Enhanced Electrical Performance and Stability of Solution-Processed Thin-Film Transistors with In2O3/In2O3:Gd Heterojunction Channel Layer

Abstract

1. Introduction

2. Experimental Section

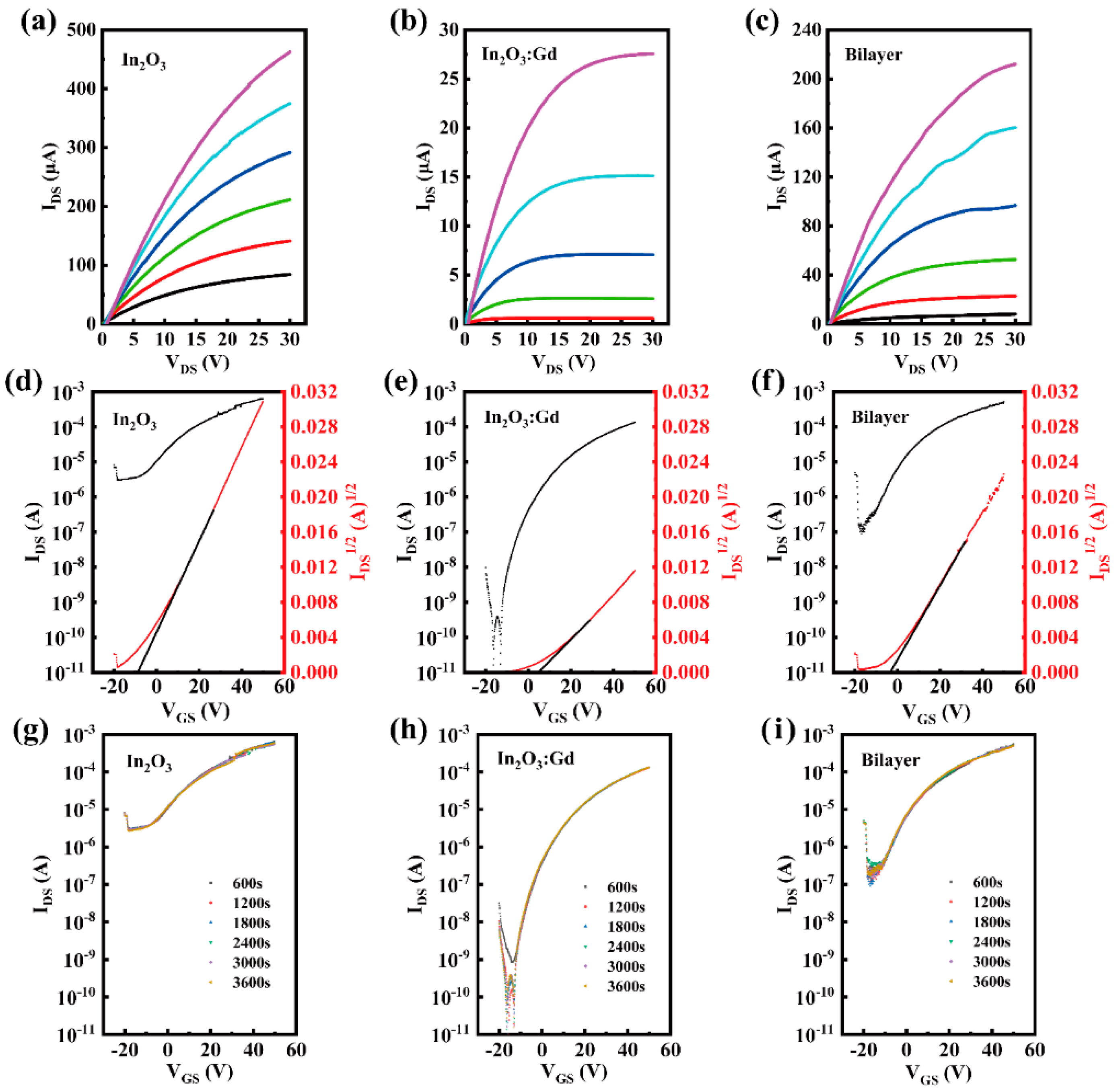

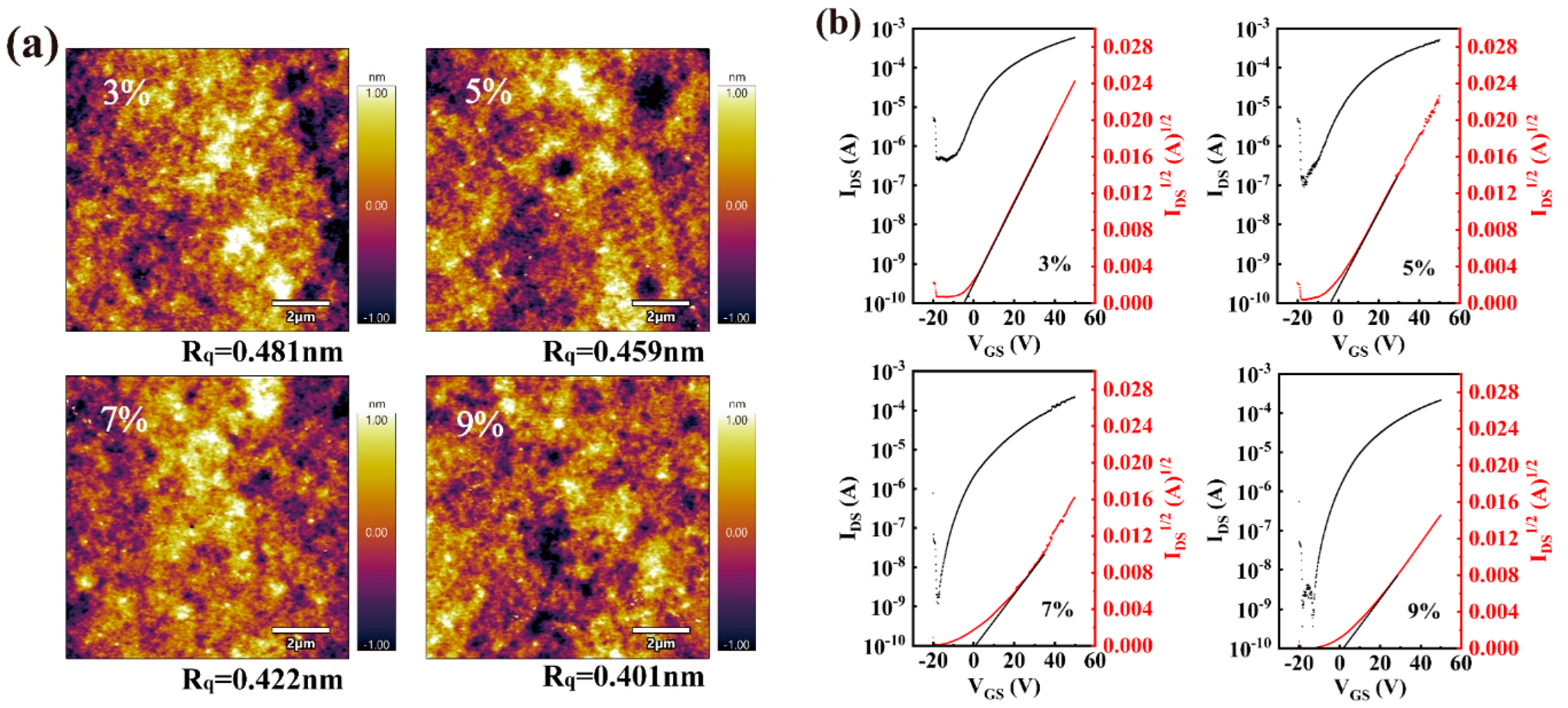

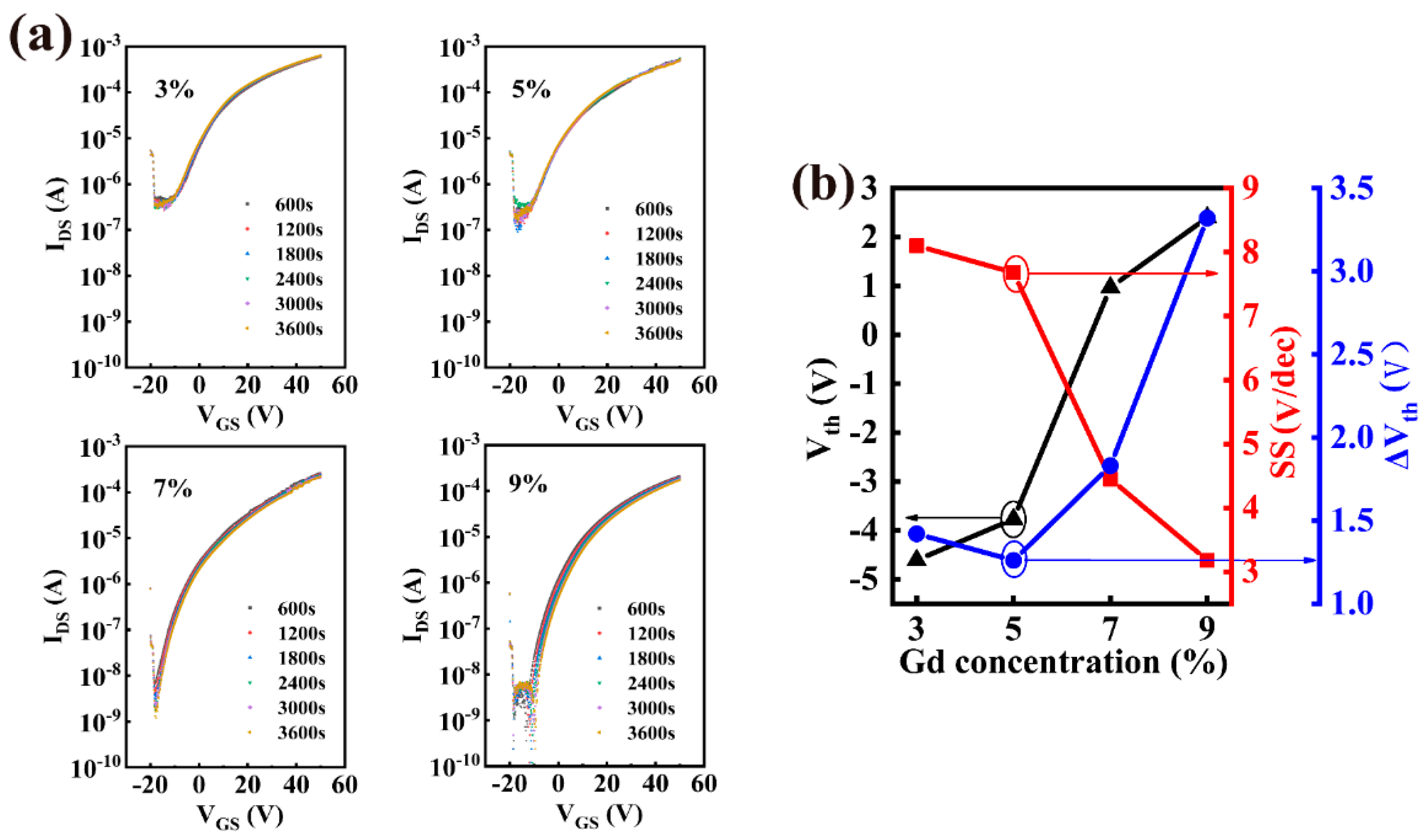

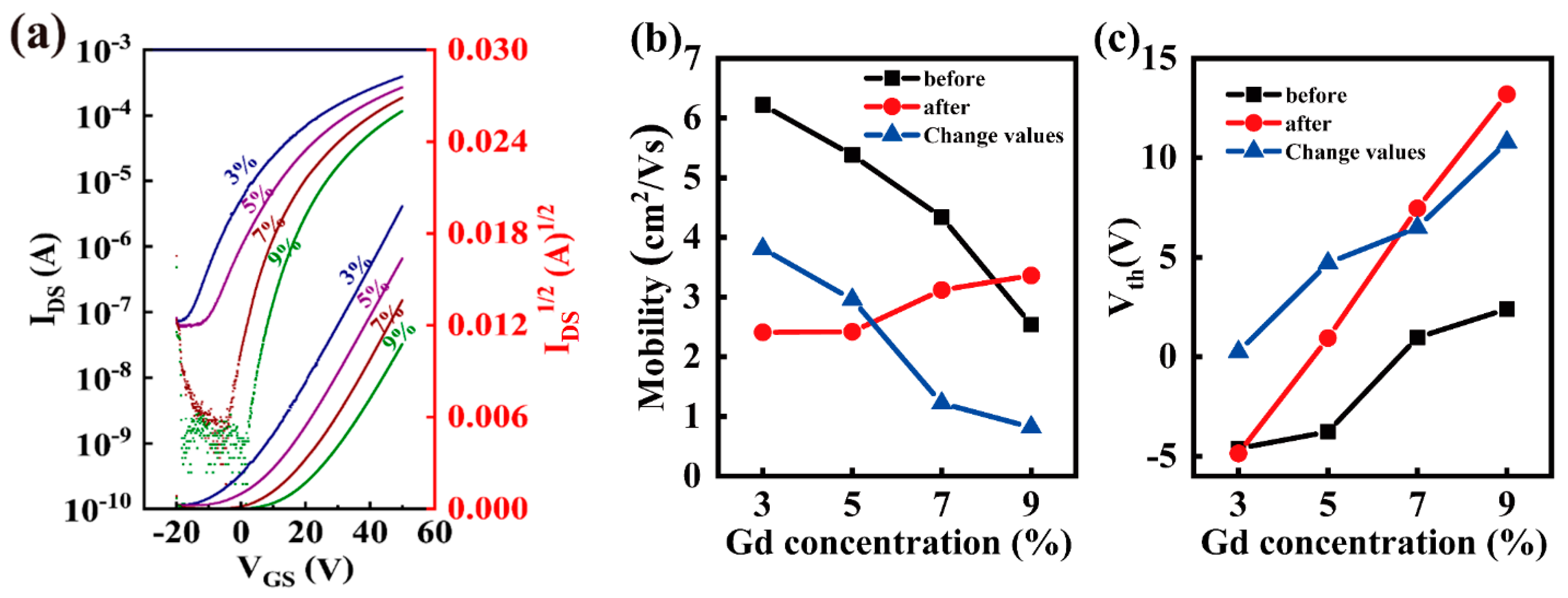

3. Result and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yu, X.; Zhou, N.; Smith, J.; Lin, H.; Stallings, K.; Yu, J.; Marks, T.J.; Facchetti, A. Synergistic approach to high-performance oxide thin film transistors using a bilayer channel architecture. ACS Appl. Mater. Interfaces 2013, 5, 7983–7988. [Google Scholar] [CrossRef] [PubMed]

- Abliz, A.; Huang, C.W.; Wang, J.; Xu, L.; Liao, L.; Xiao, X.; Wu, W.W.; Fan, Z.; Jiang, C.; Li, J.; et al. Rational Design of ZnO:H/ZnO Bilayer Structure for High-Performance Thin-Film Transistors. ACS Appl. Mater. Interfaces 2016, 8, 7862–7868. [Google Scholar] [CrossRef]

- Bang, K.; Son, G.-C.; Son, M.; Jun, J.-H.; An, H.; Baik, K.H.; Myoung, J.-M.; Ham, M.-H. Effects of Li doping on the structural and electrical properties of solution-processed ZnO films for high-performance thin-film transistors. J. Alloy. Compd. 2018, 739, 41–46. [Google Scholar] [CrossRef]

- Chen, X.; Wan, J.; Wu, H.; Liu, C. ZnO bilayer thin film transistors using H2O and O3 as oxidants by atomic layer deposition. Acta Mater. 2020, 185, 204–210. [Google Scholar] [CrossRef]

- Khim, D.; Lin, Y.H.; Nam, S.; Faber, H.; Tetzner, K.; Li, R.; Zhang, Q.; Li, J.; Zhang, X.; Anthopoulos, T.D. Modulation-Doped In2O3/ZnO Heterojunction Transistors Processed from Solution. Adv. Mater. 2017, 29, 1605837. [Google Scholar] [CrossRef]

- Zhao, X.; Li, J.; Yang, Y.; Zhu, C.; Huang, J.; Duan, J.; Lu, Y.; Lan, P.; Song, W. Low indium content In–Zn–O system towards transparent conductive films: Structure, properties and comparison with AZO and GZO. J. Mater. Sci. Mater. Electron. 2017, 28, 13297–13302. [Google Scholar] [CrossRef]

- Li, H.; Han, D.; Dong, J.; Yu, W.; Liang, Y.; Luo, Z.; Zhang, S.; Zhang, X.; Wang, Y. Enhanced electrical properties of dual-layer channel ZnO thin film transistors prepared by atomic layer deposition. Appl. Surf. Sci. 2018, 439, 632–637. [Google Scholar] [CrossRef]

- He, J.; Li, G.; Lv, Y.; Wang, C.; Liu, C.; Li, J.; Flandre, D.; Chen, H.; Guo, T.; Liao, L. Defect Self-Compensation for High-Mobility Bilayer InGaZnO/In2O3 Thin-Film Transistor. Adv. Electron. Mater. 2019, 5, 1900125. [Google Scholar] [CrossRef]

- Yuan, Z.; Zhu, X.; Wang, X.; Cai, X.; Zhang, B.; Qiu, D.; Wu, H. Annealing effects of In2O3 thin films on electrical properties and application in thin film transistors. Thin Solid Film. 2011, 519, 3254–3258. [Google Scholar] [CrossRef]

- Kim, T.; Jang, B.; Bae, J.-H.; Park, H.; Cho, C.S.; Kwon, H.-J.; Jang, J. Improvement in the Performance of Sol–Gel Processed In2O3Thin-Film Transistor Depending on Sb Dopant Concentration. IEEE Electron. Device Lett. 2017, 38, 1027–1030. [Google Scholar] [CrossRef]

- Parthiban, S.; Kwon, J.-Y. Role of dopants as a carrier suppressor and strong oxygen binder in amorphous indium-oxide-based field effect transistor. J. Mater. Res. 2014, 29, 1585–1596. [Google Scholar] [CrossRef]

- Jaehnike, F.; Pham, D.V.; Bock, C.; Kunze, U. Role of gallium and yttrium dopants on the stability and performance of solution processed indium oxide thin-film transistors. J. Mater. Chem. C 2019, 7, 7627–7635. [Google Scholar] [CrossRef]

- Lee, S.-H.; Kim, T.; Lee, J.; Avis, C.; Jang, J. Solution-processed gadolinium doped indium-oxide thin-film transistors with oxide passivation. Appl. Phys. Lett. 2017, 110, 122102. [Google Scholar] [CrossRef]

- Abliz, A.; Xu, L.; Wan, D.; Duan, H.; Wang, J.; Wang, C.; Luo, S.; Liu, C. Effects of yttrium doping on the electrical performances and stability of ZnO thin-film transistors. Appl. Surf. Sci. 2019, 475, 565–570. [Google Scholar] [CrossRef]

- Jeon, S.; Kim, S.I.; Park, S.; Song, I.; Park, J.; Kim, S.; Kim, C. Low-Frequency Noise Performance of a Bilayer InZnO–InGaZnO Thin-Film Transistor for Analog Device Applications. IEEE Electron. Device Lett. 2010, 31, 1128–1130. [Google Scholar] [CrossRef]

- Li, H.; Han, D.; Liu, L.; Dong, J.; Cui, G.; Zhang, S.; Zhang, X.; Wang, Y. Bi-layer Channel AZO/ZnO Thin Film Transistors Fabricated by Atomic Layer Deposition Technique. Nanoscale Res. Lett. 2017, 12, 223. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Cho, S.W.; Yun, M.G.; Ahn, C.H.; Kim, S.H.; Cho, H.K. Bi-layer channel structure-based oxide thin-film transistors consisting of ZnO and Al-doped ZnO with different Al compositions and stacking sequences. Electron. Mater. Lett. 2015, 11, 198–205. [Google Scholar] [CrossRef]

- Xiao, P.; Dong, T.; Lan, L.; Lin, Z.; Song, W.; Song, E.; Sun, S.; Li, Y.; Gao, P.; Luo, D.; et al. High-mobility flexible thin-film transistors with a low-temperature zirconium-doped indium oxide channel layer. Phys. Status Solidi (RRL)-Rapid Res. Lett. 2016, 10, 493–497. [Google Scholar] [CrossRef]

- Chauhan, R.N.; Tiwari, N.; Liu, P.-T.; Shieh, H.-P.D.; Kumar, J. Silicon induced stability and mobility of indium zinc oxide based bilayer thin film transistors. Appl. Phys. Lett. 2016, 109, 202107. [Google Scholar] [CrossRef]

- Yun, M.G.; Ahn, C.H.; Kim, Y.K.; Cho, S.W.; Cho, H.K.; Kim, H. Effects of top-layer thickness on electrical performance and stability in VZTO/ZTO bi-layer thin-film transistors. J. Alloy. Compd. 2016, 672, 449–456. [Google Scholar] [CrossRef]

- Hsu, H.-H.; Chang, C.-Y.; Cheng, C.-H.; Chiou, S.-H.; Huang, C.-H. High Mobility Bilayer Metal–Oxide Thin Film Transistors Using Titanium-Doped InGaZnO. IEEE Electron. Device Lett. 2014, 35, 87–89. [Google Scholar] [CrossRef]

- Choi, J.H.; Yang, J.-H.; Nam, S.; Pi, J.-E.; Kim, H.-O.; Kwon, O.-S.; Park, E.-S.; Hwang, C.-S.; Cho, S.H. InZnO/AlSnZnInO Bilayer Oxide Thin-Film Transistors with High Mobility and High Uniformity. IEEE Electron. Device Lett. 2016, 37, 1295–1298. [Google Scholar] [CrossRef]

- Seul, H.J.; Kim, M.J.; Yang, H.J.; Cho, M.H.; Cho, M.H.; Song, W.B.; Jeong, J.K. Atomic Layer Deposition Process-Enabled Carrier Mobility Boosting in Field-Effect Transistors through a Nanoscale ZnO/IGO Heterojunction. ACS Appl. Mater. Interfaces 2020, 12, 33887–33898. [Google Scholar] [CrossRef]

- Liang, K.; Wang, Y.; Shao, S.; Luo, M.; Pecunia, V.; Shao, L.; Zhao, J.; Chen, Z.; Mo, L.; Cui, Z. High-performance metal-oxide thin-film transistors based on inkjet-printed self-confined bilayer heterojunction channels. J. Mater. Chem. C 2019, 7, 6169–6177. [Google Scholar] [CrossRef]

- Lee, H.; Zhang, X.; Kim, J.W.; Kim, E.J.; Park, J. Investigation of the Electrical Characteristics of Bilayer ZnO/In2O3 Thin-Film Transistors Fabricated by Solution Processing. Materials 2018, 11, 2103. [Google Scholar] [CrossRef]

- Yue, D.; Guo, S.; Han, S.; Cao, P.; Zeng, Y.; Xu, W.; Fang, M.; Liu, W.; Zhu, D.; Lu, Y.; et al. Facile fabrication of MgZnO/ZnO composites for high performance thin film transistor. J. Alloy. Compd. 2021, 873, 159840. [Google Scholar] [CrossRef]

- Nam, S.; Yang, J.-H.; Cho, S.H.; Choi, J.H.; Kwon, O.-S.; Park, E.-S.; Lee, S.-J.; Cho, K.-I.; Jang, J.; Hwang, C.-S. Solution-processed indium-free ZnO/SnO2 bilayer heterostructures as a low-temperature route to high-performance metal oxide thin-film transistors with excellent stabilities. J. Mater. Chem. C 2016, 4, 11298–11304. [Google Scholar] [CrossRef]

- Yang, C.P.; Chang, S.J.; Chang, T.H.; Wei, C.Y.; Juan, Y.M.; Chiu, C.J.; Weng, W.Y. Thin-Film Transistors With Amorphous Indium–Gallium-Oxide Bilayer Channel. IEEE Electron. Device Lett. 2017, 38, 572–575. [Google Scholar] [CrossRef]

- Lee, W.J.; Choi, J.G.; Sung, S.; Kim, C.H.; Na, S.; Joo, Y.C.; Park, S.; Yoon, M.H. Rapid and Reliable Formation of Highly Densified Bilayer Oxide Dielectrics on Silicon Substrates via DUV Photoactivation for Low-Voltage Solution-Processed Oxide Thin-Film Transistors. ACS Appl. Mater. Interfaces 2021, 13, 2820–2828. [Google Scholar] [CrossRef]

- Xu, W.; Zhang, G.; Feng, X. Room temperature fabricated high performance IAZO thin film transistors with dual-active-layer structure and sputtered Ta2O5 gate insulator. J. Alloy. Compd. 2021, 862, 158030. [Google Scholar] [CrossRef]

- Huang, W.; Guo, P.; Zeng, L.; Li, R.; Wang, B.; Wang, G.; Zhang, X.; Chang, R.P.H.; Yu, J.; Bedzyk, M.J.; et al. Metal Composition and Polyethylenimine Doping Capacity Effects on Semiconducting Metal Oxide-Polymer Blend Charge Transport. J. Am. Chem. Soc. 2018, 140, 5457–5473. [Google Scholar] [CrossRef] [PubMed]

- Seo, J.S.; Bae, B.S. Improved electrical performance and bias stability of solution-processed active bilayer structure of indium zinc oxide based TFT. ACS Appl. Mater. Interfaces 2014, 6, 15335–15343. [Google Scholar] [CrossRef] [PubMed]

- Jeong, S.; Ha, Y.G.; Moon, J.; Facchetti, A.; Marks, T.J. Role of gallium doping in dramatically lowering amorphous-oxide processing temperatures for solution-derived indium zinc oxide thin-film transistors. Adv. Mater. 2010, 22, 1346–1350. [Google Scholar] [CrossRef] [PubMed]

- Su, J.; Wang, Q.; Ma, Y.; Li, R.; Dai, S.; Wang, Y.; Yang, H.; Zhang, X. Amorphous InZnO:Li/ZnSnO:Li dual-active-layer thin film transistors. Mater. Res. Bull. 2019, 111, 165–169. [Google Scholar] [CrossRef]

- Saha, J.K.; Billah, M.M.; Jang, J. Triple-Stack ZnO/AlZnO/YZnO Heterojunction Oxide Thin-Film Transistors by Spray Pyrolysis for High Mobility and Excellent Stability. ACS Appl. Mater. Interfaces 2021, 13, 37350–37362. [Google Scholar] [CrossRef]

- Liu, A.; Liu, G.X.; Zhu, H.H.; Xu, F.; Fortunato, E.; Martins, R.; Shan, F.K. Fully solution-processed low-voltage aqueous In2O3 thin-film transistors using an ultrathin ZrOx dielectric. ACS Appl. Mater. Interfaces 2014, 6, 17364–17369. [Google Scholar] [CrossRef]

- Cho, M.H.; Choi, C.H.; Seul, H.J.; Cho, H.C.; Jeong, J.K. Achieving a Low-Voltage, High-Mobility IGZO Transistor through an ALD-Derived Bilayer Channel and a Hafnia-Based Gate Dielectric Stack. ACS Appl. Mater. Interfaces 2021, 13, 16628–16640. [Google Scholar] [CrossRef] [PubMed]

| Gd Concentration | Saturation Mobility (/V s) | Threshold Voltage (V) | Subthreshold Swing (V/dec) | Off-State Current (A) | On/Off Ratio | ΔVth (V) |

|---|---|---|---|---|---|---|

| / (3%) | 6.22 | −4.61 | 8.10 | 3.55 | 1.84 | 1.42 |

| / (5%) | 5.38 | −3.77 | 7.68 | 7.86 | 9.01 | 1.26 |

| / (7%) | 4.34 | 0.97 | 4.54 | 1.24 | 3.18 | 1.83 |

| / (9%) | 2.54 | 2.40 | 3.18 | 9.12 | 3.71 | 3.32 |

| Gd Concentration | Saturation Mobility (/V s) | Threshold Voltage (V) | Subthreshold Swing (V/dec) | Off-State Current (A) | On/Off Ratio |

|---|---|---|---|---|---|

| / (3%) | 2.41 | −4.86 | 8.82 | 7.54 | 8.03 |

| / (5%) | 2.42 | 0.94 | 8.28 | 5.76 | 8.65 |

| / (7%) | 3.12 | 7.46 | 3.93 | 1.06 | 3.44 |

| / (9%) | 3.36 | 13.19 | 3.40 | 2.96 | 8.38 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Zhang, X.; Zhang, P.; Song, G.; Yuan, L. Enhanced Electrical Performance and Stability of Solution-Processed Thin-Film Transistors with In2O3/In2O3:Gd Heterojunction Channel Layer. Nanomaterials 2022, 12, 2783. https://doi.org/10.3390/nano12162783

Li S, Zhang X, Zhang P, Song G, Yuan L. Enhanced Electrical Performance and Stability of Solution-Processed Thin-Film Transistors with In2O3/In2O3:Gd Heterojunction Channel Layer. Nanomaterials. 2022; 12(16):2783. https://doi.org/10.3390/nano12162783

Chicago/Turabian StyleLi, Shasha, Xinan Zhang, Penglin Zhang, Guoxiang Song, and Li Yuan. 2022. "Enhanced Electrical Performance and Stability of Solution-Processed Thin-Film Transistors with In2O3/In2O3:Gd Heterojunction Channel Layer" Nanomaterials 12, no. 16: 2783. https://doi.org/10.3390/nano12162783

APA StyleLi, S., Zhang, X., Zhang, P., Song, G., & Yuan, L. (2022). Enhanced Electrical Performance and Stability of Solution-Processed Thin-Film Transistors with In2O3/In2O3:Gd Heterojunction Channel Layer. Nanomaterials, 12(16), 2783. https://doi.org/10.3390/nano12162783