Multilayer Coatings for Tribology: A Mini Review

Abstract

1. Introduction

2. Development of Multilayer TMN Coatings

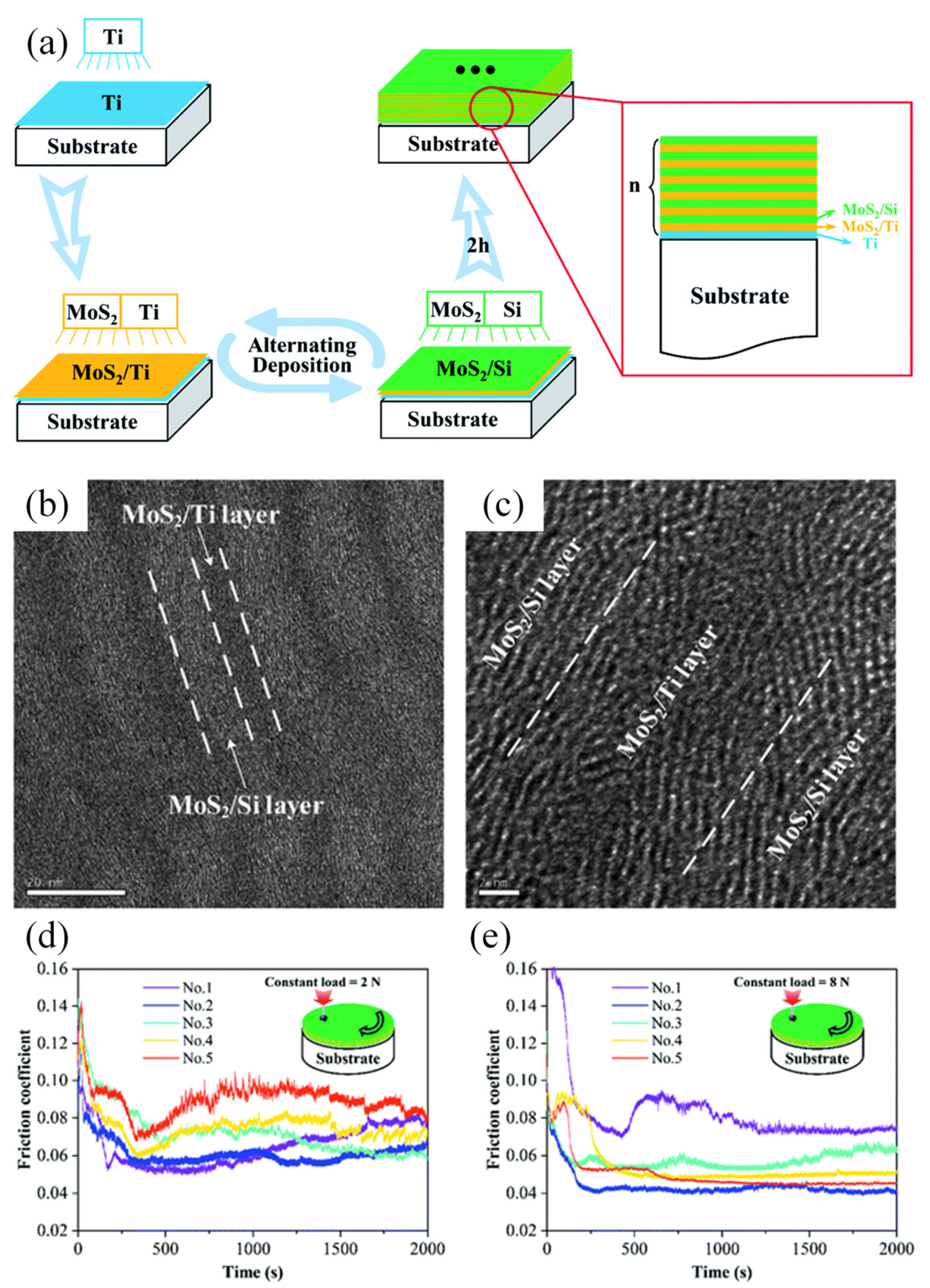

2.1. Ti-Based Multilayer TMN Coatings

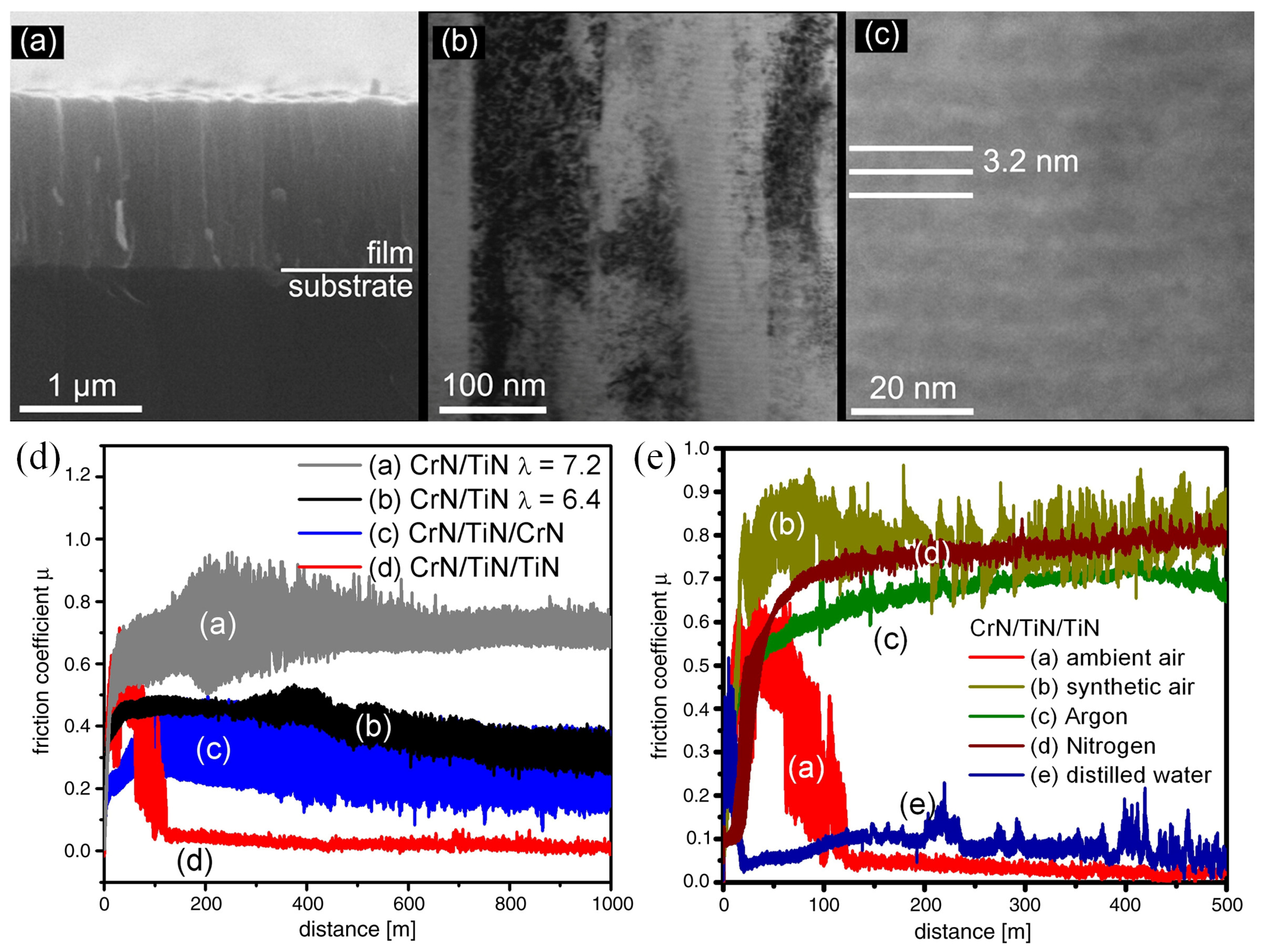

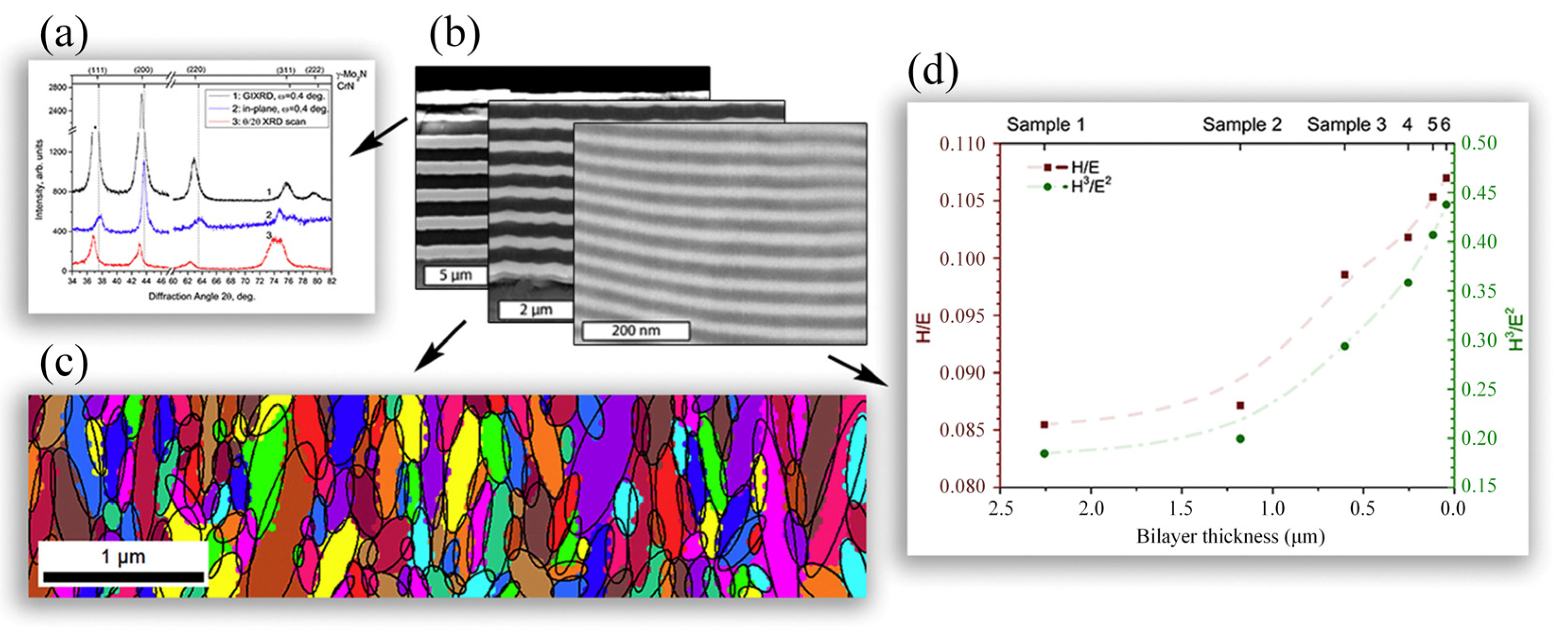

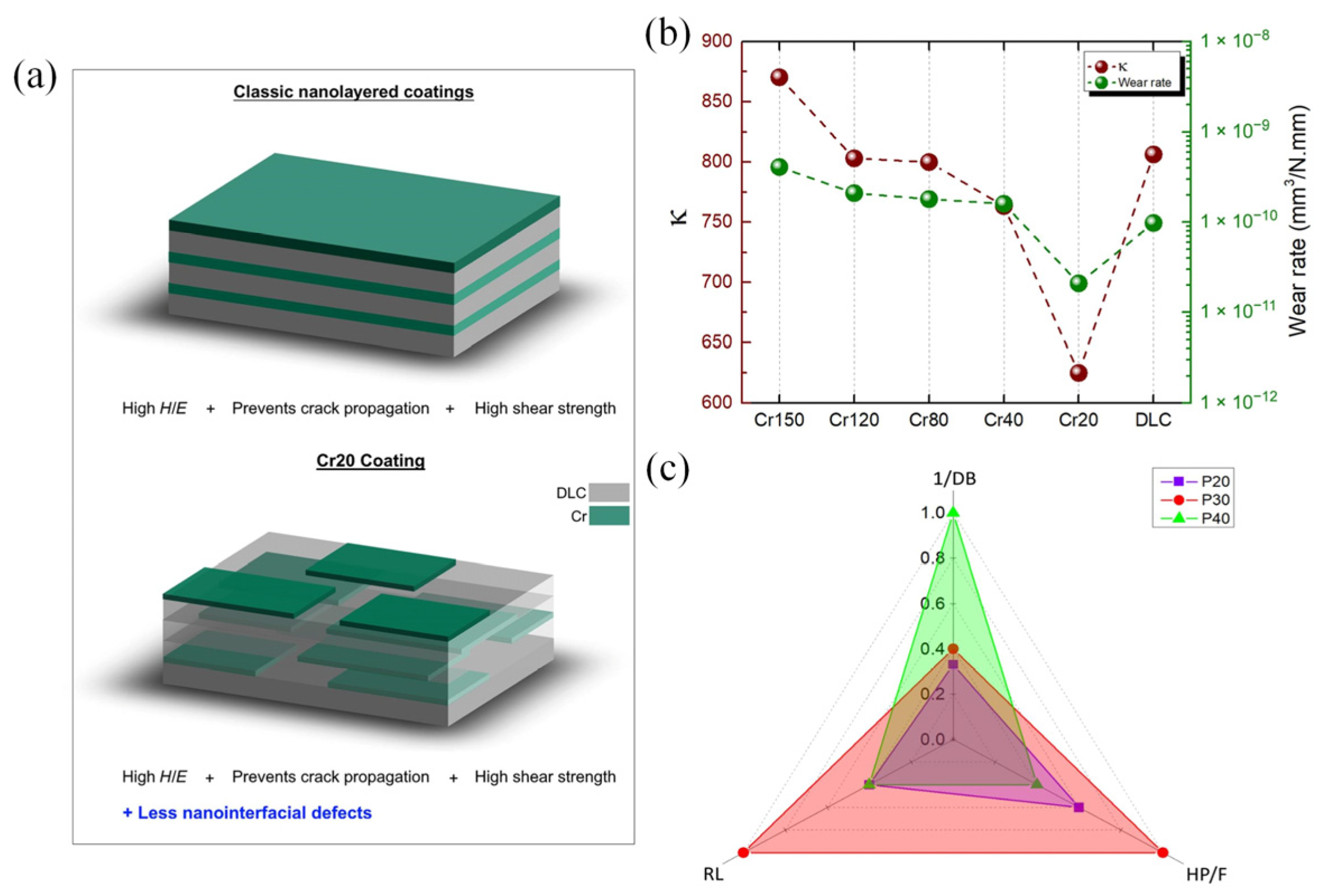

2.2. Cr-Based Multilayer TMN Coatings

2.3. TMN Coatings with Other Elements

2.4. Doping with Different Elements

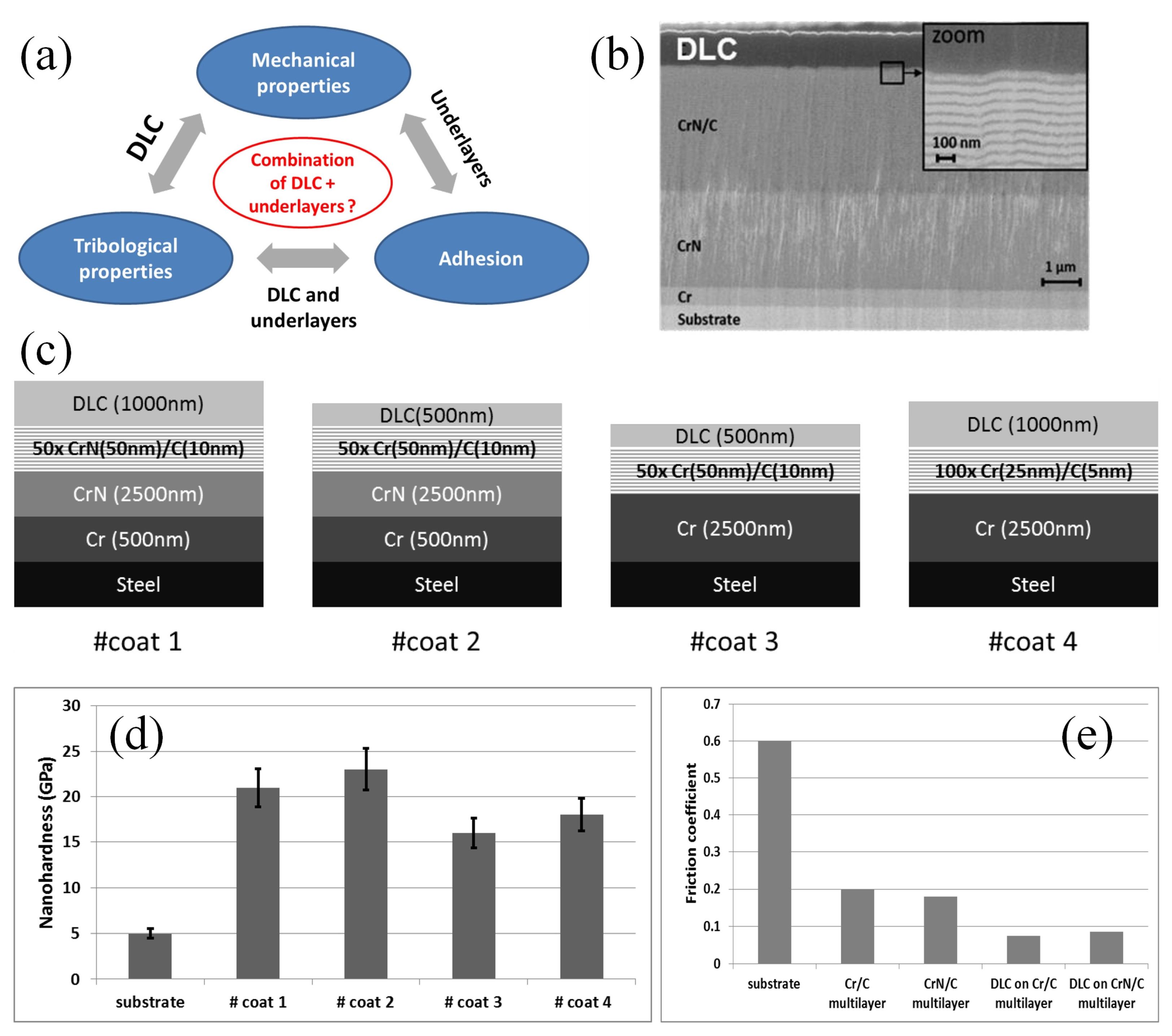

3. Development of Multilayer DLC Coatings

4. Other Multilayer Coatings for Tribology Applications

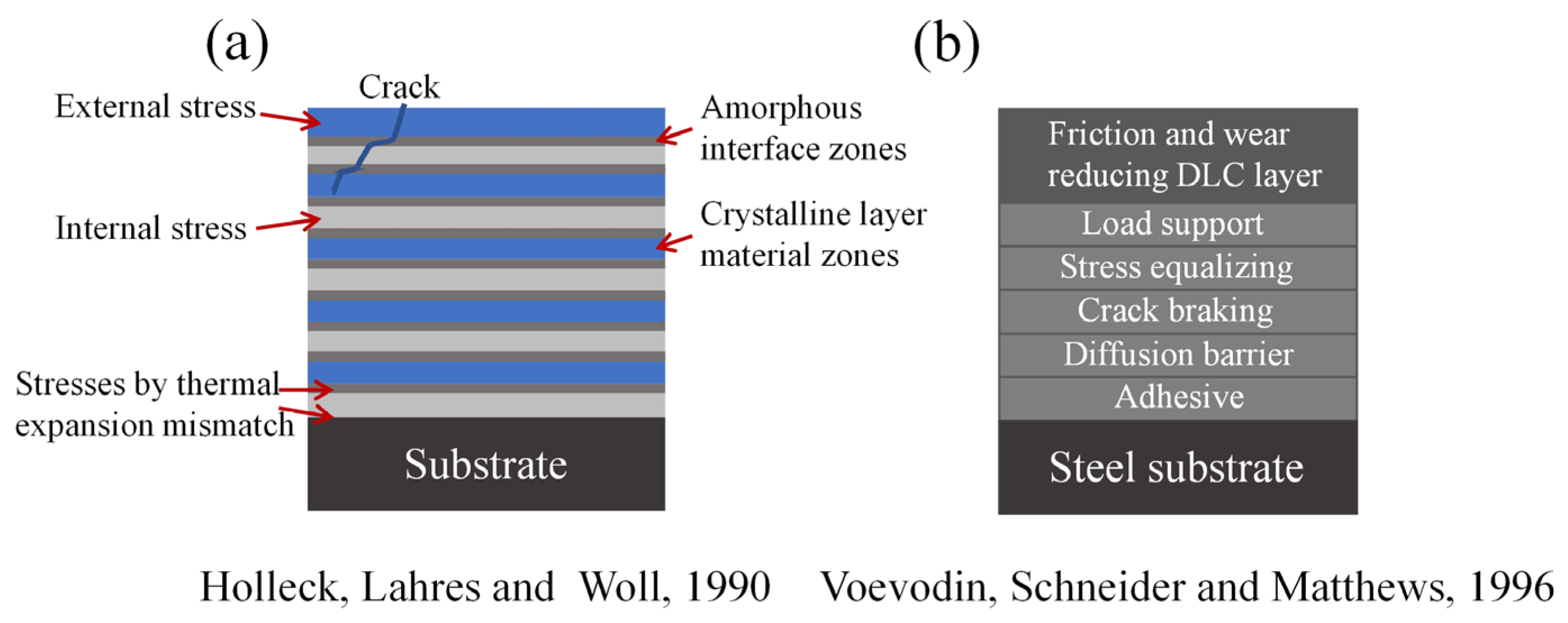

5. Mechanisms for Controlling Friction and Wear Using Multilayer Coatings

6. Conclusions and Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Luo, J.; Zhou, X. Superlubricitive engineering—Future industry nearly getting rid of wear and frictional energy consumption. Friction 2020, 8, 643–665. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Approaches for Achieving Superlubricity in Two-Dimensional Materials. ACS Nano 2018, 12, 2122–2137. [Google Scholar] [CrossRef] [PubMed]

- Luo, J.; Liu, M.; Ma, L. Origin of friction and the new frictionless technology—Superlubricity: Advancements and future outlook. Nano Energy 2021, 86, 106092. [Google Scholar] [CrossRef]

- Cao, Z.; Xia, Y.; Chen, C.; Zheng, K.; Zhang, Y. A synergetic strategy based on laser surface texturing and lubricating grease for improving the tribological and electrical properties of Ag coating under current-carrying friction. Friction 2021, 9, 978–989. [Google Scholar] [CrossRef]

- Chen, J.; Xia, Y.; Hu, Y.; Hou, B. Tribological performance and conductive capacity of Ag coating under boundary lubrication. Tribol. Int. 2017, 110, 161–172. [Google Scholar] [CrossRef]

- Feng, X.; Xia, Y. Tribological properties of Ti-doped DLC coatings under ionic liquids lubricated conditions. Appl. Surf. Sci. 2012, 258, 2433–2438. [Google Scholar] [CrossRef]

- Dubar, M.; Dubois, A.; Dubar, L. Wear analysis of tools in cold forging: PVD versus CVD TiN coatings. Wear 2005, 259, 1109–1116. [Google Scholar] [CrossRef]

- Clarysse, F.; Lauwerens, W.; Vermeulen, M. Tribological properties of PVD tool coatings in forming operations of steel sheet. Wear 2008, 264, 400–404. [Google Scholar] [CrossRef]

- Shtansky, D.V.; Kiryukhantsev-Korneev, P.V.; Bashkova, I.A.; Sheveiko, A.N.; Levashov, E.A. Multicomponent nanostructured films for various tribological applications. Int. J. Refract. Met. Hard Mater. 2010, 28, 32–39. [Google Scholar] [CrossRef]

- Musil, J. Hard nanocomposite coatings: Thermal stability, oxidation resistance and toughness. Surf. Coat. Technol. 2012, 207, 50–65. [Google Scholar] [CrossRef]

- Veprek, S. Recent search for new superhard materials: Go nano! J. Vac. Sci. Technol. A 2013, 31, 050822. [Google Scholar] [CrossRef]

- Mayrhofer, H.; Mitterer, C.; Hultman, L.; Clemens, H. Microstructural design of hard coatings. Prog. Mater. Sci. 2006, 51, 1032–1114. [Google Scholar] [CrossRef]

- Łępicka, M.; Grądzka-Dahlke, M.; Pieniak, D.; Pasierbiewicz, K.; Kryńska, K.; Niewczas, A. Tribological performance of titanium nitride coatings: A comparative study on TiN-coated stainless steel and titanium alloy. Wear 2019, 422–423, 68–80. [Google Scholar] [CrossRef]

- Komarov, F.F.; Konstantinov, V.M.; Kovalchuk, A.V.; Konstantinov, S.V.; Tkachenko, H.A. The effect of steel substrate pre-hardening on structural, mechanical, and tribological properties of magnetron sputtered TiN and TiAlN coatings. Wear 2016, 352–353, 92–101. [Google Scholar] [CrossRef]

- Zhu, Y.; Qu, H.; Luo, M.; He, C.; Qu, J. Dry friction and wear properties of several hard coating combinations. Wear 2020, 456–457, 203352. [Google Scholar] [CrossRef]

- Lin, F.; Xia, Y.; Feng, X. Conductive and tribological properties of TiN-Ag composite coatings under grease lubrication. Friction 2021, 9, 774–788. [Google Scholar] [CrossRef]

- Ferreira, R.; Carvalho, Ó.; Sobral, L.; Carvalho, S.; Silva, F. Influence of morphology and microstructure on the tribological behavior of arc deposited CrN coatings for the automotive industry. Surf. Coat. Technol. 2020, 397, 126047. [Google Scholar] [CrossRef]

- Wan, S.; Wang, H.; Xia, Y.; Tieu, A.K.; Tran, B.H.; Zhu, H.; Zhang, G.; Qiang, Z. Investigating the corrosion-fatigue wear on CrN coated piston rings from laboratory wear tests and field trial studies. Wear 2019, 432–433, 202940. [Google Scholar] [CrossRef]

- Chowdhury, M.S.I.; Bose, B.; Yamamoto, K.; Shuster, L.S.; Paiva, J.; Fox-Rabinovich, G.S.; Veldhuis, S.C. Wear performance investigation of PVD coated and uncoated carbide tools during high-speed machining of TiAl6V4 aerospace alloy. Wear 2020, 446–447, 203168. [Google Scholar] [CrossRef]

- Kong, J.-Z.; Xu, P.; Cao, Y.-Q.; Li, A.-D.; Wang, Q.-Z.; Zhou, F. Improved corrosion protection of CrN hard coating on steel sealed with TiOxNy-TiN composite layers. Surf. Coat. Technol. 2020, 381, 125108. [Google Scholar] [CrossRef]

- Krysina, O.V.; Ivanov, Y.F.; Prokopenko, N.A.; Shugurov, V.V.; Petrikova, E.A.; Denisova, Y.A.; Tolkachev, O.S. Influence of Nb addition on the structure, composition and properties of single-layered ZrN-based coatings obtained by vacuum-arc deposition method. Surf. Coat. Technol. 2020, 387, 125555. [Google Scholar] [CrossRef]

- Vasylyev, M.A.; Mordyuk, B.N.; Sidorenko, S.I.; Voloshko, S.M.; Burmak, A.P.; Kruhlov, I.O.; Zakiev, V.I. Characterization of ZrN coating low-temperature deposited on the preliminary Ar+ ions treated 2024 Al-alloy. Surf. Coat. Technol. 2019, 361, 413–424. [Google Scholar] [CrossRef]

- Mareus, R.; Mastail, C.; Anğay, F.; Brunetière, N.; Abadias, G. Study of columnar growth, texture development and wettability of reactively sputter-deposited TiN, ZrN and HfN thin films at glancing angle incidence. Surf. Coat. Technol. 2020, 399, 126130. [Google Scholar] [CrossRef]

- Zhu, F.; Zhu, K.; Hu, Y.; Ling, Y.; Wang, D.; Peng, H.; Xie, Z.; Yang, R.; Zhang, Z. Microstructure and Young’s modulus of ZrN thin film prepared by dual ion beam sputtering deposition. Surf. Coat. Technol. 2019, 374, 997–1005. [Google Scholar] [CrossRef]

- Sarioglu, C.; Demirler, U.; Kazmanli, M.K.; Urgen, M. Measurement of residual stresses by X-ray diffraction techniques in MoN and Mo2N coatings deposited by arc PVD on high-speed steel substrate. Surf. Coat. Technol. 2005, 190, 238–243. [Google Scholar] [CrossRef]

- Hazar, H. Characterization of MoN coatings for pistons in a diesel engine. Mater. Des. 2010, 31, 624–627. [Google Scholar] [CrossRef]

- Wang, J.; Munroe, P.; Zhou, Z.; Xie, Z. Nanostructured molybdenum nitride-based coatings: Effect of nitrogen concentration on microstructure and mechanical properties. Thin Solid Film. 2019, 682, 82–92. [Google Scholar] [CrossRef]

- Fonseca, R.M.; Soares, R.B.; Carvalho, R.G.; Tentardini, E.K.; Lins, V.F.C.; Castro, M.M.R. Corrosion behavior of magnetron sputtered NbN and Nb1-xAlxN coatings on AISI 316L stainless steel. Surf. Coat. Technol. 2019, 378, 124987. [Google Scholar] [CrossRef]

- Hao, J.; Zhang, K.; Ren, P.; Chen, J.; Wang, M.; Zhang, Y.; Wen, M. Tuning the wettability, mechanical and tribological properties of NbN films by doping rare earth cerium. J. Alloy. Compd. 2020, 814, 152339. [Google Scholar] [CrossRef]

- Agüero, A.; Juez-Lorenzo, M.; Hovsepian, P.E.; Ehiasarian, A.P.; Purandare, Y.P.; Muelas, R. Long-term behaviour of Nb and Cr nitrides nanostructured coatings under steam at 650 °C. Mechanistic considerations. J. Alloy. Compd. 2018, 739, 549–558. [Google Scholar] [CrossRef]

- Romero, E.C.; Macías, A.H.; Nonell, J.M.; Canto, O.S.; Botero, M.G. Mechanical and tribological properties of nanostructured TiAlN/TaN coatings deposited by DC magnetron sputtering. Surf. Coat. Technol. 2019, 378, 124941. [Google Scholar] [CrossRef]

- Ramos-Masana, A.; Colominas, C. Evaluation of DC-MS and HiPIMS TiB2 and TaN coatings as diffusion barriers against molten aluminum: An insight into the wetting mechanism. Surf. Coat. Technol. 2019, 375, 171–181. [Google Scholar] [CrossRef]

- Holmberg, K.; Matthews, A.; Ronkainen, H. Coatings tribology—Contact mechanisms and surface design. Tribol. Int. 1998, 31, 107–120. [Google Scholar] [CrossRef]

- Springer, R.W.; Catlett, D.S. Structure and mechanical properties of Al/AlxOy vacuum- deposited laminates. Thin Solid Film. 1978, 54, 197–205. [Google Scholar] [CrossRef]

- Springer, R.W.; Hosford, C.D. Characterization of aluminum–aluminum nitride coatings sputter deposited using the pulsed gas process. J. Vac. Sci. Technol. 1982, 20, 462–465. [Google Scholar] [CrossRef]

- Koehler, J.S. Attempt to Design a Strong Solid. Phys. Rev. B 1970, 2, 547–551. [Google Scholar] [CrossRef]

- Sans, C.; Deshpandey, C.; Doerr, H.J.; Bunshah, R.F.; Movchan, B.A.; Demchishin, A.V. Preparation and properties of TiC/Ni microlaminates. Thin Solid Film. 1983, 107, 345–351. [Google Scholar] [CrossRef]

- Bunshah, R.F.; Nimmagadda, R.; Doerr, H.J.; Movchan, B.A.; Grechanuk, N.I.; Didkin, G.G. Structure-property relationships in Cr/Cu and Ti/Ni microlaminate composites. Thin Solid Film. 1984, 112, 227–236. [Google Scholar] [CrossRef]

- Holleck, H.; Lahres, M.; Woll, P. Multilayer coatings—Influence of fabrication parameters on constitution and properties. Surf. Coat. Technol. 1990, 41, 179–190. [Google Scholar] [CrossRef]

- Matthews, A.; Eskildsen, S.S. Engineering applications for diamond-like carbon. Diam. Relat. Mater. 1994, 3, 902–911. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. Thick Ti/TiN multilayered coatings for abrasive and erosive wear resistance. Surf. Coat. Technol. 1994, 70, 19–25. [Google Scholar] [CrossRef]

- Bull, S.J.; Jones, A.M. Multilayer coatings for improved performance. Surf. Coat. Technol. 1996, 78, 173–184. [Google Scholar] [CrossRef]

- Bantle, R.; Matthews, A. Investigation into the impact wear behaviour of ceramic coatings. Surf. Coat. Technol. 1995, 74–75, 857–868. [Google Scholar] [CrossRef]

- Voevodin, A.A.; Bantle, R.; Matthews, A. Dynamic impact wear of TiCxNy and Ti-DLC composite coatings. Wear 1995, 185, 151–157. [Google Scholar] [CrossRef]

- Voevodin, A.A.; Schneider, J.M.; Rebholz, C.; Matthews, A. Multilayer composite ceramicmetal-DLC coatings for sliding wear applications. Tribol. Int. 1996, 29, 559–570. [Google Scholar] [CrossRef]

- Vetter, J.; Burgmer, W.; Dederichs, H.G.; Perry, A.J. The architecture and performance of multilayer and compositionally gradient coatings made by cathodic arc evaporation. Surf. Coat. Technol. 1993, 61, 209–214. [Google Scholar] [CrossRef]

- Leyland, A.; Bin-Sudin, M.; James, A.S.; Kalantary, M.R.; Wells, P.B.; Matthews, A.; Housden, J.; Garside, B. TiN and CrN PVD coatings on electroless nickel-coated steel substrates. Surf. Coat. Technol. 1993, 60, 474–479. [Google Scholar] [CrossRef]

- Bin-Sudin, M.; Leyland, A.; James, A.S.; Matthews, A.; Housden, J.; Garside, B. Substrate surface finish effects in duplex coatings of PAPVD TiN and CrN with electroless nickel-phosphorus interlayers. Surf. Coat. Technol. 1996, 81, 215–224. [Google Scholar] [CrossRef]

- Khadem, M.; Penkov, O.V.; Yang, H.-K.; Kim, D.-E. Tribology of multilayer coatings for wear reduction: A review. Friction 2017, 5, 248–262. [Google Scholar] [CrossRef]

- Mitterer, C.; Holler, F.; Üstel, F.; Heim, D. Application of hard coatings in aluminium die casting—Soldering, erosion and thermal fatigue behaviour. Surf. Coat. Technol. 2000, 125, 233–239. [Google Scholar] [CrossRef]

- Wei, R.; Vajo, J.J.; Matossian, J.N.; Gardos, M.N. Aspects of plasma-enhanced magnetron-sputtered deposition of hard coatings on cutting tools. Surf. Coat. Technol. 2002, 158–159, 465–472. [Google Scholar] [CrossRef]

- Bemporad, E.; Sebastiani, M.; Pecchio, C.; de Rossi, S. High thickness Ti/TiN multilayer thin coatings for wear resistant applications. Surf. Coat. Technol. 2006, 201, 2155–2165. [Google Scholar] [CrossRef]

- Evans, A.G.; Hutchinson, J.W. The mechanics of coating delamination in thermal gradients. Surf. Coat. Technol. 2007, 201, 7905–7916. [Google Scholar] [CrossRef]

- Mori, T.; Fukuda, S.; Takemura, Y. Improvement of mechanical properties of Ti/TiN multilayer film deposited by sputtering. Surf. Coat. Technol. 2001, 140, 122–127. [Google Scholar] [CrossRef]

- Cheng, Y.H.; Browne, T.; Heckerman, B.; Jiang, J.C.; Meletis, E.I.; Bowman, C.; Gorokhovsky, V. Internal stresses in TiN/Ti multilayer coatings deposited by large area filtered arc deposition. J. Appl. Phys. 2008, 104, 093502. [Google Scholar] [CrossRef]

- Cheng, Y.H.; Browne, T.; Heckerman, B.; Bowman, C.; Gorokhovsky, V.; Meletis, E.I. Mechanical and tribological properties of TiN/Ti multilayer coating. Surf. Coat. Technol. 2010, 205, 146–151. [Google Scholar] [CrossRef]

- Cheng, Y.; Pang, X.; Gao, K.; Yang, H.; Volinsky, A.A. Corrosion resistance and friction of sintered NdFeB coated with Ti/TiN multilayers. Thin Solid Film. 2014, 550, 428–434. [Google Scholar] [CrossRef]

- Lackner, J.; Major, L.; Kot, M. Microscale interpretation of tribological phenomena in Ti/TiN soft-hard multilayer coatings on soft austenite steel substrates. Bull. Pol. Acad. Sci. Tech. Sci. 2011, 59, 343–355. [Google Scholar] [CrossRef]

- Vereschaka, A.; Grigoriev, S.; Tabakov, V.; Migranov, M.; Sitnikov, N.; Milovich, F.; Andreev, N. Influence of the nanostructure of Ti-TiN-(Ti,Al,Cr)N multilayer composite coating on tribological properties and cutting tool life. Tribol. Int. 2020, 150, 106388. [Google Scholar] [CrossRef]

- Azushima, A.; Tanno, Y.; Iwata, H.; Aoki, K. Coefficients of friction of TiN coatings with preferred grain orientations under dry condition. Wear 2008, 265, 1017–1022. [Google Scholar] [CrossRef]

- Ghasemi, S.; Shanaghi, A.; Chu, P.K. Nano mechanical and wear properties of multi-layer Ti/TiN coatings deposited on Al 7075 by high-vacuum magnetron sputtering. Thin Solid Film. 2017, 638, 96–104. [Google Scholar] [CrossRef]

- Vereschaka, A.; Tabakov, V.; Grigoriev, S.; Sitnikov, N.; Milovich, F.; Andreev, N.; Bublikov, J. Investigation of wear mechanisms for the rake face of a cutting tool with a multilayer composite nanostructured Cr–CrN-(Ti,Cr,Al,Si)N coating in high-speed steel turning. Wear 2019, 438–439, 203069. [Google Scholar] [CrossRef]

- Vyas, A.; Shen, Y.G.; Zhou, Z.F.; Li, K.Y. Nano-structured CrN/CNx multilayer films deposited by magnetron sputtering. Compos. Sci. Technol. 2008, 68, 2922–2929. [Google Scholar] [CrossRef]

- Navinšek, B.; Panjan, P.; Milošev, I. Industrial applications of CrN (PVD) coatings, deposited at high and low temperatures. Surf. Coat. Technol. 1997, 97, 182–191. [Google Scholar] [CrossRef]

- Milošev, I.; Strehblow, H.H.; Navinšek, B. XPS in the study of high-temperature oxidation of CrN and TiN hard coatings. Surf. Coat. Technol. 1995, 74–75, 897–902. [Google Scholar] [CrossRef]

- Héau, C.; Fillit, R.Y.; Vaux, F.; Pascaretti, F. Study of thermal stability of some hard nitride coatings deposited by reactive magnetron sputtering. Surf. Coat. Technol. 1999, 120–121, 200–205. [Google Scholar] [CrossRef]

- Sánchez-López, J.C.; Martínez-Martínez, D.; López-Cartes, C.; Fernández, A.; Brizuela, M.; García-Luis, A.; Oñate, J.I. Mechanical behavior and oxidation resistance of Cr(Al)N coatings. J. Vac. Sci. Technol. A Vac. Surf. Film. 2005, 23, 681–686. [Google Scholar] [CrossRef]

- Barshilia, H.C.; Deepthi, B.; Rajam, K.S.; Bhatti, K.P.; Chaudhary, S. Growth and characterization of TiAlN∕CrAlN superlattices prepared by reactive direct current magnetron sputtering. J. Vac. Sci. Technol. A Vac. Surf. Film. 2009, 27, 29–36. [Google Scholar] [CrossRef]

- Huang, Z.P.; Sun, Y.; Bell, T. Friction behaviour of TiN, CrN and (TiAl)N coatings. Wear 1994, 173, 13–20. [Google Scholar] [CrossRef]

- Su, Y.L.; Yao, S.H.; Leu, Z.L.; Wei, C.S.; Wu, C.T. Comparison of tribological behavior of three films—TiN, TiCN and CrN—grown by physical vapor deposition. Wear 1997, 213, 165–174. [Google Scholar] [CrossRef]

- Lee, D.B.; Lee, Y.C.; Kwon, S.C. High temperature oxidation of a CrN coating deposited on a steel substrate by ion plating. Surf. Coat. Technol. 2001, 141, 227–231. [Google Scholar] [CrossRef]

- Ernst, W.; Neidhardt, J.; Willmann, H.; Sartory, B.; Mayrhofer, P.H.; Mitterer, C. Thermal decomposition routes of CrN hard coatings synthesized by reactive arc evaporation and magnetron sputtering. Thin Solid Film. 2008, 517, 568–574. [Google Scholar] [CrossRef]

- Du, J.W.; Chen, L.; Chen, J.; Du, Y. Mechanical properties, thermal stability and oxidation resistance of TiN/CrN multilayer coatings. Vacuum 2020, 179, 109468. [Google Scholar] [CrossRef]

- Nordin, M.; Larsson, M.; Hogmark, S. Mechanical and tribological properties of multilayered PVD TiN/CrN. Wear 1999, 232, 221–225. [Google Scholar] [CrossRef]

- Yang, Q.; Zhao, L.R. Dry sliding wear of magnetron sputtered TiN/CrN superlattice coatings. Surf. Coat. Technol. 2003, 173, 58–66. [Google Scholar] [CrossRef]

- Zhou, Y.M.; Asaki, R.; Higashi, K.; Soe, W.H.; Yamamoto, R. Sliding wear behavior of polycrystalline TiN/CrN multilayers against an alumina ball. Surf. Coat. Technol. 2000, 130, 9–14. [Google Scholar] [CrossRef]

- Srinivasan, D.; Kulkarni, T.G.; Anand, K. Thermal stability and high-temperature wear of Ti–TiN and TiN–CrN nanomultilayer coatings under self-mated conditions. Tribol. Int. 2007, 40, 266–277. [Google Scholar] [CrossRef]

- Paulitsch, J.; Schenkel, M.; Schintlmeister, A.; Hutter, H.; Mayrhofer, P.H. Low friction CrN/TiN multilayer coatings prepared by a hybrid high power impulse magnetron sputtering/DC magnetron sputtering deposition technique. Thin Solid Film. 2010, 518, 5553–5557. [Google Scholar] [CrossRef]

- Lin, S.-S.; Zhou, K.-S.; Dai, M.-J.; Hu, F.; Shi, Q.; Hou, H.-J.; Wei, C.-B.; Li, F.-Q.; Tong, X. Effects of surface roughness of substrate on properties of Ti/TiN/Zr/ZrN multilayer coatings. Trans. Nonferrous Met. Soc. China 2015, 25, 451–456. [Google Scholar] [CrossRef]

- Jianxin, D.; Jianhua, L.; Jinlong, Z.; Wenlong, S.; Ming, N. Friction and wear behaviors of the PVD ZrN coated carbide in sliding wear tests and in machining processes. Wear 2008, 264, 298–307. [Google Scholar] [CrossRef]

- Deng, J.; Liu, J.; Ding, Z.; Niu, M. Unlubricated friction and wear behaviors of ZrN coatings against hardened steel. Mater. Des. 2008, 29, 1828–1834. [Google Scholar] [CrossRef]

- Vereschaka, A.; Tabakov, V.; Grigoriev, S.; Aksenenko, A.; Sitnikov, N.; Oganyan, G.; Seleznev, A.; Shevchenko, S. Effect of adhesion and the wear-resistant layer thickness ratio on mechanical and performance properties of ZrN-(Zr,Al,Si)N coatings. Surf. Coat. Technol. 2019, 357, 218–234. [Google Scholar] [CrossRef]

- Postolnyi, B.O.; Beresnev, V.M.; Abadias, G.; Bondar, O.V.; Rebouta, L.; Araujo, J.P.; Pogrebnjak, A.D. Multilayer design of CrN/MoN protective coatings for enhanced hardness and toughness. J. Alloy. Compd. 2017, 725, 1188–1198. [Google Scholar] [CrossRef]

- Pogrebnjak, A.D.; Beresnev, V.M.; Bondar, O.V.; Postolnyi, B.O.; Zaleski, K.; Coy, E.; Jurga, S.; Lisovenko, M.O.; Konarski, P.; Rebouta, L.; et al. Superhard CrN/MoN coatings with multilayer architecture. Mater. Des. 2018, 153, 47–59. [Google Scholar] [CrossRef]

- Lee, D.B.; Kim, M.H.; Lee, Y.C.; Kwon, S.C. High temperature oxidation of TiCrN coatings deposited on a steel substrate by ion plating. Surf. Coat. Technol. 2001, 141, 232–239. [Google Scholar] [CrossRef]

- Ezazi, M.A.; Quazi, M.M.; Zalnezhad, E.; Sarhan, A.A.D. Enhancing the tribo-mechanical properties of aerospace AL7075-T6 by magnetron-sputtered Ti/TiN, Cr/CrN & TiCr/TiCrN thin film ceramic coatings. Ceram. Int. 2014, 40, 15603–15615. [Google Scholar]

- Nainaparampil, J.J.; Zabinski, J.S.; Korenyi-Both, A. Formation and characterization of multiphase film properties of (Ti–Cr)N formed by cathodic arc deposition. Thin Solid Film. 1998, 333, 88–94. [Google Scholar] [CrossRef]

- Kabir, M.S.; Munroe, P.; Zhou, Z.; Xie, Z. Scratch adhesion and tribological behaviour of graded Cr/CrN/CrTiN coatings synthesized by closed-field unbalanced magnetron sputtering. Wear 2017, 380–381, 163–175. [Google Scholar] [CrossRef]

- Özkan, D.; Yılmaz, M.A.; Erdem, C.; Türküz, C.; Sulukan, E.; Yağcı, M.B. Wear and friction behavior of CrTiN/TiCN and CrTiN/CrCN multilayer composite coatings. Ceram. Int. 2022, 48, 13732–13747. [Google Scholar] [CrossRef]

- Purushotham, K.P.; Ward, L.P.; Brack, N.; Pigram, P.J.; Evans, P.; Noorman, H.; Manory, R.R. Tribological studies of Zr-implanted PVD TiN coatings deposited on stainless steel substrates. Wear 2003, 254, 589–596. [Google Scholar] [CrossRef]

- Sui, X.; Liu, J.; Zhang, S.; Yang, J.; Hao, J. Microstructure, mechanical and tribological characterization of CrN/DLC/Cr-DLC multilayer coating with improved adhesive wear resistance. Appl. Surf. Sci. 2018, 439, 24–32. [Google Scholar] [CrossRef]

- Pu, J.; Ren, S.; Lu, Z.; Wang, L. A feasible multilayer structure design for solid lubricant coatings in a lunar environment. RSC Adv. 2016, 6, 65504–65517. [Google Scholar] [CrossRef]

- Duminica, F.D.; Belchi, R.; Libralesso, L.; Mercier, D. Investigation of Cr(N)/DLC multilayer coatings elaborated by PVD for high wear resistance and low friction applications. Surf. Coat. Technol. 2018, 337, 396–403. [Google Scholar] [CrossRef]

- Li, F.; Zhang, S.; Kong, J.; Zhang, Y.; Zhang, W. Multilayer DLC coatings via alternating bias during magnetron sputtering. Thin Solid Film. 2011, 519, 4910–4916. [Google Scholar] [CrossRef]

- Harigai, T.; Tamekuni, K.; Iijima, Y.; Degai, S.; Tanimoto, T.; Suda, Y.; Takikawa, H.; Takago, S.; Yasui, H.; Kaneko, S.; et al. Wear-resistive and electrically conductive nitrogen-containing DLC film consisting of ultra-thin multilayers prepared by using filtered arc deposition. Jpn. J. Appl. Phys. 2019, 58, SEED05. [Google Scholar] [CrossRef]

- Lin, Y.; Zia, A.W.; Zhou, Z.; Shum, P.W.; Li, K.Y. Development of diamond-like carbon (DLC) coatings with alternate soft and hard multilayer architecture for enhancing wear performance at high contact stress. Surf. Coat. Technol. 2017, 320, 7–12. [Google Scholar] [CrossRef]

- Martin, J.M.; Pascal, H.; Donnet, C.; le Mogne, T.; Loubet, J.L.; Epicier, T. Superlubricity of MoS2: Crystal orientation mechanisms. Surf. Coat. Technol. 1994, 68–69, 427–432. [Google Scholar] [CrossRef]

- Donnet, C.; Martin, J.M.; le Mogne, T.; Belin, M. Super-low friction of MoS2 coatings in various environments. Tribol. Int. 1996, 29, 123–128. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, X.; Li, J.; Luo, J. Enhancement of friction performance enabled by synergetic effect between graphene oxide and molybdenum disulfide. Carbon 2019, 154, 266–276. [Google Scholar] [CrossRef]

- Liu, Y.; Li, J.; Yi, S.; Ge, X.; Chen, X.; Luo, J. Enhancement of friction performance of nanocomposite fluorinated graphene and molybdenum disulfide coating by microdimple array. Carbon 2020, 167, 122–131. [Google Scholar] [CrossRef]

- Liu, Y.-F.; Liskiewicz, T.; Yerokhin, A.; Korenyi-Both, A.; Zabinski, J.; Lin, M.; Matthews, A.; Voevodin, A.A. Fretting wear behavior of duplex PEO/chameleon coating on Al alloy. Surf. Coat. Technol. 2018, 352, 238–246. [Google Scholar] [CrossRef]

- Mikhailov, S.; Savan, A.; Pflüger, E.; Knoblauch, L.; Hauert, R.; Simmonds, M.; van Swygenhoven, H. Morphology and tribological properties of metal (oxide)–MoS2 nanostructured multilayer coatings. Surf. Coat. Technol. 1998, 105, 175–183. [Google Scholar] [CrossRef]

- Kong, N.; Wei, B.; Li, D.; Zhuang, Y.; Sun, G.; Wang, B. A study on the tribological property of MoS2/Ti–MoS2/Si multilayer nanocomposite coating deposited by magnetron sputtering. RSC Adv. 2020, 10, 9633–9642. [Google Scholar] [CrossRef]

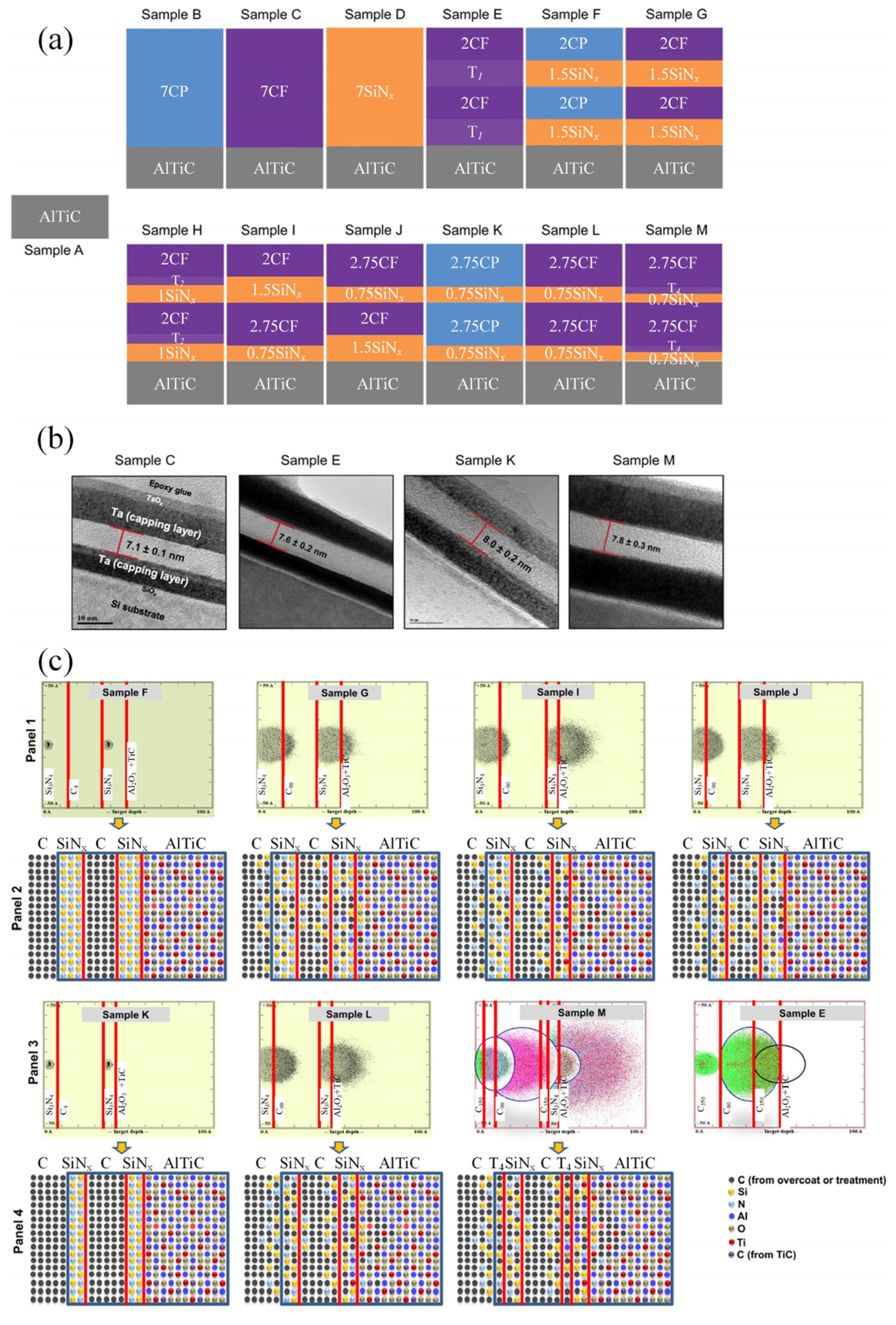

- Dwivedi, N.; Neogi, A.; Patra, T.K.; Dhand, C.; Dutta, T.; Yeo, R.J.; Kumar, R.; Hashmi, S.A.R.; Srivastava, A.K.; Tripathy, S.; et al. Angstrom-Scale Transparent Overcoats: Interfacial Nitrogen-Driven Atomic Intermingling Promotes Lubricity and Surface Protection of Ultrathin Carbon. Nano Lett. 2021, 21, 8960–8969. [Google Scholar] [CrossRef]

- Dwivedi, N.; Yeo, R.J.; Yak, L.J.K.; Satyanarayana, N.; Dhand, C.; Bhat, T.N.; Zhang, Z.; Tripathy, S.; Bhatia, C.S. Atomic Scale Interface Manipulation, Structural Engineering, and Their Impact on Ultrathin Carbon Films in Controlling Wear, Friction, and Corrosion. ACS Appl. Mater. Interfaces 2016, 8, 17606–17621. [Google Scholar] [CrossRef]

- Dwivedi, N.; Yeo, R.J.; Dhand, C.; Risan, J.; Nay, R.; Tripathy, S.; Rajauria, S.; Saifullah, M.S.M.; Sankaranarayanan, S.K.R.S.; Yang, H.; et al. Boosting contact sliding and wear protection via atomic intermixing and tailoring of nanoscale interfaces. Sci. Adv. 2019, 5, eaau7886. [Google Scholar] [CrossRef]

- Khadem, M.; Penkov, O.V.; Jais, J.; Bae, S.; Dhandapani, V.S.; Kang, B.; Kim, D. Formation of discrete periodic nanolayered coatings through tailoring of nanointerfaces—Toward zero macroscale wear. Sci. Adv. 2021, 7, eakb1224. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, X.; Li, J. Graphene lubrication. Appl. Mater. Today 2020, 20, 100662. [Google Scholar] [CrossRef]

- Chen, X.; Li, J. Superlubricity of carbon nanostructures. Carbon 2020, 158, 1–23. [Google Scholar] [CrossRef]

- Li, J.; Gao, T.; Luo, J. Superlubricity of Graphite Induced by Multiple Transferred Graphene Nanoflakes. Adv. Sci. 2018, 5, 1700616. [Google Scholar] [CrossRef]

- Dwivedi, N.; Patra, T.; Lee, J.; Yeo, R.J.; Srinivasan, S.; Dutta, T.; Sasikumar, K.; Dhand, C.; Tripathy, S.; Saifullah, M.S.M.; et al. Slippery and Wear-Resistant Surfaces Enabled by Interface Engineered Graphene. Nano Lett. 2020, 20, 905–917. [Google Scholar] [CrossRef]

- Dwivedi, N.; Ott, A.K.; Sasikumar, K.; Dou, C.; Yeo, R.J.; Sassi, B.N.U.; de Fazio, D.; Soavi, G.; Dutta, T.; Balci, O.; et al. Graphene overcoats for ultra-high storage density magnetic media. Nat. Commun. 2021, 12, 2584. [Google Scholar] [CrossRef]

- Liu, Y.; Li, J.; Ge, X.; Yi, S.; Wang, H.; Liu, Y.; Luo, J. Macroscale Superlubricity Achieved on the Hydrophobic Graphene Coating with Glycerol. ACS Appl. Mater. Interfaces 2020, 12, 18859–18869. [Google Scholar] [CrossRef]

- Wang, W.; Xie, G.; Luo, J. Superlubricity of Black Phosphorus as Lubricant Additive. ACS Appl. Mater. Interfaces 2018, 10, 43203–43210. [Google Scholar] [CrossRef]

- Wu, S.; He, F.; Xie, G.; Bian, Z.; Luo, J.; Wen, S. Black Phosphorus: Degradation Favors Lubrication. Nano Lett. 2018, 18, 5618–5627. [Google Scholar] [CrossRef]

- Ren, X.; Yang, X.; Xie, G.; Luo, J. Black Phosphorus Quantum Dots in Aqueous Ethylene Glycol for Macroscale Superlubricity. ACS Appl. Nano Mater. 2020, 3, 4799–4809. [Google Scholar] [CrossRef]

- Liu, Y.; Li, J.; Li, J.; Yi, S.; Ge, X.; Zhang, X.; Luo, J. Shear-Induced Interfacial Structural Conversion Triggers Macroscale Superlubricity: From Black Phosphorus Nanoflakes to Phosphorus Oxide. ACS Appl. Mater. Interfaces 2021, 13, 31947–31956. [Google Scholar] [CrossRef]

- Yan, H.; Fan, X.; Cai, M.; Song, S.; Zhu, M. Amino-functionalized Ti3C2Tx loading ZIF-8 nanocontainer@benzotriazole as multifunctional composite filler towards self-healing epoxy coating. J. Colloid Interface Sci. 2021, 602, 131–145. [Google Scholar] [CrossRef]

- Yan, H.; Cai, M.; Wang, J.; Zhang, L.; Li, H.; Li, W.; Fan, X.; Zhu, M. Insight into anticorrosion/antiwear behavior of inorganic-organic multilayer protection system composed of nitriding layer and epoxy coating with Ti3C2Tx Mxene. Appl. Surf. Sci. 2021, 536, 147974. [Google Scholar] [CrossRef]

- Yan, H.; Wang, J.; Cai, M.; Wang, X.; Song, S.; Zhang, L.; Li, H.; Li, W.; Fan, X.; Zhu, M. Towards long-term corrosion and wear protection of Al alloy: Synergy of Ti3C2Tx flake and micro-arc oxidation coating. Corros. Sci. 2020, 174, 108813. [Google Scholar] [CrossRef]

- Yan, H.; Cai, M.; Li, W.; Fan, X.; Zhu, M. Amino-functionalized Ti3C2Tx with anti-corrosive/wear function for waterborne epoxy coating. J. Mater. Sci. Technol. 2020, 54, 144–159. [Google Scholar] [CrossRef]

- Yan, H.; Zhang, L.; Li, H.; Fan, X.; Zhu, M. Towards high-performance additive of Ti3C2/graphene hybrid with a novel wrapping structure in epoxy coating. Carbon 2020, 157, 217–233. [Google Scholar] [CrossRef]

- Yan, H.; Li, W.; Li, H.; Fan, X.; Zhu, M. Ti3C2 MXene nanosheets toward high-performance corrosion inhibitor for epoxy coating. Prog. Org. Coat. 2019, 135, 156–167. [Google Scholar] [CrossRef]

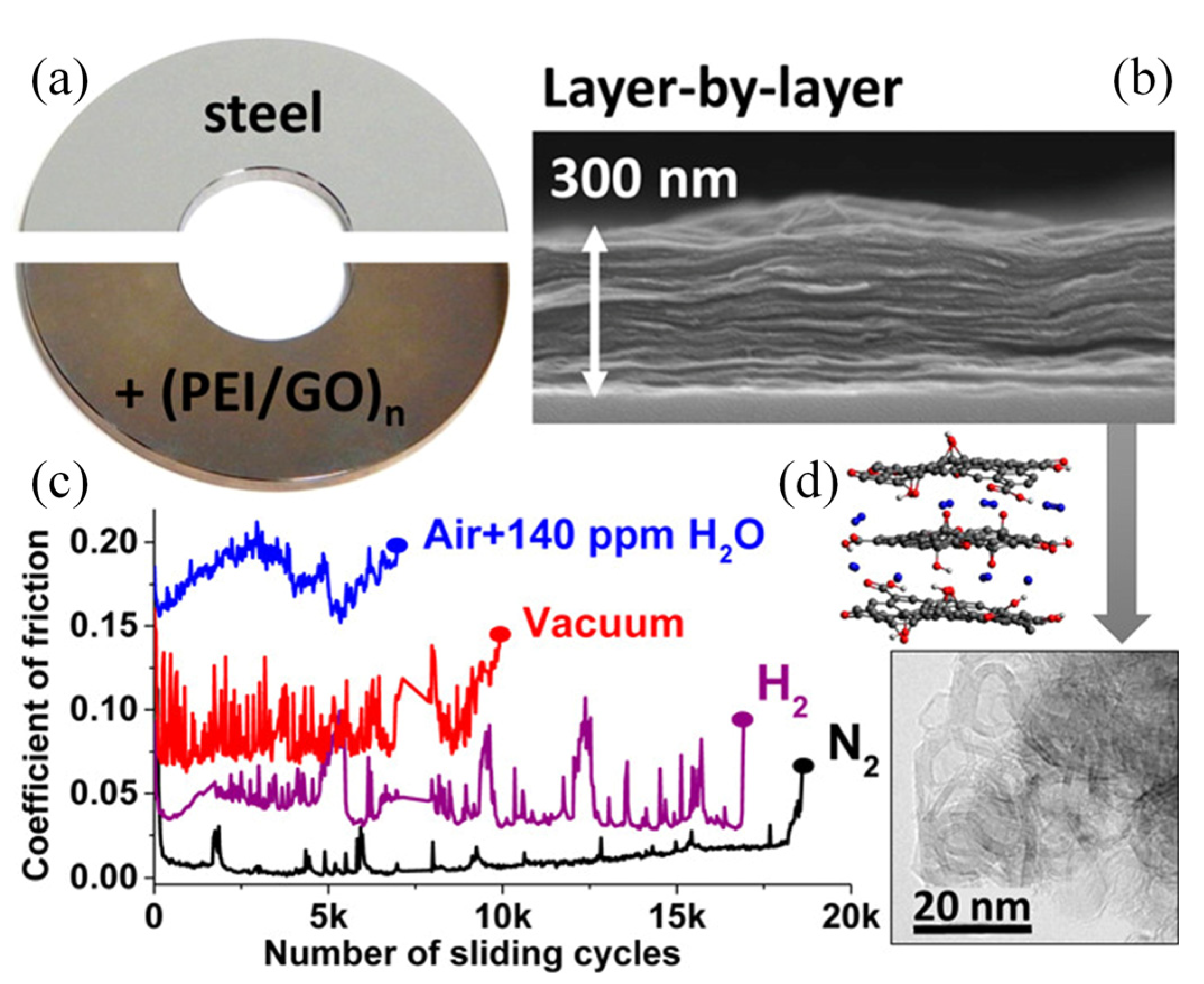

- Saravanan, P.; Selyanchyn, R.; Tanaka, H.; Darekar, D.; Staykov, A.; Fujikawa, S.; Lyth, S.M.; Sugimura, J. Macroscale superlubricity of multilayer polyethylenimine/graphene oxide coatings in different gas environments. ACS Appl. Mater. Interfaces 2016, 8, 27179–27187. [Google Scholar] [CrossRef] [PubMed]

- Saravanan, P.; Selyanchyn, R.; Tanaka, H.; Fujikawa, S.; Lyth, S.M.; Sugimura, J. Ultra-low friction between polymers and graphene oxide multilayers in nitrogen atmosphere, mediated by stable transfer film formation. Carbon 2017, 122, 395–403. [Google Scholar] [CrossRef]

| Types of Multilayer Coatings | Preparing Methods | Lubrication Properties | Friction-Reduction Mechanisms | Wear-Reduction Mechanisms |

|---|---|---|---|---|

| TiN/Ti [56] | Large area filtered cathodic arc deposition | COF reduced from 0.82 (TiN) to 0.6 (with Ti layers thickness of 25 nm) | Lower shear strength of soft Ti layers | — |

| Ti/TiN [61] | High-vacuum magnetron sputtering | COF reduced from 0.54 (TiN) to 0.48 | Formation of TiAlNxOy and TiNxOy tribolayers | — |

| TiN/CrN [76] | Reactive magnetron cathodic sputtering | COF reduced from 0.9 (TiN) and 0.6–0.7 (CrN) to 0.3–0.5 | Enhanced hardness and formation of the dense Cr2O3, and CrO3 oxide layer | |

| CrNHIPIMS/TiNDCMS [78] * | High-power impulse magnetron sputtering (HIPIMS) and DC unbalanced magnetron sputtering (DCMS) | COF reduced to 0.05 | Formation of humidity-triggered layers during dry-sliding tests under humid conditions | — |

| (Ti–Cr)N [87] | Cathodic arc deposition | COF reduced from 0.7 (TiN) and 0.75 (CrN) to 0.4 | Formation of mixed-phase films with plastic deformed wear debris | |

| CrTiN/TiCN and CrTiN/CrCN [89] | Cathodic arc PVD | COF reduced from 0.8–1.0 (bare substrates) to 0.2 | Graphitization of the amorphous carbon phase | Improved adhesion between individual layers; increased coating hardness; graphitization |

| CrN/DLC/Cr-DLC [91] | PECVD | COF reduced to 0.087 | Lubrication of DLC; supporting of CrN layers; enhancement of crack-propagation inhibition; increased elastic recovery capability | |

| Multilayer DLC with hard and soft layers [96] | Unbalanced closed-field magnetron sputtering | Lower COF during running-in process with soft top layer | Formation of transfer layer with soft top layer to provide low friction and wear | |

| MoS2/Ti–MoS2/Si [103] | Unbalanced magnetron sputtering | COF reduced to 0.0432 | Improved compactness and orientation of MoS2; improved oxidation and moisture resistance of MoS2; higher hardness; hindered dislocations motion and crack propagation | |

| C/SiNx overcoats [106] | Magnetron sputtering in situ with carbon deposition; high-energy carbon treatment | COF reduced from 0.4 (bare substrates) to lower than 0.2 | Extremely high adhesion governed by atomic intermixing, sufficient carbon thickness; high sp3 bonding | |

| Polyethylenimine/graphene oxide [124] * | Layer-by-layer deposition | COF reduced from 0.60 (substrate) to lower than 0.01 | Reduction in the contact area due to the formation of carbon nanoparticles in dry conditions | — |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Yu, S.; Shi, Q.; Ge, X.; Wang, W. Multilayer Coatings for Tribology: A Mini Review. Nanomaterials 2022, 12, 1388. https://doi.org/10.3390/nano12091388

Liu Y, Yu S, Shi Q, Ge X, Wang W. Multilayer Coatings for Tribology: A Mini Review. Nanomaterials. 2022; 12(9):1388. https://doi.org/10.3390/nano12091388

Chicago/Turabian StyleLiu, Yanfei, Shengtao Yu, Qiuyu Shi, Xiangyu Ge, and Wenzhong Wang. 2022. "Multilayer Coatings for Tribology: A Mini Review" Nanomaterials 12, no. 9: 1388. https://doi.org/10.3390/nano12091388

APA StyleLiu, Y., Yu, S., Shi, Q., Ge, X., & Wang, W. (2022). Multilayer Coatings for Tribology: A Mini Review. Nanomaterials, 12(9), 1388. https://doi.org/10.3390/nano12091388