olive, P.L.; Banuelos, A.; Orrantia, E.; Nino, N.; Sanchez, E.M.; Ruiz, F.; Bach, H.; Av-Gay, Y. Synthesis, characterization, and evaluation of antimicrobial and cytotoxic effect of silver and titanium nanoparticles. Nanomed. Nanotechnol. Biol. Med. 2010, 6, 681–688. [Google Scholar] [CrossRef] [PubMed]

- Jamkhande, P.G.; Ghule, N.W.; Bamer, A.H.; Kalaskar, M.G. Metal nanoparticles synthesis: An overview on methods of preparation, advantages and disadvantages, and applications. J. Drug Deliv. Sci. Technol. 2019, 53, 101174. [Google Scholar] [CrossRef]

- Rajput, N. Methods of preparation of nanoparticles—A review. Int. J. Adv. Eng. Technol. 2015, 7, 1806. [Google Scholar]

- Narayanan, R.; El-Sayed, M.A. Shape-dependent catalytic activity of platinum nanoparticles in colloidal solution. Nano Lett. 2004, 4, 1343–1348. [Google Scholar] [CrossRef]

- Burleson, D.J.; Driessen, M.D.; Penn, R.L. On the characterization of environmental nanoparticles. J. Environ. Sci. Heal. Part A 2004, 39, 2707–2753. [Google Scholar] [CrossRef]

- Lien, H.-L.; Zhang, W. Nanoscale iron particles for complete reduction of chlorinated ethenes. Colloids Surfaces A Physicochem. Eng. Asp. 2001, 191, 97–105. [Google Scholar] [CrossRef]

- Zhang, W. Nanoscale iron particles for environmental remediation: An overview. J. Nanoparticle Res. 2003, 5, 323–332. [Google Scholar] [CrossRef]

- Tailor, G.; Yadav, B.L.; Chaudhary, J.; Joshi, M.; Suvalka, C. Green synthesis of silver nanoparticles using Ocimum canum and their anti-bacterial activity. Biochem. Biophys. Rep. 2020, 24, 100848. [Google Scholar] [CrossRef]

- Rao, C.N.R.; Kulkarni, G.U.; Thomas, P.J.; Edwards, P.P. Metal nanoparticles and their assemblies. Chem. Soc. Rev. 2000, 29, 27–35. [Google Scholar] [CrossRef]

- Dara, P.K.; Mahadevan, R.; Digita, P.A.; Visnuvinayagam, S.; Kumar, L.R.G.; Mathew, S.; Ravishankar, C.N.; Anandan, R. Synthesis and biochemical characterization of silver nanoparticles grafted chitosan (Chi-Ag-NPs): In vitro studies on antioxidant and antibacterial applications. SN Appl. Sci. 2020, 2, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Pantidos, N.; Horsfall, L.E. Biological synthesis of metallic nanoparticles by bacteria, fungi and plants. J. Nanomed. Nanotechnol. 2014, 5, 1. [Google Scholar] [CrossRef]

- Kumar, D.; Yarmolenko, S.; Sankar, J.; Narayan, J.; Zhou, H.; Tiwari, A. Pulsed laser deposition assisted novel synthesis of self-assembled magnetic nanoparticles. Compos. Part B Eng. 2004, 35, 149–155. [Google Scholar] [CrossRef]

- Liu, T.; Zhang, T.; Zhu, M.; Qin, C. Synthesis and structures of Al–Ti nanoparticles by hydrogen plasma-metal reaction. J. Nanoparticle Res. 2012, 14, 1–8. [Google Scholar] [CrossRef]

- Lin, J.; Chen, X.; Chen, C.; Hu, J.; Zhou, C.; Cai, X.; Wang, W.; Zheng, C.; Zhang, P.; Cheng, J. Durably antibacterial and bacterially antiadhesive cotton fabrics coated by cationic fluorinated polymers. ACS Appl. Mater. Interfaces 2018, 10, 6124–6136. [Google Scholar] [CrossRef]

- Ghosh, D.; Pradhan, S.; Chen, W.; Chen, S. Titanium nanoparticles stabilized by Ti−C covalent bonds. Chem. Mater. 2008, 20, 1248–1250. [Google Scholar] [CrossRef]

- Jorge, J.R.P.; Barao, V.A.; Delben, J.A.; Faverani, L.P.; Queiroz, T.P.; Assunçao, W.G. Titanium in dentistry: Historical development, state of the art and future perspectives. J. Indian Prosthodont. Soc. 2013, 13, 71–77. [Google Scholar] [CrossRef]

- Bermudez, E.; Mangum, J.B.; Wong, B.A.; Asgharian, B.; Hext, P.M.; Warheit, D.B.; Everitt, J.I. Pulmonary responses of mice, rats, and hamsters to subchronic inhalation of ultrafine titanium dioxide particles. Toxicol. Sci. 2004, 77, 347–357. [Google Scholar] [CrossRef] [Green Version]

- Skocaj, M.; Filipic, M.; Petkovic, J.; Novak, S. Titanium dioxide in our everyday life; is it safe? Radiol. Oncol. 2011, 45, 227. [Google Scholar] [CrossRef] [Green Version]

- Kim, K.T.; Eo, M.Y.; Nguyen, T.T.H.; Kim, S.M. General review of titanium toxicity. Int. J. Implant Dent. 2019, 5, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Alzubi, F.G. Synthesis of titanium nanoparticles with controlled size variation by physical vapor deposition. Adv. Mater. TechConnect Briefs 2017, 1, 126–129. [Google Scholar]

- Schabes-Retchkiman, P.S.; Canizal, G.; Herrera-Becerra, R.; Zorrilla, C.; Liu, H.B.; Ascencio, J.A. Biosynthesis and characterization of Ti/Ni bimetallic nanoparticles. Opt. Mater. 2006, 29, 95–99. [Google Scholar] [CrossRef]

- Ghosh Chaudhuri, R.; Paria, S. Core/shell nanoparticles: Classes, properties, synthesis mechanisms, characterization, and applications. Chem. Rev. 2012, 112, 2373–2433. [Google Scholar] [CrossRef] [PubMed]

- Kumari, M.; Perera, C.S.; Dassanayake, B.S.; Dissanayake, M.; Senadeera, G.K.R. Highly efficient plasmonic dye-sensitized solar cells with silver nanowires and TiO2 nanofibres incorporated multi-layered photoanode. Electrochim. Acta 2019, 298, 330–338. [Google Scholar] [CrossRef]

- Ochiai, T.; Fujishima, A. Photoelectrochemical properties of TiO2 photocatalyst and its applications for environmental purification. J. Photochem. Photobiol. C Photochem. Rev. 2012, 13, 247–262. [Google Scholar] [CrossRef]

- de Dicastillo, C.L.; Correa, M.G.; Martínez, F.B.; Streitt, C.; Galotto, M.J. Antimicrobial effect of titanium dioxide nanoparticles. In Antimicrobial Resistance-A One Health Perspective; IntechOpen: London, UK, 2020. [Google Scholar] [CrossRef] [Green Version]

- Patil, R.B.; Chougale, A.D. Analytical methods for the identification and characterization of silver nanoparticles: A brief review. Mater. Today Proc. 2021, 47, 5520–5532. [Google Scholar] [CrossRef]

- Alaqad, K.; Saleh, T.A. Gold and silver nanoparticles: Synthesis methods, characterization routes and applications towards drugs. J. Environ. Anal. Toxicol 2016, 6, 525–2161. [Google Scholar] [CrossRef]

- Wu, Z.G.; Munoz, M.; Montero, O. The synthesis of nickel nanoparticles by hydrazine reduction. Adv. Powder Technol. 2010, 21, 165–168. [Google Scholar] [CrossRef]

- Mehravani, B.; Montazer, M.; Zille, A. Synthesis and Characterization of Silver-Chitosan Nanoparticles on Textile. ICNF 2021. Available online: http://repositorium.uminho.pt/handle/1822/72773 (accessed on 16 March 2022).

- Gour, A.; Jain, N.K. Advances in green synthesis of nanoparticles. Artif. Cells Nanomed. Biotechnol. 2019, 47, 844–851. [Google Scholar] [CrossRef] [Green Version]

- Ahmad, S.; Munir, S.; Zeb, N.; Ullah, A.; Khan, B.; Ali, J.; Bilal, M.; Omer, M.; Alamzeb, M.; Salman, S.M.; et al. Green nanotechnology: A review on green synthesis of silver nanoparticles—An ecofriendly approach. Int. J. Nanomed. 2019, 14, 5087–5107. [Google Scholar] [CrossRef] [Green Version]

- Dawadi, S.; Katuwal, S.; Gupta, A.; Lamichhane, U.; Thapa, R.; Jaisi, S.; Lamichhane, G.; Bhattarai, D.P.; Parajuli, N. Current Research on Silver Nanoparticles: Synthesis, Characterization, and Applications. J. Nanomater. 2021, 2021, 6687290. [Google Scholar] [CrossRef]

- Gharibshahi, L.; Saion, E.; Gharibshahi, E.; Shaari, A.H.; Matori, K.A. Structural and Optical Properties of Ag Nanoparticles Synthesized by Thermal Treatment Method. J. Mater. 2017, 10, 402. [Google Scholar] [CrossRef] [PubMed]

- Li, N.; Zhao, P.; Astruc, D. Anisotropic gold nanoparticles: Synthesis, properties, applications, and toxicity. Angew. Chemie Int. Ed. 2014, 53, 1756–1789. [Google Scholar] [CrossRef] [PubMed]

- Deb, S.; Patra, H.K.; Lahiri, P.; Dasgupta, A.K.; Chakrabarti, K.; Chaudhuri, U. Multistability in platelets and their response to gold nanoparticles. Nanomed. Nanotechnol. Biol. Med. 2011, 7, 376–384. [Google Scholar] [CrossRef] [PubMed]

- Khan, A.K.; Rashid, R.; Murtaza, G.; Zahra, A. Gold nanoparticles: Synthesis and applications in drug delivery. Trop. J. Pharm. Res. 2014, 13, 1169–1177. [Google Scholar] [CrossRef]

- Boisselier, E.; Astruc, D. Gold nanoparticles in nanomedicine: Preparations, imaging, diagnostics, therapies and toxicity. Chem. Soc. Rev. 2009, 38, 1759–1782. [Google Scholar] [CrossRef]

- Sharma, P.; Singh, V.; Chaudhary, R.; Joshi, V. A review on gold nanoparticles. World J. Pharm. Res. 2016, 5, 1881–1901. [Google Scholar]

- Podsiadlo, P.; Sinani, V.A.; Bahng, J.H.; Kam, N.W.S.; Lee, J.; Kotov, N.A. Gold nanoparticles enhance the anti-leukemia action of a 6-mercaptopurine chemotherapeutic agent. Langmuir 2008, 24, 568–574. [Google Scholar] [CrossRef]

- O’Neal, D.P.; Hirsch, L.R.; Halas, N.J.; Payne, J.D.; West, J.L. Photo-thermal tumor ablation in mice using near infrared-absorbing nanoparticles. Cancer Lett. 2004, 209, 171–176. [Google Scholar] [CrossRef]

- Sreedharan, S.M.; Gupta, S.; Saxena, A.K.; Singh, R. Macrophomina phaseolina: Microbased biorefinery for gold nanoparticle production. Ann. Microbiol. 2019, 69, 435–445. [Google Scholar] [CrossRef]

- Khan, T.; Ullah, N.; Khan, M.A.; Nadhman, A. Plant-based gold nanoparticles; a comprehensive review of the decade-long research on synthesis, mechanistic aspects and diverse applications. Adv. Colloid Interface Sci. 2019, 272, 102017. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.; Zhang, Y.; Ding, T.; Liu, J.; Zhao, H. Multifunctional gold nanoparticles: A novel nanomaterial for various medical applications and biological activities. Front. Bioeng. Biotechnol. 2020, 8, 990. [Google Scholar] [CrossRef] [PubMed]

- Baun, A.; Hartmann, N.B.; Grieger, K.; Kusk, K.O. Ecotoxicity of engineered nanoparticles to aquatic invertebrates: A brief review and recommendations for future toxicity testing. Ecotoxicology 2008, 17, 387–395. [Google Scholar] [CrossRef]

- Sayes, C.M.; Wahi, R.; Kurian, P.A.; Liu, Y.; West, J.L.; Ausman, K.D.; Warheit, D.B.; Colvin, V.L. Correlating nanoscale titania structure with toxicity: A cytotoxicity and inflammatory response study with human dermal fibroblasts and human lung epithelial cells. Toxicol. Sci. 2006, 92, 174–185. [Google Scholar] [CrossRef] [Green Version]

- Peralta-Videa, J.R.; Zhao, L.; Lopez-Moreno, M.L.; de la Rosa, G.; Hong, J.; Gardea-Torresdey, J.L. Nanomaterials and the environment: A review for the biennium 2008–2010. J. Hazard. Mater. 2011, 186, 1–15. [Google Scholar] [CrossRef]

- Kakoty, V.; Sarathlal, K.C.; Pandey, M.; Dubey, S.K.; Kesharwani, P.; Taliyan, R. Biological toxicity of nanoparticles. J. Nanopart. Res. 2022, 18, 603–628. [Google Scholar]

- Roy, J.; Roy, K. Assessment of toxicity of metal oxide and hydroxide nanoparticles using the QSAR modeling approach. Environ. Sci. Nano. 2021, 8, 3395–3407. [Google Scholar] [CrossRef]

- Rehman, A.U.; Nazir, S.; Irshad, R.; Tahir, K.; ur Rehman, K.; Islam, R.U.; Wahab, Z. Toxicity of heavy metals in plants and animals and their uptake by magnetic iron oxide nanoparticles. J. Mol. Liq. 2021, 321, 114455. [Google Scholar] [CrossRef]

- Rai, M.; Bonde, S.; Golinska, P.; Trzcińska-Wencel, J.; Gade, A.; Abd-Elsalam, K.; Shende, S.; Gaikwad, S.; Ingle, A.P. Fusarium as a novel fungus for the synthesis of nanoparticles: Mechanism and applications. J. Fungi 2021, 7, 139. [Google Scholar] [CrossRef]

- Hou, J.; Wang, L.; Wang, C.; Zhang, S.; Liu, H.; Li, S.; Wang, X. Toxicity and mechanisms of action of titanium dioxide nanoparticles in living organisms. J. Environ. Sci. 2019, 75, 40–53. [Google Scholar] [CrossRef]

- Nambiar, S.; Yeow, J.T.W. Conductive polymer-based sensors for biomedical applications. Biosens. Bioelectron. 2011, 26, 1825–1832. [Google Scholar] [CrossRef]

- Malinauskas, A. Chemical deposition of conducting polymers. Polymer 2001, 42, 3957–3972. [Google Scholar] [CrossRef]

- Shirakawa, H.; Louis, E.J.; MacDiarmid, A.G.; Chiang, C.K.; Heeger, A.J. Synthesis of electrically conducting organic polymers: Halogen derivatives of polyacetylene,(CH) x. J. Chem. Soc. Chem. Commun. 1977, 578–580. [Google Scholar] [CrossRef]

- Mohamed, A.L.; El-Naggar, M.E.; Hassabo, A.G. Preparation of hybrid nanoparticles to enhance the electrical conductivity and performance properties of cotton fabrics. J. Mater. Res. Technol. 2021, 12, 542–554. [Google Scholar] [CrossRef]

- Pang, H.; Xu, L.; Yan, D.-X.; Li, Z.-M. Conductive polymer composites with segregated structures. Prog. Polym. Sci. 2014, 39, 1908–1933. [Google Scholar] [CrossRef]

- Allison, L.; Hoxie, S.; Andrew, T.L. Towards seamlessly-integrated textile electronics: Methods to coat fabrics and fibers with conducting polymers for electronic applications. Chem. Commun. 2017, 53, 7182–7193. [Google Scholar] [CrossRef]

- Maráková, N.; Humpolíček, P.; Kašpárková, V.; Capáková, Z.; Martinková, L.; Bober, P.; Trchová, M.; Stejskal, J. Antimicrobial activity and cytotoxicity of cotton fabric coated with conducting polymers, polyaniline or polypyrrole, and with deposited silver nanoparticles. Appl. Surf. Sci. 2017, 396, 169–176. [Google Scholar] [CrossRef]

- Narkis, M.; Zilberman, M.; Siegmann, A. On the curiosity of electrically conductive melt processed doped-polyaniline/polymer blends versus carbon-black/polymer compounds. Polym. Adv. Technol. 1997, 8, 525–528. [Google Scholar] [CrossRef]

- Khan, S.; Narula, A.K. Bio-hybrid blended transparent and conductive films PEDOT:PSS:Chitosan exhibiting electro-active and antibacterial properties. Eur. Polym. J. 2016, 81, 161–172. [Google Scholar] [CrossRef]

- Bashir, T.; Fast, L.; Skrifvars, M.; Persson, N. Electrical resistance measurement methods and electrical characterization of poly (3, 4-ethylenedioxythiophene)-coated conductive fibers. J. Appl. Polym. Sci. 2012, 124, 2954–2961. [Google Scholar] [CrossRef]

- Mazrouaa, A.M.; Mansour, N.A.; Abed, M.Y.; Youssif, M.A.; Shenashen, M.A.; Awual, M.R. Nano-composite multi-wall carbon nanotubes using poly(p-phenylene terephthalamide) for enhanced electric conductivity. J. Environ. Chem. Eng. 2019, 7, 103002. [Google Scholar] [CrossRef]

- Ramírez Aguirre, D.P.; Flores Loyola, E.; De la Fuente Salcido, N.M.; Rodríguez Sifuentes, L.; Ramírez Moreno, A.; Marszalek, J.E. Comparative antibacterial potential of silver nanoparticles prepared via chemical and biological synthesis. Arab. J. Chem. 2020, 13, 8662–8670. [Google Scholar] [CrossRef]

- Wang, Y. Research progress on a novel conductive polymer–poly (3, 4-ethylenedioxythiophene)(PEDOT). J. Phys. Conf. Ser. 2009, 152, 12023. [Google Scholar] [CrossRef]

- Seyedin, M.Z.; Razal, J.M.; Innis, P.C.; Wallace, G.G. Strain-responsive polyurethane/PEDOT: PSS elastomeric composite fibers with high electrical conductivity. Adv. Funct. Mater. 2014, 24, 2957–2966. [Google Scholar] [CrossRef] [Green Version]

- Jonas, F.; Krafft, W.; Muys, B. Poly (3, 4-ethylenedioxythiophene): Conductive coatings, technical applications and properties. Macromolecular 1995, 100, 169–173. [Google Scholar]

- Jang, J.; Chang, M.; Yoon, H. Chemical sensors based on highly conductive poly (3, 4-ethylenedioxythiophene) nanorods. Adv. Mater. 2005, 17, 1616–1620. [Google Scholar] [CrossRef]

- Briseno, A.L.; Roberts, M.; Ling, M.-M.; Moon, H.; Nemanick, E.J.; Bao, Z. Patterning organic semiconductors using “dry” poly (dimethylsiloxane) elastomeric stamps for thin film transistors. J. Am. Chem. Soc. 2006, 128, 3880–3881. [Google Scholar] [CrossRef]

- Eslamian, M.; Soltani-Kordshuli, F. Development of multiple-droplet drop-casting method for the fabrication of coatings and thin solid films. J. Coat. Technol. Res. 2018, 15, 271–280. [Google Scholar] [CrossRef]

- Ajlouni, A.W.; AlAsiri, A.M.; Adil, S.F.; Shaik, M.R.; Khan, M.; Assal, M.E.; Al-Warthan, A. Nanocomposites of gold nanoparticles with pregabalin: The future anti-seizure drug. Arab. J. Chem. 2020, 13, 6267–6273. [Google Scholar] [CrossRef]

- Almarri, A.H. Improving the electrochromic properties of the composite films for electrochromic device. Ionics 2022, 28, 407–414. [Google Scholar] [CrossRef]

- Donaldson, P.D.; Swisher, S.L. Transparent, Low-Impedance Inkjet-Printed PEDOT: PSS Microelectrodes for Multi-modal Neuroscience. Phys. Status Solidi. 2022, 2100683. [Google Scholar] [CrossRef]

- Sanviti, M.; Mester, L.; Hillenbrand, R.; Alegria, A.; Martínez-Tong, D.E. Solvent-structured PEDOT: PSS surfaces: Fabrication strategies and nanoscale properties. Polymer 2022, 246, 124723. [Google Scholar] [CrossRef]

- Alhashmi Alamer, F.; Badawi, N.M.; Alodhayb, A.; Okasha, R.M.; Kattan, N.A. Effect of dopant on the conductivity and stability of three different cotton fabrics impregnated with PEDOT:PSS. Cellulose 2020, 27, 531–543. [Google Scholar] [CrossRef]

- Ko, Y.; Kim, J.; Jeong, H.Y.; Kwon, G.; Kim, D.; Ku, M.; Yang, J.; Yamauchi, Y.; Kim, H.Y.; Lee, C.; et al. Antibacterial poly (3,4-ethylenedioxythiophene):poly(styrene-sulfonate)/agarose nanocomposite hydrogels with thermo-processability and self-healing. Carbohydr. Polym. 2019, 203, 26–34. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Moreno, K.J.; Moggio, I.; Arias, E.; Llarena, I.; Moya, S.E.; Ziolo, R.F.; Barrientos, H. Silver nanoparticles functionalized in situ with the conjugated polymer (PEDOT: PSS). J. Nanosci. Nanotechnol. 2009, 9, 3987–3992. [Google Scholar] [CrossRef] [PubMed]

- Melendez, R.G.; Moreno, K.J.; Moggio, I.; Arias, E.; Ponce, A.; Llanera, I.; Moya, S.E. On the influence of silver nanoparticles size in the electrical conductivity of PEDOT: PSS. Mater. Sci. Forum 2010, 644, 85–90. [Google Scholar] [CrossRef]

- Ouyang, J. “Secondary doping” methods to significantly enhance the conductivity of PEDOT: PSS for its application as transparent electrode of optoelectronic devices. Displays 2013, 34, 423–436. [Google Scholar] [CrossRef]

- Ouyang, J. Solution-processed PEDOT: PSS films with conductivities as indium tin oxide through a treatment with mild and weak organic acids. ACS Appl. Mater. Interfaces 2013, 5, 13082–13088. [Google Scholar] [CrossRef]

- Pathak, C.S.; Singh, J.P.; Singh, R. Modification of electrical properties of PEDOT: PSS/p-Si heterojunction diodes by doping with dimethyl sulfoxide. Chem. Phys. Lett. 2016, 652, 162–166. [Google Scholar] [CrossRef]

- Lim, K.; Jung, S.; Lee, S.; Heo, J.; Park, J.; Kang, J.W.; Kang, Y.C.; Kim, D.G. The enhancement of electrical and optical properties of PEDOT:PSS using one-step dynamic etching for flexible application. Org. Electron. 2014, 15, 1849–1855. [Google Scholar] [CrossRef]

- Yildirim, E.; Zhu, Q.; Wu, G.; Tan, T.L.; Xu, J.; Yang, S.-W. Self-Organization of PEDOT: PSS Induced by Green and Water-Soluble Organic Molecules. J. Phys. Chem. 2019, 123, 9745–9755. [Google Scholar]

- Zhu, Q.; Yildirim, E.; Wang, X.; Soo, X.Y.D.; Zheng, Y.; Tan, T.L.; Wu, G.; Yang, S.-W.; Xu, J. Improved alignment of PEDOT: PSS induced by in-situ crystallization of “Green” dimethylsulfone molecules to enhance the polymer thermoelectric performance. Front. Chem. 2019, 7, 783. [Google Scholar] [CrossRef] [PubMed]

- Okuzaki, H.; Harashina, Y.; Yan, H. Highly conductive PEDOT/PSS microfibers fabricated by wet-spinning and dip-treatment in ethylene glycol. Eur. Polym. J. 2009, 45, 256–261. [Google Scholar] [CrossRef]

- Sedighi, A.; Montazer, M.; Mazinani, S. Fabrication of electrically conductive superparamagnetic fabric with microwave attenuation, antibacterial properties and UV protection using PEDOT/magnetite nanoparticles. Mater. Des. 2018, 160, 34–47. [Google Scholar] [CrossRef]

- Tadesse, M.G.; Mengistie, D.A.; Chen, Y. Electrically conductive highly elastic polyamide/lycra fabric treated with PEDOT:PSS and polyurethane. J. Electron. Mater. 2019, 54, 9591–9602. [Google Scholar] [CrossRef] [Green Version]

- Wang, W.-C.; Cheng, Y.-T.; Estroff, B. Electrostatic Self-assembly of Composite Nanofiber Yarn. Polymers 2021, 13, 12. [Google Scholar] [CrossRef]

- Dong, J.; Portale, G. Role of the Processing Solvent on the Electrical Conductivity of PEDOT: PSS. Adv. Mater. Interfaces 2020, 7, 2000641. [Google Scholar] [CrossRef]

- Ahmad, I.; Hussain, M.; Seo, K.; Choa, Y. Synthesis and characterization of polymer–nanoclay conductive nanocomposites. J. Appl. Polym. Sci. 2010, 116, 314–319. [Google Scholar] [CrossRef]

- Cruz-Cruz, I.; Reyes-Reyes, M.; López-Sandoval, R. Formation of polystyrene sulfonic acid surface structures on poly (3, 4-ethylenedioxythiophene): Poly (styrenesulfonate) thin films and the enhancement of its conductivity by using sulfuric acid. Thin Solid Films 2013, 531, 385–390. [Google Scholar] [CrossRef]

- Aleshin, A.N.; Williams, S.R.; Heeger, A.J. Transport properties of poly (3, 4-ethylenedioxythiophene)/poly (styrenesulfonate). Synth. Met. 1998, 94, 173–177. [Google Scholar] [CrossRef]

- Wilson, P.; Lekakou, C.; Watts, J.F. A comparative assessment of surface microstructure and electrical conductivity dependence on co-solvent addition in spin coated and inkjet printed poly (3, 4-ethylenedioxythiophene): Polystyrene sulphonate (PEDOT: PSS). Org. Electron. 2012, 13, 409–418. [Google Scholar] [CrossRef] [Green Version]

- Thomas, J.P.; Rahman, M.A.; Srivastava, S.; Kang, J.-S.; McGillivray, D.; Abd-Ellah, M.; Heinig, N.F.; Leung, K.T. Highly conducting hybrid silver-nanowire-embedded poly (3, 4-ethylenedioxythiophene): Poly (styrenesulfonate) for high-efficiency planar silicon/organic heterojunction solar cells. ACS Nano. 2018, 12, 9495–9503. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Miller, P.F.; de Mello, J.C.; de Mello, A.J.; Bradley, D.D.C. Influence of thermal treatment on the conductivity and morphology of PEDOT/PSS films. Synth. Met. 2003, 139, 569–572. [Google Scholar] [CrossRef]

- Jewłoszewicz, B.; Bogdanowicz, K.A.; Przybył, W.; Iwan, A.; Plebankiewicz, I. PEDOT: PSS in water and toluene for organic devices—Technical approach. Polymers 2020, 12, 565. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Niu, Z.; Zheng, E.; Dong, H.; Tosado, G.A.; Yu, Q. Manipulation of PEDOT: PSS with Polar and Nonpolar Solvent Post-treatment for Efficient Inverted Perovskite Solar Cells. ACS Appl. Energy Mater. 2020, 3, 9656–9666. [Google Scholar] [CrossRef]

- Yousefi, M.H.; Fallahzadeh, A.; Saghaei, J.; Darareh, M.D. Fabrication of Flexible ITO-Free OLED Using Vapor-Treated PEDOT:PSS Thin Film As Anode. J. Disp. Technol. 2016, 12, 1647–1651. [Google Scholar] [CrossRef]

- Wang, X.; Kyaw, A.K.K.; Yin, C.; Wang, F.; Zhu, Q.; Tang, T.; Yee, P.I.; Xu, J. Enhancement of thermoelectric performance of PEDOT: PSS films by post-treatment with a superacid. RSC Adv. 2018, 8, 18334–18340. [Google Scholar] [CrossRef] [Green Version]

- Salvado, R.; Loss, C.; Gonçalves, R.; Pinho, P. Textile materials for the design of wearable antennas: A survey. Sensors 2012, 12, 15841–15857. [Google Scholar] [CrossRef]

- Dias, T. Electronic Textiles: Smart Fabrics and Wearable Technology; Woodhead Publishing: Sawston, UK, 2015. [Google Scholar]

- Neves, A.I.S.; Rodrigues, D.P.; De Sanctis, A.; Alonso, E.T.; Pereira, M.S.; Amaral, V.S.; Melo, L.V.; Russo, S.; de Schrijver, I.; Alves, H. Towards conductive textiles: Coating polymeric fibres with graphene. Sci. Rep. 2017, 7, 1–10. [Google Scholar] [CrossRef]

- Abdelgawad, A.M.; El-Naggar, M.E.; Elsherbiny, D.A.; Ali, S.; Abdel-Aziz, M.S.; Abdel-Monem, Y.K. Antibacterial carrageenan/cellulose nanocrystal system loaded with silver nanoparticles, prepared via solid-state technique. J. Environ. Chem. Eng. 2020, 8, 104276. [Google Scholar] [CrossRef]

- Fouda, M.M.G.; Abdelsalam, N.R.; Gohar, I.M.A.; Hanfy, A.E.M.; Othman, S.I.; Zaitoun, A.F.; Allam, A.A.; Morsy, O.M.; El-Naggar, M. Utilization of High throughput microcrystalline cellulose decorated silver nanoparticles as an eco-nematicide on root-knot nematodes. Colloids Surf. B 2020, 188, 110805. [Google Scholar] [CrossRef] [PubMed]

- Shi, J.; Liu, S.; Zhang, L.; Yang, B.; Shu, L.; Yang, Y.; Ren, M.; Wang, Y.; Chen, J.; Chen, W. Smart textile-integrated microelectronic systems for wearable applications. Adv. Mater. 2020, 32, 1901958. [Google Scholar] [CrossRef] [PubMed]

- Aboelnaga, A.; Shaarawy, S.; Hassabo, A.G. Polyaconitic acid/functional amine/azo dye composite as a novel hyper-branched polymer for cotton fabric functionalization. Colloids Surfaces B 2018, 172, 545–554. [Google Scholar] [CrossRef] [PubMed]

- Fakharuddin, A.; Li, H.; Di Giacomo, F.; Zhang, T.; Gasparini, N.; Elezzabi, A.Y.; Mohanty, A.; Ramadoss, A.; Ling, J.; Soultati, A. Fiber-Shaped Electronic Devices. Adv. Energy Mater. 2021, 11, 2101443. [Google Scholar] [CrossRef]

- Scriven, L.E. Physics and applications of dip coating and spin coating. MRS Online Proc. Libr. 1988, 121, 717. [Google Scholar] [CrossRef]

- Elschner, A.; Kirchmeyer, S.; Lovenich, W.; Merker, U.; Reuter, K. PEDOT: Principles and Applications of an Intrinsically Conductive Polymer; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Moridi, A.; Hassani-Gangaraj, S.M.; Guagliano, M.; Dao, M. Cold spray coating: Review of material systems and future perspectives. Surf. Eng. 2014, 30, 369–395. [Google Scholar] [CrossRef]

- Wu, W. Stretchable electronics: Functional materials, fabrication strategies and applications. Sci. Technol. Adv. Mater. 2019, 20, 187–224. [Google Scholar] [CrossRef] [Green Version]

- Tyona, M.D. A theoritical study on spin coating technique. Adv. Mater. Res. 2013, 2, 195. [Google Scholar] [CrossRef] [Green Version]

- Wen, Y.; Xu, J. Scientific importance of water-processable PEDOT–PSS and preparation, challenge and new application in sensors of its film electrode: A review. J. Polym. Sci. Part A Polym. Chem. 2017, 55, 1121–1150. [Google Scholar] [CrossRef] [Green Version]

- Durán, N.; Marcato, P.D.; De Souza, G.I.H.; Alves, O.L.; Esposito, E. Antibacterial effect of silver nanoparticles produced by fungal process on textile fabrics and their effluent treatment. J. Biomed. Nanotechnol. 2007, 3, 203–208. [Google Scholar] [CrossRef] [Green Version]

- Wong, H.L.; Bendayan, R.; Rauth, A.M.; Xue, H.Y.; Babakhanian, K.; Wu, X.Y. A mechanistic study of enhanced doxorubicin uptake and retention in multidrug resistant breast cancer cells using a polymer-lipid hybrid nanoparticle system. J. Pharmacol. Exp. Ther. 2006, 317, 1372–1381. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stoppa, M.; Chiolerio, A. Wearable electronics and smart textiles: A critical review. Sensors 2014, 14, 11957–11992. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Grancarić, A.M.; Jerković, I.; Koncar, V.; Cochrane, C.; Kelly, F.M.; Soulat, D.; Legrand, X. Conductive polymers for smart textile applications. J. Ind. Text. 2018, 48, 612–642. [Google Scholar] [CrossRef]

- Castano, L.M.; Flatau, A.B. Smart textile transducers: Design, techniques, and applications. In Industrial Applications for Intelligent Polymers and Coatings; Springer: Cham, Switzerland, 2016; pp. 121–146. [Google Scholar]

- Thakur, S. Shape memory polymers for smart textile applications. Text. Adv. Appl. 2017, 12, 323–336. [Google Scholar]

- Guo, Y.; Otley, M.T.; Li, M.; Zhang, X.; Sinha, S.K.; Treich, G.M.; Sotzing, G.A. PEDOT: PSS “wires” printed on textile for wearable electronics. ACS Appl. Mater. Interfaces 2016, 8, 26998–27005. [Google Scholar] [CrossRef]

- Hassabo, A.G.; El-Naggar, M.E.; Mohamed, A.L.; Hebeish, A.A. Development of multifunctional modified cotton fabric with tri-component nanoparticles of silver, copper and zinc oxide. Carbohydr. Polym. 2019, 210, 144–156. [Google Scholar] [CrossRef]

- Poletto, M.; Pistor, V.; Zattera, A.J. Structural characteristics and thermal properties of native cellulose. Cellul. Asp. 2013, 2, 45–68. [Google Scholar]

- Abou-Okeil, A.; El-Sawy, S.M.; Abdel-Mohdy, F.A. Flame retardant cotton fabrics treated with organophosphorus polymer. Carbohydr. Polym. 2013, 92, 2293–2298. [Google Scholar] [CrossRef]

- Nallathambi, G.; Ramachandran, T.; Rajendran, V.; Palanivelu, R. Effect of silica nanoparticles and BTCA on physical properties of cotton fabrics. Mater. Res. 2011, 14, 552–559. [Google Scholar] [CrossRef] [Green Version]

- El-Rafie, M.H.; Ahmed, H.B.; Zahran, M.K. Characterization of nanosilver coated cotton fabrics and evaluation of its antibacterial efficacy. Carbohydr. Polym. 2014, 107, 174–181. [Google Scholar] [CrossRef]

- Rajendran, R.; Radhai, R.; Kotresh, T.M.; Csiszar, E. Development of antimicrobial cotton fabrics using herb loaded nanoparticles. Carbohydr. Polym. 2013, 91, 613–617. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, N.A.; Amr, A.; Eid, B.M.; Almetwally, A.A.; Mourad, M.M. Functional finishes of stretch cotton fabrics. Carbohydr. Polym. 2013, 98, 1603–1609. [Google Scholar] [CrossRef] [PubMed]

- Dong, B.H.; Hinestroza, J.P. Metal nanoparticles on natural cellulose fibers: Electrostatic assembly and in situ synthesis. ACS Appl. Mater. Interfaces 2009, 1, 797–803. [Google Scholar] [CrossRef] [PubMed]

- Karimi, L.; Yazdanshenas, M.E.; Khajavi, R.; Rashidi, A.; Mirjalili, M. Functional finishing of cotton fabrics using graphene oxide nanosheets decorated with titanium dioxide nanoparticles. J. Text. Inst. 2016, 107, 1122–1134. [Google Scholar] [CrossRef]

- Xue, C.-H.; Jia, S.-T.; Chen, H.-Z.; Wang, M. Superhydrophobic cotton fabrics prepared by sol–gel coating of TiO2 and surface hydrophobization. Sci. Technol. Adv. Mater. 2008, 9, 35001. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bozzi, A.; Yuranova, T.; Guasaquillo, I.; Laub, D.; Kiwi, J. Self-cleaning of modified cotton textiles by TiO2 at low temperatures under daylight irradiation. J. Photochem. Photobiol. A Chem. 2005, 174, 156–164. [Google Scholar] [CrossRef]

- Marsh, D.H.; Riley, D.J.; York, D.; Graydon, A. Sorption of inorganic nanoparticles in woven cellulose fabrics. Particuology 2009, 7, 121–128. [Google Scholar] [CrossRef]

- Alamer, F.A. A simple method for fabricating highly electrically conductive cotton fabric without metals or nanoparticles, using PEDOT: PSS. J. Alloys Compd. 2017, 702, 266–273. [Google Scholar] [CrossRef]

- Das, P.; Ganguly, S.; Perelshtein, I.; Margel, S.; Gedanken, A. Acoustic Green Synthesis of Graphene-Gallium Nanoparticles and PEDOT: PSS Hybrid Coating for Textile To Mitigate Electromagnetic Radiation Pollution. ACS Appl. Nano Mater. 2022, 5, 1644–1655. [Google Scholar] [CrossRef]

- Ganguly, S.; Kanovsky, N.; Das, P.; Gedanken, A.; Margel, S. Photopolymerized Thin Coating of Polypyrrole/Graphene Nanofiber/Iron Oxide onto Nonpolar Plastic for Flexible Electromagnetic Radiation Shielding, Strain Sensing, and Non-Contact Heating Applications. Adv. Mater. Interfaces 2021, 8, 2101255. [Google Scholar] [CrossRef]

- Darvishzadeh, A.; Nasouri, K. Manufacturing, modeling, and optimization of nickel-coated carbon fabric for highly efficient EMI shielding. Surf. Coatings Technol. 2021, 409, 126957. [Google Scholar] [CrossRef]

- Tang, B.; Kaur, J.; Sun, L.; Wang, X. Multifunctionalization of cotton through in situ green synthesis of silver nanoparticles. Cellulose 2013, 20, 3053–3065. [Google Scholar] [CrossRef]

- Perera, S.; Bhushan, B.; Bandara, R.; Rajapakse, G.; Rajapakse, S.; Bandara, C. Morphological, antimicrobial, durability, and physical properties of untreated and treated textiles using silver-nanoparticles. Colloids Surfaces A Physicochem. Eng. Asp. 2013, 436, 975–989. [Google Scholar] [CrossRef]

- Ahmed, H.; Khattab, T.A.; Mashaly, H.M.; El-Halwagy, A.A.; Rehan, M. Plasma activation toward multi-stimuli responsive cotton fabric via in situ development of polyaniline derivatives and silver nanoparticles. Cellulose 2020, 27, 2913–2926. [Google Scholar] [CrossRef]

- Qi, Z.; Zhang, R.; Lv, J.; Gao, D.; Wang, C. In Situ Synthesis of Silver Nanoparticles onto Cotton Fibers Modified with Carboxymethyl Chitosan. Integr. Ferroelectr. 2020, 208, 10–16. [Google Scholar] [CrossRef]

- Siavashani, V.S.; Nevin, G.; Montazer, M.; Altay, P. Highly stretchable conductive fabric using knitted cotton/lycra treated with polypyrrole/silver NPs composites post-treated with PEDOT: PSS. J. Ind. Text. 2021, 1–18. [Google Scholar] [CrossRef]

- Wang, P.; Wang, Y.; Xu, Q.; Chen, Q.; Zhang, Y.; Xu, Z. Fabrication of durable and conductive cotton fabric using silver nanoparticles and PEDOT: PSS through mist polymerization. Appl. Surf. Sci. 2022, 592, 153314. [Google Scholar] [CrossRef]

- Tang, B. In situ synthesis of gold nanoparticles on cotton fabric for multifunctional applications. Cellulose 2017, 24, 4547–4560. [Google Scholar] [CrossRef]

- Ganesan, R.M.; Prabu, H.G. Synthesis of gold nanoparticles using herbal Acorus calamus rhizome extract and coating on cotton fabric for antibacterial and UV blocking applications. Arab. J. Chem. 2019, 12, 2166–2174. [Google Scholar] [CrossRef] [Green Version]

- Mattana, G.; Cosseddu, P.; Fraboni, B.; Malliaras, G.G.; Hinestroza, J.P.; Bonfiglio, A. Organic electronics on natural cotton fibres. Org. Electron. 2011, 12, 2033–2039. [Google Scholar] [CrossRef]

- Xin, C.; Hu, Z.; Fang, Z.; Chaudhary, M.; Xiang, H.; Xu, X.; Chen, Z. Flexible and wearable plasmonic-enabled organic/inorganic hybrid photothermoelectric generators. Mater. Today Energy. 2021, 22, 100859. [Google Scholar] [CrossRef]

- Chen, C.; Zhao, D.; Zhou, Q.; Wu, Y.; Zhou, X.; Wang, H. Facile preparation and characterization of polyaniline and CeO2 co-decorated TiO2 nanotube array and its highly efficient photoelectrocatalytic activity. Nanoscale Res. Lett. 2019, 14, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Perelshtein, I.; Applerot, G.; Perkas, N.; Grinblat, J.; Gedanken, A. A one-step process for the antimicrobial finishing of textiles with crystalline TiO2 nanoparticles. Chem. Eur. 2012, 18, 4575–4582. [Google Scholar] [CrossRef]

- Abidi, N.; Hequet, E.; Tarimala, S.; Dai, L.L. Cotton fabric surface modification for improved UV radiation protection using sol–gel process. J. Appl. Polym. Sci. 2007, 104, 111–117. [Google Scholar] [CrossRef]

- Karimi, L.; Yazdanshenas, M.E.; Khajavi, R.; Rashidi, A.; Mirjalili, M. Optimizing the photocatalytic properties and the synergistic effects of graphene and nano titanium dioxide immobilized on cotton fabric. Appl. Surf. Sci. 2015, 332, 665–673. [Google Scholar] [CrossRef]

- Long, M.; Zheng, L.; Tan, B.; Shu, H. Photocatalytic self-cleaning cotton fabrics with platinum (IV) chloride modified TiO2 and N-TiO2 coatings. Appl. Surf. Sci. 2016, 386, 434–441. [Google Scholar] [CrossRef]

- Noman, M.T.; Ashraf, M.A.; Jamshaid, H.; Ali, A. A novel green stabilization of TiO2 nanoparticles onto cotton. Fibers Polym. 2018, 19, 2268–2277. [Google Scholar] [CrossRef]

- El-Naggar, M.E.; Shaarawy, S.; Abdel-Aziz, M.S.; Katry, H.A.E.M.; Youssef, A.M. Functionalization of cotton fabrics with titanium oxide doped silver nanoparticles: Antimicrobial and UV protection activities. Luminescence 2022, 37, 854–864. [Google Scholar] [CrossRef]

- Maiaugree, W.; Pimanpang, S.; Towannang, M.; Saekow, S.; Jarernboon, W.; Amornkitbamrung, V. Optimization of TiO2 nanoparticle mixed PEDOT–PSS counter electrodes for high efficiency dye sensitized solar cell. J. Non. Cryst. Solids. 2012, 358, 2489–2495. [Google Scholar] [CrossRef]

- Ramesh, G.; Palaniappan, S.; Basavaiah, K. One-step synthesis of PEDOT-PSS● TiO2 by peroxotitanium acid: A highly stable electrode for a supercapacitor. Ionics 2018, 24, 1475–1485. [Google Scholar] [CrossRef]

- Cesarini, M.; Vasile, F.; Natali, D. Inkjet printed hybrid light sensors based on titanium dioxide and PEDOT: PSS. Semicond. Sci. Technol. 2019, 34, 24005. [Google Scholar] [CrossRef]

- Berendjchi, A.; Khajavi, R.; Yousefi, A.A.; Yazdanshenas, M.E. A facile route for fabricating a dye sensitized solar cell on a polyester fabric substrate. J. Clean. Prod. 2017, 149, 521–527. [Google Scholar] [CrossRef]

- Pasricha, A. Comparative study of leaching of silver nanoparticles from fabric and effective effluent treatment. J. Environ. Sci. 2012, 24, 852–859. [Google Scholar] [CrossRef]

| Methods | Advantages | Disadvantages | References |

|---|---|---|---|

| Dip-Coating method | No additional electrical instrument is required Design of conductive layers on the nanoscale It is a straightforward, cost-effective, and energy-efficient solution | Compatibility in the production of long fibers is low The speed of manufacture is slow The film may or may not solidify during the dip coating process | [107,108] |

| Spray-Coating method | Cost-effective, adjustable thickness, and large area coverage It can produce a very thin, dense, and stable film on the surface of the substrate | Compatibility in the production of long fibers is low The conductive layer is not uniform | [107,109] |

| Drop-Coating method | A simple procedure, no material waste is produced, and no requirement for special equipment It is commercially available | Limitations in large area coverage and thickness control, and poor uniformity | [110,111] |

| Spin-Coating method | The most commonly used method due to the ease of use and production of low-material waste No special equipment is required | The inefficiency of the material used The method uses only approximately 2 to 5 of the materials spread on the substrate The remaining 95 to 98 are discarded | [110,112,113] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alhashmi Alamer, F.; Beyari, R.F. Overview of the Influence of Silver, Gold, and Titanium Nanoparticles on the Physical Properties of PEDOT:PSS-Coated Cotton Fabrics. Nanomaterials 2022, 12, 1609. https://doi.org/10.3390/nano12091609

Alhashmi Alamer F, Beyari RF. Overview of the Influence of Silver, Gold, and Titanium Nanoparticles on the Physical Properties of PEDOT:PSS-Coated Cotton Fabrics. Nanomaterials. 2022; 12(9):1609. https://doi.org/10.3390/nano12091609

Chicago/Turabian StyleAlhashmi Alamer, Fahad, and Rawan F. Beyari. 2022. "Overview of the Influence of Silver, Gold, and Titanium Nanoparticles on the Physical Properties of PEDOT:PSS-Coated Cotton Fabrics" Nanomaterials 12, no. 9: 1609. https://doi.org/10.3390/nano12091609

APA StyleAlhashmi Alamer, F., & Beyari, R. F. (2022). Overview of the Influence of Silver, Gold, and Titanium Nanoparticles on the Physical Properties of PEDOT:PSS-Coated Cotton Fabrics. Nanomaterials, 12(9), 1609. https://doi.org/10.3390/nano12091609