Abstract

Amidst the new techniques facing the improvement of cooling and insulating efficiency and the design of electric transformers, constrained by the current technologies, one of the more promising is the substitution of traditional dielectric oils for nanofluids. Research on nanofluids for their application in transformers as a coolant and dielectric medium have been performed during the last two decades and continue today. This review tries to collect and analyze the available information in this field and to offer it already dissected to researchers, focusing on the preparation methods and how nanoparticles affect the main properties of the base fluids. Here we also addressed the influence of different parameters as particle characteristics or environmental conditions in nanofluids performance, the evolution with time of the measured properties, or the neighboring relationship of nanofluids with other transformer components. In this sense, the most reviewed articles reflect enhancements of thermal conductivity or dielectric strength, as well as an improvement of time evolution of these properties, with respect to those that are found in base fluids, and, also, a better interaction between these nanofluids and dielectric cellulosics. Thus, the use of dielectric nanofluids in transformers may allow these machines to work safer or over their design parameters, reducing the risk of failure of the electrical networks and enhancing their life expectancy. Nevertheless, these advantages will not be useful unless a proper stability of nanofluids is ensured, which is achieved in a small part of revised articles. A compendium of the preparation methodology with this aim is proposed, to be checked in future works.

1. Introduction

Beyond their potential applications in the generation and storage of energy, nanoparticles may play an important role in energy transmission systems. Current electric systems need to adapt to meet the challenges resulting from the increase in electric transportation, which will require grids with higher capacity and reliability. The near-future needs in terms of design and capabilities of power transformers, key grid elements, and attempts to increase the life expectancy and efficiency of equipment have boosted the development of techniques to improve the cooling and isolation of these machines, such as the application of dielectric oil-based nanofluids. Proposed originally in 1998 by Segal et al. [1], who started research in this area, the main idea was to translate the supposed advantages of nanofluids as a coolant medium (pointed out a few years earlier by Choi et al. [2]) to the cooling systems of high power transformers. This is achieved by the addition and dispersion of low quantities of nanoparticles in traditional transformer mineral oils.

Theoretically, the larger thermal conductivity of nanoparticles in comparison to the fluid may lead to an improvement in cooling and, therefore, a reduction in hot-spots and the mean temperatures of the copper wires. This provides an opportunity for the power enhancement of this equipment, while protecting the components from thermal failure more effectively. Nevertheless, to ensure that the use of nanofluids on transformers is viable, other properties must be considered.

Nanoparticles have unique properties that arise from scale effects. Due to their size, their surface/volume (S/V) ratio is much larger than bulk materials. Consequently, the relative presence of atoms and their availability for surface interactions with surrounding media is higher, providing them with special properties. This is why, over the last two decades, different researchers have put their efforts into the study of dielectric nanofluids. They have investigated properties that are related to thermal transport and cooling, such as thermal conductivity, viscosity, convective coefficient, and specific heat; electric isolation capabilities of the fluid (mainly dielectric strength); and those that define the relationship between the fluid and other components of the system or how the materials evolve over time under different stresses and environments, such as stability, aging resilience, and the degree of polymerization of the dielectric cellulosic.

The results were very often positive and unexpected. This encouraged further investigation, with the aim of obtaining a suitable thermal-dielectric nanofluid. This article attempts to collate and summarize these works. This information is presented to the readers introducing both a general view of the current development of the dielectric nanofluids for transformers or a specific revelation in one of the multiple aspects of this topic. We first focus on the preparation methods that are found in dielectric-nanofluid research and how they condition the stability of the resulting dispersions. A great variety of preparation methodologies and nanofluid components (base oils, particles, and treatments) were found in the papers that we reviewed. An attempt to describe standardized methods that can be applied to produce successful dielectric nanofluids with long-term stability has been carried out. The subsequent sections point to the critical properties of the prepared nanofluids, and to the essential aspects which the application of dielectric nanofluids rely on. In this sense, the focus has been on the cooling capacities and the dielectric properties of nanofluids. The conditions that are required for their optimization have been approached. Their evolution with time and how the nanoparticle presence affects other transformer components have also been analyzed.

2. Preparation and Stability of Dielectric Nanofluids

2.1. Nanoparticle Characteristics

The idea of using nanoparticles in fluids first arose from the need to avoid the disadvantages that microfluids (those with a portion of the dispersed particles in the microscale) presented as coolants [2]. These disadvantages included instability, the sedimentation of the solid fraction, resulting in the loss of any improvement in the base fluid properties, and undesirable consequences such as abrasion of the pipes and an increase in the pumping power requirements due to a penalty on pressure drop. It must be considered that the current mean time of residence of a traditional dielectric fluid in a transformer that is under use is several years [3,4]. So, the aim is to find nanofluid dispersions that last as long as possible, with reduced maintenance and economical operation of installations.

The disadvantages of microfluids are mainly due to the size and concentration of the particles that are used. The stability of the particle dispersion depends on these parameters, as they predetermine if gravity, buoyancy forces, and the surface interactions with the fluid are in equilibrium. A greater mean size or a lower S/V ratio leads to a reduction in the surface interactions and to greater gravitational forces, promoting sedimentation [5]. Similarly, a higher concentration of particles promotes aggregation as successful contacts between particles rises. Moreover, it increases abrasion and the pumping requirements.

Thus, a fluid with fewer and smaller particles may have an optimized number and strength of interactions among the different components, reaching a new equilibrium of forces that keeps the dispersion stable. At the same time, due to the low concentration of particles that are used, this nanofluid may be less abrasive and would have a viscosity and density that is close to the base fluid, resulting in a more suitable fluid for use in cooling circuits. All these provisions have been considered during the preparation of dielectric nanofluids.

By definition, nanoparticles have a maximum size of 100 nm in any direction [6], but most of the references we examined were carried out with mean sizes below 20 nm (63%), or with maximum sizes below 50 nm (78%), in order to increase the S/V ratio. The reviewed papers are classified as a function of the size of the added particles in Table 1.

Table 1.

Mean and maximum distribution size of nanoparticles that are used in dielectric nanofluids.

As mentioned earlier, the stability of the particle dispersion depends on the particle size, and this parameter grows with time due to aggregation. This phenomenon occurs when particles collide with each other, and it becomes more frequent as the particle concentration increases. This, together with the consequences of over viscosity that were discussed earlier, hinders the use of elevated concentrations, even though it is supposed that the beneficial effects of nanoparticles would increase with concentration.

A compromise solution was pursued. A volume fraction below 1% is recommended [81], in which is a mass fraction of 5.9% or 52 g/L for magnetite in mineral oil, and 4.47% or 39 g/L for titania in mineral oil. Table 2 summarizes the concentration ranges of the tested nanofluids, very often only ten to one hundred times the trace concentration, or even less. Approximately 77% of the reviewed papers presented concentrations that were less than the recommended values.

Table 2.

Nanoparticle content in dielectric nanofluids in the revised literature.

Dielectric cooling fluids for transformers are organic chain compounds that are obtained from petroleum and vegetal sources, as is the case for mineral oils and ester-based fluids, respectively. These are mainly non-polar and hydrophobic molecules, so their interactions with nanoparticle surfaces are not electrostatic such as those in watery colloids [5]. Beyond size and concentration, the surface characteristics and interactions with the surrounding medium must be considered, along with other aspects, both internal and external, that can affect stability. According to the references, this includes the shape and behavior under high temperatures and magnetic fields. Thus, nanoparticles that are added to dielectric fluids should necessarily gather chemical stability under the expected work conditions and tend to interact with the base fluid.

Since the beginning of these investigations, the most common nanoparticles have been metal oxides, which are very stable compounds, specifically magnetite (Fe2O3) and other iron species (38% of thermal-dielectric nanofluids) and titania (TiO2, 20%). Alumina (Al2O3) and silica (SiO2) are also common (approximately 10% each), with other metallic oxides (10%), and all other nanoparticles (12%) occurring less frequently. Some examples can be found using mixtures of the previous oxides [128], or pure metal nanoparticles, which tend naturally to oxidize. Over time, as they become more frequent in other fields of nanotechnology, different nanostructures such as graphene, fullerene, and carbon nanotubes (CNT) have been used with the expectation that their organic composition will make them suitable for dispersions with long-term stability. Table 3 gives a breakdown of the different nanoparticles that were found in the works that we reviewed, specifically dedicated to thermal-dielectric analysis.

Table 3.

Composition of nanoparticles that were used in references.

From the point of view of their properties, mainly based on their respective bulk materials, these nanoparticles fulfil the condition of having thermal conductivities that are several times greater than the dielectric base fluids, approximately ten times greater for magnetite, and more than ten thousand times greater for diamond and carbon nanotubes (Table 4) [5,26,30,82,88,130].

Table 4.

Thermal conductivities of nanoparticles and dielectric oil.

Nanoparticles can also be classified according to their electric conductivity as conductive, semiconductive, and insulating [35], as Table 5 shows [82,130,141]. Contrary to the general belief, the addition of resistive nanoparticles is not required to achieve dielectric nanofluids.

Table 5.

Classification of nanoparticles in function of their electric conductivity.

Considering shape, it seems that nanoparticles with an elongated shape, such as nanotubes with high length/diameter (L/D) aspect ratios tend easily to aggregate [27,61,142]. A clear majority of the nanoparticles that were used in the reviewed research were described as spherical or quasi-spherical, especially the metallic oxides, but there are examples with other geometries, such as sheets [115].

Considering other aspects, it is very important to condition the nanofluid component selection for the expected application and the associated environmental conditions, trying to fulfil the requirements for the physical integrity of the particles over time, suitable behavior, and a beneficial relationship with the base fluid. It appears that coolant-nanofluid dispersion could be improved by controlling the operating temperature. The Brownian movement of particles in fluid is enhanced as the temperature increases, so perdurable interactions between the particles become less probable, hindering aggregation, as noticed in [9,143]. Nevertheless, it is compulsory for these nanoparticles to withstand such conditions. Magnetic nanoparticles can be affected by external magnetic fields; as they line up according to the field direction, their Brownian movement is constrained, and their interactions get stronger [33,99,100].

2.2. Synthesis and Production Methods of Nanoparticles

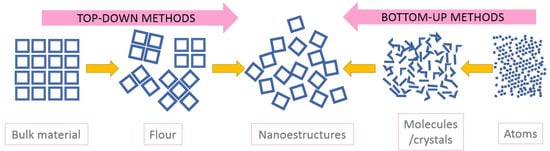

The nanoparticles that were used in the reviewed papers were usually provided by industrial suppliers, as in [61], either in the form of flour or a concentrated dispersion, with defined specifications in terms of the distribution of sizes, shape, or composition. This limits the researchers’ ability to control variables which affect the stability of the nanofluids, such as the size and surface characteristics. As a result, many researchers have synthesized their own nanoparticles in order to control these aspects and study their effects on nanofluid properties. The methods that were followed for this purpose are shared by various branches of nanotechnology; they can be split into two categories: bottom-up, and top-down methods, represented in Figure 1 [144].

Figure 1.

Synthesis methods of nanoparticles and nanostructures.

Top-down methods involve the reduction of the particle sizes of a pre-existing bulk material by grinding, or vaporization-condensation; in bottom-up methods, nanoparticles are created by a chemical reaction or the physical interactions of precursors, atom by atom, as in coprecipitation or solvothermal techniques. Although the bottom-up methods are more complex, they are more versatile, since the rate of addition of reagents to the solution and its concentration [145,146], together with the time of reaction [21,55,66,108,146] or temperature [147], affects the mean size and composition of the nanoparticles, and can be used to control them [109,139]. By reducing the reaction time or concentration of the reagents, smaller particles are produced, although the dependence of size on time was not seen in all of the studies [23]. Others have found a relationship between the size and the moisture that is present in reagents during synthesis [148,149], which may promote the growth of particles.

Several examples of bottom-up methods were found in the reviewed papers. Starting with metal oxides, ferrous and ferric oxides arise from the co-precipitation of their cations from respective chloride, nitrate, or sulphate salts in a watery solution following the addition of bases such as ammonia or sodium hydroxide under shaking [137]. This procedure, based on pH changes, was followed in many works [107,145,149,150,151,152,153,154,155], including those specific to thermal-dielectric nanofluids with transformer oils [8,20,34,58,96,123,124,156]. Alternative methods used the reaction of iron precursors in alcoholic-organic solutions [23,55,139,146,157], and again there were examples in thermal-dielectric research [7,19,21,55,66,108,109].

These processes produce different iron oxides, classified as a function of their Fe2+/Fe3+ ratio and predominant allotropic phase, as magnetite (Fe3O4), maghemite (α-Fe2O3), or hematite (α-Fe2O3), among others. The abundance of the different phases depends on the concentration of the reactants, the temperature, and the presence of an oxidant or inert atmosphere. If magnetite is preferred over the other phases, a 2/1 mol ratio of ferric/ferrous salts is commonly used [8,20,34,137,149,150,152,154,155,156,157,158], (or even lower, [107]); nitrogen environments are also used [55,107,108,153] to offset the oxidation of ferrous cations during the reaction. In other cases, the production of maghemite was promoted by the addition of oxidants, or by bubbling a heated solution with oxygen [20,158]. Some of these particles also include cobalt [23], magnesium, manganese [124], or nickel oxides [124,159] in their composition in addition to iron oxides.

Solvothermal processes are frequently used in the synthesis of titanium and zinc oxides [101,148,160,161], they are also used to evaluate the effect on the thermal-dielectric properties of fluids [3,25,57,63,65]. During these processes, organic precursors of titanium or zinc react with organic solvents, frequently followed by calcination [65,148,160]. Again, the characteristics of the products depend on the process that is followed, e.g., which acid is used as a reagent [161].

Organic nanoparticles, such as CNT and graphene, are also very common research subjects in a wide range of disciplines, recently including nanodielectrics [116]. CNT were commonly produced by the bottom-up catalytic decomposition of methane diluted in hydrogen [142,162]. Other works used a different process to obtain graphene [116]. First, graphite flour was oxidized in three steps by sulphuric acid, acid salts, and hydrogen peroxide, to produce graphene oxide (GO). Second, the oxide was reduced by sodium borohydride or hydrazine hydrate with ammonia. Other organic nanoparticles have been produced using other techniques; for example, nanocarbon was condensed by dispersing water over the smoke from the combustion of acetylene in a leakage of oxygen [163].

Top-down methods are more frequently used for the formation of metallic nanoparticles [2,143]. Metallic wires with a diameter less than 0.25 mm are exploded by subjecting them to a voltage in a liquid medium. However, there are also examples of the bottom-up production of metallic nanoparticles, such as those using copper acetates in a hydro-alcoholic solution [164]. Similarly, there are examples of both methods for other compositions such as binary salts [73,165].

Sometimes, a combination of different methods may be used in the same synthesis process. For example, carbon nanotubes may be chemically shortened using nitric and sulphuric acids, before magnetite is produced by a reaction on the surface of the tubes, thus coating the tubes [145]. Other processes put bottom-up synthesized or commercial particles through a top-down milling step [61,73,148].

The reaction temperature varies depending on the production method and the reactions that are involved in it, ranging from the rated temperature to approximately 1000 °C. According to the literature, oxides can be synthesized by co-precipitation at room temperature [8,149,152,153,157] or at approximately 100 °C [7,19,20,34,107,123,124,137,145,151,154,155], or by the decomposition or solvothermal way at approximately 200 °C [23,101,146,159], 300 °C, [21,55,139], or even above 500 °C, [3,65,160]. Sometimes, the complete synthesis process is subdivided into several steps, each at a different temperature [7,19,21,55,66,108,109].

The solvothermal method and its variations, requires high temperatures and pressures, as illustrated in many methodological descriptions [18,25,65,101,157,160], in order to improve the solubility of reagents and to promote their reaction. The consequent calcination takes place between 450 and 500 °C [65,148,160].

Metallic nanoparticles that are created by bottom-up methods using precursor reactions need similar temperatures to metal oxides, approximately 100 °C [164]. Meanwhile, the catalytic decomposition of methane for carbon nanotubes requires a higher temperature of 1000 °C in order to take place [142,162].

Table 6 collates this classification of references, which can be used to discern which synthesis procedures are suitable for laboratory equipment as a function of temperature.

Table 6.

Temperature during nanoparticle synthesis reaction in studied research.

2.3. Nanoparticle Surface Treatments

Depending on the expected application of nanoparticles, further treatments may be necessary, where surfactantion is the most common when nanofluids are involved. This consists of the coating of particles with products that make them more prone to remain in suspension [5].

Substances are selected for this is according to the particle and base fluid [25,38,124,151], environmental conditions that they must withstand [22,142], and the effects of the surfactant on the properties of the fluid [73]. Considering the addition of nanoparticles to an oil or ester, most of examples that we reviewed show surface functionalization with organic acids of different hydrocarbon chain lengths, mainly oleic acid (55% of the papers where the presence/absence of a surfactant is mentioned). Table 7 summarizes the products that were used as nanoparticle surfactants in the reviewed papers, including the composition of the particles that were treated and the base fluid of the nanofluids that were prepared with them. The length of the organic acids regulates the particles that are susceptible to being functionalized, as shorter molecules are only suitable for dispersing a lower fraction of the particles in suspension [166].

Table 7.

Surfactants that were used in thermal-dielectric nanofluids.

These can be included either as reagents during the synthesis of particles [8,21,25,55,59,65,66,107,108,109,133,139,156,157], added to nanoparticles [7,19,34,51,57,58,61,66,70,73,85,91,96,113,124,137,148,149,151,152,153,158], or at both times [107]; they can be in a aqueous solution [20,25,67,107,123,124], organic solvent [7,19,21,51,59,61,73,108,109,128], or oil [34,107]. When using water as a solvent and organic acids as the surfactant, it may be convenient to add substances to enable the contact with the particles, sodium hydroxide or organic solvents such as acetone, for example [107,150].

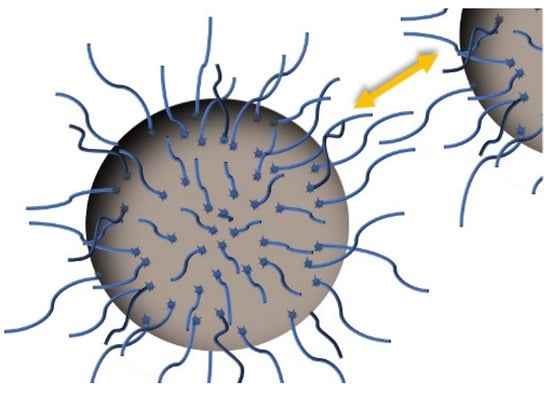

Under shacking and with the proper amount of energy, acid molecules are adsorbed by particles through physical or chemical interactions; since the latter are stronger, they are better at maintaining the coating [20]. Theoretically, the carboxylic groups in surfactant molecules bond to the nanoparticle surface in different ways [151]: keeping organic chains towards the surrounding medium, changing surface polarity [64,75,149], and occupying the active surface [110]. Due to their length, these chains hinder approaching particles by increasing the osmotic pressure, which is known as steric repulsion and is represented in Figure 2. The larger distances between the particles means that the strength of the van der Waals forces and polar interactions among them are reduced [23,84,90,110,139,167]. Additionally, interactions between these chains and the surrounding oil are enhanced as organic acids are soluble in it [27,61,130,164]. Therefore, this creates coated particles with both an improved resistance to aggregation and relationship with the surrounding oil. This theory is demonstrated in some works by the fact that these particles tend to migrate from water to the organic phase when they are put together [20,158], and that the mean size in suspension is much lower when a surfactant is used [23,30,101], A beneficial side effect is that the coated particles, which were susceptible to oxidation, are protected [34,40,107,164].

Figure 2.

Steric repulsion between surfacted nanoparticles.

Treatment is often carried out above the rated temperature in order to assure the adsorption of these reagents [7,8,19,58,66,73,96,108,109,123,124,129,156]. In the cases that we reviewed related to dielectric nanofluids, the temperatures during surfactantion were approximately 80–90 °C [8,34,73,129]. Another important factor is the surfactant concentration. As shown in Table 8 (in grams of surfactant per liter of fluid, volume percentage, milliliters of surfactant per gram of nanoparticle or weight percentage), the quantities of surfactant that were used during treatment were relatively low; it must be below the critical micelle concentration to avoid its own aggregation and negative consequences for fluid viscosity [168]. An optimal concentration from the point of view of stability or nanoparticle size distribution can be achieved [30]. In some examples, the surfactantion process was repeated to increase the surfactant adsorption [21,107].

Table 8.

Surfactant concentrations that were found in the references.

Surfactants maintain the crystal structure of the treated particles [23,148] and slightly increase their size [23]; on the other hand, modifications of the pre-existing surface of particles also have been seen by the addition of acid substances [34,137,162].

2.4. Nanoparticle Recovery from Dispersion

Once the particles are ready, after synthesis or surfactantion, they must be recovered from the reaction solution. A number of methods were used in the papers that we reviewed, including: filtration [61,65,124,148], centrifugation [20,21,51,55,65,66,101,108,109,116,124,139,148,149,151,152,157,159,161,164], heating [128], and natural [158] or magnetic decantation [8,23,34,107,123,124,137,150,153,155,156,169] for magnetic particles. Sometimes chemical agents were added to reduce the solubility of the particles in the solvent in order to enable their extraction [21,66].

This step can be used to select specific particles. For example, during natural decantation, it is possible to take just the particles in the organic phase and to return those in the aqueous phase to the previous processes [20,158].

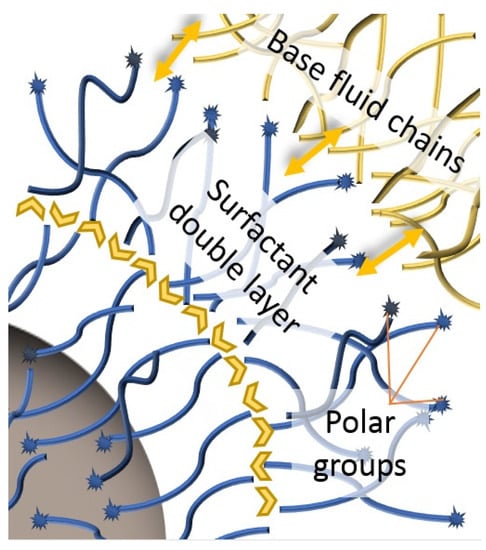

Recovery is followed by different phases of washing to eliminate excess reagents and solvents, or to optimize the surfactant coating [55,150,151]. During the formation of the surfactant coating, carboxylic groups bond chemically with the particle surface; this makes them lipophilic due to the hydrocarbon chains. However, if the saturation amount of surfactant is exceeded, these extra molecules interact physically with those that are attached to particles through their chains, creating a second layer [61,90,107,110,148,170], represented in Figure 3. For carboxylic groups facing the fluid [61,110,148,170], this gives the particles a polar or hydrophilic nature which, although not suitable for addition to and sustenance in transformer oils, is sought for certain applications [107,170].

Figure 3.

Hydrophilic double layer of surfactants and dielectric fluid.

The necessary amount of surfactant for each situation is difficult to know as it depends on the composition, concentration, morphology, and the size of the particles, so washing is a suitable way to remove the extra layer. Water [34,107,116,137,149,152,153,154,155], alcohol [65,139], organic solvents [23,123], or a combination of them [7,19,20,25,101,108,109,146,148,150,151,157,159,164,169] are used in this step. After mixing and shaking, the nanoparticle must be recovered again. To eliminate the remnants from washing, or moisture in general, the particles are dried by heating them at temperatures up to 100 °C, in air or a vacuum, for between 12 and 72 h [7,8,19,20,25,34,51,61,66,101,108,109,137,139,146,148,151,152,156,158,159,161]. Alternatively, a nitrogen gas stream can be used for the same process [20]. The drying processes can affect the size distribution of nanoparticle flour since they promote aggregation [73]. Particles are thereafter kept in the form of flour or suspended as a concentrated nanofluid.

2.5. Preparation of Nanofluids

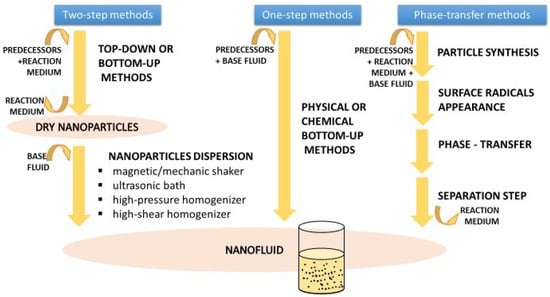

As one of the main branches of nanotechnology with several potential applications in different fields such as medicine and engineering, different nanofluid preparation methods have been developed and adapted for their final characteristics by researchers and producers based on the raw materials and available equipment. A compendium is available describing the wide range of production methods [5]. This explains that they are classified in three categories: two-step and one-step methods, and all other methods. The first two differ from each other in how nanoparticles are introduced into the base fluid. Two-step methods first produce nanoparticles as dry powders, which are added and dispersed in a second stage, while one-step methods produce nanoparticles directly within the final fluid. Other methods require the transference of nanoparticles between phases during synthesis; this takes place when new radicals appear on the surface of the particles, changing the inclination of solids to a determinate fluid. These alternatives are represented in Figure 4.

Figure 4.

Available preparation methodologies for nanofluids.

Every methodology presents its own disadvantages [5]. In two-step methods, as particles must be recovered from the reaction solution and kept as a powder, aggregation processes take place. Dispersion in the base fluid, which is carried out by magnetic/mechanic shakers, ultrasonic baths, or homogenizers that are used to ensure a proper distribution of particles, are useful in breaking up the aggregates created during handling. Despite the dispersion steps, aggregates continue to be created. This may have consequences for the stability of the nanofluids as aggregates migrate to the bottom of the dispersion faster. Therefore, surface treatments with surfactants to avoid aggregation become necessary. The main problem with one-step methods is that, as the nanoparticles remain in reaction fluid, so do the reaction waste products and the residual reactants; these are able to distort the nanoparticle effects over the base fluid properties [5]. Moreover, there is little knowledge about the characteristics of these additional particles.

Two-step methods were followed in most of the papers that we reviewed. Regardless of their origin, a certain amount of nanoparticles were added to a nanofluid preparation until the desired concentration in the base fluid was achieved. One-step methods were found only in articles using water [171,172]. Thermal-dielectric nanofluids are habitually based on mineral oils, but there are several examples being prepared using esters. In this case, natural esters prevailed over synthetic alternatives, as shown in Table 9. Frequently, base fluids suffer pre-treatments such as filtration or drying to eliminate impurities that affect their performance as an isolation medium, as specified in the regulations for transformer oils by the International Council on Large Electronic Systems (CIGRE).

Table 9.

Classification of references as a function of the base fluid that was used.

To disperse particles in the base fluid, in these cases both magnetic/mechanical shakers and ultrasonic baths are used [7,8,19,25,50,65,66,73,85,92,95,107,108,109,150,156], frequently for less than 30 min, especially with the former, according to Table 10. The aggregates are thus broken apart, ensuring the homogeneity of the nanofluids. Therefore, sonication is sometimes used as a final step in the particle preparation as it occurs with milling [61]. An alternative method of homogenization is available where a mixture of the base fluid and solid fraction are passed through a high-pressure homogenizer that divides the sample stream into different micro-channels [26]. The mixture suffers high velocities, shear forces, crashes, and cavitation, which break the aggregates apart and disperse the particles. Another method uses a high shear homogenizer that breaks the aggregates apart by friction, with samples set between its stator and turning rotor [179].

Table 10.

Homogenization times during nanofluids preparation.

During these phases, especially with ultrasounds, the samples are exposed to heating [184] which can harm the bonds between the surfactant and particles. In some articles, variations on the general method of dispersion are used. For example, the dispersion process may be repeated several times to eliminate excess surfactant completely, in an attempt to optimize the coating of particles and to avoid the formation of a double layer of organic acids [123]. In other studies, sonication is implemented with regular stops to prevent the excessive heating of samples under treatment [25,68,163,174], while others include a cooling system [184].

Once the nanofluid is prepared, before its application, it is frequently dried under heat or/and vacuum, as with nanoparticles, for at least for 12 h [18,24,53,62,73,85,92,95,108,109,115,133]. This enhances the dielectric strength of the fluid, prevents the formation of new bubbles, gives the fluid time to dissipate existing bubbles [3,7,19,63,88], and can even eliminate traces of volatile solvents [61].

2.6. Nanofluid Stability Assessment

The stability of nanofluids can be measured first by sight [12,18,20,21,60,66,110,132,162,179], as when sedimentation of the solid fraction occurs, the appearance of the suspension changes. An initially homogenous suspension will develop different zones: the upper zone is similar to the base fluid, the intermediate zone is opaquer and it is colored by the nanoparticles, and the lower zone is composed of settled wet particles, as shown in Figure 5. The widths of the zones evolve with time; as the first and last grow, the second decreases until it vanishes completely, which takes longer in more stable dispersions. Some studies accelerate this process by submitting the samples to centrifugation, which is also faster as the stability decreases [5].

Figure 5.

Oil-based nanofluid dispersion evolution with time.

To achieve accurate and objective measurements better than human sight, there are techniques to assess the stability of nanofluids, such as colorimetry and turbidimetry, which compare the different stages over time. Alternatively, the evolution of the mean size of dispersion, measured using dynamic light scattering (DLS), can also be useful as this is the parameter that is first-affected by aggregation [59,70,86,90,106,110]. Stability can be assessed based on the magnetic field that is used to separate particles from the dispersion [107] or by controlling the concentration evolution of the dispersion [27].

Other techniques are based in properties that are indirectly related to stability, as Z potential measurements. The Z potential reflects the difference in potential between the dispersion medium and the layer of fluid that is closest to the particles, typically a double layer of ordered molecules. The larger the Z potential, the more electrically stabilized the suspension [5,115], according to Table 11 [6]. Additionally, the electrostatic repulsion between the particles increases with the surface charge of the particles in the fluid [27,89,108]. When the base fluid is water, it seems reasonable that the stability of the particle suspension will increase as the electrostatic interactions grow, as is widely described in the literature [22,112,163,170,179], where the stability of a nanofluid is defined as a function of the Z potential magnitude.

Table 11.

Nanofluid stability classification regarding Z potential.

In the case of nanofluids that are based on oils, contradictions have been found. It was mentioned earlier that in this case, the optimal coating of particles with surfactant is believed to be a monolayer, but this supposes that organic non-polar chains are on the surface. According to the definition of the Z potential, this situation corresponds to the zero potential; this is supported in the literature [170], but the opinion is not shared by other researchers who link the monolayer and the resulting stability to the higher absolute value of the Z potential [72,89,115,124,143]. In the same way, they disagree on what tendency the Z potential shows during the formation of a second layer of surfactant. One fact that supports the most common interpretation is that in one reference the potential was higher at higher temperatures, and thus more stable [143]. Similarly, in other studies the optimal properties were found in those samples whose Z potential was higher [21,25].

Unlike Z potential measurements, UV spectrophotometry is not constrained in viscous [27] or concentrated nanofluids (over 0.1% volume [185]). It is based on the change in the light absorbance of nanofluid samples over time. As with sedimentation, where the concentration of the particles and turbidity decrease over time, so does the light absorbance. Some examples of the application of UV spectrophotometry in oil nanofluids were found in the papers that we reviewed [27,29,94,101,129].

The specific test for magnetically-induced aggregation is acoustic spectroscopy. The attenuation of an acoustic wave depends on the structure of the material that it propagates through, showing very different and defining results if the wave propagation and linear-aggregate directions match [33,167].

Before preparing nanofluids, in order to check if nanoparticles are suitable for transformer oil, the samples can be dispersed in water/oil mixtures. They are suitable if they remain inside the organic phase [151]. Moreover, to quantify this tendency, a lipophilic grade can be measured; this is the amount of alcohol that must be added to the mixture to cause the particles to migrate to the watery phase [148].

The stability gaps that were shown by the oil-based nanofluids that were prepared by the authors of the different references, according to themselves, are given in Table 12. These are the time that lapsed from the preparation of a nanofluid until its solid content is clearly at the bottom of the vessel, following the evolution that is seen in Figure 5. Conclusions can be drawn from this information. For the studies that noticed a life span of more than one year, and for which information was available, a number of techniques and design choices were applied during the preparation of the nanofluids. This included low concentrations [20,21,25], small mean sizes [20,21,25,41], optimized mixings [25], and lipophilic particles (naturally [12,29] or by treatment [20,21,25]). In the last case, particles were submitted to washing [20,21,25] or preselection processes [20], and the surfactantion was boosted thermally [21,25] or chemically [20]. It must be noticed that the life span of the dispersions that are based on natural esters (more viscous than the mineral alternatives) were over 1 month, and 55% of the samples which were stable for more than one year were titania and mineral oil nanofluids.

Table 12.

Stability lasting of nanofluids in the analyzed research.

On the other hand, unstable nanofluids have been produced with higher mean particle sizes [82,87,88,110], higher concentrations [87,143,156], and without the surface treatments of particles to make them more lipophilic [64,82,130]. Only two of the nanofluids whose surfactantion was thermally promoted were classified as unstable [8,156].

Comparing both situations, it seems that only those nanofluids that combine the proper size, concentration, and surface conditions may last the required time.

3. Achievements Found in Literature

Although convection is the main mechanism of heat transport when fluids are the cooling medium, nanoparticles are included in the base fluids with the purpose of improving the contribution of thermal conduction. The thermal conductivity of solids is several times higher than that of fluids, by one or two orders of magnitude [88], so theoretically the thermal conductivity of a nanofluid would be intermediate between those of its components, an increase of as much as the solid fraction in suspension. Also, because the convective coefficient depends on the thermal conductivity of the cooling fluid [186], both may be enhanced by the presence of nanoparticles. Nevertheless, this presence could be detrimental to convection, which depends on the nanofluid’s viscosity and evolution with temperature, but this parameter is affected by the nanoparticles. Additionally, improvements in conduction are constrained by the concentration limits that are set by the stability requirements. Again, a compromise solution between all of these parameters must be achieved.

Thus, since the proposal of cooling nanofluids, researchers have focused on demonstrating these tendencies, and have tried to determine how to achieve a meaningful improvement in conduction without harming convection, or any other essential properties of the base fluid.

3.1. Cooling Capacity

Several direct measurements of the thermal conductivity of nanofluids have been done with samples based on a variety of cooling oils. The aim was not only to verify the effect of nanoparticles on conductivity [25], but also to show how different variables affect it. Logically, one of the variables was the concentration of solids, but others such as nanoparticle type, environmental conditions, and preparation method were also explored. These variations let researchers identify greater increases in conductivity, giving an idea of the potential improvement that nanoparticles could bring. These results are shown in Table 13, where it can be noticed that although there are examples where the variation was negative or below the confidence interval (5–10%), most of results show maximum increases of more than 20%, and some are approximately 100%. Some mathematical models support increases in the conductivity of oils by more than 500% [8,126]. To help with the comprehension of these results, Table 14 summarizes some characteristics of these nanofluids from previous sections of this review.

Table 13.

Maximal thermal conductivity variation in oil-based cooling nanofluids with respect to the base fluid.

Table 14.

Nanofluids characteristics and their effects on thermal conductivity of base fluids.

Thus, several of the papers that we reviewed support the theory that thermal conductivity grows in line with the nanoparticle concentration [8,21,26,39,61,73,88,115,124,129,130,131], although there is not unanimity [64]. This trend is supported when the results are from different sources, which use nanofluids that share most characteristics except the concentration of solids, are compared, as with AlN in [61,73].

Together, the research points to an optimal preparation concentration, as the growth of conductivity decelerates at higher concentrations [73,124]. Other studies show that the growth in the conductivity is not linear before saturation, but it grows at an increasing rate [130].

The variety of nanoparticles or the pre-treatments they suffer, can condition these results. It has been shown that the conductivity variations of nanofluids with a similar concentration can differ due to changes in the particles’ characteristics, such as their composition [26,61,91,131], allotropic structures [25], or shape [26,61,130]. Some effects can be explained by the conductivity of the nanoparticles’ bulk material [26,91,113,115,131]; nevertheless, the lack of specific investigations comparing their effect on the function of the composition prevents us from making conclusions about which of them are better. Changes in the conductivity may also be a result of differences in the nanoparticle size. In addition, when considering surfacted particles, it has been noticed that the surfactants themselves can increase the thermal conductivity of the base fluid; the higher the concentration, the bigger the increase [61,73]. However, this effect is small compared to the nanoparticle effect on the base fluid [58,73].

Environmental effects on the thermal conductivity of nanofluids were also addressed. The natural tendency of the thermal conductivity of oils is to decrease as the temperature increases [21,131,143]. This was observed in some of the investigations with dielectric nanofluids [64,91,113,124,131], but the opposite behavior was seen in others [21,39,130], as it was in some oils [22,143]. Considering the magnitude of the conductivity variation with temperature, larger relative increases were observed in the base fluid at high temperatures [21,129,130], with signs indicating the existence of an optimal temperature [21]. Nevertheless, other studies have shown linear variations, as it is theoretically predicted [91,124,131].

Magnetic fields positively affect the conductivity of nanofluids for a determined concentration, and with a saturation tendency at higher fields [8]. The magnitude of this enhancement depends on the directions of the field and temperature gradients and, when they match each other, it is maximal. It seems that particles are aligned according to the field direction, creating a preferential direction for heat transport by conduction, which is able to provide a five-fold increase to the enhancements [8].

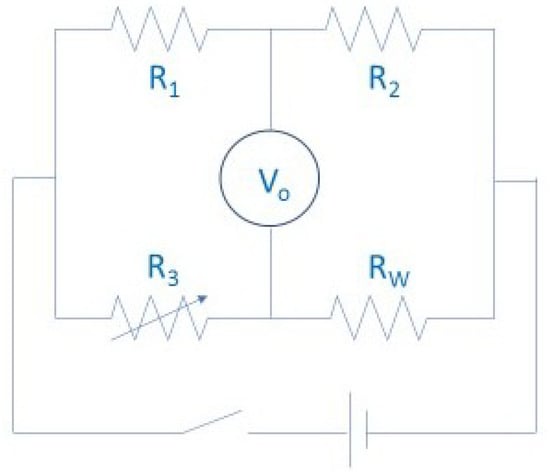

These measurements were carried out with accurate equipment, which was designed for conductivity analysis in other materials, mainly solids, but was adapted to fluid requirements. During the experiments, convection was generally limited in the samples by fast measurements and constrained fluxes of oil. These were largely based on hot transient wires and discs [8,22,26,27,49,61,64,73,88,124,131,143], represented in Figure 6, which were heated by an electrical heat source at the same time as a probe. The thermal conductivity results were found by linking the changes in resistivity (R3), voltage (V0), and temperature in the wires due to the heat dissipation across the tested material. The temperature is controlled by measuring the electrical parameters of the circuit, and the thermal conductivity of the probe surrounding material can be obtained by comparing the evolution of the temperature and the amount of heat that is produced by the electrical circuit. Other experiments used the temperature oscillation technique [175], 3ω-wire method [165], or laser flash method [25].

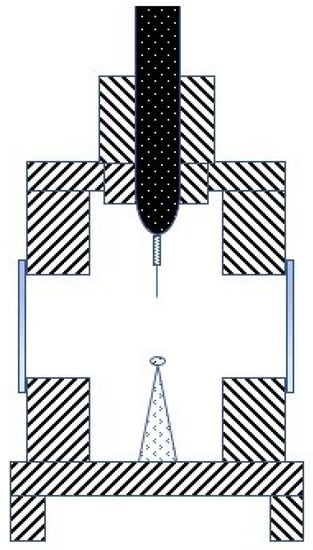

Figure 6.

Hot transient wire scheme.

According to the literature, natural convection [49,123] and overall heat transfer [61,110,118] are also enhanced by nanoparticles, with similar results seen for conductivity in terms of the concentration of nanoparticles [61,118] and surfactants [110]. More precisely, the improvement in conductivity was lower than that which was found for the overall heat transfer coefficient, pointing to an improvement in convection [61]. In the same way, the shape and composition of nanoparticles may also affect the heat transfer [61].

Characteristics that could condition the convection performance of a coolant oil, such as viscosity, especially with natural flux, were not generally harmed by the presence of nanoparticles. Although slight increases were found [49,51,56,58,61,81,86,91,94,111,115,127,180], they were just as frequent as those with no effects [12,25,26,51,59,60,62,64,98,119,121,123,130]. Indeed, reductions in the viscosity were also noticed [22,51,84,91,95]. Researchers have demonstrated that the resulting viscosity depends on the nanoparticle concentration [26,51,56,58,111,115,126,127,130]. To ensure stability, nanofluids were prepared with low concentrations, and the particles were mainly spherical; it is reasonable that the viscosity was not significantly affected as a result. Another idea is that nanoparticles may act as a lubricant between the layers of fluid, as they remain oriented in the flux direction [26]. The viscosity of nanofluids decreases as the temperature increases, such as with the base fluids [49,51,56,58,59,64,86,94,123,127], and seems to be enhanced by the presence of external electric fields, as a function of the nanoparticle concentration [71,119]. Nevertheless, an essential modification was identified, which changed the behavior of the base fluid from a Newtonian to a non-Newtonian fluid at a determinate concentration of nanoparticles [22,26,143] or at low temperatures [143], due to an increase in the number of interactions [130].

Heating tests with nanofluids samples were also done, controlling the temperatures in the fluid, isolators, and heaters. Here, nanofluids showed better cooling capacities and the temperatures that were measured in the tester components were lower [49,69,76,77,80,118,119,131] and those in the coolant were higher [21,80,129] than in tests that were carried out with the base fluids, with some exceptions [60]; the time that was required to reach these temperatures was also lower [21]. It was noticed that these differences became more pronounced at higher particle concentrations [21,80,119,129] when the base fluid was less thermally conductive [131] or when an external electric field is applied on the nanofluid cooling circuits [119]. The existence of optimal concentrations has also been noticed [118].

Similar results were obtained in other studies with other base fluids such as water or ethylene-glycol, which showed improved conductivity [172,173,175,176,179,183] and convection coefficients [173] as the concentration of particles increased. These results were dependent on the composition [27,175], shape [142,183], and size [173,176] of the nanoparticles.

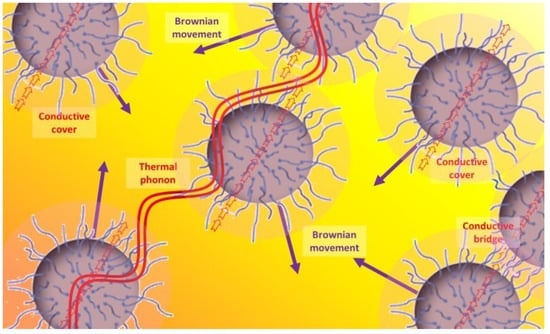

Explanations for these phenomena were given according to four main theories, represented in Figure 7 [49]. These are the Brownian movement of nanoparticles in fluids that are caused by the heat (purple arrows), particle-fluid interface behavior (darker corona around the particles and red arrows), ballistic phonon transport (red waves), and higher thermal conductivity of temporary particle clusters (red arrows shared by two different particles) [129,187], as mentioned earlier.

Figure 7.

Heat transference mechanisms in nanofluids.

The first explanation justifies the improvements in the convection and its coefficient because of the Brownian movement of nanoparticles in the base fluid [16,22,39,87,143,165,171,175,176,178], especially for spherical [165] and small [176] particles. This movement would be linked to the fourth explanation. According to this, the nanoparticles continuously form temporary clusters due to their movement, that create conductive paths for thermal transport [27,39,73,87,130,165,175,177,181]. Considering the second explanation, the molecules in the layers of fluid that are closest to the particles apparently tend to keep more regular organization, resulting in behavior that is more similar to that of solids and a higher thermal conductivity [130,131,177,178]. Finally, according to the third explanation, thermal phonons are able to have ballistic transport between close nanoparticles due to their wavelength and the distances and diameters that are involved [16,130,131,177,178].

Increases in the dispersion concentration or temperature would enhance the magnitude of Brownian motion and temporary clustering [130], and can explain the behavior that was observed with these parameters, when caution is taken not to promote settlement. The differences that were seen for different particle compositions may be due to their bulk material conductivities [26,131], or because one kind of particle is more prone to maintain stability than others in specific circumstances [22].

Another property which has been studied is specific heat; it has been addressed by a few researchers using dielectric oils. These results demonstrated that the specific heat decreased when nanoparticles were added [69,131], and the effect was more pronounced as the concentration of particles increased [124,131] (as in watery nanofluids [163]), or when their thermal conductivity was bigger [131]. The specific heat also tended to increase with increasing temperature [69,124].

3.2. Flash, Fire and Pour Points

From a thermal point of view, not only the cooling capacities of nanofluids are important. If the aim is their use of equipment under high working temperatures, such as transformers, security must be considered. Dielectric oils and the gases they create, are potentially flammable, so the effect of nanoparticles on flash and fire points must be controlled. Again, not many investigations were found in this direction, but most results seem promising as these temperatures rise slightly due to the presence of nanoparticles [51,81,94,121], not more than the 3 °C seen with other kinds of base fluids [181]. In the worst case [111], a decrease of 8 °C (5.12%) was noticed.

Regarding the effect of nanoparticles on oil pour point, depending on the nanoparticle, it can be increased or decreased [51].

4. Dielectric Properties

In light of the application of nanofluids in power transformer cooling, the need to characterize their dielectric properties arose naturally. Dielectric cooling fluids must be able to withstand voltages that are greater than the rated values of the equipment in order to ensure the operation and safety of the components in case of an electrical fault.

This capacity was expected to decrease in dielectric nanofluids in comparison to the base fluids, due to the presence of nanoparticles, as occurs when the transformer oils are not prefiltered in line with the recommended standards [3,42] or with microparticles [41,94]. Nanoparticles are often more electrically conductive than transformer oils, so theoretically, this may harm the fluid’s ability to hinder or delay discharges and streamers. However, the results were unexpectedly good, driving interest in this field of nanotechnology. This improvement in the dielectric properties was observed using many of the variety of tests that are available.

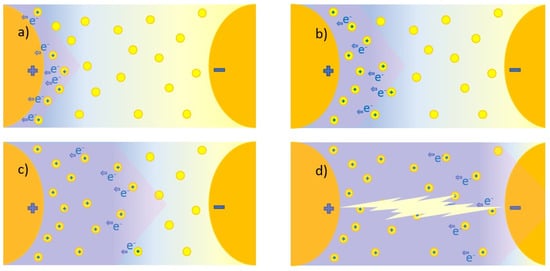

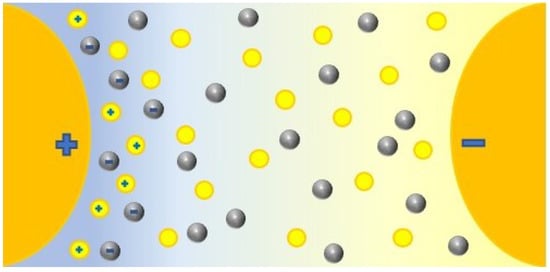

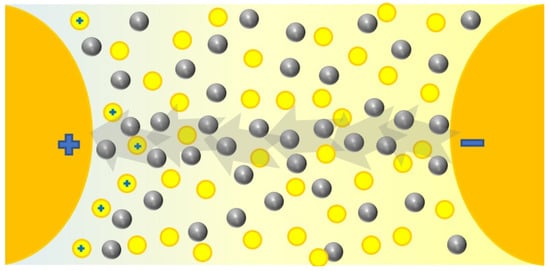

4.1. Dielectric Strength

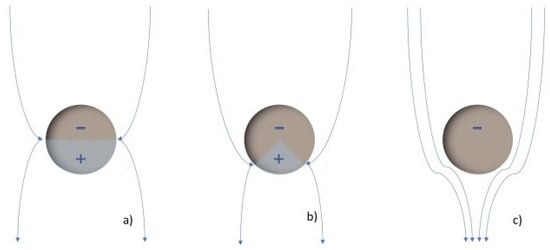

The dielectric strength represents the dielectric fluid capacity of withstanding voltages without the formation of a conductive channel through which an electric current may be established. This capacity is not constant; it depends on the magnitude of the electric field, as it might be sufficient to promote the ionization of fluid molecules and subsequent warming and gas formation, which finally translates to the enhancement of the electric conductivity, represented in Figure 8. Here, there are represented the electrodes that creates an electric field. The yellow circles represent the molecules inside the base fluid, polarized by the field. During ionization, slow cations and fast electrons are created from the oil molecules (a); the electrons tent to migrate towards the anode or positive pole, while the cations create a positively charged area. If the required conditions are fulfilled, this could enhance the local electric field, promoting more ionization in the surroundings and providing feedback to this process (b). This results in the conductive red zone spreading in the fluid, an effect that is known as streamers (c). When completed, a conductive channel of ions and gas is available, and discharge takes place (d). This process, mentioned in several references [10,28,38,67,83,84,89,120,134,136], is supported by simulations [188,189] in which an ionizing wave was observed by representing the estimated electric field, temperature, and the electric net charge over time. Discharge occurs from a determined voltage, dependent on the dielectric media, known as breakdown voltage (BDV).

Figure 8.

Streamer development and discharge in dielectric fluids: (a) Creation of ionized area in the positive electrode by migration of the electrons, (b) Increasement of the electric field in this area that promotes more ionization and migration of the electrons, (c) propagation of the ionization towards the negative electrode, (d) Completion of the ionization between the electrodes and occurrence of the discharge.

Studies of the BDV have been developed by a narrow range of tests, to be representative of all the possible types of dielectric fault. This includes direct (DC) or alternating current (AC) breakdown voltage tests, where the samples of dielectric nanofluids are submitted to increasing voltages inside a cell until an electric arc appears between two electrodes, according to IEC 60156 standards for a lapse of time. Lightning impulse breakdown voltage tests are also common (IEC 60897), with the difference that, while the stresses in DC or AC breakdown tests are less acute, lightning impulse tests involve the application of higher voltages for shorter time intervals [14,37,40,83], thus including this kind of failure in investigations. Finally, partial discharges are analyzed (IEC 60270) by finding the voltage that is necessary for their appearance, called the partial discharge inception voltage (PDIV), where localized currents reach a determined magnitude as a function of the background noise [43,44]. Once the PDIV is known, tests are carried out at or above this voltage, measuring the magnitude and concurrency of the discharges [11,28,62].

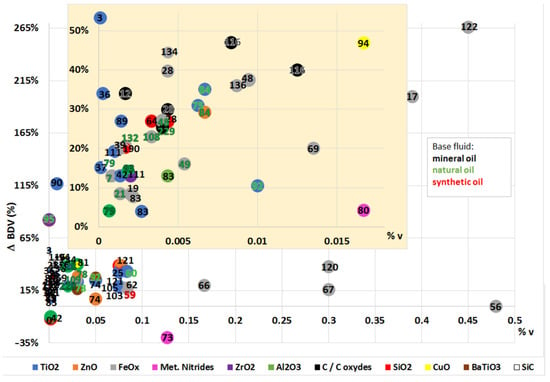

The following tables collect the results from these tests that were carried out under different conditions. Starting with those from alternating current tests, Table 15 shows the range of improvements that were reached in each of the studies that we reviewed. Dispersion in the conditions of nanofluids makes it difficult to notice if a specific component is more prone to greater increases in the breakdown voltages, although they seem more constrained in vegetal base fluids, as their starting BDVs are higher. It must be remembered that the breakdown voltages of the base fluids were already above the required values as they are applied in actual transformers, so any increase would be a step towards more reliable and powerful equipment. Although not all of the tests reflected improvements, most of them were more than 10%, higher than the estimated error of the measurement techniques.

Table 15.

Maximal variations of AC breakdown voltage of nanofluids with respect to the base oils.

In the Figure 9 the different maximal breakdown voltage variations that were noticed in the reviewed works are presented, including the information about the composition of the nanoparticles that were used during the research (represented by the color of the spot in the graph, explained in the legend), their concentration (volume percentage), and the type of base fluid (depending on the colors of the bibliographic reference number, black for mineral oils, green for natural esters, and red for synthetic esters). A deeper view is possible with this figure as it is easy to notice the range of variations that are usually reached with the addition of nanoparticles, as well as which are the most common in these kinds of work, and at which the concentrations or the predominance of works were carried out with mineral oils as bases.

Figure 9.

Comparative of the BDV (AC or lightning impulse) maximal variations depending on the base fluid and the volumetric concentration and type of nanoparticles.

This appears more clearly when the results are refined by statistical methods. By adjusting the obtained data to statistic distributions (frequently Weibull [12,21,35,37,40,64,79,89,93,98,99,103,116], but not exclusively [79,84]), values for the low probability cases may be inferred. These, also in Table 15, represent the minimum voltages at which breakdown could take place, so they are very useful during the design phases, as they represent the maximum voltage that the dielectric can withstand without the risk of failure. Thus, equipment is designed with assigned values that are below these limits. When comparing these statistics from the base fluids with nanofluids, it can be seen that the improvements in the breakdown voltage are frequently even better, with the majority over 20%. Less frequently, DC breakdown voltage tests have been also developed that also show enhanced dielectric strength when in nanofluids compared to the base fluids [14,16,18,45,51,52,104,131], with some exceptions [52].

Similar results are collected in Table 16 and Table 17 relative to the lightning impulse and partial discharges tests, respectively. The lightning impulse results can be separated into two groups based on their polarity. Standards require that these tests must be done using a needle/sphere configuration of electrodes as shown in Figure 10 ([133]), so these tests are driven by changing their polarity, and what conditions fault development occurs is due to their different geometry.

Table 16.

Maximal variations of the breakdown voltage and time to breakdown of nanofluids with respect to the base oils in lightning impulse tests.

Table 17.

Maximal variations of the partial discharge inception voltage and magnitude of the discharges in nanofluids.

Figure 10.

Lightning impulse tests electrodes configuration.

Thus, the results are named according to the polarity of the needle electrode. The negative impulse tests have been classified together with the positive ones, but the sign is opposite. One can see increases in both the voltages and times that are required for a positive streamer to appear; this means that dielectric nanofluids are not only able to withstand higher stresses, but they also take more time to develop failures, giving extra time to stop them. On the other hand, negative streamers show decreases in the voltages and times in most of the references.

This behavior, on the whole, is satisfactory. Firstly, it is usual that the lightning impulse voltages in base fluids are bigger when the polarity is negative rather than positive. Secondly, variations in the negative voltages with nanoparticles are softer than the positive ones, as can be seen in Table 16. Therefore, the use of nanoparticles provides an opportunity to improve the lower lightning impulse breakdown voltage in this kind of dielectric fluid, while the higher voltage decreases much less, or can even improve. Similar trends are observed with the times to streamer formation.

Partial discharges seem constrained in oil nanofluids, as their PDIVs rise while their magnitude and concurrency decline, according to results in Table 17, where the percentages for the partial discharge magnitude are negative. Nevertheless, here again, not all the results were positive [11,28]; these cases show that from a determined voltage, nanofluids changed their behavior and their partial discharges went from being smaller than to larger than the base fluid in the same conditions. Also, for a voltage that is higher than the PDIV, higher acceleration of the streamer velocity was observed in nanofluids, such that they reach a fast-streamer speed at a lower voltage than the respective base fluids [40].

There is a spread theory that tries to explain this behavior of dielectric nanofluids based on the supposed capacity of the nanoparticles to capture electrons in their surface [3,10,11,12,13,14,17,21,28,35,37,38,39,40,41,42,45,46,47,48,52,66,68,73,74,78,83,84,98,99,100,103,104,108,111,114,116,120,122,126,135,136,188,189,190]. This may come from the polarization of nanoparticles with free charges under electric fields; this creates potential wells on the surface and leads field lines, and, therefore, electrons to nanoparticles, which are captured until saturation, as shown in Figure 11. First, the nanoparticle is polarized (a); secondly, it traps negative charges in its surface, increasing the negative charged volume, which distorts the electric field (b); finally the surface is saturated of negative charges (c). In fact, an equilibrium between the captures and liberations may be reached [12,116,188], which in practice, together with the lower mobility of particles [115], would cause a delay in the migration of electrons and their effects, hindering the appearance of streamers, regarding the behavior of the base fluid that is represented in Figure 8. Thus, in Figure 12 the role of the nanoparticles (grey spheres) is represented, that kept the free electrons launched by the base fluid molecules (yellow circles) and reduce the evolution of the electric field.

Figure 11.

Polarization-charging of a nanoparticle under electric stress: (a) Distribution of surface charges in the nanoparticle once polarized, (b) increasement of the negative charge due to the capture of free electrons in surface potential wells, (c) saturation of the potential wells and the nanoparticle.

Figure 12.

Capture of electrons by nanoparticles and delay of the streamer.

Theoretically, this capacity may depend on the particles’ easiness of polarization and depth of traps. These again depend on the particle composition, specifically on their conductivity and permittivity, and their size, respectively. In the first place, traps should be available before electron emergence as soon as possible, so polarization time, represented by the relaxation time constant (τr), might be under streamer spreading time, in the order of nano to microseconds:

According to the previous equation [10,98], particles with a higher conductivity (σ2) and reduced permittivity (ε2) would be more suitable for application in dielectric base fluids, whose properties (σ1 and ε1) also affect the constant. In the second place, the deeper the wells, the harder it would be to scape for electrons and the bigger their capacity, thus being related to the nanoparticle sizes, yet bigger particles present deeper wells [10]. It could also be beneficial from the point of view of saturation charge of each nanoparticle [10], as their surface increases with size, although on the whole, the total available surface of nanoparticles would be minor.

Nevertheless, the particles that were included in dielectric fluids, collected in Table 5, were not only conductive but also semi-conductive or insulating, also presenting improvements of the dielectric strength that were even higher than those that were seen in similar conditions for conductive nanoparticles] [10,35,37,51,83,121,126]. It could be because polarization of these other kinds of particles takes place anyway, not with free charges, but by means of their own surface charges [10,79,83]. This theory is supported by the dielectric constant enhancement that is seen in reviewed articles and explained latterly, as it represents polarization ability.

Other sources link the capture capacity to the formation of a Stern double layer around the particles that may perform as a capacitor [37,41,42,103]. Whatever the cause of electron trapping, its effects on the dielectric properties are clear, being a plausible explanation for the trends that were found in the test results. In AC and positive lightning impulse tests, the lower mobility of the captured electrons should translates to a reduction in the local electric field enhancement at the anode, and thus the need for higher voltages and more time for streamers [17,21,47,66,74,83,99,104,126]. In negative lightning impulse tests, when the needle (where field is more accentuated) acts as a cathode, negatively-charged particles may contribute to the enhancement of the field, reducing the dielectric strength [80,83], as was noticed in the papers that we reviewed. Partial discharges nourish themselves from electrons so nanoparticles hinder their occurrence; hence, higher voltages become necessary [28,73] and discharges are less frequent and lower [11].

To try and verify this theory, specific tests were done using measurements of the energy levels and trap density. These were the thermally stimulated current (TSC) [73,104,105,106,109,114] and pulse electroacoustic tests (PEA [44,105,106,108,114]. The first involves subjecting nanofluid samples to progressively increasing temperatures after they are stressed in a continuous electric field and cooled. These samples, placed in electric circuits as if they were capacitors, will release the electrons that are caught in potential traps as the temperature rises while the electric current is controlled. The results show that currents from nanofluids are much bigger than those from base fluids, what can be read as a confirmation of the presence of a larger number of traps on the nanoparticles’ surface, although they are also present in the base fluid [73,104,105,109,114]. Meanwhile, the second test measures the time evolution of the samples which have been stressed by DC voltage, by using acoustic pressure waves that interact with the field and charge [44,106,114]. In these tests, a lower density charge [114] and electric field [106,114] were noticed in nanofluids compared to the base fluids. When the stress ceased, the decay rates of the charge were larger in the nanofluids, showing an enhanced capacity to dissipate it [44,105,106]. Again, this appears to confirm the described theory according to the charge and field tendency, as electrons would be able to dissipate by jumping from one particle to another according to the trapping-de-trapping mechanism. The noticed reduction in the mobility of charges in dielectric nanofluids is more evidence that supports this theory [53].

Simulations of the breakdown processes, which have been done using models that try to represent the behavior of nanofluids, have also found differences compared to the base fluids, reaching similar conclusions. Thus, in instant density-of-charge curves, while the base fluids showed a rapid rise in the number of cations and electrons in the propagation wave front, nanofluids also experienced this phenomenon with anions together with a reduction in the presence of free electrons. Moreover, it was seen how the wave front progress was delayed at the same instant it was placed closer to the needle in the nanofluid simulations [188,189], which also happened when plotting the maximal field [10,188]. The electric potential between the electrodes was always bigger in the base fluid simulations [10,188]. These effects were more pronounced when the relaxation time constant of the studied nanofluids was lower [10,188,189]. Here again, the capture capacity of the nanoparticles seems to be a suitable explanation. Nevertheless, some authors cast serious doubts about the universal applicability of the scavenging capacity theory to all the dielectric nanofluids [70].

From these results the current interest of researchers in these kinds of investigations can be justified. However, they have not only focused on the effect of nanoparticles on the dielectric strength, but also on its dependence on other variables, as mentioned in previous sections. In this sense, it has been noticed that variations in the dielectric strength were more accentuated for more concentrated nanofluids, with bigger increases of AC [3,12,19,21,28,36,37,39,41,48,49,57,59,60,64,73,74,80,82,83,86,89,90,98,99,108,116,120,121,122,124,129,131,136], DC [14,28,51,131], and lightning impulse breakdown [14,36,37,67,73,83,85,99,108,120,133,136]. This was also observed in the times to breakdown [83] and PDIV [11,28,73]. Partial discharges, for their part, were reduced as the presence of nanoparticles increased [80,136]. These tendencies are noticeable when comparing research that was carried out with different concentrations ([67,120] and [37,126] and [83]).

Several researchers observed the existence of optimal concentrations at which the dielectric strength started to decrease. These results, collected in Table 18, belong to the lower gaps in the concentrations of the prepared nanofluids in the reviewed papers that are shown in Table 2. The higher availability of traps may enhance electron capture when the concentration of nanoparticles is higher [116], until a determined point at which aggregation results in a reduction of the relative surface and a diminution of the capture capacity [19,36,37,111], especially if stability is affected [21].

Table 18.

Optimal concentrations of nanofluids with respect to their dielectric properties.

In fact, in one of analyzed cases, the optimal concentration corresponded with that where the Z potential was the highest [68]. In other cases, the optimal concentration from point of view of dielectric strength aligned with that of the maximum thermally stimulated current [73,75]. This can even be taken to an extreme when nanoparticle aggregation leads to the formation of “electrically conductive bridges” [13,21,28,38,67,83,102,120,122,129], as the one that is represented in Figure 13, to the point where the breakdown voltage of the nanofluid is lower than that of the base fluid [21]. Another reason could be the fact that these charged aggregates enhance the local electric field, promoting streamer occurrence [28,67,73].

Figure 13.

Conductive path of nanoparticles at high concentrations.

It has already been mentioned that, according to this theory, the size of the dispersed nanoparticles should condition the dielectric strength relative to the surface of the solid fraction, and hence the number of available traps would increase as the size of the particles decreased [52,73,116]. Nonetheless, TSC measurements have shown that the depth of the traps increases as the size of nanoparticles increases [109]. Size may also affect the test results depending on the type of electric stresses that are applied. In the case of slow tests, for AC and DC a larger amount of charge is launched than in the lightning impulse or partial discharges. If the size distributions of nanoparticles have a large enough surface, it could be assumed that there would be traps for every charge. On the contrary, if the particles were too big or in the case of aggregation, the relative surface would be comparatively low, and the positive effect of the particles on the dielectric strength may only be seen for the last two kinds of faults [73,133]. As a result, a dependence on the nanoparticles mean size has been observed [21], with the breakdown voltages increasing with particle size [108,109,133], as well as with smaller sizes when comparing different investigations in which other parameters were alike ([66,108]) ([42,83]) ([37,83]). Thus, a compromise solution between the number and depth of traps together with the stability of the dispersion should be reached by controlling the size distribution in nanofluids, as suggested by the existence of an optimal size for the dielectric properties [133].

The surfactant effect by itself over the base fluids and over nanofluids, has also been addressed. In the first less frequent case, the results seem to depend on the surfactant and base fluid combination, as it has been observed with deterioration [85,88], no effect [88], and improvement [73,85] of the dielectric strength. On the other side, most of the studies reflect an improvement of this parameter in nanofluids due to the presence of surfactants [19,36,41,124]; this can also be seen when comparing the references with similar conditions ([36,42]) ([36,83]). The surfactant that is used conditions the magnitude of the effect [54]. This happens even though the surfactant layers reduce the depth of the traps, as the highest potential is reached at the particle surface due to the reverse polarization of these coatings [109]. This behavior could be explained by the aggregation avoidance that is provided by the surfactants that outweighs its drawbacks and improves the dispersion of the particles [85]. Again, an optimal surfactant concentration seems to exist [19], which fits with the formation of simple or double layers and their consequences for the final behavior of nanoparticles. In this case, it is to be noted that this concentration is approximately 2.7% nanoparticles by mass content.

Other determinants include the nanoparticle composition and properties, specifically their electric conductivity [10,28,40,86,111,116,121,124,130,131] and hydrophilicity [32,64], base fluid composition [14], and concoction procedure [21,25]. In general, the achieved variation of the dielectric properties depends on the nature of the nanoparticles that are used [128]. Sometimes a mixture of different solid fraction nanofluids show better capacities that the individual nanofluid that is used for the mixture [128].

4.2. Dielectric Response Spectroscopy

The concept of dielectric response spectroscopy is comprised of different interdependent parameters that together build a non-destructive alternative for dielectric strength tests using breakdown voltage measurements, such as dielectric relaxation spectrometry [102]. This is based on the polarization of samples with time-dependent electric fields, which causes anisotropy and finally affects the relative permittivity or dielectric constant, volumetric resistivity, and dissipation factor [102], which are controlled. In reality, it is used as a supplement rather than an alternative, since most researchers apply both techniques, although not always completely.

Resistivity (and its opposite, conductivity) had been studied as a function of frequency [40,66,75,95,108]; the resistivity decreases as the frequency increases. The results that were obtained from tests with thermal-dielectric nanofluids were inconclusive, as they present both increases [39,40,48,63,82,104,124,127,130,131] and decreases [53,60,66,80,92,95,111,115,129,130,131] in conductivity, and while the resistivity remained approximately constant at the rated frequencies [37,75,108], at short frequencies they registered higher resistivities than the base fluids [66,75,108]. This could be explained by the number of electrons that were launched at short cycles or high frequencies, as particles might not be capable of capturing them completely [66,108].

The dielectric constant, that represents the capability of a material to become polarized, increases with the presence of nanoparticles [22,40,51,53,59,66,74,75,104,108,112,115,126,129,131] and decreases as the frequency rises [40,51,53,66,75,95,108]. Although not all the references completely support this statement [129], equations for its calculation based on the properties and proportion of the nanofluids’ components confirm this tendency [123,124,126], and indicate that it is larger with conductive particles [22,51,126]. This also seems to depend on the size, as some theories relate to smaller particles with higher permittivity [108].

Finally, the dissipation factor (tan δ) analyzes the dielectric losses of an insulator by representing how much the fluid’s impedance deviates from the reactive component due to conductance and polarization losses [54,66]. It is a measurement of insulant quality, as it gets worse, i.e., its value increases, when pollutants, moisture, or products of degradation are present. In these nanofluids it shows erratic behavior, as with resistivity, both increasing [39,40,48,59,60,95,97,108,112,113,115,126,127] and decreasing [51,53,66,75,80,95,113,129], compared to the base fluids, and decreasing as the frequency increases [40,51,53,59,75,95,108,112].