Effect of Fiber Mass Fraction on Microstructure and Properties of 2D CF-GO/EP Composite Prepared by VIHPS

Abstract

:1. Introduction

2. Experimental Materials and Methods

2.1. Experimental Materials

2.2. Vacuum Infiltration Hot-Press Forming Process

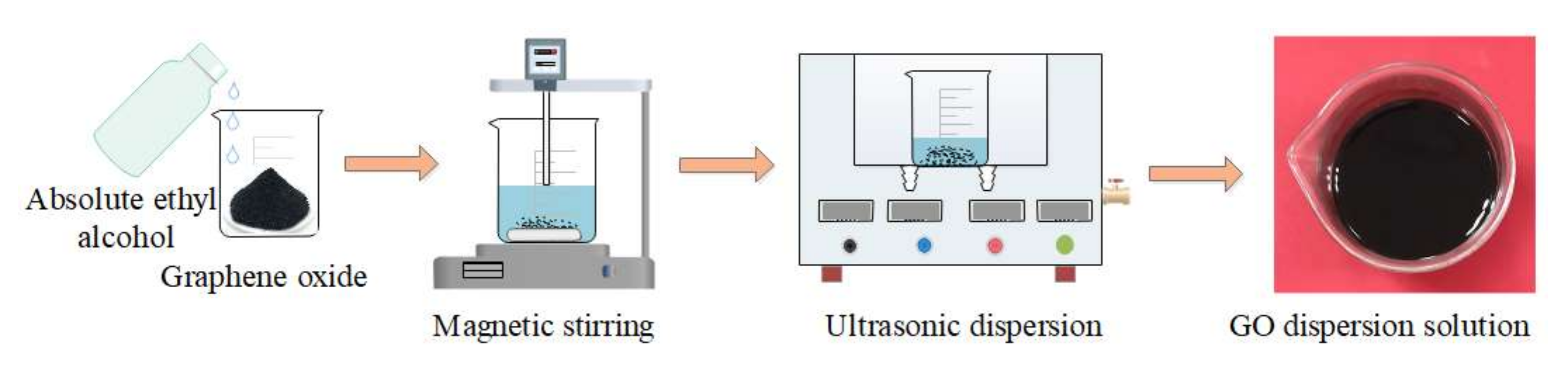

- (1)

- Preparation of the GO dispersion solution

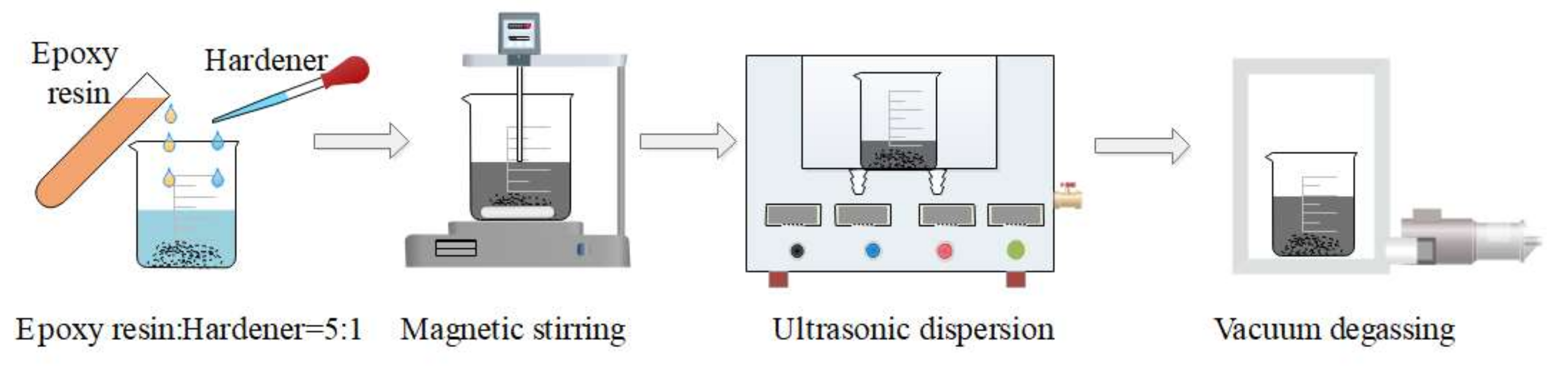

- (2)

- Preparation of the mixed solution of GO and epoxy resin

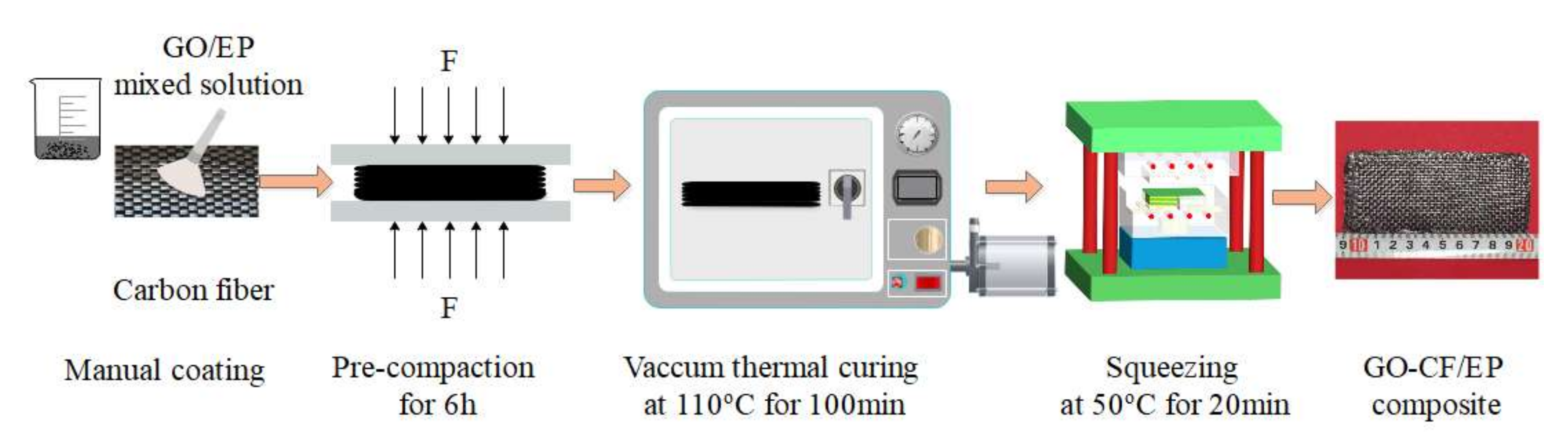

- (3)

- Preparation of GO-CF/EP composite

2.3. Testing and Characterization

3. Results and Discussion

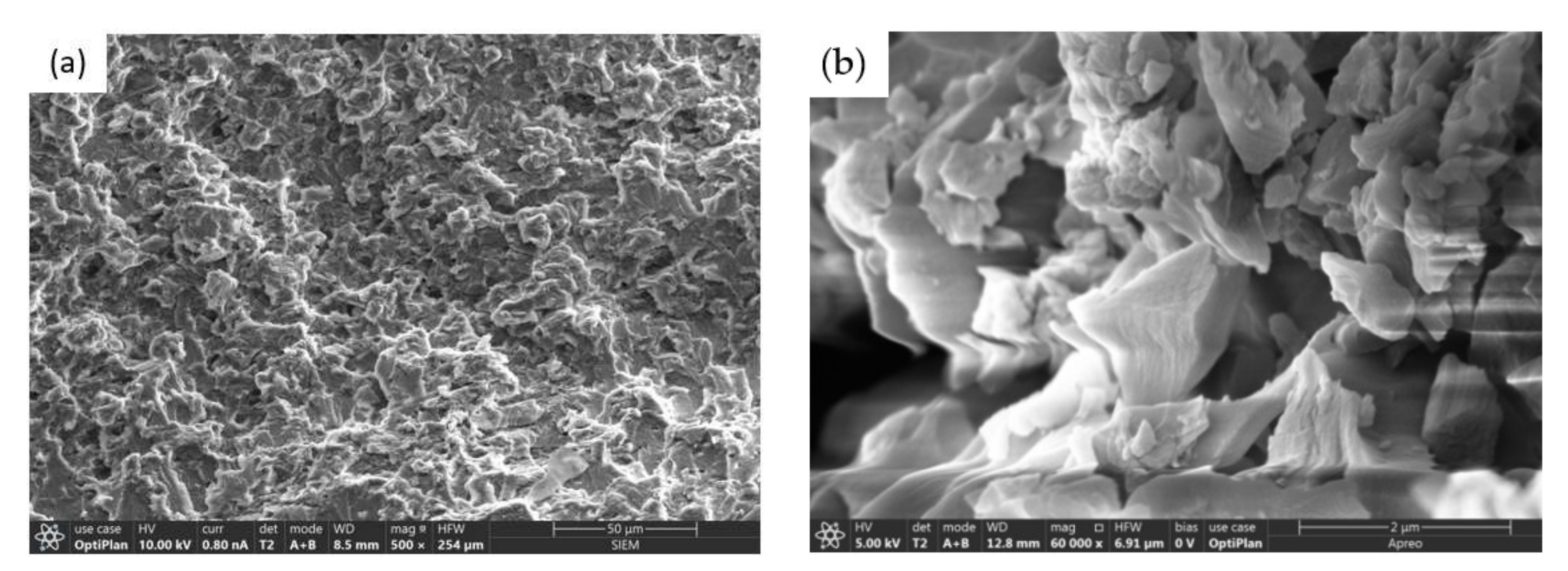

3.1. Dispersion Levels of GO

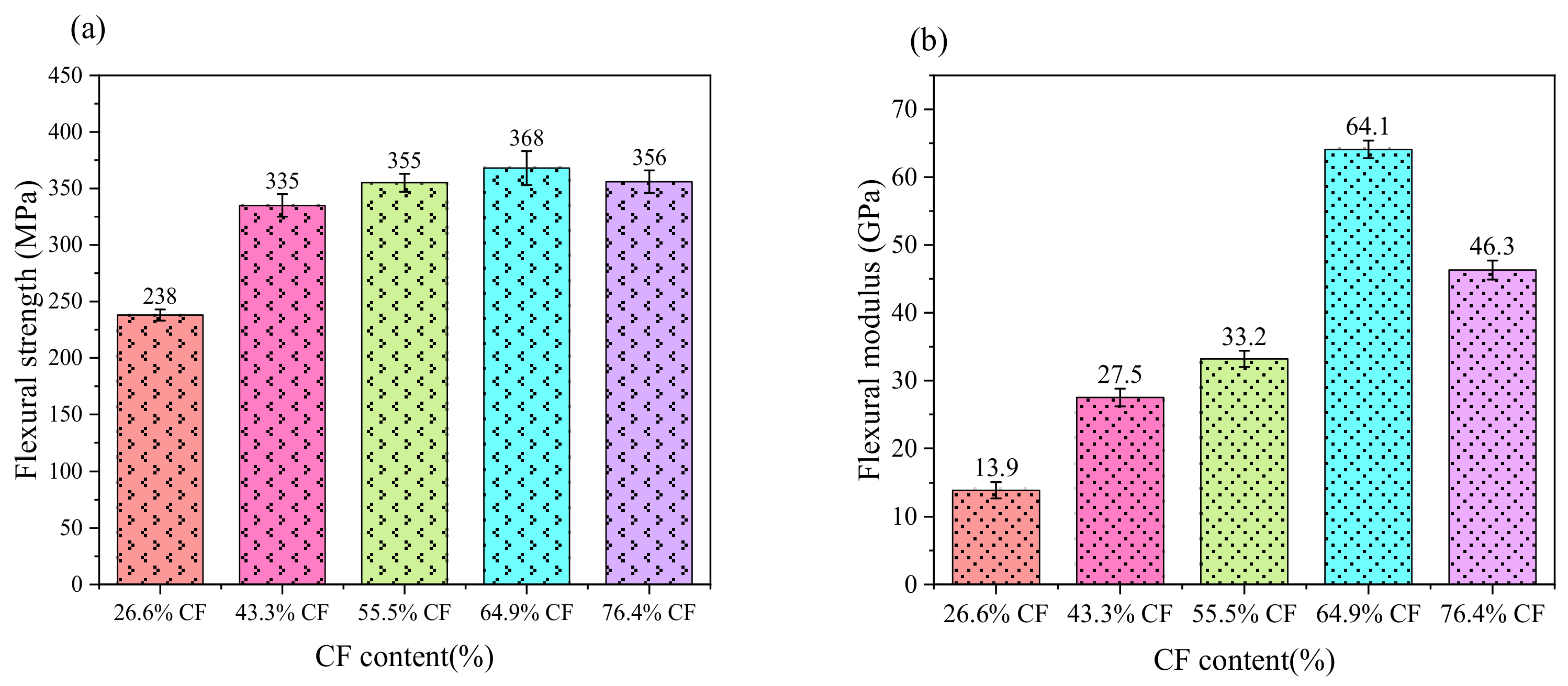

3.2. Flexural Property

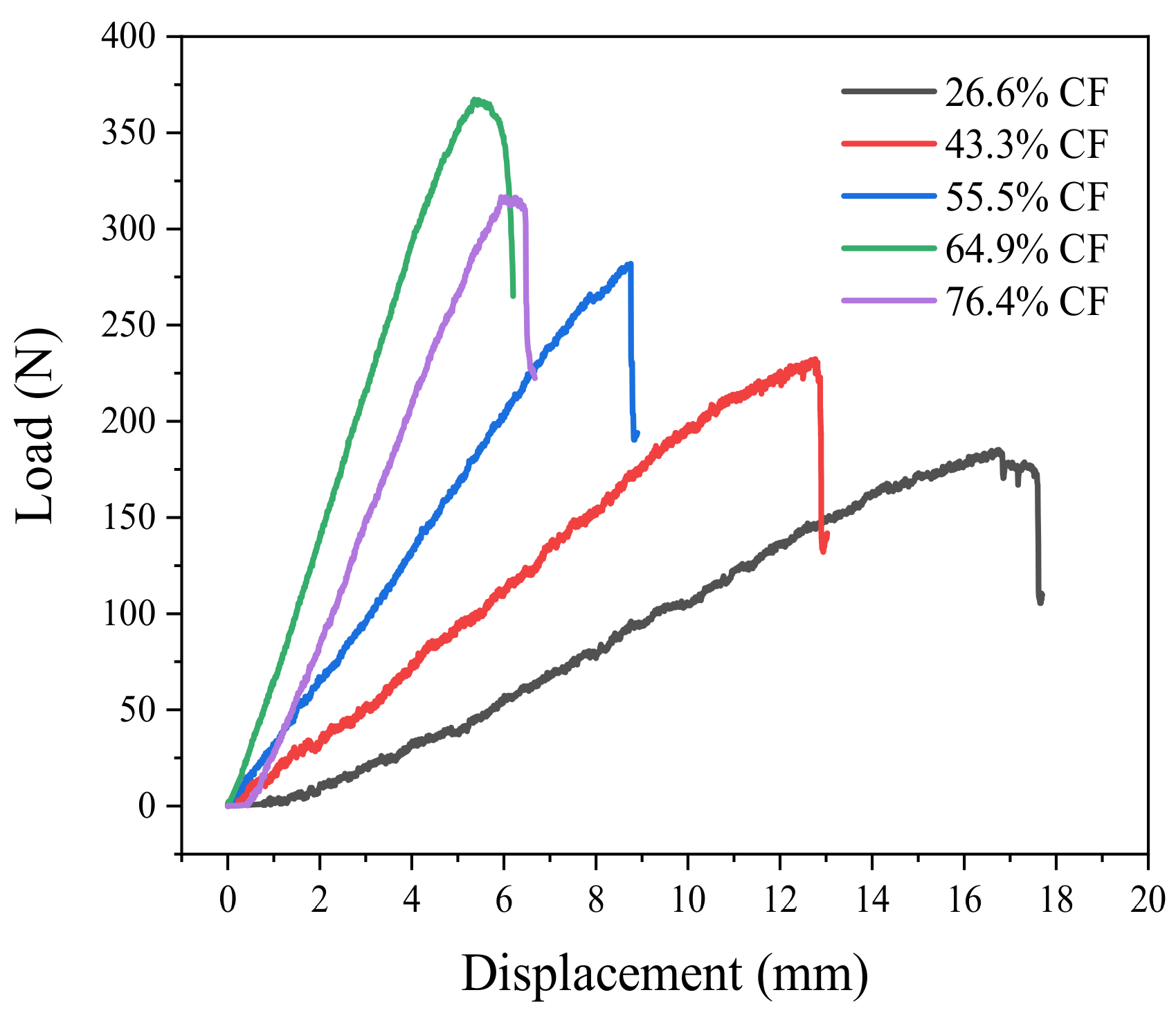

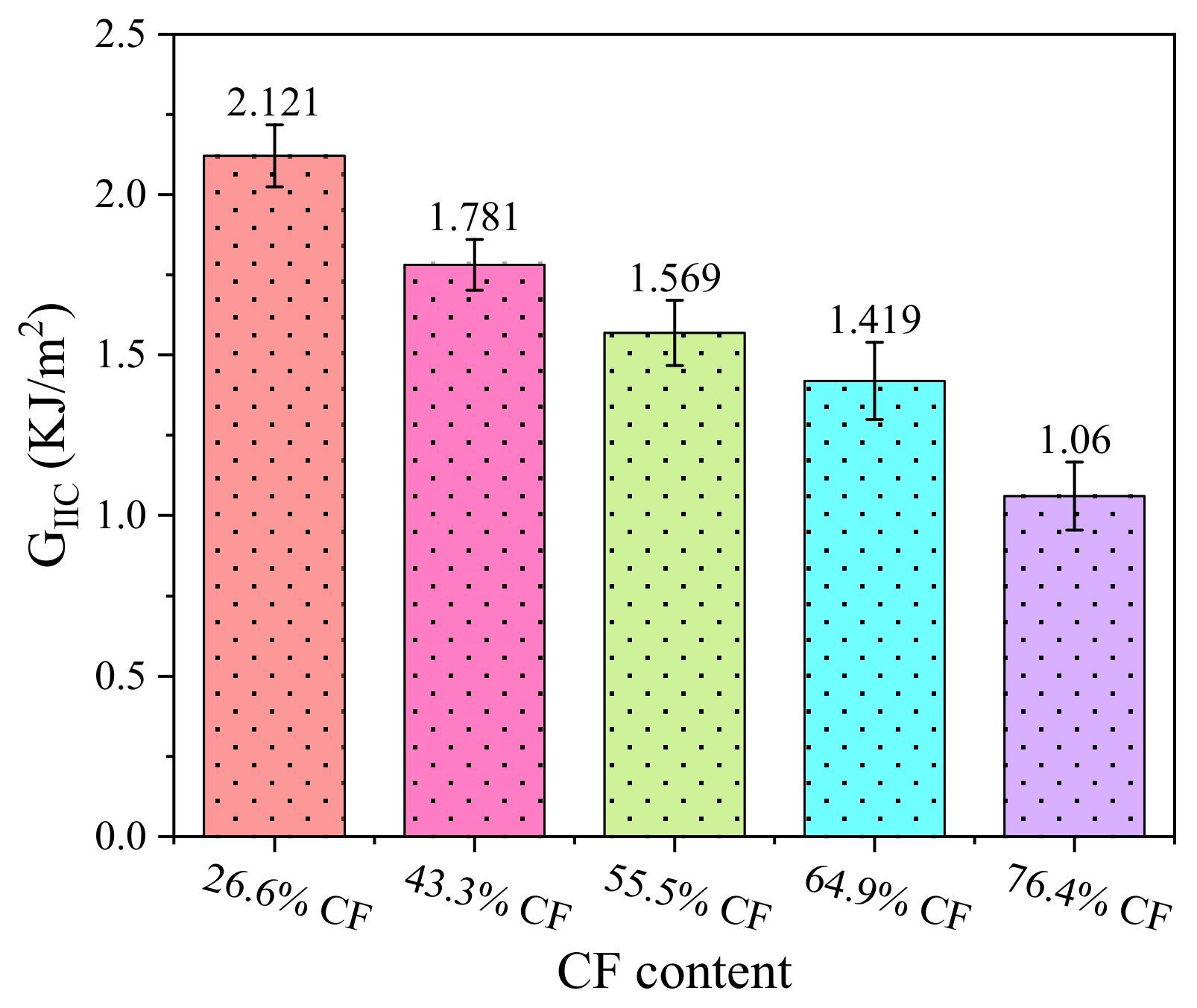

3.3. Interlayer Fracture Toughness

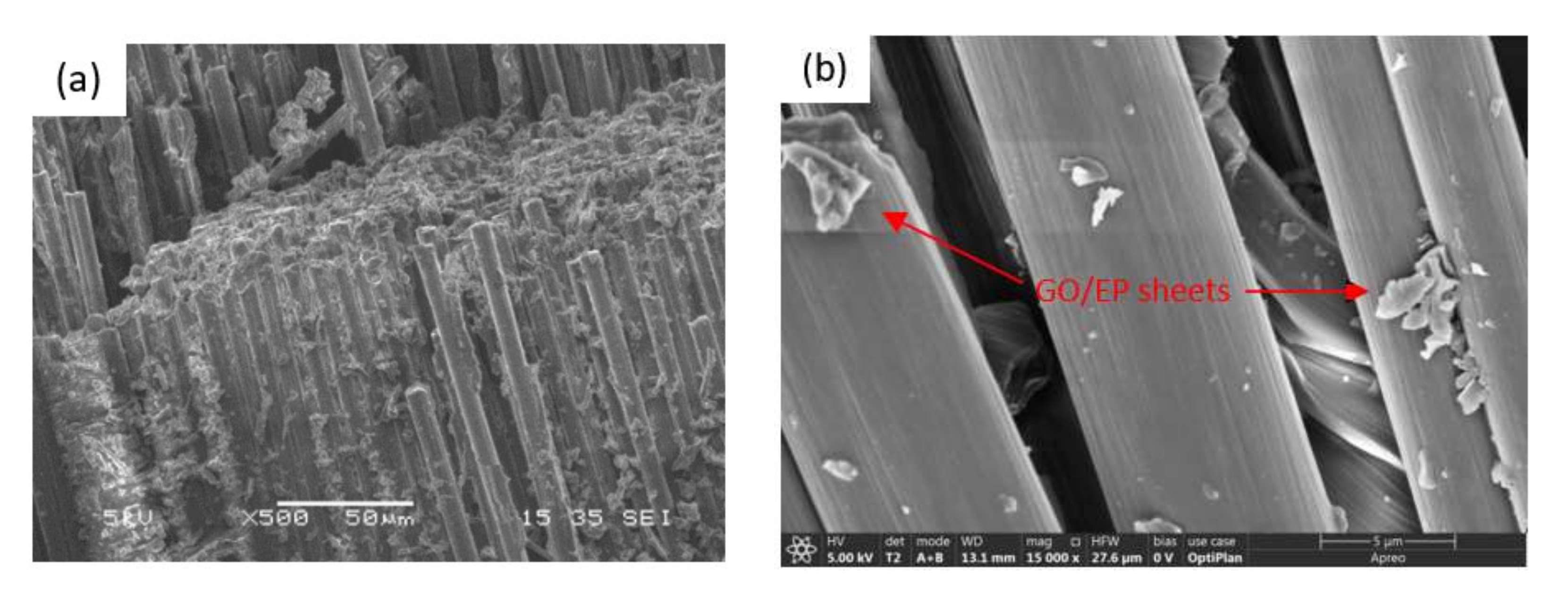

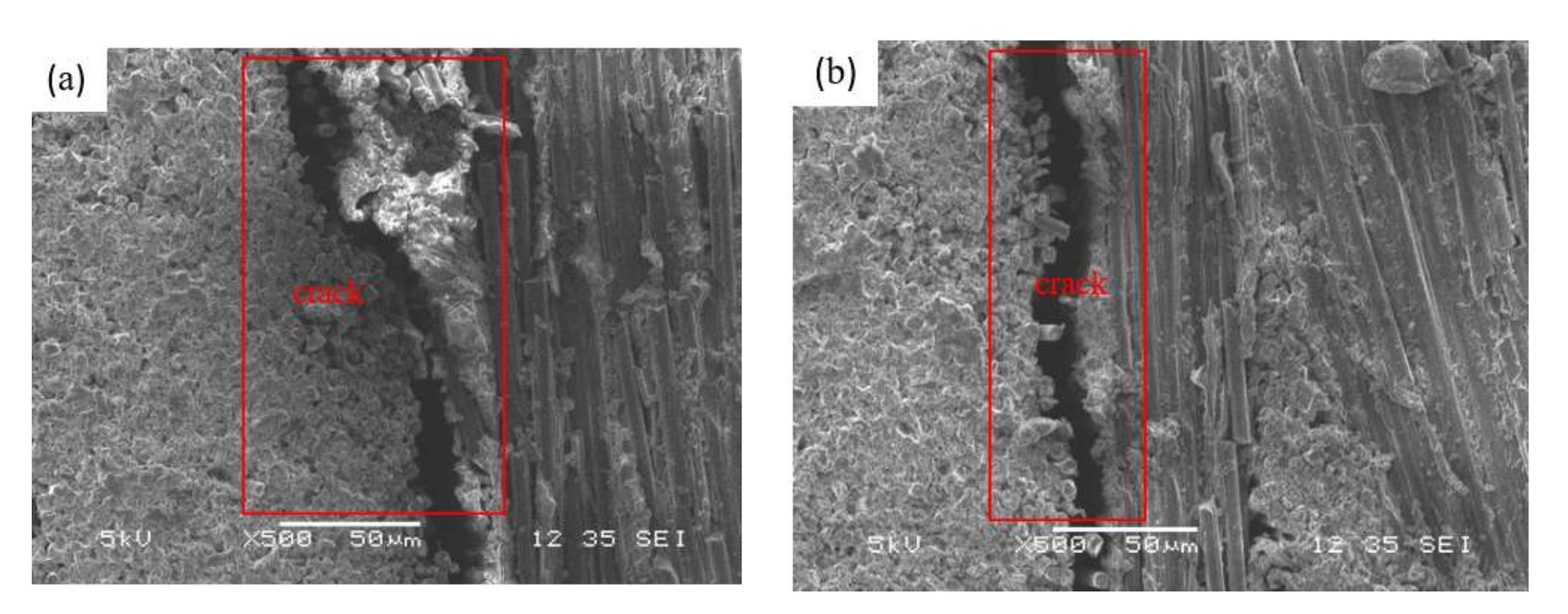

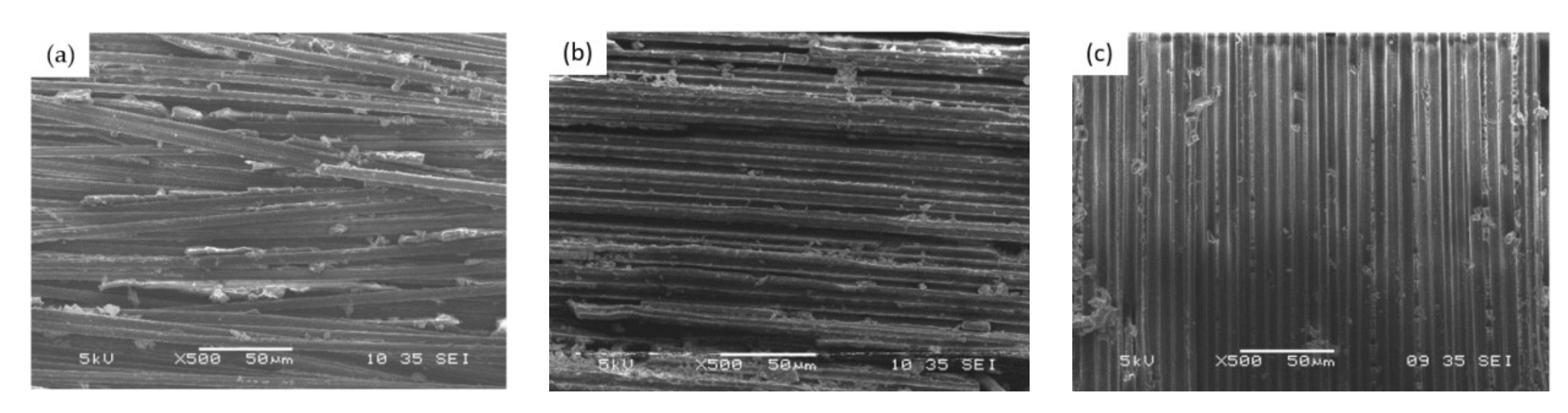

3.4. Fracture Morphology Analysis

4. Conclusions

- (1)

- Based on a new vacuum pressure infiltration CFRP method, 2D graphene oxide carbon fiber reinforced epoxy resin matrix (2D CF-GO/EP) composites were prepared, and the microstructure of the CF–GO/EP composites and GO/EP composites was observed by scanning electron microscopy. The results showed that the GO was evenly dispersed in the composites, and the impregnation effect of the resin matrix was also ideal. The flexural and fracture resistance of the composites were improved after the addition of GO.

- (2)

- The three-point flexural test results show that the flexural strength and flexural modulus of the composites with different fiber mass fractions show the same changing trend. With the increase of fiber mass fraction from 26.6% to 76.4%, the flexural strength and flexural modulus increase first and then decrease and reach the maximum value at 64.9%. The main reason is that too high fiber mass fraction will lead to the mutual extrusion and influence of carbon fibers, and too low epoxy matrix between fiber bundles will reduce the interlaminar bonding performance of the composites. Therefore, there will be delamination between composite layers, which will affect the overall bearing strength and stress limit of the composites.

- (3)

- ENF test results show that with the increase of fiber mass fraction in the composite laminated plate, mode Ⅱ interlaminar fracture toughness (GIIC) gradually decreases, and 26.6% content of carbon fiber composite has strong interlayer bonding properties. When the carbon fiber mass fraction increased to 76.4%, the GIIC was reduced by 50%. When the fiber mass fraction increases gradually, the bond between fiber bundles becomes weak. When the composite is subjected to a bending load, the prefabricated cracks propagate rapidly, and the composite shows small fracture toughness.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ning, H.M.; Li, J.H.; Hu, N.; Yan, C.; Liu, Y.L.; Wu, L.K.; Liu, F.; Zhang, J.Y. Interlaminar mechanical properties of carbon fiber reinforced plastic laminates modified with graphene oxide interleaf. Carbon 2015, 91, 224–233. [Google Scholar] [CrossRef] [Green Version]

- Sakai, T.; Shamsudim, N.S.B.; Fukushima, R.; Kageyama, K. Effect of matrix crystallinity of carbon fiber reinforced polyamide 6 on static bending properties. Adv. Compos. Mater. 2020, 30, 71–84. [Google Scholar] [CrossRef]

- Beom-Gon, C.; Jung-Eun, L.; Sang-Ha, H. Enhancement in mechanical properties of polyamide 66-carbon fiber composites containing graphene oxide-carbon nanotube hybrid nanofillers synthesized through in situ interfacial polymerization. Compos. Part A Appl. Sci. Manuf. 2020, 135, 105938. [Google Scholar]

- Xu, H.; Li, X.R.; Li, P.Y.; Ma, L.H.; Li, H.Y.; Shi, L.L.; Wang, M.Y.; Chen, H.G.; Song, G.J. Enhancing mechanical performances of polystyrene composites via constructing carbon nanotube/graphene oxide aerogel and hot pressing. Compos. Sci. Technol. 2020, 195, 8191. [Google Scholar] [CrossRef]

- Park, Y.T.; Qian, Y.; Chan, C.; Suh, T.; Nejhad, M.G.; Macosko, C.W.; Stein, A. Epoxy toughening with low graphene loading. Adv. Funct. Mater. 2015, 25, 575–585. [Google Scholar] [CrossRef]

- Nash, N.; Ray, D.; Young, T.; Stanley, W. The influence of hydrothermal conditioning on the Mode-I, thermal and flexural properties of Carbon/Benzoxazine composites with a thermoplastic toughening interlayer. Compos. Part A Appl. Sci. Manuf. 2015, 76, 135–144. [Google Scholar] [CrossRef]

- Koloor, S.R.; Tamin, M. Mode-II interlaminar fracture and crack-jump phenomenon in CFRP composite laminate materials. Compos. Struct. 2018, 204, 594–606. [Google Scholar] [CrossRef]

- Dico, G.L.; Wicklein, B.; Lisuzzo, L.; Lazzara, G.; Aranda, P.; Ruiz-Hitzky, E. Multicomponent bionanocomposites based on clay nanoarchitectures for electrochemical devices. Beilstein J. Nanotechnol. 2019, 10, 1303–1315. [Google Scholar] [CrossRef]

- Lin, Q.L.; Qu, L.J.; Lu, Q.F.; Fang, C.Q. Preparation and properties of graphene oxide nanosheets/cyanate ester resin composites. Polymer Testing 2013, 32, 330–337. [Google Scholar] [CrossRef]

- Kamar, N.T.; Hossain, M.M.; Khomenko, A.; Haq, M.; Drzal, L.T.; Loos, A. Interlaminar reinforcement of glass fiber/epoxy composites with graphene nanoplatelets. Compos. Part A Appl. Sci. Manuf. 2015, 70, 82–92. [Google Scholar] [CrossRef]

- Mahmud, H.A.; Radue, M.S.; Pisani, W.A.; Odegard, G.M. Computational Modeling of Hybrid Carbon Fiber/Epoxy Composites Reinforced with Functionalized and Non-Functionalized Graphene Nanoplatelets. Nanomaterials 2021, 11, 2919. [Google Scholar] [CrossRef]

- Rehman, S.; Gomez, J.; Villaro, E.; Cossey, D.; Karagiannidis, P.G. Bio-Based Epoxy/Amine Reinforced with Reduced Graphene Oxide (rGO) or GLYMO-rGO: Study of Curing Kinetics, Mechanical Properties, Lamination and Bonding Performance. Nanomaterials 2022, 12, 222. [Google Scholar] [CrossRef] [PubMed]

- Ma, W.S.; Li, J.; Zhao, X.S. Improving the thermal and mechanical properties of silicone polymer by incorporating functionalized graphene oxide. J. Mater. Sci. 2013, 48, 5287–5294. [Google Scholar] [CrossRef]

- Yan, M.L.; Jiao, W.C.; Li, J.; Huang, Y.F.; Chu, Z.M.; Chen, X.D.; Shen, F.; Wang, Y.; Wang, R.G.; He, X.D. Enhancement of the cryogenic-interfacial-strength of carbon fiber composites by chemical grafting of graphene oxide/attapulgite on T300. Polym. Compos. 2020, 41, 5072–5081. [Google Scholar] [CrossRef]

- Lokasani, B.; Sampath, P.; Soney, V. Experimental investigation on graphene oxides coated carbon fibre/epoxy hybrid composites: Mechanical and electrical properties. Compos. Sci. Technol. 2019, 179, 134–144. [Google Scholar]

- Zhao, X.R.; Chen, W.; Han, X.; Zhao, Y.; Du, S.Y. Enhancement of interlaminar fracture toughness in textile-reinforced epoxy composites with polyamide 6/graphene oxide interlaminar toughening tackifier. Compos. Sci. Technol. 2020, 191, 108094. [Google Scholar] [CrossRef]

- Sun, G.Y.; Tong, S.W.; Chen, D.D.; Gong, Z.H.; Li, Q. Mechanical properties of hybrid composites reinforced by carbon and basalt fibers. Int. J. Mech. Sci. 2018, 148, 636–651. [Google Scholar] [CrossRef]

- Yang, M.; Ma, F.W.; Pu, Y.F.; Zhi, Y.S. Response of carbon-basalt hybrid fiber reinforcement polymer under flexure load. Mater. Res. Express 2018, 5, 85602. [Google Scholar]

- Chandran, A.R.; Radhika, N. Investigation on mechanical properties and wear behaviour of chopped carbon-basalt epoxy hybrid composite. Mater. Res. Express 2019, 6, 105303. [Google Scholar] [CrossRef]

- Ma, Y.Q.; Wang, J.; Zhao, Y.T.; Wei, X.L.; Ju, L.Y.; Chen, Y. A New Vacuum Pressure Infiltration CFRP Method and Preparation Experimental Study of Composite. Polymers 2020, 12, 419. [Google Scholar] [CrossRef] [Green Version]

- Ye, J.J.; Cai, H.; Liu, L.; Zhai, Z.; Victor, A.C.; Wang, Y.K.; Lei, W.; Yang, D.M.; Chen, X.F.; Ye, J.Q. Microscale intrinsic properties of hybrid unidirectional/woven composite laminates: Part Ⅰ experimental tests. Compos. Struct. 2020, 262, 113369. [Google Scholar] [CrossRef]

- Abhishek, K.; Pathak, M.B.; Ashish, G.; Yokozeki, T.; Sanjay, R. Improved mechanical properties of carbon fiber/graphene oxide-epoxy hybrid composites. Compos. Sci. Technol. 2016, 135, 28–38. [Google Scholar]

- Shao, P.; Chen, G.Q.; Yang, W.S.; Zhang, Q.; Ju, B.Y.; Wang, Z.J.; Tan, X.; Pei, Y.Y.; Zhong, S.J.; Hussain, M.; et al. Effect of hot extrusion temperature on graphene nanoplatelets reinforced Al6061 composite fabricated by pressure infiltration method. Carbon 2020, 162, 455–464. [Google Scholar] [CrossRef]

- Yong, C.S.; Han, S.K.; Woo, L. Mode II interlaminar fracture toughness of carbon nanotubes/epoxy film-interleaved carbon fiber composites. Compos. Struct. 2020, 236, 111808. [Google Scholar]

- Chio, Y.C.; Chou, H.Y.; Shen, M.Y. Effects of adding graphene nanoplatelets and nanocarbon aerogels to epoxy resins and their carbon fiber composites. Mater. Des. 2019, 178, 107869. [Google Scholar] [CrossRef]

- Hu, Q.L.; Memon, H.; Qiu, Y.P.; Liu, W.S.; Wei, Y. A Comprehensive Study on the Mechanical Properties of Different 3D Woven Carbon Fiber-Epoxy Composites. Materials 2020, 13, 2765. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Ma, C.G.; Chen, G.; Dai, P.B. Interlaminar fracture toughness and conductivity of carbon fiber/epoxy resin composite laminate modified by carbon black-loaded polypropylene non-woven fabric interleave. Compos. Struct. 2020, 234, 111649. [Google Scholar] [CrossRef]

- Abhishek, K.; Samit, R. Characterization of mixed mode fracture properties of nanographene reinforced epoxy and Mode I delamination of its carbon fiber composite. Compos. Part B Eng. 2018, 134, 98–105. [Google Scholar]

- Samit, R.; Abhishek, K. Effect of Particle Size on Mixed-Mode Fracture of Nanographene Reinforced Epoxy and Mode I Delamination of its Carbon Fiber Composite. Compos. Struct. 2018, 181, 1–8. [Google Scholar]

- Domun, N.; Paton, K.R.; Bamber, B.R.K.; Kaboglu, C.; Vahid, S.; Zhang, T.; Dear, J.P.; Kinloch, A.J.; Hadavinia, H. On the extent of fracture toughness transfer from 1D/2D nanomodified epoxy matrices to glass fibre composites. J. Mater. Sci. 2020, 55, 4717–4733. [Google Scholar] [CrossRef] [Green Version]

| Fiber Type | Fiber Diameter of the Monofilament (10−6 m) | Ultimate Tensile Strength (MPa) | Young’s Modulus (GPa) | Elongation (%) | Density (g/cm3) |

|---|---|---|---|---|---|

| T300 | 6~8 | 3500 | 230 | 1.5 | 1.76 |

| Purity | Layers | Thickness | Diameter | Carbon Content | Oxygen Content | Sulfur Content | Stripping Rate |

|---|---|---|---|---|---|---|---|

| 99% | 1~2 | 1 nm | 0.2~10 um | <46% | >48% | <1.5% | 96% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Y.; Chen, Y.; Li, F.; Xu, Y.; Xu, W.; Zhao, Y.; Guo, H.; Li, Y.; Yang, Z.; Xu, Y. Effect of Fiber Mass Fraction on Microstructure and Properties of 2D CF-GO/EP Composite Prepared by VIHPS. Nanomaterials 2022, 12, 1184. https://doi.org/10.3390/nano12071184

Ma Y, Chen Y, Li F, Xu Y, Xu W, Zhao Y, Guo H, Li Y, Yang Z, Xu Y. Effect of Fiber Mass Fraction on Microstructure and Properties of 2D CF-GO/EP Composite Prepared by VIHPS. Nanomaterials. 2022; 12(7):1184. https://doi.org/10.3390/nano12071184

Chicago/Turabian StyleMa, Yuqin, Yi Chen, Fei Li, Yiren Xu, Wei Xu, Yatao Zhao, Haiyin Guo, Yatao Li, Zedu Yang, and Yi Xu. 2022. "Effect of Fiber Mass Fraction on Microstructure and Properties of 2D CF-GO/EP Composite Prepared by VIHPS" Nanomaterials 12, no. 7: 1184. https://doi.org/10.3390/nano12071184

APA StyleMa, Y., Chen, Y., Li, F., Xu, Y., Xu, W., Zhao, Y., Guo, H., Li, Y., Yang, Z., & Xu, Y. (2022). Effect of Fiber Mass Fraction on Microstructure and Properties of 2D CF-GO/EP Composite Prepared by VIHPS. Nanomaterials, 12(7), 1184. https://doi.org/10.3390/nano12071184