Tunable Electronic Properties of Few-Layer Tellurene under In-Plane and Out-of-Plane Uniaxial Strain

Abstract

:1. Introduction

2. Methods

3. Results and Discussion

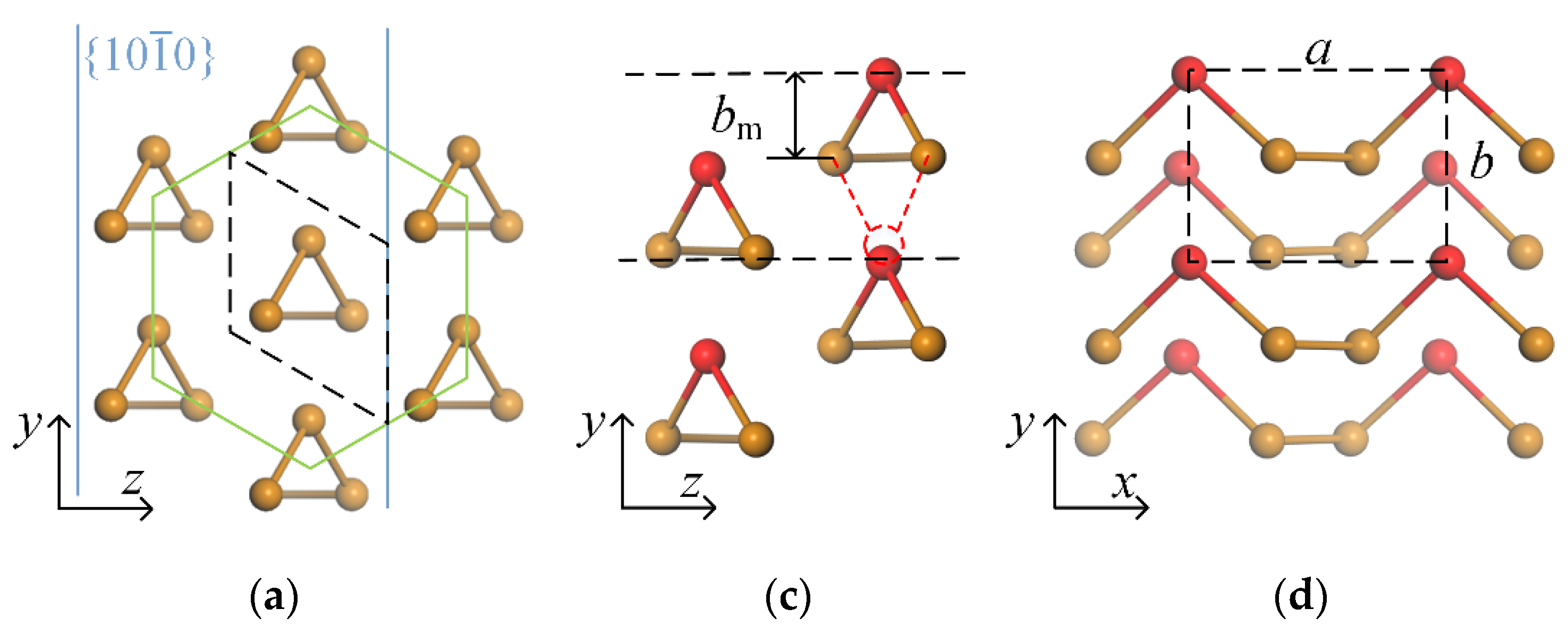

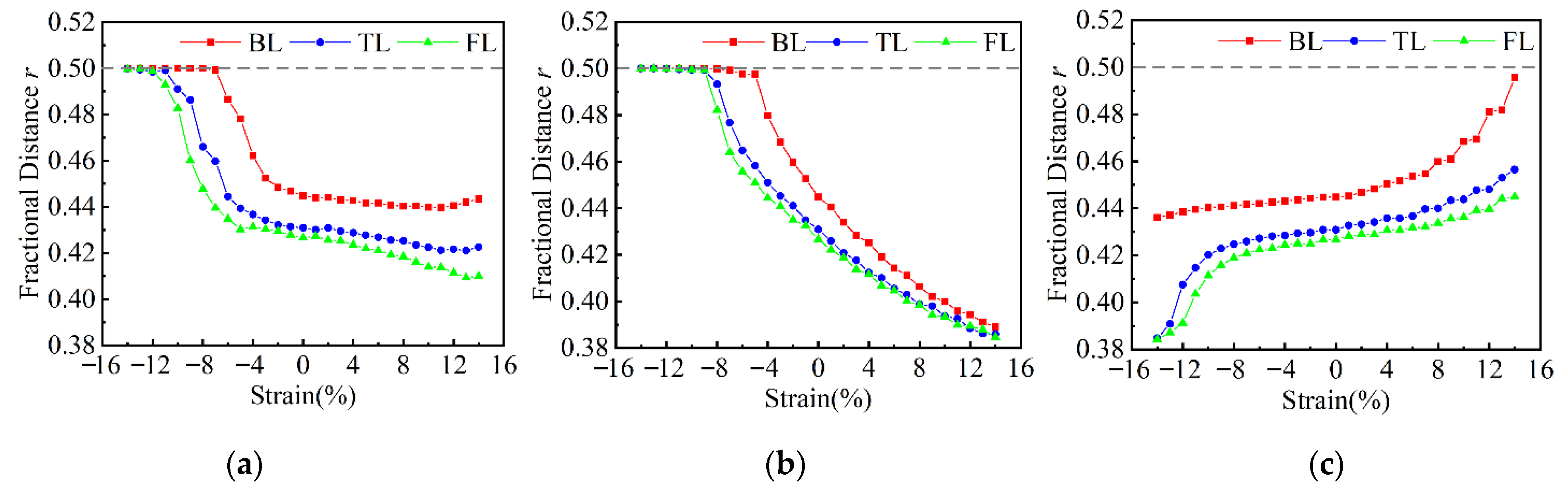

3.1. Crystal Structures

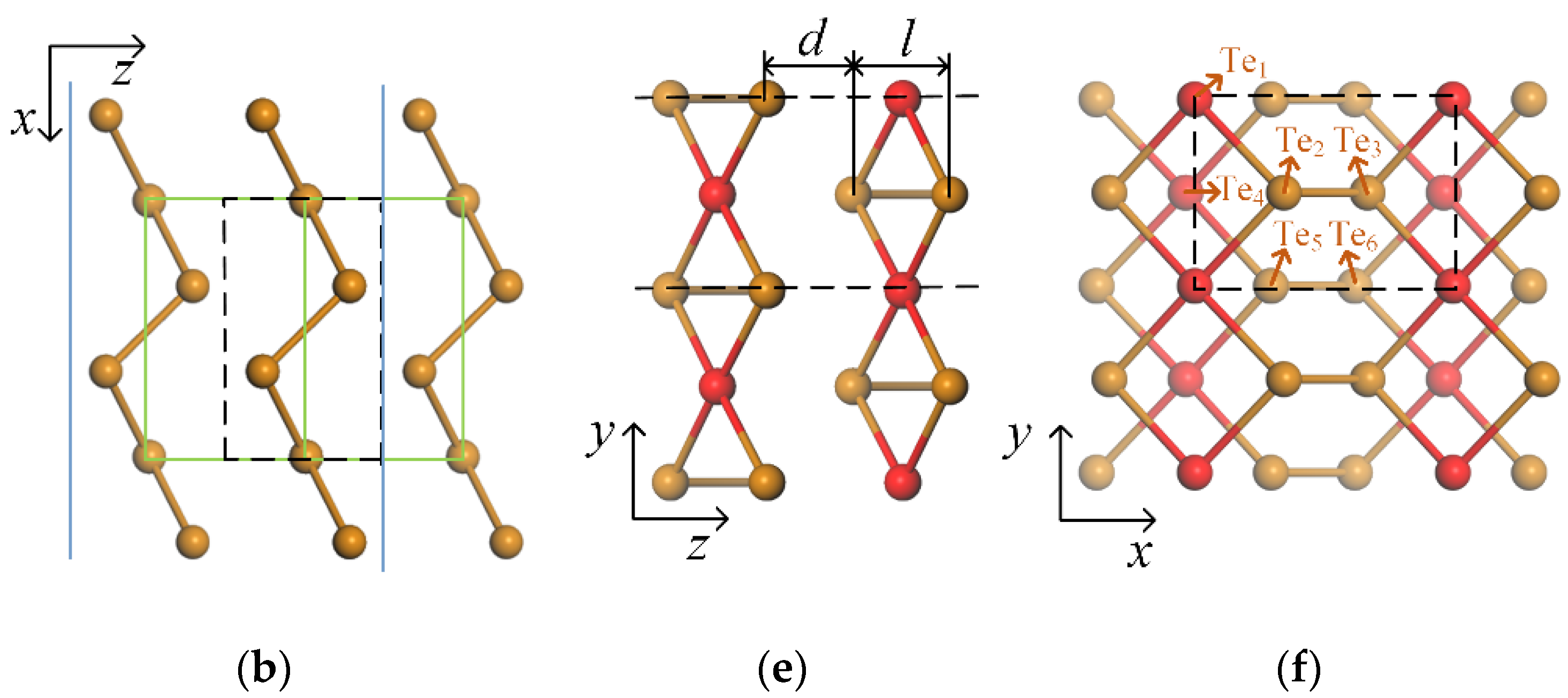

3.2. Mechanical and Electronic Properties

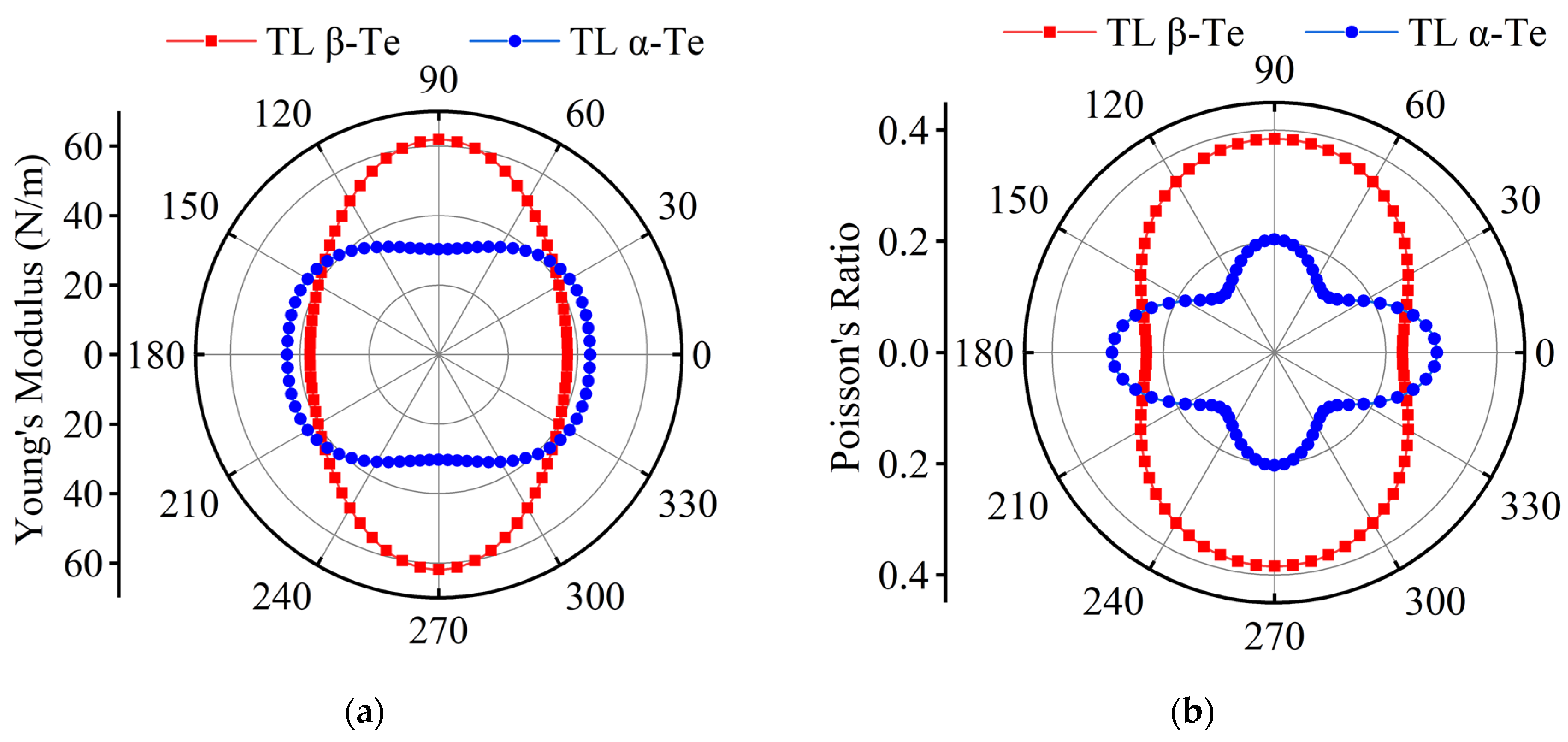

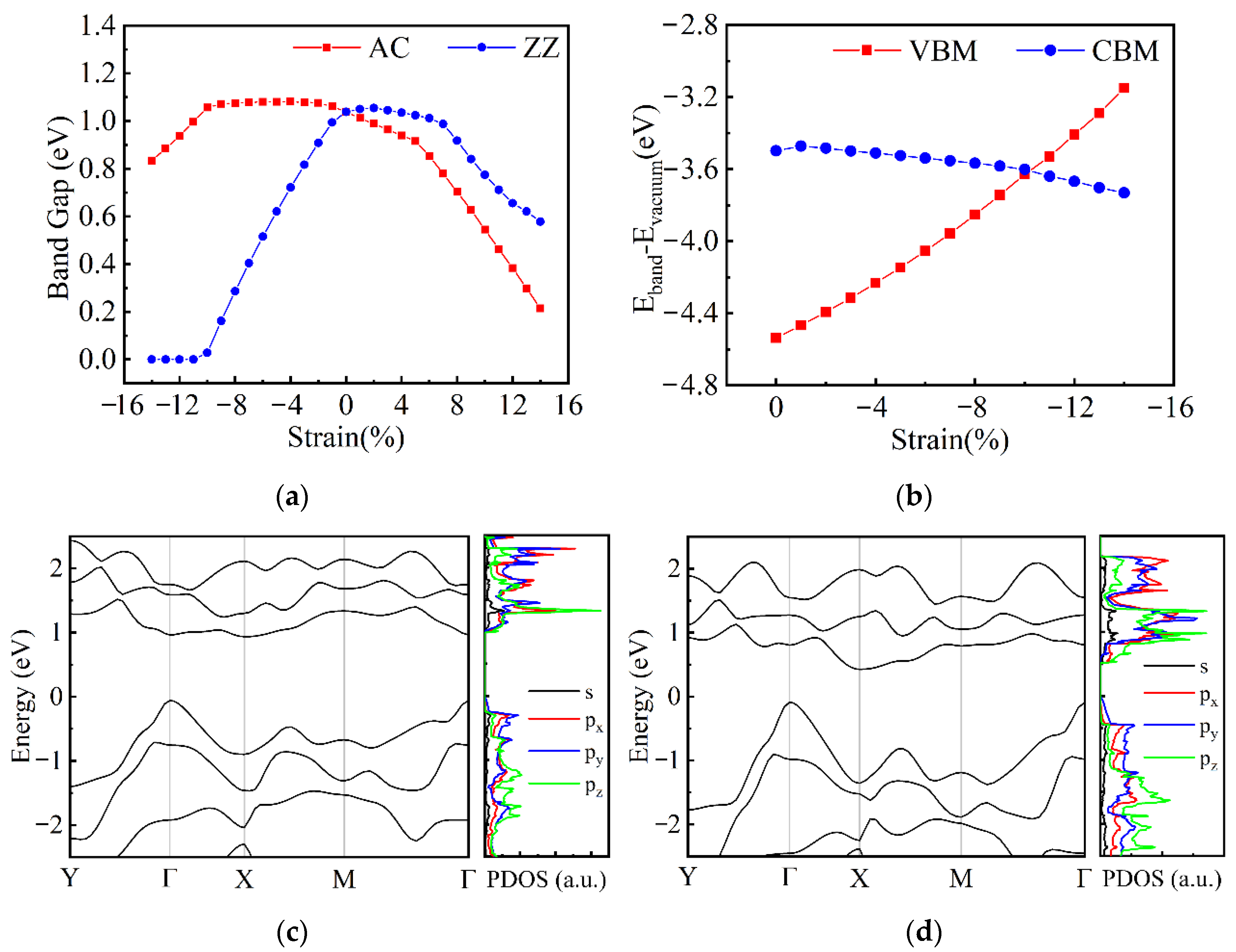

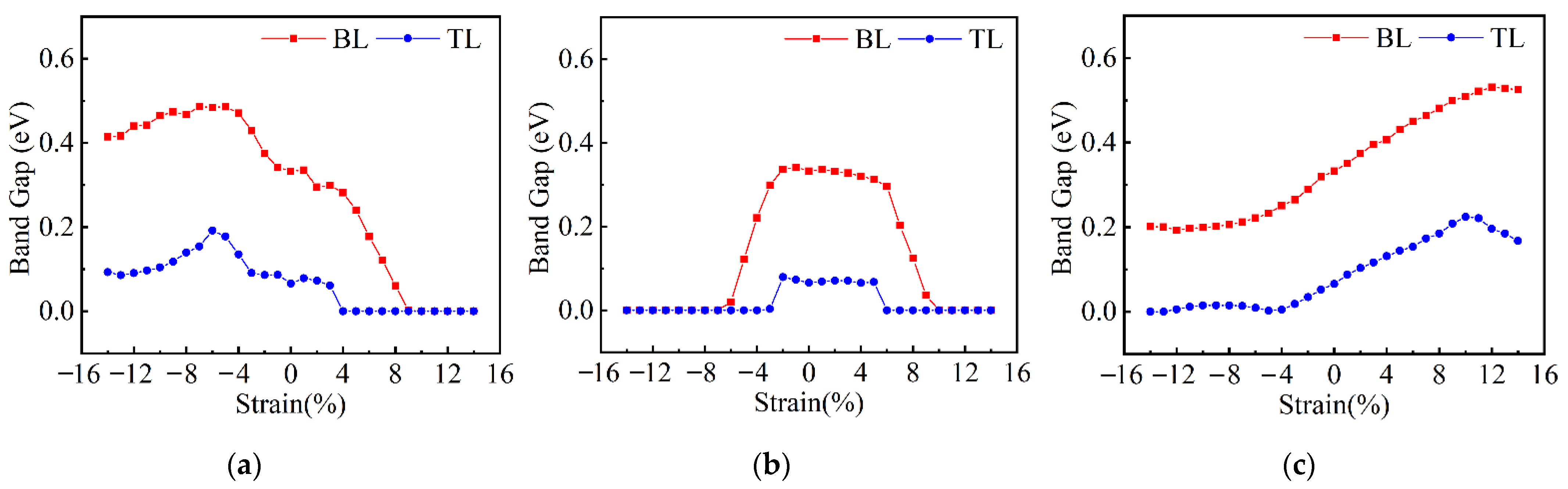

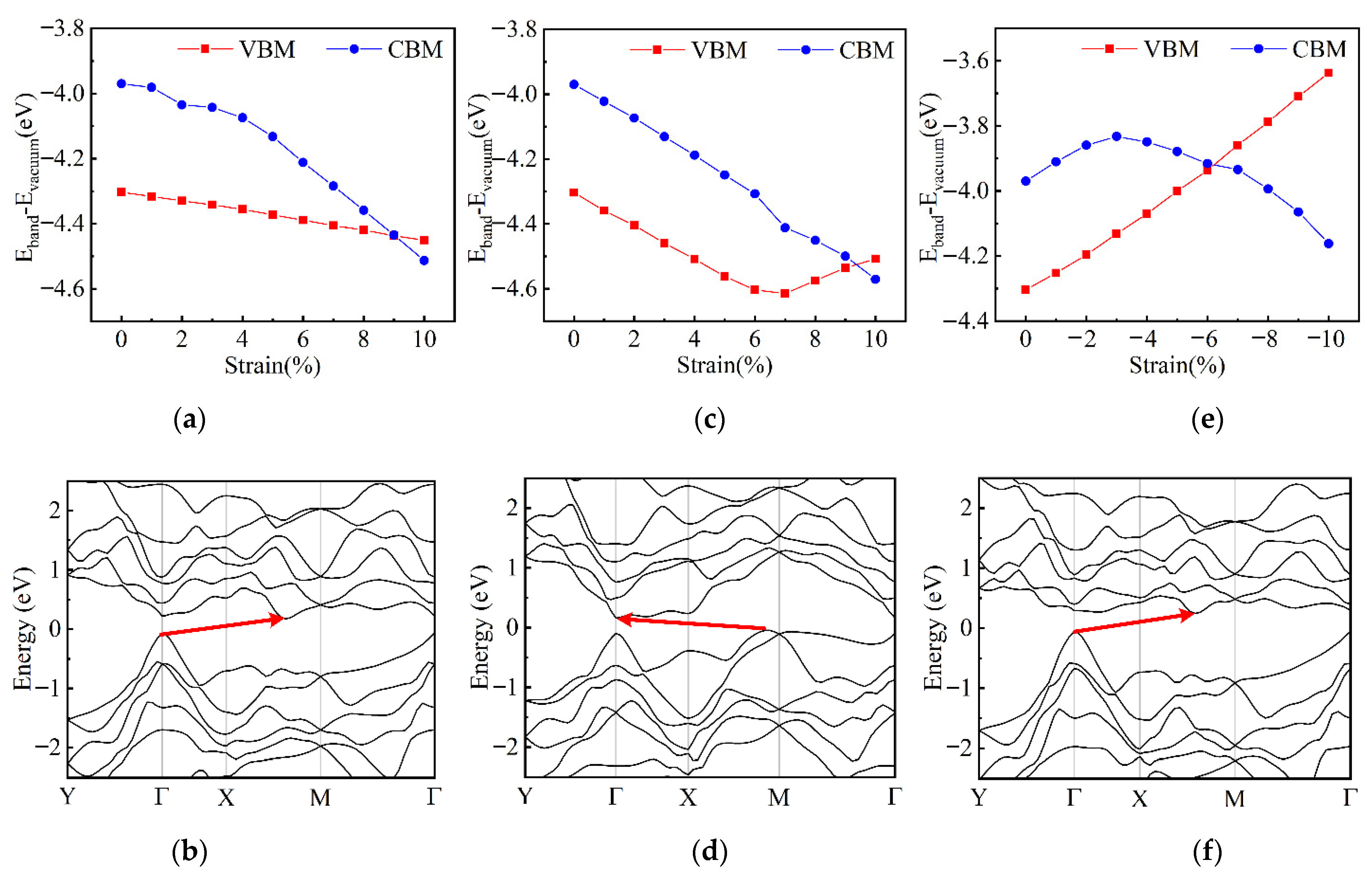

3.3. Effects of Uniaxial Strain on Electronic Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mannix, A.J.; Kiraly, B.; Hersam, M.C.; Guisinger, N.P. Synthesis and chemistry of elemental 2D materials. Nat. Rev. Chem. 2017, 1, 14. [Google Scholar] [CrossRef]

- Yang, Z.; Hao, J. Progress in pulsed laser deposited two-dimensional layered materials for device applications. J. Mater. Chem. C 2016, 4, 8859–8878. [Google Scholar] [CrossRef] [Green Version]

- Wang, G.; Hou, C.; Long, H.; Yang, L.; Wang, Y. Electronic and optoelectronic nanodevices based on two-dimensional semiconductor materials. Acta Phys.-Chim. Sin. 2019, 35, 1319–1340. [Google Scholar] [CrossRef]

- Long, M.; Wang, P.; Fang, H.; Hu, W. Progress, challenges, and opportunities for 2D material based photodetectors. Adv. Funct. Mater. 2019, 29, 1803807. [Google Scholar] [CrossRef]

- Yang, D.; Yang, R.; Priya, S.; Liu, S. Recent advances in flexible perovskite solar cells: Fabrication and applications. Angew. Chem. Int. Ed. 2019, 58, 4466–4483. [Google Scholar] [CrossRef]

- Li, Y.; Ang, K.W. Hardware Implementation of Neuromorphic Computing Using Large-Scale Memristor Crossbar Arrays. Adv. Intell. Syst. 2021, 3, 2000137. [Google Scholar] [CrossRef]

- Liu, X.; Ren, J.C.; Shen, T.; Li, S.; Liu, W. Lateral InSe p–n Junction Formed by Partial Doping for Use in Ultrathin Flexible Solar Cells. J. Phys. Chem. Lett. 2019, 10, 7712–7718. [Google Scholar] [CrossRef]

- Prakash, A.; Cai, Y.; Zhang, G.; Zhang, Y.W.; Ang, K.W. Black Phosphorus N-Type Field-Effect Transistor with Ultrahigh Electron Mobility via Aluminum Adatoms Doping. Small 2017, 13, 1602909. [Google Scholar] [CrossRef]

- Qi, J.; Li, X.; Qian, X.; Feng, J. Bandgap engineering of rippled MoS2 monolayer under external electric field. Appl. Phys. Lett. 2013, 102, 173112. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, C.V.; Hieu, N.N.; Ilyasov, V.V. Band gap modulation of bilayer MoS2 under strain engineering and electric field: A density functional theory. J. Electron. Mater. 2016, 45, 4038–4043. [Google Scholar] [CrossRef]

- Li, Z.; Chen, F. Ion beam modification of two-dimensional materials: Characterization, properties, and applications. Appl. Phys. Rev. 2017, 4, 011103. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Mishchenko, O.A.; Carvalho, O.A.; Neto, A.C. 2D materials and van der Waals heterostructures. Science 2016, 353, acc9439. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, Y.; Weiss, N.O.; Duan, X.; Cheng, H.C.; Huang, Y.; Duan, X. Van der Waals heterostructures and devices. Nat. Rev. Mater. 2016, 1, 16042. [Google Scholar] [CrossRef]

- Cao, K.; Feng, S.; Han, Y.; Gao, L.; Ly, T.H.; Xu, Z.; Lu, Y. Elastic straining of free-standing monolayer graphene. Nat. Commun. 2020, 11, 284. [Google Scholar] [CrossRef] [Green Version]

- Akinwande, D.; Brennan, C.J.; Bunch, J.S.; Egberts, P.; Felts, J.R.; Gao, H.; Zhu, Y. A review on mechanics and mechanical properties of 2D materialls—Graphene and beyond. Extrem. Mech. Lett. 2017, 13, 42–77. [Google Scholar] [CrossRef] [Green Version]

- Bao, H.; Huang, Y.; Yang, Z.; Miao, Y.; Chu, P.K.; Xu, K.; Ma, F. Tensile loading induced phase transition and rippling in single-layer MoS2. Appl. Surf. Sci. 2017, 404, 180–187. [Google Scholar] [CrossRef]

- Manzeli, S.; Allain, A.; Ghadimi, A.; Kis, A. Piezoresistivity and strain-induced band gap tuning in atomically thin MoS2. Nano Lett. 2015, 15, 5330–5335. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Deng, W.; Chen, X.; Wu, Y.; Shi, J.; Zheng, J.; Zhang, Y. Carrier mobility tuning of MoS2 by strain engineering in CVD growth process. Nano Res. 2021, 14, 2314–2320. [Google Scholar] [CrossRef]

- Yu, L.; Ruzsinszky, A.; Perdew, J.P. Bending two-dimensional materials to control charge localization and Fermi-level shift. Nano Lett. 2016, 16, 2444–2449. [Google Scholar] [CrossRef]

- Chen, S.; Sood, A.; Pop, E.; Goodson, K.E.; Donadio, D. Strongly tunable anisotropic thermal transport in MoS2 by strain and lithium intercalation: First-principles calculations. 2D Mater. 2019, 6, 025033. [Google Scholar] [CrossRef] [Green Version]

- Liu, T.; Liu, S.; Tu, K.H.; Schmidt, H.; Chu, L.; Xiang, D.; Martin, J.; Eda, G.; Ross, C.A.; Garaj, S. Crested two-dimensional transistors. Nat. Nanotechnol. 2019, 14, 223–226. [Google Scholar] [CrossRef] [PubMed]

- Guo, J.; Wen, R.; Zhai, J.; Wang, Z.L. Enhanced NO2 gas sensing of a single-layer MoS2 by photogating and piezo-phototronic effects. Sci. Bull. 2019, 64, 128–135. [Google Scholar] [CrossRef] [Green Version]

- Lin, P.; Pan, C.; Wang, Z.L. Two-dimensional nanomaterials for novel piezotronics and piezophototronics. Mater. Today Nano 2018, 4, 17–31. [Google Scholar] [CrossRef]

- Zhu, Z.; Cai, X.; Yi, S.; Chen, J.; Dai, Y.; Niu, C.; Guo, Z.; Xie, M.; Liu, F.; Cho, J.H.; et al. Multivalency-driven formation of Te-based monolayer materials: A combined first-principles and experimental study. Phys. Rev. Lett. 2017, 119, 106101. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, Y.; Xiao, C.; Chen, M.; Hua, C.; Zou, J.; Wu, C.; Jiang, J.; Yang, S.A.; Ji, W. Two-dimensional ferroelectricity and switchable spin-textures in ultra-thin elemental Te multilayers. Mater. Horiz. 2018, 5, 521–528. [Google Scholar] [CrossRef]

- Xiang, Y.; Gao, S.; Xu, R.G.; Wu, W.; Leng, Y. Phase transition in two-dimensional tellurene under mechanical strain modulation. Nano Energy 2019, 58, 202–210. [Google Scholar] [CrossRef]

- Wang, Y.; Qiu, G.; Wang, R.; Huang, S.; Wang, Q.; Liu, Y.; Du, Y.; Goddard, W.A.; Kim, M.J.; Xu, X.; et al. Field-effect transistors made from solution-grown two-dimensional tellurene. Nat. Electron. 2018, 1, 228–236. [Google Scholar] [CrossRef]

- Xie, Z.; Xing, C.; Huang, W.; Fan, T.; Li, Z.; Zhao, J.; Xiang, Y.; Guo, Z.; Li, J.; Yang, Z.; et al. Ultrathin 2D nonlayered tellurium nanosheets: Facile liquid-phase exfoliation, characterization, and photoresponse with high performance and enhanced stability. Adv. Funct. Mater. 2018, 28, 1705833. [Google Scholar] [CrossRef]

- Chen, J.; Dai, Y.; Ma, Y.; Dai, X.; Ho, W.; Xie, M. Ultrathin β-tellurium layers grown on highly oriented pyrolytic graphite by molecular-beam epitaxy. Nanoscale 2017, 9, 15945–15948. [Google Scholar] [CrossRef] [Green Version]

- Apte, A.; Bianco, E.; Krishnamoorthy, A.; Yazdi, S.; Rao, R.; Glavin, N.; Kumazoe, H.; Varshney, V.; Roy, A.; Shimojo, F.; et al. Polytypism in ultrathin tellurium. 2D Mater. 2018, 6, 015013. [Google Scholar] [CrossRef] [Green Version]

- Yang, S.; Chen, B.; Qin, Y.; Zhou, Y.; Liu, L.; Durso, M.; Zhuang, H.; Shen, Y.; Tongay, S. Highly crystalline synthesis of tellurene sheets on two-dimensional surfaces: Control over helical chain direction of tellurene. Phys. Rev. Mater. 2018, 2, 104002. [Google Scholar] [CrossRef]

- Amani, M.; Tan, C.; Zhang, G.; Zhao, C.; Bullock, J.; Song, X.; Kim, H.; Shrestha, V.R.; Gao, Y.; Crozier, K.B.; et al. Solution-synthesized high-mobility tellurium nanoflakes for short-wave infrared photodetectors. ACS Nano 2018, 12, 7253–7263. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Yang, A.; Lan, T.; Fan, C.; Pan, J.; Liu, Z.; Chu, J.; Yuan, H.; Wang, X.; Rong, M.; et al. Tellurene based chemical sensor. J. Mater. Chem. A 2019, 7, 26326–26333. [Google Scholar] [CrossRef]

- Dong, Y.; Zeng, B.; Zhang, X.; Li, D.; He, J.; Long, M. Study on the strain-induced mechanical property modulations in monolayer Tellurene. J. Appl. Phys. 2019, 125, 064304. [Google Scholar] [CrossRef]

- Ma, H.; Hu, W.; Yang, J. Control of highly anisotropic electrical conductance of tellurene by strain-engineering. Nanoscale 2019, 11, 21775–21781. [Google Scholar] [CrossRef]

- Sopiha, K.V.; Malyi, O.I.; Persson, C. First-principles mapping of the electronic properties of two-dimensional materials for strain-tunable nanoelectronics. ACS Appl. Nano Mater. 2019, 2, 5614–5624. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Yao, S.; Liao, P.; Jin, S.; Wang, Q.; Kim, M.J.; Cheng, G.J.; Wu, W. Strain-Engineered Anisotropic Optical and Electrical Properties in 2D Chiral-Chain Tellurium. Adv. Mater. 2020, 32, 2002342. [Google Scholar] [CrossRef]

- Gao, S.; Wang, Y.; Wang, R.; Wu, W. Piezotronic effect in 1D van der Waals solid of elemental tellurium nanobelt for smart adaptive electronics. Semicond. Sci. Technol. 2017, 32, 104004. [Google Scholar] [CrossRef] [Green Version]

- Du, Y.; Qiu, G.; Wang, Y.; Si, M.; Xu, X.; Wu, W.; Ye, P.D. One-dimensional van der Waals material tellurium: Raman spectroscopy under strain and magneto-transport. Nano Lett. 2017, 17, 3965–3973. [Google Scholar] [CrossRef] [Green Version]

- Ju, W.; Li, T.; Wang, H.; Yong, Y.; Li, X. Hybrid functional studies on the electronic properties of ultrathin black phosphorus under normal strain. Comput. Mater. Sci. 2015, 109, 20–24. [Google Scholar] [CrossRef]

- Castellanos-Gomez, A.; Roldán, R.; Cappelluti, E.; Buscema, M.; Guinea, F.; van der Zant, H.S.; Steele, G.A. Local strain engineering in atomically thin MoS2. Nano Lett. 2013, 13, 5361–5366. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kohn, W.; Sham, L.J. Self-consistent equations including exchange and correlation effects. Phys. Rev. 1965, 140, A1133. [Google Scholar] [CrossRef] [Green Version]

- Giannozzi, P.; Baroni, S.; Bonini, N.; Calandra, M.; Car, R.; Cavazzoni, C.; Ceresoli, D.; Chiarotti, G.L.; Cococcioni, M.; Dabo, I.; et al. QUANTUM ESPRESSO: A modular and open-source software project for quantum simulations of materials. J. Phys. Condens. Matter 2009, 21, 395502. [Google Scholar] [CrossRef] [PubMed]

- Burke, K.; Perdew, J.P.; Wang, Y. Derivation of a generalized gradient approximation: The PW91 density functional. In Electronic Density Functional Theory; Springer: Boston, MA, USA, 1998; pp. 81–111. [Google Scholar]

- Grimme, S. Semiempirical GGA-type density functional constructed with a long-range dispersion correction. J. Comput. Chem. 2006, 27, 1787–1799. [Google Scholar] [CrossRef]

- Wang, L.; Kutana, A.; Zou, X.; Yakobson, B.I. Electro-mechanical anisotropy of phosphorene. Nanoscale 2015, 7, 9746–9751. [Google Scholar] [CrossRef]

- Zhou, J.; Huang, R. Internal lattice relaxation of single-layer graphene under in-plane deformation. J. Mech. Phys. Solids 2008, 56, 1609–1623. [Google Scholar] [CrossRef]

- Zhuang, H.L.; Hennig, R.G. Computational search for single-layer transition-metal dichalcogenide photocatalysts. J. Phys. Chem. C 2013, 117, 20440–20445. [Google Scholar] [CrossRef]

- Cahangirov, S.; Topsakal, M.; Aktürk, E.; Şahin, H.; Ciraci, S. Two-and one-dimensional honeycomb structures of silicon and germanium. Phys. Rev. Lett. 2009, 102, 236804. [Google Scholar] [CrossRef] [Green Version]

- Cai, X.; Ren, Y.; Wu, M.; Xu, D.; Luo, X. Strain-induced phase transition and giant piezoelectricity in monolayer tellurene. Nanoscale 2020, 12, 167–172. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Zhou, X.; Qiao, J.; Zhou, L.; Kong, X.; Pan, Y.; Cheng, Z.; Chai, Y.; Ji, W. Charge-governed phase manipulation of few-layer tellurium. Nanoscale 2018, 10, 22263–22269. [Google Scholar] [CrossRef] [Green Version]

| Phase | Layer Number | a (Å) | b (Å) | l (Å) | d (Å) | r | ΔE (eV/atom) |

|---|---|---|---|---|---|---|---|

| α-Te | ML | 5.49 | 4.17 | 2.16 | / | 0.50 | 0.228 |

| BL | 5.80 | 4.24 | 2.10 | 1.79 | 0.43 | 0.134 | |

| TL | 5.89 | 4.28 | 2.07 | 1.77 | 0.42 | 0.095 | |

| FL | 5.92 | 4.30 | 2.08 | 1.75 | 0.42 | 0.073 | |

| β-Te | ML | 5.49 | 4.17 | 2.16 | / | 0.50 | 0.228 |

| BL | 5.78 | 4.18 | 2.1 | 1.88 | 0.50 | 0.137 | |

| TL | 5.89 | 4.18 | 2.05 | 1.87 | 0.50 | 0.101 | |

| FL | 5.94 | 4.19 | 2.04 | 1.83 | 0.50 | 0.081 |

| Phase | Layer Number | AC Direction | ZZ Direction | NM Direction | |||

|---|---|---|---|---|---|---|---|

| Tensile | Compressive | Tensile | Compressive | Tensile | Compressive | ||

| α-Te | BL | SMT at 13% | decrease | slight | SMT at −8% | decrease | decrease |

| TL | SMT at 11% | decrease | slight | SMT at −7% | decrease | increase then decrease | |

| FL | SMT at 10% | SMT at −11% | slight | SMT at −8% | decrease | increase then decrease | |

| β-Te | ML | decrease | decrease | decrease | SMT at −11% | decrease | / |

| BL | SMT at 10% | increase then decrease | SMT at 10% | SMT at −7% | decrease | increase then decrease | |

| TL | SMT at 4% | increase then decrease | SMT at 6% | SMT at −4% | decrease | increase then decrease | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, G.; Ding, Y.; Guan, Y.; Wang, Y.; Yang, L. Tunable Electronic Properties of Few-Layer Tellurene under In-Plane and Out-of-Plane Uniaxial Strain. Nanomaterials 2022, 12, 875. https://doi.org/10.3390/nano12050875

Wang G, Ding Y, Guan Y, Wang Y, Yang L. Tunable Electronic Properties of Few-Layer Tellurene under In-Plane and Out-of-Plane Uniaxial Strain. Nanomaterials. 2022; 12(5):875. https://doi.org/10.3390/nano12050875

Chicago/Turabian StyleWang, Genwang, Ye Ding, Yanchao Guan, Yang Wang, and Lijun Yang. 2022. "Tunable Electronic Properties of Few-Layer Tellurene under In-Plane and Out-of-Plane Uniaxial Strain" Nanomaterials 12, no. 5: 875. https://doi.org/10.3390/nano12050875

APA StyleWang, G., Ding, Y., Guan, Y., Wang, Y., & Yang, L. (2022). Tunable Electronic Properties of Few-Layer Tellurene under In-Plane and Out-of-Plane Uniaxial Strain. Nanomaterials, 12(5), 875. https://doi.org/10.3390/nano12050875