SnSe-Coated Microfiber Resonator for All-Optical Modulation

Abstract

:1. Introduction

2. Device Fabrication

3. Principle of the All-Optical SnSe-Coated Microfiber Modulation

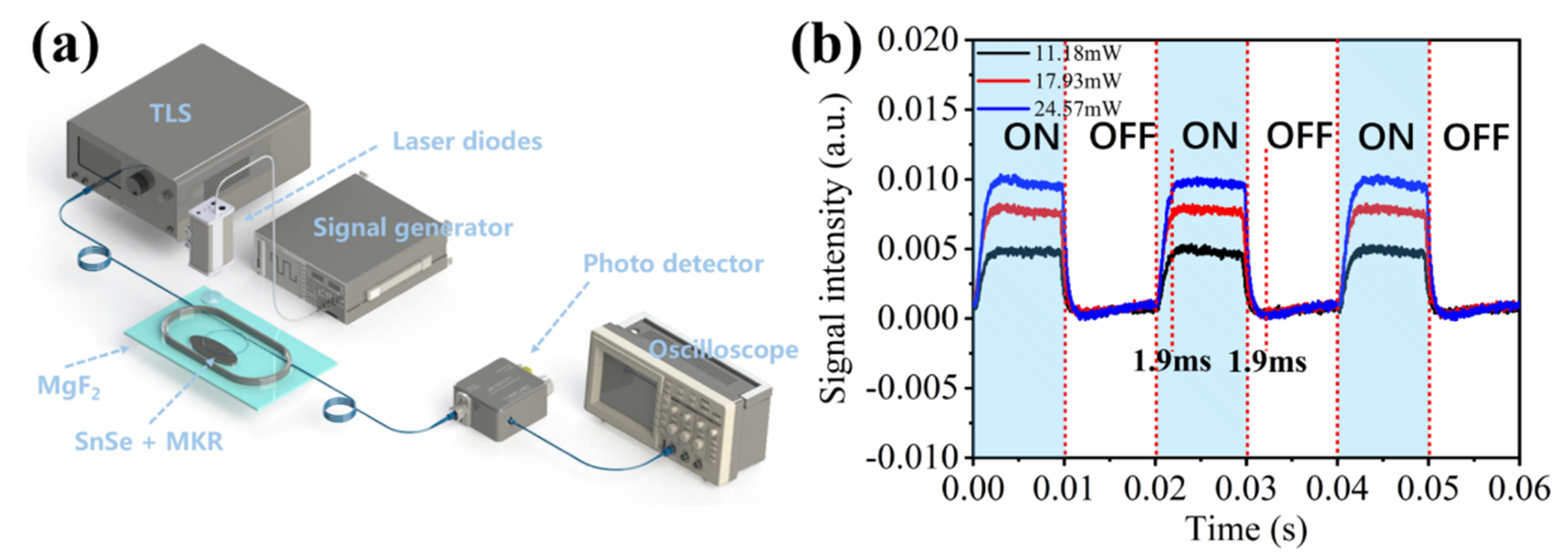

4. Experimental Details, Results, and Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tan, T.; Jiang, X.; Wang, C.; Yao, B.; Zhang, H. 2D Material Optoelectronics for Information Functional Device Applications: Status and Challenges. Adv. Sci. 2020, 7, 2000058. [Google Scholar] [CrossRef] [PubMed]

- Qiu, Q.; Huang, Z. Photodetectors of 2D Materials from Ultraviolet to Terahertz Waves. Adv. Mater. 2021, 33, 2008126. [Google Scholar] [CrossRef] [PubMed]

- Yu, S.; Wu, X.; Wang, Y.; Guo, X.; Tong, L. 2D Materials for Optical Modulation: Challenges and Opportunities. Adv. Mater. 2017, 29, 1606128. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Wang, C.; Ouyang, H.; Song, Y.; Jiang, T. All-optical modulation with 2D layered materials: Status and prospects. Nanophotonics 2020, 9, 2107–2124. [Google Scholar] [CrossRef]

- Fang, Y.; Ge, Y.; Wang, C.; Zhang, H. Mid-Infrared Photonics Using 2D Materials: Status and Challenges. Laser Photonics Rev. 2020, 14, 1900098. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.E.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric Field Effect in Atomically Thin Carbon Films. Science 2016, 306, 666–669. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Huang, Z.; Lang, Y.; Wang, X.; Zhu, H.; Shen, Z.; Guan, H.; Hong, J.; Gui, X.; Qiu, W.; et al. Broadband all-light-control with WS 2 coated microfibers. Opt. Express 2019, 27, 12817. [Google Scholar] [CrossRef]

- Manzeli, S.; Ovchinnikov, D.; Pasquier, D.; Yazyev, O.V.; Kis, A. 2D transition metal dichalcogenides. Nat. Rev. Mater. 2017, 2, 17033. [Google Scholar] [CrossRef]

- Jariwala, D.; Sangwan, V.K.; Lauhon, L.J.; Marks, T.J.; Hersam, M.C. Emerging device applications for semiconducting two-dimensional transition metal dichalcogenides. ACS Nano 2014, 8, 1102–1120. [Google Scholar] [CrossRef] [Green Version]

- Kumar, P.; Singh, S.; Hashmi, S.A.R.; Kim, K.H. MXenes: Emerging 2D materials for hydrogen storage. Nano Energy 2021, 85, 105989. [Google Scholar] [CrossRef]

- Liu, H.; Neal, A.T.; Zhu, Z.; Luo, Z.; Xu, X.; Tománek, D.; Ye, P.D. Phosphorene: An unexplored 2D semiconductor with a high hole mobility. ACS Nano 2014, 8, 4033–4041. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, Z.B.; Feng, M.; Jiang, W.S.; Xin, W.; Wang, P.; Sheng, Q.W.; Liu, Y.G.; Wang, D.N.; Zhou, W.Y.; Tian, J.G. Broadband all-optical modulation using a graphene-covered-microfiber. Laser Phys. Lett. 2013, 10, 065901. [Google Scholar] [CrossRef]

- Li, Y.; Xu, Z.; Tan, S.; Fang, F.; Yang, L.; Yuan, B.; Sun, Q. Recent advances in microfiber sensors for highly sensitive biochemical detection. J. Phys. D Appl. Phys. 2019, 52, 493002. [Google Scholar] [CrossRef]

- Li, C.; Yang, W.; Wang, M.; Yu, X.; Fan, J.; Xiong, Y.; Yang, Y.; Li, L. A review of coating materials used to improve the performance of optical fiber sensors. Sensors 2020, 20, 4215. [Google Scholar] [CrossRef]

- Hao, T.; Chang, Z.; Chiang, K.S. Externally pumped low-loss graphene-based fiber Mach-Zehnder all-optical switches with mW switching powers. Opt. Express 2019, 27, 4216. [Google Scholar] [CrossRef]

- Chen, G.; Zhang, Z.; Wang, X.; Li, H.; Jiang, M.; Guan, H.; Qiu, W.; Lu, H.; Dong, J.; Zhu, W.; et al. Highly sensitive all-optical control of light in WS 2 coated microfiber knot resonator. Opt. Express 2018, 26, 27650. [Google Scholar] [CrossRef]

- John, K.J.; Pradeep, B.; Mathai, E. Tin selenide (SnSe) thin films prepared by reactive evaporation. J. Mater. Sci. 1994, 29, 1581–1583. [Google Scholar] [CrossRef]

- Xu, H.; Hao, L.; Liu, H.; Dong, S.; Wu, Y.; Liu, Y.; Cao, B.; Wang, Z.; Ling, C.; Li, S.; et al. Flexible SnSe Photodetectors with Ultrabroad Spectral Response up to 10.6 μm Enabled by Photobolometric Effect. ACS Appl. Mater. Interfaces 2020, 12, 35250–35258. [Google Scholar] [CrossRef]

- Hao, L.; Du, Y.; Wang, Z.; Wu, Y.; Xu, H.; Dong, S.; Liu, H.; Liu, Y.; Xue, Q.; Han, Z.; et al. Wafer-size growth of 2D layered SnSe films for UV-Visible-NIR photodetector arrays with high responsitivity. Nanoscale 2020, 12, 7358–7365. [Google Scholar] [CrossRef]

- Pei, T.; Bao, L.; Ma, R.; Song, S.; Ge, B.; Wu, L.; Zhou, Z.; Wang, G.; Yang, H.; Li, J.; et al. Epitaxy of Ultrathin SnSe Single Crystals on Polydimethylsiloxane: In-Plane Electrical Anisotropy and Gate-Tunable Thermopower. Adv. Electron. Mater. 2016, 2, 1600292. [Google Scholar] [CrossRef]

- Pallavolu, M.R.; Minnam Reddy, V.R.; Guddeti, P.R.; Park, C. Development of SnSe thin films through selenization of sputtered Sn-metal films. J. Mater. Sci. Mater. Electron. 2019, 30, 15980–15988. [Google Scholar] [CrossRef]

- Lou, J.; Wang, Y.; Tong, L. Microfiber optical sensors: A review. Sensors 2014, 14, 5823–5844. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Brambilla, G.; Xu, F.; Horak, P.; Jung, Y.; Koizumi, F.; Sessions, N.P.; Koukharenko, E.; Feng, X.; Murugan, G.S.; Wilkinson, J.S.; et al. Optical fiber nanowires and microwires: Fabrication and applications. Opt. InfoBase Conf. Pap. 2009, 1, 107–161. [Google Scholar] [CrossRef]

- Anh Le, D.D.; Lee, S.; Han, Y.-G. Relative humidity sensor based on a few-mode microfiber knot resonator by mitigating group index difference. In Proceedings of the 2017 25th Optical Fiber Sensors Conference, Jeju, Korea, 24–28 April 2017. [Google Scholar] [CrossRef]

- Kazemzadeh, M.; Khodarahmi, M.J.; Karimi-Alavijeh, H. Polymer-Assisted Fabrication of High Performance Optical Microfiber Knot Resonators. In Proceedings of the 2019 27th Iranian Conference on Electrical Engineering (ICEE), Yazd, Iran, 30 April–2 May 2019; pp. 364–366. [Google Scholar] [CrossRef]

- El-Menyawy, E.M.; Azab, A.A.; El-Khalawany, L.M.; Okasha, N.; Terra, F.S. Influence of annealing temperatures on the structural, optical and electrical properties of SnSe films. J. Mater. Sci. Mater. Electron. 2018, 29, 8354–8363. [Google Scholar] [CrossRef]

- Lim, K.S.; Jasim, A.A.; Damanhuri, S.S.A.; Harun, S.W.; Rahman, B.M.A.; Ahmad, H. Resonance condition of a microfiber knot resonator immersed in liquids. Appl. Opt. 2011, 50, 5912–5916. [Google Scholar] [CrossRef]

- Wang, R.; Li, D.; Wu, H.; Jiang, M.; Sun, Z.; Tian, Y.; Bai, J.; Ren, Z. All-Optical Intensity Modulator by Polarization-Dependent Graphene-Microfiber Waveguide. IEEE Photonics J. 2017, 9, 1–8. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, F.; Tang, X.; Chen, X.; Chen, Y.; Huang, W.; Liang, Z.; Wu, L.; Ge, Y.; Song, Y.; et al. All-Optical Phosphorene Phase Modulator with Enhanced Stability under Ambient Conditions. Laser Photonics Rev. 2018, 12, 1800016. [Google Scholar] [CrossRef]

- Optical, A.; Systems, C.; Engineering, E. Thermo-optic all-optical devices based on two-dimensional materials. Photonics Res. 2018, 6, 22–28. [Google Scholar]

- Meng, Y.; Deng, L.; Liu, Z.; Xiao, H.; Guo, X.; Liao, M.; Guo, A.; Ying, T.; Tian, Y. All-optical tunable microfiber knot resonator with graphene-assisted sandwich structure. Opt. Express 2017, 25, 18451. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, L.; Ming, J.; Zhang, Z.; Shang, J.; Yu, L.; Guan, H.; Zhang, W.; Xu, Z.; Qiu, W.; Chen, Z.; et al. SnSe-Coated Microfiber Resonator for All-Optical Modulation. Nanomaterials 2022, 12, 694. https://doi.org/10.3390/nano12040694

Chen L, Ming J, Zhang Z, Shang J, Yu L, Guan H, Zhang W, Xu Z, Qiu W, Chen Z, et al. SnSe-Coated Microfiber Resonator for All-Optical Modulation. Nanomaterials. 2022; 12(4):694. https://doi.org/10.3390/nano12040694

Chicago/Turabian StyleChen, Lei, Jingyuan Ming, Zhishen Zhang, Jumei Shang, Lingyun Yu, Heyuan Guan, Weina Zhang, Zefeng Xu, Wentao Qiu, Zhe Chen, and et al. 2022. "SnSe-Coated Microfiber Resonator for All-Optical Modulation" Nanomaterials 12, no. 4: 694. https://doi.org/10.3390/nano12040694

APA StyleChen, L., Ming, J., Zhang, Z., Shang, J., Yu, L., Guan, H., Zhang, W., Xu, Z., Qiu, W., Chen, Z., & Lu, H. (2022). SnSe-Coated Microfiber Resonator for All-Optical Modulation. Nanomaterials, 12(4), 694. https://doi.org/10.3390/nano12040694