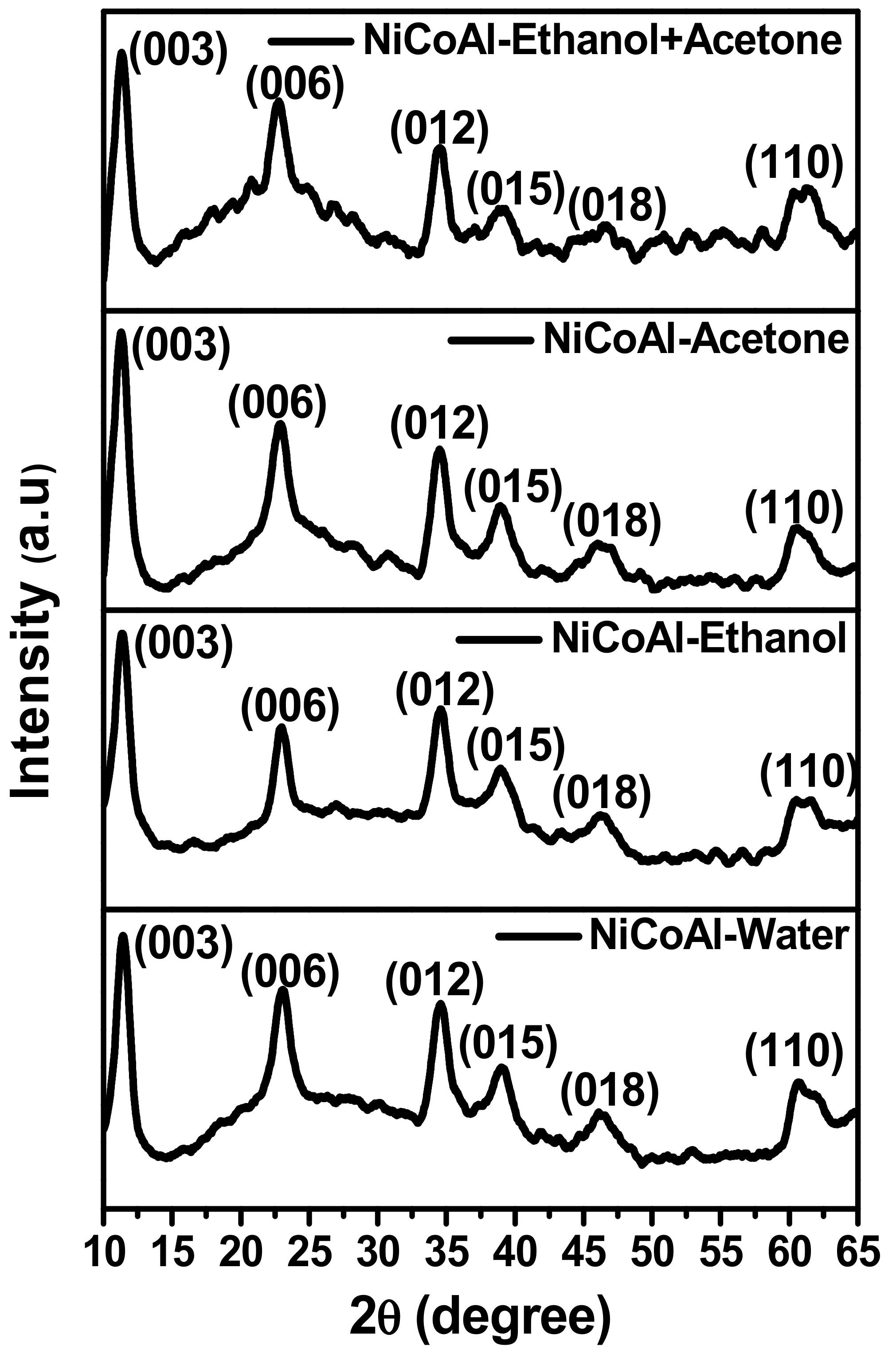

3.1. XRD Analysis

Figure 1 shows the X-ray diffraction (XRD) patterns of samples. The peaks at 2 θ for all the samples displayed in

Table 1 were indexed to (003), (006), (012), (015), (018), and (110) planes of layered hydrotalcite-like material [

31,

32]. This indicates the successful synthesis of LDH samples. Subsequently, the Williamson–Hall (W-H) Equations (1) and (2) were applied to estimate the crystallite sizes and lattice strains for all the samples by taking into consideration the values of the wavelength of the X-ray, the peaks at 2

θ (in degree), and the full width at half maximum (in radian) [

33].

Knowing that

, we can write Equation (1) as

where

βT is the diffraction peak,

D is the crystalline size,

K is the shape factor (0.9), and

λ is the wavelength of Cukα radiation (

λ = 0.15405 nm).

Using Equations (1) and (2), we drew W-H plots with 4Sinθ along the

x-axis and

βTCosθ along the

y-axis for all the samples as displayed in

Figure S1a–d (ESI). The values of the linear fit served to estimate the crystallite sizes using the

y-intercepts, and from the values of slopes of the fit, we extracted the strains, as shown in

Table 2.

Considering the peaks at 2 θ indexed to (003), we calculated the basal spacing for all the samples using the Bragg Equation (3) [

33]. Thereafter, from the Equations (4) and (5) [

34], the constant lattices “a” and “c”, which indicate the distance between cations in the lamella and the interlamellar distance, respectively, were calculated.

Table 3 displays the calculated values of the basal spacing as well as the constant lattices “a” and “c” for all the samples.

where

n is the order of peak reflection,

λ is the wavelength of Cukα radiation (

λ = 0.15405 nm),

d is the basal spacing corresponding to the Miller indexes, and

θ is the Bragg angle (in radians).

This W-H study demonstrated that the use of ethanol, acetone, and the ethanol–acetone solution differently affected the crystalline structure of LDH. It was noticed that the peak at 2 θ indexed to (003) shifted towards lower angles for the samples washed with ethanol, acetone, and the ethanol–acetone solution, respectively, compared to the sample washed with deionised water only indicating an expansion of the basal spacing which could be attributed to the ionic radius of anions intercalated between layers [

23,

35,

36]. This was in line with the calculated basal spacing shown in

Table 3. In contrast, the constant lattice “a” showed an increase for samples washed with ethanol, acetone, and the ethanol–acetone solution compared to the one washed with deionised water only, indicating an increment in the distance between cations in the lamella and a difference in the nature of the ionic radii [

31]. Moreover, the constant lattice “c” showed an increase for the samples washed with ethanol, acetone, and the ethanol–acetone solution. However, compared to the sample washed with acetone, the sample washed with the ethanol–acetone solution exhibited a constant lattice “c” slightly low. This could be attributed to the nature of the interlamellar anion and their orientation. Adding to this, the electrostatic interactions between cations, ionic radius of anions within the interlamellar, and the electrostatic force between anions and hydroxyls layers of the lamellar could also be the cause [

31,

34]. Furthermore, the crystallite sizes for the samples washed with ethanol, acetone, and the ethanol–acetone solution showed an increment compared to the sample washed with deionised water only. However, the sample washed with acetone showed a slight decrease in the size of its crystallite compared to the sample washed with ethanol. More importantly, the sample washed with the ethanol–acetone solution showed a drastic increase in its crystallite size compared to its counterparts. The structural modification observed after the W-H analysis indicates that the nature of the interlamellar domain of samples were not identical which confirms that each solvent impacted the LDH structure differently.

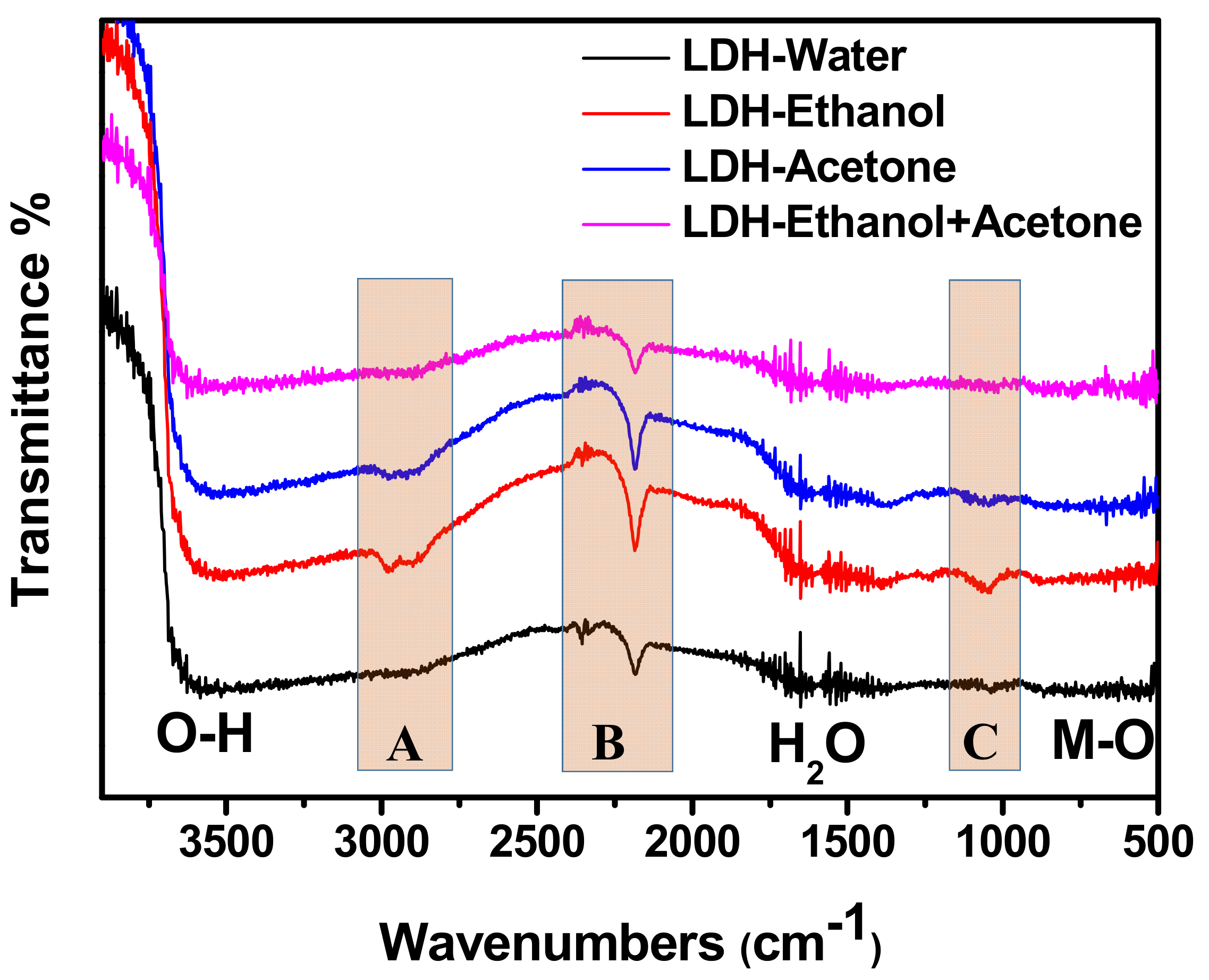

3.2. FTIR Analysis

FTIR measurements were carried out to further investigate the nature of the interlamellar domains for all the samples.

Figure 2 displays the FTIR spectra for all the samples; the vibration bands assigned to OH stretching of water molecules and OH groups at the brucite-like layer and interlamellar were observed for all the samples [

3]. This was followed by bands attributed to the bending vibration of water [

24]. Furthermore, the region ranging from 600 to 850 cm

−1 ascribed to the stretching and bending vibrations of metal-oxygen (M-O) in the brucite-like lattice was also depicted for all the samples [

3,

24]. This indicates the hydrotalcite nature of all the samples [

36]. Subsequently, a focus was given on three regions labelled as A, B, and C. The region B was assigned to the stretching vibrations of the C≡N functional group as well as to different orientations that adsorbed carbon species had taken [

3,

37]. Meanwhile, region C was ascribed to the stretching vibrations of carbonate anion [

15]. Region A was attributed to the C–H stretch. However, this vibrational band was more obvious only for the sample washed with ethanol and appeared less prominent for the sample washed with acetone. Afterwards, it completely disappeared for the sample washed with the ethanol and acetone solution. Moreover, the C–H stretch vibrational band was not depicted for the sample washed with deionised water only. More importantly, the same situation observed in region A was also noticed in region C. This could be attributed to the nature of the interactions of the intermolecular strength such as hydrogen bonding in each sample and the influence of affected molecules of water in their chemical environments [

14,

35]. This demonstrates that each solvent affected the interlamellar domain differently.

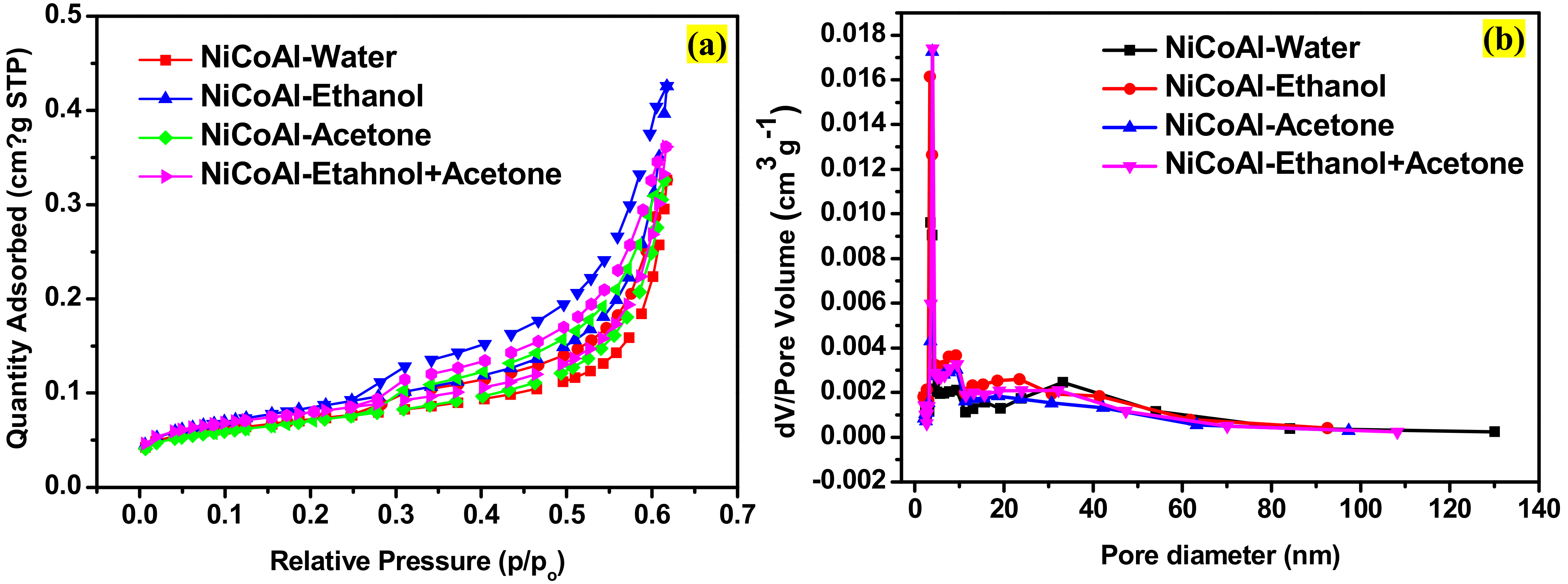

3.4. N2 Adsorption/Desorption Analysis

The nitrogen adsorption–desorption isotherm for NiCoAl-water, NiCoAl-Ethanol, NiCoAl-Acetone, and NiCoAl-Ethanol + Acetone shown in

Figure 4a displays hysteresis loops of typical type IV isotherm, indicating a mesoporous structure [

11,

35]. Subsequently,

Figure 4b shows the pore diameter distribution for all the samples. The textural properties of samples are displayed in

Table 4.

As can be seen in

Table 4, an increment in the surface area was recorded for the sample washed with ethanol compared to the one washed with deionised water only. Thereafter, the surface area drastically dropped for the sample washed with acetone. However, for the sample washed with the ethanol–acetone solution, the surface area showed an increase compared to the samples washed with deionised water only and the one washed with acetone. The same situation was observed with the pore volume parameters of samples. An increase was depicted in the pore volume of the sample washed with ethanol compared to the one washed with deionised water only. Then, it dropped for the sample washed with acetone. Afterwards, it showed an increment for the sample washed with the ethanol–acetone solution compared to the ones washed with deionised water only and the sample washed with acetone. Subsequently, an increment of 9.591 nm was depicted in the pore size of the sample washed with ethanol compared to the one washed with deionised water only, which was 8.452 nm. Then, it dropped to 8.952 nm for the sample washed with acetone. However, the pore size of the sample washed with the ethanol-acetone solution was 8.575 nm, which was smaller in comparison to the sample washed with acetone. It was reported that the nature of the pore distribution is the result of the formation procedure and the ions located in the layer, while the pore size is influenced by the synthesis route and the relationship between the LDH lamellar [

34]. In addition, Q. Wang et al. demonstrated that when a LDH is dispersed into an organic solvent, the molecules of the solvent strips the molecules of water from the surface of the hydroxide metal and replaces them. Consequently, the type of the solvent used and its boiling point will determine the nature of surface properties [

26]. This leads to the conclusion that the changes noticed on the specific surface area and the pore parameters of samples were due to the nature of the interlamellar domain of each sample, which was affected by the type of solvent used. Adding to this, the boiling point of each solvent could also be the reason.

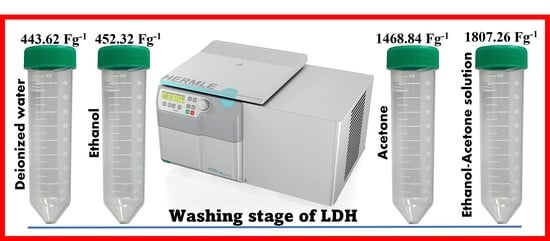

3.5. Electrochemical Analysis

The electrochemical performances of samples were investigated by the cyclic voltammetry (CV) in 1.0 M KOH electrolyte in a three-electrode system.

Figure S4a–d (ESI) displays the CV curves of all the samples at the scan rate of 10 mVs

−1 in a potential window ranging from 0.0 to 0.6 V. For all the samples, typical faradaic peaks were observed at 0.36 and 0.49 V for NiCoAl-Water, 0.33 and 0.52 V for NiCoAl-Ethanol, 0.28 and 0.40 V for NiCoAl-Acetone, and 0.24 and 0.38V for NiCoAl-Ethanol + Acetone, demonstrating that the specific capacitances were the results of quasi-reversible faradic redox reactions [

21] attributed to a combined effect of Ni and Co components in the ternary NiCoAl-LDH [

12] according to Equations (6) and (7) [

38]. However, Al played the role of stabilising the active sites of the host layers, which is beneficial for the surface redox reaction of the ternary NiCoAl. This improves the electrochemical activity of the reversible reaction of Ni

2+ and Co

2+. Adding to this, Al also enhances the electrolyte accessibility and charge transportation by increasing the hydrophilicity of the components within NiCoAl-LDH [

38].

Subsequently,

Figure 5a–d displays the CV curves of all the samples at scan rates of 10, 30, 50, 75, and 100 mVs

−1 in a potential window of 0.6 V. No inherent shape change was noticed for NiCoAl-Water (

Figure 5a), NiCoAl-Ethanol (

Figure 5b), and NiCoAl-Acetone (

Figure 5c) as the scan rate increased from 10 mVs

−1 up to 100 mVs

−1, indicating a relatively high-current capability [

3]. However, some shifts were noticed in the CV curves of NiCoAl-Acetone as the scan rate increased from 10 to 100 mVs

−1, which could be attributed to the internal diffusion resistance [

39,

40]. Furthermore,

Figure 5d reveals the CV curves of NiCoAl-Ethanol + Acetone at different scan rates, ranging from 10 to 100 mVs

−1 in a potential window of 0.6 V. A shape distortion was observed as the scan rate moved from 10 mVs

−1 to 30 mVs

−1; afterwards, no change in the shape was noticed again. This could indicate that NiCoAl-Ethanol + Acetone is a good candidate for fast discharge-charge in power applications [

41].

Figure S4e (ESI) compares the CV curves of NiCoAl-Ethanol, NiCoAl-Acetone, and NiCoAl-Ethanol + Acetone at a scan rate of 30 mV

−1, as it can be noticed that at a higher scan rate, NiCoAl-Ethanol + Acetone displayed a CV curve with an almost rectangular shape in contrary to its CV curve recorded at a scan rate 10 mV

−1; this could explain that the overall electrochemical capacitance is a result of dual contribution of both pseudocapacitance and double-layer capacitance [

41].

Figure 5e displays the comparative CV curves of all the samples at the scan rate of 10 mVs

−1. As it can be noticed, the CV area of the sample washed with the ethanol–acetone solution was much more enlarged compared to other samples. This indicates that the sample washed with the ethanol–acetone solution possessed high specific capacitance compared to its counterparts. The specific capacitances of NiCoAl-Water, NiCoAl-Ethanol, NiCoAl-Acetone, and NiCoAl-Ethanol + Acetone were calculated from CV curves at the scan rate of 10 mVs

−1 using Equation (8) [

42], and the calculated values are displayed in

Table 5. Meanwhile,

Table 6 compares the specific capacitance recorded for NiCoAl-Ethanol + Acetone with other reported NiCoAl-LDH electrodes.

where

Csp is the specific capacitance (Fg-1),

V is the scan rate (Vs-1), m is the mass of active material dropped-cast on the substrate (g), ∆V is the potential window applied for the measurements (

Vi to

Vf), and the integral term is the absolute area of the CV curve.

Subsequently,

Figure 5f displays the comparative Nyquist plots for NiCoAl-Water, NiCoAl-Ethanol, NiCoAl-Acetone, and NiCoAl-Ethanol + Acetone samples. Generally, Rs represents the resistance of the electrolytic solution, while Rct stands for the charge transfer impedance between electrode and electrolyte [

11]. As can be noticed, NiCoAl-Ethanol + Acetone exhibited low Rct compared to other samples. This result is in accordance with the CV results discussed earlier. The values of Rct and Rs for all the samples are displayed in

Table 7.

Figure S5a–d (ESI) displays the Nyquist plots for all the samples exhibiting partial semicircles in the high-frequency region followed by the almost vertical lines in the low-frequency region. The partial semicircles recorded in the high-frequency region confirmed the faradaic reaction for all samples, as depicted earlier in the CV analysis [

44], whereas the almost vertical lines in the low-frequency region revealed the diffusion of redox species as well as their kinetics [

45].

It must be reminded that the sample washed with ethanol (NiCoAl-Ethanol) possessed the highest specific surface area compared to its counterparts. It is known that an electrode material with a high specific surface area yields high performance [

11,

23,

35]. However, in our case, NiCoAl-Ethanol exhibited low specific capacitance compared to NiCoAl-Ethanol + Acetone and NiCoAl-Acetone, even though their specific surface areas were lower compared to NiCoAl-Ethanol. This could explain that in the case of LDH material the specific surface area is not the only factor that contributes to the overall electrochemical performance, and that the crystalline domain also is involved [

25]. When we considered the crystalline structure profiles of all the samples (refer to

Table 1,

Table 2 and

Table 3), we noticed that NiCoAl-Ethanol possessed low crystallite size compared to NiCoAl-Ethanol + Acetone. Yasuhiro Domi et al. reported on lithium-ion battery electrodes with excellent electrochemical performance and stated that the larger crystallite size was the cause of good electrochemical performance [

36]. On this basis, we can assume that the larger crystallite size recorded for NiCoAl-Ethanol + Acetone could be the reason why it exhibited good electrochemical performance compared to NiCoAl-Ethanol. On the other hand, the reason why NiCoAl-Acetone exhibited good electrochemical performance compared to NiCoAl-Ethanol, although it possesses smaller crystallite size and low specific surface area compared to NiCoAl-Ethanol, could be attributed to its basal spacing, which is larger compared to other electrodes (refer to

Table 3). Y. Lin et al. reported on NiCo-SDBS-LDH with improved electrochemical performance compared to the pristine material, even though the pristine material exhibited a high specific surface area compared to NiCo-SDBS-LDH. The authors stated that the excellent electrochemical performance recorded was due to the expansion of the basal spacing of NiCo-SDBS-LDH [

23]. On the same note, T. Wang et al. also reported that the expansion of basal spacing enhances the electrochemical performance because it favours the penetration of electrolyte ions during the charge storage stage [

25].