The Influence of Argon Cluster Ion Bombardment on the Characteristics of AlN Films on Glass-Ceramics and Si Substrates

Abstract

:1. Introduction

2. Materials and Methods

2.1. Deposition Technique and Cluster Treatment Setup

2.2. Characterization Methods

3. Results and Discussion

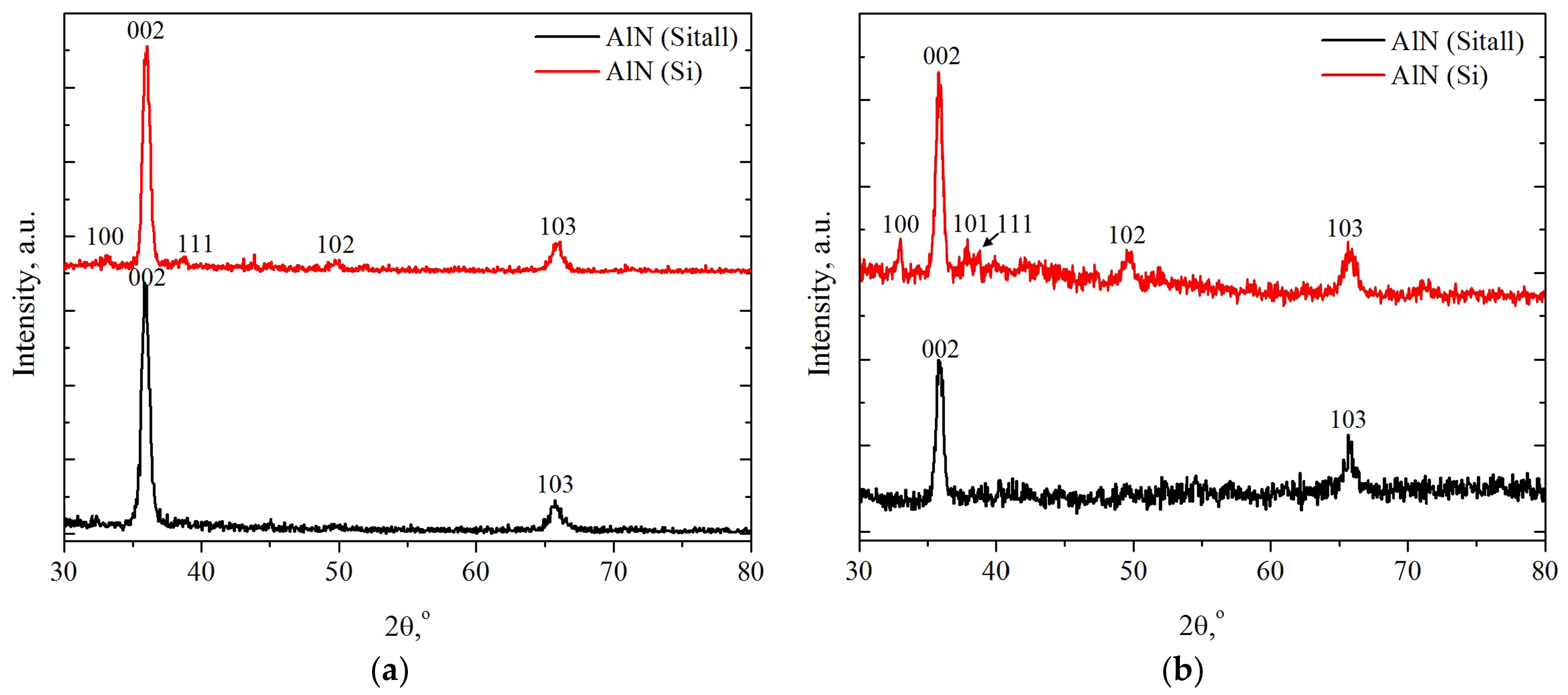

3.1. XRD Analysis

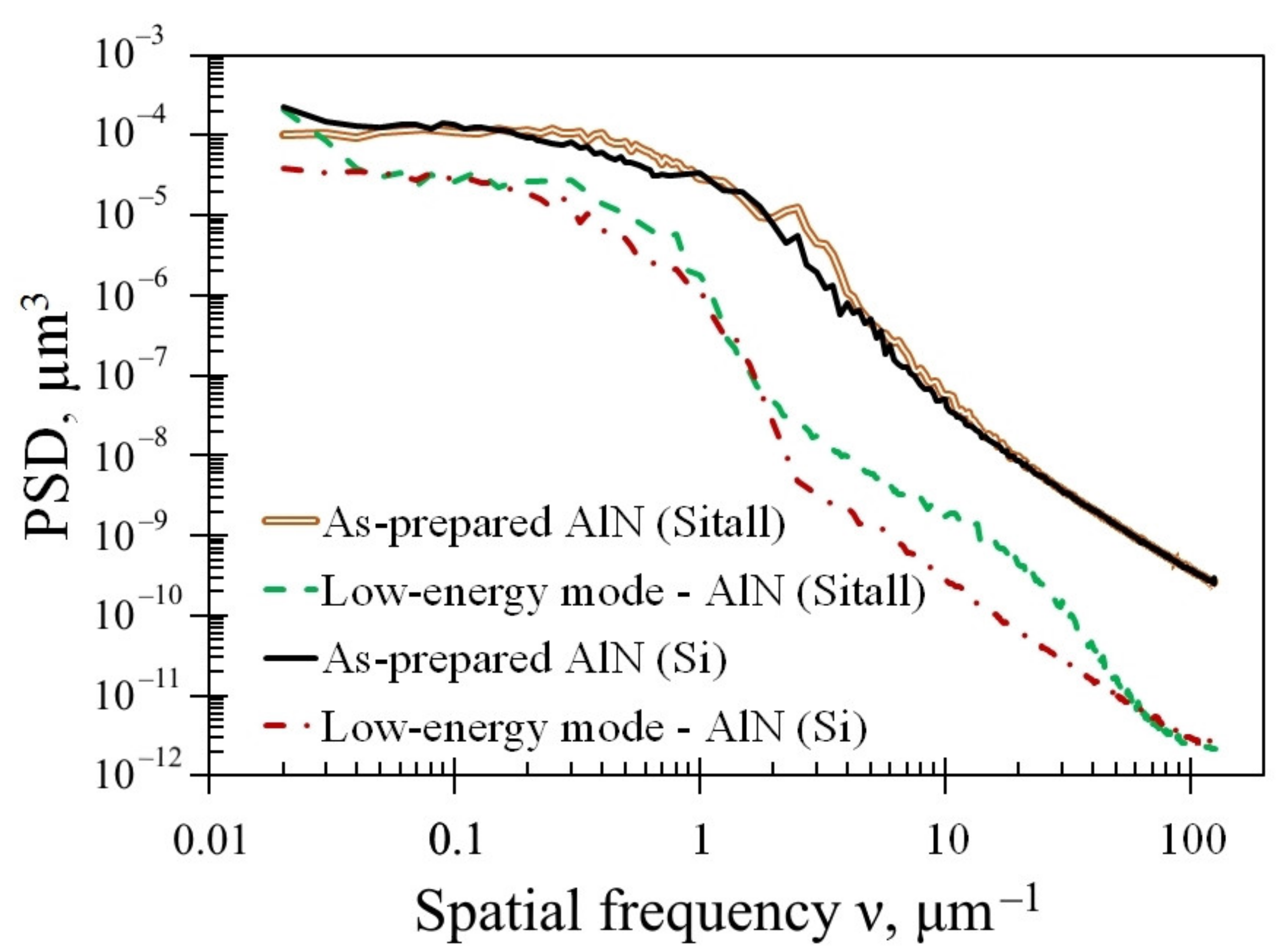

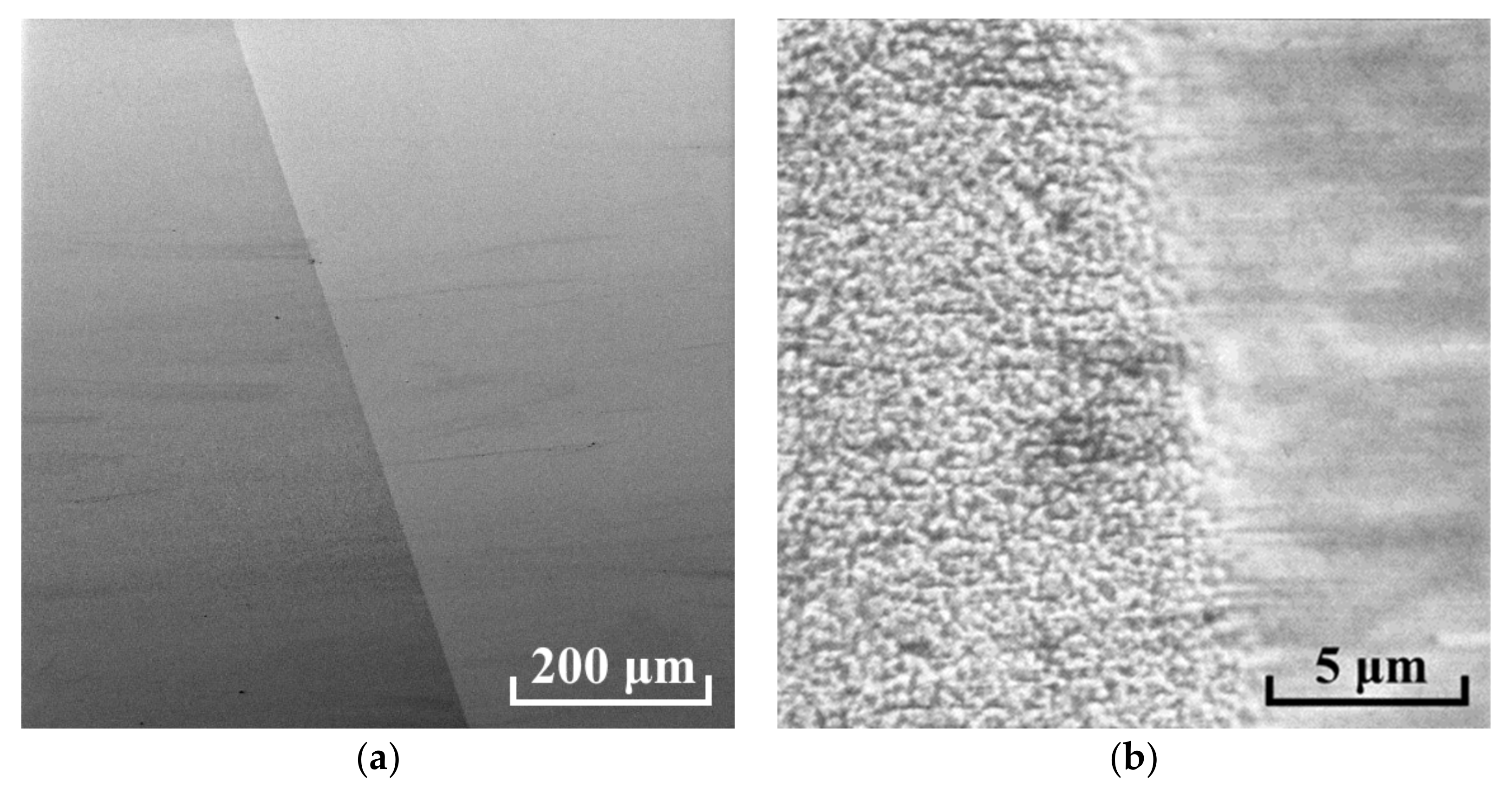

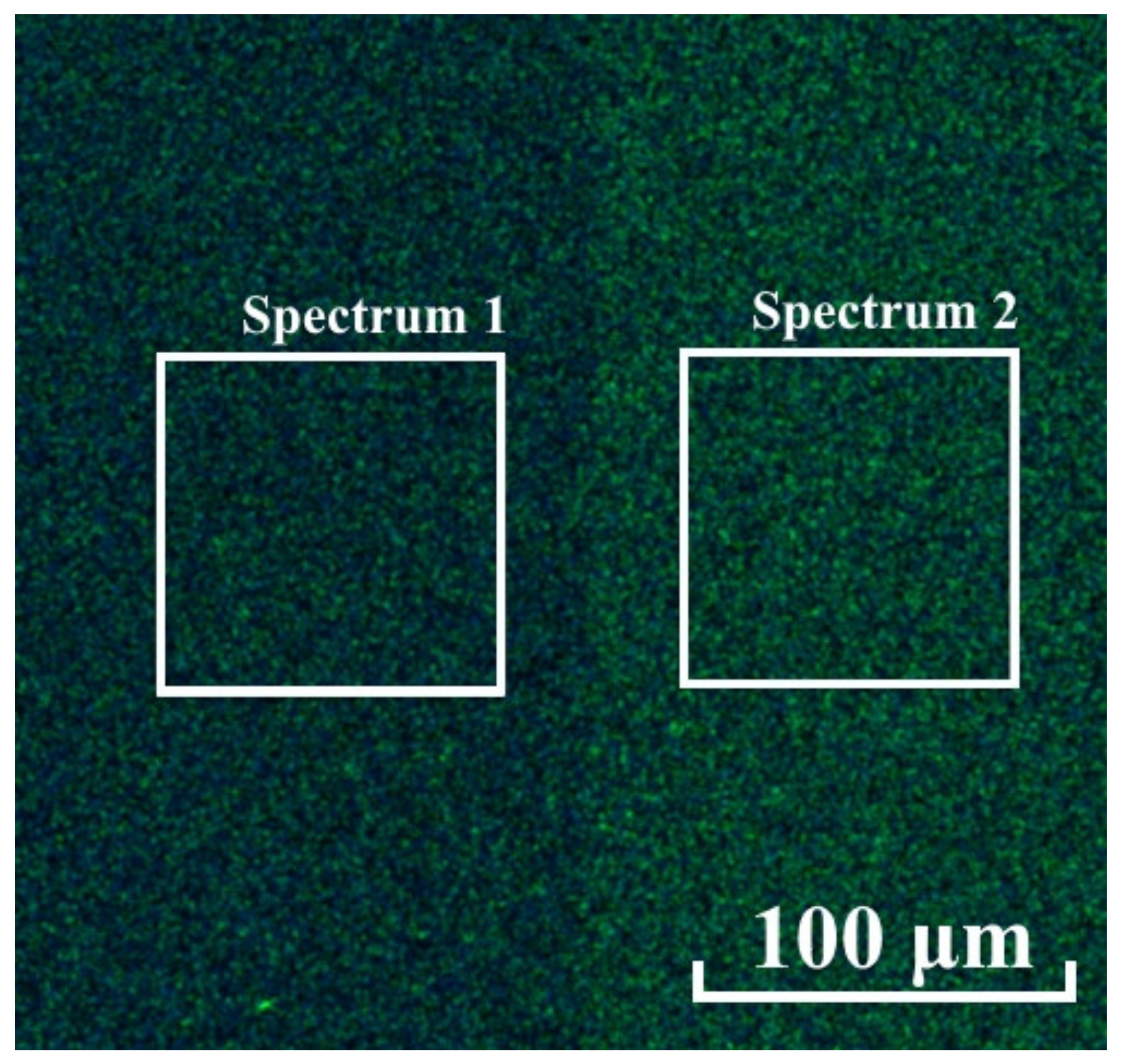

3.2. Surface Analysis

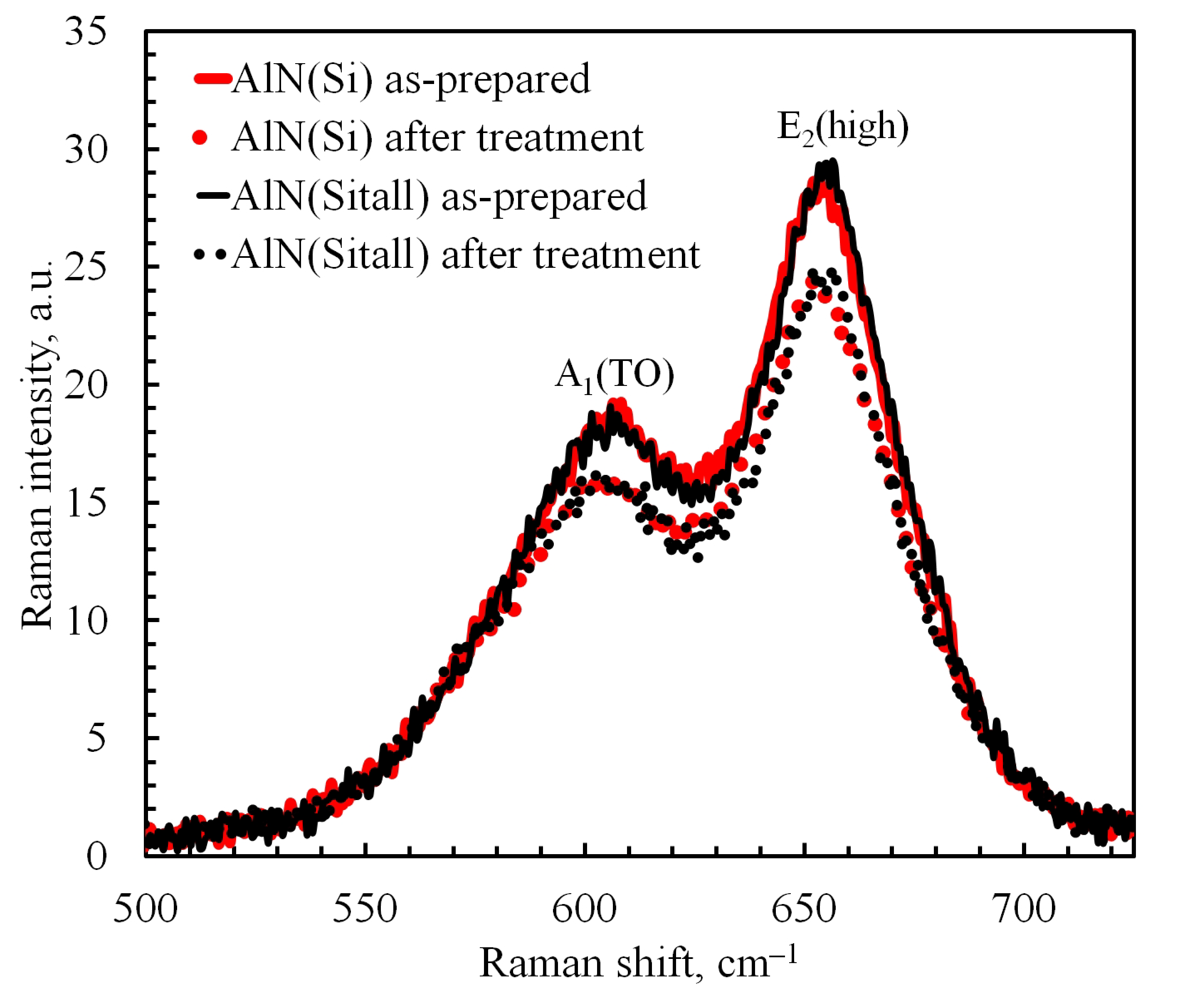

3.3. Raman Spectroscopy

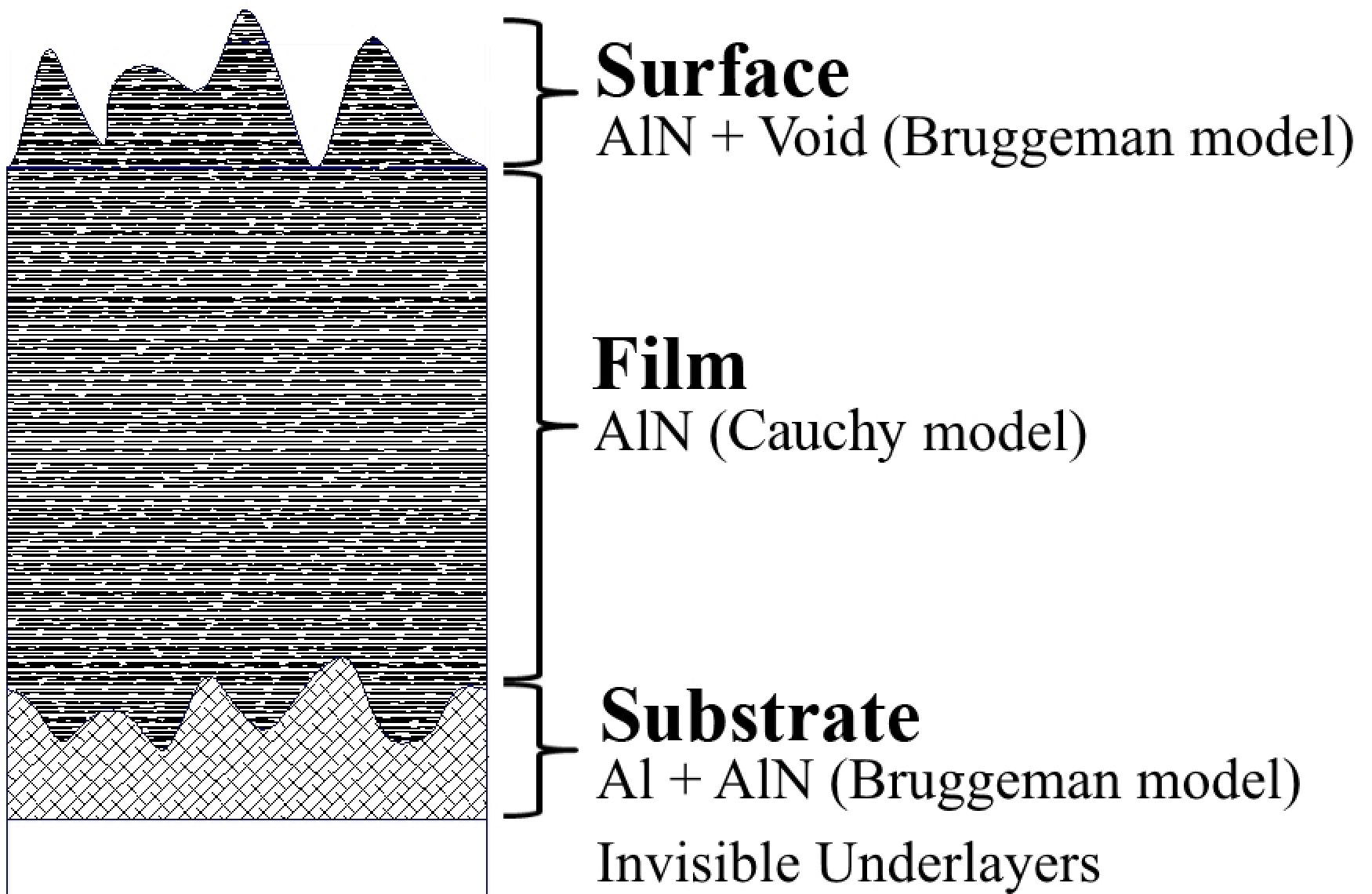

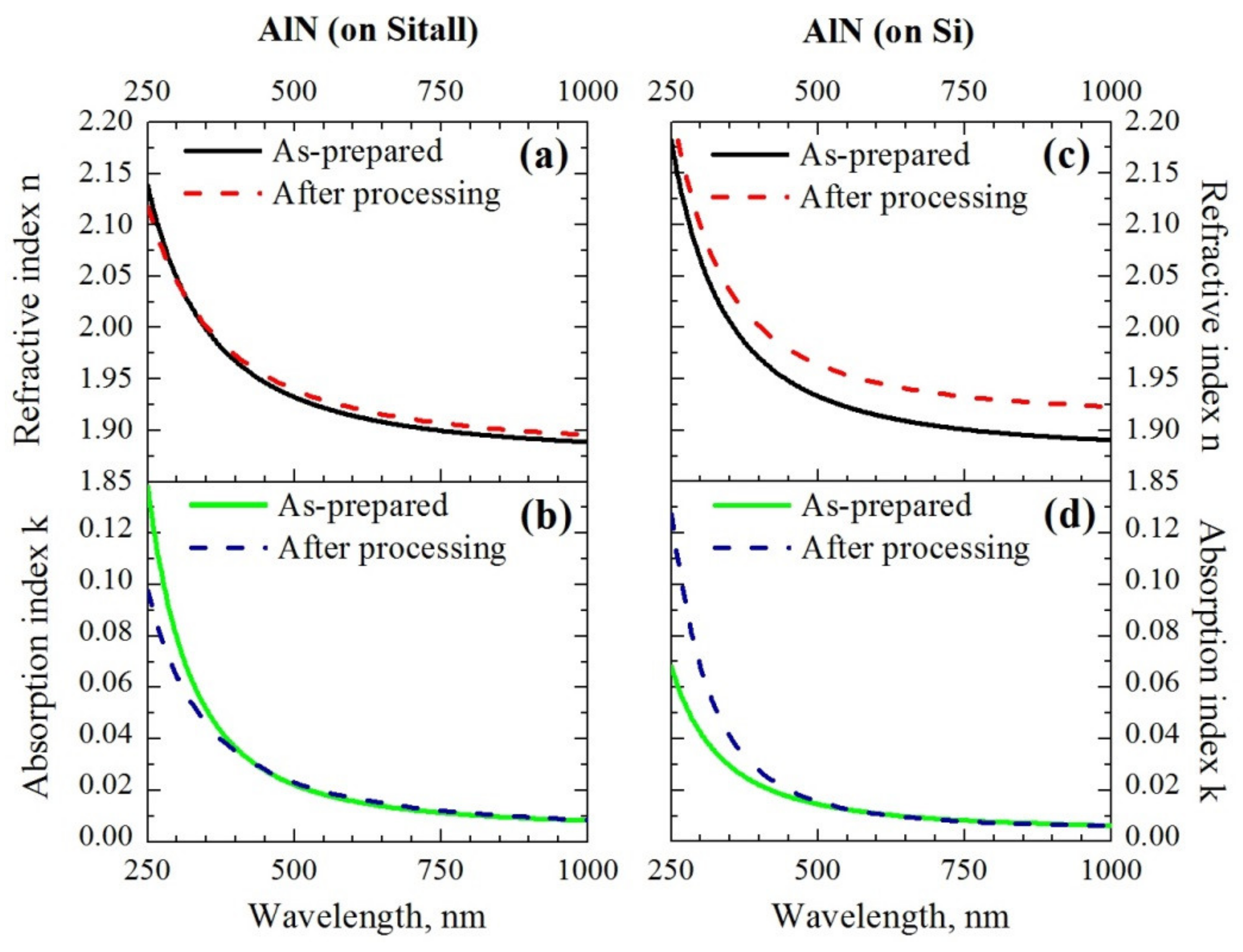

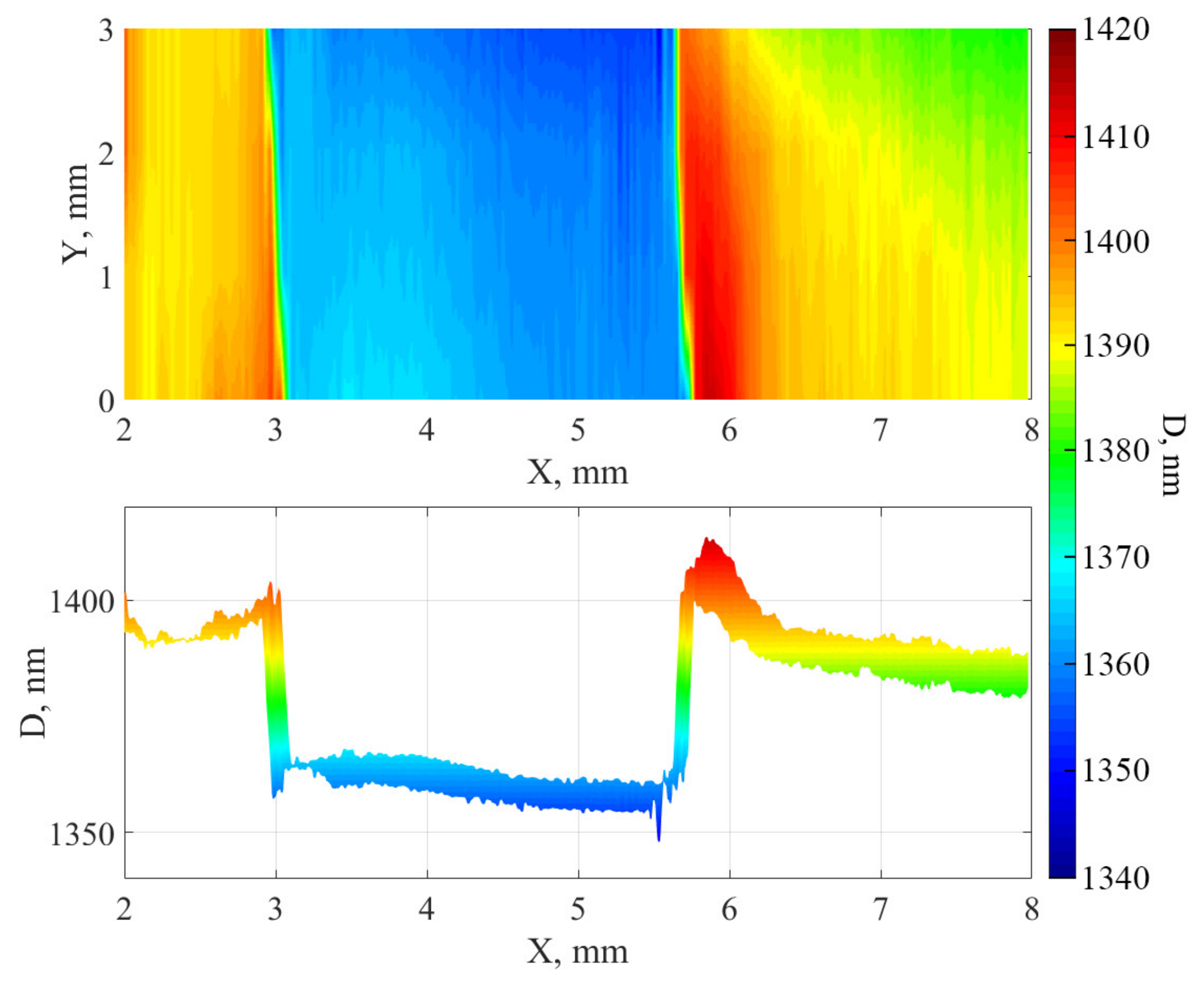

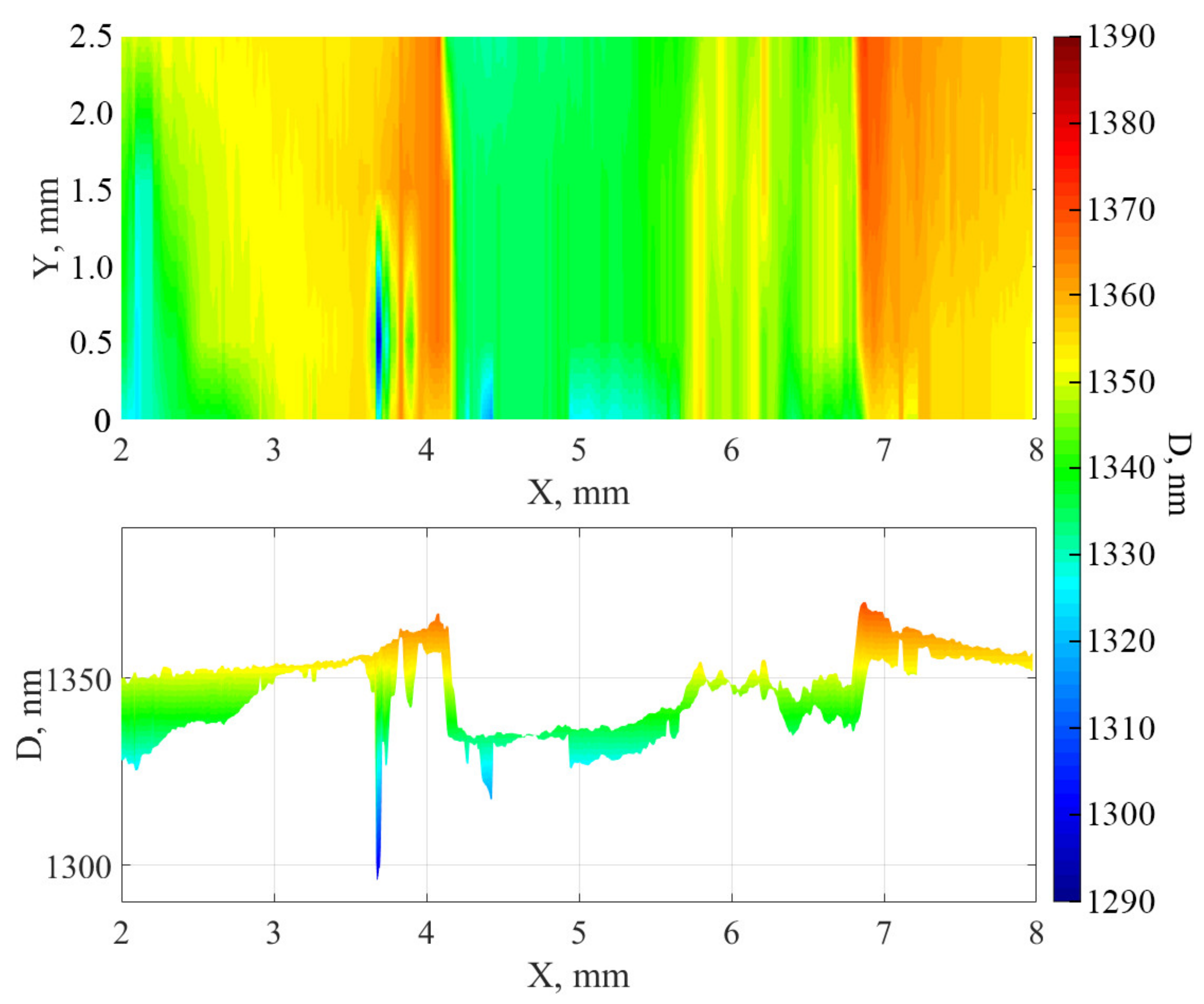

3.4. Ellipsometry

3.5. Scanning Electron Microscopy

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Piazza, G.; Felmetsger, V.; Muralt, P.; Olsson, R.H.; Ruby, R. Piezoelectric aluminum nitride thin films for microelectromechanical systems. MRS Bull. 2012, 37, 1051–1061. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Cai, Y.; Zhou, J.; Xie, Y.; Xu, Q.; Zou, Y.; Liu, S. Surface acoustic wave-based ultraviolet photodetectors: A review. Sci. Bull. 2020, 65, 587–600. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Cai, Y.; Zhang, Y.; Tovstopyat, A.; Liu, S.; Sun, C. Materials, Design, and Characteristics of Bulk Acoustic Wave Resonator: A Review. Micromachines 2020, 11, 630. [Google Scholar] [CrossRef] [PubMed]

- Hou, Y.; Zhang, M.; Han, G.; Si, C.; Zhao, Y.; Ning, J. A review: Aluminum nitride MEMS contour-mode resonator. J. Semicond. 2016, 37, 101001. [Google Scholar] [CrossRef]

- Iborra, E.; Olivares, J.; Clement, M.; Vergara, L.; Sanz-Hervás, A.; Sangrador, J. Piezoelectric properties and residual stress of sputtered AlN thin films for MEMS applications. Sens. Actuators A Phys. 2004, 115, 501–507. [Google Scholar] [CrossRef]

- Oikawa, H.; Akiyama, R.; Kanazawa, K.; Kuroda, S.; Harayama, I.; Nagashima, K.; Sekiba, D.; Ashizawa, Y.; Tsukamoto, A.; Nakagawa, K. Deposition and characterization of amorphous aluminum nitride thin films for a gate insulator. Thin Solid Film. 2015, 574, 110–114. [Google Scholar] [CrossRef]

- Iqbal, A.; Mohd-Yasin, F. Reactive Sputtering of Aluminum Nitride (002) Thin Films for Piezoelectric Applications: A Review. Sensors 2018, 18, 1797. [Google Scholar] [CrossRef] [Green Version]

- Harris, H.; Biswas, N.; Temkin, H.; Gangopadhyay, S.; Strathman, M. Plasma enhanced metalorganic chemical vapor deposition of amorphous aluminum nitride. J. Appl. Phys. 2001, 90, 5825–5831. [Google Scholar] [CrossRef] [Green Version]

- Fei, C.; Liu, X.; Zhu, B.; Li, D.; Yang, X.; Yang, Y.; Zhou, Q. AlN piezoelectric thin films for energy harvesting and acoustic devices. Nano Energy 2018, 51, 146–161. [Google Scholar] [CrossRef]

- Cimalla, V.; Pezoldt, J.; Ambacher, O. Group III nitride and SiC based MEMS and NEMS: Materials properties, technology and applications. J. Phys. D Appl. Phys. 2007, 40, 6386–6434. [Google Scholar] [CrossRef]

- Lin, C.-M.; Chen, Y.-Y.; Felmetsger, V.V.; Lien, W.-C.; Riekkinen, T.; Senesky, D.G.; Pisano, A.P. Surface acoustic wave devices on AlN/3C–SiC/Si multilayer structures. J. Micromech. Microeng. 2013, 23, 025019. [Google Scholar] [CrossRef]

- Xiong, C.; Pernice, W.H.P.; Sun, X.; Schuck, C.; Fong, K.Y.; Tang, H.X. Aluminum nitride as a new material for chip-scale optomechanics and nonlinear optics. New J. Phys. 2012, 14, 95014. [Google Scholar] [CrossRef]

- Di Pietrantonio, F.; Benetti, M.; Cannata, D.; Beccherelli, R.; Verona, E. Guided lamb wave electroacoustic devices on micromachined AlN/Al plates. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2010, 57, 1175–1182. [Google Scholar] [CrossRef]

- Khelif, A.; Wilm, M.; Laude, V.; Ballandras, S.; Djafari-Rouhani, B. Guided elastic waves along a rod defect of a two-dimensional phononic crystal. Phys. Rev. E 2004, 69, 067601. [Google Scholar] [CrossRef] [Green Version]

- DeMiguel-Ramos, M.; Clement, M.; Olivares, J.; Capilla, J.; Sangrador, J.; Iborra, E. Induced surface roughness to promote the growth of tilted-AlN films for shear mode resonators. In Proceedings of the 2013 Joint European Frequency and Time Forum & International Frequency Control Symposium (EFTF/IFC), Prague, Czech Republic, 21–25 July 2013; pp. 274–277. [Google Scholar] [CrossRef]

- Bryan, I.; Bryan, Z.; Bobea, M.; Hussey, L.; Kirste, R.; Collazo, R.; Sitar, Z. Homoepitaxial AlN thin films deposited on m-plane (11¯00) AlN substrates by metalorganic chemical vapor deposition. J. Appl. Phys. 2014, 116, 133517. [Google Scholar] [CrossRef]

- Jacquot, A.; Lenoir, B.; Dauscher, A.; Verardi, P.; Craciun, F.; Stölzer, M.; Gartnerd, M.; Dinescu, M. Optical and thermal characterization of AlN thin films deposited by pulsed laser deposition. Appl. Surf. Sci. 2002, 186, 507–512. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, M.S.; Yun, H.J.; Ryu, S.Y.; Choi, B.J. Effect of growth temperature on AlN thin films fabricated by atomic layer deposition. Ceram. Int. 2018, 44, 17447–17452. [Google Scholar] [CrossRef]

- Kumari, N.; Singh, A.K.; Barhai, P.K. Study of properties of AlN thin films deposited by reactive magnetron sputtering. Int. J. Thin Fil. Sci. Tec. 2014, 3, 43–49. [Google Scholar] [CrossRef]

- Aissa, K.A.; Achour, A.; Elmazria, O.; Simon, Q.; Elhosni, M.; Boulet, P.; Robert, S.; Djouadi, M.A. AlN films deposited by dc magnetron sputtering and high power impulse magnetron sputtering for SAW applications. J. Phys. D Appl. Phys. 2015, 48, 145307. [Google Scholar] [CrossRef]

- Phan, D.-T.; Chung, G.-S. The effect of geometry and post-annealing on surface acoustic wave characteristics of AlN thin films prepared by magnetron sputtering. Appl. Surf. Sci. 2011, 257, 8696–8701. [Google Scholar] [CrossRef]

- Tan, X.-Q.; Liu, J.-Y.; Niu, J.-R.; Liu, J.-Y.; Jun-Ying Tian, J.-Y. Recent Progress in Magnetron Sputtering Technology Used on Fabrics. Materials 2018, 11, 1953. [Google Scholar] [CrossRef] [Green Version]

- Gudmundsson, J.T. Physics and technology of magnetron sputtering discharges. Plasma Sources Sci. Technol. 2020, 29, 113001. [Google Scholar] [CrossRef]

- Liang, J.; Liu, Q.; Li, T.; Luo, Y.; Lu, S.; Shi, X.; Zhang, F.; Asiri, A.M.; Sun, X. Magnetron sputtering enabled sustainable synthesis of nanomaterials for energy electrocatalysis. Green Chem. 2021, 23, 2834–2867. [Google Scholar] [CrossRef]

- Khan, S.; Shahid, M.; Mahmood, A.; Shah, A.; Ahmed, I.; Mehmood, M.; Aziz, U.; Raza, Q.; Alam, M. Texture of the nano-crystalline AlN thin films and the growth conditions in DC magnetron sputtering. Prog. Nat. Sci. Mater. Int. 2015, 25, 282–290. [Google Scholar] [CrossRef]

- Riah, B.; Camus, J.; Ayad, A.; Rammal, M.; Zernadji, R.; Rouag, N.; Djouadi, M.A. Hetero-Epitaxial Growth of AlN Deposited by DC Magnetron Sputtering on Si(111) Using a AlN Buffer Layer. Coatings 2021, 11, 1063. [Google Scholar] [CrossRef]

- Auner, G.W.; Jin, F.; Naik, V.M.; Naik, R. Microstructure of low temperature grown AlN thin films on Si(111). J. Appl. Phys. 1999, 85, 7879–7883. [Google Scholar] [CrossRef]

- Medjani, F.; Sanjinés, R.; Allidi, G.; Karimi, A. Effect of substrate temperature and bias voltage on the crystallite orientation in RF magnetron sputtered AlN thin films. Thin Solid Film. 2006, 515, 260–265. [Google Scholar] [CrossRef]

- Loebl, H.P.; Klee, M.; Metzmacher, C.; Brand, W.; Milsom, R.; Lok, P. Piezoelectric thin AlN films for bulk acoustic wave (BAW) resonators. Mater. Chem. Phys. 2003, 79, 143–146. [Google Scholar] [CrossRef]

- Flannery, C.M.; Von Kiedrowski, H. Effects of surface roughness on surface acoustic wave propagation in semiconductor materials. Ultrasonics 2002, 40, 83–87. [Google Scholar] [CrossRef]

- Flannery, C.M.; Von Kiedrowski, H. Dispersion of surface acoustic waves on rough anisotropic materials. In Proceedings of the 2001 IEEE Ultrasonics Symposium. Proceedings, An International Symposium, Atlanta, GA, USA, 7–10 October 2001; Volume 1, pp. 583–586. [Google Scholar] [CrossRef]

- Assouar, M.B.; Elmazria, O.; Kirsch, P.; Alnot, P.; Mortet, V.; Tiusan, C. High-frequency surface acoustic wave devices based on AlN/diamond layered structure realized using e-beam lithography. J. Appl. Phys. 2007, 101, 114507. [Google Scholar] [CrossRef] [Green Version]

- Yamada, I. Materials Processing by Cluster Ion Beams: History, Technology and Applications, 1st ed.; CRC Press: London, UK, 2015; 260p. [Google Scholar]

- Yamada, I.; Matsuo, J.; Toyoda, N.; Kirkpatrick, A. Materials processing by gas cluster ion beams. Mat. Sci. Eng. R 2001, 34, 231–295. [Google Scholar] [CrossRef]

- Wu, A.T.; Swenson, D.R.; Insepov, Z. Modification on surface oxide layer structure and surface morphology of niobium by gas cluster ion beam treatments. Phys. Rev. Spec. Top. 2010, 13, 093504. [Google Scholar] [CrossRef]

- Ieshkin, A.E.; Kireev, D.S.; Ermakov, Y.A.; Trifonov, A.S.; Presnov, D.E.; Garshev, A.V.; Anufriev, Y.V.; Prokhorova, I.G.; Krupenin, V.A.; Chernysh, V.S. The quantitative analysis of silicon carbide surface smoothing by Ar and Xe cluster ions. Nucl. Instrum. Methods Phys. Res. B 2018, 421, 27–31. [Google Scholar] [CrossRef]

- Korobeishchikov, N.G.; Nikolaev, I.V.; Roenko, M.A. Finishing Surface Treatment of Potassium Titanyl Phosphate Single Crystals by Argon Cluster Ions. Tech. Phys. Lett. 2019, 45, 274–277. [Google Scholar] [CrossRef]

- Swenson, D.R.; Degenkolb, E.; Insepov, Z. Study of gas cluster ion beam surface treatments for mitigating RF breakdown. Phys. C 2006, 441, 75–78. [Google Scholar] [CrossRef]

- Chen, H.; Chen, F.; Wang, X.M.; Yu, X.K.; Liu, J.R.; Ma, K.B.; Chu, W.K.; Cheng, H.H.; Yu, I.S.; Ho, Y.T.; et al. Smoothing of Si0.7Ge0.3 virtual substrates by gas-cluster-ion beam. Appl. Phys. Lett. 2005, 87, 103504. [Google Scholar] [CrossRef]

- Toyoda, N.; Yamada, I. Gas cluster ion beam technology for nano-fabrication. Adv. Sci. Technol. 2013, 82, 1–8. [Google Scholar] [CrossRef]

- Teo, E.J.; Toyoda, N.; Yang, C.; Bettiol, A.A.; Teng, J.H. Nanoscale smoothing of plasmonic films and structures. Appl. Phys. A 2014, 117, 719–723. [Google Scholar] [CrossRef]

- Nikolaev, I.V.; Korobeishchikov, N.G.; Roenko, M.A.; Geydt, P.V.; Strunin, V.I. Smoothing of Polycrystalline AlN Thin Films with Argon Cluster Ions. Tech. Phys. Lett. 2021. [Google Scholar] [CrossRef]

- Korobeishchikov, N.G.; Nikolaev, I.V.; Roenko, M.A. Effect of argon cluster ion beam on fused silica surface morphology. Nucl. Instrum. Methods Phys. Res. Sect. B 2019, 438, 1–5. [Google Scholar] [CrossRef]

- Korobeishchikov, N.G.; Stishenko, P.V.; Popenko, Y.A.; Roenko, M.A.; Nikolaev, I.V. Interaction of accelerated argon cluster ions with a silicon dioxide surface. AIP Conf. Proc. 2017, 1876, 020064. [Google Scholar] [CrossRef]

- Korobeishchikov, N.G.; Nikolaev, I.V.; Roenko, M.A.; Atuchin, V.V. Precise sputtering of silicon dioxide by argon cluster ion beams. Appl. Phys. A 2018, 124, 833. [Google Scholar] [CrossRef]

- Toby, B.H.; Von Dreele, R.B. GSAS-II: The genesis of a modern open-source all purpose crystallography software package. J. Appl. Cryst. 2013, 46, 544–549. [Google Scholar] [CrossRef]

- Wojdyr, M. Fityk: A general-purpose peak fitting program. J. Appl. Cryst. 2010, 43, 1126–1128. [Google Scholar] [CrossRef]

- Spesivtsev, E.V.; Rykhlitskii, S.V.; Shvets, V.A. Development of methods and instruments for optical ellipsometry at the Institute of Semiconductor Physics of the Siberian Branch of the Russian Academy of Sciences. Optoelectron. Instrument. Proc. 2011, 47, 419–425. [Google Scholar] [CrossRef]

- Azzam, R.M.A.; Bashara, N.M. Ellipsometry and Polarized Light, 1st ed.; North-Holland Pub. Co.: Amsterdam, The Netherlands, 1977; 529p. [Google Scholar]

- Tompkins, H.G.; Irene, E.A. Handbook of Ellipsometry, 1st ed.; William Andrew Publishing: Norwich, NY, USA; Springer: Berlin/Heidelberg, Germany, 2005; Volume 16, 870p. [Google Scholar]

- Sanz-Hervás, A.; Clement, M.; Iborra, E.; Vergara, L.; Olivares, J.; Sangrador, J. Degradation of the piezoelectric response of sputtered c-axis AlN thin films with traces of non-(0002) X-ray diffraction peaks. Appl. Phys. Lett. 2006, 88, 161915. [Google Scholar] [CrossRef]

- Sanz-Hervás, A.; Iborra, E.; Clement, M.; Sangrador, J.; Aguilar, M. Influence of crystal properties on the absorp-tion IR spectra of polycrystalline AlN thin films. Diam. Relat. Mater. 2003, 12, 1186–1189. [Google Scholar] [CrossRef]

- Artieda, A.; Barbieri, M.; Sandu, C.S.; Muralt, P. Effect of substrate roughness on c-oriented AlN thin films. J. Appl. Phys. 2009, 105, 024504. [Google Scholar] [CrossRef]

- Hwang, B.-H.; Chen, C.-S.; Lu, H.-Y.; Hsu, T.-C. Growth mechanism of reactively sputtered aluminum nitride thin films. Mat. Sci. Eng. A 2002, 325, 380–388. [Google Scholar] [CrossRef]

- Duquenne, C.; Besland, M.-P.; Tessier, P.Y.; Gautron, E.; Scudeller, Y.; Averty, D. Thermal conductivity of aluminium nitride thin films prepared by reactive magnetron sputtering. J. Phys. D: Appl. Phys. 2011, 45, 015301. [Google Scholar] [CrossRef]

- Fang, S.J.; Haplepete, S.; Chen, W.; Helms, C.R. Analyzing atomic force microscopy images using spectral methods. J. Appl. Phys. 1997, 82, 5891–5898. [Google Scholar] [CrossRef]

- Duparré, A.; Ferre-Borrull, J.; Gliech, S.; Notni, G.; Steinert, J.; Bennett, J.M. Surface characterization techniques for determining the root-mean-square roughness and power spectral densities of optical components. Appl. Opt. 2002, 41, 154–171. [Google Scholar] [CrossRef] [Green Version]

- Persson, B.N.J.; Albohr, O.; Tartaglino, U.; Volokitin, A.I.; Tosatti, E. On the nature of surface roughness with application to contact mechanics, sealing, rubber friction and adhesion. J. Phys. Condens. Matter. 2004, 17, R1–R62. [Google Scholar] [CrossRef] [Green Version]

- Martínez, J.F.G.; Nieto-Carvajal, I.; Abad, J.; Colchero, J. Nanoscale measurement of the power spectral density of surface roughness: How to solve a difficult experimental challenge. Nanoscale Res. Lett. 2012, 7, 174. [Google Scholar] [CrossRef] [Green Version]

- Redkin, A.N.; Yakimov, E.E.; Roshchupkin, D.V.; Korepanov, V.I. Characterization of highly textured piezoelectric AlN films obtained from aluminum and ammonium chloride by a simple vapor deposition process. Thin Solid Film. 2019, 684, 15–20. [Google Scholar] [CrossRef]

- Chen, D.; Xu, D.; Wang, J.; Zhao, B.; Zhang, Y. Influence of the texture on Raman and X-ray diffraction characteristics of poly-crystalline AlN films. Thin Solid Film. 2008, 517, 986–989. [Google Scholar] [CrossRef]

- Cao, Y.G.; Chen, X.L.; Lan, Y.C.; Li, J.Y.; Xu, Y.P.; Xu, T.; Liu, Q.L.; Liang, J.K. Blue emission and Raman scattering spectrum from AlN nanocrystalline powders. J. Cryst. Growth 2000, 213, 198–202. [Google Scholar] [CrossRef]

- Lughi, V.; Clarke, D.R. Defect and stress characterization of AlN films by Raman spectroscopy. Appl. Phys. Lett. 2006, 89, 241911. [Google Scholar] [CrossRef]

- Sachkov, V.A.; Volodin, V.A. Localization of Optical Phonons in Diamond Nanocrystals. J. Exp. Theor. Phys. 2019, 129, 816–824. [Google Scholar] [CrossRef]

- Tai, Z.; Yang, C.; Hu, X.; Xie, Y. Structural and optical properties of Er-doped AlN. Integr. Ferroelectr. 2018, 192, 154–163. [Google Scholar] [CrossRef]

- Venkataraj, S.; Severin, D.; Drese, R.; Koerfer, F.; Wuttig, M. Structural, optical and mechanical properties of aluminium nitride films prepared by reactive DC magnetron sputtering. Thin Solid Film. 2006, 502, 235–239. [Google Scholar] [CrossRef]

| Scan Size, μm2 | Roughness Parameter | AlN (on Si) | AlN (on Sitall) | ||

|---|---|---|---|---|---|

| As Prepared | After Cluster Processing | As Prepared | After Cluster Processing | ||

| 100 × 100 | ⟨Rq⟩, nm | 9.7 | 4.2 | 9.2 | 4.8 |

| ⟨σeff⟩, nm | 10.0 | 4.5 | 9.7 | 5.0 | |

| 40 × 40 | ⟨Rq⟩, nm | 11.0 | 4.2 | 13.7 | 4.8 |

| ⟨σeff⟩, nm | 11.8 | 4.2 | 14.8 | 5.0 | |

| 2 × 2 | ⟨Rq⟩, nm | 20.5 | 1.5 | 22.3 | 1.8 |

| ⟨σeff⟩, nm | 21.5 | 1.5 | 24.0 | 3.2 | |

| - | ⟨σtotal⟩, nm | 29.2 | 9.7 | 32.5 | 12.5 |

| Raman Peak Parameters | AlN (on Si) | AlN (on Sitall) | ||

|---|---|---|---|---|

| As Prepared | After Cluster Processing | As Prepared | After Cluster Processing | |

| A1(TO) position, cm−1 | 602.0 | 599.6 | 601.0 | 599.7 |

| A1(TO) FWHM, cm−1 | 57.1 | 59.3 | 55.6 | 58.7 |

| E2(high) position, cm−1 | 655.9 | 655.2 | 655.9 | 656.0 |

| E2(high) FWHM, cm−1 | 39.5 | 41.5 | 38.8 | 39.1 |

| A1(TO)/E2(high) | 0.67 | 0.64 | 0.65 | 0.65 |

| Parameter | AlN (on Sitall) | AlN (on Si) | ||||

|---|---|---|---|---|---|---|

| As Prepared | After Cluster Processing | *After Cluster Processing | As Prepared |

After Cluster Processing |

*After Cluster Processing | |

| d2Ra(AFM), ± 0.05 nm | 14–15.6 | 7.4 | 7.4 | 15–22 | 6.4–7.2 | 6.4–7.2 |

| d2Ra, ± 1.5 nm | 20.2 | 12.4 | 7.4 | 18.7 | 26.5 | 7.2 |

| Dtotal, ± 5 nm | 1490 | 1465 | 1453 | 1460 | 1455 | 1415 |

| Hetch, ± 5 nm | - | −25 | −37 | - | −5 | −45 |

| Hetch(AFM), ± 5 nm | - | −43 | −43 | - | −30 | −30 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nikolaev, I.V.; Geydt, P.V.; Korobeishchikov, N.G.; Kapishnikov, A.V.; Volodin, V.A.; Azarov, I.A.; Strunin, V.I.; Gerasimov, E.Y. The Influence of Argon Cluster Ion Bombardment on the Characteristics of AlN Films on Glass-Ceramics and Si Substrates. Nanomaterials 2022, 12, 670. https://doi.org/10.3390/nano12040670

Nikolaev IV, Geydt PV, Korobeishchikov NG, Kapishnikov AV, Volodin VA, Azarov IA, Strunin VI, Gerasimov EY. The Influence of Argon Cluster Ion Bombardment on the Characteristics of AlN Films on Glass-Ceramics and Si Substrates. Nanomaterials. 2022; 12(4):670. https://doi.org/10.3390/nano12040670

Chicago/Turabian StyleNikolaev, Ivan V., Pavel V. Geydt, Nikolay G. Korobeishchikov, Aleksandr V. Kapishnikov, Vladimir A. Volodin, Ivan A. Azarov, Vladimir I. Strunin, and Evgeny Y. Gerasimov. 2022. "The Influence of Argon Cluster Ion Bombardment on the Characteristics of AlN Films on Glass-Ceramics and Si Substrates" Nanomaterials 12, no. 4: 670. https://doi.org/10.3390/nano12040670

APA StyleNikolaev, I. V., Geydt, P. V., Korobeishchikov, N. G., Kapishnikov, A. V., Volodin, V. A., Azarov, I. A., Strunin, V. I., & Gerasimov, E. Y. (2022). The Influence of Argon Cluster Ion Bombardment on the Characteristics of AlN Films on Glass-Ceramics and Si Substrates. Nanomaterials, 12(4), 670. https://doi.org/10.3390/nano12040670