Reviewing Performance Measures of the Die-Sinking Electrical Discharge Machining Process: Challenges and Future Scopes

Abstract

1. Introduction

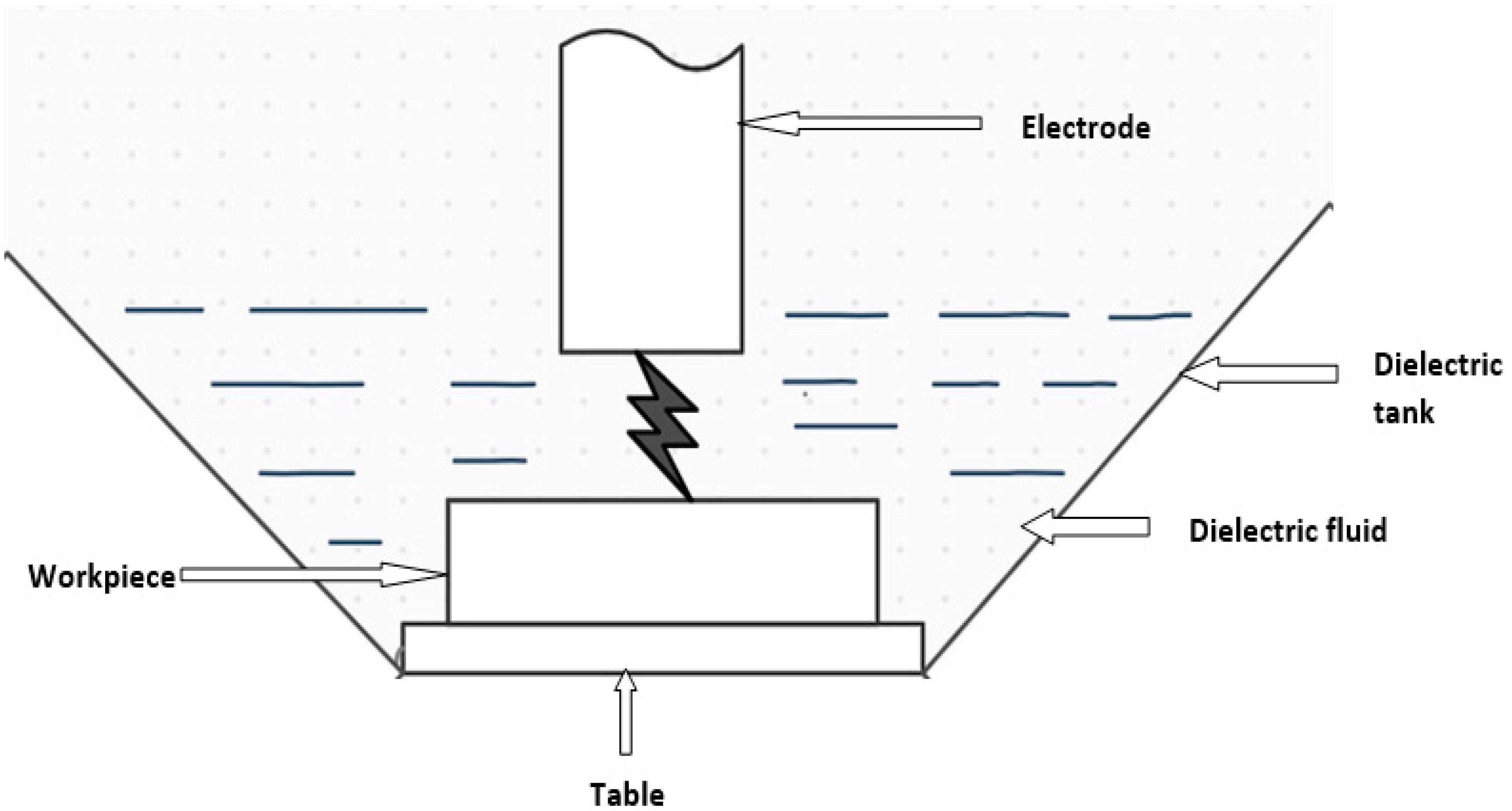

The Electrical Discharge Machining Principle

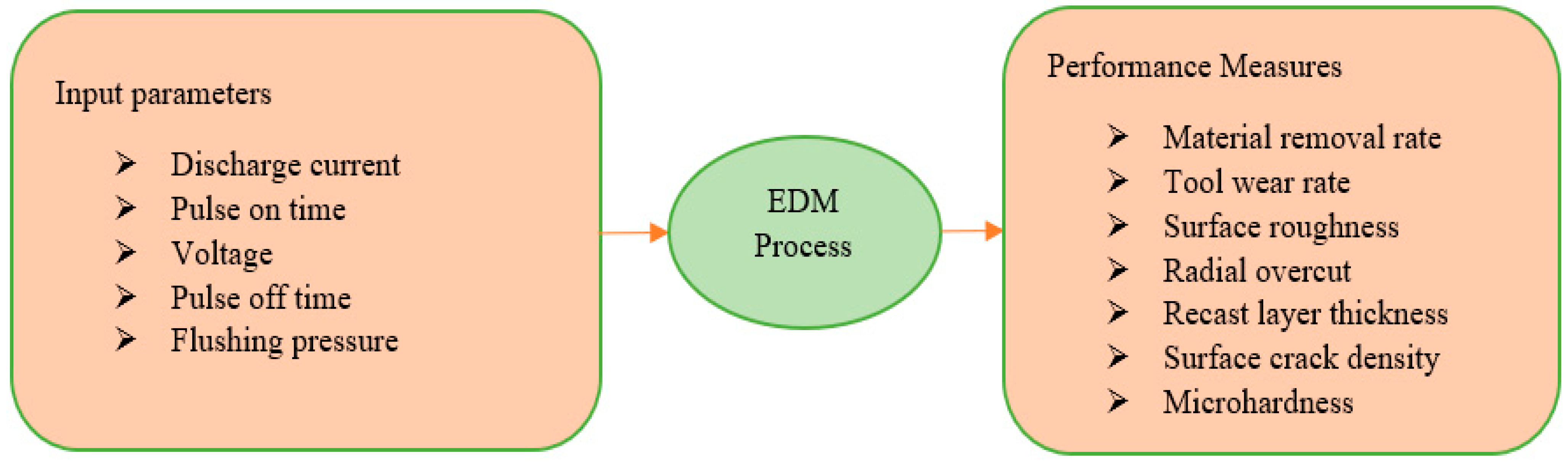

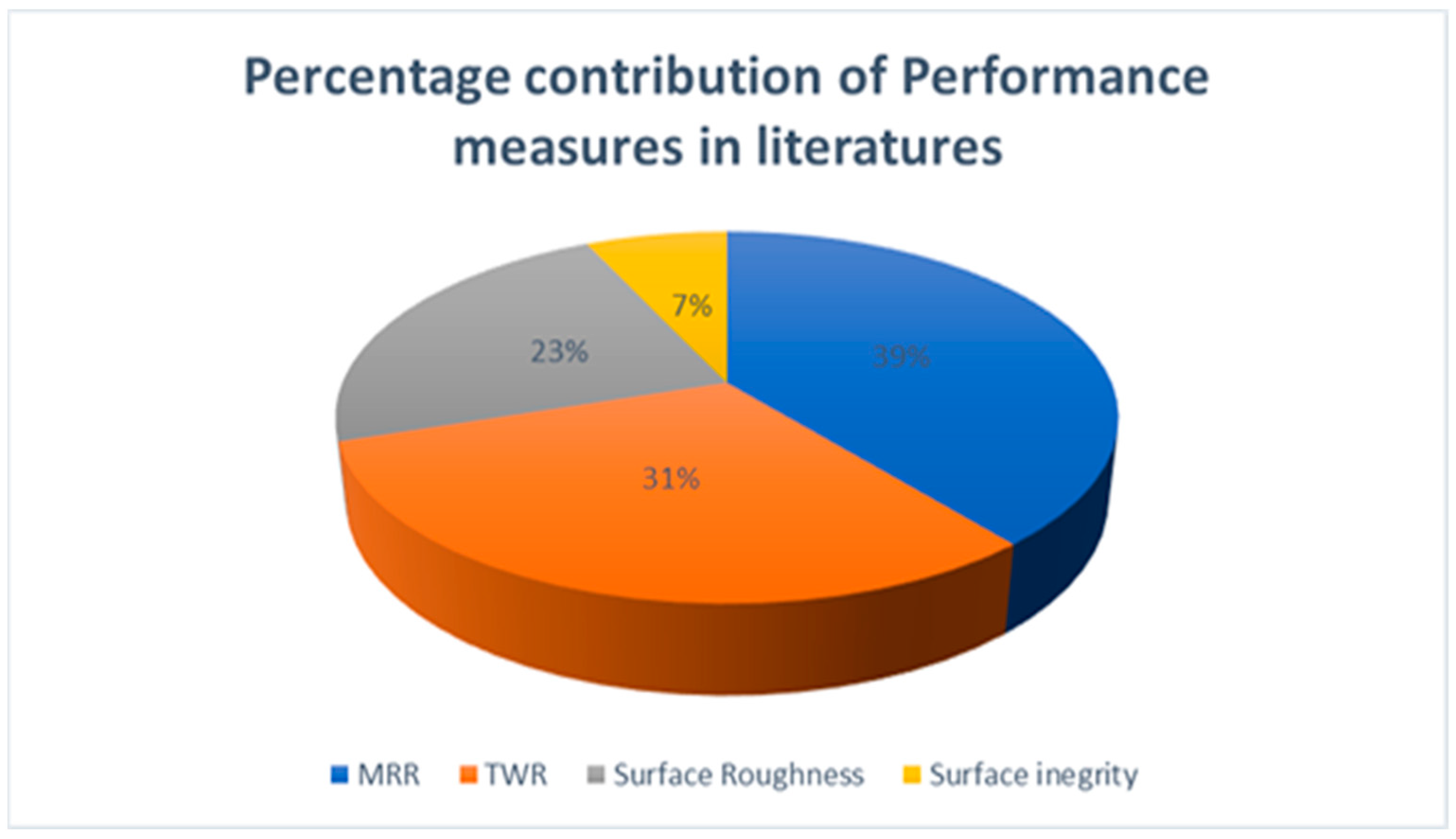

2. Performance Measures

2.1. Material Removal Rate (MRR)

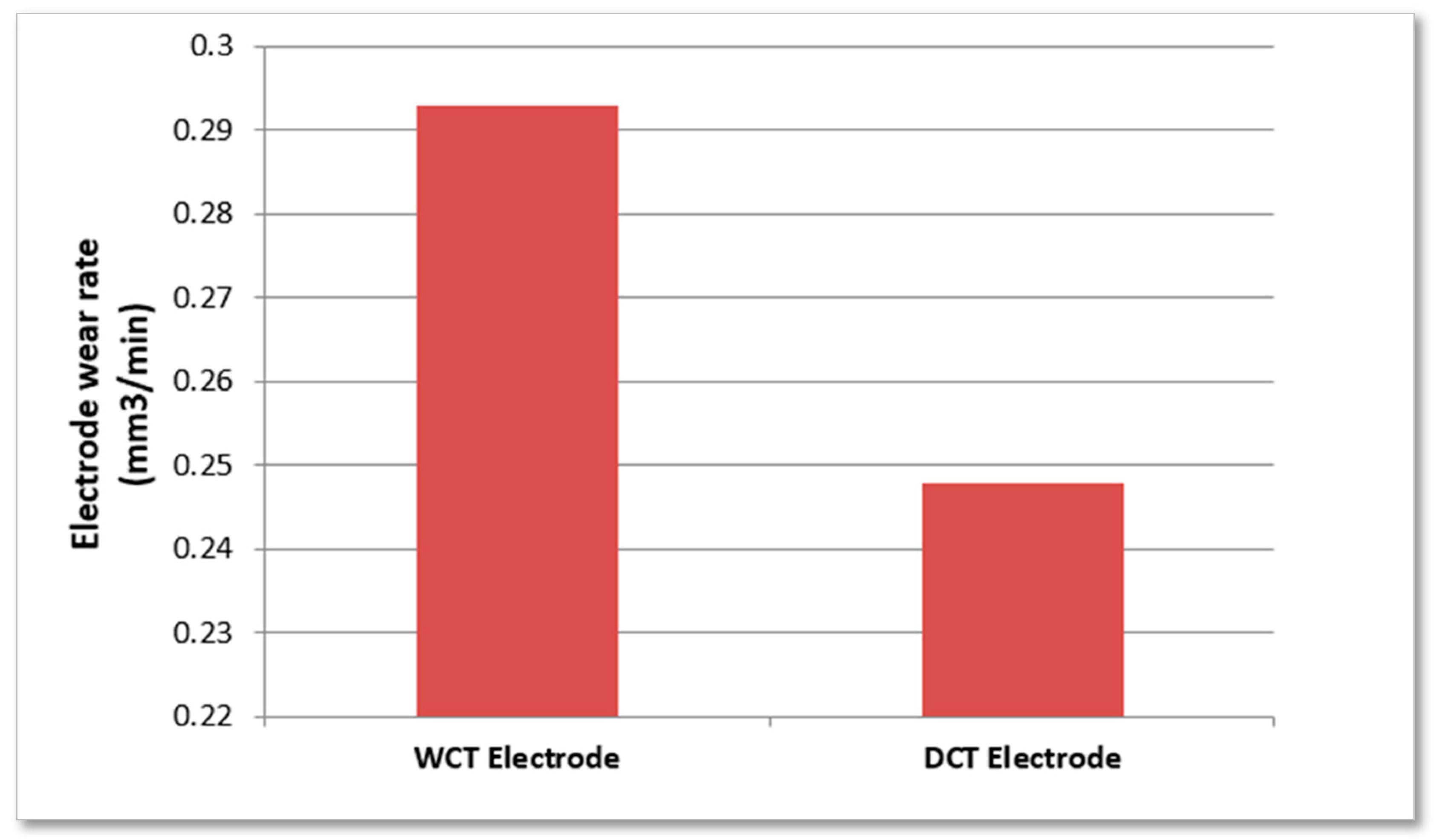

2.2. Tool Wear Rate (TWR)

2.3. Surface Roughness

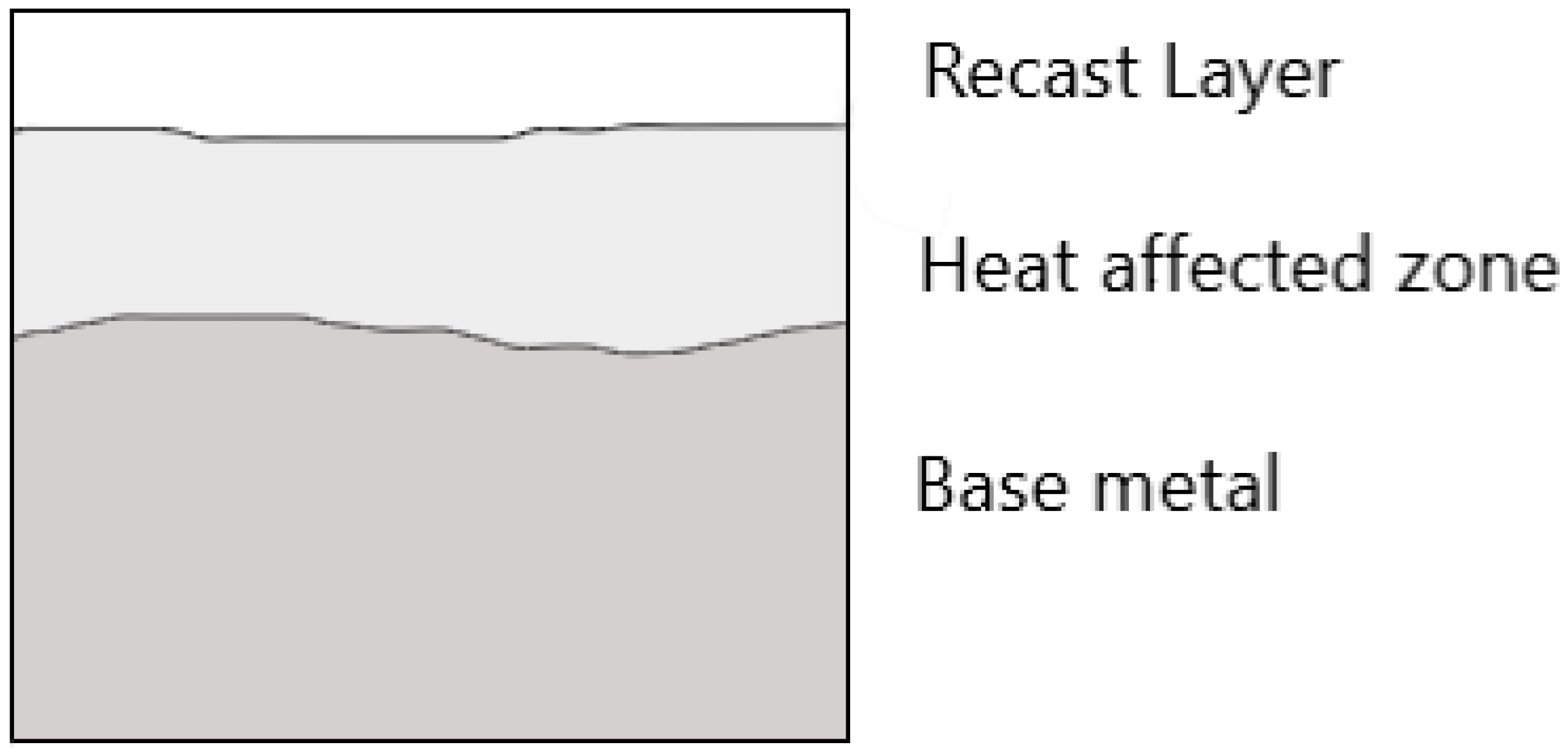

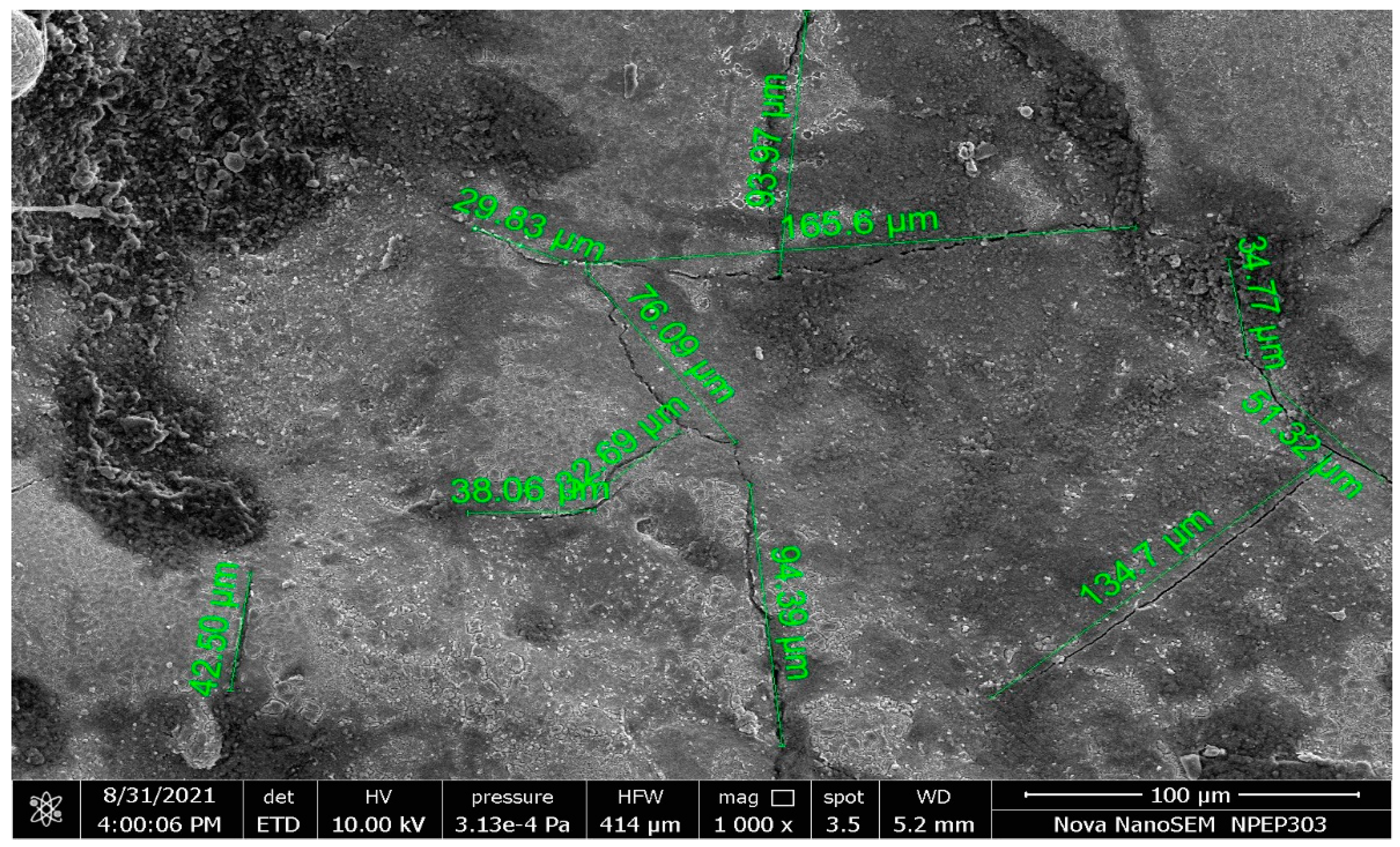

2.4. Surface Integrity

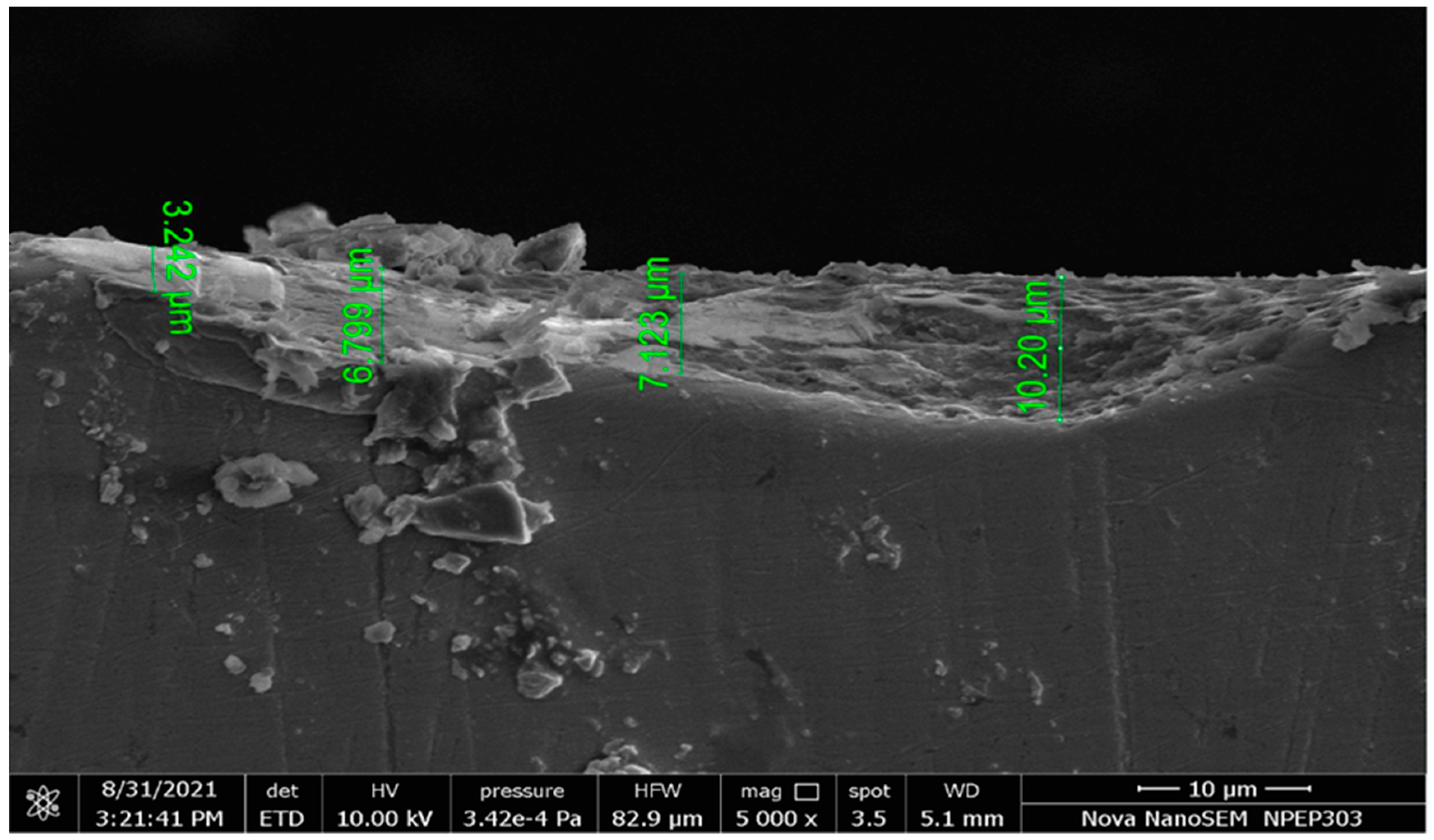

2.4.1. RCT on Workpiece

2.4.2. RCT on Electrode

3. Statistical Tools and Artificial Intelligence Techniques Applied in EDM

4. Conclusions

- Surface integrity, surface crack density, microhardness, and radial overcut of the machined surface have not been given adequate importance, as measured by the researchers. Therefore, an attempt must be made to evaluate these measures with the greatest priority.

- It was also observed that a few works have been carried out on aerospace materials such as Nimonic, Titanium alloys, Hastelloy, Hayeness alloys, Magnesium alloys, etc. [27,114,119,122,134]. These alloys have vital applications in manufacturing parts in the aircraft and automotive industries. Hence, the machinability of these novel workpieces must be explored in EDM.

- Few studies have looked at the process’s long-term viability, such as energy consumption, machining noise, and machining debris during EDM machining.

- In order to produce energy-efficient and clean EDM operations, these sustainable measures, as well as other machining measures, should be evaluated. Another example is the prior cryogenic treatment of the EDM tool to reduce the TWR. Despite research demonstrating the method’s efficacy, no standardization of the procedure or refusal to establish a cutting process for hard materials has been proposed. A similar gap exists when it comes to the use of powder-mixed composites and the accompanying ultrasonic assistance.

- Although not discussed, the thermal model of heat transfer efficiency and flushing characteristics needs to be addressed for novel ultra-hard material processing. In addition, there is an optimization and standardization need for surface-engineered tools.

- There are several reports in the literature for achieving low surface roughness in the EDM process. PMEDM (powder-mixed EDM) has been attempted for machining rigid material with the desired accuracy. However, quantitative correlation and benchmarking of process parameters remain to be implemented.

- The survey revealed a considerable scope for further research. The discharge dynamics and heat transfer characteristic thermal modeling, flushing out effects, and assistance from ultrasonic cavitation need quantitative understanding. Enhanced MRR and reduced TWR are critical essential assessment criteria for an EDM process. Potential benefits from the use of surface-engineered tools also need further probing.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mordecai, N.L.; Lee, T.C.; Huddleston, J. Developments in spark erosion of ceramics. Br. Ceram. Trans. 1995, 94, 21–24. [Google Scholar]

- Zhang, J.H.; Lee, T.C.; Lau, W.S. Study on the electro-discharge machining of a hot-pressed aluminum oxide-based ceramic. J. Mater. Processing Technol. 1997, 63, 908–912. [Google Scholar] [CrossRef]

- Kunieda, M.; Yoshida, M. Electrical Discharge Machining in Gas. CIRP Ann. 1997, 46, 143–146. [Google Scholar] [CrossRef]

- Kunieda, M.; Furudate, C. High Precision Finish Cutting by Dry WEDM. CIRP Ann. 2001, 50, 121–124. [Google Scholar] [CrossRef]

- Kunieda, M.; Miyoshi, Y.; Takaya, T.; Nakajima, N.; Yu, Z.; Yoshida, M. High-Speed 3D Milling by Dry EDM. CIRP Ann. 2003, 52, 147–150. [Google Scholar] [CrossRef]

- Furudate, C.; Kunieda, M. Gap Phenomena in Dry WEDM. Denki-Kakou-Gijutsu 2002, 26, 21–27. (In Japan) [Google Scholar]

- Wong, Y.S.; Lim, L.C.; Lee, L.C. Effects of Flushing on electro-discharge Machined Surfaces. J. Mater. Processing Technol. 1995, 48, 299–305. [Google Scholar] [CrossRef]

- Godinho, L.H.H.; Noble, C.F. The Use of Water as inter-electrode Medium in Pulsed EDM. In Proceedings of the Fifth International Symposium for Electro-Machining, ISEM 6, Wolfsberg, Switzerland, 21–24 June 1977; pp. 63–67. [Google Scholar]

- Masuzawa, T. Machining Characteristics of EDM Using Water as a Dielectric Fluid. In Proceedings of the Twenty-Second Machine Tool Design and Research Conference; Macmillan Education: London, UK, 1981; pp. 441–447. [Google Scholar] [CrossRef]

- Jilam, S.T.; Pandey, P.C. Experimental Investigations Into the Performance of Water as Dielectric in EDM. Int. J. Mach. Tool Des. Res. 1984, 24, 31–43. [Google Scholar] [CrossRef]

- Masuzawa, T.; Tanaka, K. Water-based Dielectric Solution for EDM. CIRP Ann. 1983, 32, 119–122. [Google Scholar] [CrossRef]

- Singh, S.; Maheshwari, S.; Pandey, P.C. Some investigations into the electric discharge machining of hardened tool steel using different electrode materials. J. Mater. Processing Technol. 2004, 149, 272–277. [Google Scholar] [CrossRef]

- Boothroyd, G.; Winston, A.K. Non-conventional machining processes. In Fundamentals of Machining and Machine Tools; Marcel Dekker, Inc.: New York, NY, USA, 1989; p. 491. [Google Scholar]

- McGeough, J.A. Electro Discharge Machining in Advanced Methods of Machining; Chapman & Hall: London, UK, 1988; p. 130. [Google Scholar]

- Sen, B.; Kiyawat, N.; Singh, P.K.; Mitral, S.; Ykmd, J.H.; Purkait, P. Developments in Electric Power Supply Configurations for Electrical-Discharge-Machining (EDM). In Proceedings of the Fifth International Conference on Power Electronics and Drive Systems, 2003. PEDS 2003, Singapore, 17–20 November 2003; IEEE: Piscataway, NJ, USA, 2003; pp. 659–664. [Google Scholar]

- Wong, Y.S.; Rahmana, M.; Lima, H.S.; Hanb, H.; Ravi, N. Investigation of Micro-EDM Material Removal Characteristics Using Single RC-Pulse Discharges. J. Mater. Processing Technol. 2003, 140, 303–307. [Google Scholar] [CrossRef]

- Lee, H.T.; Tai, T.Y. Relationship between EDM parameters and surface crack formation. J. Mater. Processing Technol. 2003, 142, 676–683. [Google Scholar] [CrossRef]

- Guu, Y.H.; Ti-Kuang Hou, M. Effect of machining parameters on surface textures in EDM of Fe-Mn-Al alloy. Mater. Sci. Eng. 2007, 466, 61–67. [Google Scholar] [CrossRef]

- Kiyak, M.; Cakir, O. Examination of machining parameters on surface roughness in EDM of tool steel. J. Mater. Processing Technol. 2007, 191, 141–144. [Google Scholar] [CrossRef]

- Lee, L.C.; Lim, L.C.; Narayanan, V.; Venkatesh, V.C. Quantification of surface damage of tool steels after EDM. Int. J. Mach. Tools Manuf. 1988, 28, 359–372. [Google Scholar] [CrossRef]

- Rebelo, J.C.; Dias, A.M.; Kremer, D.; Lebrun, J.L. Influence of EDM Pulse Energy on The Surface Integrity of Martensitic Steels. J. Mater. Processing Technol. 1998, 84, 90–96. [Google Scholar] [CrossRef]

- Luo, Y.F. An Investigation into The Actual EDM Off-Time In SEA Machining. J. Mater. Processing Technol. 1998, 74, 61–68. [Google Scholar] [CrossRef]

- Konig, W.; Dauw, D.F.; Levy, G.; Panten, U. EDM-future steps towards the machining of ceramics. CIRP Ann. 1988, 37, 623–631. [Google Scholar] [CrossRef]

- Chen, Y.; Mahdivian, S.M. Analysis of electro-discharge machining process and its comparison with experiments. J. Mater. Processing Technol. 2002, 104, 150–157. [Google Scholar] [CrossRef]

- Pawade, M.M.; Banwait, S.S. A brief review of die sinking electrical discharging machining process towards automation. Am. J. Mech. Eng. 2013, 1, 43–49. [Google Scholar] [CrossRef]

- Abdulkareem, S.; Khan, A.A.; Konneh, M. Cooling effect on electrode and process parameters in EDM. Mater. Manuf. Processes 2010, 25, 462–466. [Google Scholar] [CrossRef]

- Choudhary, R.; Garg, H.; Prasad, M.; Kumar, D. Effect of Cryogenic Treatment of Tool Electrode on the Machining Performance and Surface Finish during Electrical Discharge Machining of Hastelloy C-4. Mater. Today Proc. 2017, 4, 1158–1166. [Google Scholar] [CrossRef]

- Gopalakannan, S.; Senthilvelan, T. A parametric study of electrical discharge machining process parameters on machining of cast Al/B4C metal matrix nanocomposites. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2013, 227, 993–1004. [Google Scholar] [CrossRef]

- Khanra, A.K.; Sarkar, B.R.; Bhattacharya, B.; Pathak, L.C.; Godkhindi, M.M. Performance of ZrB2–Cu composite as an EDM electrode. J. Mater. Processing Technol. 2007, 183, 122–126. [Google Scholar] [CrossRef]

- Kumar, S.; Dhingra, K.A.; Kumar, S. Parametric optimization of powder mixed electrical discharge machining for nickel-based super alloy Inconel-800 using response surface methodology. Mech. Adv. Mater. Mod. Processes 2017, 3, 7. [Google Scholar] [CrossRef]

- Kuppan, P.; Narayanan, S.; Oyyaravelu, R.; Balan, A.S.S. Performance evaluation of electrode materials in electric discharge deep hole drilling of Inconel 718 superalloy. Procedia Eng. 2017, 174, 53–59. [Google Scholar] [CrossRef]

- Dewangan, S.; Gangopadhyay, S.; Biswas, K.C. Multi-response optimization of surface integrity characteristics of EDM process using grey-fuzzy logic-based hybrid approach. Eng. Sci. Technol. Int. J. 2015, 18, 361–368. [Google Scholar] [CrossRef]

- Mohanty, P.C.; Mahapatra, S.S.; Singh, R.M. An experimental investigation of machinability of Inconel 718 in electrical discharge machining. Procedia Mater. Sci. 2014, 6, 605–611. [Google Scholar] [CrossRef][Green Version]

- Rahman, M.M. Modeling of machining parameters of Ti-6Al-4V for electric discharge machining: A neural network approach. Sci. Res. Essays 2012, 7, 881–890. [Google Scholar] [CrossRef]

- Rajesha, S.; Sharma, A.K.; Kumar, P. On electro-discharge machining of Inconel 718 with the hollow tool. J. Mater. Eng. Perform. 2012, 21, 882–891. [Google Scholar] [CrossRef]

- Kuppan, P.; Narayanan, S.; Rajadurai, A. Effect of process parameters on the material removal rate and surface roughness in electric discharge drilling of Inconel 718 using graphite electrode. Int. J. Manuf. Technol. Manag. 2011, 23, 214–233. [Google Scholar] [CrossRef]

- Mohanty, C.P.; Mahapatra, S.S.; Singh, M.R. An intelligent approach to optimize the EDM process parameters using utility concept and QPSO algorithm. Eng. Sci. Technol. Int. J. 2017, 20, 552–562. [Google Scholar] [CrossRef]

- Kuppan, P.; Rajadurai, A.; Narayanan, S. Influence of EDM process parameters in deep-hole drilling of Inconel 718. Int. J. Adv. Manuf. Technol. 2008, 38, 74–84. [Google Scholar] [CrossRef]

- Mohan, B.; Rajadurai, A.; Satyanarayana, K.G.G. Electric discharge machining of Al-SiC metal matrix composites using rotary tube electrode. J. Mater. Processing Technol. 2004, 153–154, 978–985. [Google Scholar] [CrossRef]

- Pradhan, B.B.; Masanta, M.; Sarkar, B.R.; Bhattacharyya, B. Investigation of electro-discharge micro-machining of titanium super alloy. Int. J. Adv. Manuf. Technol. 2009, 41, 1094–1106. [Google Scholar] [CrossRef]

- Yan, B.H.; Wang, C.C. The machining characteristics of Al2O3/6061Al composite using rotary electro-discharge machining with a tube electrode. J. Mater. Processing Technol. 1999, 95, 222–231. [Google Scholar] [CrossRef]

- Majumder, A.; Das, P.K.; Majumder, A.; Debnath, M. An approach to optimize the EDM process parameters using desirability-based multi-objective PSO. Prod. Manuf. Res. 2014, 2, 228–240. [Google Scholar] [CrossRef]

- Mohanty, C.P.; Mahapatra, S.S.; Singh, M.R. A particle swarm approach for multi-objective optimization of the electrical discharge machining process. J. Intell. Manuf. 2016, 27, 1171–1190. [Google Scholar] [CrossRef]

- Kapoor, J.; Singh, S.; Khamba, J.S. Effect of cryogenic treated brass wire electrode on material removal rate in wire electrical discharge machining. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2012, 226, 2750–2758. [Google Scholar] [CrossRef]

- Gill, S.S.; Singh, J. Effect of deep cryogenic treatment on machinability of titanium alloy (Ti-6246) in electric discharge drilling. Mater. Manuf. Processes 2010, 25, 378–385. [Google Scholar] [CrossRef]

- Kumar, S.V.; Kumar, M.P. Machining process parameter and surface integrity in conventional EDM and cryogenic EDM of Al–SiCp MMC. J. Manuf. Processes 2017, 20, 70–78. [Google Scholar] [CrossRef]

- Pandey, A.; Kumar, R. Some studies using cryogenically treated Rotary Cu-tool electrode Electrical Discharge Machining. Mater. Today Proc. 2018, 5, 7635–7639. [Google Scholar] [CrossRef]

- Srivastava, V.; Pandey, P.M. Effect of process parameters on the performance of EDM process with ultrasonic assisted cryogenically cooled electrode. J. Manuf. Processes 2012, 14, 393–402. [Google Scholar] [CrossRef]

- Kumar, S.; Batish, A.; Singh, R.; Singh, T.P. A mathematical model to predict material removal rate during electric discharge machining of cryogenically treated titanium alloys. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2015, 229, 214–228. [Google Scholar] [CrossRef]

- Chaudhari, S.B.; Shekhawat, S.P.; Kushwaha, A.S. The advanced technology of cryo processing for the enhancement of tool material machining characteristics: A Review. Int. J. Emerg. Technol. Adv. Eng. 2012, 2, 1–2. [Google Scholar]

- Molinari, A.; Pellizzari, M.; Gialanella, S.; Straffelini, G.; Stiasny, K.H. Effect of deep cryogenic treatment on the mechanical properties of tool steels. J Mater. Process.Technol. 2001, 118, 350–355. [Google Scholar] [CrossRef]

- Akincioğlu, S.; Gökkaya, H.; Uygur, İ. A review of cryogenic treatment on cutting tools. Int. J. Adv. Manuf. Technol. 2015, 78, 1609–1627. [Google Scholar] [CrossRef]

- Talla, G.; Sahoo, D.K.; Gangopadhyay, S.; Biswas, C.K. Modeling and multi-objective optimization of powder mixed electric discharge machining process of aluminum/alumina metal matrix composite. Eng. Sci. Technol. Int. J. 2015, 18, 369–373. [Google Scholar] [CrossRef]

- Kolli, M.; Kumar, A. Effect of dielectric fluid with surfactant and graphite powder on Electrical Discharge Machining of titanium alloy using Taguchi method. Eng. Sci. Technol. Int. J. 2015, 18, 524–535. [Google Scholar] [CrossRef]

- Kansal, H.K.; Singh, S.; Kumar, P. Effect of silicon powder mixed EDM on machining rate of AISI D2 die steel. J. Manuf. Process. 2007, 9, 13–22. [Google Scholar] [CrossRef]

- Singh, S.; Yeh, M.F. Optimization of abrasive powder mixed EDM of aluminum matrix composites with multiple responses using Gray relational analysis. J. Mater. Eng. Perform. 2012, 21, 481–491. [Google Scholar] [CrossRef]

- Kumar, H.; Davim, J.P. Role of powder in the machining of Ale10%Sicp metal matrix composites by powder mixed electric discharge machining. J. Compos. Mater. 2011, 45, 133. [Google Scholar] [CrossRef]

- Ming, Q.H.; He, L.Y.Y. Powder-Suspension Dielectric Fluid for EDM. J. Mater. Process. Technol. 1995, 52, 44–54. [Google Scholar] [CrossRef]

- Narumiya, H.; Mohri, N.; Saito, N.; Otake, H.; Tsunekawa, Y.; Takawashi, T.; Kobayashe, K. EDM by Powder Suspended Working Fluid. In Proceedings of the 9th International Symposium for Electrical Machining, Bucharest, Romania, 7–9 May 2015; pp. 207–210. [Google Scholar]

- ÖZERKAN, B.; ÇOĞUN, C. Effect of Powder Mixed Dielectric on Machining Performance in Electric Discharge Machining (EDM). GUU J. Sci. 2005, 18, 211–228. [Google Scholar]

- Tzeng, Y.F.; Lee, C.Y. Effects of Powder Characteristics on Electro- Discharge Machining Efficiency. Int. J. Adv. Manuf. Technol. 2001, 17, 586–592. [Google Scholar] [CrossRef]

- Chow, H.-M.; Yan, B.H.; Huang, F.Y.; Hung, J.C. Study of Added Powder in Kerosene for the Micro-slit Machining of Titanium Alloy using Electro-discharge Machining. J. Mater. Processing Technol. 2000, 101, 95103. [Google Scholar] [CrossRef]

- Uno, Y.; Okada, A.; Hayashi, Y.; Tabuchi, Y. Surface Modification by EDM with Nickel Powder Mixed Fluid. Int. J. Electr. Mach. 1998, 4, 4752. [Google Scholar]

- Kremer, D.; Lebrun, J.L.; Hosari, B.; Moisan, A. Effects of Ultrasonic Vibrations on the Performances in EDM. CIRP Ann.-Manuf. Technol. 1989, 38, 199–202. [Google Scholar] [CrossRef]

- Abdullah, A.; Shabgard, M.R. Effect of ultrasonic vibration of tool on electrical discharge machining of cemented tungsten carbide (WC-Co). Int. J. Adv. Manuf. Technol. 2007, 38, 1137–1147. [Google Scholar] [CrossRef]

- Lin, Y.C.; Yan, B.H.; Chang, Y.S. Machining characteristics of titanium alloy(Ti-6Al-4V) using a combination process of EDM with USM. J. Mater. Process. Technol. 2000, 104, 171–177. [Google Scholar] [CrossRef]

- Jia, Z.; Zhang, J.; Ai, X. Combined machining of USM and EDM for advanced ceramics. J. Adv. Mater. 1995, 26, 16–20. [Google Scholar]

- Nikzad, M. Ultrasonic Assisted Electro Discharge Machining. Ph.D. Thesis, Amirkabir University of Technology, Tehran, Iran, 2004. [Google Scholar]

- Wansheng, Z.; Zhenlong, W.; Shichun, D.; Guanxin, C.; Hongyu, W. Ultrasonic and electric discharge machining to deep and small hole on titanium alloy. J. Mater. Processing Technol. 2002, 120, 101–106. [Google Scholar] [CrossRef]

- Yan, B.H.; Wang, A.C.; Huang, C.Y.; Huang, F.Y. Study of precision micro-holes in borosilicate glass using micro EDM combined with micro ultrasonic vibration machining. Int. J. Mach. Tools Manuf. 2002, 42, 1105–1112. [Google Scholar] [CrossRef]

- Ghoreishi, M.; Atkinson, J. A comparative experimental study of machining characteristics in vibratory, rotary and vibro-rotary electro-discharge machining. J. Mater. Processing Technol. 2002, 120, 374–384. [Google Scholar] [CrossRef]

- Shabgard, M.R.; Sadizadeh, B.; Kakoulvand, H. The effect of ultrasonic vibration of work piece in electrical discharge machining of AISIH13 tool steel. World Acad. Sci. Eng. Technol. 2009, 3, 332–336. [Google Scholar]

- Huang, H.; Zhang, H.; Zhou, L.; Zheng, H.Y. Ultrasonic vibration assisted electro-discharge machining of microholes in Nitinol. J. Micromechanics Microengineering 2003, 13, 693. [Google Scholar] [CrossRef]

- Lee, T.C.; Zhang, J.H.; Lau, W.S. Machining of engineering ceramics by ultrasonic vibration assisted EDM method. Mater. Manuf. Process. 1998, 13, 133–146. [Google Scholar] [CrossRef]

- Yu, J.W.; Dabrowski, L.; Yin, S.H.; Lechniak, Z. Productivity of EDM process assisted by ultrasonic waves. In Solid State Phenomena; Trans Tech Publications Ltd.: Freienbach, Switzerland, 2011; Volume 175, pp. 157–160. [Google Scholar]

- Murti, V.S.R.; Philip, P.K. An analysis of the debris in ultrasonic-assisted electrical discharge machining. Wear 1987, 117, 241–250. [Google Scholar] [CrossRef]

- Thoe, T.B.; Aspinwall, D.K.; Killey, N. Combined ultrasonic and electrical discharge machining of ceramic coated nickel alloy. J. Mater. Processing Technol. 1999, 92, 323–328. [Google Scholar] [CrossRef]

- Zhixin, J.; Jianhua, Z.; Xing, A. Study on a new kind of combined machining technology of ultrasonic machining and electrical discharge machining. Int. J. Mach. Tools Manuf. 1997, 37, 193–199. [Google Scholar] [CrossRef]

- Straka, Ľ.; Hašová, S. Optimization of material removal rate and tool wear rate of Cu electrode in die-sinking EDM of tool steel. Int. J. Adv. Manuf. Technol. 2018, 97, 2647–2654. [Google Scholar] [CrossRef]

- Amorim, F.L.; Weingaertner, W.L. The behavior of graphite and copper electrodes on the finish die-sinking electrical discharge machining (EDM) of AISI P20 tool steel. J. Braz. Soc. Mech. Sci. Eng. 2007, 29, 366–371. [Google Scholar] [CrossRef]

- Khan, A.A. Electrode wear and material removal rate during EDM of aluminum and mild steel using copper and brass electrodes. Int. J. Adv. Manuf. Technol. 2008, 39, 482–487. [Google Scholar] [CrossRef]

- Zarepour, H.; Tehrani, A.F.; Karimi, D.; Amini, S. Statistical analysis on electrode wear in EDM of tool steel DIN 1.2714 used in forging dies. J. Mater. Process. Technol. 2007, 187–188, 711–714. [Google Scholar] [CrossRef]

- Wang, P.J.; Tsai, K.M. Semiempirical model on work removal and tool wear in electrical discharge machining. J. Mater. Process. Technol. 2001, 114, 1–17. [Google Scholar] [CrossRef]

- Khan, A.A.; Mridha, S. Performance of copper and aluminum electrode during EDM of stainless steel and carbide. Int. J. Manuf. Sci. Prod. 2006, 7, 1–7. [Google Scholar] [CrossRef]

- Zaw, H.M.; Fuh, J.Y.H.; Nee, A.Y.C.; Lu, L. Fabrication of a new EDM electrode material using sintering techniques. J. Mater. Process. Technol. 1999, 89–90, 182–186. [Google Scholar] [CrossRef]

- Puertas, I.; Luis, C.J.; Alvarez, L. Analysis of the influence of EDM parameters on surface quality, MRR and EW of WC-Co. J. Mater. Process. Technol. 2004, 153–154, 1026–1032. [Google Scholar] [CrossRef]

- Kunieda, M.; Kobayashi, T. Clarifying mechanism of determining tool electrode wear ratio in EDM using spectroscopic measurement of vapor density. J. Mater. Process. Technol. 2004, 149, 284–288. [Google Scholar] [CrossRef]

- Mascaraque-Ramírez, C.; Franco, P. Experimental study of tool degradation in EDM processes: Electrode material loss at the border and central zones. Int. J. Adv. Manuf. Technol. 2017, 95, 3497–3511. [Google Scholar] [CrossRef]

- Joudivand Sarand, M.H.; Shabgard, M.R. Investigation of the effect of thermal diffusivity coefficient of tool material on electrode-tool Wear in the EDM process. Arch. Civil. Mech. Eng. 2015, 15, 806–821. [Google Scholar] [CrossRef]

- Kiyak, M.; Aldemir, B.E.; Altan, E. Effects of discharge energy density on wear rate and surface roughness in EDM. Int. J. Adv. Manuf. Technol. 2015, 79, 513–518. [Google Scholar] [CrossRef]

- Puthumana, G.; Bissacco, G.; Hansen, H.N. Modeling of the effect of tool wear per discharge estimation error on the depth of machined cavities in micro-EDMmilling. Int. J. Adv. Manuf. Technol. 2017, 92, 3253–3264. [Google Scholar] [CrossRef]

- Venugopal, T.; Rao, A.K.M.R. Fabrication of differently shaped tool electrodes for micro-EDM. J. Mater. Sci. Surf. Eng. 2017, 5, 641–646. [Google Scholar]

- Torres, A.; Luis, C.J.; Puertas, I. Analysis of the influence of EDM parameters on surface finish, material removal rate, and electrode wear of an INCONEL 600 alloy. Int. J. Adv. Manuf. Technol. 2015, 80, 123–140. [Google Scholar] [CrossRef]

- Torres, A.; Luis, C.J.; Puertas, I. EDM machinability and surface roughness analysis of TiB2 using copper electrodes. J. Alloys Comp. 2017, 690, 337–347. [Google Scholar] [CrossRef]

- Uhlmann, E.; Domingos, D.C. Automated dressing of graphite electrodes for electrical discharge machining (EDM) of seal slots in turbine components. Proc. Manuf. 2016, 6, 45–52. [Google Scholar] [CrossRef]

- Trych-Wildner, A.; Wildner, K. Multifilament carbon fibre tool electrodes in micro EDM—Evaluation of process performance based on influence of input parameters. Int. J. Adv. Manuf. Technol. 2017, 91, 3737–3747. [Google Scholar] [CrossRef]

- Barenji, R.V.; Pourasl, H.H.; Khojastehnezhad, V.M. Electrical discharge machining of the AISI D6 tool steel: Prediction and modeling of the material removal rate and tool wear ratio. Prec. Eng. 2016, 45, 435–444. [Google Scholar] [CrossRef]

- Haque, R.; Sekh, M.; Kibria, G.; Haidar, S. Comparative study of parametric effects on the performance of simple and powder mixed EDM using aluminium and graphite powder on Inconel X750 alloy. Mater. Today Proc. 2021, 46, 8366–8373. [Google Scholar] [CrossRef]

- Kumar, V.; Kumar, P. Experimental investigation of the process parameters in cryogenic cooled electrode in EDM. J. Mech. Sci. Technol. 2015, 29, 3865–3871. [Google Scholar] [CrossRef]

- Kanth Grover, N. Wear Properties of Cryogenic Treated Electrodes on Machining of En-31. Mater. Today Proc. 2015, 2, 1406–1413. [Google Scholar]

- Kumar, S.; Batish, A.; Singh, R.; Bhattacharya, A. Effect of cryogenically treated copper-tungsten electrode on tool wear rate during electro-discharge machining of Ti-5Al-2.5 Sn alloy. Wear 2017, 386, 223–229. [Google Scholar] [CrossRef]

- Mathai, V.J.; Vaghela, R.V.; Dave, H.K.; Raval, H.K.; Desai, K.P. Study of the Effect of Cryogenic Treatment of Tool Electrodes during Electro Discharge Machining. In Proceedings of the Eighth International Conference on Precision Meso, Micro & Nano Engineering (COPEN-8: 2013) At: National Institute of Technology, Calicut, India, 13–15 December 2013. [Google Scholar]

- Shastri, R.K.; Mohanty, C.P.; Jadhav, P.S. Study of the Effect of Cryogenically treated tools during Rapid Drill Electro-discharge machining of Ti-6Al-4V alloy. Mater. Today: Proc. 2019, 18, 3122–3127. [Google Scholar] [CrossRef]

- Da Silva, F.J.; Franco, S.D.; Machado, A.R.; Ezugwu, E.O.; Souza, A.M., Jr. Performance of cryogenically treated HSS tools. Wear 2006, 261, 674–685. [Google Scholar] [CrossRef]

- Kumar, A.; Maheshwari, S.; Sharma, C.; Beri, N. Machining efficiency evaluation of cryogenically treated copper electrode in additive mixed EDM. Mater. Manuf. Processes 2012, 27, 1051–1058. [Google Scholar] [CrossRef]

- Kumar, S.; Singh, R.; Batish, A.; Singh, T.P. Modeling the tool wear rate in powder mixed electro-discharge machining of titanium alloys using dimensional analysis of cryogenically treated electrodes and work piece. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2017, 231, 271–282. [Google Scholar] [CrossRef]

- Sundaram, M.M.; Yildiz, Y.; Rajurkar, K.P. Experimental study of the effect of cryogenic treatment on the performance of electro discharge machining. In Proceedings of the ASME 2009 International Manufacturing Science and Engineering Conference, West Lafayette, IN, USA, 4–7 October 2009; American Society of Mechanical Engineers Digital Collection: New York, NY, USA, 2009; pp. 215–222. [Google Scholar]

- Guu, Y.H.; Hocheng, H.; Chou, C.Y.; Deng, C.S. Effect of electrical discharge machining on surface characteristics and machining damage of AISI D2 tool steel. Mater. Sci. Eng. A 2003, 358, 37–43. [Google Scholar] [CrossRef]

- Rahul; Datta, S.; Masanta, M.; Biswal, B.B.; Mahapatra, S.S. Analysis on surface characteristics of electro-discharge machined Inconel 718. Int. J. Mater. Prod. Technol. 2018, 56, 135–168. [Google Scholar] [CrossRef]

- Bhattacharyya, B.; Gangopadhyay, S.; Sarkar, B.R. Modelling and analysis of EDM ED job surface integrity. J. Mater. Processing Technol. 2007, 189, 169–177. [Google Scholar] [CrossRef]

- Keskin, Y.; Halkacı, H.S.; Kizil, M. An experimental study for determination of the effects of machining parameters on surface roughness in electrical discharge machining (EDM). Int. J. Adv. Manuf. Technol. 2006, 28, 1118–1121. [Google Scholar] [CrossRef]

- Lee, H.T.; Yur, J.P.P. Characteristic analysis of EDMed surfaces using the Taguchi approach. Mater. Manuf. Processes 2000, 15, 781–806. [Google Scholar] [CrossRef]

- Liao, Y.S.; Huang, J.T.; Chen, Y.H. A study to achieve a fine surface finish in wire-EDM. J. Mater. Processing Technol. 2004, 149, 165–171. [Google Scholar] [CrossRef]

- Mandal, A.; Dixit, A.R.; Chattopadhyaya, S.; Paramanik, A.; Hloch, S.; Królczyk, G. Improvement of surface integrity of Nimonic C 263 super alloy produced by WEDM through various post-processing techniques. Int. J. Adv. Manuf. Technol. 2017, 93, 433–443. [Google Scholar] [CrossRef]

- Aspinwall, D.K.; Soo, S.L.; Berrisford, A.E.; Walder, G. Work piece surface roughness and integrity after WEDM of Ti– 6Al–4V and Inconel 718 using minimum damage generator technology. CIRP Ann. 2008, 57, 187–190. [Google Scholar] [CrossRef]

- Bleys, P.; Kruth, J.-P.; Lauwers, B.; Schacht, B.; Balasubramanian, V.; Froyen, L.; Van Humbeeck, J. Surface and Sub-Surface Quality of Steel after EDM. Adv. Eng. Mater. 2006, 8, 15–25. [Google Scholar] [CrossRef]

- Goyal, P.; Suri, N.M.; Kumar, S.; Kumar, R. Investigating the surface properties of EN-31 die-steel after machining with powder metallurgy EDM electrodes. Mater. Today: Proc. 2017, 4, 3694–3700. [Google Scholar] [CrossRef]

- Li, L.; Li, Z.Y.; Wei, X.T.; Cheng, X. Machining characteristics of Inconel 718 by sinking-EDM and wire-EDM. Mater. Manuf. Processes 2015, 30, 968–973. [Google Scholar] [CrossRef]

- Sreenivasa Rao, M.; Venkaiah, N. Parametric optimization in machining of Nimonic-263 alloy using RSM and particle swarm optimization. Procedia Mater. Sci. 2015, 10, 70–79. [Google Scholar] [CrossRef]

- Datta, S.; Biswal, B.B.; Mahapatra, S.S. A novel satisfaction function and distance-based approach for machining performance optimization during electro-discharge machining on super alloy Inconel 718. Arab. J. Sci. Eng. 2017, 42, 1999–2020. [Google Scholar]

- Shastri, R.K.; Mohanty, C.P. Machinability investigation on Nimonic C263 alloy in electric discharge machine. Mater. Today Proc. 2019, 26, 529–533. [Google Scholar] [CrossRef]

- Zhang, Z.; Yu, H.; Zhang, Y.; Yang, K.; Li, W.; Chen, Z.; Zhang, G. Analysis and optimization of process energy consumption and environmental impact in electrical discharge machining of titanium superalloys. J. Clean. Prod. 2018, 198, 833–846. [Google Scholar] [CrossRef]

- Shastri, R.K.; Mohanty, C.P. Sustainable Electrical Discharge Machining of Nimonic C263 Superalloy. Arab. J. Sci. Eng. 2021, 46, 7273–7293. [Google Scholar] [CrossRef]

- Rajhi, W.; Alatawi, I.; Subhani, T.; Ayadi, B.; Al-Ghamdi, A.; Khaliq, A. A contribution to numerical prediction of surface damage and residual stresses on die-sinking EDM of Ti6Al4V. J. Manuf. Processes. 2021, 68, 1458–1484. [Google Scholar] [CrossRef]

- Pei, H.; Wang, J.; Li, Z.; Li, Z.; Yao, X.; Wen, Z.; Yue, Z. Oxidation behavior of recast layer of air-film hole machined by EDM technology of Ni-based single crystal blade and its effect on creep strength. Surf. Coat. Technol. 2021, 419, 127285. [Google Scholar] [CrossRef]

- Li, C.; Xu, X.; Li, Y.; Tong, H.; Ding, S.; Kong, Q.; Zhao, L.; Ding, J. Effects of dielectric fluids on surface integrity for the recast layer in high speed EDM drilling of nickel alloy. J. Alloys Compd. 2019, 783, 95–102. [Google Scholar] [CrossRef]

- Xavior, M.A.; Ashwath, P.; Ali, H.; Moideen, A.; Banu, P.; Raneez, M.; Sancylal, S. Effect of recast layer thickness on the mechanical characteristics of INCONEL 718 machined by spark EDM process. Mater. Today Proc. 2018, 5, 8249–8255. [Google Scholar] [CrossRef]

- Reddy, B.S.; Rao, A.K.; Janardhana, G.R. Multi-objective optimization of surface roughness, recast layer thickness and surface crack density in WEDM of Al2124/SiCp using desirability approach. Mater. Today Proc. 2021, 39, 1320–1326. [Google Scholar] [CrossRef]

- Sahu, S.N.; Nayak, N.C. Multi-objective optimisation of EDM process using ANN integrated with NSGA-II algorithm. Int. J. Manuf. Technol. Manag. 2018, 32, 381–395. [Google Scholar] [CrossRef]

- Kumar, V.; Jangra, K.K.; Kumar, V.; Sharma, N. GA-based optimisation using RSM in WEDM of Nimonic-90: A nickel-based super alloy. Int. J. Ind. Syst. Eng. 2018, 28, 53–69. [Google Scholar] [CrossRef]

- Gostimirovic, M.; Pucovsky, V.; Sekulic, M.; Radovanovic, M.; Madic, M. Evolutionary multi-objective optimization of energy efficiency in electrical discharge machining. J. Mech. Sci. Technol. 2018, 32, 4775–4785. [Google Scholar] [CrossRef]

- Mandal, P.; Mondal, S.C. Multi-objective optimization of Cu-MWCNT composite electrode in electro discharge machining using MOPSO-TOPSIS. Measurement 2021, 169, 108347. [Google Scholar] [CrossRef]

- Sahoo, S.K.; Thirupathi, N.; Saraswathamma, K. Experimental Investigation and Multi-Objective Optimization of Die sink EDM Process Parameters on Inconel-625 alloy by using Utility Function Approach. Mater. Today Proc. 2020, 24, 995–1005. [Google Scholar] [CrossRef]

- Kumari, S.; Sonia, P.; Singh, B.; Abhishek, K.; Saxena, K.K. Optimization of surface roughness in EDM of pure magnesium (Mg) using TLBO. Mater. Today Proc. 2020, 26, 2458–2461. [Google Scholar] [CrossRef]

| Year | Author | Novelties in EDM |

|---|---|---|

| 2004 | Singh et al. [12] | EDM was utilized to machine hardened tool steel with different tool electrodes such as copper, copper-tungsten, brass, and aluminium. |

| 2007 | Khanra et al. [29] | The ZrB2-Cu composite electrode was used to machine the material in EDM. High MRR and low TWR were reported by using this composite electrode. |

| 2007 | Abdullah and Shabgard [65] | The effect of ultrasonic vibration-assisted copper tools on the machining of cemented tungsten carbide was investigated. |

| 2010 | Abdulkareem et al. [26] | Electrode cooling was carried out during EDM of titanium alloy. The effect of electrode cooling on electrode wear was deliberated. |

| 2013 | Gopalakannan et al. [28] | EDM was employed to machine a metal matrix nanocomposite synthesized by the ultrasonic cavitation method. |

| 2015 | Dewangan et al. [32] | A Grey-Fuzzy logic-based hybrid optimization technique was reported to improve the surface integrity of material during EDM processing. |

| 2017 | Kumar et al. [99] | Surface integrity and metallurgical characteristics of Inconel 825 were investigated by machining with cryogenically treated copper electrodes. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shastri, R.K.; Mohanty, C.P.; Dash, S.; Gopal, K.M.P.; Annamalai, A.R.; Jen, C.-P. Reviewing Performance Measures of the Die-Sinking Electrical Discharge Machining Process: Challenges and Future Scopes. Nanomaterials 2022, 12, 384. https://doi.org/10.3390/nano12030384

Shastri RK, Mohanty CP, Dash S, Gopal KMP, Annamalai AR, Jen C-P. Reviewing Performance Measures of the Die-Sinking Electrical Discharge Machining Process: Challenges and Future Scopes. Nanomaterials. 2022; 12(3):384. https://doi.org/10.3390/nano12030384

Chicago/Turabian StyleShastri, Renu Kiran, Chinmaya Prasad Mohanty, Sitaram Dash, Karthick Muthaiah Palaniappan Gopal, A. Raja Annamalai, and Chun-Ping Jen. 2022. "Reviewing Performance Measures of the Die-Sinking Electrical Discharge Machining Process: Challenges and Future Scopes" Nanomaterials 12, no. 3: 384. https://doi.org/10.3390/nano12030384

APA StyleShastri, R. K., Mohanty, C. P., Dash, S., Gopal, K. M. P., Annamalai, A. R., & Jen, C.-P. (2022). Reviewing Performance Measures of the Die-Sinking Electrical Discharge Machining Process: Challenges and Future Scopes. Nanomaterials, 12(3), 384. https://doi.org/10.3390/nano12030384