Washable Fabric Triboelectric Nanogenerators for Potential Application in Face Masks

Abstract

:1. Introduction

2. Materials and Methods

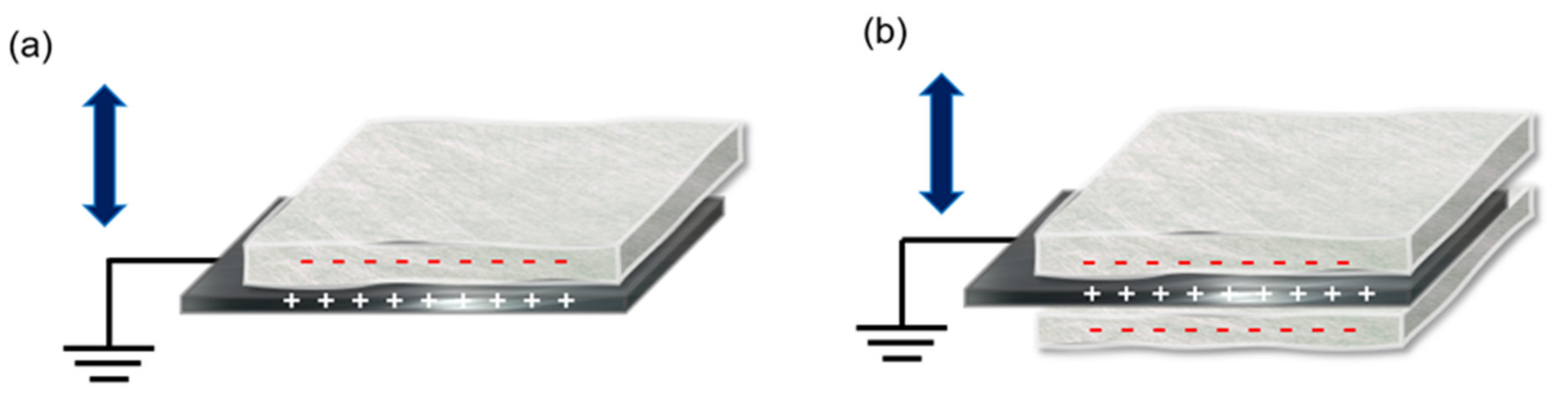

2.1. Fabrication of Fabric-Based TENGs

2.2. Washing and Measurement of the Characteristics of the FTENGs

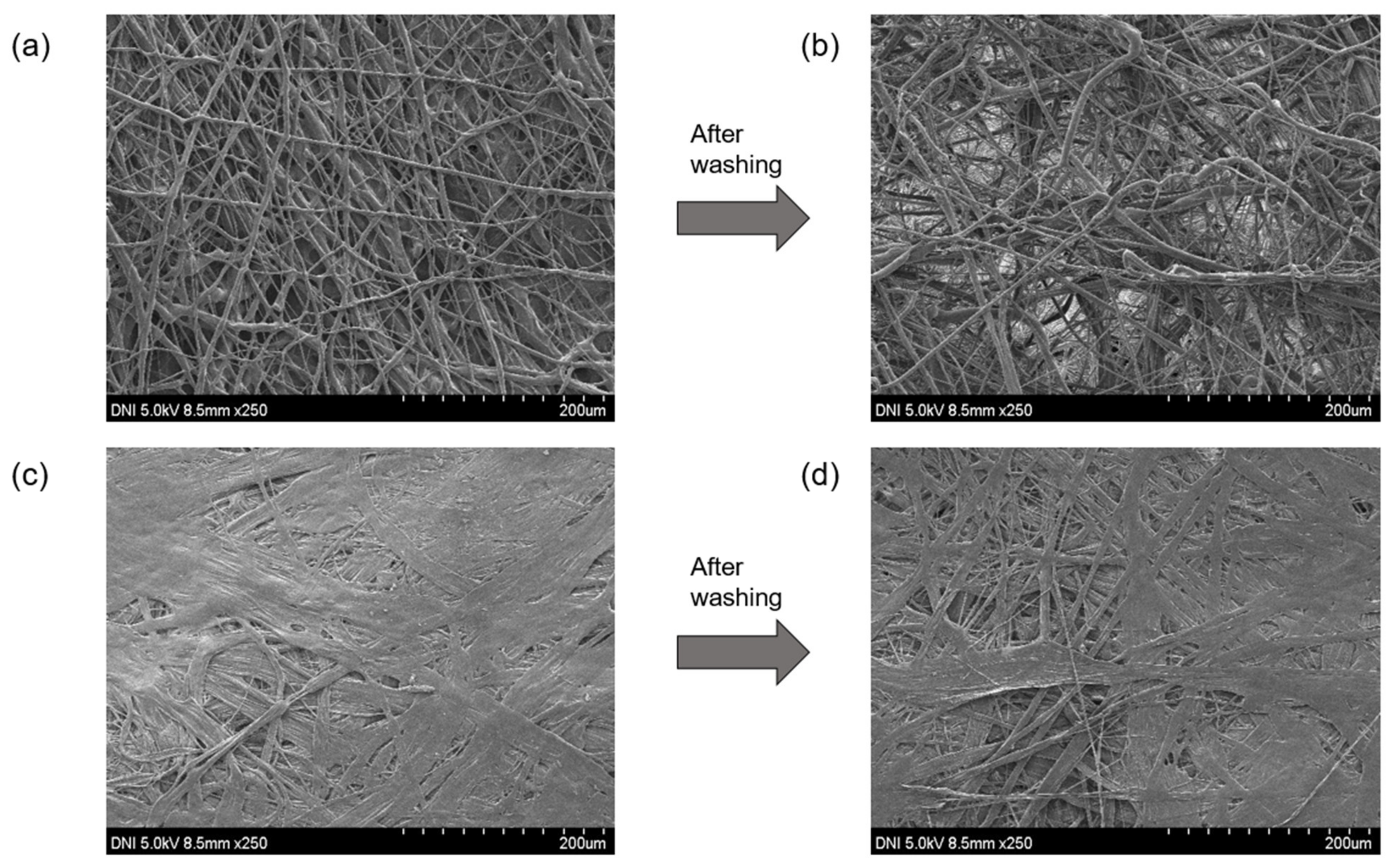

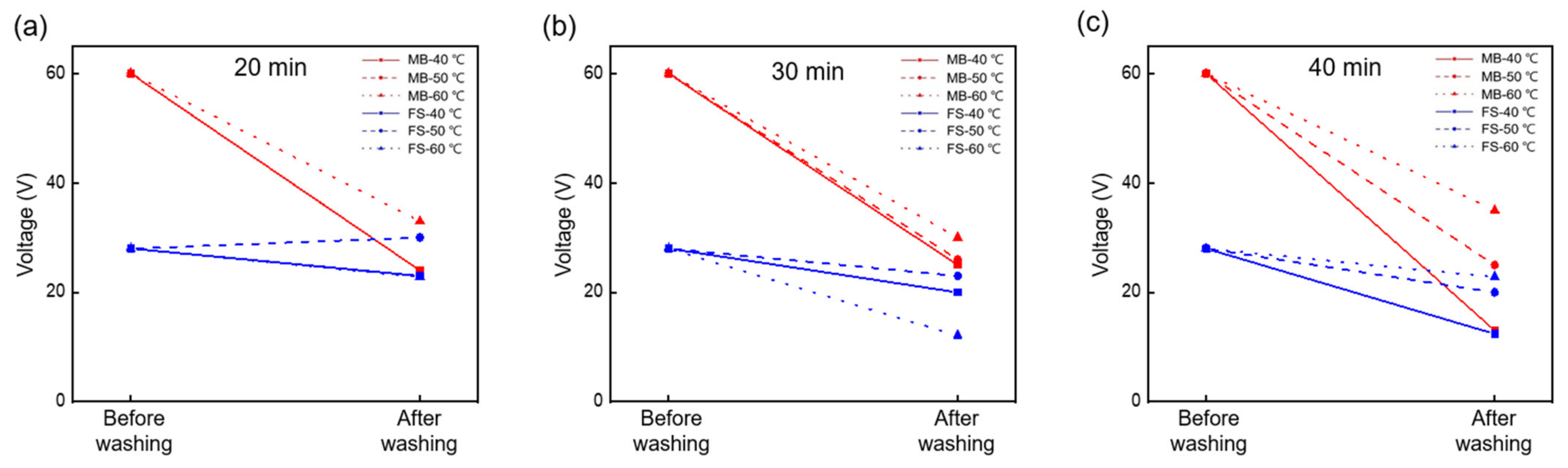

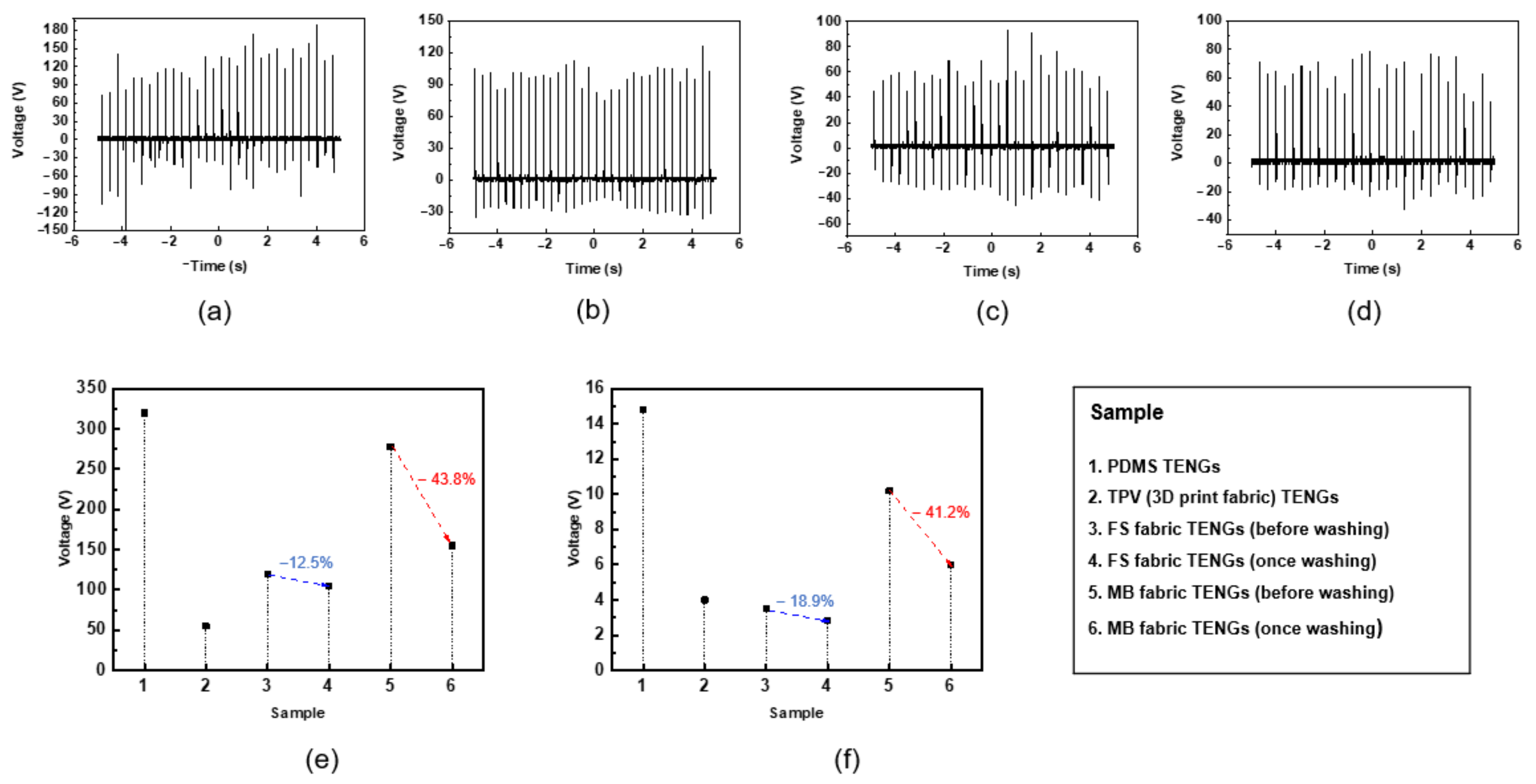

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, C.; Wang, A.C.; Ding, W.; Guo, H.; Wang, Z.L. Triboelectric Nanogenerator: A Foundation of the Energy for the New Era. Adv. Energy Mater. 2019, 9, 1802906. [Google Scholar] [CrossRef]

- Peng, X.; Dong, K.; Ye, C.; Jiang, Y.; Zhai, S.; Cheng, R.; Liu, D.; Gao, X.; Wang, J.; Wang, Z.L. A Breathable, Biodegradable, Antibacterial, and Self-Powered Electronic Skin Based on All-Nanofiber Triboelectric Nanogenerators. Sci. Adv. 2020, 6, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Kwon, J.-H.; Jeong, J.; Lee, Y.; Biswas, S.; Park, J.-K.; Lee, S.; Lee, D.-W.; Lee, S.; Bae, J.-H.; Kim, H. Importance of Architectural Asymmetry for Improved Triboelectric Nanogenerators with 3D Spacer Fabrics. Macromol. Res. 2021, 29, 443–447. [Google Scholar] [CrossRef]

- Bai, Z.; Xu, Y.; Li, J.; Zhu, J.; Gao, C.; Zhang, Y.; Wang, J.; Guo, J. An Eco-Friendly Porous Nanocomposite Fabric-Based Triboelectric Nanogenerator for Efficient Energy Harvesting and Motion Sensing. ACS Appl. Mater. Interfaces 2020, 12, 42880–42890. [Google Scholar] [CrossRef]

- Wang, Z.L. Triboelectric Nanogenerator (TENG)—Sparking an Energy and Sensor Revolution. Adv. Energy Mater. 2020, 10, 2000137. [Google Scholar] [CrossRef]

- Zheng, Y.; Liu, T.; Wu, J.; Xu, T.; Wang, X.; Han, X.; Cui, H.; Xu, X.; Pan, C.; Li, X. Energy Conversion Analysis of Multilayered Triboelectric Nanogenerators for Synergistic Rain and Solar Energy Harvesting. Adv. Mater. 2022, 34, 2202238. [Google Scholar] [CrossRef]

- Li, X.; Lau, T.H.; Guan, D.; Zi, Y. A universal method for quantitiative analysis of triboelectric nanogenerators. J. Mater. Chem. 2019, 7, 19485. [Google Scholar] [CrossRef]

- Wu, J.; Zheng, Y.; Li, X. Recent Progress in Self-Powered Sensors Based on Triboelectric Nanogenerators. Sensors 2021, 21, 7129. [Google Scholar] [CrossRef]

- Niu, S.; Wang, Z.L. Theoretical Systems of Triboelectric Nanogenerators. Nano Energy 2014, 14, 161–192. [Google Scholar] [CrossRef]

- Zhang, C.; Lin, Z. Nano Today Tribotronics—A New Field by Coupling Triboelectricity and Semiconductor. Nano Today 2016, 11, 521–536. [Google Scholar] [CrossRef]

- Zhao, Z.; Yan, C.; Liu, Z.; Fu, X.; Peng, L.M.; Hu, Y.; Zheng, Z. Machine-Washable Textile Triboelectric Nanogenerators for Effective Human Respiratory Monitoring through Loom Weaving of Metallic Yarns. Adv. Mater. 2016, 28, 10267–10274. [Google Scholar] [CrossRef]

- Jeong, J.; Kwon, J.H.; Lim, K.; Biswas, S.; Tibaldi, A.; Lee, S.; Oh, H.J.; Kim, J.H.; Ko, J.; Lee, D.W.; et al. Comparative Study of Triboelectric Nanogenerators with Differently Woven Cotton Textiles for Wearable Electronics. Polymers 2019, 11, 1443. [Google Scholar] [CrossRef]

- Dong, K.; Peng, X.; Wang, Z.L. Fiber/Fabric-Based Piezoelectric and Triboelectric Nanogenerators for Flexible/Stretchable and Wearable Electronics and Artificial Intelligence. Adv. Mater. 2020, 32, 1902549. [Google Scholar] [CrossRef]

- Kwon, D.H.; Kwon, J.H.; Jeong, J.; Lee, Y.; Biswas, S.; Lee, D.W.; Lee, S.; Bae, J.H.; Kim, H. Textile Triboelectric Nanogenerators with Diverse 3d-Spacer Fabrics for Improved Output Voltage. Electronics 2021, 10, 937. [Google Scholar] [CrossRef]

- Lim, K.; Kim, D.K.; Jeong, J.B.; Choi, S.; Biswas, S.; Tibaldi, A.; Ma, T.Y.; Lee, S.; Kim, J.H.; Ko, J.; et al. Enhanced Output Voltage of Nano Energy Harvester with Diverse Textiles. Mol. Cryst. Liq. Cryst. 2019, 687, 113–117. [Google Scholar] [CrossRef]

- Kwak, S.S.; Kim, H.; Seung, W.; Kim, J.; Hinchet, R.; Kim, S.W. Fully Stretchable Textile Triboelectric Nanogenerator with Knitted Fabric Structures. ACS Nano 2017, 11, 10733–10741. [Google Scholar] [CrossRef]

- Liu, G.; Nie, J.; Han, C.; Jiang, T.; Yang, Z.; Pang, Y.; Xu, L.; Guo, T.; Bu, T.; Zhang, C.; et al. Self-Powered Electrostatic Adsorption Face Mask Based on a Triboelectric Nanogenerator. ACS Appl. Mater. Interfaces 2018, 10, 7126–7133. [Google Scholar] [CrossRef]

- Varghese, H.; Chandran, A. Triboelectric Nanogenerator from Used Surgical Face Mask and Waste Mylar Materials Aiding the Circular Economy. ACS Appl. Mater. Interfaces 2021, 13, 51132–51140. [Google Scholar] [CrossRef]

- Fois, A.; Tocco, F.; Dell’Osa, A.; Melis, L.; Bertelli, U.; Concu, A.; ManuelloBertetto, A.; Serra, C. Innovative Smart Face Mask to Protect Workers from COVID-19 Infection. In Proceedings of the 2021 IEEE International Symposium on Medical Measurements and Applications (MeMeA), Lausanne, Switzerland, 23–25 June 2021; pp. 1–6. [Google Scholar]

- Lu, Q.; Chen, H.; Zeng, Y.; Xue, J.; Cao, X.; Wang, N.; Wang, Z. Intelligent facemask based on triboelectric nanogenerator for respiratory monitoring. Nano Energy 2022, 91, 106612. [Google Scholar] [CrossRef]

- Santra, P.K.; Singh, A.K.; Kulkarni, G.U.; Kundu, S.; Rao, T.S.; Ganesha, M.K. Aesthetically Acceptable, Breath Freiendly Triboelectric Face Masks: Desgin, Fabrication, and Its Efficacy. Energy Technol. 2021, 9, 2100614. [Google Scholar] [CrossRef]

- Ghatak, B.; Banerjee, S.; Ali, S.B.; Bandyopadhyay, R.; Das, N.; Mandal, D.; Tudu, B. Design of a self-powered triboelectric face mask. Nano Energy 2021, 79, 105387. [Google Scholar] [CrossRef]

- Chowdhury, H.; Chowdhury, T.; Sait, S.M. Estimating Marine Plastic Pollution from COVID-19 Face Masks in Coastal Regions. Mar. Pollut. Bull. 2021, 168, 112419. [Google Scholar] [CrossRef]

- Wang, Y.; Shim, E.; He, N.; Pourdeyhimi, B.; Gao, W. Modeling the Triboelectric Behaviors of Elastomeric Nonwoven Fabrics. Adv. Mater. 2022, 34, 2106429. [Google Scholar] [CrossRef]

- Zou, H.; Zhang, Y.; Guo, L.; Wang, P.; He, X.; Dai, G.; Zheng, H.; Chen, C.; Wang, A.C.; Xu, C.; et al. Quantifying the Triboelectric Series. Nat. Commun. 2019, 10, 1427. [Google Scholar] [CrossRef]

- Ning, N.; Li, S.; Wu, H.; Tian, H.; Yao, P.; Hu, G.H.; Tian, M.; Zhang, L. Preparation, Microstructure, and Microstructure-Properties Relationship of Thermoplastic Vulcanizates (TPVs): A Review. Prog. Polym. Sci. 2018, 79, 61–97. [Google Scholar] [CrossRef]

| MB FTENGs | Time (min) | 20 | 30 | 40 | ||||||

| Temperature (°C) | 40 | 50 | 60 | 40 | 50 | 60 | 40 | 50 | 60 | |

| Degradation Ratio (%) | 60 | 60 | 45 | 58.3 | 56.7 | 50 | 78.3 | 58.3 | 41.7 | |

| FS FTENGs | Time (min) | 20 | 30 | 40 | ||||||

| Temperature (°C) | 40 | 50 | 60 | 40 | 50 | 60 | 40 | 50 | 60 | |

| Degradation Ratio (%) | 17.9 | 7.1 | 18.6 | 28.6 | 17.9 | 56.8 | 55.7 | 28.6 | 18.6 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeon, S.-H.; Lee, Y.; Biswas, S.; Choi, H.; Han, S.; Kim, M.; Lee, D.-W.; Lee, S.; Kim, H.; Bae, J.-H. Washable Fabric Triboelectric Nanogenerators for Potential Application in Face Masks. Nanomaterials 2022, 12, 3152. https://doi.org/10.3390/nano12183152

Jeon S-H, Lee Y, Biswas S, Choi H, Han S, Kim M, Lee D-W, Lee S, Kim H, Bae J-H. Washable Fabric Triboelectric Nanogenerators for Potential Application in Face Masks. Nanomaterials. 2022; 12(18):3152. https://doi.org/10.3390/nano12183152

Chicago/Turabian StyleJeon, Sang-Hwa, Yongju Lee, Swarup Biswas, Hyojeong Choi, Selim Han, Minseo Kim, Dong-Wook Lee, Sohee Lee, Hyeok Kim, and Jin-Hyuk Bae. 2022. "Washable Fabric Triboelectric Nanogenerators for Potential Application in Face Masks" Nanomaterials 12, no. 18: 3152. https://doi.org/10.3390/nano12183152

APA StyleJeon, S.-H., Lee, Y., Biswas, S., Choi, H., Han, S., Kim, M., Lee, D.-W., Lee, S., Kim, H., & Bae, J.-H. (2022). Washable Fabric Triboelectric Nanogenerators for Potential Application in Face Masks. Nanomaterials, 12(18), 3152. https://doi.org/10.3390/nano12183152