Aspects of Uniform Horizontal Magnetic Field and Nanoparticle Aggregation in the Flow of Nanofluid with Melting Heat Transfer

Abstract

:1. Introduction

- To explore the fluid flow, heat, and mass-transfer behaviour with and without NP aggregation.

- What effect do different dimensionless factors have on the flow, heat, and mass-transport behaviour of nanofluids?

2. Mathematical Formulation

2.1. Thermophysical Properties for Aggregation Approach

2.2. Thermal Characteristics of Particles Aggregation

2.3. Similarity Transformations

3. Results and Discussions

4. Conclusions

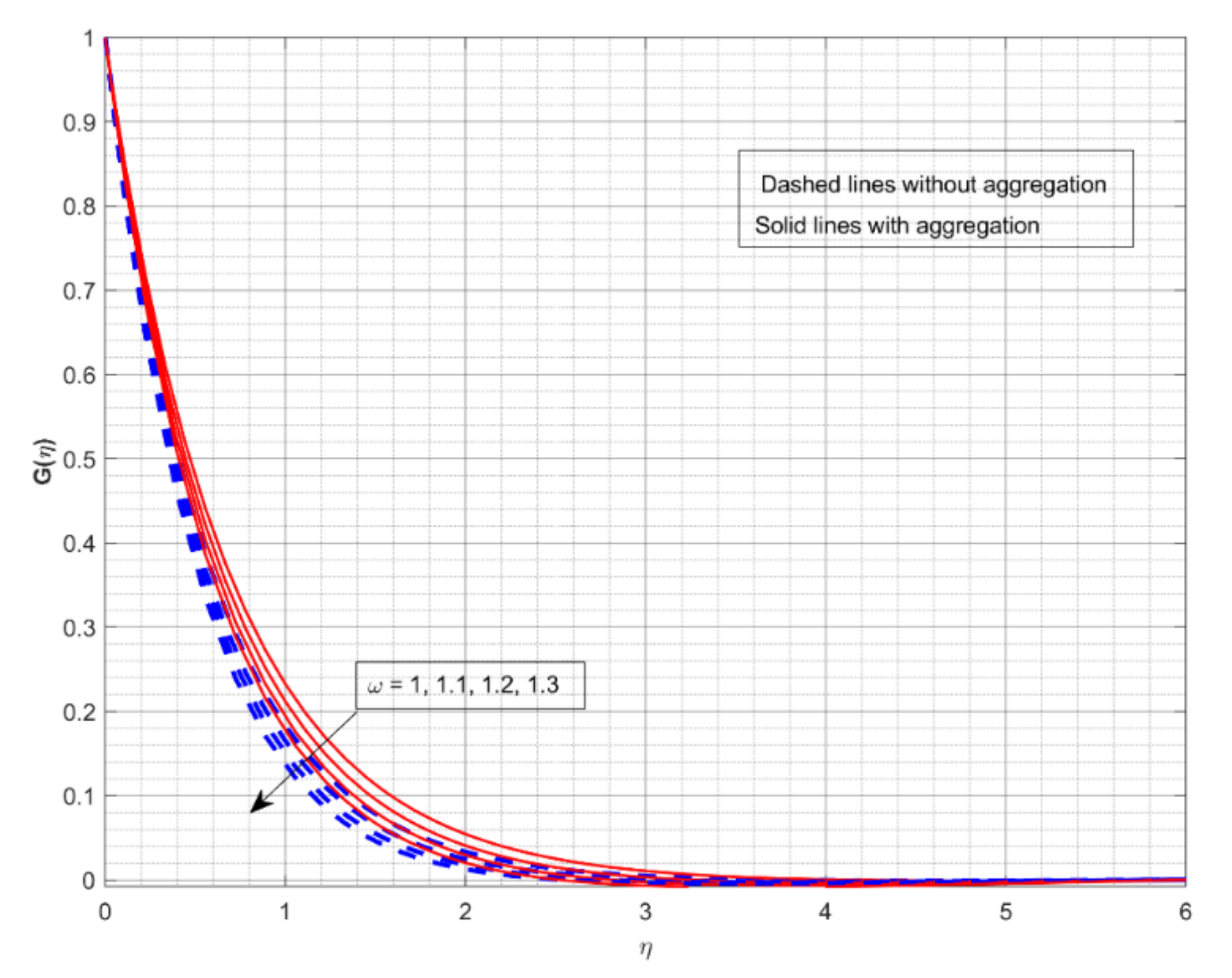

- The velocity profile improves faster in the case of NP aggregation for improved values of the rotation strength parameter.

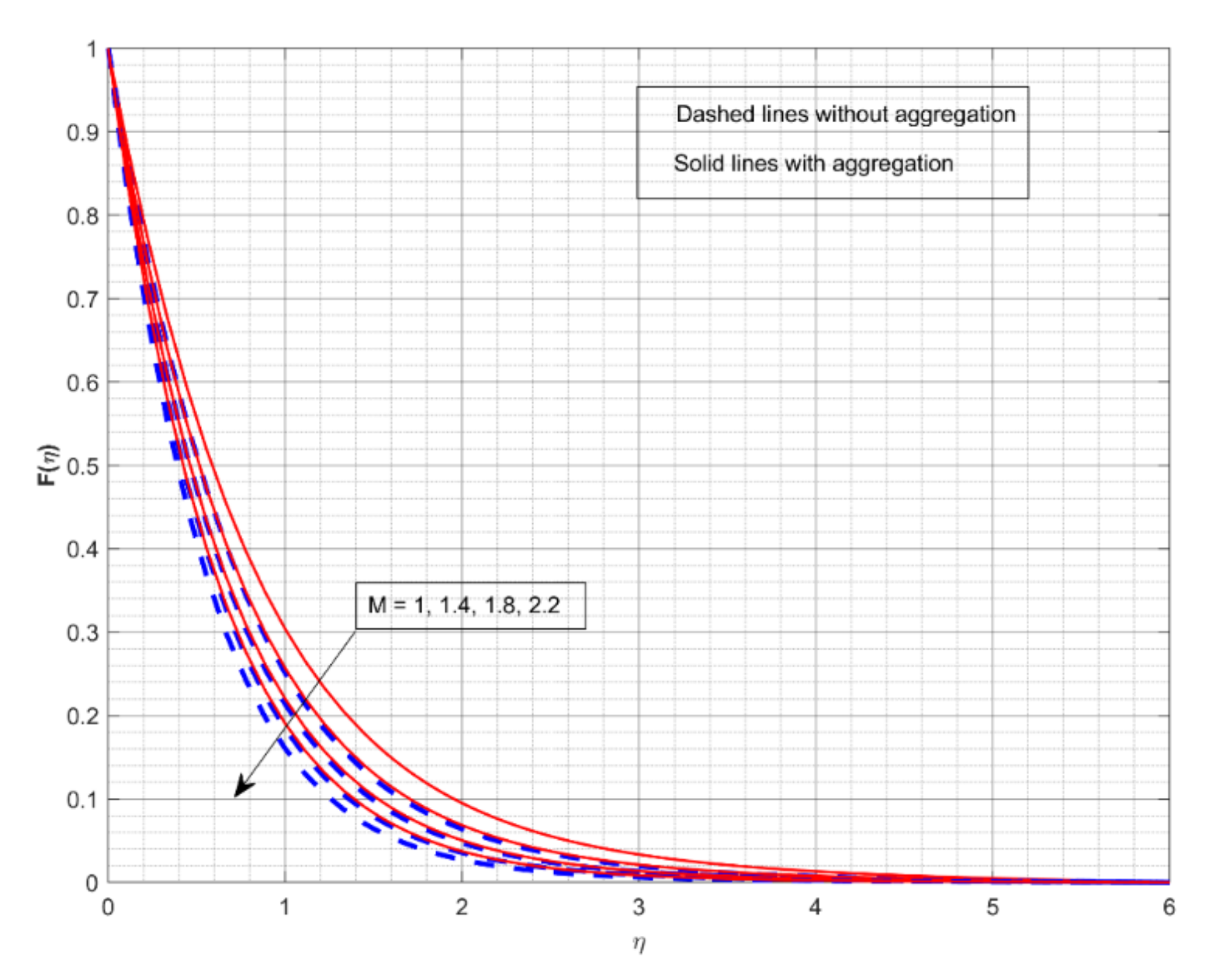

- The velocity profile declines faster in the case of NP non-aggregation for improved values of the magnetic parameter.

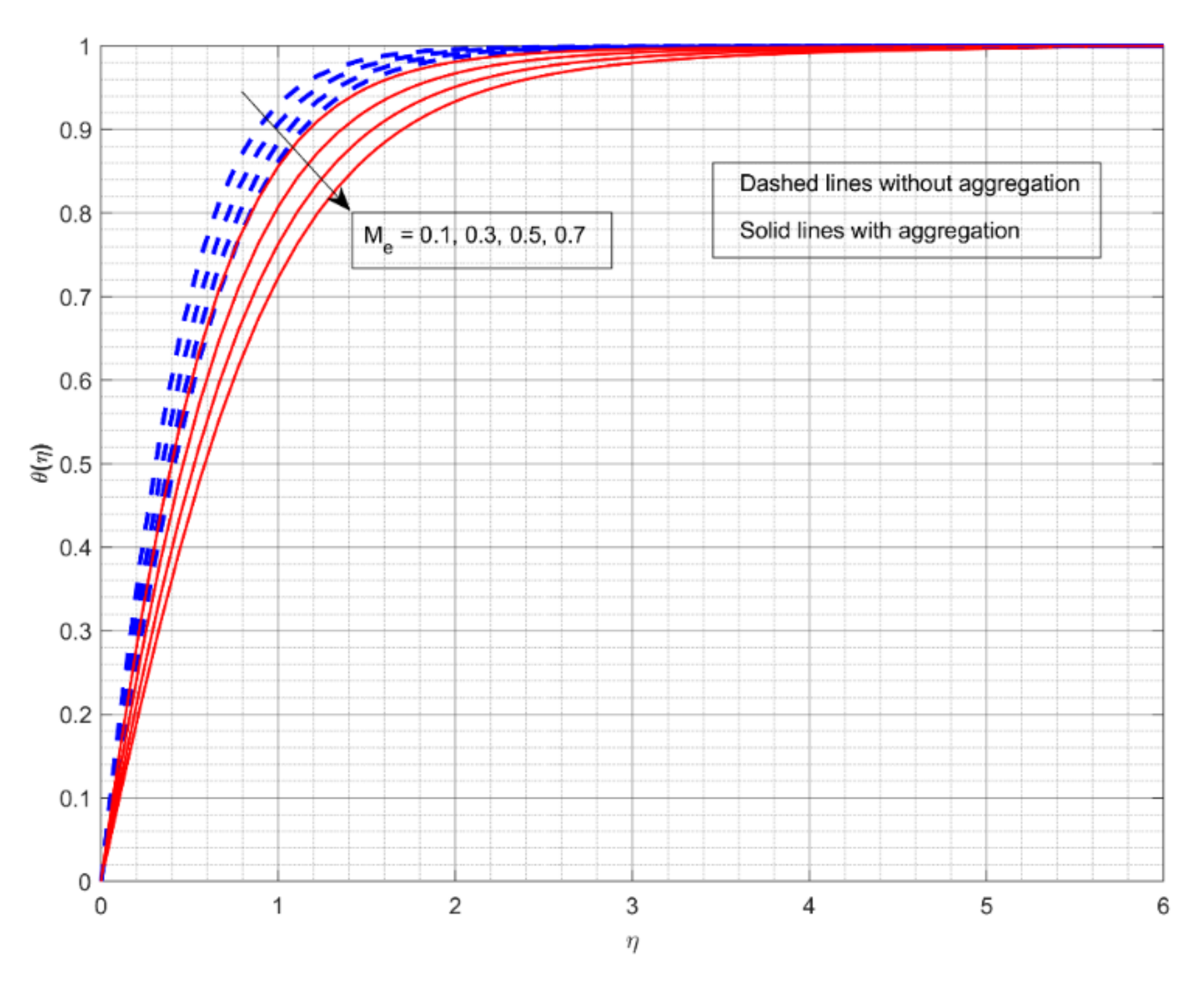

- The liquid flow without aggregation of NPs exhibits better heat transmission for increased values of the melting parameter than the other case.

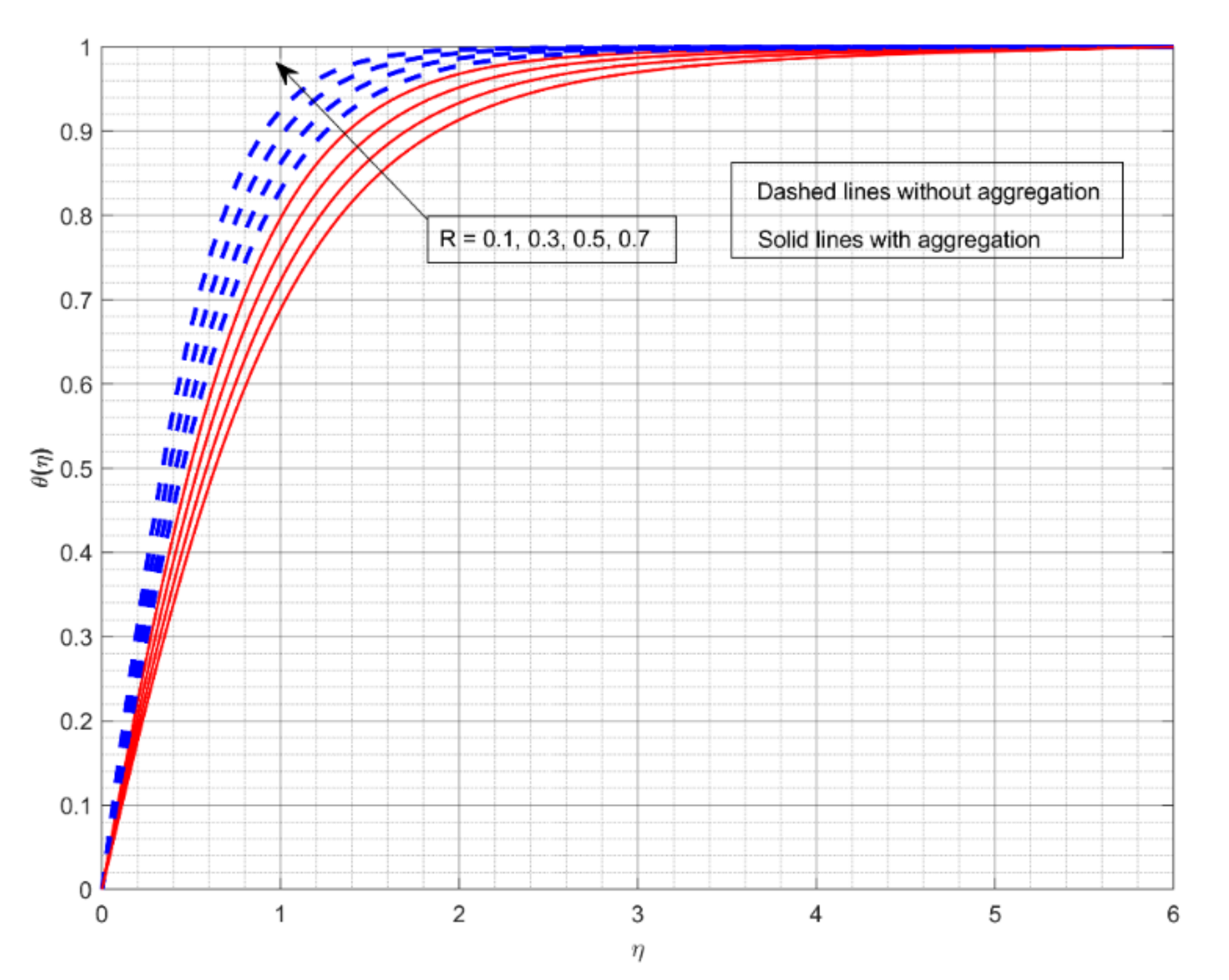

- The liquid flow without aggregation of NPs displays higher-quality heat transfer for intensified values of the radiation parameter than the remaining case.

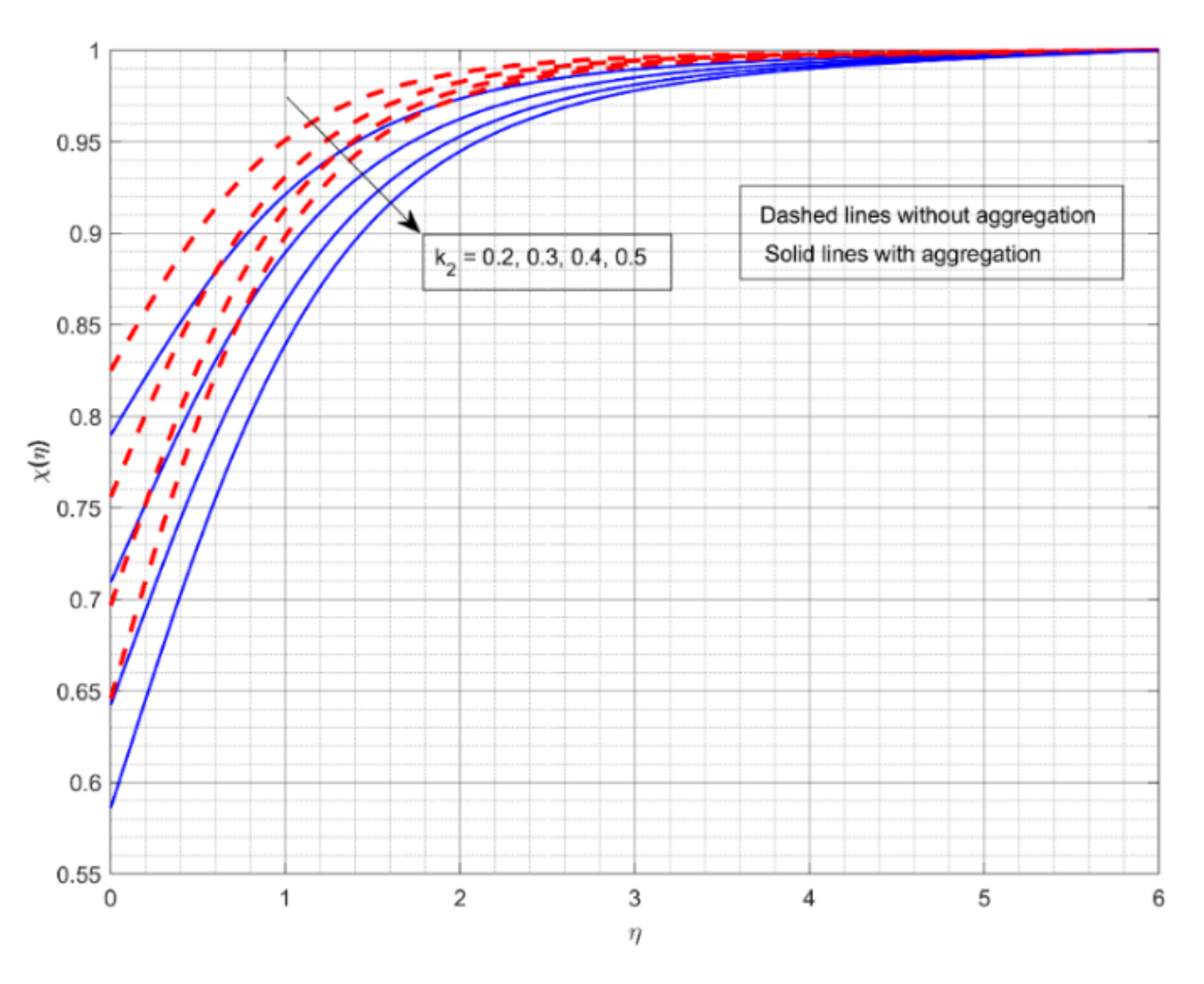

- Mass transport declines slower for upward values of strength of the homogeneous reaction parameter for the fluid-flow case without the aggregation condition.

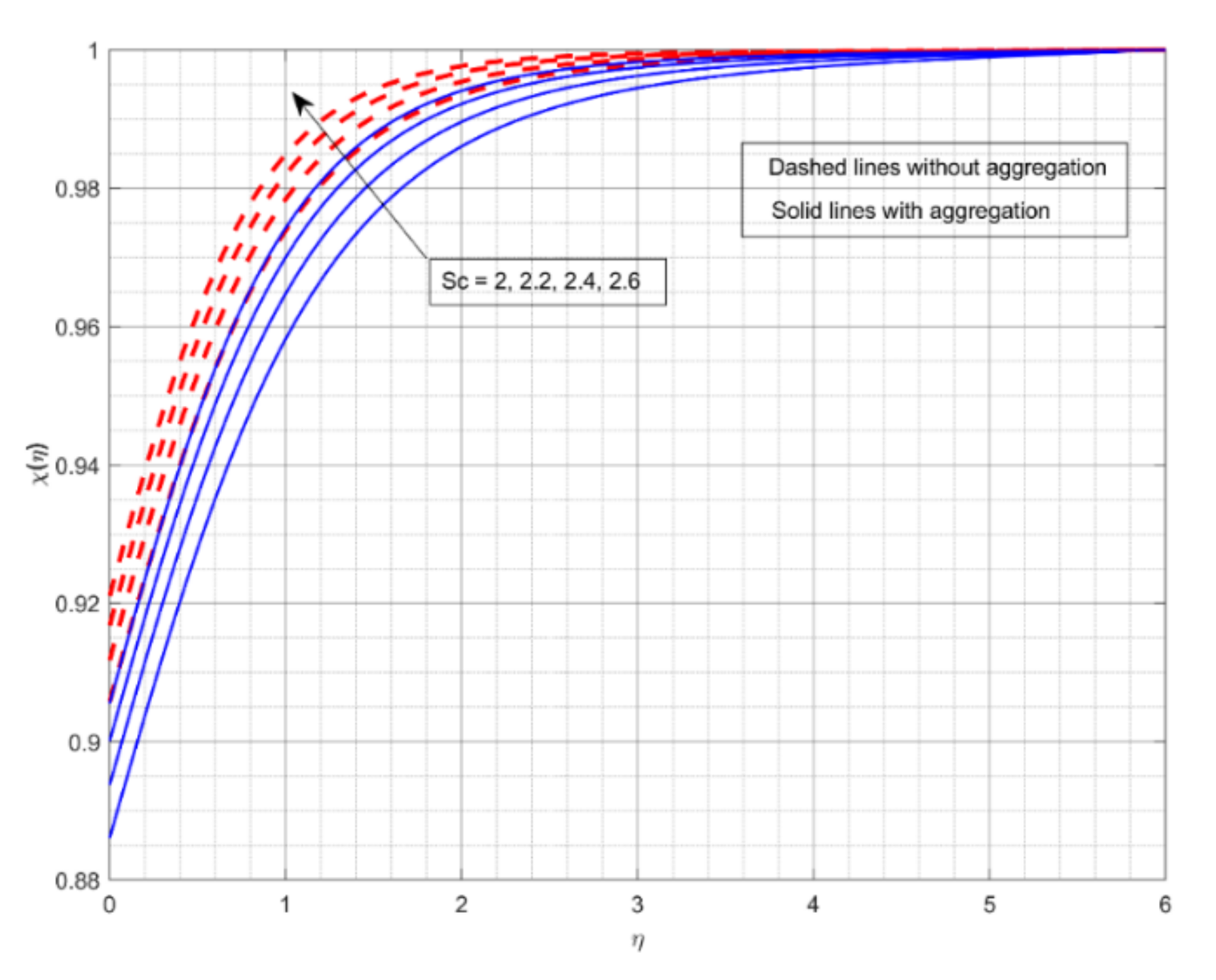

- Mass transport in the case of NP aggregation drops faster for cumulative values of strength of the heterogeneous reaction parameter.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Electric field | Pressure | ||

| Current density | Angular disk speed | ||

| and | Diffusion coefficients | Latent heat of the fluid | |

| Ambient temperature | Schmidt number | ||

| Radiation parameter | Mean absorption coefficient | ||

| Rate constant | Strength of heterogeneous reaction parameter | ||

| Thermal conductivity | Dynamic viscosity | ||

| and | Chemical species | Magnetic field strength | |

| Volume fraction | Dimensionless velocity profiles | ||

| Magnetic conductivity | Magnetic parameter | ||

| Dimensionless pressure | Dimensionless thermal profile | ||

| Heat capacity of the solid surface | Rotation strength parameter | ||

| Constant | Dynamic viscosity | ||

| Melting parameter | Strength of homogeneous reaction parameters | ||

| Solid temperature | Angle between the horizontal magnetic field components | ||

| Velocity components | Dimensionless similarity coordinate | ||

| Temperature | Density | ||

| Prandtl number | Subscripts | ||

| Temperature of the melting surface | Fluid | ||

| Stefan–Boltzmann constant | Aggregate | ||

| Cylindrical coordinates | Nanofluid | ||

| Heat capacitance | Solid nanoparticle |

References

- Serour, N.M.; El-Shazly, A.H.; El-Gayar, D.A.; Nosier, S.A. A Review on Titanium Dioxide Based Nanofluids: Synthesis and Stabilizing Techniques in Both “Pure (Single System) and Mixed (Hybrid System) Base Fluids”. Mater. Sci. Forum 2020, 1008, 53–71. [Google Scholar] [CrossRef]

- Rawat, S.K.; Upreti, H.; Kumar, M. Thermally stratified nanofluid flow over porous surface cone with Cattaneo–Christov heat flux approach and heat generation (or) absorption. SN Appl. Sci. 2020, 2, 302. [Google Scholar] [CrossRef] [Green Version]

- Rawat, S.K.; Kumar, M. Cattaneo–Christov Heat Flux Model in Flow of Copper Water Nanofluid Through a Stretching/Shrinking Sheet on Stagnation Point in Presence of Heat Generation/Absorption and Activation Energy. Int. J. Appl. Comput. Math. 2020, 6, 1–26. [Google Scholar] [CrossRef]

- Li, Y.-X.; Khan, M.I.; Gowda, R.J.P.; Ali, A.; Farooq, S.; Chu, Y.-M.; Khan, S.U. Dynamics of aluminum oxide and copper hybrid nanofluid in nonlinear mixed Marangoni convective flow with entropy generation: Applications to renewable energy. Chin. J. Phys. 2021, 73, 275–287. [Google Scholar] [CrossRef]

- Saleh, B.; Madhukesh, J.K.; Kumar, R.S.V.; Afzal, A.; Abdelrhman, Y.; Aly, A.A.; Gowda, R.J.P. Aspects of magnetic dipole and heat source/sink on the Maxwell hybrid nanofluid flow over a stretching sheet. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2022, 09544089211056243. [Google Scholar] [CrossRef]

- Khan, U.; Zaib, A.; Pop, I.; Abu Bakar, S.; Ishak, A. Stagnation point flow of a micropolar fluid filled with hybrid nanoparticles by considering various base fluids and nanoparticle shape factors. Int. J. Numer. Methods Heat Fluid Flow 2021. [Google Scholar] [CrossRef]

- Kumar, R.N.; Suresha, S.; Gowda, R.J.P.; Megalamani, S.B.; Prasannakumara, B.C. Exploring the impact of magnetic dipole on the radiative nanofluid flow over a stretching sheet by means of KKL model. Pramana 2021, 95, 1–9. [Google Scholar] [CrossRef]

- Ellahi, R.; Hassan, M.; Zeeshan, A. Aggregation effects on water base Al2O3-nanofluid over permeable wedge in mixed convection. Asia-Pac. J. Chem. Eng. 2015, 11, 179–186. [Google Scholar] [CrossRef]

- Benos, L.; Karvelas, E.; Sarris, I. Crucial effect of aggregations in CNT-water nanofluid magnetohydrodynamic natural convection. Therm. Sci. Eng. Prog. 2019, 11, 263–271. [Google Scholar] [CrossRef]

- Karvelas, E.; Lampropoulos, N.; Benos, L.; Karakasidis, T.; Sarris, I. On the magnetic aggregation of Fe3O4 nanoparticles. Comput. Methods Programs Biomed. 2020, 198, 105778. [Google Scholar] [CrossRef]

- Mahanthesh, B. Flow and heat transport of nanomaterial with quadratic radiative heat flux and aggregation kinematics of nanoparticles. Int. Commun. Heat Mass Transf. 2021, 127, 105521. [Google Scholar] [CrossRef]

- Mackolil, J.; Mahanthesh, B. Inclined magnetic field and nanoparticle aggregation effects on thermal Marangoni convection in nanoliquid: A sensitivity analysis. Chin. J. Phys. 2020, 69, 24–37. [Google Scholar] [CrossRef]

- BagheriMotlagh, M.; Kalteh, M. Molecular dynamics simulation of nanofluid convective heat transfer in a nanochannel: Effect of nanoparticles shape, aggregation and wall roughness. J. Mol. Liq. 2020, 318, 114028. [Google Scholar] [CrossRef]

- Swain, K.; Mahanthesh, B. Thermal Enhancement of Radiating Magneto-Nanoliquid with Nanoparticles Aggregation and Joule Heating: A Three-Dimensional Flow. Arab. J. Sci. Eng. 2020, 46, 5865–5873. [Google Scholar] [CrossRef]

- Sabu, A.; Mackolil, J.; Mahanthesh, B.; Mathew, A. Nanoparticle aggregation kinematics on the quadratic convective magnetohydrodynamic flow of nanomaterial past an inclined flat plate with sensitivity analysis. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2021, 09544089211056235. [Google Scholar] [CrossRef]

- Turkyilmazoglu, M. MHD fluid flow and heat transfer due to a stretching rotating disk. Int. J. Therm. Sci. 2012, 51, 195–201. [Google Scholar] [CrossRef]

- Turkyilmazoglu, M. Three dimensional MHD stagnation flow due to a stretchable rotating disk. Int. J. Heat Mass Transf. 2012, 55, 6959–6965. [Google Scholar] [CrossRef]

- Kumar, R.N.; Mallikarjuna, H.B.; Tigalappa, N.; Gowda, R.J.P.; Sarwe, D.U. Carbon nanotubes suspended dusty nanofluid flow over stretching porous rotating disk with non-uniform heat source/sink. Int. J. Comput. Methods Eng. Sci. Mech. 2021, 23, 119–128. [Google Scholar] [CrossRef]

- Khan, U.; Zaib, A.; Waini, I.; Ishak, A.; Sherif, E.-S.M.; Xia, W.-F.; Muhammad, N. Impact of Smoluchowski Temperature and Maxwell Velocity Slip Conditions on Axisymmetric Rotated Flow of Hybrid Nanofluid past a Porous Moving Rotating Disk. Nanomaterials 2022, 12, 276. [Google Scholar] [CrossRef]

- Shoaib, M.; Zubair, G.; Nisar, K.S.; Raja, M.A.Z.; Khan, M.I.; Gowda, R.P.; Prasannakumara, B. Ohmic heating effects and entropy generation for nanofluidic system of Ree-Eyring fluid: Intelligent computing paradigm. Int. Commun. Heat Mass Transf. 2021, 129, 105683. [Google Scholar] [CrossRef]

- Makinde, O.D. Heat and mass transfer by MHD mixed convection stagnation point flow toward a vertical plate embedded in a highly porous medium with radiation and internal heat generation. Meccanica 2011, 47, 1173–1184. [Google Scholar] [CrossRef]

- Archana, M.; Gireesha, B.J.; Prasannakumara, B.C.; Gorla, R.S.R. Numerical exploration of the combined effects of non-linear thermal radiation and variable thermo-physical properties on the flow of Casson nanofluid over a wedge. Multidiscip. Model. Mater. Struct. 2017, 13, 628–647. [Google Scholar] [CrossRef]

- Garia, R.; Rawat, S.K.; Kumar, M.; Yaseena, M. Hybrid nanofluid flow over two different geometries with Cattaneo–Christov heat flux model and heat generation: A model with correlation coefficient and probable error. Chin. J. Phys. 2021, 74, 421–439. [Google Scholar] [CrossRef]

- Rawat, S.K.; Upreti, H.; Kumar, M. Comparative Study of Mixed Convective MHD Cu-Water Nanofluid Flow over a Cone and Wedge using Modified Buongiorno’s Model in Presence of Thermal Radiation and Chemical Reaction via Cattaneo-Christov Double Diffusion Model. J. Appl. Comput. Mech. 2021, 7, 1383–1402. [Google Scholar] [CrossRef]

- Yaseen, M.; Rawat, S.K.; Kumar, M. Cattaneo–Christov heat flux model in Darcy–Forchheimer radiative flow of MoS2–SiO2/kerosene oil between two parallel rotating disks. J. Therm. Anal. 2022, 1–23. [Google Scholar] [CrossRef]

- Khan, M.I.; Ahmad, S.; Hayat, T.; Alsaedi, A.; Khan, M.I.; Khan, M.W.A. Transportation of homogeneous–heterogeneous reactions in flow of Sutterby fluid confined between two co-axially rotating disks. Phys. Scr. 2019, 95, 055211. [Google Scholar] [CrossRef]

- Gowda, R.P.; Naveenkumar, R.; Madhukesh, J.; Prasannakumara, B.; Gorla, R.S.R. Theoretical analysis of SWCNT-MWCNT/H2O hybrid flow over an upward/downward moving rotating disk. Proc. Inst. Mech. Eng. Part N J. Nanomater. Nanoeng. Nanosyst. 2021, 235, 97–106. [Google Scholar] [CrossRef]

- Christopher, A.J.; Magesh, N.; Gowda, R.J.P.; Kumar, R.N.; Kumar, R.S.V. Hybrid nanofluid flow over a stretched cylinder with the impact of homogeneous–heterogeneous reactions and Cattaneo–Christov heat flux: Series solution and numerical simulation. Heat Transf. 2021, 50, 3800–3821. [Google Scholar] [CrossRef]

- Abbas, S.; Khan, W.; Waqas, M.; Irfan, M.; Asghar, Z. Exploring the features for flow of Oldroyd-B liquid film subjected to rotating disk with homogeneous/heterogeneous processes. Comput. Methods Programs Biomed. 2020, 189, 105323. [Google Scholar] [CrossRef]

- Sunthrayuth, P.; Abdelmohsen, S.A.; Rekha, M.; Raghunatha, K.; Abdelbacki, A.M.; Gorji, M.; Prasannakumara, B. Impact of nanoparticle aggregation on heat transfer phenomena of second grade nanofluid flow over melting surface subject to homogeneous-heterogeneous reactions. Case Stud. Therm. Eng. 2022, 32, 101897. [Google Scholar] [CrossRef]

- Mabood, F.; Yusuf, T.A.; Khan, W.A. Cu–Al2O3–H2O hybrid nanofluid flow with melting heat transfer, irreversibility analysis and nonlinear thermal radiation. J. Therm. Anal. 2020, 143, 973–984. [Google Scholar] [CrossRef]

- Radhika, M.; Gowda, R.J.P.; Naveenkumar, R.; Siddabasappa; Prasannakumara, B.C. Heat transfer in dusty fluid with suspended hybrid nanoparticles over a melting surface. Heat Transf. 2020, 50, 2150–2167. [Google Scholar] [CrossRef]

- Reddy, M.G.; Gowda, R.P.; Kumar, R.N.; Prasannakumara, B.; Kumar, K.G. Analysis of modified Fourier law and melting heat transfer in a flow involving carbon nanotubes. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2021, 235, 1259–1268. [Google Scholar] [CrossRef]

- Mallikarjuna, H.B.; Nirmala, T.; Gowda, R.J.P.; Manghat, R.; Kumar, R.S.V. Two-dimensional Darcy–Forchheimer flow of a dusty hybrid nanofluid over a stretching sheet with viscous dissipation. Heat Transf. 2021, 50, 3934–3947. [Google Scholar] [CrossRef]

- Khan, S.A.; Khan, M.I.; Alzahrani, F. Melting heat transportation in chemical reactive flow of third grade nanofluid with irreversibility analysis. Int. Commun. Heat Mass Transf. 2021, 129, 105696. [Google Scholar] [CrossRef]

- Turkyilmazoglu, M. Flow and heat over a rotating disk subject to a uniform horizontal magnetic field. Z. Nat. A 2022. [Google Scholar] [CrossRef]

- Chaudhary, M.A.; Merkin, J.H. A simple isothermal model for homogeneous-heterogeneous reactions in boundary-layer flow. I Equal diffusivities. Fluid Dyn. Res. 1995, 16, 311–333. [Google Scholar] [CrossRef]

- Chaudhary, M.; Merkin, J. Homogeneous-heterogeneous reactions in boundary-layer flow: Effects of loss of reactant. Math. Comput. Model. 1996, 24, 21–28. [Google Scholar] [CrossRef]

- Jain, S.; Bohra, S. Radiation effects in flow through porous medium over a rotating disk with variable fluid properties. Adv. Math. Phys. 2016, 2016, 1–12. [Google Scholar] [CrossRef]

- Acharya, N.; Das, K.; Kundu, P.K. Effects of aggregation kinetics on nanoscale colloidal solution inside a rotating channel. J. Therm. Anal. 2019, 138, 461–477. [Google Scholar] [CrossRef]

- Imtiaz, M.; Shahid, F.; Hayat, T.; Alsaedi, A. Melting heat transfer in Cu-water and Ag-water nanofluids flow with homogeneous-heterogeneous reactions. Appl. Math. Mech. 2019, 40, 465–480. [Google Scholar] [CrossRef]

- Kelson, N.; Desseaux, A. Note on porous rotating disk flow. ANZIAM J. 2000, 42, 837–855. [Google Scholar] [CrossRef]

- Bachok, N.; Ishak, A.; Pop, I. Flow and heat transfer over a rotating porous disk in a nanofluid. Phys. B Condens. Matter 2011, 406, 1767–1772. [Google Scholar] [CrossRef]

- Turkyilmazoglu, M. Nanofluid flow and heat transfer due to a rotating disk. Comput. Fluids 2014, 94, 139–146. [Google Scholar] [CrossRef]

- Mackolil, J.; Mahanthesh, B. Sensitivity analysis of Marangoni convection in TiO2–EG nanoliquid with nanoparticle aggregation and temperature-dependent surface tension. J. Therm. Anal. 2020, 143, 2085–2098. [Google Scholar] [CrossRef]

| Properties | Titanium Dioxide | Ethylene Glycol |

|---|---|---|

| 4250 | 1114 | |

| 8.9538 | 0.252 | |

| 686.2 | 2415 | |

| - | 0.0157 | |

| Pr | - | 204 |

| Comparison | ||||

|---|---|---|---|---|

| Kelson and Desseaux [42] | --------- | 0.884474 | 0.615922 | 0.510233 |

| Bachok et al. [43] | 0.9337 | ----------- | 0.6159 | 0.5102 |

| Turkyilmazoglu [44] | 0.93387794 | 0.88447411 | 0.61592201 | 0.51023262 |

| Present results | 0.93387796 | 0.88447419 | 0.61592208 | 0.51023268 |

| With NP Aggregation | Without NP Aggregation | |||

|---|---|---|---|---|

| 1 | 1 | 0.1 | 2.854255 | 2.2615356 |

| 1.2 | 3.01796 | 2.3703244 | ||

| 1.4 | 3.173434 | 2.4741029 | ||

| 0.7 | 2.553056 | 1.2322237 | ||

| 0.8 | 2.77959 | 1.4191719 | ||

| 0.9 | 3.01131 | 1.6031328 | ||

| 0.2 | 3.268001 | 2.5461544 | ||

| 0.3 | 3.290309 | 2.5706962 | ||

| 0.4 | 3.315727 | 2.5983268 | ||

| With NP Aggregation | Without NP Aggregation | |||

|---|---|---|---|---|

| 1.5 | 0.1 | 0.5 | −1.626265245 | −1.971101726 |

| 2 | −1.66620651 | −2.033848278 | ||

| 2.5 | −1.689853329 | −2.080828565 | ||

| 3 | −1.70217352 | −2.116501732 | ||

| 0.2 | −1.720653807 | −2.074617612 | ||

| 0.3 | −1.829349688 | −2.19135168 | ||

| 0.4 | −1.955731004 | −2.323852014 | ||

| 0.1 | −1.562051004 | −1.84010788 | ||

| 0.2 | −1.578645315 | −1.877819681 | ||

| 0.3 | −1.594653976 | −1.911974024 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, F.; Kumar, R.N.; Prasannakumara, B.C.; Khan, U.; Zaib, A.; Abdel-Aty, A.-H.; Yahia, I.S.; Alqahtani, M.S.; Galal, A.M. Aspects of Uniform Horizontal Magnetic Field and Nanoparticle Aggregation in the Flow of Nanofluid with Melting Heat Transfer. Nanomaterials 2022, 12, 1000. https://doi.org/10.3390/nano12061000

Wang F, Kumar RN, Prasannakumara BC, Khan U, Zaib A, Abdel-Aty A-H, Yahia IS, Alqahtani MS, Galal AM. Aspects of Uniform Horizontal Magnetic Field and Nanoparticle Aggregation in the Flow of Nanofluid with Melting Heat Transfer. Nanomaterials. 2022; 12(6):1000. https://doi.org/10.3390/nano12061000

Chicago/Turabian StyleWang, Fuzhang, Rangaswamy Naveen Kumar, Ballajja C. Prasannakumara, Umair Khan, Aurang Zaib, Abdel-Haleem Abdel-Aty, Ibrahim S. Yahia, Mohammed S. Alqahtani, and Ahmed M. Galal. 2022. "Aspects of Uniform Horizontal Magnetic Field and Nanoparticle Aggregation in the Flow of Nanofluid with Melting Heat Transfer" Nanomaterials 12, no. 6: 1000. https://doi.org/10.3390/nano12061000

APA StyleWang, F., Kumar, R. N., Prasannakumara, B. C., Khan, U., Zaib, A., Abdel-Aty, A.-H., Yahia, I. S., Alqahtani, M. S., & Galal, A. M. (2022). Aspects of Uniform Horizontal Magnetic Field and Nanoparticle Aggregation in the Flow of Nanofluid with Melting Heat Transfer. Nanomaterials, 12(6), 1000. https://doi.org/10.3390/nano12061000