Crystallographic Anisotropy Dependence of Interfacial Sliding Phenomenon in a Cu(16)/Nb(16) ARB (Accumulated Rolling Bonding) Nanolaminate

Abstract

1. Introduction

2. Materials and Methods

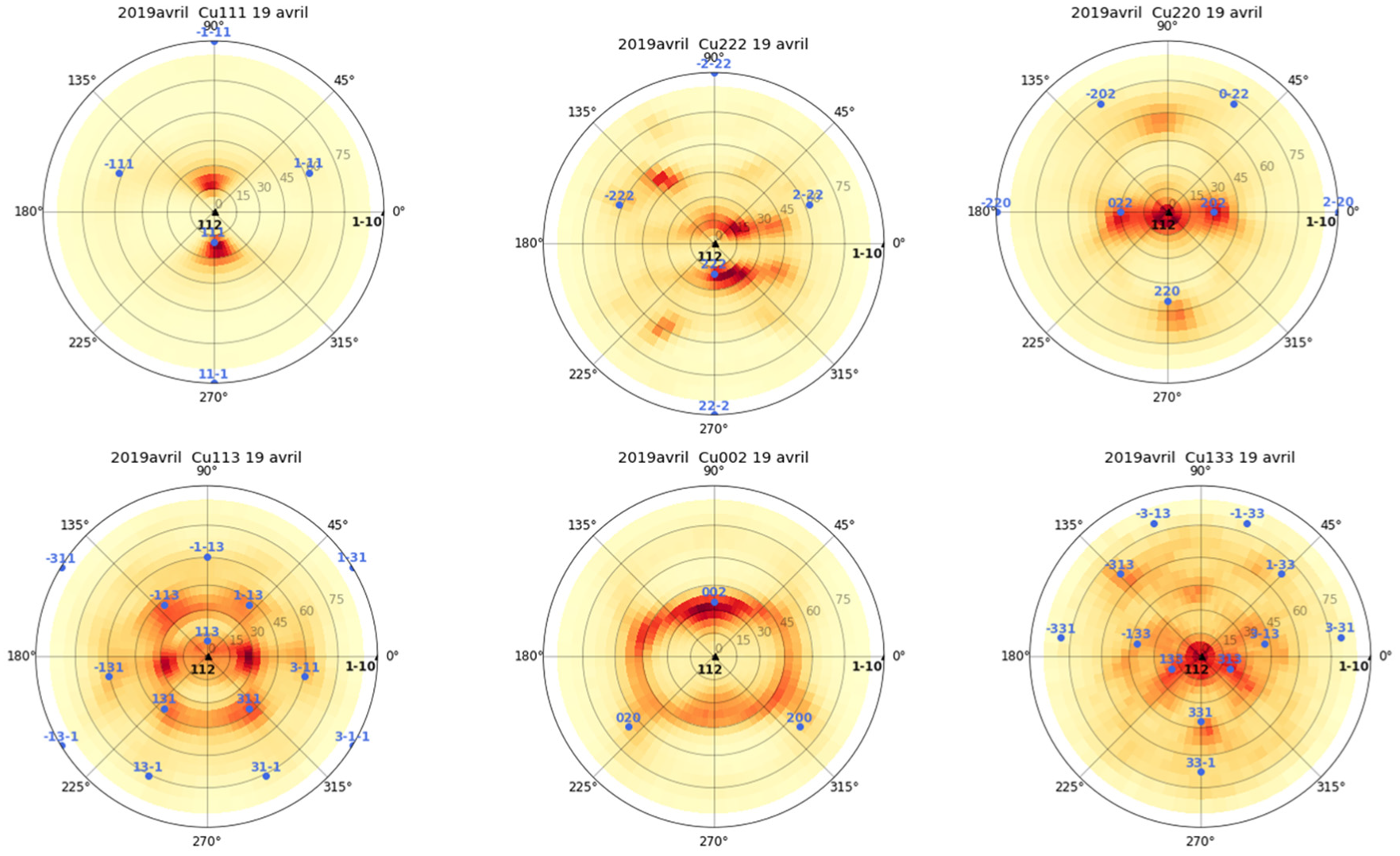

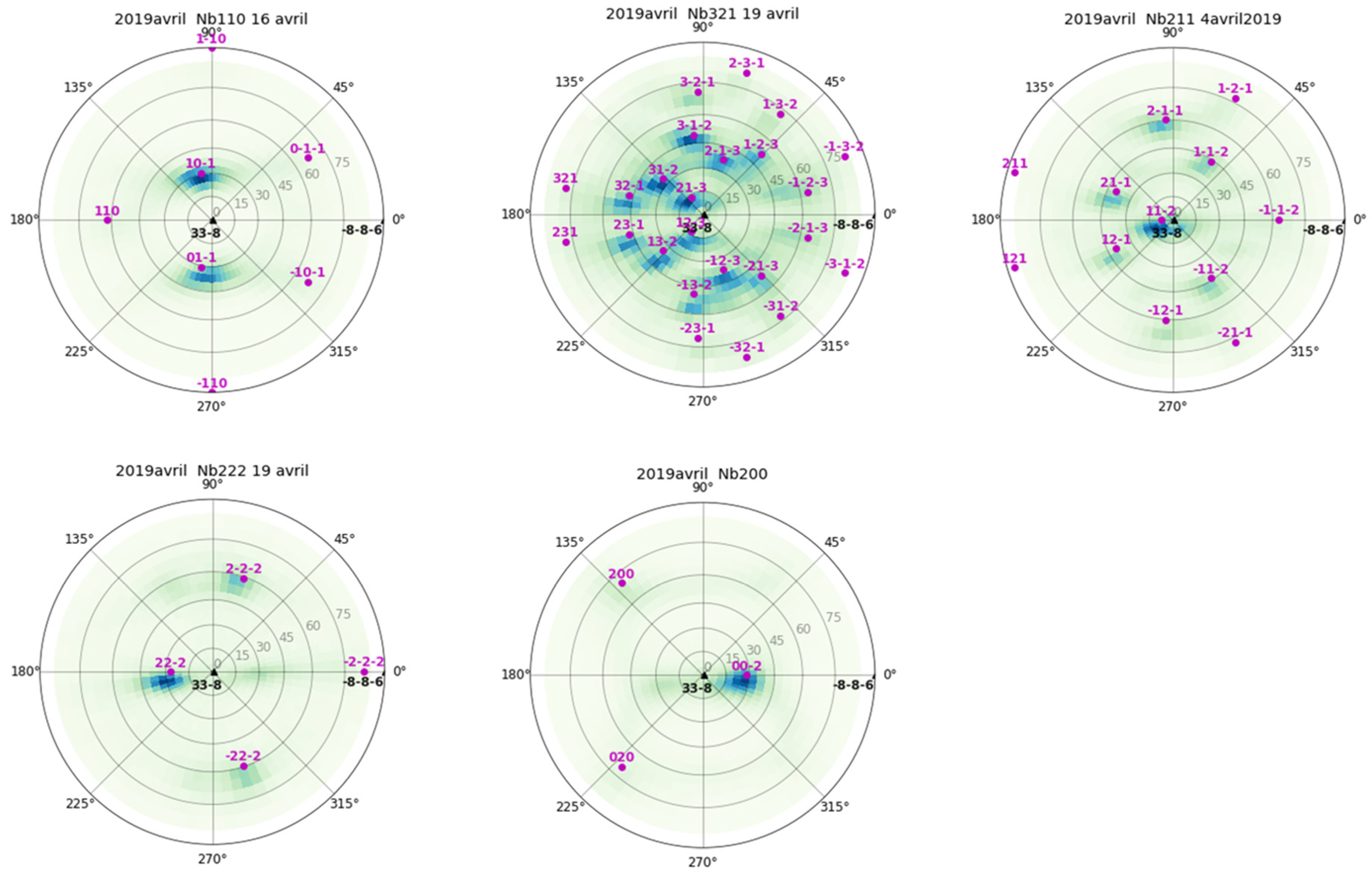

2.1. Materials

2.2. Nanoindentation

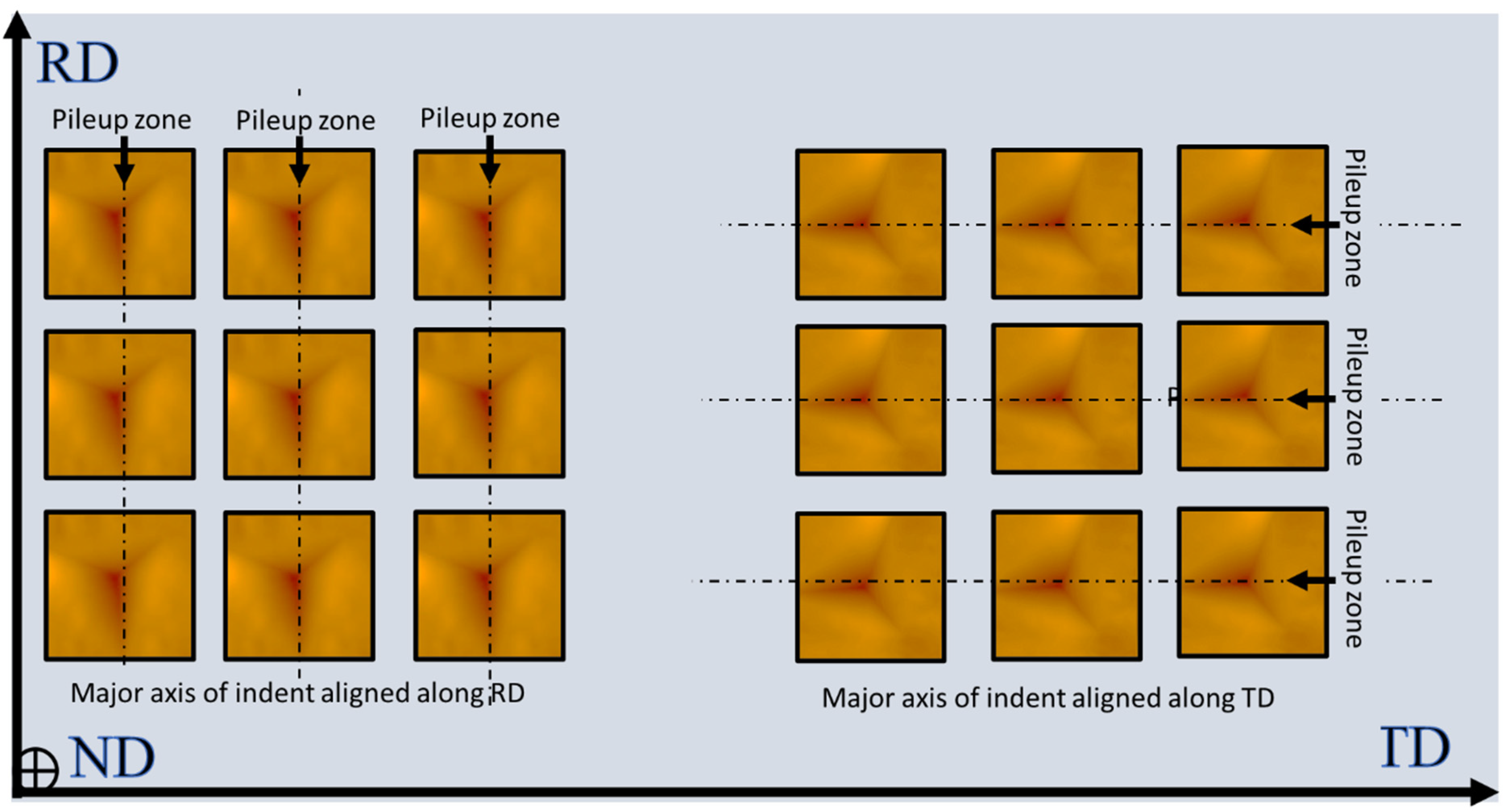

2.3. Surface Pile-Up Profile

2.4. TEM + EDX Sample Preparation and Analysis

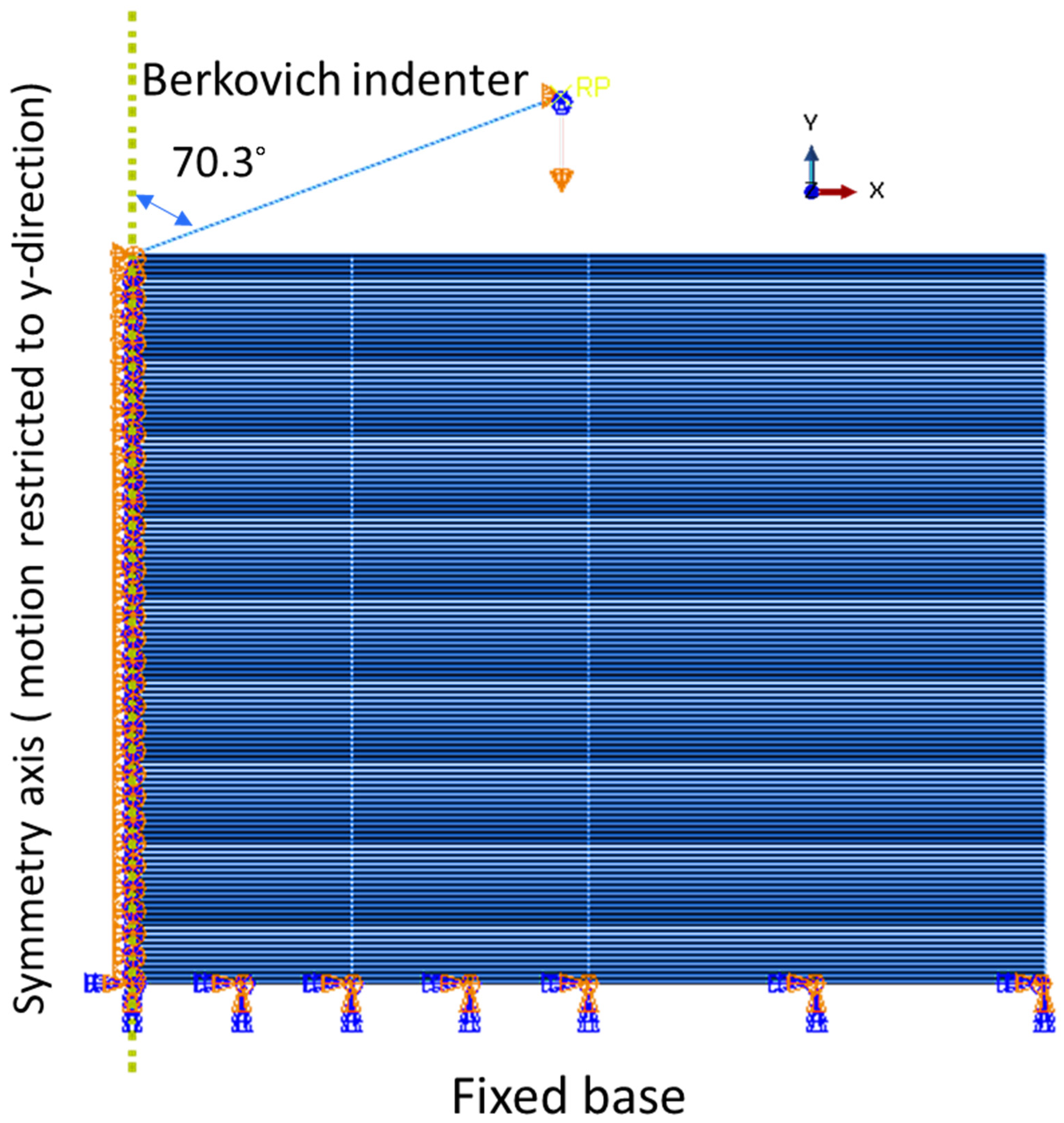

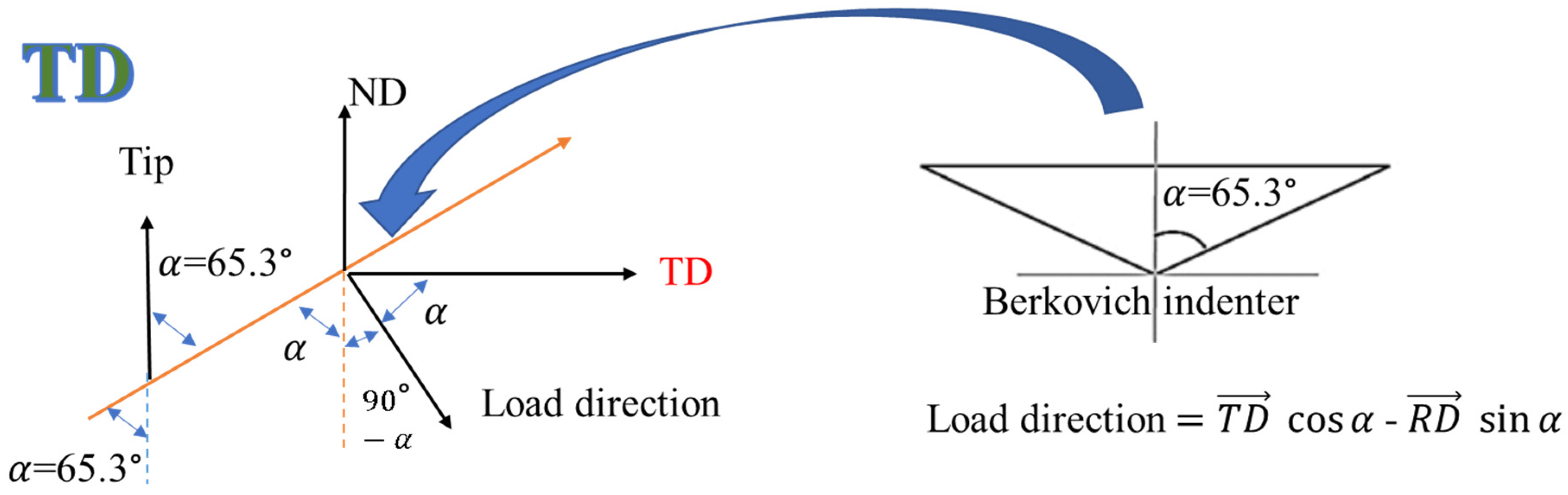

2.5. Simulation of Nanoindentation of Cu(16)/Nb(16) ARB Nanolaminate

3. Results

3.1. Nanoindentation Analysis of Cu(16)/Nb(16) ARB Nanolaminate

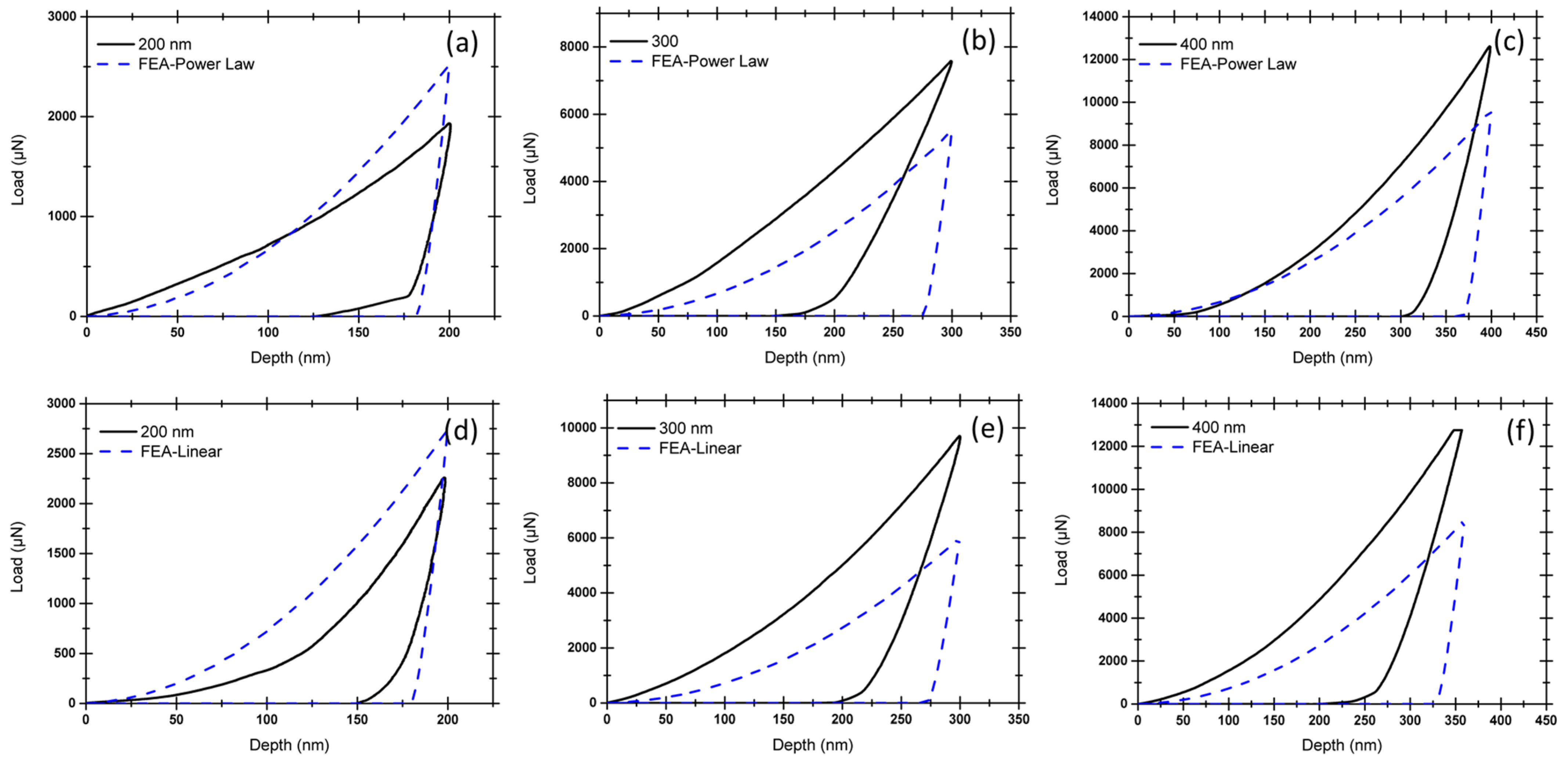

3.2. Simulation of Indentation on 16 nm Cu(16)/Nb(16) ARB Nanolaminate

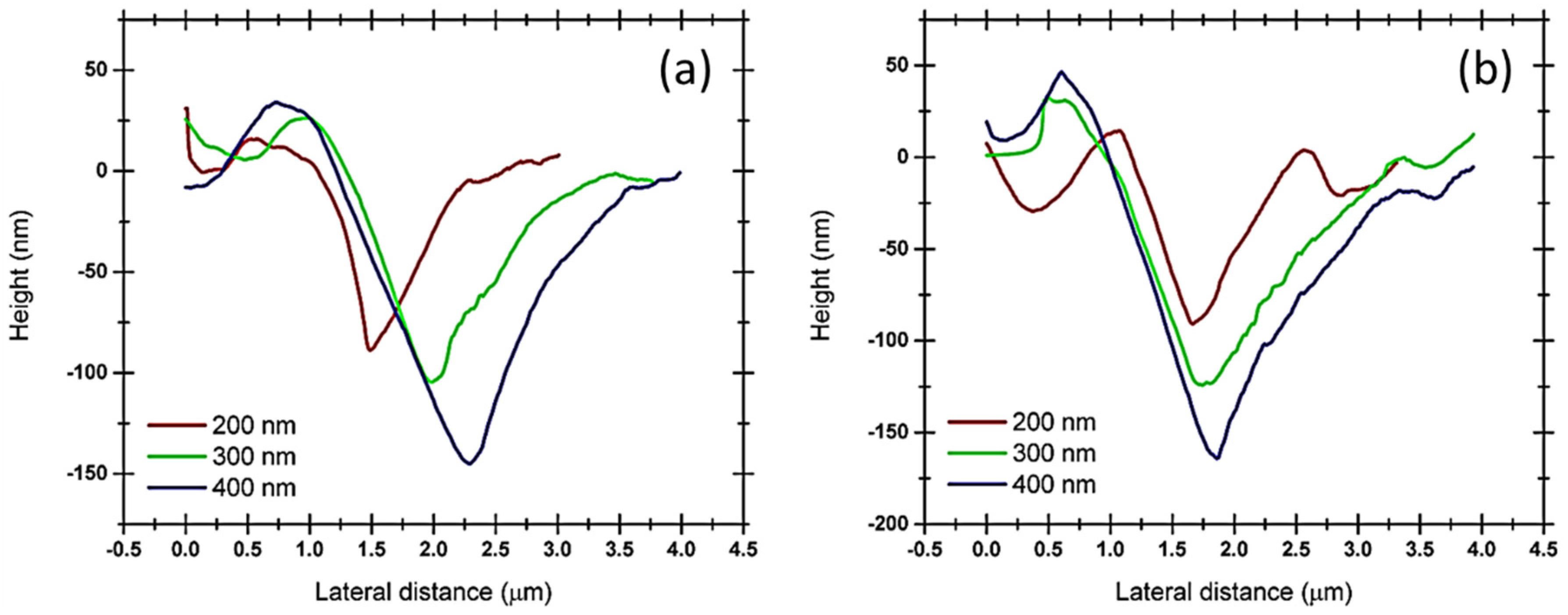

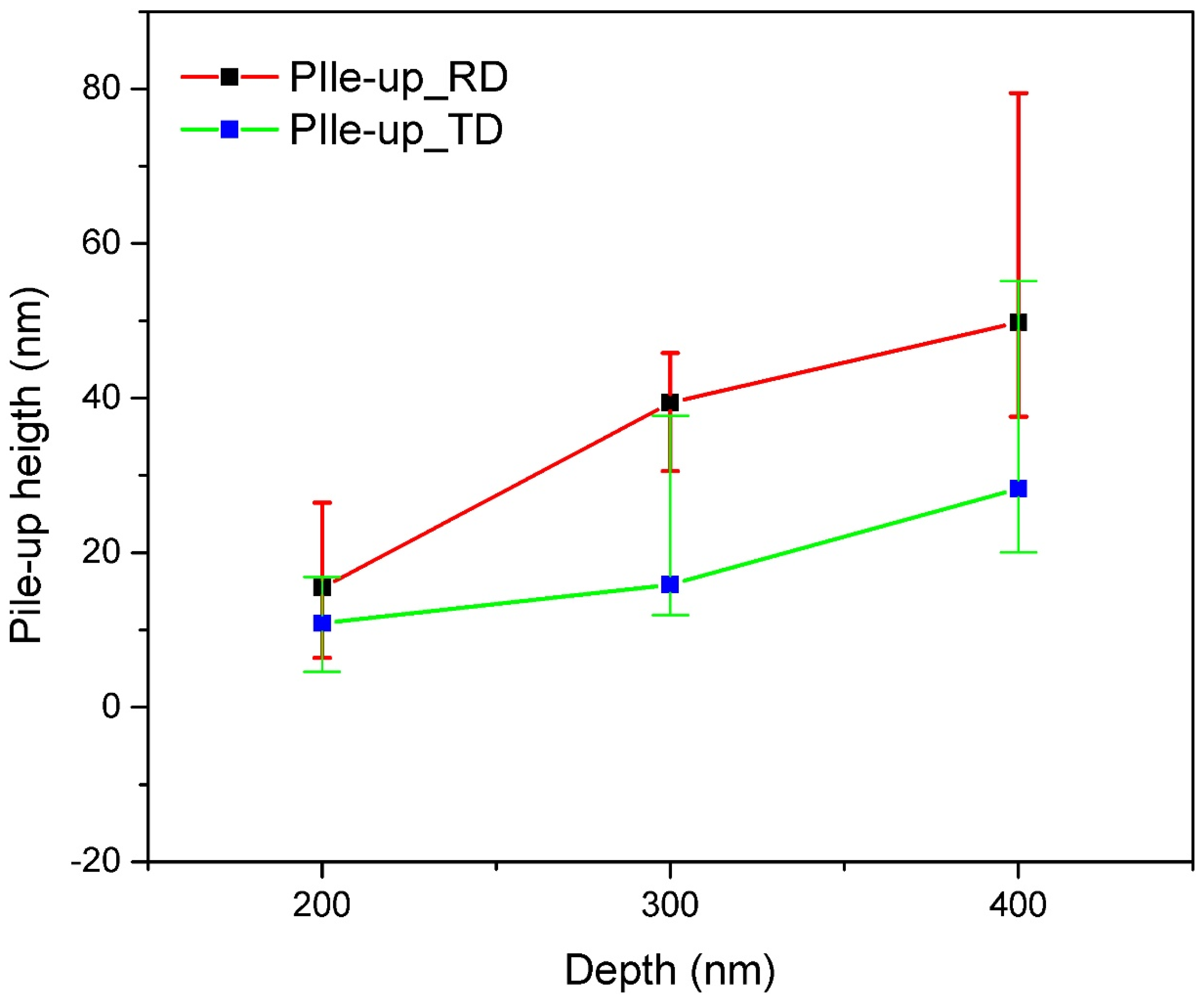

3.3. Pile-Up of Indentations along TD and RD of the Cu(16)/Nb(16) ARB Nanolaminate

4. Discussion

4.1. Nanoindentation Performed along TD and RD of Cu(16)/Nb(16) ARB Nanolaminate

4.2. Pile-Up as a Measure of Anisotropy of Cu(16)/Nb(16) ARB Nanolaminate

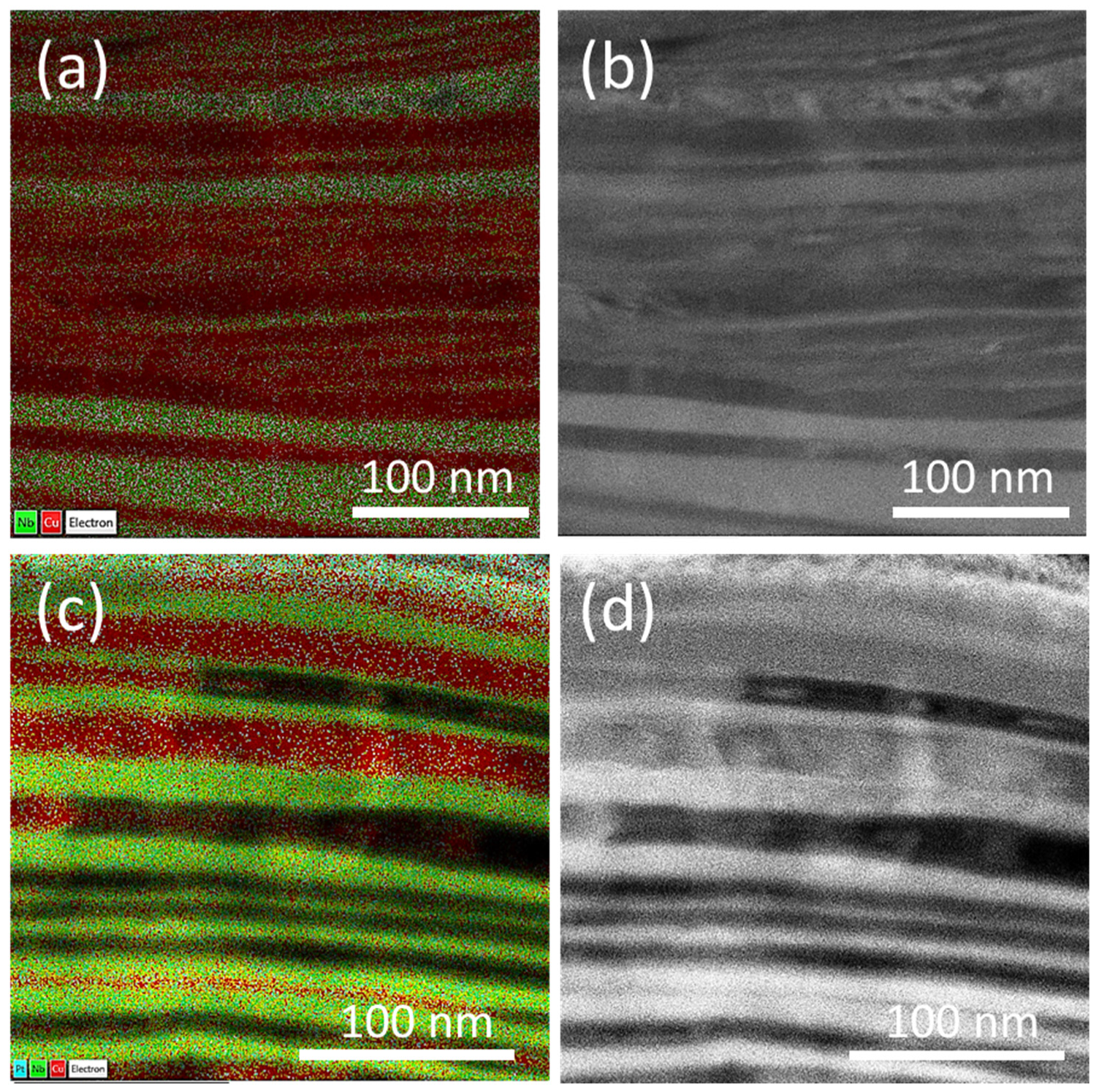

4.3. TEM + EDX Analysis of Cu(16)/Nb(16) ARB Nanolaminate

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Misra, A.; Verdier, M.; Lu, Y.C.; Kung, H.; Mitchell, T.E.; Nastasi, M.; Embury, J.D. Structure and mechanical properties of Cu-X (X = Nb, Cr, Ni) nanolayered composites. Scr. Mater. 1998, 39, 555–560. [Google Scholar] [CrossRef]

- Bufford, D.; Bi, Z.; Jia, Q.X.; Wang, H.; Zhang, X. Nanotwins and stacking faults in high-strength epitaxial Ag/Al multilayer films. Appl. Phys. Lett. 2012, 101, 223112. [Google Scholar] [CrossRef]

- Mara, N.A.; Bhattacharyya, D.; Dickerson, P.; Hoagland, R.G.; Misra, A. Deformability of ultrahigh strength 5 nm Cu∕ Nb nanolayered composites. Appl. Phys. Lett. 2008, 92, 231901. [Google Scholar] [CrossRef]

- Misra, A.; Zhang, X.; Hammon, D.; Hoagland, R.G. Work hardening in rolled nanolayered metallic composites. Acta Mater. 2005, 53, 221–226. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Zhang, X.; Wang, R.H.; Lei, S.Y.; Zhang, P.; Niu, J.J.; Liu, G.; Zhang, G.J.; Sun, J. Length-scale-dependent deformation and fracture behavior of Cu/X (X= Nb, Zr) multilayers: The constraining effects of the ductile phase on the brittle phase. Acta Mater. 2011, 59, 7368–7379. [Google Scholar] [CrossRef]

- Budiman, A.S.; Han, S.-M.; Li, N.; Wei, Q.-M.; Dickerson, P.; Tamura, N.; Kunz, M.; Misra, A. Plasticity in the nanoscale Cu/Nb single-crystal multilayers as revealed by synchrotron Laue X-ray microdiffraction. J. Mater. Res. 2012, 27, 599–611. [Google Scholar] [CrossRef][Green Version]

- Budiman, A.S.; Narayanan, K.R.; Li, N.; Wang, J.; Tamura, N.; Kunz, M.; Misra, A. Plasticity evolution in nanoscale Cu/Nb single-crystal multilayers as revealed by synchrotron X-ray microdiffraction. Mater. Sci. Eng. A 2015, 635, 6–12. [Google Scholar] [CrossRef]

- Han, W.Z.; Misra, A.; Mara, N.A.; Germann, T.C.; Baldwin, J.K.; Shimada, T.; Luo, S.N. Role of interfaces in shock-induced plasticity in Cu/Nb nanolaminates. Philos. Mag. 2011, 91, 4172–4185. [Google Scholar] [CrossRef]

- Ding, C.; Xu, J.; Shan, D.; Guo, B.; Langdon, T.G. Sustainable fabrication of Cu/Nb composites with continuous laminated structure to achieve ultrahigh strength and excellent electrical conductivity. Compos. Part B Eng. 2021, 211, 108662. [Google Scholar] [CrossRef]

- Liu, Z.; Snel, J.; Boll, T.; Wang, J.Y.; Monclús, M.A.; Molina-Aldareguía, J.M.; LLorca, J. High temperature strength retention of Cu/Nb nanolaminates through dynamic strain ageing. Mater. Sci. Eng. A 2021, 799, 140117. [Google Scholar] [CrossRef]

- Shishvan, S.S. High-temperature tensile and creep behavior of Cu–Nb composites: A discrete dislocation plasticity investigation. Int. J. Plast. 2021, 136, 102876. [Google Scholar] [CrossRef]

- Demkowicz, M.J.; Hoagland, R.G.; Hirth, J.P. Interface structure and radiation damage resistance in Cu-Nb multilayer nanocomposites. Phys. Rev. Lett. 2008, 100, 136102. [Google Scholar] [CrossRef]

- Zhu, Y.; Ameyama, K.; Anderson, P.M.; Beyerlein, I.J.; Gao, H.; Kim, H.S.; Lavernia, E.; Mathaudhu, S.; Mughrabi, H.; Ritchie, R.O. Heterostructured materials: Superior properties from hetero-zone interaction. Mater. Res. Lett. 2021, 9, 1–31. [Google Scholar] [CrossRef]

- Gao, R.; Jin, M.; Li, Q.-J.; So, K.P.; Zhang, L.; Wang, X.; Fang, Q.; Sun, C.; Shao, L.; Li, J. Hybrid diffusive-displacive helium outgassing in Cu/Nb multilayer composites. Scr. Mater. 2021, 194, 113706. [Google Scholar] [CrossRef]

- Costescu, R.M.; Cahill, D.G.; Fabreguette, F.H.; Sechrist, Z.A.; George, S.M. Ultra-low thermal conductivity in W/Al2O3 nanolaminates. Science 2004, 303, 989–990. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.Y.; Zhang, P.; Zhang, X.; Wang, R.H.; Liu, G.; Zhang, G.J.; Sun, J. Mechanical properties of fcc/fcc Cu/Nb nanostructured multilayers. Mater. Sci. Eng. A 2012, 545, 118–122. [Google Scholar] [CrossRef]

- Misra, A.; Hirth, J.P.; Hoagland, R.G. Length-scale-dependent deformation mechanisms in incoherent metallic multilayered composites. Acta Mater. 2005, 53, 4817–4824. [Google Scholar] [CrossRef]

- Vepřek, S. The search for novel, superhard materials. J. Vac. Sci. Technol. A Vac. Surf. Film. 1999, 17, 2401–2420. [Google Scholar] [CrossRef]

- Hoagland, R.G.; Mitchell, T.E.; Hirth, J.P.; Kung, H. On the strengthening effects of interfaces in multilayer fee metallic composites. Philos. Mag. A 2002, 82, 643–664. [Google Scholar] [CrossRef]

- Liu, Y.; Bufford, D.; Wang, H.; Sun, C.; Zhang, X. Mechanical properties of highly textured Cu/Ni multilayers. Acta Mater. 2011, 59, 1924–1933. [Google Scholar] [CrossRef]

- Nizolek, T.J.; Begley, M.R.; McCabe, R.J.; Avallone, J.T.; Mara, N.A.; Beyerlein, I.J.; Pollock, T.M. Strain fields induced by kink band propagation in Cu-Nb nanolaminate composites. Acta Mater. 2017, 133, 303–315. [Google Scholar] [CrossRef]

- Budiman, A.S.; Li, N.; Wei, Q.; Baldwin, J.K.; Xiong, J.; Luo, H.; Trugman, D.; Jia, Q.X.; Tamura, N.; Kunz, M. Growth and structural characterization of epitaxial Cu/Nb multilayers. Thin Solid Film. 2011, 519, 4137–4143. [Google Scholar] [CrossRef]

- Knez, M.; Nielsch, K.; Niinistö, L. Synthesis and surface engineering of complex nanostructures by atomic layer deposition. Adv. Mater. 2007, 19, 3425–3438. [Google Scholar] [CrossRef]

- Kukli, K.; Ihanus, J.; Ritala, M.; Leskela, M. Tailoring the dielectric properties of HfO2–Ta2O5 nanolaminates. Appl. Phys. Lett. 1996, 68, 3737–3739. [Google Scholar] [CrossRef]

- Betz, G.; Wehner, G.K. Sputtering of multicomponent materials. Sputtering Part. Bombard. II 1983, 52, 11–90. [Google Scholar]

- Lu, Y.Y.; Kotoka, R.; Ligda, J.P.; Cao, B.B.; Yarmolenko, S.N.; Schuster, B.E.; Wei, Q. The microstructure and mechanical behavior of Mg/Ti multilayers as a function of individual layer thickness. Acta Mater. 2014, 63, 216–231. [Google Scholar] [CrossRef]

- Carpenter, J.S.; Vogel, S.C.; LeDonne, J.E.; Hammon, D.L.; Beyerlein, I.J.; Mara, N.A. Bulk texture evolution of Cu–Nb nanolamellar composites during accumulative roll bonding. Acta Mater. 2012, 60, 1576–1586. [Google Scholar] [CrossRef]

- Brenner, A. Electrodeposition of Alloys: Principles and Practice; Elsevier: Amsterdam, The Netherlands, 2013; ISBN 1483223116. [Google Scholar]

- Piraux, L.; George, J.M.; Despres, J.F.; Leroy, C.; Ferain, E.; Legras, R.; Ounadjela, K.; Fert, A. Giant magnetoresistance in magnetic multilayered nanowires. Appl. Phys. Lett. 1994, 65, 2484–2486. [Google Scholar] [CrossRef]

- Jones, A.C.; Hitchman, M.L. Chemical Vapour Deposition: Precursors, Processes and Applications; Royal Society of Chemistry: London, UK, 2009; ISBN 0854044655. [Google Scholar]

- Valiev, R.Z.; Langdon, T.G. Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Langdon, T.G. Using high-pressure torsion for metal processing: Fundamentals and applications. Prog. Mater. Sci. 2008, 53, 893–979. [Google Scholar] [CrossRef]

- Saito, Y.; Utsunomiya, H.; Tsuji, N.; Sakai, T. Novel ultra-high straining process for bulk materials—Development of the accumulative roll-bonding (ARB) process. Acta Mater. 1999, 47, 579–583. [Google Scholar] [CrossRef]

- Ali, H.P.A.; Radchenko, I.; Li, N.; Budiman, A. The roles of interfaces and other microstructural features in Cu/Nb nanolayers as revealed by in situ beam bending experiments inside an scanning electron microscope (SEM). Mater. Sci. Eng. A 2018, 738, 253–263. [Google Scholar]

- Ali, H.P.A.; Radchenko, I.; Li, N.; Budiman, A. Effect of multilayer interface through in situ fracture of Cu/Nb and Al/Nb metallic multilayers. J. Mater. Res. 2019, 34, 1564–1573. [Google Scholar]

- Ali, H.P.A.; Budiman, A. Advances in In situ microfracture experimentation techniques: A case of nanoscale metal–metal multilayered materials. J. Mater. Res. 2019, 34, 1449–1468. [Google Scholar]

- Wu, K.; Chang, H.; Maawad, E.; Gan, W.M.; Brokmeier, H.G.; Zheng, M.Y. Microstructure and mechanical properties of the Mg/Al laminated composite fabricated by accumulative roll bonding (ARB). Mater. Sci. Eng. A 2010, 527, 3073–3078. [Google Scholar] [CrossRef]

- Eizadjou, M.; Talachi, A.K.; Manesh, H.D.; Shahabi, H.S.; Janghorban, K. Investigation of structure and mechanical properties of multi-layered Al/Cu composite produced by accumulative roll bonding (ARB) process. Compos. Sci. Technol. 2008, 68, 2003–2009. [Google Scholar] [CrossRef]

- Yang, D.; Cizek, P.; Hodgson, P. Ultrafine equiaxed-grain Ti/Al composite produced by accumulative roll bonding. Scr. Mater. 2010, 62, 321–324. [Google Scholar] [CrossRef]

- Ghalandari, L.; Moshksar, M.M. High-strength and high-conductive Cu/Ag multilayer produced by ARB. J. Alloys Compd. 2010, 506, 172–178. [Google Scholar] [CrossRef]

- Tayyebi, M.; Eghbali, B. Study on the microstructure and mechanical properties of multilayer Cu/Ni composite processed by accumulative roll bonding. Mater. Sci. Eng. A 2013, 559, 759–764. [Google Scholar] [CrossRef]

- Beyerlein, I.J.; Mara, N.A.; Carpenter, J.S.; Nizolek, T.; Mook, W.M.; Wynn, T.A.; McCabe, R.J.; Mayeur, J.R.; Kang, K.; Zheng, S. Interface-driven microstructure development and ultra high strength of bulk nanostructured Cu-Nb multilayers fabricated by severe plastic deformation. J. Mater. Res. 2013, 28, 1799–1812. [Google Scholar] [CrossRef]

- Fischer-Cripps, A.C.; Nicholson, D.W. Nanoindentation. Mechanical engineering series. Appl. Mech. Rev. 2004, 57, B12. [Google Scholar] [CrossRef]

- Mitchell, T.E.; Lu, Y.C.; Griffin, A.J., Jr.; Nastasi, M.; Kung, H. Structure and mechanical properties of copper/niobium multilayers. J. Am. Ceram. Soc. 1997, 80, 1673–1676. [Google Scholar] [CrossRef]

- Zhang, G.P.; Liu, Y.; Wang, W.; Tan, J. Experimental evidence of plastic deformation instability in nanoscale Au∕ Cu multilayers. Appl. Phys. Lett. 2006, 88, 13105. [Google Scholar] [CrossRef]

- Li, Y.P.; Zhu, X.F.; Tan, J.; Wu, B.; Wang, W.; Zhang, G.P. Comparative investigation of strength and plastic instability in Cu/Au and Cu/Cr multilayers by indentation. J. Mater. Res. 2009, 24, 728–735. [Google Scholar] [CrossRef]

- Li, Y.P.; Zhu, X.F.; Zhang, G.P.; Tan, J.; Wang, W.; Wu, B. Investigation of deformation instability of Au/Cu multilayers by indentation. Philos. Mag. 2010, 90, 3049–3067. [Google Scholar] [CrossRef]

- Gerberich, W.W.; Kramer, D.E.; Tymiak, N.I.; Volinsky, A.A.; Bahr, D.F.; Kriese, M.D. Nanoindentation-induced defect–interface interactions: Phenomena, methods and limitations. Acta Mater. 1999, 47, 4115–4123. [Google Scholar] [CrossRef]

- Esqué-de los Ojos, D.; Očenášek, J.; Alcalá, J. Sharp indentation crystal plasticity finite element simulations: Assessment of crystallographic anisotropy effects on the mechanical response of thin fcc single crystalline films. Comput. Mater. Sci. 2014, 86, 186–192. [Google Scholar] [CrossRef]

- Biener, M.M.; Biener, J.; Hodge, A.M.; Hamza, A.V. Dislocation nucleation in bcc Ta single crystals studied by nanoindentation. Phys. Rev. B 2007, 76, 165422. [Google Scholar] [CrossRef]

- Morris, J.R.; Bei, H.; Pharr, G.M.; George, E.P. Size effects and stochastic behavior of nanoindentation pop in. Phys. Rev. Lett. 2011, 106, 165502. [Google Scholar] [CrossRef] [PubMed]

- Zheng, S.; Beyerlein, I.J.; Carpenter, J.S.; Kang, K.; Wang, J.; Han, W.; Mara, N.A. High-strength and thermally stable bulk nanolayered composites due to twin-induced interfaces. Nat. Commun. 2013, 4, 1696. [Google Scholar] [CrossRef] [PubMed]

- Carpenter, J.S.; McCabe, R.J.; Zheng, S.J.; Wynn, T.A.; Mara, N.A.; Beyerlein, I.J. Processing parameter influence on texture and microstructural evolution in Cu-Nb multilayer composites fabricated via accumulative roll bonding. Metall. Mater. Trans. A 2014, 45, 2192–2208. [Google Scholar] [CrossRef]

- Kocks, U.F.; Tomé, C.N.; Wenk, H.-R. Texture and Anisotropy: Preferred Orientations in Polycrystals and Their Effect on Materials Properties; Cambridge University Press: Cambridge, UK, 1998; ISBN 052179420X. [Google Scholar]

- Beyerlein, I.J.; Mara, N.A.; Wang, J.; Carpenter, J.S.; Zheng, S.J.; Han, W.Z.; Zhang, R.F.; Kang, K.; Nizolek, T.; Pollock, T.M. Structure-property-functionality of bimetal interfaces. JOM 2012, 64, 1192–1207. [Google Scholar] [CrossRef]

- Demkowicz, M.J.; Thilly, L. Structure, shear resistance and interaction with point defects of interfaces in Cu–Nb nanocomposites synthesized by severe plastic deformation. Acta Mater. 2011, 59, 7744–7756. [Google Scholar] [CrossRef]

- Sahay, R.; Budiman, A.S.; Harito, C.; Gunawan, F.E.; Navarro, E.; Escoubas, S.; Cornelius, T.W.; Aziz, I.; Lee, P.S.; Thomas, O. Berkovich nanoindentation study of 16 nm Cu/Nb ARB nanolaminate: Effect of anisotropy on the surface pileup. MRS Adv. 2021, 6, 495–499. [Google Scholar] [CrossRef]

- Radchenko, I.; Anwarali, H.P.; Tippabhotla, S.K.; Budiman, A.S. Effects of interface shear strength during failure of semicoherent metal–metal nanolaminates: An example of accumulative roll-bonded Cu/Nb. Acta Mater. 2018, 156, 125–135. [Google Scholar] [CrossRef]

- Wang, J.; Misra, A. An overview of interface-dominated deformation mechanisms in metallic multilayers. Curr. Opin. Solid State Mater. Sci. 2011, 15, 20–28. [Google Scholar] [CrossRef]

- Lichinchi, M.; Lenardi, C.; Haupt, J.; Vitali, R. Simulation of Berkovich nanoindentation experiments on thin films using finite element method. Thin Solid Film. 1998, 312, 240–248. [Google Scholar] [CrossRef]

- Wang, Y. Effects of indenter angle and friction on the mechanical properties of film materials. Results Phys. 2016, 6, 509–514. [Google Scholar] [CrossRef][Green Version]

- Huang, X.; Pelegri, A.A. Finite element analysis on nanoindentation with friction contact at the film/substrate interface. Compos. Sci. Technol. 2007, 67, 1311–1319. [Google Scholar] [CrossRef]

- Knapp, J.A.; Follstaedt, D.M.; Barbour, J.C.; Myers, S.M. Finite-element modeling of nanoindentation for determining the mechanical properties of implanted layers and thin films. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 1997, 127, 935–939. [Google Scholar] [CrossRef]

- Song, W.J.R.; Tippabhotla, S.K.; Tay, A.A.O.; Budiman, A.S. Numerical simulation of the evolution of stress in solar cells during the entire manufacturing cycle of a conventional silicon wafer based photovoltaic laminate. IEEE J. Photovolt. 2017, 8, 210–217. [Google Scholar] [CrossRef]

- Song, W.J.R.; Tippabhotla, S.K.; Tay, A.A.O.; Budiman, A.S. Effect of interconnect geometry on the evolution of stresses in a solar photovoltaic laminate during and after lamination. Sol. Energy Mater. Sol. Cells 2018, 187, 241–248. [Google Scholar] [CrossRef]

- Budiman, A.S.; Shin, H.-A.-S.; Kim, B.-J.; Hwang, S.-H.; Son, H.-Y.; Suh, M.-S.; Chung, Q.-H.; Byun, K.-Y.; Tamura, N.; Kunz, M. Measurement of stresses in Cu and Si around through-silicon via by synchrotron X-ray microdiffraction for 3-dimensional integrated circuits. Microelectron. Reliab. 2012, 52, 530–533. [Google Scholar] [CrossRef]

- Tian, T.; Morusupalli, R.; Shin, H.; Son, H.-Y.; Byun, K.-Y.; Joo, Y.-C.; Caramto, R.; Smith, L.; Shen, Y.L.; Kunz, M. On the mechanical stresses of cu through-silicon via (tsv) samples fabricated by sk hynix vs. sematech–enabling robust and reliable 3-d interconnect/integrated circuit (ic) technology. Procedia Eng. 2016, 139, 101–111. [Google Scholar] [CrossRef]

- Tippabhotla, S.K.; Song, W.J.R.; Tay, A.A.O.; Budiman, A.S. Effect of encapsulants on the thermomechanical residual stress in the back-contact silicon solar cells of photovoltaic modules–A constrained local curvature model. Sol. Energy 2019, 182, 134–147. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Misra, A.; Krug, H. Deformation behavior of nanostructured metallic multilayers. Adv. Eng. Mater. 2001, 3, 217–222. [Google Scholar] [CrossRef]

- McKeown, J.; Misra, A.; Kung, H.; Hoagland, R.G.; Nastasi, M. Microstructures and strength of nanoscale Cu–Ag multilayers. Scr. Mater. 2002, 46, 593–598. [Google Scholar] [CrossRef]

- Anderson, P.M.; Li, C. Hall-Petch relations for multilayered materials. Nanostruct. Mater. 1995, 5, 349–362. [Google Scholar] [CrossRef]

- Was, G.S.; Foecke, T. Deformation and fracture in microlaminates. Thin Solid Film. 1996, 286, 1–31. [Google Scholar] [CrossRef]

- Embury, J.D.; Hirth, J.P. On dislocation storage and the mechanical response of fine scale microstructures. Acta Metall. Mater. 1994, 42, 2051–2056. [Google Scholar] [CrossRef]

- Rao, S.I.; Hazzledine, P.M. Atomistic simulations of dislocation–interface interactions in the Cu-Ni multilayer system. Philos. Mag. A 2000, 80, 2011–2040. [Google Scholar] [CrossRef]

- Nizolek, T.; Beyerlein, I.J.; Mara, N.A.; Avallone, J.T.; Pollock, T.M. Tensile behavior and flow stress anisotropy of accumulative roll bonded Cu-Nb nanolaminates. Appl. Phys. Lett. 2016, 108, 2–6. [Google Scholar] [CrossRef]

- Chen, T.; Yuan, R.; Beyerlein, I.J.; Zhou, C. Predicting the size scaling in strength of nanolayered materials by a discrete slip crystal plasticity model. Int. J. Plast. 2020, 124, 247–260. [Google Scholar] [CrossRef]

- Bahr, D.F.; Kramer, D.E.; Gerberich, W.W. Non-linear deformation mechanisms during nanoindentation. Acta Mater. 1998, 46, 3605–3617. [Google Scholar] [CrossRef]

- Budiman, A.S.; Sahay, R.; Ali, H.P.A.; Tippabhotla, S.K.; Radchenko, I.; Raghavan, N. Interface-mediated plasticity and fracture in nanoscale Cu/Nb Multilayers as revealed by in situ clamped microbeam bending. Mater. Sci. Eng. A 2020, 140705. [Google Scholar] [CrossRef]

- Cheng, Y.-T.; Cheng, C.-M. What is indentation hardness? Surf. Coat. Technol. 2000, 133, 417–424. [Google Scholar] [CrossRef]

- Friedman, L.H.; Chrzan, D.C. Scaling theory of the Hall-Petch relation for multilayers. Phys. Rev. Lett. 1998, 81, 2715. [Google Scholar] [CrossRef]

- Cammarata, R.C.; Schlesinger, T.E.; Kim, C.; Qadri, S.B.; Edelstein, A.S. Nanoindentation study of the mechanical properties of copper-nickel multilayered thin films. Appl. Phys. Lett. 1990, 56, 1862–1864. [Google Scholar] [CrossRef]

- Wang, J.; Misra, A. Strain hardening in nanolayered thin films. Curr. Opin. Solid State Mater. Sci. 2014, 18, 19–28. [Google Scholar] [CrossRef]

- Anderson, P.M.; Foecke, T.; Hazzledine, P.M. Dislocation-based deformation mechanisms in metallic nanolaminates. Mrs Bull. 1999, 24, 27–33. [Google Scholar] [CrossRef]

- Phillips, M.A.; Clemens, B.M.; Nix, W.D. A model for dislocation behavior during deformation of Al/Al3Sc (fcc/L12) metallic multilayers. Acta Mater. 2003, 51, 3157–3170. [Google Scholar] [CrossRef]

- Cammarata, R.C.; Sieradzki, K.; Spaepen, F. Simple model for interface stresses with application to misfit dislocation generation in epitaxial thin films. J. Appl. Phys. 2000, 87, 1227–1234. [Google Scholar] [CrossRef]

- Casals, O.; Očenášek, J.; Alcala, J. Crystal plasticity finite element simulations of pyramidal indentation in copper single crystals. Acta Mater. 2007, 55, 55–68. [Google Scholar] [CrossRef]

- Koehler, J.S. Attempt to design a strong solid. Phys. Rev. B 1970, 2, 547. [Google Scholar] [CrossRef]

- Chirranjeevi, B.G.; Abinandanan, T.A.; Gururajan, M.P. A phase field study of morphological instabilities in multilayer thin films. Acta Mater. 2009, 57, 1060–1067. [Google Scholar] [CrossRef]

- Anderson, P.M.; Bingert, J.F.; Misra, A.; Hirth, J.P. Rolling textures in nanoscale Cu/Nb multilayers. Acta Mater. 2003, 51, 6059–6075. [Google Scholar] [CrossRef]

- Kim, Y.; Budiman, A.S.; Baldwin, J.K.; Mara, N.A.; Misra, A.; Han, S.M. Microcompression study of Al-Nb nanoscale multilayers. J. Mater. Res. 2012, 27, 592. [Google Scholar] [CrossRef]

- Hoagland, R.G.; Kurtz, R.J.; Henager, C.H., Jr. Slip resistance of interfaces and the strength of metallic multilayer composites. Scr. Mater. 2004, 50, 775–779. [Google Scholar] [CrossRef]

- Wang, J.; Hoagland, R.G.; Hirth, J.P.; Misra, A. Atomistic simulations of the shear strength and sliding mechanisms of copper–niobium interfaces. Acta Mater. 2008, 56, 3109–3119. [Google Scholar] [CrossRef]

| Material | Property | RD | TD |

|---|---|---|---|

| Cu | Young’s modulus, GPa | 110 | 110 |

| Poisson’s ratio | 0.34 | 0.34 | |

| Yield strength, GPa | 0.649 | 0.649 | |

| Hardening rate, GPa | 7.008 | 7.008 | |

| Nb | Young’s modulus, GPa | 105 | 105 |

| Poisson’s ratio | 0.4 | 0.4 | |

| Yield strength, GPa | 0.844 | 0.844 | |

| Hardening rate, GPa | 10.120 | 10.120 |

| Material | Property | RD | TD |

|---|---|---|---|

| Cu(16)/Nb(16) ARB Interface | Normal stiffness, mN/µm2 | 1 × 105 | 1 × 105 |

| Tangential stiffness, mN/µm2 | 1 × 105 | 1 × 105 | |

| Normal strength, GPa | 10 | 10 | |

| Tangential strength, GPa | 10 | 2 [56] | |

| Bond degradation type | linear | linear | |

| Bond degradation strain | 0.3 | 0.3 |

| Slip Directions | [1, −1, 0] | [−1, 0, 1] | [0, 1, −1] | [1, −1, 0] | [1, 0, 1] | [0, 1, 1] | [1, 1, 0] | [1, 0, −1] | [0, 1, 1] | [1, 1, 0] | [1, 0, 1] | [0, 1, −1] |

| Slip planes | (1, 1, 1) | (1, 1, 1) | (1, 1, 1) | (1, 1, −1) | (1, 1, −1) | (1, 1, −1) | (1, −1, 1) | (1, −1, 1) | (1, −1, 1) | (−1, 1, 1) | (−1, 1, 1) | (−1, 1, 1) |

| m(RD) (nm) | 0 | 0.198 | −0.198 | 0 | 0.984 | 0.984 | 1.17 | −0.031 | 1.207 | 1.175 | 1.207 | −0.031 |

| m(TD) (nm) | −2.144 | 3.399 | −1.255 | 0 | 0 | 0 | 0.582 | −0.425 | 1.008 | 1.577 | 2.003 | −0.425 |

| Direction | Depth (nm) | Experimentally Obtained Pile-Up (nm) | Simulated Pile-Up (nm) |

|---|---|---|---|

| TD | 200 | 10.86 | 16 |

| TD | 300 | 15.88 | 24 |

| TD | 400 | 28.28 | 28 |

| RD | 200 | 15.45 | 19 |

| RD | 300 | 39.44 | 28 |

| RD | 400 | 49.77 | 37 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sahay, R.; Budiman, A.S.; Aziz, I.; Navarro, E.; Escoubas, S.; Cornelius, T.W.; Gunawan, F.E.; Harito, C.; Lee, P.S.; Thomas, O.; et al. Crystallographic Anisotropy Dependence of Interfacial Sliding Phenomenon in a Cu(16)/Nb(16) ARB (Accumulated Rolling Bonding) Nanolaminate. Nanomaterials 2022, 12, 308. https://doi.org/10.3390/nano12030308

Sahay R, Budiman AS, Aziz I, Navarro E, Escoubas S, Cornelius TW, Gunawan FE, Harito C, Lee PS, Thomas O, et al. Crystallographic Anisotropy Dependence of Interfacial Sliding Phenomenon in a Cu(16)/Nb(16) ARB (Accumulated Rolling Bonding) Nanolaminate. Nanomaterials. 2022; 12(3):308. https://doi.org/10.3390/nano12030308

Chicago/Turabian StyleSahay, Rahul, Arief S. Budiman, Izzat Aziz, Etienne Navarro, Stéphanie Escoubas, Thomas W. Cornelius, Fergyanto E. Gunawan, Christian Harito, Pooi See Lee, Olivier Thomas, and et al. 2022. "Crystallographic Anisotropy Dependence of Interfacial Sliding Phenomenon in a Cu(16)/Nb(16) ARB (Accumulated Rolling Bonding) Nanolaminate" Nanomaterials 12, no. 3: 308. https://doi.org/10.3390/nano12030308

APA StyleSahay, R., Budiman, A. S., Aziz, I., Navarro, E., Escoubas, S., Cornelius, T. W., Gunawan, F. E., Harito, C., Lee, P. S., Thomas, O., & Raghavan, N. (2022). Crystallographic Anisotropy Dependence of Interfacial Sliding Phenomenon in a Cu(16)/Nb(16) ARB (Accumulated Rolling Bonding) Nanolaminate. Nanomaterials, 12(3), 308. https://doi.org/10.3390/nano12030308