Advanced Nanomechanical Characterization of Biopolymer Films Containing GNPs and MWCNTs in Hybrid Composite Structure

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Output of Nanocomposite Test Films

2.3. Instrumental Methods

3. Results and Discussion

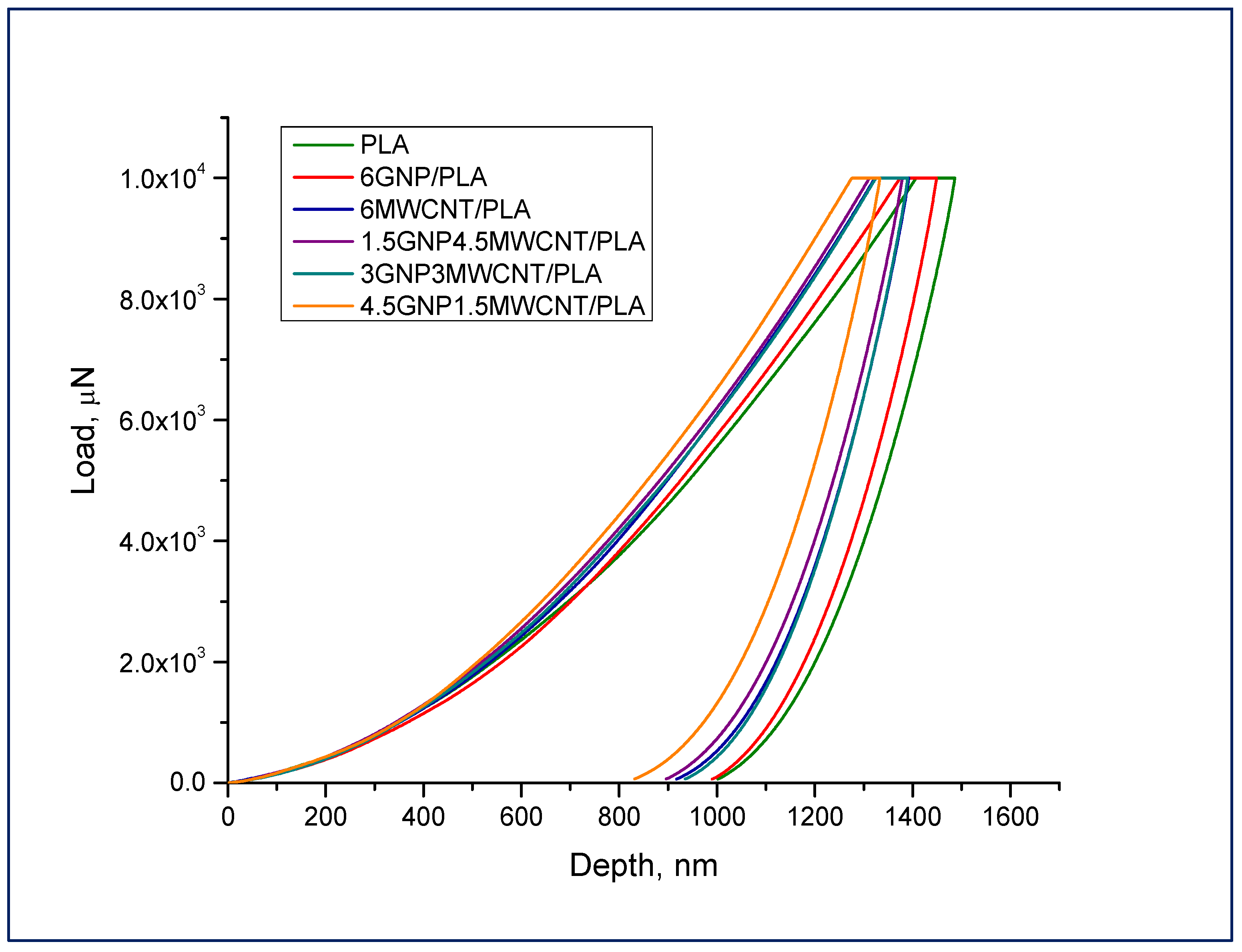

3.1. Quasi-Static Nanoindentation

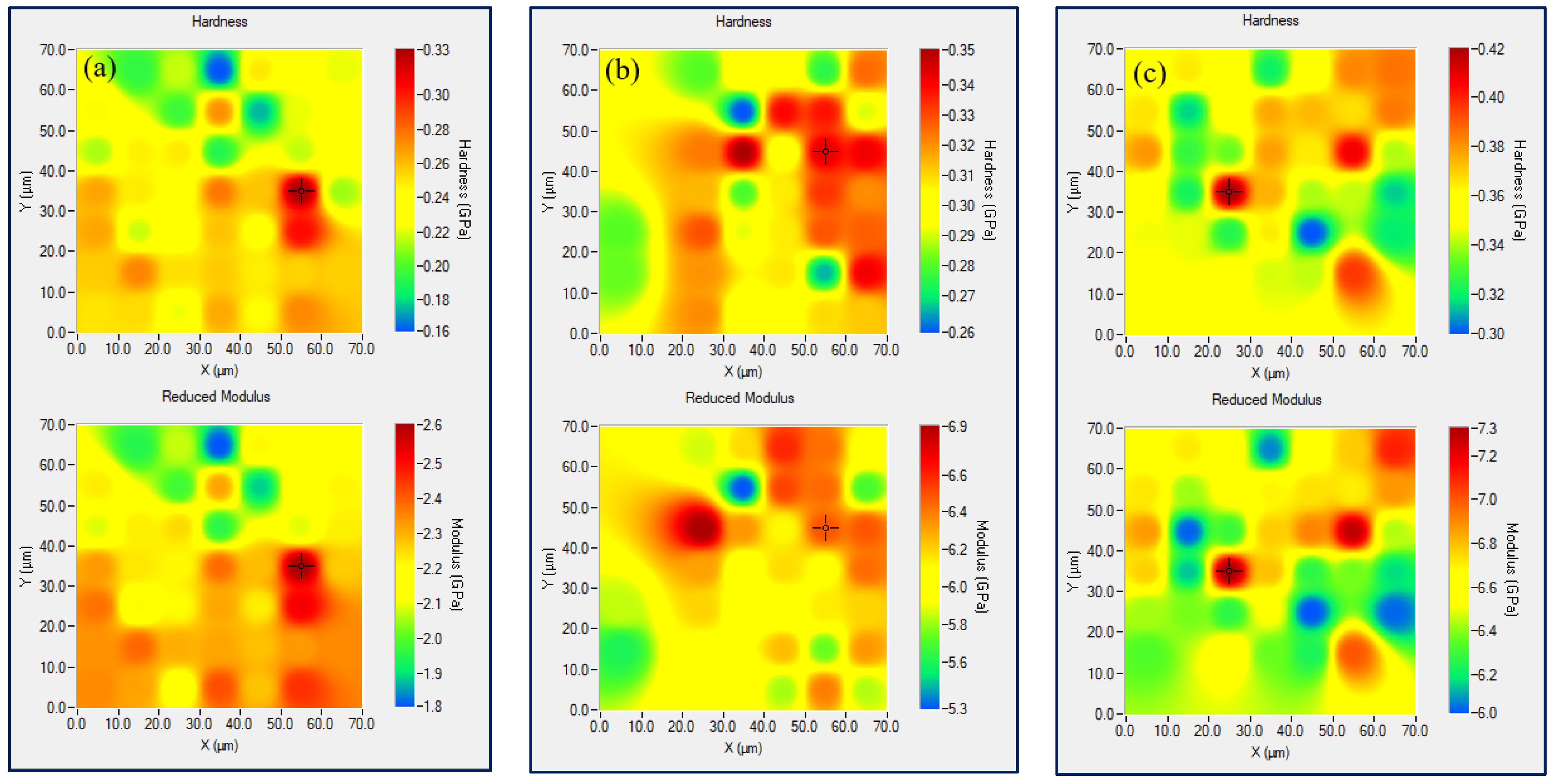

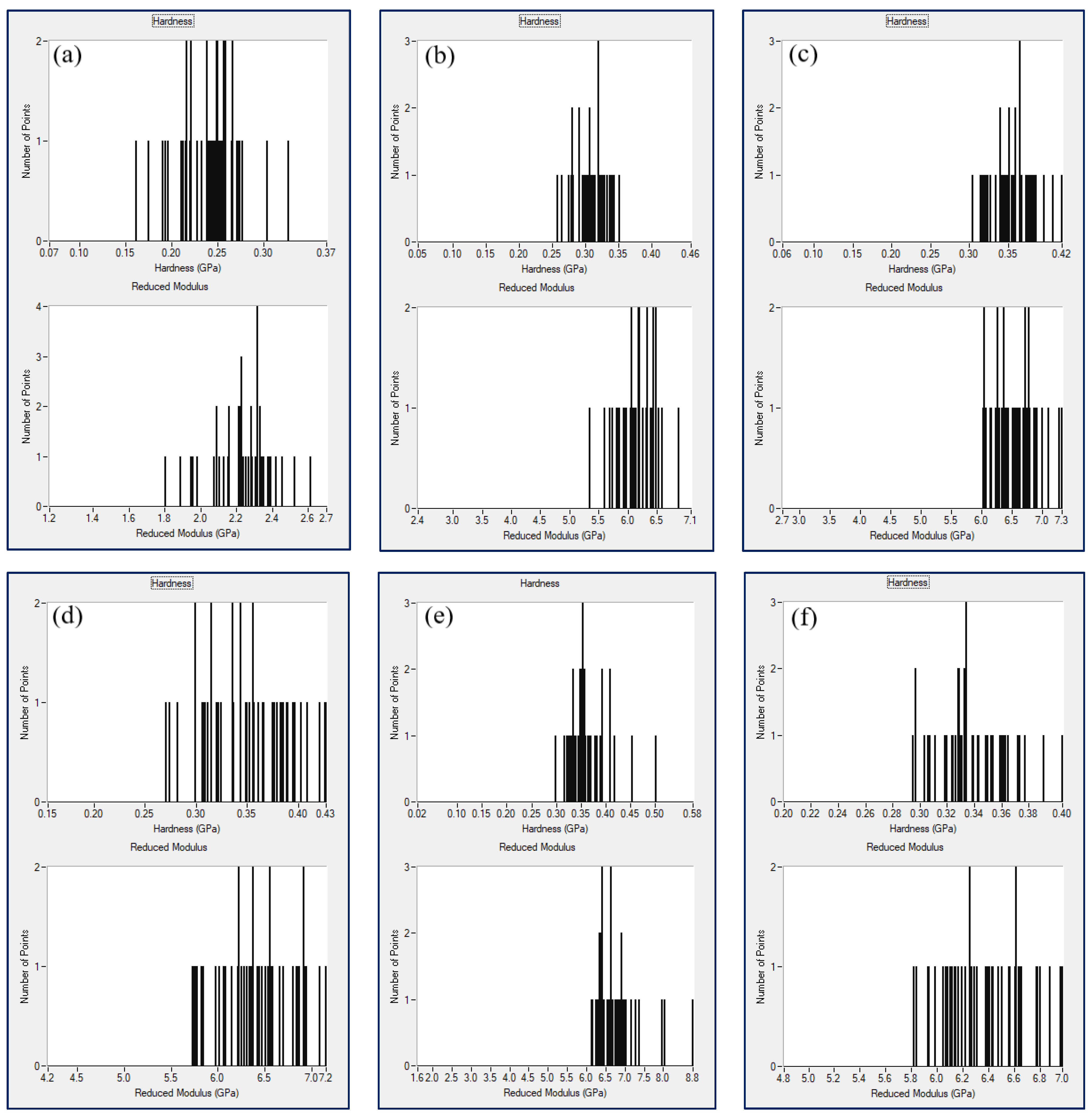

3.2. XPM Analysis

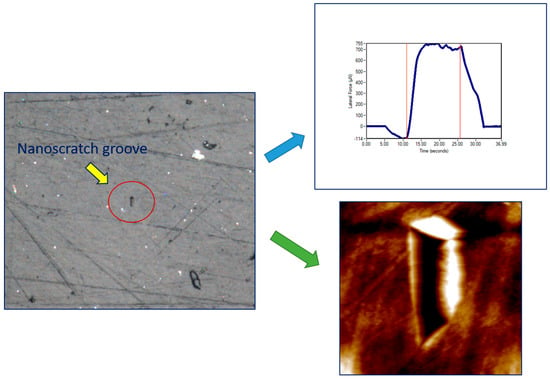

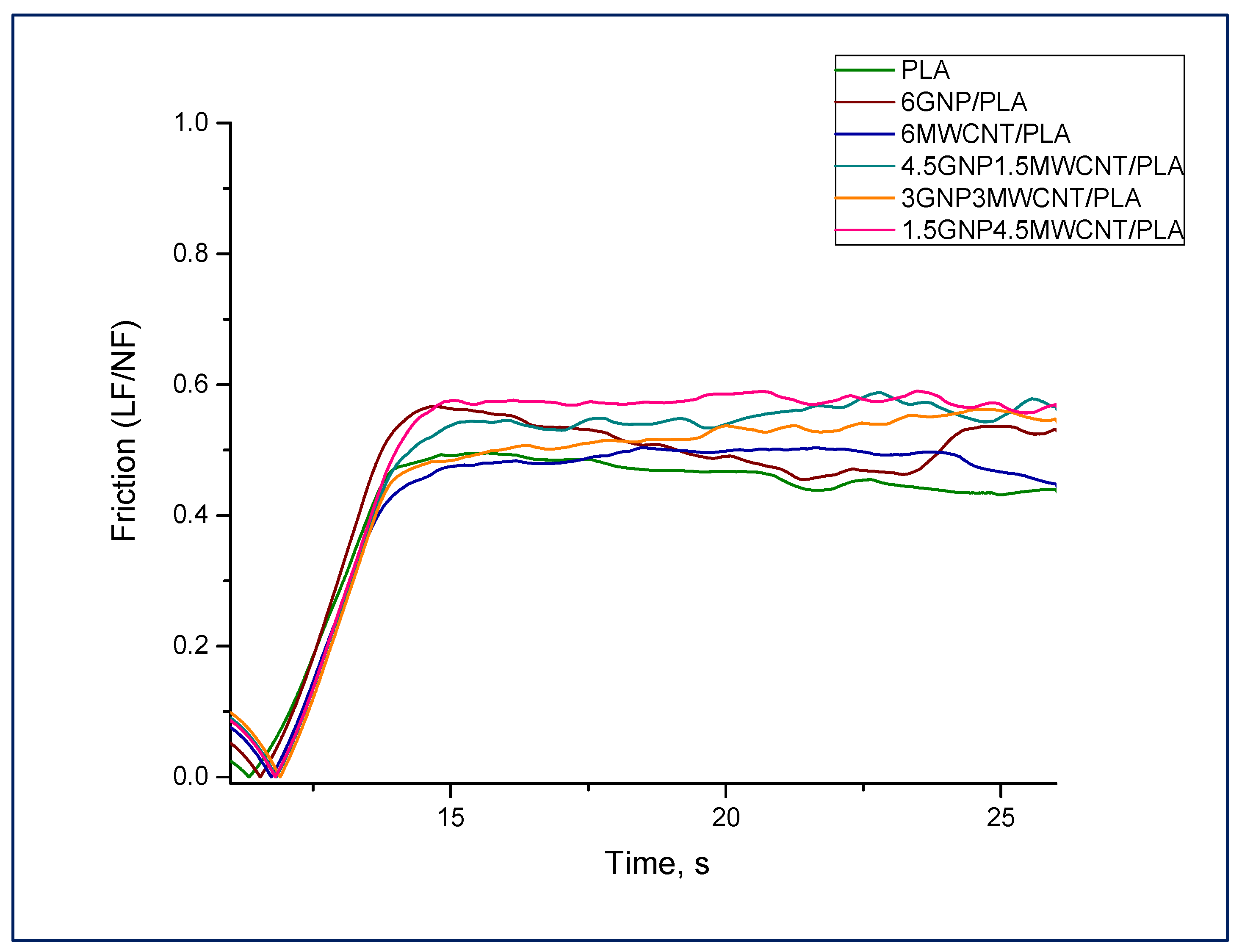

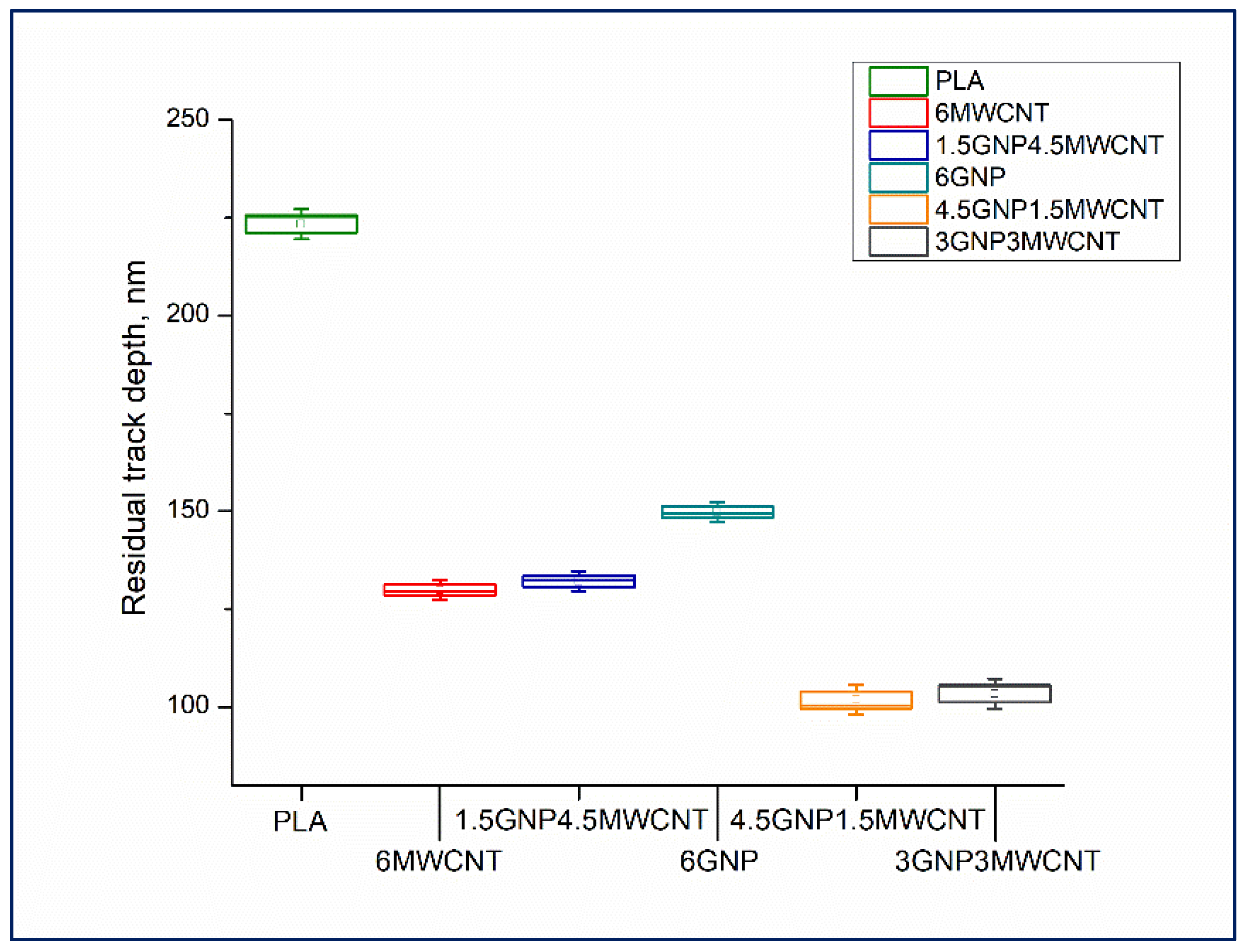

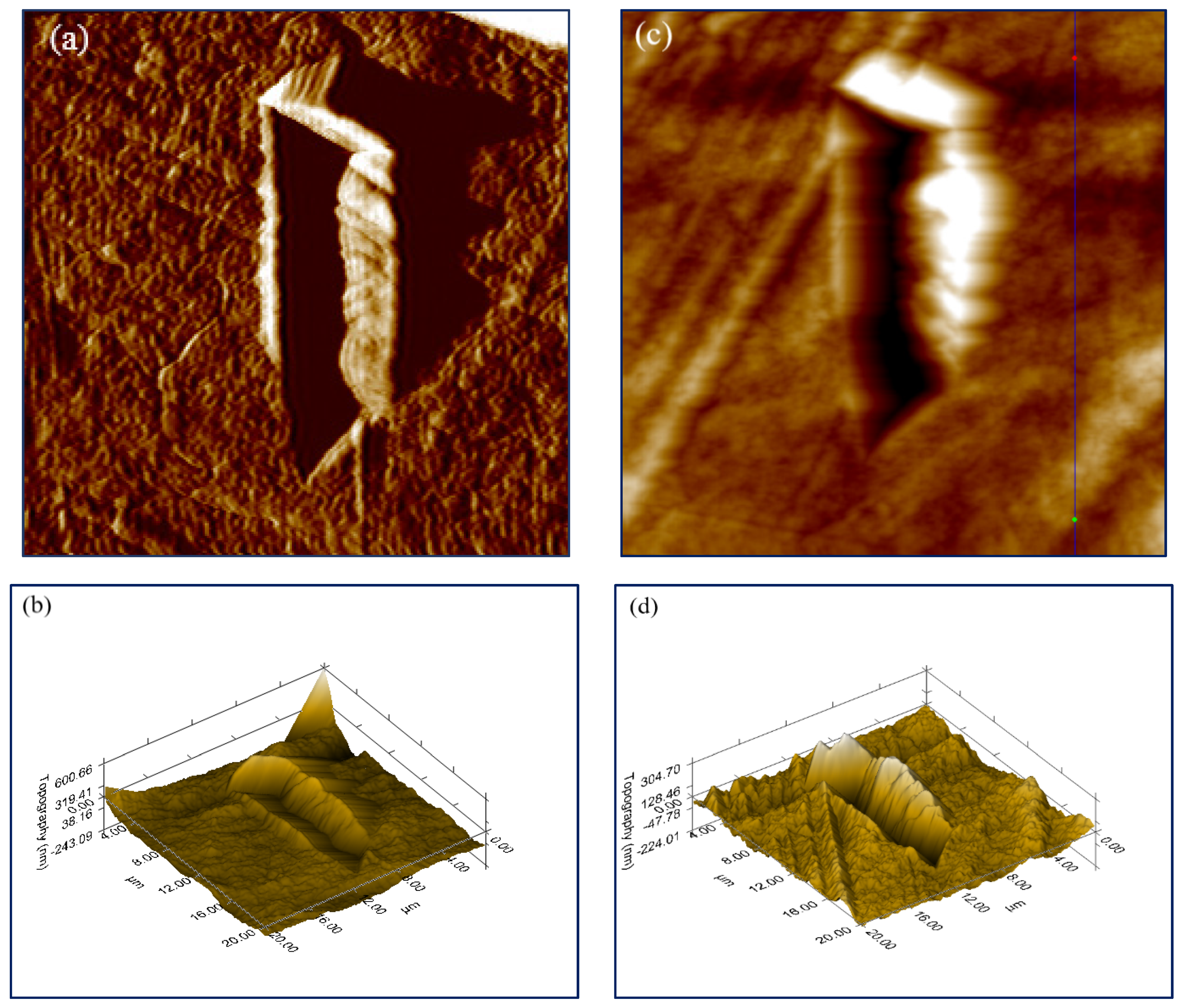

3.3. Nanoscratch Testing

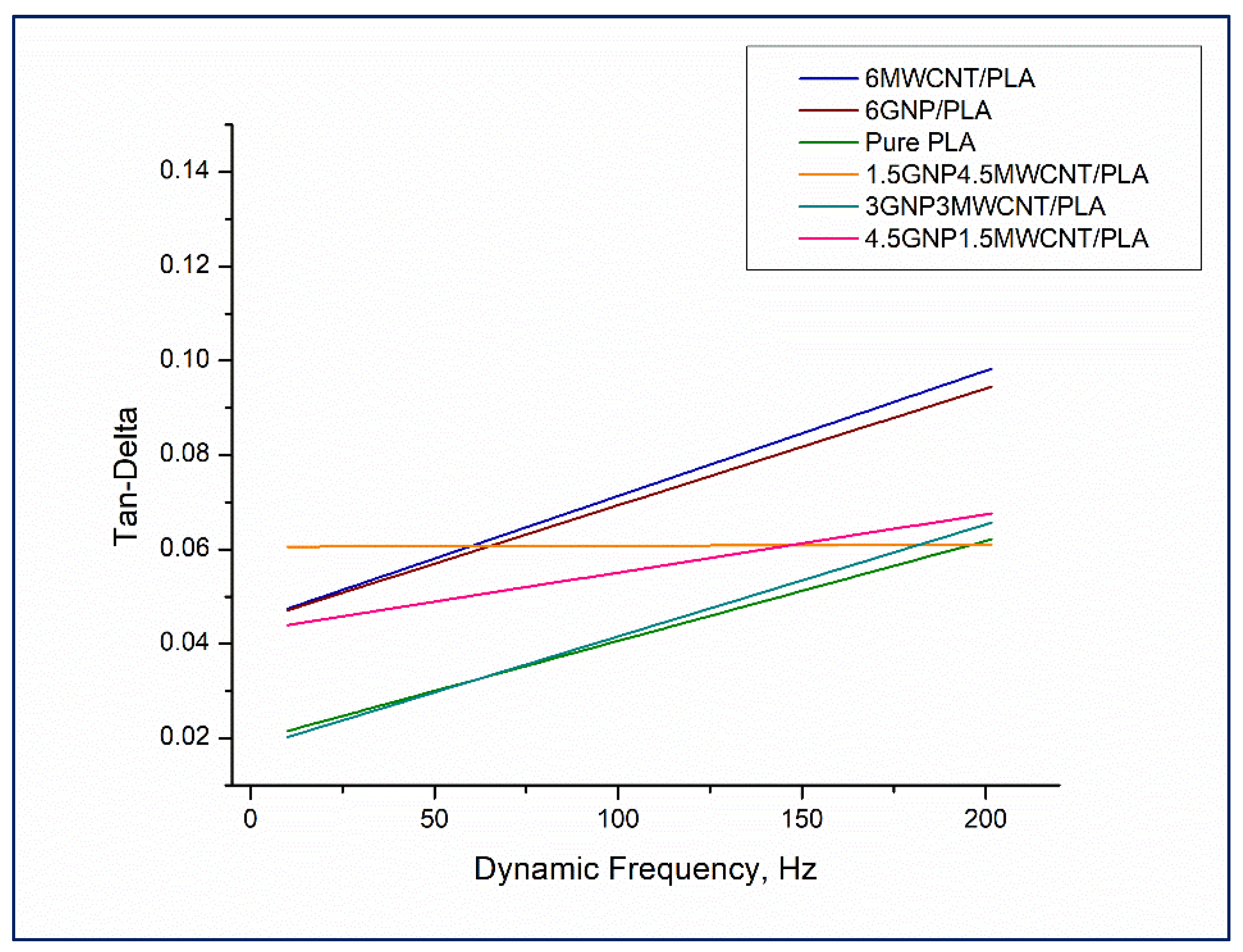

3.4. Nanodynamic Mechanical Analysis

3.5. TEM Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bryaskova, R.; Philipova, N.; Georgiev, N.; Lalov, I.; Bojinov, V.; Detrembleur, C. Photoactive mussels inspired polymer coatings: Preparation and antibacterial activity. J. Appl. Polym. Sci. 2021, 138, 50769. [Google Scholar] [CrossRef]

- Oh, M.; Kim, W.D.; Zhang, M.; Kim, T.; Yoo, D.; Kim, S.H.; Lee, D. Mechanical behavior of ABS plastic-matrix nanocomposites with three different carbon-based nanofillers. Polym. Bull. 2021, 78, 3751–3762. [Google Scholar] [CrossRef]

- Pardoen, T.; Klavzer, N.; Gayot, S.; Van Loock, F.; Chevalier, J.; Morelle, X.; Destoop, V.; Lani, F.; Camanho, P.; Brassart, L.; et al. Nanomechanics serving polymer-based composite research. C. R. Phys. 2021, 22, 331–352. [Google Scholar] [CrossRef]

- Li, H.; Chen, J.; Chen, Q.; Liu, M. Determining the constitutive behavior of nonlinear visco-elastic-plastic PMMA thin films using nanoindentation and finite element simulation. Mater. Design 2021, 197, 109239. [Google Scholar] [CrossRef]

- Bayer, I.S. Thermomechanical Properties of Polylactic Acid-Graphene Composites: A State-of-the-art Review for Biomedical Applications. Materials 2017, 10, 748. [Google Scholar] [CrossRef] [Green Version]

- Sanes, J.; Sánches, C.; Pamies, R.; Avilés, M.-D.; Bermúdes, M.-D. Extrusion of Polymer Nanocomposites with Graphene and Graphene Derivative Nanofillers: An Overview of Recent Developments. Materials 2020, 13, 549. [Google Scholar] [CrossRef] [Green Version]

- Li, M.-X.; Kim, S.-H.; Choi, S.-W.; Goda, K.; Lee, W.-I. Effect of reinforcing particles on hydrolytic degradation behavior of poly (lactic acid) composites. Compos. Part B 2016, 96, 248–254. [Google Scholar] [CrossRef]

- Sikdar, D.; Katti, D.; Katti, K.; Mohanty, B. Effect of Organic Modifiers on Dynamic and Static Nanomechanical Properties and Crystallinity of Intercalated Clay–Polycaprolactam Nanocomposites. J. Appl. Polym. Sci. 2007, 105, 790–802. [Google Scholar] [CrossRef]

- Eichhorn, W.; Avrushchenko, B.; Winters, D. Carbon nanotube filled composite material analysis utilizing nano and conventional testing techniques. Inter. Conf. Digit. Print. Techn. 2010, 5, 470–474. [Google Scholar]

- Li, X.; Xiao, Y.; Bergeret, A.; Longerey, M.; Che, J. Preparation of Polylactide/Graphene Composites from Liquid-Phase Exfoliated Graphite Sheets. Polym. Comp. 2014, 35, 396–403. [Google Scholar] [CrossRef]

- Ren, D.; Xu, D.; Yu, Y. Viscoelastic properties of bamboo fiber and its polymer composites revealed with nanodynamic mechanical analysis. In Proceedings of the 21st IAPRI World Conference on Packaging 2018—Packaging: Driving a Sustainable Future, Zhuhai, China, 19–22 June 2018; pp. 757–770. [Google Scholar] [CrossRef]

- Agrawal, R.; Nieto, A.; Chen, H.; Mora, M.; Agarwal, A. Nanoscale Damping Characteristics of Boron Nitride Nanotubes and Carbon Nanotubes Reinforced Polymer Composites. ACS Appl. Mater. Interfaces 2013, 5, 12057. [Google Scholar] [CrossRef]

- Chen, Y.; Balani, K.; Agarwal, A. Analytical model to evaluate interface characteristics of carbon nanotube reinforced aluminum oxide nanocomposites. Appl. Phys. Lett. 2008, 92, 011916. [Google Scholar] [CrossRef] [Green Version]

- Lahiri, D.; Rouzaud, F.; Namin, S.; Keshri, A.K.; Valdés, J.J.; Kos, L.; Tsoukias, N.; Agarwal, A. Carbon Nanotube Reinforced Polylactide–Caprolactone Copolymer: Mechanical Strengthening and Interaction with Human Osteoblasts in Vitro. ACS Appl. Mater. Interfaces 2009, 1, 2470–2476. [Google Scholar] [CrossRef]

- Dokukin, M.; Sokolov, I. High-resolution high-speed dynamic mechanical spectroscopy of cells and other soft materials with the help of atomic force microscopy. Sci. Rep. 2015, 5, 12630. [Google Scholar] [CrossRef]

- Rath, A.; Mathesan, S.; Ghosh, P. Nanomechanical characterization and molecular mechanism study of nanoparticle reinforced and cross-linked chitosan biopolymer. J. Mech. Behav. Mater. 2016, 55, 42–52. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Díez-Pascual, A.M.; Gómez-Fatou, M.A.; Ania, F.; Flores, A. Nanoindentation in polymer nanocomposites. Prog. Mater. Sci. 2015, 67, 1–94. [Google Scholar] [CrossRef] [Green Version]

- Han, C.H.; Sanei, S.H.R.; Alisafaei, F. On the origin of indentation size effects and depth dependent mechanical properties of elastic polymers. J. Polym. Eng. 2016, 36, 103–111. [Google Scholar] [CrossRef]

- Nĕmeček, J.; Lukeš, J.; Nĕmeček, J. High-speed mechanical mapping of blended cement pastes and its comparison with standard modes of nanoindentation. Mater. Today Commun. 2020, 23, 100806. [Google Scholar] [CrossRef]

- Nĕmeček, J.; Nĕmeček, J.; Lukeš, J. Nanoindentation and Accelerated Property Mapping of Portland Cement Paste. Acta Polytech. 2020, 27, 96–100. [Google Scholar] [CrossRef]

- Gao, Y.; Picot, O.T.; Bilotti, E.; Peijs, T. Influence of filler size on the properties of poly(lactic acid)(PLA)/graphene nanoplatelet (GNP) nanocomposites. Eur. Polym. J. 2017, 86, 117–131. [Google Scholar] [CrossRef]

- Batakliev, T.; Georgiev, V.; Angelov, V.; Ivanov, E.; Kalupgian, C.; Muñoz, P.A.R.; Fechine, G.J.M.; Andrade, R.J.E.; Kotsilkova, R. Synergistic Effect of Graphene Nanoplatelets and Multiwall Carbon Nanotubes Incorporated in PLA Matrix: Nanoindentation of Composites with Improved Mechanical Properties. J. Mater. Eng. Perform. 2021, 30, 3822–3830. [Google Scholar] [CrossRef]

- Batakliev, T.; Petrova-Doycheva, I.; Angelov, V.; Georgiev, V.; Ivanov, E.; Kotsilkova, R.; Casa, M.; Cirillo, C.; Adami, R.; Sarno, M.; et al. Effects of graphene nanoplatelets and multiwall carbon nanotubes on the structure and mechanical properties of Poly(lactic acid) composites: A comparative study. Appl. Sci. 2019, 9, 469. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Xu, P.; Han, R.; Ren, J.; Li, L.; Han, N.; Xing, F.; Zhu, J. A review on the mechanical properties for thin film and block structure characterized by using nanoscratch test. Nanotechnol. Rev. 2019, 8, 628–644. [Google Scholar] [CrossRef]

- Dasari, A.; Yu, Z.-Z.; Mai, Y.-W. Nanoscratching of nylon 66-based ternary nanocomposites. Acta Mater. 2007, 55, 635–646. [Google Scholar] [CrossRef]

- Odegard, G.M.; Gates, T.S.; Herring, H.M. Characterization of viscoelastic properties of polymeric materials through nanoindentation. Exp. Mech. 2005, 45, 130–136. [Google Scholar] [CrossRef]

- Grimmer, C.S.; Dharan, C.K.H. High-cycle fatigue life extension of glass fiber/polymer composites with carbon nanotubes. J. Wuhan Univ. Technol.–Mat. Sci. Edit. 2009, 24, 167–173. [Google Scholar] [CrossRef]

- Szeluga, U.; Kumanek, B.; Trzebicka, B. Synergy in Hybrid Polymer/Nanocarbon Composites. A Review. Compos. Part A 2015, 73, 204–231. [Google Scholar] [CrossRef]

| No | Nanocomposite Surface | Average Roughness, nm |

|---|---|---|

| 1 | PLA | 36.1 |

| 2 | 6 wt%GNP/PLA | 25.0 |

| 3 | 6 wt%MWCNT/PLA | 24.0 |

| 4 | 4.5 wt%GNP1.5 wt%MWCNT/PLA | 15.1 |

| 5 | 3 wt%GNP3 wt%MWCNT/PLA | 18.0 |

| 6 | 1.5 wt%GNP4.5 wt%MWCNT/PLA | 14.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Batakliev, T.; Ivanov, E.; Angelov, V.; Spinelli, G.; Kotsilkova, R. Advanced Nanomechanical Characterization of Biopolymer Films Containing GNPs and MWCNTs in Hybrid Composite Structure. Nanomaterials 2022, 12, 709. https://doi.org/10.3390/nano12040709

Batakliev T, Ivanov E, Angelov V, Spinelli G, Kotsilkova R. Advanced Nanomechanical Characterization of Biopolymer Films Containing GNPs and MWCNTs in Hybrid Composite Structure. Nanomaterials. 2022; 12(4):709. https://doi.org/10.3390/nano12040709

Chicago/Turabian StyleBatakliev, Todor, Evgeni Ivanov, Verislav Angelov, Giovanni Spinelli, and Rumiana Kotsilkova. 2022. "Advanced Nanomechanical Characterization of Biopolymer Films Containing GNPs and MWCNTs in Hybrid Composite Structure" Nanomaterials 12, no. 4: 709. https://doi.org/10.3390/nano12040709

APA StyleBatakliev, T., Ivanov, E., Angelov, V., Spinelli, G., & Kotsilkova, R. (2022). Advanced Nanomechanical Characterization of Biopolymer Films Containing GNPs and MWCNTs in Hybrid Composite Structure. Nanomaterials, 12(4), 709. https://doi.org/10.3390/nano12040709