Low Solar Absorptance, High Emittance Performance Thermochromic VO2-Based Smart Radiator Device

Abstract

1. Introduction

2. Materials and Methods

2.1. Optical Design

2.2. Deposition of the Films and Fabrication of the Optimized SRD Structure

2.3. Characterization

3. Results and Discussion

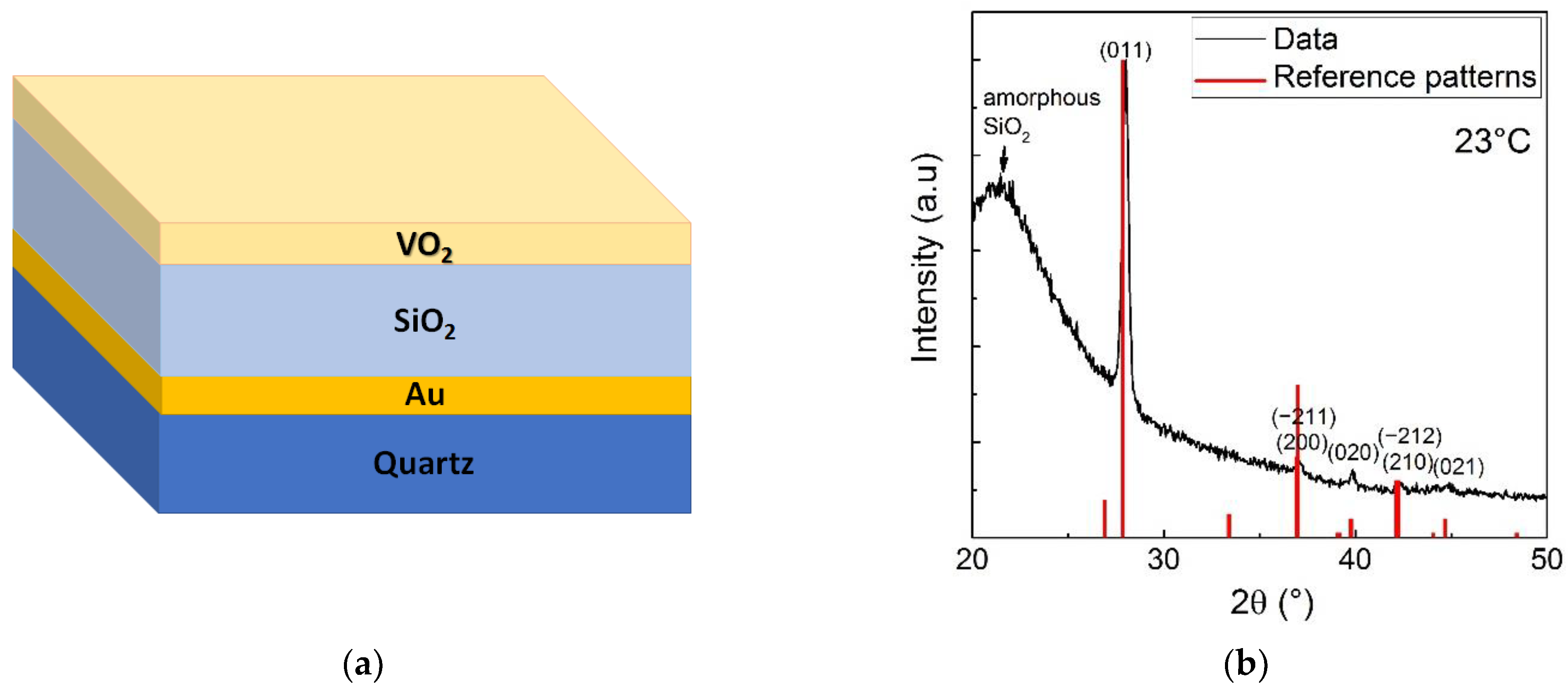

3.1. Multilayer VO2/SiO2/Au SRD Experimental Characterization

3.1.1. VO2 Layer Phase Purity and Crystallinity

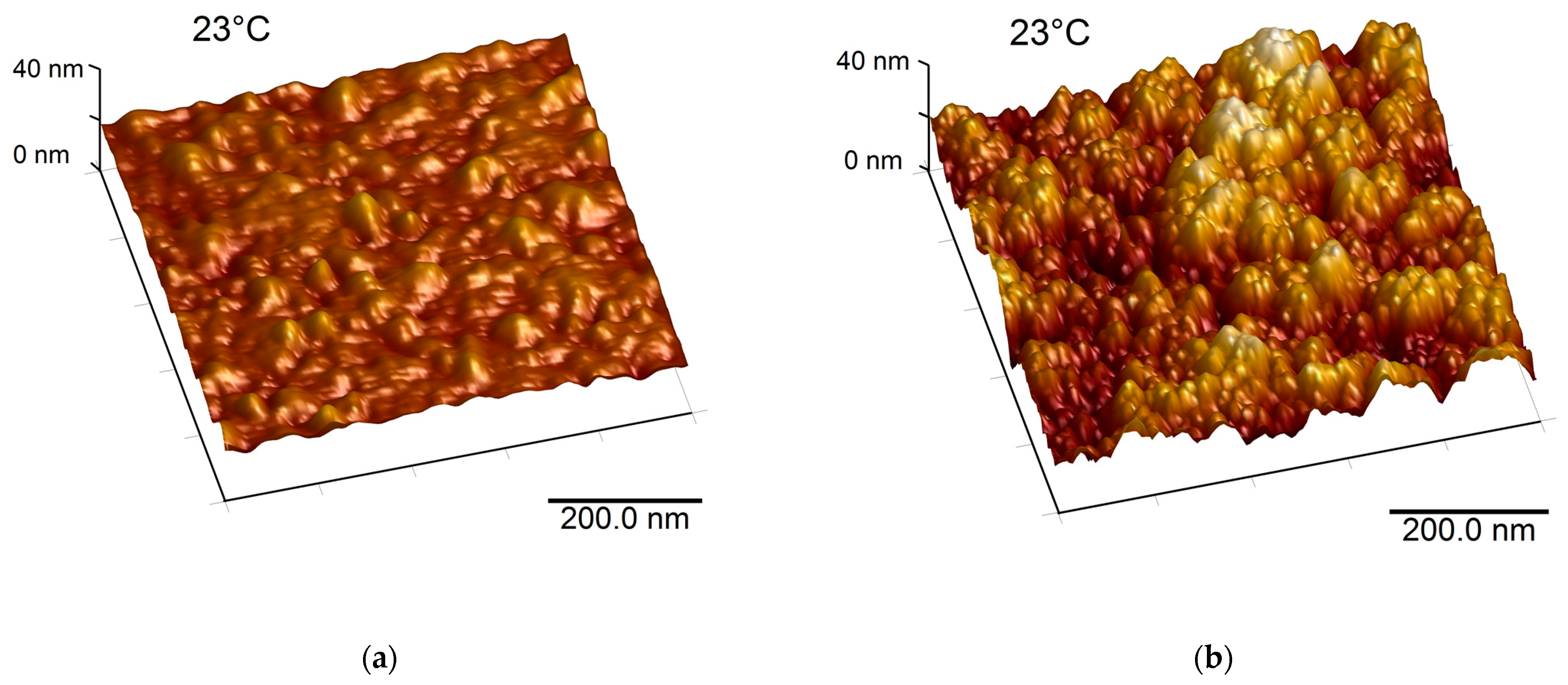

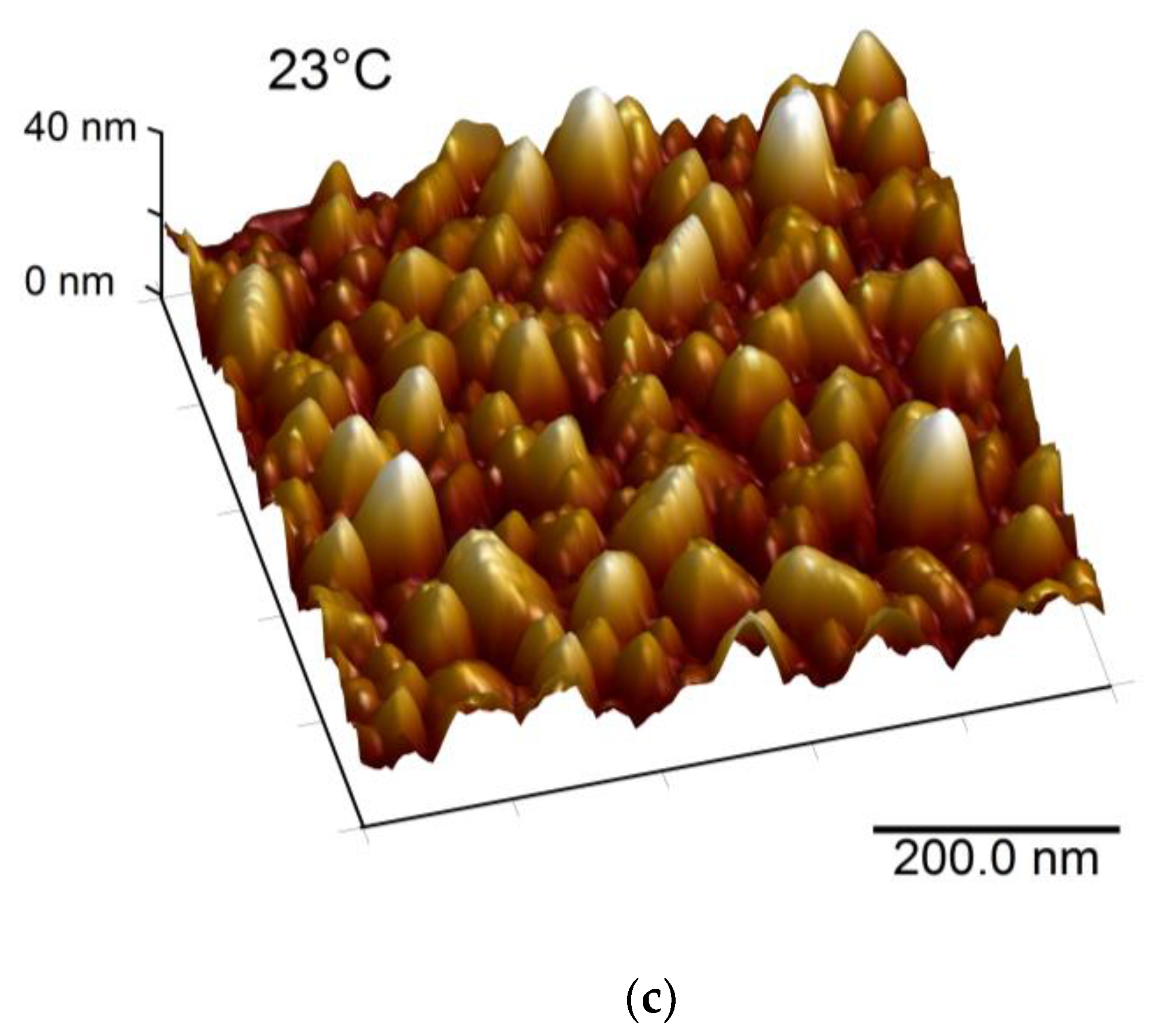

3.1.2. Surface Morphology of the SRD Layers

3.1.3. Characterization of the SRD Emittance Performance

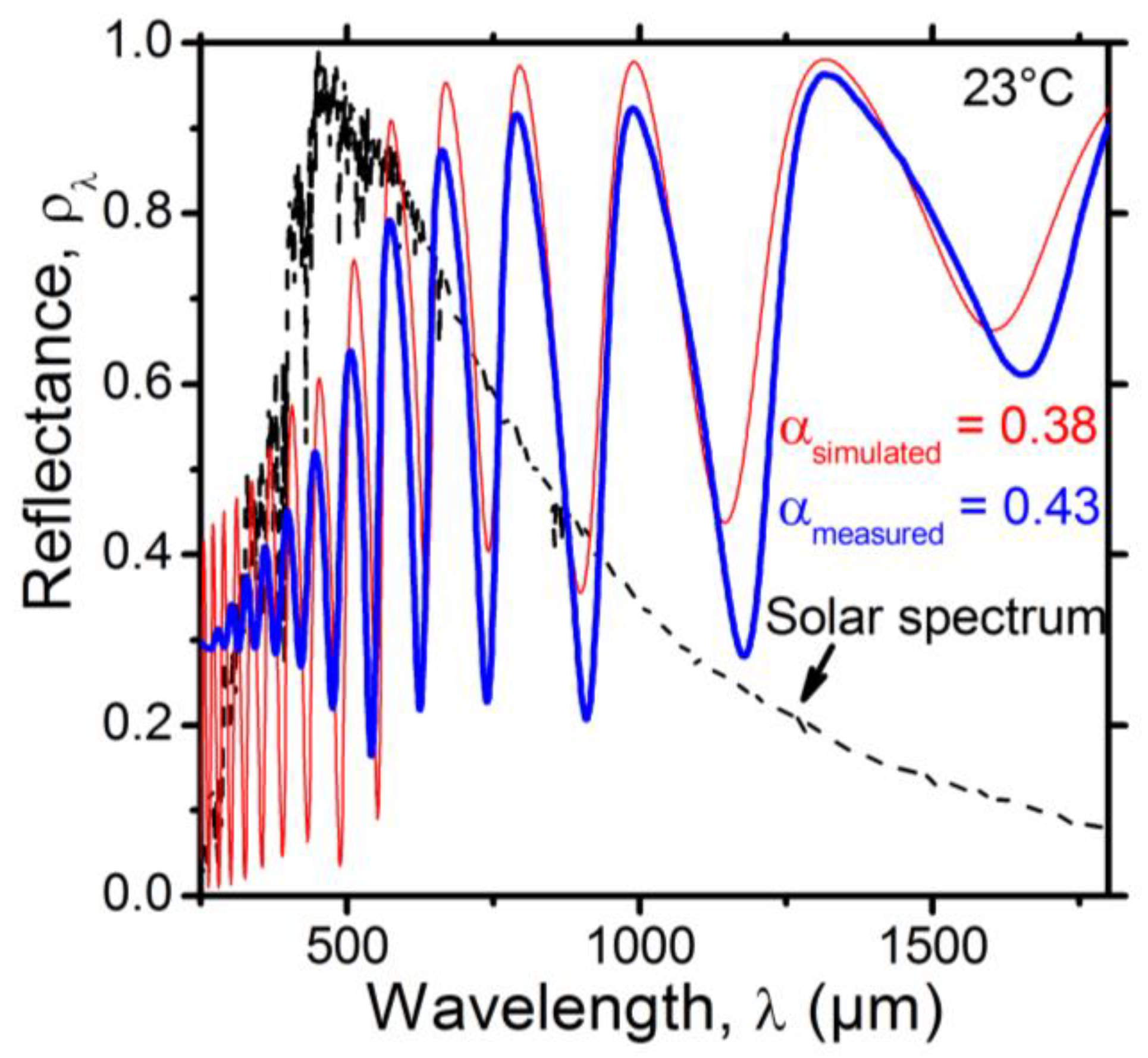

3.1.4. Characterization of the SRD Solar Absorptance

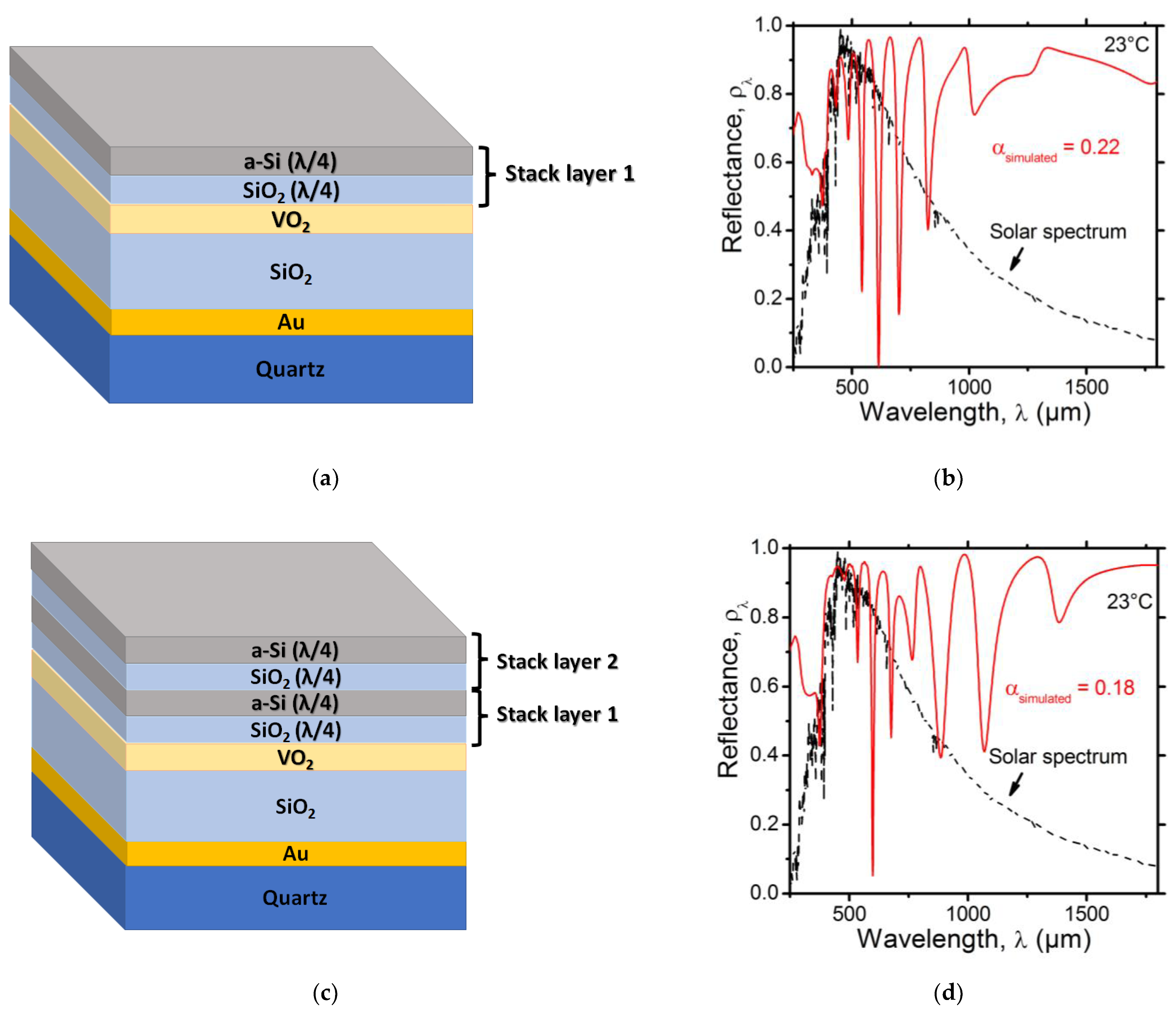

3.1.5. Design of the Additional Top Distributed Bragg Reflector

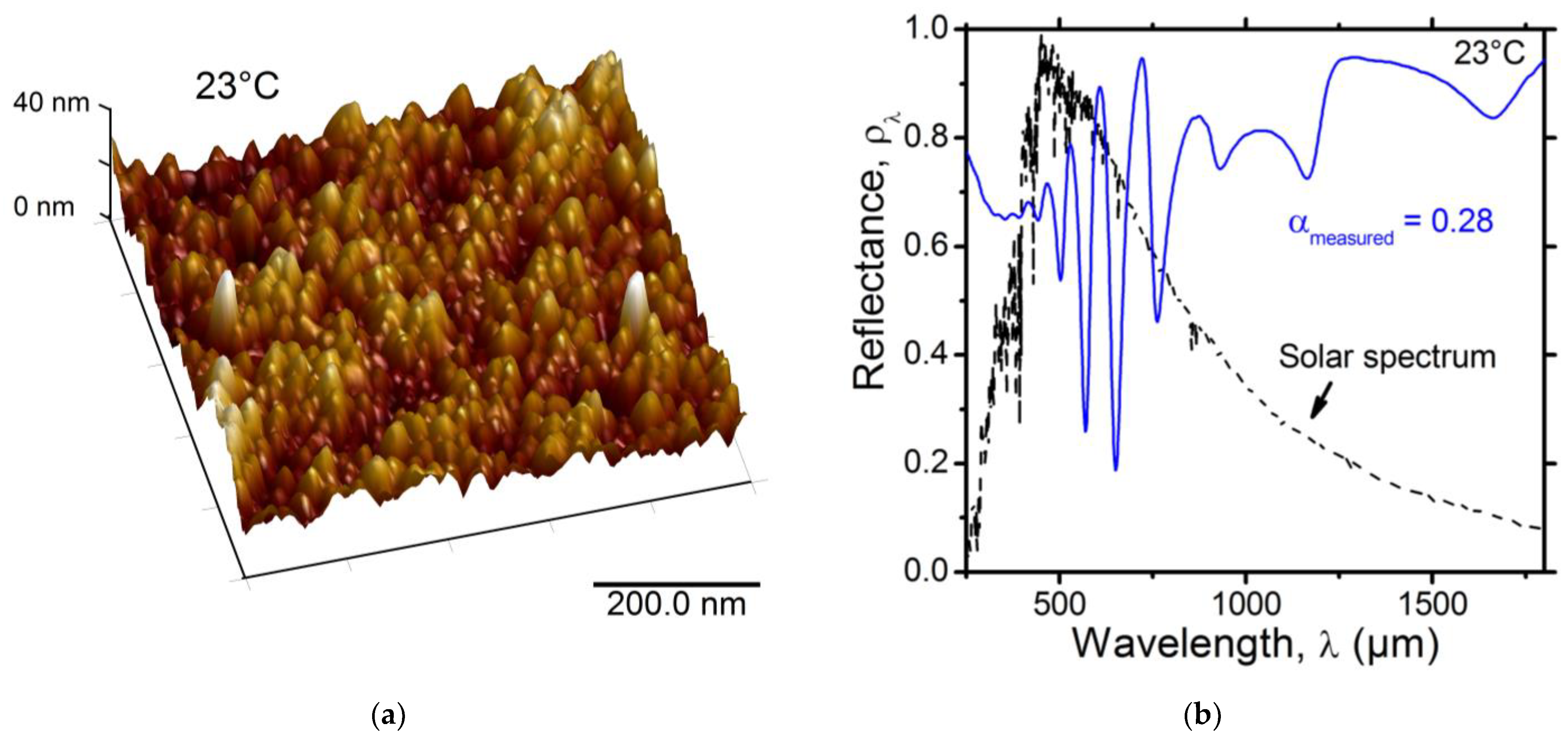

3.1.6. Surface Morphology and Solar Absorptance of the SRD with a Top Stack Layer

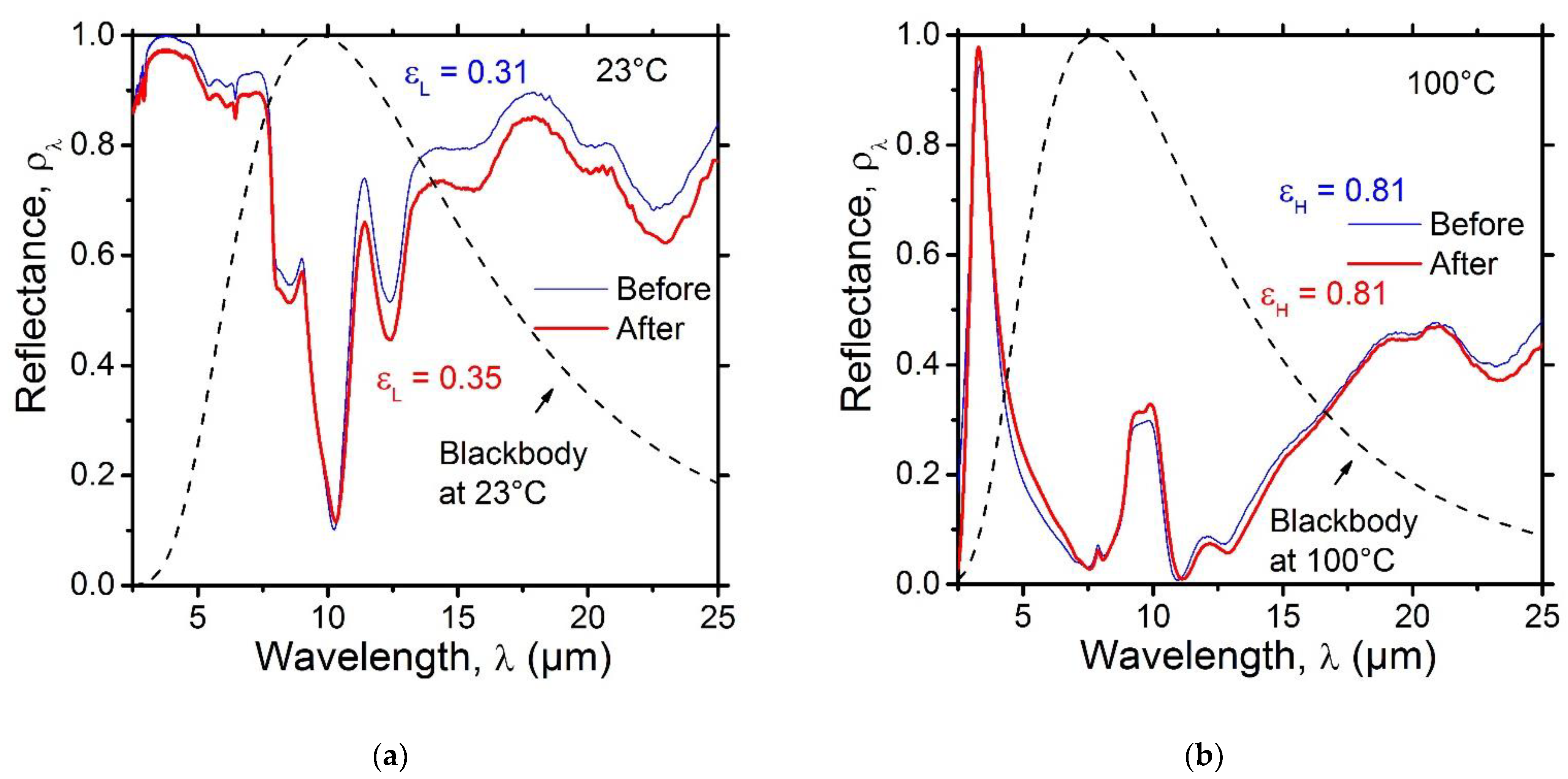

3.1.7. Characterization of the Emittance Performance of the SRD with a Top Stack Layer

4. Conclusions

Supplementary Materials

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hendaoui, A.; Emond, N.; Chaker, M.; Haddad, E. Highly tunable-emittance radiator based on semiconductor-metal transition of VO2 thin films. Appl. Phys. Lett. 2013, 102, 061107. [Google Scholar] [CrossRef]

- Hendaoui, A.; Emond, N.; Chaker, M.; Haddad, E. VO2-based smart coatings with improved emittance-switching properties for an energy-efficient near room-temperature thermal control of spacecrafts. Sol. Energy Mater. Sol. Cells 2013, 117, 494–498. [Google Scholar] [CrossRef]

- European Commission. Available online: https://ec.europa.eu/research/participants/documents/downloadPublic?documentIds=080166e5b12e044b&appId=PPGMS (accessed on 23 October 2022).

- Morin, F.J. Oxides which show a metal-to-insulator transition at the Neel temperature. Phys. Rev. Lett. 1959, 3, 34–36. [Google Scholar] [CrossRef]

- Morrison, V.R.; Chatelain, R.P.; Tiwari, K.L.; Hendaoui, A.; Bruhacs, A.; Chaker, M.; Siwick, B.J. A photoinduced metal-like phase of monoclinic vanadium dioxide. Science 2014, 346, 445–448. [Google Scholar] [CrossRef] [PubMed]

- Batista, C.; Ribeiro, R.K.; Teixeira, V. Synthesis and characterization of VO2-based thermochromic thin films for energy-efficient windows. Nanoscale Res. Lett. 2011, 6, 301. [Google Scholar] [CrossRef]

- Zhou, Y.; Chen, X.; Ko, C.; Yang, Z.; Mouli, C.; Ramanathan, S. Voltage-triggered ultrafast phase transition in vanadium dioxide switches. IEEE Electron Device Lett. 2013, 34, 2. [Google Scholar] [CrossRef]

- Houska, J. Design and reactive magnetron sputtering of thermochromic coatings. J. Appl. Phys. 2022, 131, 110901. [Google Scholar] [CrossRef]

- Kim, D.H.; Kwok, H.S. Pulsed laser deposition of VO2 thin films. Appl. Phys. Lett. 1994, 65, 3188. [Google Scholar] [CrossRef]

- Binions, R.; Hyett, G.; Piccirillo, C.; Parkin, I.P. Doped and un- doped vanadium dioxide thin films prepared by atmospheric pressure chemical vapour deposition from vanadyl acetylacetonate and tungsten hexachloride: The effects of thickness and crystallographic orientation on thermochromic properties. J. Mater. Chem. 2007, 17, 4652. [Google Scholar] [CrossRef]

- Vlček, J.; Kolenatý, D.; Houška, J.; Kozák, T.; Čerstvý, R. Controlled reactive HiPIMS—Effective technique for low-temperature (300 °C) synthesis of VO2 films with semiconductor-to-metal transition. J. Phys. D Appl. Phys. 2017, 50, 38LT01. [Google Scholar] [CrossRef]

- Houska, J.; Kolenaty, D.; Rezek, J.; Vlcek, J. Characterization of thermochromic VO2 (prepared at 250 °C) in a wide temperature range by spectroscopic ellipsometry. Appl. Surf. Sci. 2017, 421, 529–534. [Google Scholar] [CrossRef]

- Kolenatý, D.; Vlček, J.; Bárta, T.; Rezek, J.; Houška, J.; Haviar, S. High-performance thermochromic VO2-based coatings with a low transition temperature deposited on glass by a scalable technique. Sci. Rep. 2020, 10, 11107. [Google Scholar] [CrossRef] [PubMed]

- Benkahoul, M.; Chaker, M.; Margot, J.; Haddad, E.; Kruzelecky, R.; Wong, B.; Jamroz, W.; Poinas, P. Thermochromic VO2 film deposited on Al with tunable thermal emissivity for space applications. Sol. Energy Mater. Sol. Cells 2011, 95, 3504–3508. [Google Scholar] [CrossRef]

- Voti, R.L.; Larciprete, M.C.; Leahu, G.; Sibilia, C.; Bertolotti, M. Optimization of thermochromic VO2 based structures with tunable thermal emissivity. J. Appl. Phys. 2012, 112, 034305. [Google Scholar] [CrossRef]

- Hendaoui, A.; Chaker, M.; Haddad, E. Passively Variable Emittance Device and Method for Making the Same. U.S. Patent US8908253B2, 9 December 2014. [Google Scholar]

- Wang, X.; Cao, Y.; Zhang, Y.; Yan, L.; Li, Y. Fabrication of VO2-based multilayer structure with variable emittance. Appl. Surf. Sci. 2015, 344, 230–235. [Google Scholar] [CrossRef]

- Sun, K.; Riedel, C.A.; Urbani, A.; Simeoni, M.; Mengali, S.; Zalkovskij, M.; Bilenberg, B.; de Groot, C.H.; Muskens, O.L. VO2 Thermochromic Metamaterial-Based Smart Optical Solar Reflector. ACS Photonics 2018, 5, 2280–2286. [Google Scholar] [CrossRef]

- Kim, H.; Lahneman, D.; Rohde, C.; Piqué, A. VO2-based thin-film radiators with variable thermal emissivity. Thin Solid Film 2022, 759, 139455. [Google Scholar] [CrossRef]

- Beaini, R.; Baloukas, B.; Loquai, S.; Klemberg-Sapieha, J.E.; Martinu, L. Thermochromic VO2-based smart radiator devices with ultralow refractive index cavities for increased performance. Sol. Energy Mater. Sol. Cells 2020, 205, 110260. [Google Scholar] [CrossRef]

- Elyutin, V.V.; Butt, M.A.; Khonina, S.N. Cold mirror based on High-Low-High refractive index dielectric materials. In Proceedings of the 3rd International Conference Information Technology and Nanotechnology 2017, Samara, Russia, 25−27 April 2017. [Google Scholar] [CrossRef]

- Zegadi, R.; Lorrain, N.; Meziani, S.; Dumeige, Y.; Bodiou, L.; Guendouz, M.; Zegadi, A.; Charrier, J. Theoretical Demonstration of the Interest of Using Porous Germanium to Fabricate Multilayer Vertical Optical Structures for the Detection of SF6 Gas in the Mid-Infrared. Sensors 2022, 22, 844. [Google Scholar] [CrossRef]

- Larouche, S.; Martinu, L. OpenFilters: Open-source software for the design, optimization, and synthesis of optical filters. Appl. Opt. 2008, 47, C219. [Google Scholar] [CrossRef]

- Pinto, H.M.; Correia, J.; Binions, R.; Piccirillo, C.; Parkin, I.P.; Teixeira, V. Determination of the Optical Constants of VO2 and Nb-doped VO2 Thin Films. Mater. Sci. Forum 2008, 587–588, 640–644. [Google Scholar] [CrossRef]

- MacLeod, H.A. Thin-Film Optical Filters, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2001; pp. 1–667. [Google Scholar] [CrossRef]

- Hendaoui, A. Substrate Temperature-Dependent Structural, Optical, and Electrical Properties of Thermochromic VO2(M) Nanostructured Films Grown by a One-Step Pulsed Laser Deposition Process on Smooth Quartz Substrates. Adv. Condens. Matter Phys. 2021, 7700676. [Google Scholar] [CrossRef]

- Alam, A.; Manuilskiy, A.; Thim, J.; O’Nils, M.; Lindgren, J.; Lidén, J. Online surface roughness characterization of paper and paperboard using a line of light triangulation technique. Nord. Pulp Pap. Res. J. 2012, 27, 3. [Google Scholar] [CrossRef]

- Porras-Hermoso, A.; Alfonso-Corcuera, D.; Piqueras, J.; Roibás-Millán, E.; Cubas, J.; Pérez-Álvarez, J.; Pindado, S. Design, Ground Testing and On-Orbit Performance of a Sun Sensor Based on COTS Photodiodes for the UPMSat-2 Satellite. Sensors 2021, 21, 4905. [Google Scholar] [CrossRef] [PubMed]

- Soltani, M.; Chaker, M.; Haddad, E.; Kruzelecky, R.V.; Nikanpour, N. Optical switching of vanadium dioxide thin films deposited by reactive pulsed laser deposition. J. Vac. Sci. Technol. A. 2004, 22, 859. [Google Scholar] [CrossRef]

- Niu, C.; Zhu, T.; Lv, Y. Influence of Surface Morphology on Absorptivity of Light-Absorbing Materials. Int. J. Photoenergy 2019, 2019, 476217. [Google Scholar] [CrossRef]

- Amirzada, M.R.; Tatzel, A.; Viereck, V.; Hillmer, H. Surface roughness analysis of SiO2 for PECVD, PVD and IBD on different substrates. Appl. Nanosci. 2016, 6, 215–222. [Google Scholar] [CrossRef]

- Hendaoui, A.; Emond, N.; Dorval, S.; Chaker, M.; Haddad, E. Enhancement of the positive emittance-switching performance of thermochromic VO2 films deposited on Al substrate for an efficient passive thermal control of spacecrafts. Curr. Appl. Phys. 2013, 13, 875–879. [Google Scholar] [CrossRef]

- Sato, S.; Sai, H.; Ohshima, T.; Imaizumi, M.; Shimazaki, K.; Kondo, M. Electron and proton irradiation effects on substrate-type amorphous silicon solar cells. In Proceedings of the 37th IEEE Photovoltaic Specialists Conference, Seattle, WA, USA, 19–24 June 2011; pp. 001615–001619. [Google Scholar] [CrossRef]

- Garcia-Barrientos, A.; Bernal-Ponce, J.L.; Plaza-Castillo, J.; Cuevas-Salgado, A.; Medina-Flores, A.; Garcia-Monterrosas, M.S.; Torres-Jacome, A. Analysis, Synthesis and Characterization of Thin Films of a-Si:H (n-type and p-type) Deposited by PECVD for Solar Cell Applications. Materials 2021, 14, 6349. [Google Scholar] [CrossRef]

- NASA Technical Reports Server. Available online: https://ntrs.nasa.gov/api/citations/20160013391/downloads/20160013391.pdf (accessed on 23 October 2022).

- Shimazaki, K.; Tachikawa, S.; Ohnishi, A.; Nagasaka, Y. Radiative and Optical Properties of La1−xSrxMnO3 (0≤x≤0.4) in the Vicinity of Metal–Insulator Transition Temperatures from 173 to 413K. Int. J. Thermophys. 2001, 22, 1549–1561. [Google Scholar] [CrossRef]

- Tachikawa, S.; Ohnishi, A.; Shimakawa, Y.; Ochi, A.; Okamoto, A.; Nakamura, Y. Development of a Variable Emittance Radiator Based on a Perovskite Manganese Oxide. J. Thermophys. Heat Transf. 2003, 17, 264–268. [Google Scholar] [CrossRef]

- Tachikawa, S.; Ohnishi, A.; Nakamura, Y.; Okamoto, A. Design and Optical Performance Evaluation of Smart Radiation Device with Multi-layer Coating. In Proceedings of the 38rd International Conference On Environmental Systems, San Francisco, CA, USA, 29 June–2 July 2008. [Google Scholar] [CrossRef]

- Tachikawa, S.; Nagano, H.; Ohnishi, A.; Nagasaka, Y. Advanced Passive Thermal Control Materials and Devices for Spacecraft: A Review. Int. J. Thermophys. 2022, 43, 91. [Google Scholar] [CrossRef]

- Wei, H.; Gu, J.; Ren, F.; Zhang, L.; Xu, G.; Wang, B.; Song, S.; Zhao, J.; Dou, S.; Li, Y. Smart Materials for Dynamic Thermal Radiation Regulation. Small 2021, 17, 2100446. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hendaoui, A. Low Solar Absorptance, High Emittance Performance Thermochromic VO2-Based Smart Radiator Device. Nanomaterials 2022, 12, 4422. https://doi.org/10.3390/nano12244422

Hendaoui A. Low Solar Absorptance, High Emittance Performance Thermochromic VO2-Based Smart Radiator Device. Nanomaterials. 2022; 12(24):4422. https://doi.org/10.3390/nano12244422

Chicago/Turabian StyleHendaoui, Ali. 2022. "Low Solar Absorptance, High Emittance Performance Thermochromic VO2-Based Smart Radiator Device" Nanomaterials 12, no. 24: 4422. https://doi.org/10.3390/nano12244422

APA StyleHendaoui, A. (2022). Low Solar Absorptance, High Emittance Performance Thermochromic VO2-Based Smart Radiator Device. Nanomaterials, 12(24), 4422. https://doi.org/10.3390/nano12244422