1. Introduction

With a growth of modern ultrahigh voltage transmission coverage, the load of high-voltage transmission and substation equipment also grows rapidly. After long-term operation, the equipment usually contracts the problems of contact reliability decreasing and overheating [

1,

2,

3]. In recent years, electrical joint compounds (EJCs) have been proposed as a promising alternative to enhance the electrical contact reliability. EJCs are mainly composed of base oil, conductive filler and thickener, which are mainly used to increase the actual effective contact area by coating the contact surface of the equipment, thus reducing the electrical contact resistance, hindering the energy consumption and overheating of electrical joints [

4]. In addition, the power compound also acts a sealing effect on the electrical contact surface which prevents water vapor, corrosive gases and dust from penetrating into the electrical contact surfaces, causing corrosion, aging and wear, and improves the lifetime of the electrical connections [

5,

6,

7].

In addition to high-temperature stability and moderate hardness, high-quality EJC should also have good electrical conductivity and appropriate friction properties, and the latter two properties are more difficult to improve. In recent years, the frictional and conductivity enhancement of EJC has attracted tremendous research interests. The physical and chemical properties of the EJC can be effectively optimized by improving the additives in the EJC.

Some researchers have improved the conductive fillers by choosing nanometal materials to increase the specific surface area of the fillers and thus enhance their contact properties. Ge, X.Y. et al. synthesized a new conductive grease with Sb-doped SnO

2 (ATO) as an additive, and ATO can significantly improve the tribological properties of the grease [

8]. Kang, H. et al. investigated the composite grease of copper nanopowder and silicone oil and found that the addition of copper nanopowder greatly enhanced the thermal conductivity [

9].

Carbon-based materials have not only high electrical conductivity but also larger specific surface area and lower cost compared to nanometal particles, so it becomes an important means to improve the performance of EJC. Cao, Z.F. et al. used Ketjen black (KB), acetylene black (AB) and carbon black (CB) to prepare conductive grease and found that the conductive grease prepared with KB had better frictional properties and excellent electrical conductivity under various temperature environments [

10]. Liu, H.T. et al. and Ge, X.Y. et al. investigated the effects of carbon nanotubes as conductive additives on the electrical conductivity and tribological properties of greases; the results showed that carbon nanotubes could greatly reduce the bulk resistivity of the base grease while improving the tribological properties of the base grease to some extent [

11,

12]. Qu, Y.H. et al. and Lim, S. et al. investigated the electrical conductivity of graphene and the effect of copper paste incorporation on the microstructure and properties of EJC; the results showed that graphene incorporation resulted in lower rheological properties and higher electrical conductivity of EJC [

13,

14]. Liang, W. et al. used reduced graphene oxide (RGO) as a substrate to improve thermal grease performance and enhance thermal management by self-assembly of hBN nanosheets on the RGO surface [

15]. From the above case, the addition of carbon-based materials such as graphene can favorably affect the various properties of EJC.

Mechanically exfoliated few-layered graphene has low defect density, low cost and, more importantly, its preparation process is environmentally friendly. Combined with its chemical stability and high thermal and electric conductivity, MEG would be a promising additive to improve the key performance of silicon EJCs. In this paper, we use MEG as an additive to tune the physicochemical properties of EJCs. Various measurements, such as penetration, drip point, volume resistivity and frictional properties, were conducted to systematically characterize the performance of the resulted EJCs; we found that the addition of MEG is highly effective in improving drip point and frictional properties, as well as reducing penetration and volume resistivity.

2. Materials and Methods

2.1. Materials

Main materials for MEG preparation: expanded graphite (C, 0.05 mm) produced by Risheng Graphite Co., Ltd. (Qingdao, China); sodium carboxymethyl cellulose (CMC) for graphene slurry dispersion; filtered pure water prepared by laboratory water purifier (conductivity 4.26 μS/cm).

Main materials for EJC: phenylmethyl silicone oil 255#-300CS (viscosity 300 mm2/s 25 °C, relative density 1.020–1.080, flashpoint ≥300 °C, freezing point ≤−40) produced by Xinda Chemical Co., Ltd. (Bengbu, China); irregular copper powder (electrolytic, 2 μm) produced by Zhuyu Alloy Material Co., Ltd. (Nangong, China); graphite powder (1000 mesh, particle size 13 μm) produced by Hegang Zhenjin Graphene New Material Research Institute (Hegang, China).

2.2. Preparation of Graphene

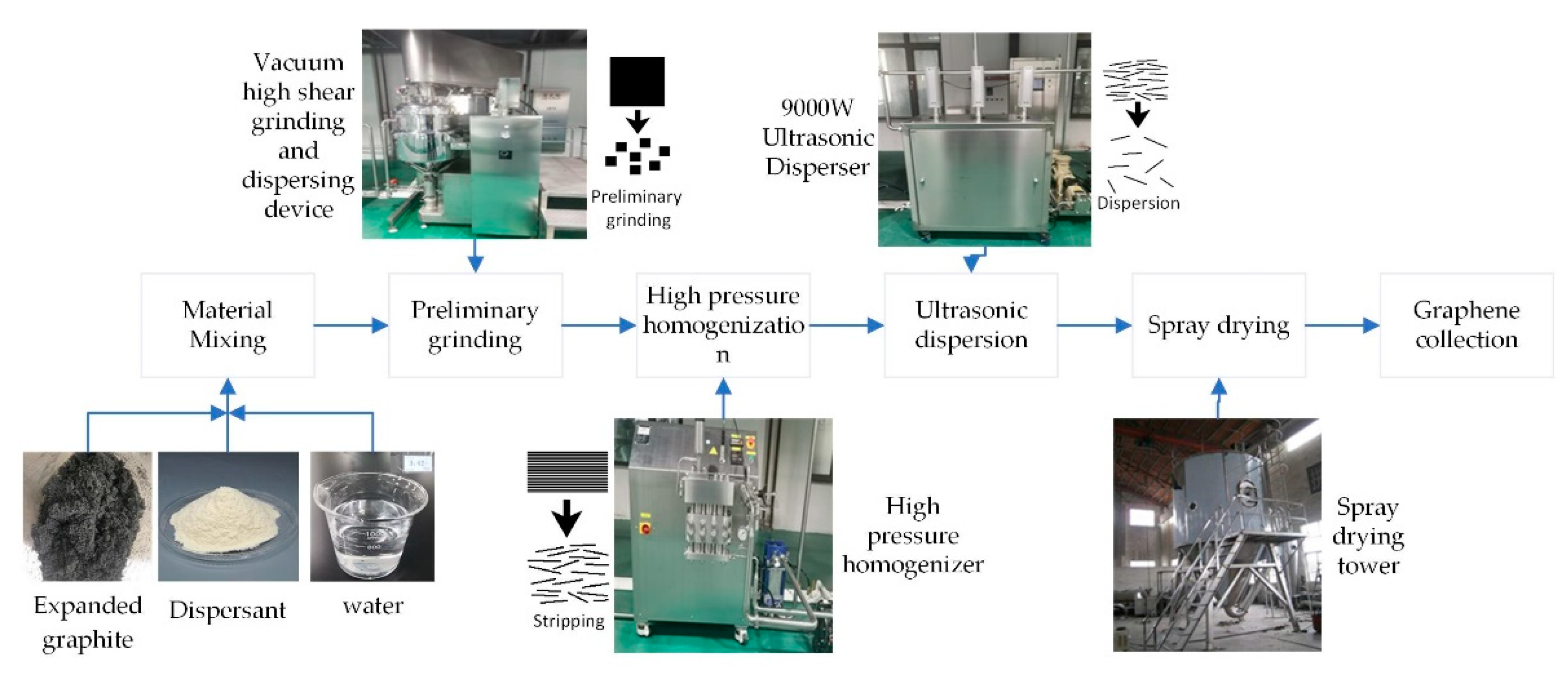

Few-layered graphene is prepared by the mechanically exfoliated method, with the main consideration to break the van der Waals interactions between the graphite layers by mechanical shear, impact and cavitation. The MEG preparation process is shown in

Figure 1.

(1) Preliminary grinding: After weighing 2 kg of expanded graphite, 47.5 kg of pure water and 0.5 kg of CMC, the raw material was poured into the vacuum high shear grinding and dispersing device, with 2200 r/min for 2 h. During the time, the grinding tank made planetary stirring to the expanded graphite, which generates strong mixing shear force through high-speed tumbling and friction of raw materials to achieve the purpose of prestripping.

(2) High-pressure homogenization: The initially sheared ground graphene feedstock was moved into the high-pressure homogenizer through a preset pipeline. The pressure was set at 80 MPa for 1 h. The purpose of this operation is to further disrupt the van der Waals forces between graphite layers and form few-layer graphene slurry. This step was repeated 5-10 times until the graphene was exfoliated to about 5 layers.

(3) Ultrasonic dispersion: The graphene slurry was pressed into the ultrasonic device by air pressure and dispersed in a 9000 watts ultrasonic device. The ultrasonic device was designed to further disperse the flake graphene and prevent the appearance of graphene agglomerates.

(4) Spray drying: The completely separated graphene slurry was transferred to the spray drying tower, and spray drying was carried out at 90 °C. After this, the graphene slurry was transformed into dry solid graphene powder, and finally the few-layer graphene powder was obtained in the drying tower collection device.

2.3. Preparation of EJC

(1) Formulation determination: To investigate the effect of adding mechanically exfoliated MEG on the physicochemical properties of kinetic composite grease, two sets of formulations were prepared, pure copper powder and copper powder + MEG, in which copper powder was the base filler and MEG was the additional filler. Meanwhile, considering the large difference in the volume to mass ratio between MEG and copper powder, the copper powder + graphite formulation was added as a control group to further improve the experimental persuasiveness. Considering the limitation of the softness and hardness of the slurry, the filler ratio was limited to 77–81 wt% according to engineering experience, and the formulation was adjusted by 1 wt% of the filler content; different filler contents are indicated by using I, II, III, IV and V. The final obtained three groups of conductive grease conductive filler in proportion to the total mass are as follows: copper powder type, copper powder accounted for 77, 78, 79, 90 and 81 wt%; copper powder + graphite type, copper powder accounted for 76 wt%, graphite accounted for 1, 2, 3, 4, and 5 wt%; copper powder + MEG type, copper powder accounted for 76 wt%, MEG accounted for 1, 2, 3, 4, and 5 wt%.

(2) Material pretreatment: We weighed a certain amount of phenylmethyl silicone oil using an analytical balance and let it stand in a room temperature and constant temperature environment for 3 min to eliminate surface air bubbles. Then, we put the copper powder, MEG and graphite into the electric thermostatic blast drying oven (80 °C for 30 min) in advance to remove the moisture in the powder. Next, we added the copper powder into the high-speed disperser (1500 r/min) to perform mechanical stirring for 10 min to make it evenly dispersed. In addition, when preparing copper powder + MEG type EJC, MEG should be added into base oil in advance and stirred in the high-speed disperser (2200 r/min), followed by 30 min ultrasonic dispersion to prevent MEG agglomeration.

(3) Initial mixing: The sample mixing was accompanied by mechanical stirring throughout, and the filler equipped in advance was added to the base solution at a uniform rate. After the filler was mixed with phenylmethyl silicone oil, half of the thickening agent was added, and the solution became semisolid at this time. The mixture was stirred continuously until it softened to a paste and was left to stand for 3 min.

(4) Mixing and stirring: We put the preliminary mixed sample into the mixer (set three procedures: the first one, regular high-speed dispersion under atmospheric pressure for 80 s, rotational speed 1200 r/min, draw off the large air bubbles in the sample; the second procedure, vacuum high-speed dispersion for 120 s, rotational speed 1800 r/min, vacuum the air bubbles in the sample thoroughly; the third, release atmospheric pressure high-speed dispersion for 60 s, rotational speed 1500 r/min; the ratio of revolution to rotation for all three procedures is 1:0.5), during which the remaining thickening machine was added in two stages, waiting for the vacuum stirring to be complete, and left to cool naturally to room temperature to make the finished product of EJC.

2.4. Characterization

Characterization of the surface morphology of MEG using field emission scanning electron microscopy (SU8020, Hitachi, Tokyo, Japan), atomic force microscopy (Dimension Icon, Bruker, Germany), Raman scattering spectroscopy (Renishaw in Via, Renishaw, UK), and infrared spectroscopy (Nicolet IS10, Nicolet, Madison, WI, USA).

The automatic Tapered Entry Tester (WM-221A, Wanmu Instrument Co., Ltd., Guangdong, China) was used to measure the dropping point of EJC. The EJC was loaded into the cone tester at 25 °C; the 1/4 cone and cone rod combination piece, which was released from the cone penetration meter, made the cone fall for 5 s and measured the penetration depth. A total of three measurements were made on the samples, and the average value was taken.

A grease-dropping point tester (SYP4110-I, Shenkai Petroleum Instruments Co., Ltd., Shanghai, China) was used to determine the dropping point of MEG EJC. The sample of electric EJC was loaded into the grease cup of the dropping point tester, during which the equipment was energized and kept warming up, and the temperature of the sample when the grease dropped the first drop and reached the test tube during the test was observed and recorded, which was the measured dropping point.

The volumetric resistivity of the sample was determined by using a volumetric surface resistance tester (GEST-121, Guangshi Jingdian Instruments & Equipment Co., Ltd., Beijing, China), firstly cleaning the surface of the electrode plate with alcohol and then further cleaning the plate with deionized water after drying. The electrode plate was dried naturally and then filled with power compound until the electrode was full, and the excess power compound sample was scraped off. We added 500 V DC voltage to the test electrode plate, tested the resistance value of the test sample by measuring the leakage current perpendicular to the sample or along the surface of the sample and calculated the volume resistivity of the sample.

The friction coefficient of EJC was measured by using a microcomputer-controlled four-ball friction tester (MRS-10A, Vipin Testing Machine Co., Ltd., Jinan, China). Before the test, the steel balls were ultrasonically cleaned in petroleum ether for about 10 min. in the form of sliding friction, and the average friction coefficient and the diameter of the abrasion spots were detected. At the end of the test, the steel ball was removed and cleaned in the ultrasonic cleaner with petroleum ether for 5 min. The average grinding spot diameter of the steel ball was measured by a using digital metallographic microscope, and the surface morphology of the steel ball grinding marks was observed.

2.5. Application

Practical application of EJC in power systems: The surface of the copper–copper power joint busbar was polished and coated with EJC, and a tightening torque of 10 N was applied to the bolt between the overlap of the two plates. The cold contact resistance measured using a circuit resistance tester was less than 12 μΩ, which has good serviceability.

4. Conclusions

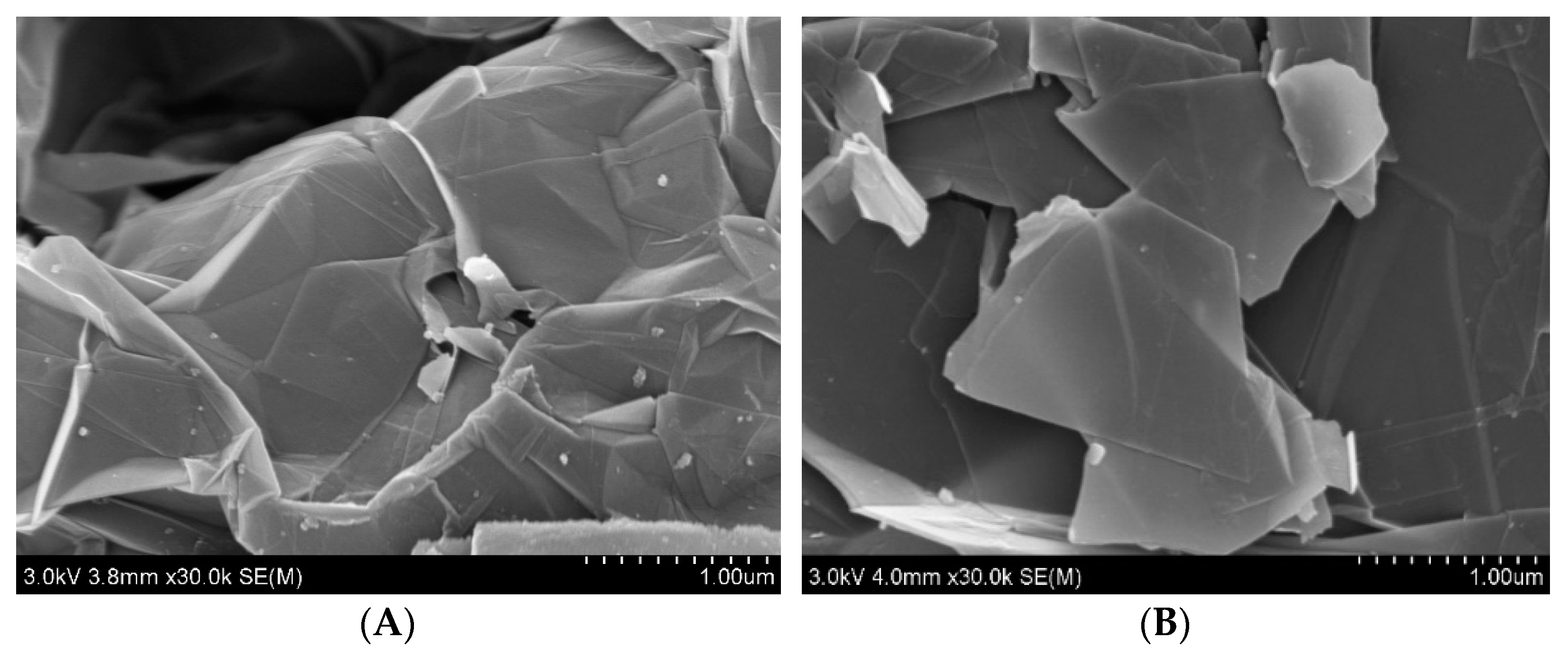

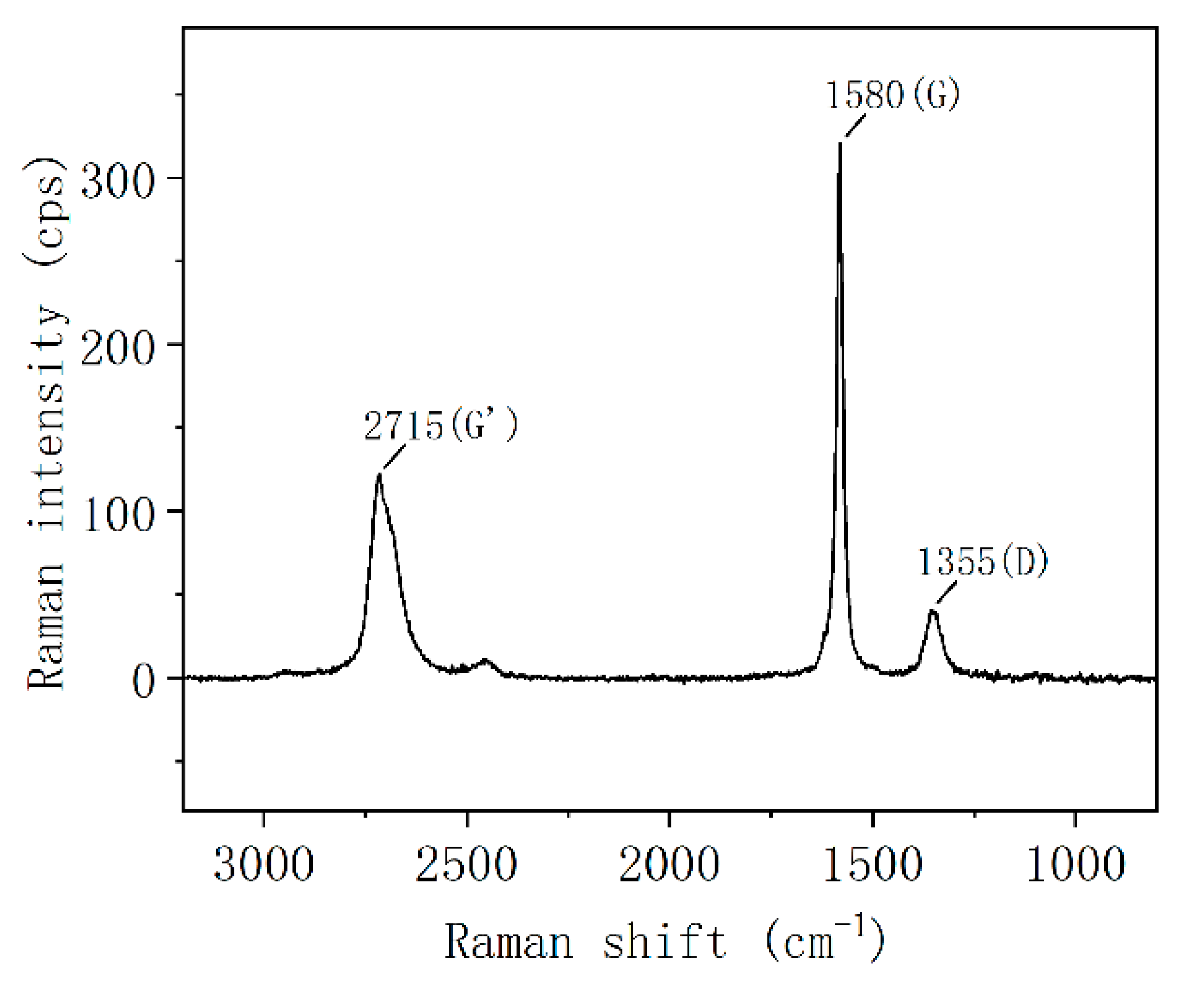

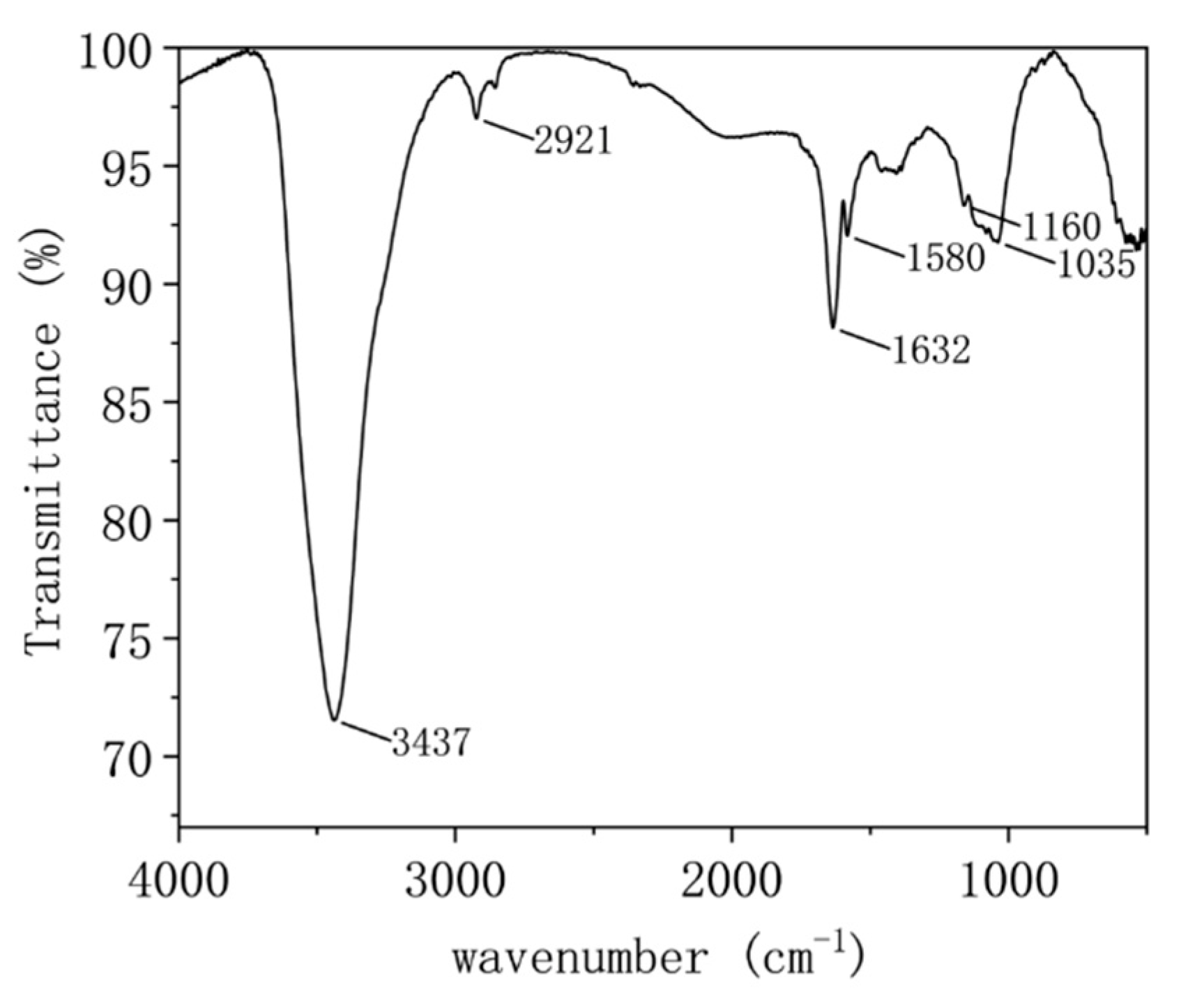

The mechanically exfoliated graphene was prepared by high-vacuum shear grinding and high-pressure homogenization method using expanded graphite as the raw material. The prepared samples were characterized by field emission scanning electron microscopy, atomic force microscopy, Raman spectroscopy and infrared spectroscopy. The average number of layers of the prepared mechanically exfoliated graphene was found to be 5–6, and the transverse dimensions of the single flakes were 0.5μm–5μm, with smooth surfaces and less in-plane defects.

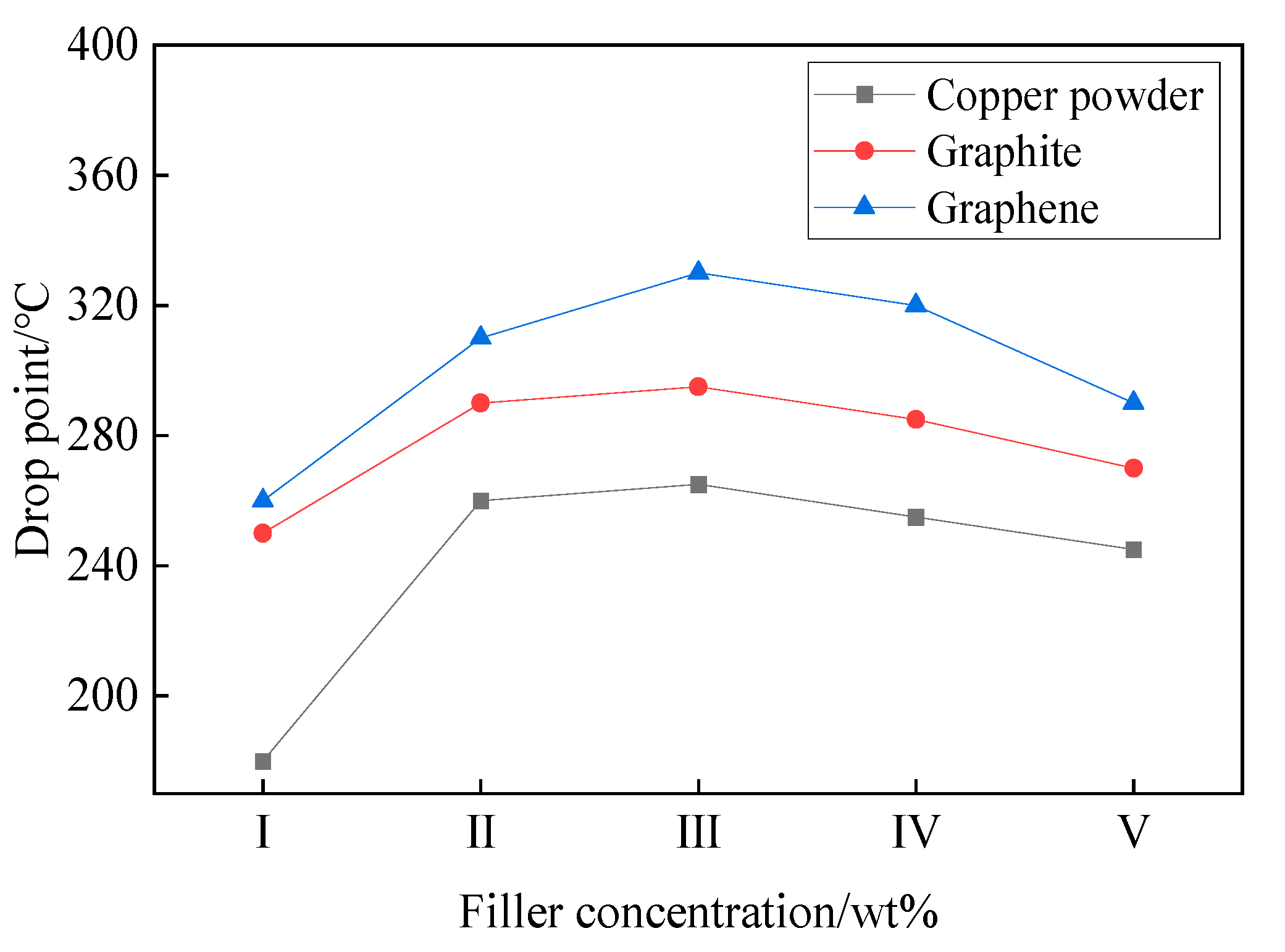

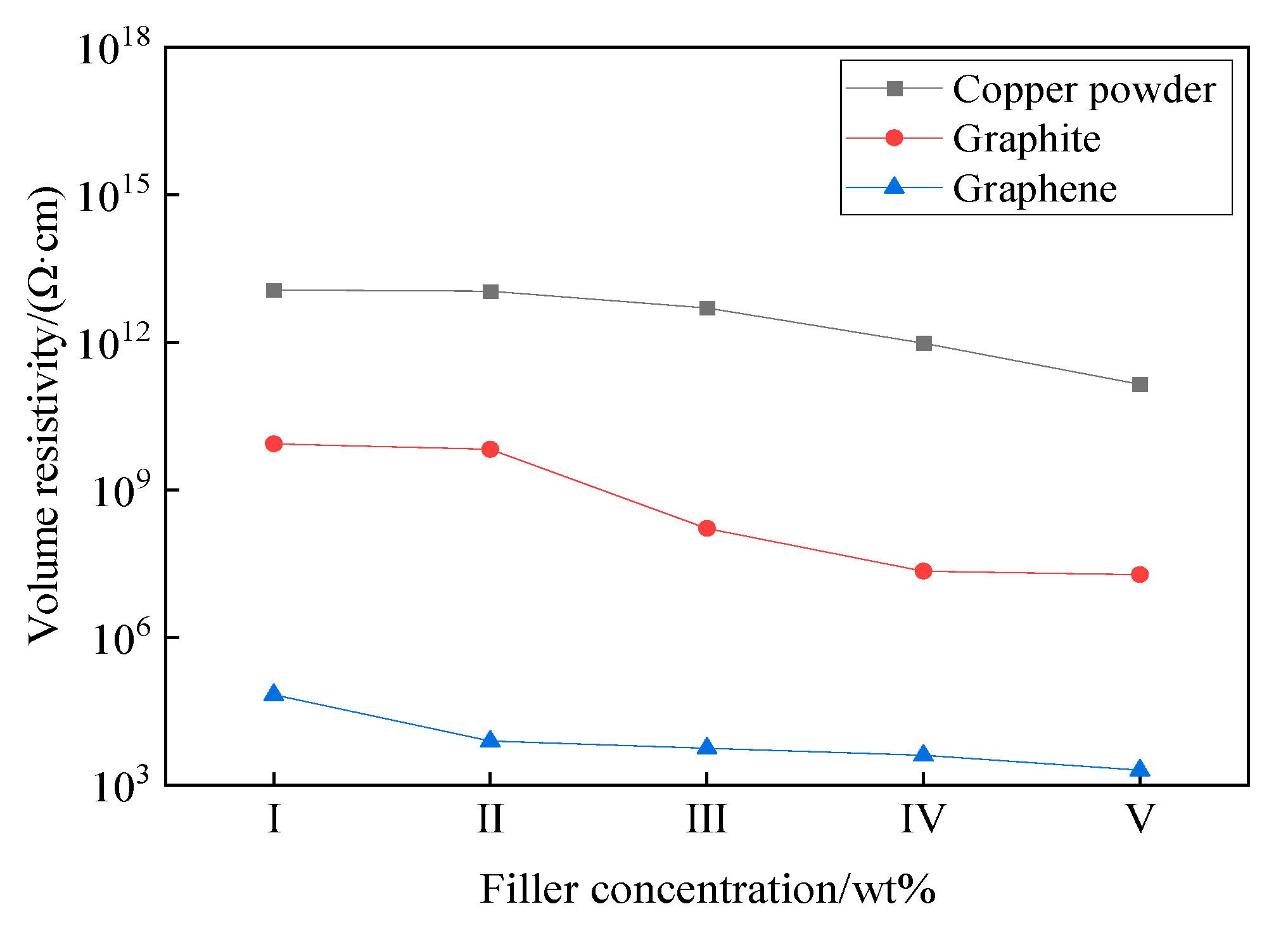

The electrical joint compound was prepared with phenylmethyl silicone oil as the base oil and copper and graphite and graphene as the conductive fillers. The cone penetration, dropping point, volume resistivity and friction properties of the electrical joint compound were characterized. It was found that the cone penetration of the power complex grease decreased with the increase of the filler ratio, and the cone penetration decrease was more obvious due to the change of graphene ratio. The dropping point of the electrical joint compound increased first and then decreased with the increase of filler, among which the electrical joint compound filled with mechanically exfoliated graphene had higher dropping point, and the highest dropping point was at 3 wt% of graphene ratio. The volume resistivity of the graphene power loading grease also decreased significantly compared to the other controls. In addition, the graphene filler greatly optimized the frictional properties of the electrical joint compound, possessing the smallest average friction coefficient and wear spot size at a graphene concentration of 4 wt%.

In summary, it was found that the graphene prepared by the mechanical peeling method causes a significant improvement of the electrical joint compound penetration, drop point, volume resistivity and friction properties, which are all beneficial to enhance the contact performance of electrical joints and guarantee the stable and efficient transmission of electric power.