Recent Progress on Triboelectric Nanogenerators for Vibration Energy Harvesting and Vibration Sensing

Abstract

:1. Introduction

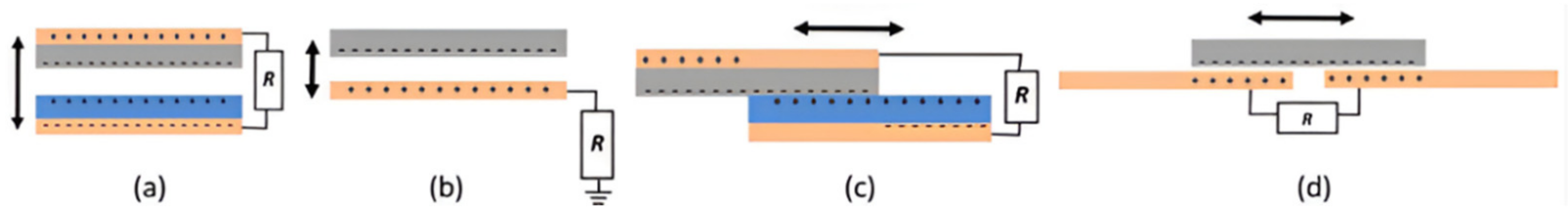

2. Working Mechanism of a TENG

3. Triboelectric Nanogenerators for Vibration Energy Harvesting

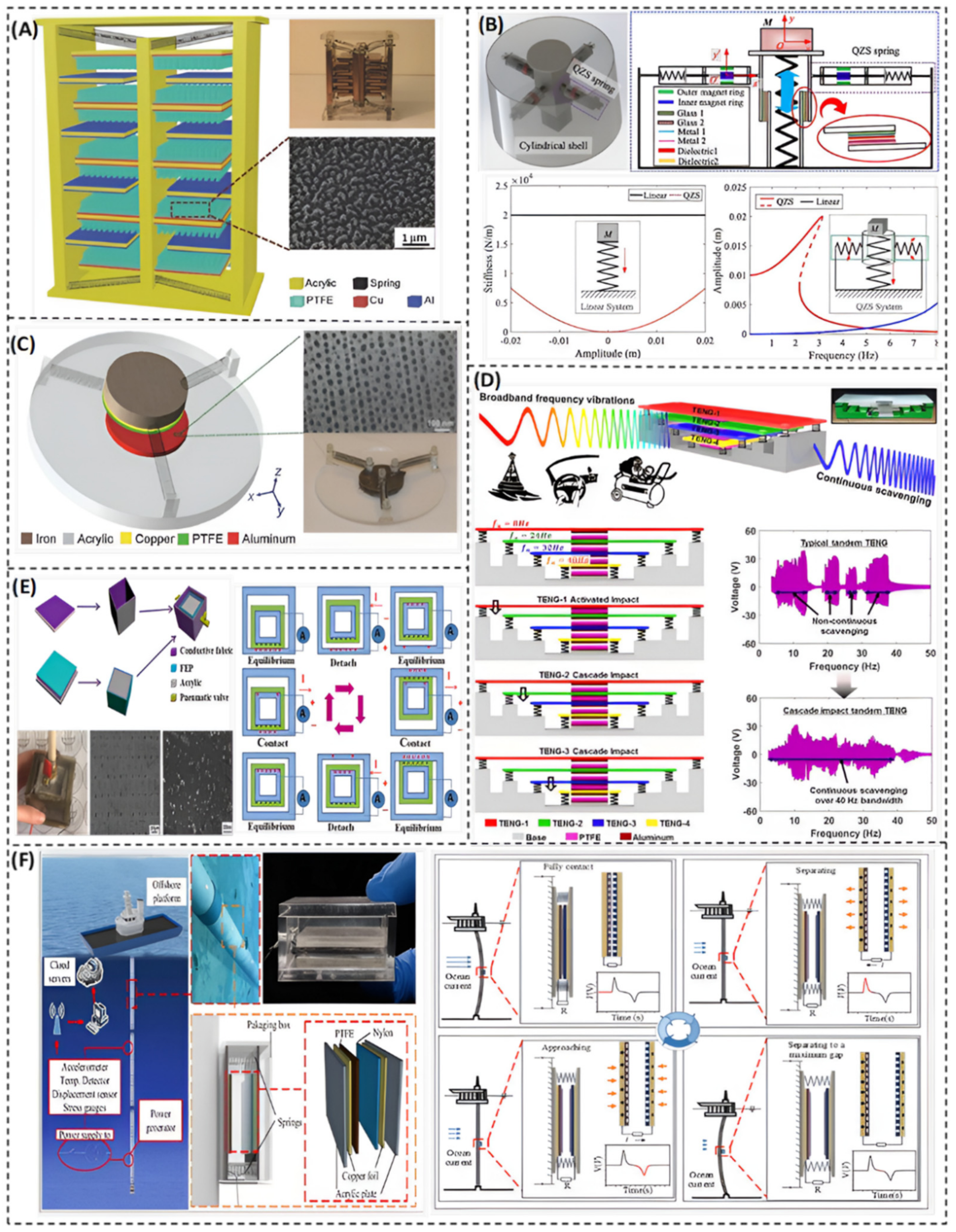

3.1. TENG-Based Vibration Energy Harvesting

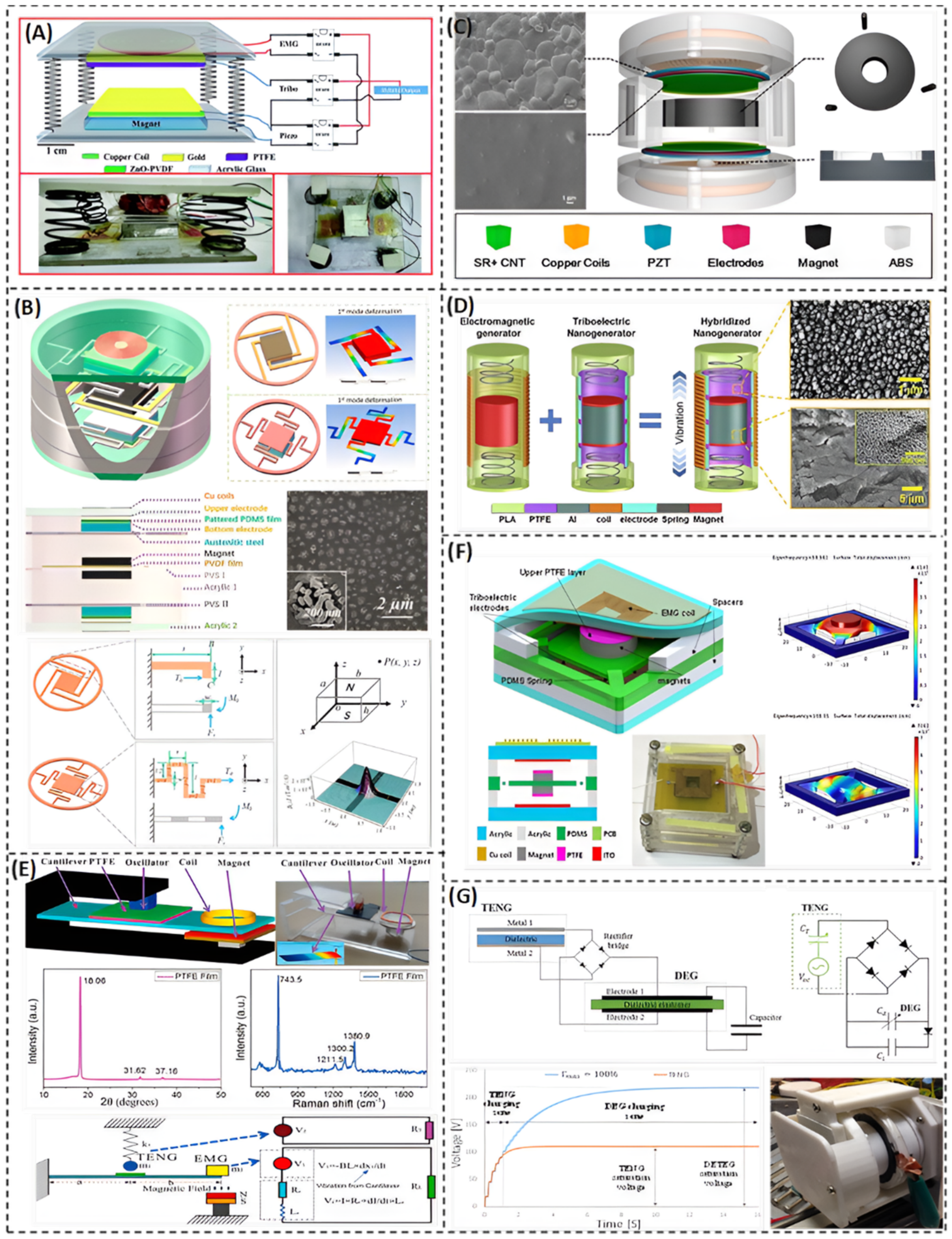

3.2. Hybrid TENG-Based Vibration Energy Harvesting

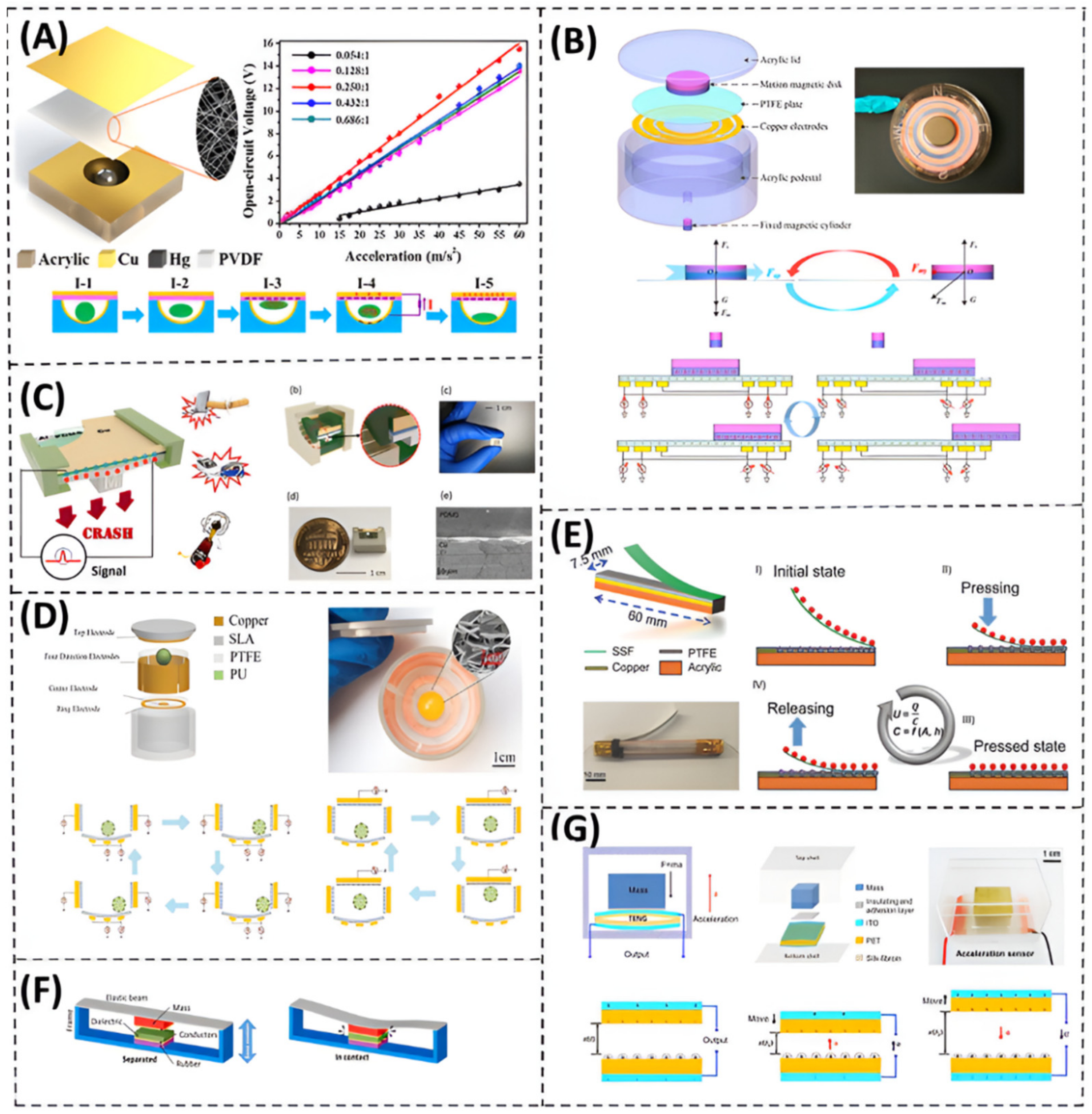

4. Triboelectric Nanogenerators for Vibration Measurements

4.1. Triboelectric Sensors for Displacement Measurements

4.2. Triboelectric Sensors for Acceleration Measurements

5. TENGs for Both Vibration Energy Harvesting and Vibration Sensing

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sojan, S.; Kulkarni, R.K. A Comprehensive Review of Energy Harvesting Techniques and Its Potential Applications. Int. J. Comput. Appl. 2016, 139, 14–19. [Google Scholar] [CrossRef]

- Beeby, S.P.; Tudor, M.J.; White, N.M. Energy harvesting vibration sources for microsystems applications. Meas. Sci. Technol. 2006, 17, r175. [Google Scholar] [CrossRef]

- Fang, L.H.; Hassan, S.I.S.; Rahim, R.B.A.; Malek, M.F.A. A study of vibration energy harvester. ARPN J. Eng. Appl. Sci. 2016, 11, 5028–5041. [Google Scholar]

- Kim, W.; Bhatia, D.; Hwang, H.J.; Choi, K.; Choi, D. Double impact triboelectric nanogenerators for harvesting broadband vibrations from vehicles. Funct. Compos. Struct. 2019, 1, 035003. [Google Scholar] [CrossRef]

- Zhu, Q.; Guan, M.; He, Y. Vibration energy harvesting in automobiles to power wireless sensors. In Proceedings of the IEEE International Conference on Information and Automation, ICIA, Shenyang, China, 6 June 2012; pp. 349–354. [Google Scholar] [CrossRef]

- Carder, D.S. Observed vibrations of bridges. Bull. Seismol. Soc. Am. 1937, 27, 267–303. [Google Scholar] [CrossRef]

- Xabibulla, G.; Gazaloy, J.; Nishonova, G. Causes and extinguishing equipment of vibrations occurred by machinery and mechanisms. Sci. Prog. 2021, 2, 950. [Google Scholar]

- Homayounfar, S.Z.; Andrew, T.L. Wearable Sensors for Monitoring Human Motion: A Review on Mechanisms, Materials, and Challenges. SLAS Technol. 2019, 25, 9–24. [Google Scholar] [CrossRef]

- Choi, Y.M.; Lee, M.G.; Jeon, Y. Wearable biomechanical energy harvesting technologies. Energies 2017, 10, 1483. [Google Scholar] [CrossRef]

- Safaei, M.; Sodano, H.A.; Anton, S.R. A review of energy harvesting using piezoelectric materials: State-of-the-art a decade later (2008–2018). Smart Mater. Struct. 2019, 28, 113001. [Google Scholar] [CrossRef]

- Xu, J.; Tang, J. Multi-directional energy harvesting by piezoelectric cantilever-pendulum with internal resonance. Appl. Phys. Lett. 2015, 107, 213902. [Google Scholar] [CrossRef]

- Wang, L.; Tong, X.; Yang, H.; Wei, Y.; Miao, Y. Design and analysis of a hollow triangular piezoelectric cantilever beam harvester for vibration energy collection. Int. J. Pavement Res. Technol. 2019, 12, 259–268. [Google Scholar] [CrossRef]

- Chilabi, H.J.; Salleh, H.; Supeni, E.E.; As’arry, A.B.; Rezali, K.A.M.; Atrah, A.B. Harvesting energy from planetary gear using piezoelectric material. Energies 2020, 13, 223. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, Q.; Wang, W.; Feng, J. A low-frequency, wideband quad-stable energy harvester using combined nonlinearity and frequency up-conversion by cantilever-surface contact. Mech. Syst. Signal Process. 2018, 112, 305–318. [Google Scholar] [CrossRef]

- Song, H.C.; Kumar, P.; Maurya, D.; Kang, M.G.; Reynolds, W.T.; Jeong, D.Y. Ultra-low resonant piezoelectric MEMS energy harvester with high power density. J. Microelectromech. Syst. 2017, 26, 1226–1234. [Google Scholar] [CrossRef]

- Wu, J.; Hu, Z.; Gao, X.; Cheng, M.; Zhao, X.; Su, W.; Li, X.; Wang, Z.; Zhou, Z.; Dong, S.; et al. Electrode shape dependence of the barbell-shaped magneto-mechano-electric energy harvester for low-frequency applications. Sens. Actuators A Phys. 2019, 297, 111535. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, Q.; Wang, W. Low-frequency wideband vibration energy harvesting by using frequency up-conversion and quin-stable nonlinearity. J. Sound Vib. 2017, 399, 169–181. [Google Scholar] [CrossRef]

- Fan, K.; Cai, M.; Liu, H.; Zhang, Y. Capturing energy from ultra-low frequency vibrations and human motion through a monostable electromagnetic energy harvester. Energy 2019, 169, 356–368. [Google Scholar] [CrossRef]

- Fan, K.; Zhang, Y.; Liu, H.; Cai, M.; Tan, Q. A nonlinear two-degree-of-freedom electromagnetic energy harvester for ultra-low frequency vibrations and human body motions. Renew. Energy 2019, 138, 292–302. [Google Scholar] [CrossRef]

- Haroun, A.; Yamada, I.; Warisawa, S. Micro electromagnetic vibration energy harvester based on free/impact motion for low frequency-large amplitude operation. Sens. Actuators A Phys. 2015, 224, 87–98. [Google Scholar] [CrossRef]

- Haroun, A.; Yamada, I.; Warisawa, S. Study of electromagnetic vibration energy harvesting with free/impact motion for low frequency operation. J. Sound Vib. 2015, 349, 389–402. [Google Scholar] [CrossRef]

- Chae, S.H.; Ju, S.; Choi, Y.; Chi, Y.E.; Ji, C.H. Electromagnetic linear vibration energy harvester using sliding permanent magnet array and ferrofluid as a lubricant. Micromachines 2017, 8, 288. [Google Scholar] [CrossRef] [Green Version]

- Ambrozkiewicz, B.; Litak, G.; Wolszczak, P. Modelling of electromagnetic energy harvester with rotational pendulum using mechanical vibrations to scavenge electrical energy. Appl. Sci. 2020, 10, 671. [Google Scholar] [CrossRef]

- Kecik, K.; Mitura, A. Energy recovery from a pendulum tuned mass damper with two independent harvesting sources. Int. J. Mech. Sci. 2020, 174, 105568. [Google Scholar] [CrossRef]

- Basset, P.; Galayko, D.; Paracha, A.M.; Marty, F.; Dudka, A.; Bourouina, T. A batch-fabricated and electret-free silicon electrostatic vibration energy harvester. J. Micromech. Microeng. 2009, 19, 115025. [Google Scholar] [CrossRef]

- Sidek, O.; Khalid, M.A.; Ishak, M.Z.; Miskam, M.A. Design and simulation of SOI-MEMS electrostatic vibration energy harvester for micro power generation. In Proceedings of the ECCE—International Conference on Electrical, Control and Computer Engineering, Pahang, Malaysia, 21 June 2011. [Google Scholar] [CrossRef]

- Dudka, A.; Basset, P.; Cottone, F.; Blokhina, E.; Galayko, D. Wideband electrostatic vibration energy harvester (e-VEH) having a low start-up voltage employing a high-voltage integrated interface. J. Phys. 2013, 476, 012127. [Google Scholar] [CrossRef]

- Dragunov, V.; Dorzhiev, V. Electrostatic vibration energy harvester with increased charging current. J. Phys. 2013, 476, 3–8. [Google Scholar] [CrossRef]

- Dorzhiev, V.; Karami, A.; Basset, P.; Dragunov, V.; Galayko, D. MEMS electrostatic vibration energy harvester without switches and inductive elements. J. Phys. 2014, 557, 012126. [Google Scholar] [CrossRef]

- Basset, P.; Galayko, D.; Cottone, F.; Guillemet, R.; Blokhina, E.; Marty, F.; Bourouina, T. Electrostatic vibration energy harvester with combined effect of electrical nonlinearities and mechanical impact. J. Micromech. Microeng. 2014, 24, 035001. [Google Scholar] [CrossRef]

- Wu, C.; Wang, A.C.; Ding, W.; Guo, H.; Wang, Z.L. Triboelectric Nanogenerator: A Foundation of the Energy for the New Era. Adv. Energy Mater. 2019, 9, 1802906. [Google Scholar] [CrossRef]

- Bera, B. Literature Review on Triboelectric Nanogenerator. Imp. J. Interdiscip. Res. 2016, 2, 1263–1271. [Google Scholar]

- Zhang, H.; Yao, L.; Quan, L.; Zheng, X. Theories for triboelectric nanogenerators: A comprehensive review. Nanotechnol. Rev. 2020, 9, 610–625. [Google Scholar] [CrossRef]

- Niu, S.; Wang, S.; Lin, L.; Liu, Y.; Zhou, Y.S.; Hu, Y.; Wang, Z.L. Theoretical study of contact-mode triboelectric nanogenerators as an effective power source. Energy Environ. Sci. 2013, 6, 3576–3583. [Google Scholar] [CrossRef]

- Lin, Z.; Chen, J.; Yang, J. Recent Progress in Triboelectric Nanogenerators as a Renewable and Sustainable Power Source. J. Nanomater. 2016, 2016, 5651613. [Google Scholar] [CrossRef]

- Wu, C.; Huang, H.; Li, R.; Fan, C. Research on the potential of spherical triboelectric nanogenerator for collecting vibration energy and measuring vibration. Sensors 2020, 20, 1063. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, Y.; Su, Y.; Chen, J.; Adams, K.; Lee, S.; Hu, C.; Wang, Z.L. Triboelectric nanogenerator for harvesting vibration energy in full space and as self-powered acceleration sensor. Adv. Funct. Mater. 2014, 24, 1401–1407. [Google Scholar] [CrossRef]

- Xu, M.; Wang, P.; Wang, Y.C.; Zhang, S.L.; Wang, A.C.; Zhang, C.; Wang, Z.; Pan, X.; Wang, Z.L. A Soft and Robust Spring Based Triboelectric Nanogenerator for Harvesting Arbitrary Directional Vibration Energy and Self-Powered Vibration Sensing. Adv. Energy Mater. 2018, 8, 1702432. [Google Scholar] [CrossRef]

- Zhang, Z.; Cai, J. High output triboelectric nanogenerator based on PTFE and cotton for energy harvester and human motion sensor. Curr. Appl. Phys. 2020, 22, 1–5. [Google Scholar] [CrossRef]

- Rahman, M.T.; Sohel Rana, S.; Salauddin, M.; Maharjan, P.; Bhatta, T.; Kim, H.; Park, J.Y. A highly miniaturized freestanding kinetic-impact-based non-resonant hybridized electromagnetic-triboelectric nanogenerator for human induced vibrations harvesting. Appl. Energy 2020, 279, 115799. [Google Scholar] [CrossRef]

- Wang, X.; Wen, Z.; Guo, H.; Wu, C.; He, X.; Lin, L.; Wang, Z.L. Fully Packaged Blue Energy Harvester by Hybridizing a Rolling Triboelectric Nanogenerator and an Electromagnetic Generator. ACS Nano 2016, 10, 11369–11376. [Google Scholar] [CrossRef]

- Hu, Y.; Yang, J.; Jing, Q.; Niu, S.; Wu, W.; Wang, Z.L. Triboelectric nanogenerator built on suspended 3D spiral structure as vibration and positioning sensor and wave energy harvester. ACS Nano 2013, 7, 10424–10432. [Google Scholar] [CrossRef]

- Zeng, Q.; Wu, Y.; Tang, Q.; Liu, W.; Wu, J.; Zhang, Y.; Yin, G.; Yang, H.; Yuan, S.; Tan, D.; et al. A high-efficient breeze energy harvester utilizing a full-packaged triboelectric nanogenerator based on flow-induced vibration. Nano Energy 2020, 70, 104524. [Google Scholar] [CrossRef]

- Lu, S.; Gao, L.; Chen, X.; Tong, D.; Lei, W.; Yuan, P.; Mu, X.; Yu, H. Simultaneous energy harvesting and signal sensing from a single triboelectric nanogenerator for intelligent self-powered wireless sensing systems. Nano Energy 2020, 75, 104813. [Google Scholar] [CrossRef]

- He, W.; Fu, X.; Zhang, D.; Zhang, Q.; Zhuo, K.; Yuan, Z.; Ma, R. Recent progress of flexible/wearable self-charging power units based on triboelectric nanogenerators. Nano Energy 2021, 84, 105880. [Google Scholar] [CrossRef]

- Li, G.Z.; Wang, G.G.; Cai, Y.W.; Sun, N.; Li, F.; Zhou, H.L.; Zhao, H.X.; Zhang, X.N.; Han, J.C.; Yang, Y. A high-performance transparent and flexible triboelectric nanogenerator based on hydrophobic composite films. Nano Energy 2020, 75, 104918. [Google Scholar] [CrossRef]

- Bertacchini, A.; Larcher, L.; Lasagni, M.; Pavan, P. Ultra-low cost triboelectric energy harvesting solutions for embedded sensor systems. In Proceedings of the IEEE-NANO—15th International Conference on Nanotechnology, Rome, Italy, 27 July 2015. [Google Scholar] [CrossRef]

- Jang, S.; Kim, H.; Oh, J.H. Simple and rapid fabrication of pencil-on-paper triboelectric nanogenerators with enhanced electrical performance. Nanoscale 2017, 9, 13034–13041. [Google Scholar] [CrossRef]

- Jing, T.; Xu, B.; Yang, Y.; Li, M.; Ga, Y. Organogel electrode enables highly transparent and stretchable triboelectric nanogenerators of high power density for robust and reliable energy harvesting. Nano Energy 2020, 78, 105373. [Google Scholar] [CrossRef]

- Zhu, J.; Zhu, M.; Shi, Q.; Wen, F.; Liu, L.; Dong, B.; Haroun, A.; Yang, Y.; Vachon, P.; Guo, X.; et al. Progress in TENG technology—A journey from energy harvesting to nanoenergy and nanosystem. EcoMat 2020, 2, e12058. [Google Scholar] [CrossRef]

- Haroun, A.; Le, X.; Gao, S.; Dong, B.; He, T.; Zhang, Z.; Wen, F.; Xu, S.; Lee, C. Progress in micro/nano sensors and nanoenergy for future AIoT-based smart home applications. Nano Express 2021, 2, 022005. [Google Scholar] [CrossRef]

- Xie, L.; Zhai, N.; Liu, Y.; Wen, Z.; Sun, X. Hybrid Triboelectric Nanogenerators: From Energy Complementation to Integration. Research 2021, 2021, 9143762. [Google Scholar] [CrossRef]

- Vidal, J.V.; Slabov, V.; Kholkin, A.L.; dos Santos, S.M.P. Hybrid Triboelectric-Electromagnetic Nanogenerators for Mechanical Energy Harvesting: A Review. Nano-Micro Lett. 2021, 13, 1–58. [Google Scholar] [CrossRef]

- Ha, M.; Canon Bermudez, G.S.; Kosub, T.; Mönch, I.; Zabila, Y.; Oliveros Mata, E.S.; Illing, R.; Wang, Y.; Fassbender, J.; Makarov, D. Printable and Stretchable Giant Magnetoresistive Sensors for Highly Compliant and Skin-Conformal Electronics. Adv. Mater. 2021, 33, 2005521. [Google Scholar] [CrossRef]

- Dionisio, R.; Torres, P.; Ramalho, A.; Ferreira, R. Magnetoresistive sensors and piezoresistive accelerometers for vibration measurements: A comparative study. J. Sens. Actuator Netw. 2021, 10, 22. [Google Scholar] [CrossRef]

- Qian, S.; Qin, L.; He, J.; Zhang, N.; Qian, J.; Mu, J.; Geng, W.; Hou, X.; Chou, X. A lead-free stretchable piezoelectric composite for human motion monitoring. Mater. Lett. 2020, 261, 127119. [Google Scholar] [CrossRef]

- Gao, Q.; Cheng, T.; Wang, Z.L. Triboelectric mechanical sensors—Progress and prospects. Extreme Mech. Lett. 2021, 42, 101100. [Google Scholar] [CrossRef]

- Du, T.; Zuo, X.; Dong, F.; Li, S.; Mtui, A.E.; Zou, Y.; Zhang, P.; Zhao, J.; Zhang, Y.; Sun, P.; et al. A self-powered and highly accurate vibration sensor based on bouncing-ball triboelectric nanogenerator for intelligent ship machinery monitoring. Micromachines 2021, 12, 218. [Google Scholar] [CrossRef]

- Chen, J.; Wang, Z.L. Reviving Vibration Energy Harvesting and Self-Powered Sensing by a Triboelectric Nanogenerator. Joule 2017, 1, 480–521. [Google Scholar] [CrossRef]

- Lin, Z.; Long, W.; Chen, L.J.; Niu, S.; Zi, Y. Green Energy and Technology Triboelectric Nanogenerators, 1st ed.; Springer: Berlin/Heidelberg, Gemany, 2016; p. 925. [Google Scholar]

- Niu, S.; Liu, Y.; Chen, X.; Wang, S.; Zhou, Y.S.; Lin, L.; Xie, Y.; Wang, Z.L. Theory of freestanding triboelectric-layer-based nanogenerators. Nano Energy 2015, 12, 760–774. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, N.; Li, J.; Dong, L.; Wang, T.; Wang, Z.; Wang, G.; Zhou, X.; Zhang, J. Harvesting ultralow frequency (<1 Hz) mechanical energy using triboelectric nanogenerator. Nano Energy 2019, 65, 104011. [Google Scholar] [CrossRef]

- He, J.; Fan, X.; Mu, J.; Wang, C.; Qian, J.; Li, X.; Hou, X.; Geng, W.; Wang, X.; Chou, X. 3D full-space triboelectric-electromagnetic hybrid nanogenerator for high-efficient mechanical energy harvesting in vibration system. Energy 2020, 194, 116871. [Google Scholar] [CrossRef]

- Yang, W.; Chen, J.; Jing, Q.; Yang, J.; Wen, X.; Su, Y.; Zhu, G.; Bai, P.; Wang, Z.L. 3D stack integrated triboelectric nanogenerator for harvesting vibration energy. Adv. Funct. Mater. 2014, 24, 4090–4096. [Google Scholar] [CrossRef]

- Wang, K.; Zhou, J.; Ouyang, H.; Chang, Y.; Xu, D. A dual quasi-zero-stiffness sliding-mode triboelectric nanogenerator for harvesting ultralow-low frequency vibration energy. Mech. Syst. Signal Process. 2021, 151, 107368. [Google Scholar] [CrossRef]

- Yang, J.; Chen, J.; Yang, Y.; Zhang, H.; Yang, W.; Bai, P.; Su, Y.; Wang, Z.L. Broadband vibrational energy harvesting based on a triboelectric nanogenerator. Adv. Energy Mater. 2013, 4, 1301322. [Google Scholar] [CrossRef]

- Bhatia, D.; Hwang, H.J.; Huynh, N.D.; Lee, S.; Lee, C.; Nam, Y.; Kim, J.G.; Choi, D. Continuous scavenging of broadband vibrations via omnipotent tandem triboelectric nanogenerators with cascade impact structure. Sci. Rep. 2019, 9, 8223. [Google Scholar] [CrossRef]

- Lv, S.; Yu, B.; Huang, T.; Yu, H.; Wang, H.; Zhang, Q.; Zhu, M. Gas-enhanced triboelectric nanogenerator based on fully-enclosed structure for energy harvesting and sensing. Nano Energy 2018, 55, 463–469. [Google Scholar] [CrossRef]

- Li, R.; Zhang, H.; Wang, L.; Liu, G. A Contact-Mode Triboelectric Nanogenerator for Energy. Sensors 2021, 21, 1514. [Google Scholar] [CrossRef] [PubMed]

- Singh, H.H.; Kumar, D.; Khare, N. A synchronous piezoelectric-triboelectric-electromagnetic hybrid generator for harvesting vibration energy Sustain. Energy Fuels 2020, 5, 212–218. [Google Scholar] [CrossRef]

- He, X.; Wen, Q.; Sun, Y.; Wen, Z. A low-frequency piezoelectric-electromagnetic-triboelectric hybrid broadband vibration energy harvester. Nano Energy 2017, 40, 300–307. [Google Scholar] [CrossRef]

- He, J.; Wen, T.; Qian, S.; Zhang, Z.; Tian, Z.; Zhu, J.; Mu, J.; Hou, X.; Geng, W.; Cho, J.; et al. Triboelectric-piezoelectric-electromagnetic hybrid nanogenerator for high-efficient vibration energy harvesting and self-powered wireless monitoring system. Nano Energy 2018, 43, 326–339. [Google Scholar] [CrossRef]

- Zhu, J.; Wang, A.; Hu, H.; Zhu, H. Hybrid electromagnetic and triboelectric nanogenerators with multi-impact for wideband frequency energy harvesting. Energies 2017, 10, 2024. [Google Scholar] [CrossRef]

- Gupta, R.K.; Shi, Q.; Dhakar, L.; Wang, T.; Heng, C.H.; Lee, C. Broadband energy harvester using non-linear polymer spring and electromagnetic/triboelectric hybrid mechanism. Sci. Rep. 2017, 7, 41396. [Google Scholar] [CrossRef] [Green Version]

- Haroun, A.; Lee, C. Dielectric-elastomer-enhanced triboelectric nanogenerator with amplified outputs. Sens. Actuators A Phys. 2022, 333, 113270. [Google Scholar] [CrossRef]

- Hassani, F.A.; Shi, Q.; Wen, F.; He, T.; Haroun, A.; Yang, Y.; Feng, Y.; Lee, C. Smart materials for smart healthcare—Moving from sensors and actuators to self-sustained nanoenergy nanosystems. Smart Mater. Med. 2020, 1, 92–124. [Google Scholar] [CrossRef]

- Haroun, A.; Yamada, I.; Warisawa, S. Investigation of Kinetic Energy Harvesting from Human Body Motion Activities Using Free/Impact Based Micro Electromagnetic Generator. Diabetes Cholest. Metab. 2016, 1, 12–16. [Google Scholar]

- Seol, M.L.; Han, J.W.; Park, S.J.; Jeon, S.B.; Choi, Y.K. Hybrid energy harvester with simultaneous triboelectric and electromagnetic generation from an embedded floating oscillator in a single package. Nano Energy 2016, 23, 50–59. [Google Scholar] [CrossRef]

- Salauddin, M.; Toyabur, R.M.; Maharjan, P.; Park, J.Y. High performance human-induced vibration driven hybrid energy harvester for powering portable electronics. Nano Energy 2018, 45, 236–246. [Google Scholar] [CrossRef]

- Wang, S.; Niu, S.; Yang, J.; Lin, L.; Wang, Z.L. Quantitative measurements of vibration amplitude using a contact-mode freestanding triboelectric nanogenerator. ACS Nano 2014, 8, 12004–12013. [Google Scholar] [CrossRef]

- Zhou, Y.S.; Zhu, G.; Niu, S.; Liu, Y.; Bai, P.; Jing, Q.; Wang, Z.L. Nanometer resolution self-powered static and dynamic motion sensor based on micro-grated triboelectrification. Adv. Mater. 2013, 26, 1719–1724. [Google Scholar] [CrossRef]

- Yu, H.; He, X.; Ding, W.; Hu, Y.; Yang, D.; Lu, S.; Wu, C.; Zou, H.; Liu, R.; Lu, C.; et al. A Self-Powered Dynamic Displacement Monitoring System Based on Triboelectric Accelerometer. Adv. Energy Mater. 2017, 7, 1700565. [Google Scholar] [CrossRef]

- Jing, Q.; Choi, Y.S.; Smith, M.; Ćatić, N.; Ou, C.; Kar-Narayan, S. Aerosol-Jet Printed Fine-Featured Triboelectric Sensors for Motion Sensing. Adv. Mater. Technol. 2019, 4, 1800328. [Google Scholar] [CrossRef]

- Li, S.; Liu, D.; Zhao, Z.; Zhou, L.; Yin, X.; Li, X.; Gao, Y.; Zhang, C.; Zhang, Q.; Wang, J.; et al. A Fully Self-Powered Vibration Monitoring System Driven by Dual-Mode Triboelectric Nanogenerators. ACS Nano 2020, 14, 2475–2482. [Google Scholar] [CrossRef]

- Liu, D.; Yin, X.; Guo, H.; Zhou, L.; Li, X.; Zhang, C.; Wang, J.; Wang, Z.L. A constant current triboelectric nanogenerator arising from electrostatic breakdown. Sci. Adv. 2019, 5, eaav6437. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, C.; Fang, L.; Zou, H.; Wang, Y.; Chi, J.; Che, L.; Zhou, X.; Wang, Z.; Wang, T.; Dong, L.; et al. Theoretical investigation and experimental verification of the self-powered acceleration sensor based on triboelectric nanogenerators (TENGs). Extreme Mech. Lett. 2021, 42, 101021. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, L.; Deng, W.; Jin, L.; Chun, F.; Pan, H.; Wang, Z.L. Self-Powered Acceleration Sensor Based on Liquid Metal Triboelectric Nanogenerator for Vibration Monitoring. ACS Nano 2017, 11, 7440–7446. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Ding, W.; Dai, Y.; Dong, K.; Wu, C.; Zhang, L.; Lin, Z.; Cheng, J.; Wang, Z.L. Self-Powered Multifunctional Motion Sensor Enabled by Magnetic-Regulated Triboelectric Nanogenerator. ACS Nano 2018, 12, 5726–5733. [Google Scholar] [CrossRef]

- Dai, K.; Wang, X.; Yi, F.; Jiang, C.; Li, R.; You, Z. Triboelectric nanogenerators as self-powered acceleration sensor under high-g impact. Nano Energy 2018, 45, 84–93. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, Y.-C.; Zhang, Y.; Zou, H.; Lin, Z.; Zhang, G.; Zou, C.; Wang, Z.L. Elastic-Beam Triboelectric Nanogenerator for High-Performance Multifunctional Applications: Sensitive Scale, Acceleration/Force/Vibration Sensor, and Intelligent Keyboard. Adv. Energy Mater. 2018, 8, 1802159. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, F.; Li, N.; Yao, T.; Lv, D.; Cao, G. Self-Powered Multifunctional Triboelectric Sensor Based on PTFE/PU for Linear, Rotary, and Vibration Motion Sensing. Adv. Mater. Technol. 2020, 5, 2000159. [Google Scholar] [CrossRef]

- Adly, M.A.; Arafa, M.H.; Hegazi, H.A. Modeling and optimization of an inertial triboelectric motion sensor. Nano Energy 2021, 85, 105952. [Google Scholar] [CrossRef]

- Liu, C.; Wang, Y.; Zhang, N.; Yang, X.; Wang, Z.; Zhao, L.; Yang, W.; Dong, L.; Che, L.; Wang, G.; et al. A self-powered and high sensitivity acceleration sensor with V-Q-a model based on triboelectric nanogenerators (TENGs). Nano Energy 2020, 67, 104228. [Google Scholar] [CrossRef]

- Xiao, X.; Zhang, X.; Wang, S.; Ouyang, H.; Chen, P.; Song, L.; Yuan, H.; Ji, Y.; Wang, P.; Li, Z.; et al. Honeycomb Structure Inspired Triboelectric Nanogenerator for Highly Effective Vibration Energy Harvesting and Self-Powered Engine Condition Monitoring. Adv. Energy Mater. 2019, 9, 1902460. [Google Scholar] [CrossRef]

- Wang, L.; He, T.; Zhang, Z.; Zhao, L.; Lee, C.; Luo, G.; Mao, Q.; Yang, P.; Lin, Q.; Li, X.; et al. Self-sustained autonomous wireless sensing based on a hybridized TENG and PEG vibration mechanism. Nano Energy 2021, 80, 105555. [Google Scholar] [CrossRef]

- Kim, G.W.; Kim, J. Compliant bistable mechanism for low frequency vibration energy harvester inspired by auditory hair bundle structures. Smart Mater. Struct. 2013, 22, 014005. [Google Scholar] [CrossRef]

- Li, Z.; Bai, S.; Madsen, O.; Chen, W.; Zhang, J. Design, modeling and testing of a compact variable stiffness mechanism for exoskeletons. Mech. Mach. Theory 2020, 151, 103905. [Google Scholar] [CrossRef]

| TENG Energy Harvester | Only TENG/Hybrid | TENG Mode | TENG Materials | Dimensions | Input Excitation | Electrical Output |

|---|---|---|---|---|---|---|

| 3D Stack Integrated (Yang et al.) [64] | TENG | Contact- separation | PTFE/Al | 231.67 cm3 | 40 Hz | @ 2 MΩ |

| QZS-TENG (Wang et al.) [65] | TENG | Sliding | Bonded glass/ metal | cm3 | 3 Hz | 4.06 mW |

| 3D-TENG (Yang et al.) [66] | TENG | Contact- separation + in plane-sliding | PTFE/Al | 23.56 cm3 | 6 m/s2 and 36 Hz | V = 123 V, I = 21 µA |

| CIT-TENG (Bhatia et al.) [67] | TENG | Contact- separation (impact) | PTFE/Al | 25 × 7 × 5.5 cm3 | 0.2g m/s2@ 40 Hz range | 5 V and 0.75 μA from air compressor |

| Gas-enhanced (Lv et al.) [68] | TENG | Contact- separation | FEP/ conductive fabric | 5 × 5 × 5 cm3 | 3 Hz | Vo = 500 V, Isc = 11 µA, Max. P = 0.8 W @ 8 MΩ |

| Marine pipe EH (Li et al.) [69] | TENG | Contact- separation | PTFE and nylon/ nylon | 5 × 5 × 1 cm3 | 8 Hz and 4 mm | @ 200 MΩ |

| PNG-EMG-TENG (Hemojit et al.) [70] | Hybrid | Contact- separation | PTFE/gold | 6 × 6 × 6 cm3 | ND | Voc = 192 V, Isc = 2.78 mA |

| PET (He et al.) [71] | Hybrid | Contact- separation | Patterned PDMS/steel | Ø 51 × H 37 mm2 | 0.5 g m/s2 and 20 Hz | P= 41 µW, V = 12.6 V @ 800.1 KΩ |

| TPE (He et al.) [72] | Hybrid | Contact- separation | SR + CNT | Ø 48 × H 27 mm2 | 20 Hz | V = 2V, I = 1 mA. |

| MFKI-HNG (Toyabur et al.) [40] | Hybrid | Contact- separation | PTFE/Al | Ø 26 × H 50.5 mm2 | 1g m/s2 and 5 Hz | = 3.67 mW/cm3 |

| EMG-TENG (Zhu et al.) [73] | Hybrid | Contact- separation | PTFE/CB film | 6 × 2 × 1 cm3 | 1g m/s2 and 18 Hz | TENG: 30 µW and EMG: 53 µW |

| Polymer-based EMG-TENG (Kumar et al.) [74] | Hybrid | Contact- separation | PTFE/ITO | 2 × 2 × 1 cm3 | 0.1–2 g m/s2 | TENG: 4.8 µW/cm3, EMG: 6 µW/cm3 (max) |

| DETEG (Haroun et al.) [75] | Hybrid | Contact- separation | PTFE/Al | 8 × 7 × 6 cm3 | 5 Hz | = 500 W/m2 |

| Sensor | Sensor Type | TENG Mode | Triboelectric Materials | Dimensions | Input Excitation | Performance |

|---|---|---|---|---|---|---|

| CF-TENG (Wang et al.) [80] | Displacement | Contact- separation | FEP/Al | 200 cm3 | 15 Hz and 3.5 μm | Isc = 10 nA, Voc = 0.54 V |

| Micro-grating motion sensor (Zhou et al.) [81] | Displacement | Sliding | cm3 | 1 Hz | Resolution = 173 nm | |

| FTENG (Yu et al.) [82] | Displacement | Sliding | FEP/Cu | Ø25 mm × ≅ 65 mm | 3 Hz | Sensitivity = 0.391 Vs2 m−1 |

| AJP motion sensor (Jing et al.) [83] | Displacement | Sliding | PVDF-TrFE/Ag | (25 × 7 × 5.5) cm3 | ND | Max. sensitivity = 630 μV/μm |

| AC/DC-TENG (Li et al.) [84] | Displacement | Sliding | FEP/NA | Electrodes: (20 × 20) mm2 | 2 Hz and 5 mm | Vo = 3 V |

| Liquid-metal-based TENG (Zhang et al.) [87] | Acceleration | Contact- separation | PVDF/Hg | (30 × 30 × 6) mm3 | 60 m/s2 | Isc = 300 nA, Voc = 15.5 V, sensitivity = 0.26 V·s/m2 |

| MFMS (Wu et al.) [88] | Acceleration | Sliding | PTFE/NdFeB | (Ø 40 × H 19) mm2. V = 23.88 cm3 | ND | ND |

| High-g sensor (Dai et al.) [89] | Acceleration | Contact- separation | PDMS/Cu | (14 × 14 × 8) mm3 | ND | Sensitivity = 1.8 mV/g @ 200 μm beam thickness |

| MMS (Wang et al.) [90] | Acceleration | Contact- separation | PU/PTFE | ND | 50 Hz and 3 m s−2 | Vo = 330 mV |

| Elastic-beam TENG (Chen et al.) [91] | Acceleration | Contact- separation | PTFE/stainless steel foil (SSF) | (7.5 × 60) mm2 | Sensitivity = 900 V N−1 | |

| Inertial sensor (Adly et al.) [92] | Acceleration | Contact- separation | Teflon/Al | (200 × 50 × 20) mm3 | 30 Hz | Vo = 6.2 V |

| V-Q-a TENG (Liu et al.) [93] | Acceleration | Contact- separation | ITO/PET | (3.5 × 6) cm2 | 1–11 m/s2 | = 371.8 mW/m2 sensitivity = 20.4 V/(m/s2) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haroun, A.; Tarek, M.; Mosleh, M.; Ismail, F. Recent Progress on Triboelectric Nanogenerators for Vibration Energy Harvesting and Vibration Sensing. Nanomaterials 2022, 12, 2960. https://doi.org/10.3390/nano12172960

Haroun A, Tarek M, Mosleh M, Ismail F. Recent Progress on Triboelectric Nanogenerators for Vibration Energy Harvesting and Vibration Sensing. Nanomaterials. 2022; 12(17):2960. https://doi.org/10.3390/nano12172960

Chicago/Turabian StyleHaroun, Ahmed, Mohamed Tarek, Mohamed Mosleh, and Farouk Ismail. 2022. "Recent Progress on Triboelectric Nanogenerators for Vibration Energy Harvesting and Vibration Sensing" Nanomaterials 12, no. 17: 2960. https://doi.org/10.3390/nano12172960

APA StyleHaroun, A., Tarek, M., Mosleh, M., & Ismail, F. (2022). Recent Progress on Triboelectric Nanogenerators for Vibration Energy Harvesting and Vibration Sensing. Nanomaterials, 12(17), 2960. https://doi.org/10.3390/nano12172960