Controllable Preparation and Strengthening Strategies towards High-Strength Carbon Nanotube Fibers

Abstract

1. Introduction

2. The Structure and Preparation of Carbon Nanotubes

2.1. The Structure of Carbon Nanotubes

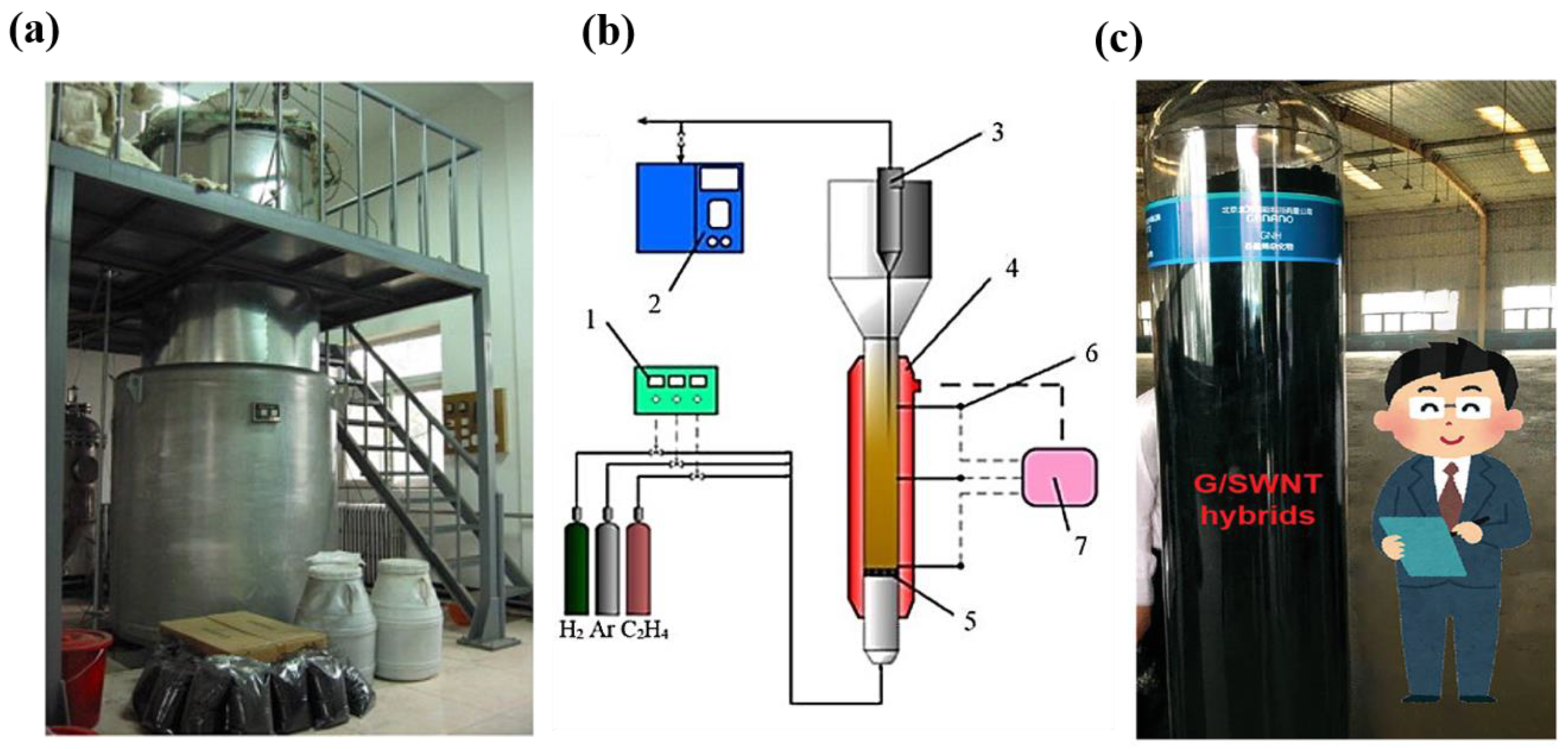

2.2. Controllable Preparation of Carbon Nanotubes

3. Assembly Technology of Carbon Nanotube Fibers at Different Scales

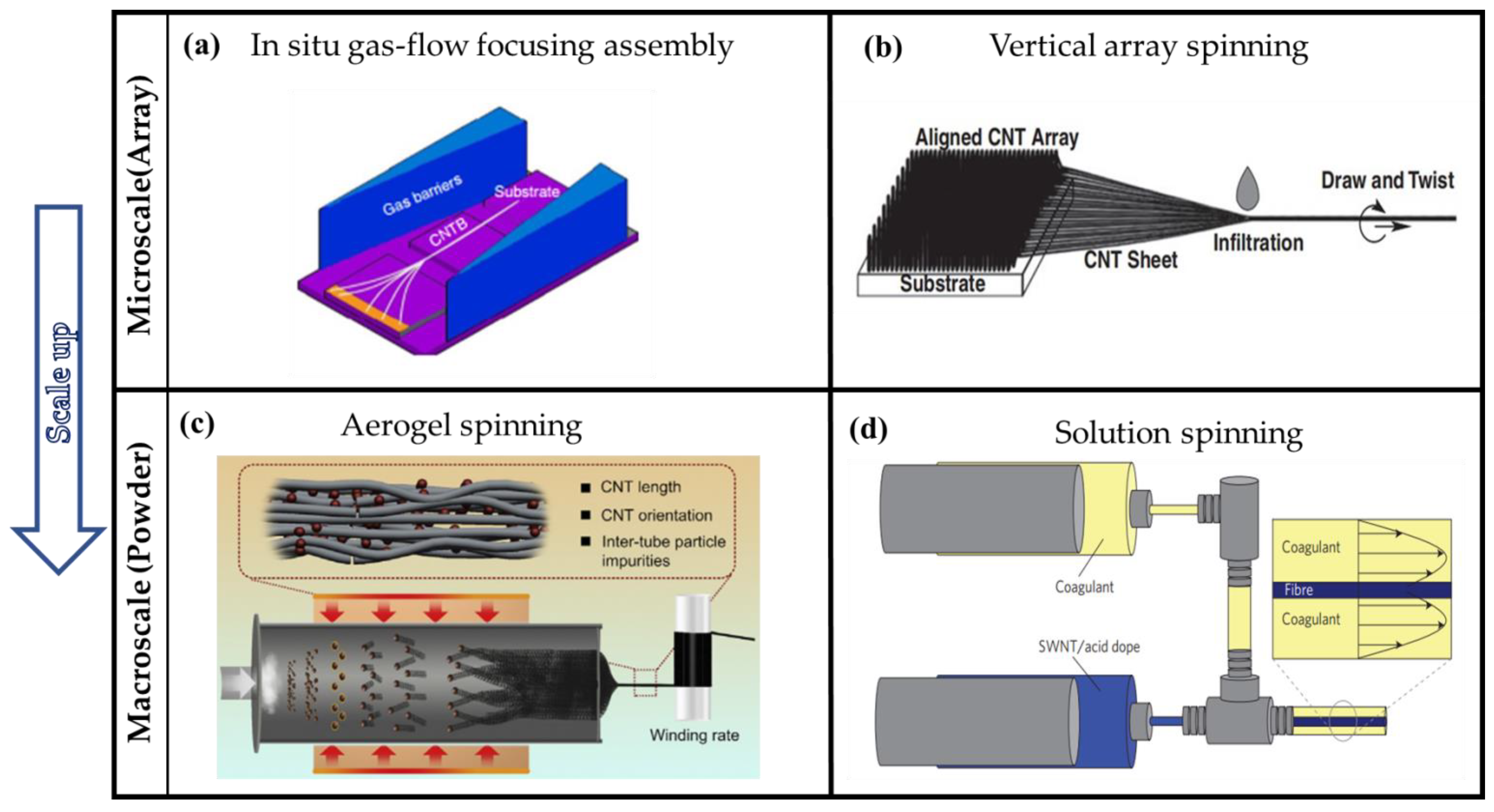

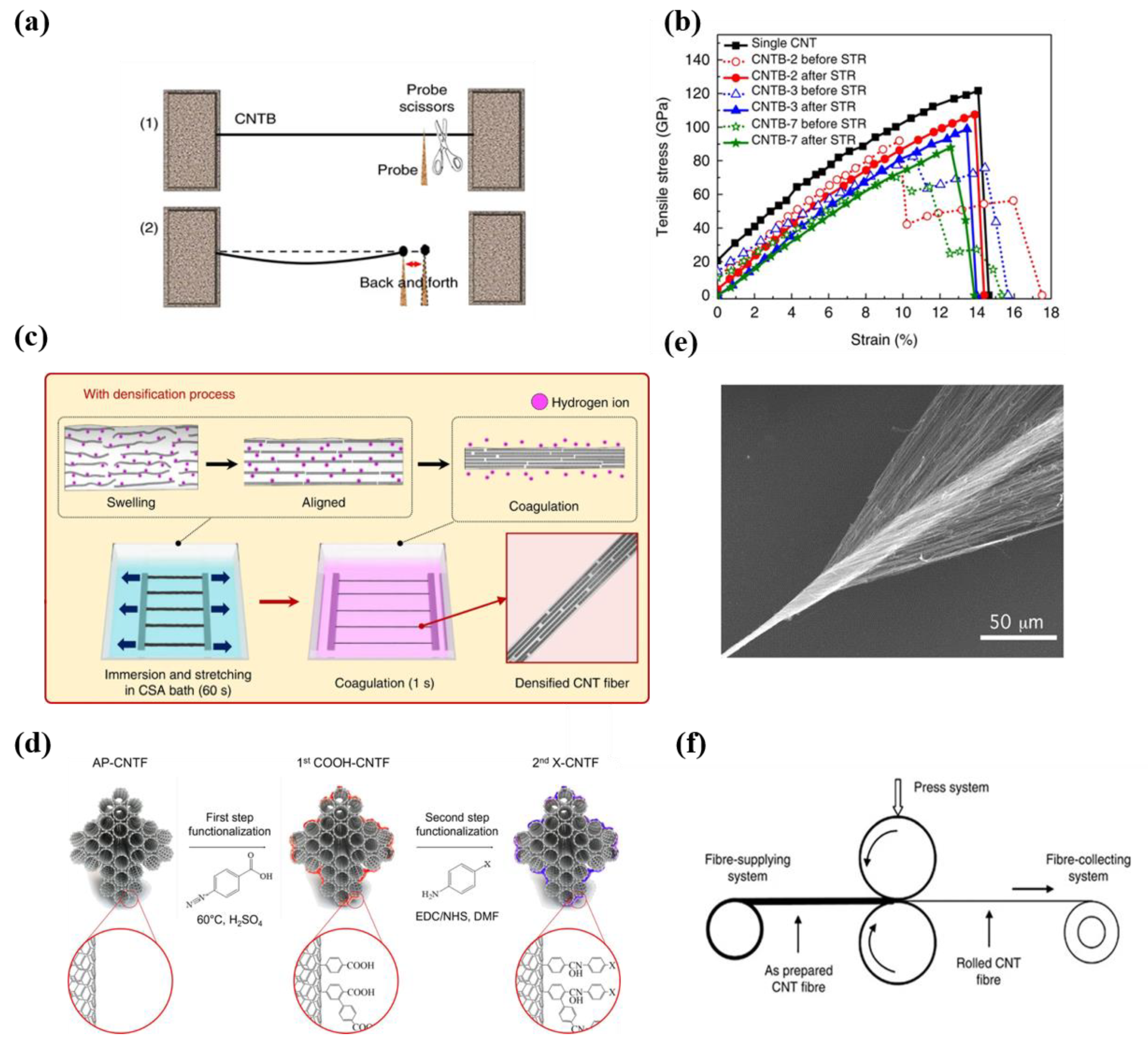

3.1. Preparation of Nanoscale Carbon Nanotube Fibers

3.2. Preparation of Microscale Carbon Nanotube Fibers

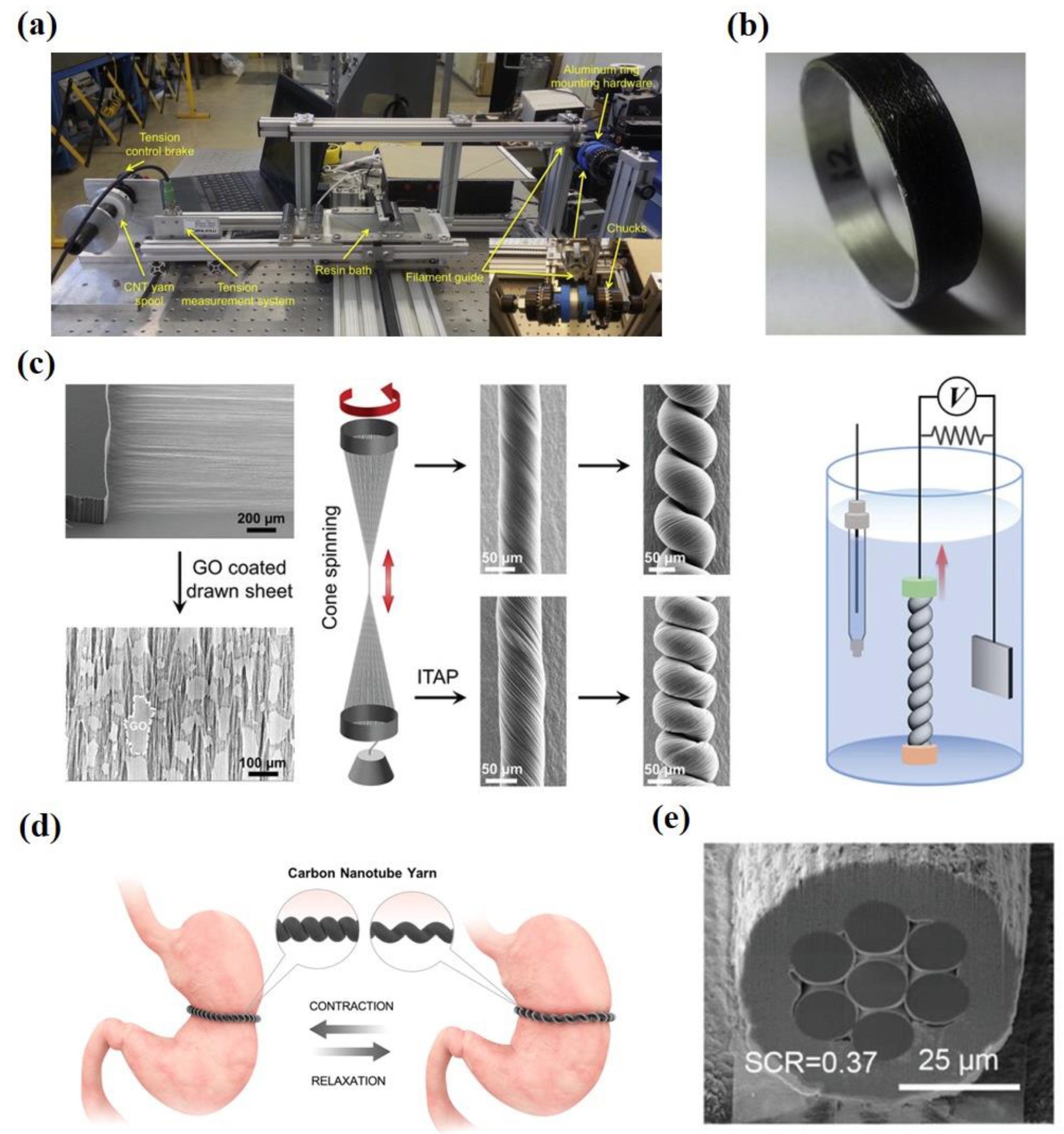

3.2.1. Solution Spinning

3.2.2. Vertical-Array Spinning

3.2.3. Aerogel Spinning

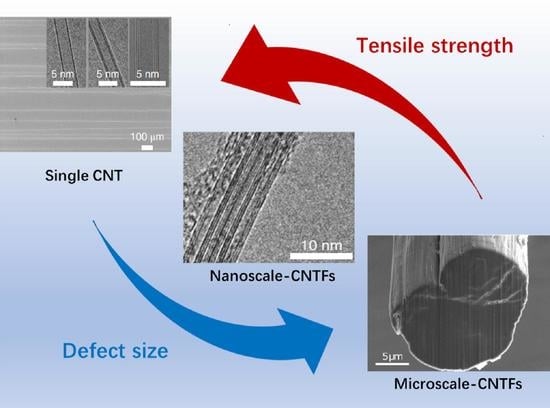

4. Tensile Property of Carbon Nanotube Fibers at Different Scales

4.1. Tensile Strength of Single Carbon Nanotubes

4.2. Tensile Strength of Carbon Nanotube Fibers at Different Scales

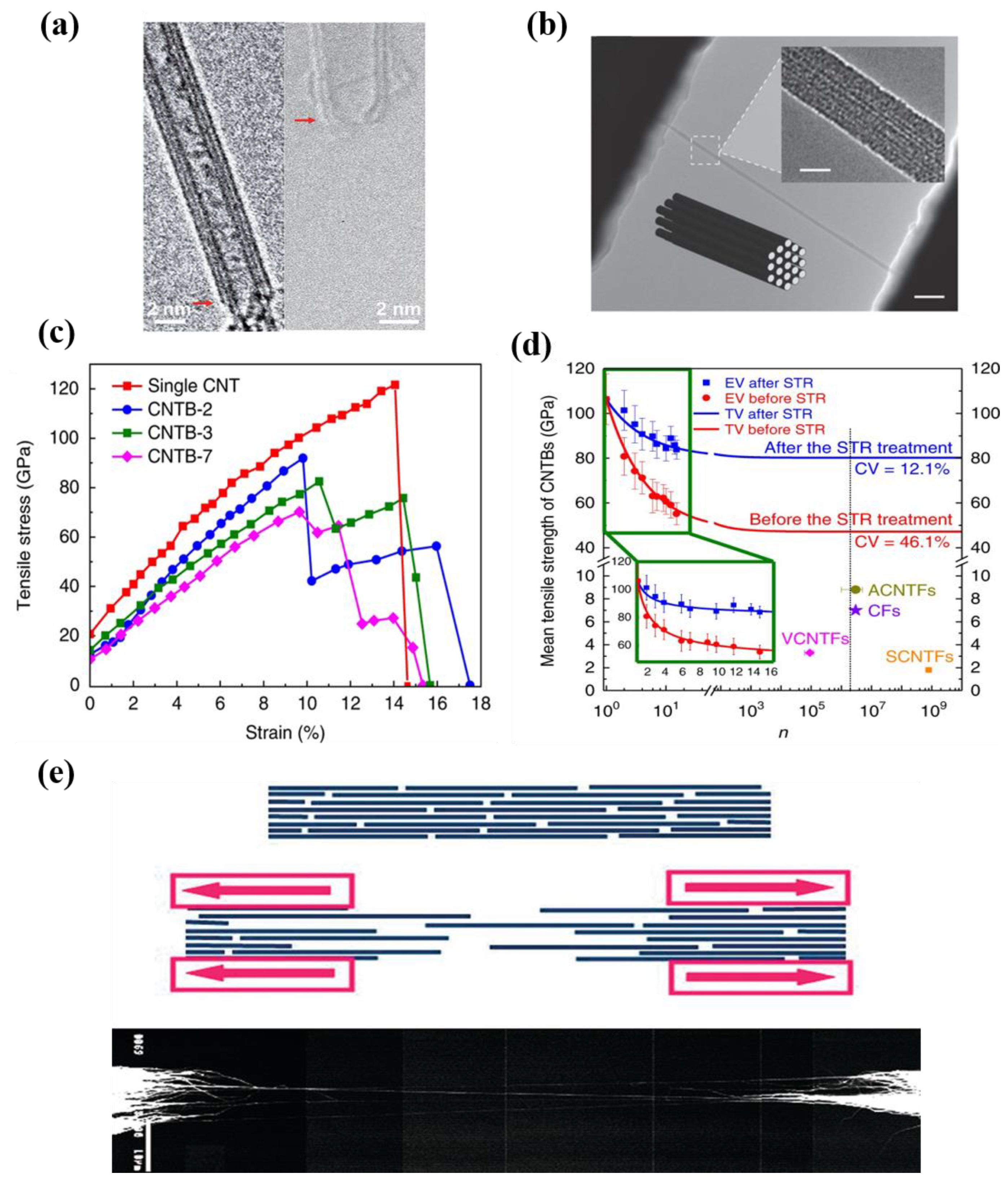

4.2.1. Nanoscale Carbon Nanotube Fibers

4.2.2. Microscale Carbon Nanotube Fibers

4.3. Characteristics of Tensile Strength Transfer across Scales

5. Optimization Strategies for the Tensile Strength of Carbon Nanotube Fibers at Different Scales

5.1. Defects Control

5.2. Control of Tube–Tube Interactions

5.2.1. Initial Strain

5.2.2. Length-Dependent Interactions

5.2.3. Packing Density

6. Prospects for the Application of High-Strength Carbon Nanotube Fibers

6.1. Structural Reinforcing Material

6.2. Energy Storage

6.3. Artificial Muscle

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yakobson, B.I.; Smalley, R.E. Fullerene Nanotubes: C 1,000,000 and Beyond. Am. Sci. 1997, 85, 324–337. [Google Scholar]

- Coulson, C.A. Valence, 2nd ed.; Oxford University Press: London, UK, 1952; pp. 350. [Google Scholar]

- Demczyk, B.G.; Wang, Y.M.; Cumings, J.; Hetman, M.; Han, W.; Zettl, A.; Ritchie, R.O. Direct Mechanical Measurement of the Tensile Strength and Elastic Modulus of Multiwalled Carbon Nanotubes. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2002, 334, 173–178. [Google Scholar] [CrossRef]

- Xu, W.; Chen, Y.; Zhan, H.; Wang, J.N. High-Strength Carbon Nanotube Film from Improving Alignment and Densification. Nano Lett. 2016, 16, 946–952. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.N.; Luo, X.G.; Wu, T.; Chen, Y. High-Strength Carbon Nanotube Fibre-Like Ribbon with High Ductility and High Electrical Conductivity. Nat. Commun. 2014, 5, 1–8. [Google Scholar] [CrossRef]

- Lee, J.; Lee, D.M.; Jung, Y.; Park, J.; Lee, H.S.; Kim, Y.K.; Park, C.R.; Jeong, H.S.; Kim, S.M. Direct Spinning and Densification Method for High-Performance Carbon Nanotube Fibers. Nat. Commun. 2019, 10, 1–10. [Google Scholar] [CrossRef]

- Gao, E.L.; Lu, W.B.; Xu, Z.P. Strength Loss of Carbon Nanotube Fibers Explained in a Three-Level Hierarchical Model. Carbon 2018, 138, 134–142. [Google Scholar] [CrossRef]

- Salvetat, J.P.; Bonard, J.M.; Thomson, N.H.; Kulik, A.J.; Forro, L.; Benoit, W.; Zuppiroli, L. Mechanical Properties of Carbon Nanotubes. Appl. Phys.A Mater. Sci. Process. 1999, 69, 255–260. [Google Scholar] [CrossRef]

- Zhang, R.; Zhang, Y.; Zhang, Q.; Xie, H.; Qian, W.; Wei, F. Growth of Half-Meter Long Carbon Nanotubes Based on Schulz-Flory Distribution. ACS Nano 2013, 7, 6156–6161. [Google Scholar] [CrossRef]

- Bai, Y.; Zhang, R.; Ye, X.; Zhu, Z.; Xie, H.; Shen, B.; Cai, D.; Liu, B.; Zhang, C.; Jia, Z.; et al. Carbon Nanotube Bundles with Tensile Strength over 80 Gpa. Nat. Nanotechnol. 2018, 13, 589–595. [Google Scholar] [CrossRef]

- Wei, X.L.; Chen, Q.; Peng, L.M.; Cui, R.L.; Li, Y. Tensile Loading of Double-Walled and Triple-Walled Carbon Nanotubes and Their Mechanical Properties. J. Phys. Chem. C 2009, 113, 17002–17005. [Google Scholar] [CrossRef]

- Zhu, L.Y.; Wang, J.L.; Ding, F. The Great Reduction of a Carbon Nanotube’s Mechanical Performance by a Few Topological Defects. ACS Nano 2016, 10, 6410–6415. [Google Scholar] [CrossRef] [PubMed]

- Tagawa, T.; Miyata, T. Size Effect on Tensile Strength of Carbon Fibers. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 1997, 238, 336–342. [Google Scholar] [CrossRef]

- Yang, M.; Koutsos, V.; Zaiser, M. Size Effect in the Tensile Fracture of Single-Walled Carbon Nanotubes with Defects. Nanotechnology 2007, 18, 155708. [Google Scholar] [CrossRef]

- Bai, Y.; Yue, H.; Wang, J.; Shen, B.; Sun, S.; Wang, S.; Wang, H.; Li, X.; Xu, Z.; Zhang, R.; et al. Super-Durable Ultralong Carbon Nanotubes. Science 2020, 369, 1104–1106. [Google Scholar] [CrossRef] [PubMed]

- Vigolo, B.; Penicaud, A.; Coulon, C.; Sauder, C.; Pailler, R.; Journet, C.; Bernier, P.; Poulin, P. Macroscopic Fibers and Ribbons of Oriented Carbon Nanotubes. Science 2000, 290, 1331–1334. [Google Scholar] [CrossRef]

- Koziol, K.; Vilatela, J.; Moisala, A.; Motta, M.; Cunniff, P.; Sennett, M.; Windle, A. High-Performance Carbon Nanotube Fiber. Science 2007, 318, 1892–1895. [Google Scholar] [CrossRef]

- Zhou, T.; Niu, Y.T.; Li, Z.; Li, H.F.; Yong, Z.Z.; Wu, K.J.; Zhang, Y.Y.; Li, Q.W. The Synergetic Relationship between the Length and Orientation of Carbon Nanotubes in Direct Spinning of High-Strength Carbon Nanotube Fibers. Mater. Des. 2021, 203, 109557. [Google Scholar] [CrossRef]

- Zhang, X.H.; Lu, W.B.; Zhou, G.H.; Li, Q.W. Understanding the Mechanical and Conductive Properties of Carbon Nanotube Fibers for Smart Electronics. Adv. Mater. 2020, 32, 1902028. [Google Scholar] [CrossRef] [PubMed]

- Yadav, M.D.; Dasgupta, K.; Patwardhan, A.W.; Joshi, J.B. High Performance Fibers from Carbon Nanotubes: Synthesis, Characterization, and Applications in Composites—A Review. Ind. Eng. Chem. Res. 2017, 56, 12407–12437. [Google Scholar] [CrossRef]

- Li, K.; Ni, X.; Wu, Q.; Yuan, C.; Li, C.; Li, D.; Chen, H.; Lv, Y.; Ju, A. Carbon-Based Fibers: Fabrication, Characterization and Application. Adv. Fiber Mater. 2022, 4, 631–682. [Google Scholar] [CrossRef]

- Lu, W.; Zu, M.; Byun, J.-H.; Kim, B.-S.; Chou, T.-W. State of the Art of Carbon Nanotube Fibers: Opportunities and Challenges. Adv. Mater. 2012, 24, 1805–1833. [Google Scholar] [CrossRef] [PubMed]

- Mikhalchan, A.; Jose Vilatela, J. A Perspective on High-Performance Cnt Fibres for Structural Composites. Carbon 2019, 150, 191–215. [Google Scholar] [CrossRef]

- Iijima, S. Helical Microtubules of Graphitic Carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Prasek, J.; Drbohlavova, J.; Chomoucka, J.; Hubalek, J.; Jasek, O.; Adam, V.; Kizek, R. Methods for Carbon Nanotubes Synthesis-Review. J. Mater. Chem. 2011, 21, 15872–15884. [Google Scholar] [CrossRef]

- Treacy, M.M.J.; Ebbesen, T.W.; Gibson, J.M. Exceptionally High Young’s Modulus Observed for Individual Carbon Nanotubes. Nature 1996, 381, 678–680. [Google Scholar] [CrossRef]

- Salvetat, J.P.; Kulik, A.J.; Bonard, J.M.; Briggs, G.A.D.; Stockli, T.; Metenier, K.; Bonnamy, S.; Beguin, F.; Burnham, N.A.; Forro, L. Elastic Modulus of Ordered and Disordered Multiwalled Carbon Nanotubes. Adv. Mater. 1999, 11, 161–165. [Google Scholar] [CrossRef]

- Yu, M.F.; Lourie, O.; Dyer, M.J.; Moloni, K.; Kelly, T.F.; Ruoff, R.S. Strength and Breaking Mechanism of Multiwalled Carbon Nanotubes under Tensile Load. Science 2000, 287, 637–640. [Google Scholar] [CrossRef]

- Wei, C.Y.; Cho, K.J.; Srivastava, D. Tensile Strength of Carbon Nanotubes under Realistic Temperature and Strain Rate. Phys. Rev. B 2003, 67, 115407. [Google Scholar] [CrossRef]

- Mielke, S.L.; Troya, D.; Zhang, S.; Li, J.L.; Xiao, S.P.; Car, R.; Ruoff, R.S.; Schatz, G.C.; Belytschko, T. The Role of Vacancy Defects and Holes in the Fracture of Carbon Nanotubes. Chem. Phys. Lett. 2004, 390, 413–420. [Google Scholar] [CrossRef]

- Yuan, Q.; Xu, Z.; Yakobson, B.I.; Ding, F. Efficient Defect Healing in Catalytic Carbon Nanotube Growth. Phys. Rev. Lett. 2012, 108, 245505. [Google Scholar] [CrossRef]

- Sun, X.; Bao, W.; Lv, Y.; Deng, J.; Wang, X. Synthesis of High Quality Single-Walled Carbon Nanotubes by Arc Discharge Method in Large Scalele. Mater. Lett. 2007, 61, 3956–3958. [Google Scholar] [CrossRef]

- Maser, W.K.; Munoz, E.; Benito, A.M.; Martinez, M.T.; de la Fuente, G.F.; Maniette, Y.; Anglaret, E.; Sauvajol, J.L. Production of High-Density Single-Walled Nanotube Material by a Simple Laser-Ablation Method. Chem. Phys. Lett. 1998, 292, 587–593. [Google Scholar] [CrossRef]

- Huang, S.M.; Maynor, B.; Cai, X.Y.; Liu, J. Ultralong, Well-Aligned Single-Walled Carbon Nanotube Architectures on Surfaces. Adv. Mater. 2003, 15, 1651–1655. [Google Scholar] [CrossRef]

- Kong, J.; Soh, H.T.; Cassell, A.M.; Quate, C.F.; Dai, H.J. Synthesis of Individual Single-Walled Carbon Nanotubes on Patterned Silicon Wafers. Nature 1998, 395, 878–881. [Google Scholar] [CrossRef]

- Wen, Q.; Qian, W.; Nie, J.; Cao, A.; Ning, G.; Wang, Y.; Hu, L.; Zhang, Q.; Huang, J.; Wei, F. 100 Mm Long, Semiconducting Triple-Walled Carbon Nanotubes. Adv. Mater. 2010, 22, 1867–1871. [Google Scholar] [CrossRef] [PubMed]

- Joseyacaman, M.; Mikiyoshida, M.; Rendon, L.; Santiesteban, J.G. Catalytic Growth of Carbon Microtubules with Fullerene Structure. Appl. Phys. Lett. 1993, 62, 202–204. [Google Scholar] [CrossRef]

- Cheng, H.M.; Li, F.; Su, G.; Pan, H.Y.; He, L.L.; Sun, X.; Dresselhaus, M.S. Large-Scale and Low-Cost Synthesis of Single-Walled Carbon Nanotubes by the Catalytic Pyrolysis of Hydrocarbons. Appl. Phys. Lett. 1998, 72, 3282–3284. [Google Scholar] [CrossRef]

- Cheng, H.M.; Li, F.; Sun, X.; Brown, S.D.M.; Pimenta, M.A.; Marucci, A.; Dresselhaus, G.; Dresselhaus, M.S. Bulk Morphology and Diameter Distribution of Single-Walled Carbon Nanotubes Synthesized by Catalytic Decomposition of Hydrocarbons. Chem. Phys. Lett. 1998, 289, 602–610. [Google Scholar] [CrossRef]

- Wang, Y.; Wei, F.; Luo, G.H.; Yu, H.; Gu, G.S. The Large-Scale Production of Carbon Nanotubes in a Nano-Agglomerate Fluidized-Bed Reactor. Chem. Phys. Lett. 2002, 364, 568–572. [Google Scholar] [CrossRef]

- Wei, F.; Zhang, Q.; Qian, W.-Z.; Yu, H.; Wang, Y.; Luo, G.-H.; Xu, G.-H.; Wang, D.-Z. The Mass Production of Carbon Nanotubes Using a Nano-Agglomerate Fluidized Bed Reactor: A Multiscale Space-Time Analysis. Powder Technol. 2008, 183, 10–20. [Google Scholar] [CrossRef]

- Wang, Q.X.; Ning, G.Q.; Wei, F.; Luo, G.H. Production of High Quality Single-Walled Carbon Nanotubes in a Nano-Agglomerated Fluidized Bed Reactor. In Proceedings of the Symposium on Materials and Devices for Smart Systems Held at the 2003 MRS Fall Meeting, Boston, MA, USA, 1–5 December 2003; pp. 313–318. [Google Scholar]

- Zhang, Q.; Yu, H.; Liu, Y.; Qian, W.; Wang, Y.; Luo, G.; Wei, F. Few Walled Carbon Nanotube Production in Large-Scale by Nano-Agglomerate Fluidized-Bed Process. Nano 2008, 3, 45–50. [Google Scholar] [CrossRef]

- Zhu, Z.; Wei, N.; Cheng, W.; Shen, B.; Sun, S.; Gao, J.; Wen, Q.; Zhang, R.; Xu, J.; Wang, Y.; et al. Rate-Selected Growth of Ultrapure Semiconducting Carbon Nanotube Arrays. Nat. Commun. 2019, 10, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Z.; Cui, C.; Bai, Y.; Gao, J.; Jiang, Y.; Li, B.; Wang, Y.; Zhang, Q.; Qian, W.; Wei, F. Advances in Precise Structure Control and Assembly toward the Carbon Nanotube Industry. Adv. Funct. Mater. 2021, 32, 2109401. [Google Scholar] [CrossRef]

- Salvetat, J.P.; Briggs, G.A.D.; Bonard, J.M.; Bacsa, R.R.; Kulik, A.J.; Stockli, T.; Burnham, N.A.; Forro, L. Elastic and Shear Moduli of Single-Walled Carbon Nanotube Ropes. Phys. Rev. Lett. 1999, 82, 944–947. [Google Scholar] [CrossRef]

- Kis, A.; Csanyi, G.; Salvetat, J.P.; Lee, T.N.; Couteau, E.; Kulik, A.J.; Benoit, W.; Brugger, J.; Forro, L. Reinforcement of Single-Walled Carbon Nanotube Bundles by Intertube Bridging. Nat. Mater. 2004, 3, 153–157. [Google Scholar] [CrossRef]

- Yu, M.F.; Files, B.S.; Arepalli, S.; Ruoff, R.S. Tensile Loading of Ropes of Single Wall Carbon Nanotubes and Their Mechanical Properties. Phys. Rev. Lett. 2000, 84, 5552–5555. [Google Scholar] [CrossRef]

- Naraghi, M.; Filleter, T.; Moravsky, A.; Locascio, M.; Loutfy, R.O.; Espinosa, H.D. A Multiscale Study of High Performance Double-Walled Nanotube-Polymer Fibers. ACS Nano 2010, 4, 6463–6476. [Google Scholar] [CrossRef]

- Filleter, T.; Bernal, R.; Li, S.; Espinosa, H.D. Ultrahigh Strength and Stiffness in Cross-Linked Hierarchical Carbon Nanotube Bundles. Adv. Mater. 2011, 23, 2855–2860. [Google Scholar] [CrossRef]

- Jia, J.; Zhao, J.; Xu, G.; Di, J.; Yong, Z.; Tao, Y.; Fang, C.; Zhang, Z.; Zhang, X.; Zheng, L.; et al. A Comparison of the Mechanical Properties of Fibers Spun from Different Carbon Nanotubes. Carbon 2011, 49, 1333–1339. [Google Scholar] [CrossRef]

- Davis, V.A.; Parra-Vasquez, A.N.G.; Green, M.J.; Rai, P.K.; Behabtu, N.; Prieto, V.; Booker, R.D.; Schmidt, J.; Kesselman, E.; Zhou, W.; et al. True Solutions of Single-Walled Carbon Nanotubes for Assembly into Macroscopic Materials. Nat. Nanotechnol. 2009, 4, 830–834. [Google Scholar] [CrossRef]

- Jung, Y.; Cho, Y.S.; Lee, J.W.; Oh, J.Y.; Park, C.R. How Can We Make Carbon Nanotube Yarn Stronger? Compos. Sci. Technol. 2018, 166, 95–108. [Google Scholar] [CrossRef]

- Ericson, L.M.; Fan, H.; Peng, H.Q.; Davis, V.A.; Zhou, W.; Sulpizio, J.; Wang, Y.H.; Booker, R.; Vavro, J.; Guthy, C.; et al. Macroscopic, Neat, Single-Walled Carbon Nanotube Fibers. Science 2004, 305, 1447–1450. [Google Scholar] [CrossRef] [PubMed]

- Jiang, K.; Li, Q.; Fan, S. Nanotechnology: Spinning Continuous Carbon Nanotube Yarns. Nature 2002, 419, 801. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.L.; Kinloch, I.A.; Windle, A.H. Direct Spinning of Carbon Nanotube Fibers from Chemical Vapor Deposition Synthesis. Science 2004, 304, 276–278. [Google Scholar] [CrossRef]

- Jassal, M.; Ghosh, S. Aramid Fibres—An Overview. Indian J. Fibre Text. Res. 2002, 27, 290–306. [Google Scholar]

- Khayyam, H.; Jazar, R.N.; Nunna, S.; Golkarnarenji, G.; Badii, K.; Fakhrhoseini, S.M.; Kumar, S.; Naebe, M. Pan Precursor Fabrication, Applications and Thermal Stabilization Process in Carbon Fiber Production: Experimental and Mathematical Modelling. Prog. Mater Sci. 2020, 107, 100575. [Google Scholar] [CrossRef]

- Dalton, A.B.; Collins, S.; Munoz, E.; Razal, J.M.; Ebron, V.H.; Ferraris, J.P.; Coleman, J.N.; Kim, B.G.; Baughman, R.H. Super-Tough Carbon-Nanotube Fibres. Nature 2003, 423, 703. [Google Scholar] [CrossRef]

- Dalton, A.B.; Collins, S.; Razal, J.; Munoz, E.; Ebron, V.H.; Kim, B.G.; Coleman, J.N.; Ferraris, J.P.; Baughman, R.H. Continuous Carbon Nanotube Composite Fibers: Properties, Potential Applications, and Problems. J. Mater. Chem. 2004, 14, 1–3. [Google Scholar] [CrossRef]

- Zhang, S.; Koziol, K.K.K.; Kinloch, I.A.; Windle, A.H. Macroscopic Fibers of Well-Aligned Carbon Nanotubes by Wet Spinning. Small 2008, 4, 1217–1222. [Google Scholar] [CrossRef]

- Wong, C.P.; Ohnuma, H.; Berry, G.C. Properties of Some Rodlike Polymers in Solution. J. Polym. Sci. Part C Polym. Symp. 1978, 65, 173–192. [Google Scholar] [CrossRef]

- Parra-Vasquez, A.N.G.; Behabtu, N.; Green, M.J.; Pint, C.L.; Young, C.C.; Schmidt, J.; Kesselman, E.; Goyal, A.; Ajayan, P.M.; Cohen, Y.; et al. Spontaneous Dissolution of Ultralong Single- and Multiwalled Carbon Nanotubes. ACS Nano 2010, 4, 3969–3978. [Google Scholar] [CrossRef] [PubMed]

- Behabtu, N.; Young, C.C.; Tsentalovich, D.E.; Kleinerman, O.; Wang, X.; Ma, A.W.K.; Bengio, E.A.; ter Waarbeek, R.F.; de Jong, J.J.; Hoogerwerf, R.E.; et al. Strong, Light, Multifunctional Fibers of Carbon Nanotubes with Ultrahigh Conductivity. Science 2013, 339, 182–186. [Google Scholar] [CrossRef] [PubMed]

- Taylor, L.W.; Dewey, O.S.; Headrick, R.J.; Komatsu, N.; Peraca, N.M.; Wehmeyer, G.; Kono, J.; Pasquali, M. Improved Properties, Increased Production, and the Path to Broad Adoption of Carbon Nanotube Fibers. Carbon 2021, 171, 689–694. [Google Scholar] [CrossRef]

- Headrick, R.J.; Tsentalovich, D.E.; Berdegue, J.; Bengio, E.A.; Liberman, L.; Kleinerman, O.; Lucas, M.S.; Talmon, Y.; Pasquali, M. Structure-Property Relations in Carbon Nanotube Fibers by Downscaling Solution Processing. Adv. Mater. 2018, 30, 1704482. [Google Scholar] [CrossRef] [PubMed]

- Tsentalovich, D.E.; Ma, A.W.K.; Lee, J.A.; Behabtu, N.; Bengio, E.A.; Choi, A.; Hao, J.; Luo, Y.; Headrick, R.J.; Green, M.J.; et al. Relationship of Extensional Viscosity and Liquid Crystalline Transition to Length Distribution in Carbon Nanotube Solutions. Macromolecules 2016, 49, 681–689. [Google Scholar] [CrossRef]

- Headrick, R.J.; Williams, S.M.; Owens, C.E.; Taylor, L.W.; Dewey, O.S.; Ginestra, C.J.; Liberman, L.; Ya’akobi, A.M.; Talmon, Y.; Maruyama, B.; et al. Versatile Acid Solvents for Pristine Carbon Nanotube Assembly. Sci. Adv. 2022, 8, eabm3285. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.B.; Jiang, K.L.; Teng, C.; Liu, P.; Zhang, L.; Kong, J.; Zhang, T.H.; Li, Q.Q.; Fan, S.S. Spinning and Processing Continuous Yarns from 4-Inch Wafer Scale Super-Aligned Carbon Nanotube Arrays. Adv. Mater. 2006, 18, 1505–1510. [Google Scholar] [CrossRef]

- Zhang, M.; Atkinson, K.R.; Baughman, R.H. Multifunctional Carbon Nanotube Yarns by Downsizing an Ancient Technology. Science 2004, 306, 1358–1361. [Google Scholar] [CrossRef]

- Zhang, M.; Fang, S.L.; Zakhidov, A.A.; Lee, S.B.; Aliev, A.E.; Williams, C.D.; Atkinson, K.R.; Baughman, R.H. Strong, Transparent, Multifunctional, Carbon Nanotube Sheets. Science 2005, 309, 1215–1219. [Google Scholar] [CrossRef]

- Li, F.; Cheng, H.M.; Bai, S.; Su, G.; Dresselhaus, M.S. Tensile Strength of Single-Walled Carbon Nanotubes Directly Measured from Their Macroscopic Ropes. Appl. Phys. Lett. 2000, 77, 3161–3163. [Google Scholar] [CrossRef]

- Zhu, H.W.; Xu, C.L.; Wu, D.H.; Wei, B.Q.; Vajtai, R.; Ajayan, P.M. Direct Synthesis of Long Single-Walled Carbon Nanotube Strands. Science 2002, 296, 884–886. [Google Scholar] [CrossRef]

- Zhong, X.-H.; Li, Y.-L.; Liu, Y.-K.; Qiao, X.-H.; Feng, Y.; Liang, J.; Jin, J.; Zhu, L.; Hou, F.; Li, J.-Y. Continuous Multilayered Carbon Nanotube Yarns. Adv. Mater. 2010, 22, 692–696. [Google Scholar] [CrossRef] [PubMed]

- Steinmetz, J.; Glerup, M.; Paillet, M.; Bernier, P.; Holzinger, M. Production of Pure Nanotube Fibers Using a Modified Wet-Spinning Method. Carbon 2005, 43, 2397–2400. [Google Scholar] [CrossRef]

- He, Z.; Zhou, G.; Byun, J.-H.; Lee, S.-K.; Um, M.-K.; Park, B.; Kim, T.; Lee, S.B.; Chou, T.-W. Highly Stretchable Multi-Walled Carbon Nanotube/Thermoplastic Polyurethane Composite Fibers for Ultrasensitive, Wearable Strain Sensors. Nanoscale 2019, 11, 5884–5890. [Google Scholar] [CrossRef] [PubMed]

- Klammer, R. Huntsman Acquires Nanocomp Technologies. Surf. Coat. Int. 2018, 101, 144. [Google Scholar]

- Nanocomp Technologies. Nanocomp Technologies Awarded Air Force Contract. Adv. Mater. Process. 2010, 168, 12. [Google Scholar]

- Sammalkorpi, M.; Krasheninnikov, A.; Kuronen, A.; Nordlund, K.; Kaski, K. Mechanical Properties of Carbon Nanotubes with Vacancies and Related Defects. Phys. Rev. B 2004, 70, 245416. [Google Scholar] [CrossRef]

- Zhang, S.L.; Mielke, S.L.; Khare, R.; Troya, D.; Ruoff, R.S.; Schatz, G.C.; Belytschko, T. Mechanics of Defects in Carbon Nanotubes: Atomistic and Multiscale Simulations. Phys. Rev. B 2005, 71, 115403. [Google Scholar] [CrossRef]

- Ebbesen, T.W.; Takada, T. Topological and Sp3 Defect Structures in Nanotubes. Carbon 1995, 33, 973–978. [Google Scholar] [CrossRef]

- Samsonidze, G.G.; Samsonidze, G.G.; Yakobson, B.I. Kinetic Theory of Symmetry-Dependent Strength in Carbon Nanotubes. Phys. Rev. Lett. 2002, 88, 065501. [Google Scholar] [CrossRef]

- Yakobson, B.I. Mechanical Relaxation and “Intramolecular Plasticity” in Carbon Nanotubes. Appl. Phys. Lett. 1998, 72, 918–920. [Google Scholar] [CrossRef]

- Nardelli, M.B.; Yakobson, B.I.; Bernholc, J. Brittle and Ductile Behavior in Carbon Nanotubes. Phys. Rev. Lett. 1998, 81, 4656–4659. [Google Scholar] [CrossRef]

- Yuan, Q.; Li, L.; Li, Q.; Ding, F. Effect of Metal Impurities on the Tensile Strength of Carbon Nanotubes: A Theoretical Study. J. Phys. Chem. C 2013, 117, 5470–5474. [Google Scholar] [CrossRef]

- Wong, E.W.; Sheehan, P.E.; Lieber, C.M. Nanobeam Mechanics: Elasticity, Strength, and Toughness of Nanorods and Nanotubes. Science 1997, 277, 1971–1975. [Google Scholar] [CrossRef]

- Wei, X.; Chen, Q.; Xu, S.; Peng, L.; Zuo, J. Beam to String Transition of Vibrating Carbon Nanotubes under Axial Tension. Adv. Funct. Mater. 2009, 19, 1753–1758. [Google Scholar] [CrossRef]

- Ganesan, Y.; Peng, C.; Lu, Y.; Ci, L.; Srivastava, A.; Ajayan, P.M.; Lou, J. Effect of Nitrogen Doping on the Mechanical Properties of Carbon Nanotubes. ACS Nano 2010, 4, 7637–7643. [Google Scholar] [CrossRef] [PubMed]

- Takakura, A.; Beppu, K.; Nishihara, T.; Fukui, A.; Kozeki, T.; Namazu, T.; Miyauchi, Y.; Itami, K. Strength of Carbon Nanotubes Depends on Their Chemical Structures. Nat. Commun. 2019, 10, 1–7. [Google Scholar] [CrossRef]

- Peng, B.; Locascio, M.; Zapol, P.; Li, S.; Mielke, S.L.; Schatz, G.C.; Espinosa, H.D. Measurements of near-Ultimate Strength for Multiwalled Carbon Nanotubes and Irradiation-Induced Crosslinking Improvements. Nat. Nanotechnol. 2008, 3, 626–631. [Google Scholar] [CrossRef]

- Vilatela, J.J.; Elliott, J.A.; Windle, A.H. A Model for the Strength of Yarn-Like Carbon Nanotube Fibers. ACS Nano 2011, 5, 1921–1927. [Google Scholar] [CrossRef]

- Zhang, X.; Li, Q.; Holesinger, T.G.; Arendt, P.N.; Huang, J.; Kirven, P.D.; Clapp, T.G.; DePaula, R.F.; Liao, X.; Zhao, Y.; et al. Ultrastrong, Stiff, and Lightweight Carbon-Nanotube Fibers. Adv. Mater. 2007, 19, 4198–4201. [Google Scholar] [CrossRef]

- Weibull, W. A Statistical Distribution Function of Wide Applicability. J. Appl. Mech. Trans. Asme 1951, 18, 293–297. [Google Scholar] [CrossRef]

- Nakagawa, T.; Osaki, S. Discrete Weibull Distribution. IEEE Trans. Reliab. 1975, 24, 300–301. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, Y.; Xia, Y.; Jeelani, S. Tensile Behavior of Carbon Fiber Bundles at Different Strain Rates. Mater. Lett. 2010, 64, 246–248. [Google Scholar] [CrossRef]

- Daniels, H.E. The Statistical Theory of the Strength of Bundles of Threads. I. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1945, 183, 405–435. [Google Scholar]

- Gollwitzer, S.; Rackwitz, R. On the Reliability of Daniels Systems. Struct. Saf. 1990, 7, 229–243. [Google Scholar] [CrossRef]

- Lan, C.; Li, H.; Ju, Y. Bearing Capacity Assessment for Parallel Wire Cables. China Civ. Eng. J. 2013, 46, 31–38. [Google Scholar]

- Chi, Z.F.; Chou, T.W.; Shen, G.Y. Determination of Single Fiber Strength Distribution from Fiber Bundle Testings. J. Mater. Sci. 1984, 19, 3319–3324. [Google Scholar] [CrossRef]

- Gao, G.; Cagin, T.; Goddard, W.A. Energetics, Structure, Mechanical and Vibrational Properties of Single-Walled Carbon Nanotubes. Nanotechnology 1999, 9, 184–191. [Google Scholar] [CrossRef]

- Belytschko, T.; Xiao, S.P.; Schatz, G.C.; Ruoff, R.S. Atomistic Simulations of Nanotube Fracture. Phys. Rev. B 2002, 65, 235430. [Google Scholar] [CrossRef]

- Hu, J.; Zheng, Q. Application of 2000 mpa Parallel Wire Cables to Cable-Stayed Rail-Cum-Road Bridge with Main Span Length over 1000 m. Bridge Constr. 2019, 49, 48–53. [Google Scholar]

- Li, S.; Xu, Y.; Zhu, S.; Guan, X.; Bao, Y. Probabilistic Deterioration Model of High-Strength Steel Wires and Its Application to Bridge Cables. Struct. Infrastruct. Eng. 2015, 11, 1240–1249. [Google Scholar] [CrossRef]

- Fang, I.K.; Chen, C.R.; Chang, I.S. Field Static Load Test on Kao-Ping-Hsi Cable-Stayed Bridge. J. Bridge Eng. 2004, 9, 531–540. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, X.; DePaula, R.F.; Zheng, L.; Zhao, Y.; Stan, L.; Holesinger, T.G.; Arendt, P.N.; Peterson, D.E.; Zhu, Y.T. Sustained Growth of Ultralong Carbon Nanotube Arrays for Fiber Spinning. Adv. Mater. 2006, 18, 3160–3163. [Google Scholar] [CrossRef]

- Li, Q.; Li, Y.; Zhang, X.; Chikkannanavar, S.B.; Zhao, Y.; Dangelewicz, A.M.; Zheng, L.; Doorn, S.K.; Jia, Q.; Peterson, D.E.; et al. Structure-Dependent Electrical Properties of Carbon Nanotube Fibers. Adv. Mater. 2007, 19, 3358–3363. [Google Scholar] [CrossRef]

- Tsentalovich, D.E.; Headrick, R.J.; Mirri, F.; Hao, J.; Behabtu, N.; Young, C.C.; Pasquali, M. Influence of Carbon Nanotube Characteristics on Macroscopic Fiber Properties. ACS Appl. Mater. Interfaces 2017, 9, 36189–36198. [Google Scholar] [CrossRef]

- Zhang, X.F.; Li, Q.W.; Tu, Y.; Li, Y.A.; Coulter, J.Y.; Zheng, L.X.; Zhao, Y.H.; Jia, Q.X.; Peterson, D.E.; Zhu, Y.T. Strong Carbon-Nanotube Fibers Spun from Long Carbon-Nanotube Arrays. Small 2007, 3, 244–248. [Google Scholar] [CrossRef]

- Zhang, Y.; Zou, G.; Doorn, S.K.; Htoon, H.; Stan, L.; Hawley, M.E.; Sheehan, C.J.; Zhu, Y.; Jia, Q. Tailoring the Morphology of Carbon Nanotube Arrays: From Spinnable Forests to Undulating Foams. ACS Nano 2009, 3, 2157–2162. [Google Scholar] [CrossRef]

- Huynh, C.P.; Hawkins, S.C. Understanding the Synthesis of Directly Spinnable Carbon Nanotube Forests. Carbon 2010, 48, 1105–1115. [Google Scholar] [CrossRef]

- Xie, S.S.; Li, W.Z.; Pan, Z.W.; Chang, B.H.; Sun, L.F. Mechanical and Physical Properties on Carbon Nanotube. J. Phys. Chem. Solids 2000, 61, 1153–1158. [Google Scholar] [CrossRef]

- Fang, S.; Zhang, M.; Zakhidov, A.A.; Baughman, R.H. Structure and Process-Dependent Properties of Solid-State Spun Carbon Nanotube Yarns. J. Phys. Condens. Matter 2010, 22, 334221. [Google Scholar] [CrossRef]

- Kuznetsov, A.A.; Fonseca, A.F.; Baughman, R.H.; Zakhidov, A.A. Structural Model for Dry-Drawing of Sheets and Yarns from Carbon Nanotube Forests. ACS Nano 2011, 5, 985–993. [Google Scholar] [CrossRef] [PubMed]

- Miao, M.; Hawkins, S.C.; Cai, J.Y.; Gengenbach, T.R.; Knott, R.; Huynh, C.P. Effect of Gamma-Irradiation on the Mechanical Properties of Carbon Nanotube Yarns. Carbon 2011, 49, 4940–4947. [Google Scholar] [CrossRef]

- Cai, J.Y.; Min, J.; McDonnell, J.; Church, J.S.; Easton, C.D.; Humphries, W.; Lucas, S.; Woodhead, A.L. An Improved Method for Functionalisation of Carbon Nanotube Spun Yarns with Aryldiazonium Compounds. Carbon 2012, 50, 4655–4662. [Google Scholar] [CrossRef]

- Li, S.; Zhang, X.; Zhao, J.; Meng, F.; Xu, G.; Yong, Z.; Jia, J.; Zhang, Z.; Li, Q. Enhancement of Carbon Nanotube Fibres Using Different Solvents and Polymers. Compos. Sci. Technol. 2012, 72, 1402–1407. [Google Scholar] [CrossRef]

- Liu, K.; Sun, Y.; Lin, X.; Zhou, R.; Wang, J.; Fan, S.; Jiang, K. Scratch-Resistant, Highly Conductive, and High-Strength Carbon Nanotube-Based Composite Yarns. ACS Nano 2010, 4, 5827–5834. [Google Scholar] [CrossRef] [PubMed]

- Kozlov, M.E.; Capps, R.C.; Sampson, W.M.; Ebron, V.H.; Ferraris, J.P.; Baughman, R.H. Spinning Solid and Hollow Polymer-Free Carbon Nanotube Fibers. Adv. Mater. 2005, 17, 614–617. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Sabaruddin, F.A.; Harussani, M.M.; Kamarudin, S.H.; Rayung, M.; Asyraf, M.R.M.; Aisyah, H.A.; Norrrahim, M.N.F.; Ilyas, R.A.; Abdullah, N.; et al. Mechanical Performance and Applications of Cnts Reinforced Polymer Composites—A Review. Nanomaterials 2021, 11, 2186. [Google Scholar] [CrossRef]

- Kim, T.; Shin, J.; Lee, K.; Jung, Y.; Lee, S.B.; Yang, S.J. A Universal Surface Modification Method of Carbon Nanotube Fibers with Enhanced Tensile Strength. Compos. Part A Appl. Sci. Manuf. 2021, 140, 106182. [Google Scholar] [CrossRef]

- Cetin, M.E. Investigation of Carbon Nanotube Reinforcement to Polyurethane Adhesive for Improving Impact Performance of Carbon Fiber Composite Sandwich Panels. Int. J. Adhes. Adhes. 2022, 112, 103002. [Google Scholar] [CrossRef]

- Gardner, J.M.; Sauti, G.; Kim, J.W.; Cano, R.J.; Wincheski, R.A.; Stelter, C.J.; Grimsley, B.W.; Working, D.C.; Siochi, E.J. 3-D Printing of Multifunctional Carbon Nanotube Yarn Reinforced Components. Addit. Manuf. 2016, 12, 38–44. [Google Scholar] [CrossRef]

- Kim, J.W.; Sauti, G.; Cano, R.J.; Wincheski, R.A.; Ratcliffe, J.G.; Czabaj, M.; Gardner, N.W.; Siochi, E.J. Assessment of Carbon Nanotube Yarns as Reinforcement for Composite Overwrapped Pressure Vessels. Compos. Part A Appl. Sci. Manuf. 2016, 84, 256–265. [Google Scholar] [CrossRef]

- Han, B.; Guo, E.; Xue, X.; Zhao, Z.; Luo, L.; Qu, H.; Niu, T.; Xu, Y.; Hou, H. Fabrication and Densification of High Performance Carbon Nanotube/Copper Composite Fibers. Carbon 2017, 123, 593–604. [Google Scholar] [CrossRef]

- Zhu, P.; Wang, C.; Wang, X.; Yang, H.; Xu, G.; Qin, C.; Xiong, L.; Wen, G.; Xia, L. Superior Mechanical Properties of Lithium Aluminosilicate Composites by Pyrolytic Carbon Intercalated Carbon Fibers/Carbon Nanotubes Multi-Scale Reinforcements. Ceram. Int. 2021, 47, 32837–32846. [Google Scholar] [CrossRef]

- Sadeghi, A.M.; Esmaeili, J. Hybrid-Fibre-Reinforced Concrete Containing Multi-Wall Carbon Nanotubes. Proc. Inst. Civ. Eng. Struct. Build. 2020, 173, 646–654. [Google Scholar] [CrossRef]

- Benzait, Z.; Trabzon, L. A Review of Recent Research on Materials Used in Polymer-Matrix Composites for Body Armor Application. J. Compos. Mater. 2018, 52, 3241–3263. [Google Scholar] [CrossRef]

- Xie, W.T.; Zhang, R.Y.; Headrick, R.J.; Taylor, L.W.; Kooi, S.; Pasquali, M.; Muftu, S.; Lee, J.H. Dynamic Strengthening of Carbon Nanotube Fibers under Extreme Mechanical Impulses. Nano Lett. 2019, 19, 3519–3526. [Google Scholar] [CrossRef]

- Wang, Z.; Mun, T.J.; Machado, F.M.; Moon, J.H.; Fang, S.; Aliev, A.E.; Zhang, M.; Cai, W.; Mu, J.; Hyeon, J.S.; et al. More Powerful Twistron Carbon Nanotube Yarn Mechanical Energy Harvesters. Adv. Mater. 2022, 34, 2201826. [Google Scholar] [CrossRef]

- Jang, Y.; Kim, S.M.; Kim, K.J.; Sim, H.J.; Kim, B.J.; Park, J.W.; Baughman, R.H.; Ruhparwar, A.; Kim, S.J. Self-Powered Coiled Carbon-Nanotube Yarn Sensor for Gastric Electronics. ACS Sens. 2019, 4, 2893–2899. [Google Scholar] [CrossRef]

- Hu, X.; Jia, J.; Wang, Y.; Tang, X.; Fang, S.; Wang, Y.; Baughman, R.H.; Ding, J. Fast Large-Stroke Sheath-Driven Electrothermal Artificial Muscles with High Power Densities. Adv. Funct. Mater. 2022, 32, 2200591. [Google Scholar] [CrossRef]

- Chen, S.H.; Qiu, L.; Cheng, H.M. Carbon-Based Fibers for Advanced Electrochemical Energy Storage Devices. Chem. Rev. 2020, 120, 2811–2878. [Google Scholar] [CrossRef]

- Zhou, X.; Fang, S.; Leng, X.; Liu, Z.; Baughman, R.H. The Power of Fiber Twist. Acc. Chem. Res. 2021, 54, 2624–2636. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.H.; Haines, C.S.; Li, N.; Kim, K.J.; Mun, T.J.; Choi, C.; Di, J.T.; Oh, Y.J.; Oviedo, J.P.; Bykova, J.; et al. Harvesting Electrical Energy from Carbon Nanotube Yarn Twist. Science 2017, 357, 773–778. [Google Scholar] [CrossRef]

- Di, J.; Fang, S.; Moura, F.A.; Galvao, D.S.; Bykova, J.; Aliev, A.; de Andrade, M.J.; Lepro, X.; Li, N.; Haines, C.; et al. Strong, Twist-Stable Carbon Nanotube Yarns and Muscles by Tension Annealing at Extreme Temperatures. Adv. Mater. 2016, 28, 6598–6605. [Google Scholar] [CrossRef] [PubMed]

- Vallem, V.; Sargolzaeiaval, Y.; Ozturk, M.; Lai, Y.-C.; Dickey, M.D. Energy Harvesting and Storage with Soft and Stretchable Materials. Adv. Mater. 2021, 33, 2004832. [Google Scholar] [CrossRef] [PubMed]

- Mun, T.J.; Kim, S.H.; Park, J.W.; Moon, J.H.; Jang, Y.; Huynh, C.; Baughman, R.H.; Kim, S.J. Wearable Energy Generating and Storing Textile Based on Carbon Nanotube Yarns. Adv. Funct. Mater. 2020, 30, 2000411. [Google Scholar] [CrossRef]

- Jang, Y.; Kim, S.M.; Spinks, G.M.; Kim, S.J. Carbon Nanotube Yarn for Fiber-Shaped Electrical Sensors, Actuators, and Energy Storage for Smart Systems. Adv. Mater. 2020, 32, 1902670. [Google Scholar] [CrossRef]

- Hyeon, J.S.; Park, J.W.; Baughman, R.H.; Kim, S.J. Electrochemical Graphene/Carbon Nanotube Yarn Artificial Muscles. Sens. Actuators B—Chem. 2019, 286, 237–242. [Google Scholar] [CrossRef]

- Foroughi, J.; Spinks, G.M.; Wallace, G.G.; Oh, J.; Kozlov, M.E.; Fang, S.L.; Mirfakhrai, T.; Madden, J.D.W.; Shin, M.K.; Kim, S.J.; et al. Torsional Carbon Nanotube Artificial Muscles. Science 2011, 334, 494–497. [Google Scholar] [CrossRef]

- Lee, J.A.; Li, N.; Haines, C.S.; Kim, K.J.; Lepro, X.; Ovalle-Robles, R.; Kim, S.J.; Baughman, R.H. Electrochemically Powered, Energy-Conserving Carbon Nanotube Artificial Muscles. Adv. Mater. 2017, 29, 1700870. [Google Scholar] [CrossRef]

| Scales | Diameter | Carbon Nanotube | Tensile Strength (GPa) | Ref. |

|---|---|---|---|---|

| Single tubes | 2.0 nm | DWCNTs | 118.9 ± 4.5 | [15] |

| 1.0 to 4.0 nm | SWCNTs, DWCNTs, TWCNTs | 120 | [9] | |

| 15.71 nm | MWCNTs | 110 | [90] | |

| 1.5 to 3.0 nm | SWCNTs | 25 to 66 | [89] | |

| 1.8 to 30 nm | DWCNTs, TWCNTs | 13 to 46 | [11] | |

| 13 to 36 nm | MWCNTs | 11 to 63 | [28] | |

| Nanoscale CNTFs | 10.0 to 25.0 nm | SWCNTs, DWCNTs, TWCNTs | 47 to 80 | [10] |

| 19 to 41 nm | SWCNTs | 13 to 52 | [48] | |

| 10.8 to 27.9 nm | DWCNTs | 1.5 to 17.1 | [50] | |

| 10 to 40 nm | SWCNTs | 3.6 ± 0.4 | [38,72] | |

| Microscale CNTFs | / | DWCNTs | 9.6 | [4] |

| 7.0 to 20.0 μm | DWCNTs | 9 | [17] | |

| 8.0 to 9.8 μm | SWCNTs | 4.2 | [65] | |

| 5.0 to 9.0μm | DWCNTs | 3.76 to 5.53 | [5] | |

| 5.0 μm | DWCNTs | 3.3 | [92] | |

| 15 to 100 μm | SWCNTs | 0.15 | [16] | |

| 0.2 to 0.6 μm | SWCNTs | 0.12 | [54] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Y.; Yue, H.; Aslam, M.J.; Bai, Y.; Zhu, Z.; Wei, F. Controllable Preparation and Strengthening Strategies towards High-Strength Carbon Nanotube Fibers. Nanomaterials 2022, 12, 3478. https://doi.org/10.3390/nano12193478

Zhu Y, Yue H, Aslam MJ, Bai Y, Zhu Z, Wei F. Controllable Preparation and Strengthening Strategies towards High-Strength Carbon Nanotube Fibers. Nanomaterials. 2022; 12(19):3478. https://doi.org/10.3390/nano12193478

Chicago/Turabian StyleZhu, Yukang, Hongjie Yue, Muhammad Junaid Aslam, Yunxiang Bai, Zhenxing Zhu, and Fei Wei. 2022. "Controllable Preparation and Strengthening Strategies towards High-Strength Carbon Nanotube Fibers" Nanomaterials 12, no. 19: 3478. https://doi.org/10.3390/nano12193478

APA StyleZhu, Y., Yue, H., Aslam, M. J., Bai, Y., Zhu, Z., & Wei, F. (2022). Controllable Preparation and Strengthening Strategies towards High-Strength Carbon Nanotube Fibers. Nanomaterials, 12(19), 3478. https://doi.org/10.3390/nano12193478