Manufacturing Technics for Fabric/Fiber-Based Triboelectric Nanogenerators: From Yarns to Micro-Nanofibers

Abstract

:1. Introduction

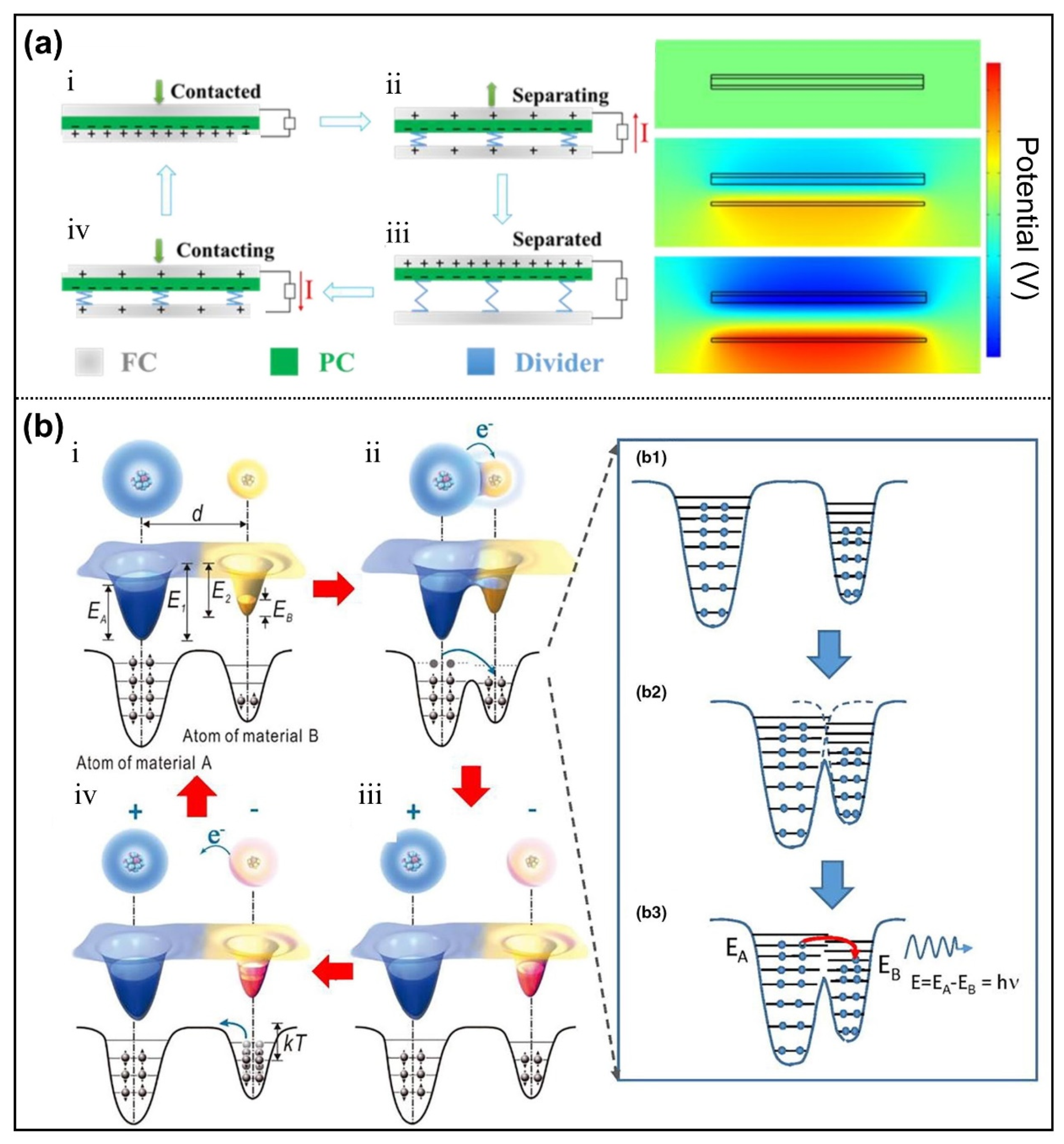

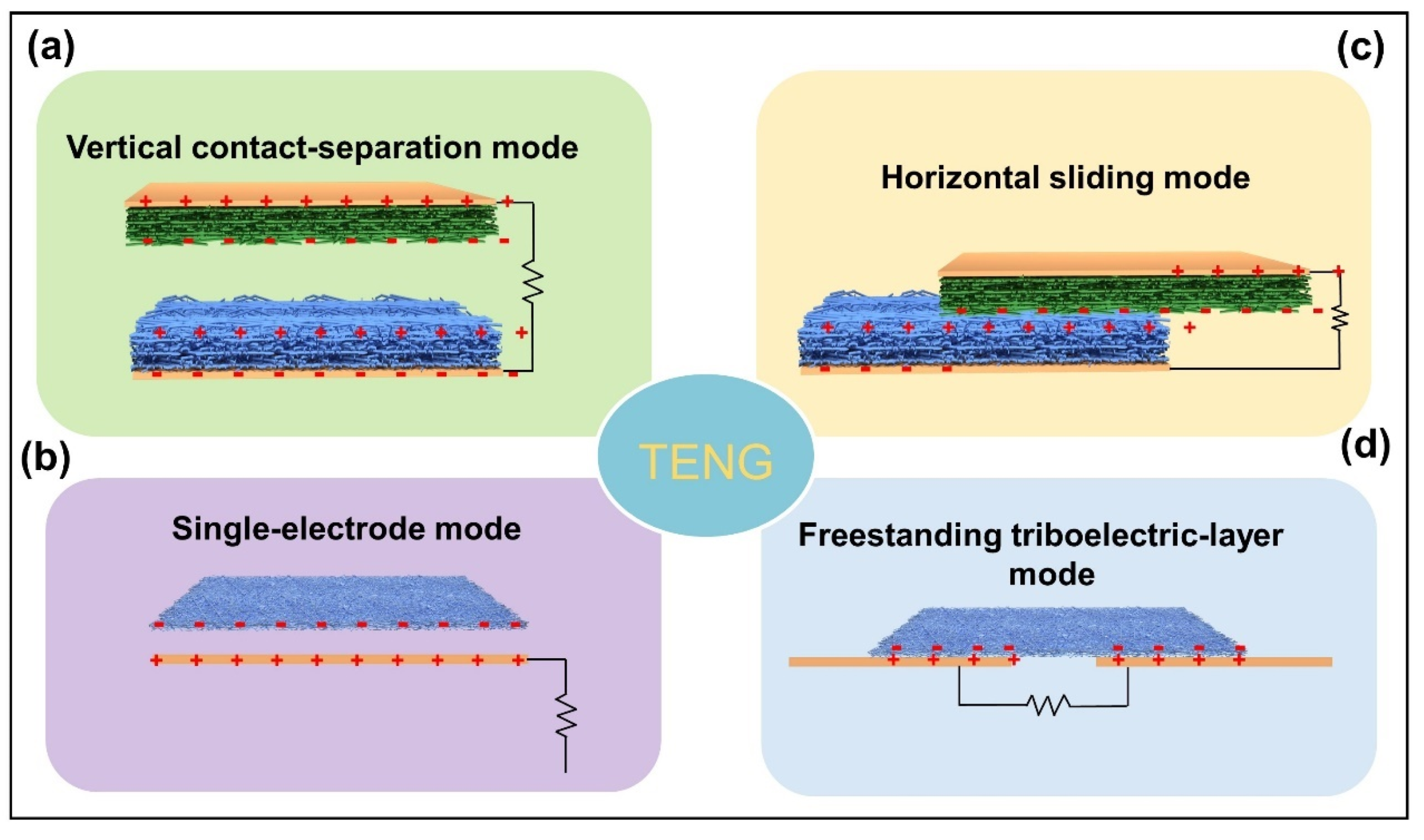

2. The Mechanism and Structure Design of TENG

2.1. Vertical Contact-Separation Mode

2.2. Single-Electrode Mode

2.3. Horizontal Sliding Mode

2.4. Freestanding Triboelectric-Layer Mode

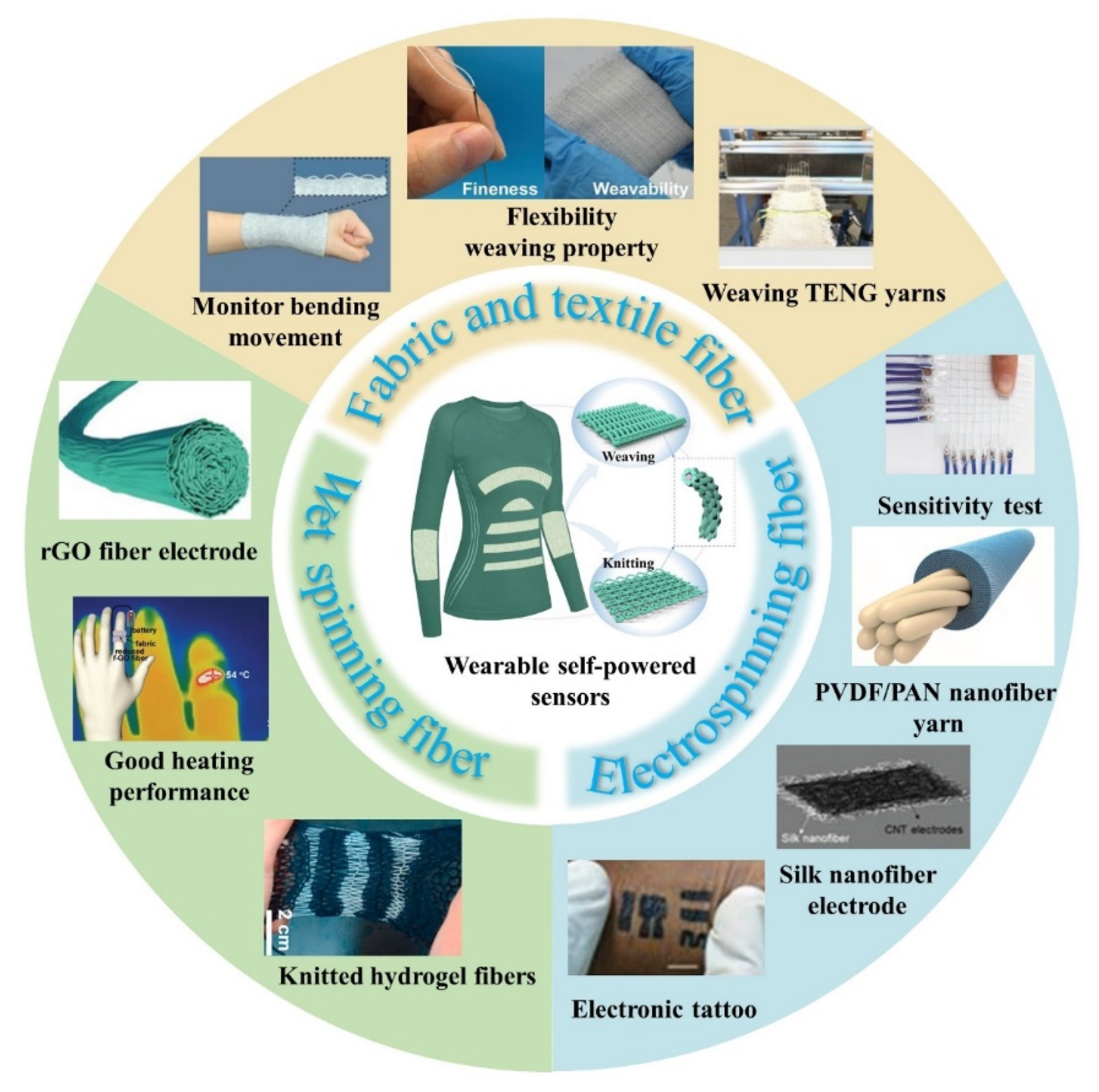

3. Fabric/Fiber-Based Triboelectric Layers in TENGs

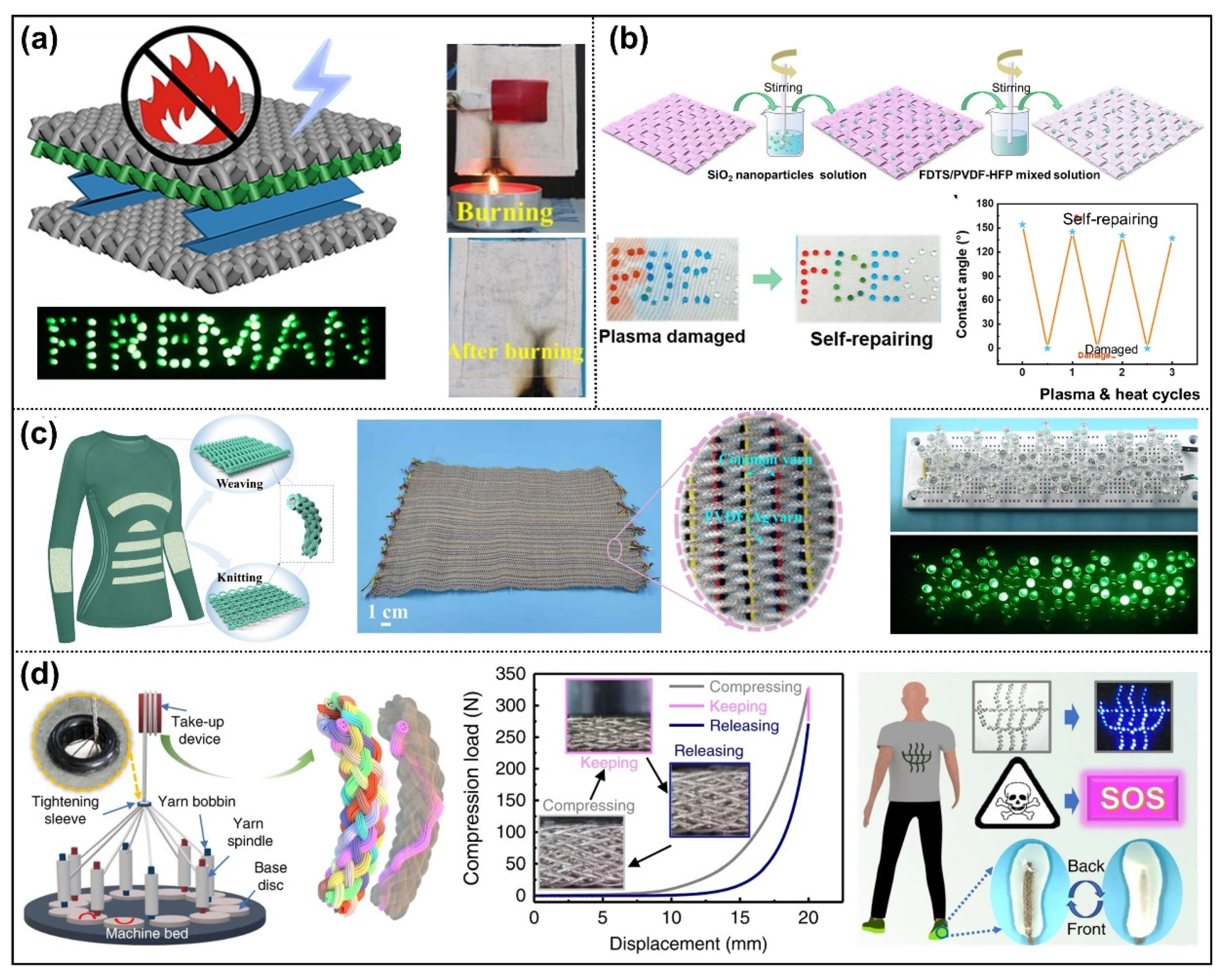

3.1. Fabric and Textile Fiber-Based TENG

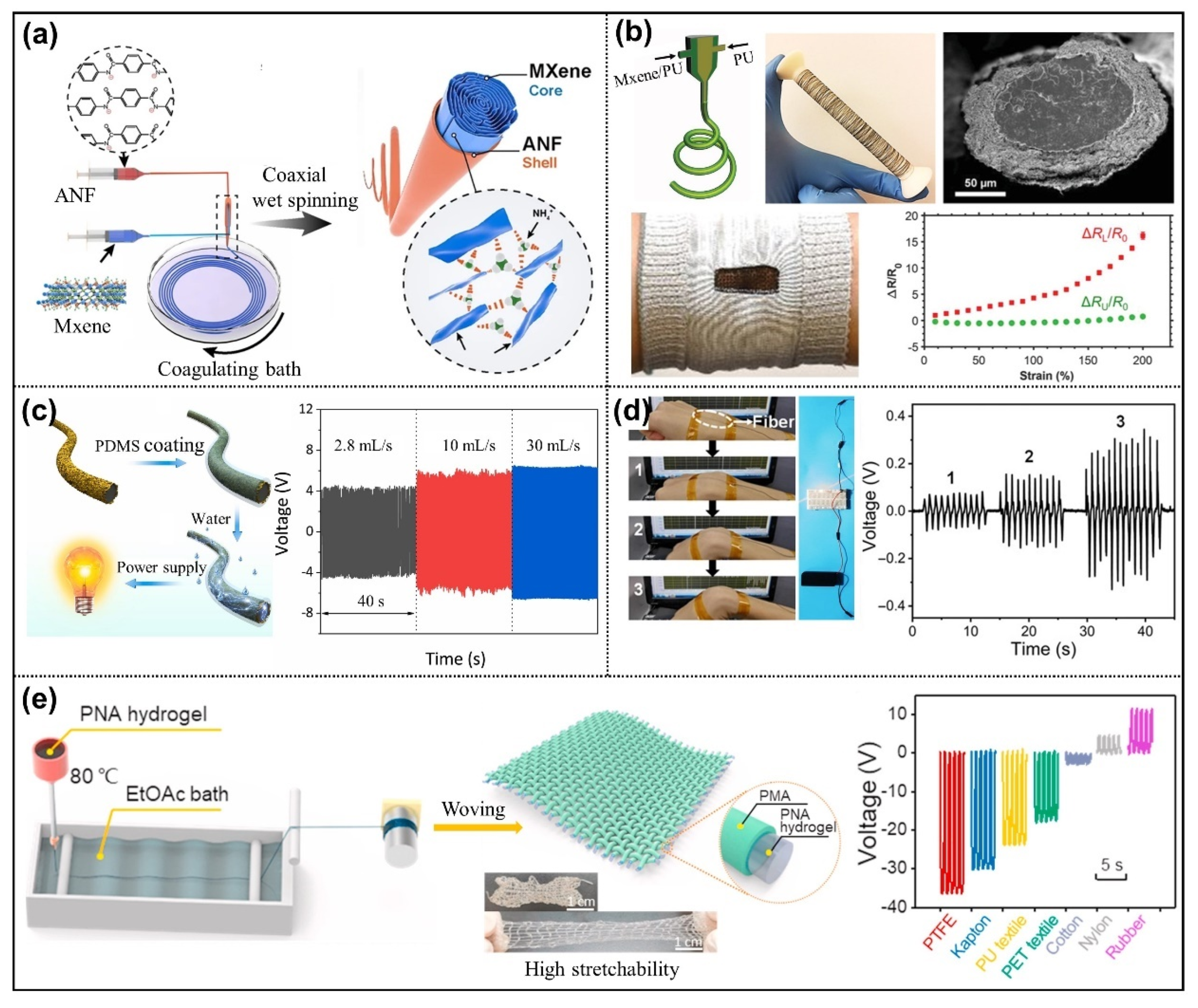

3.2. Micron Fiber-Based TENG Prepared by Wet Spinning

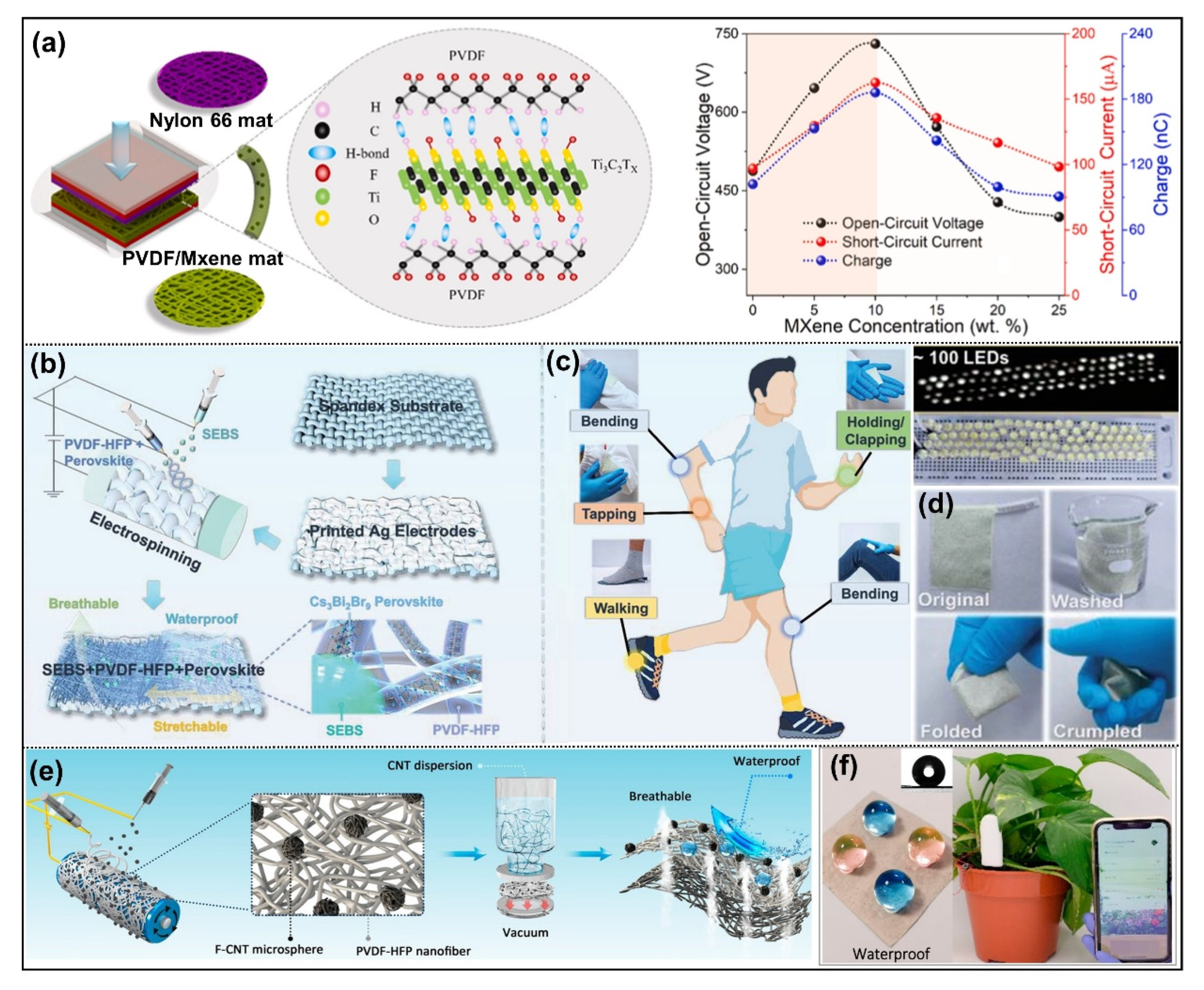

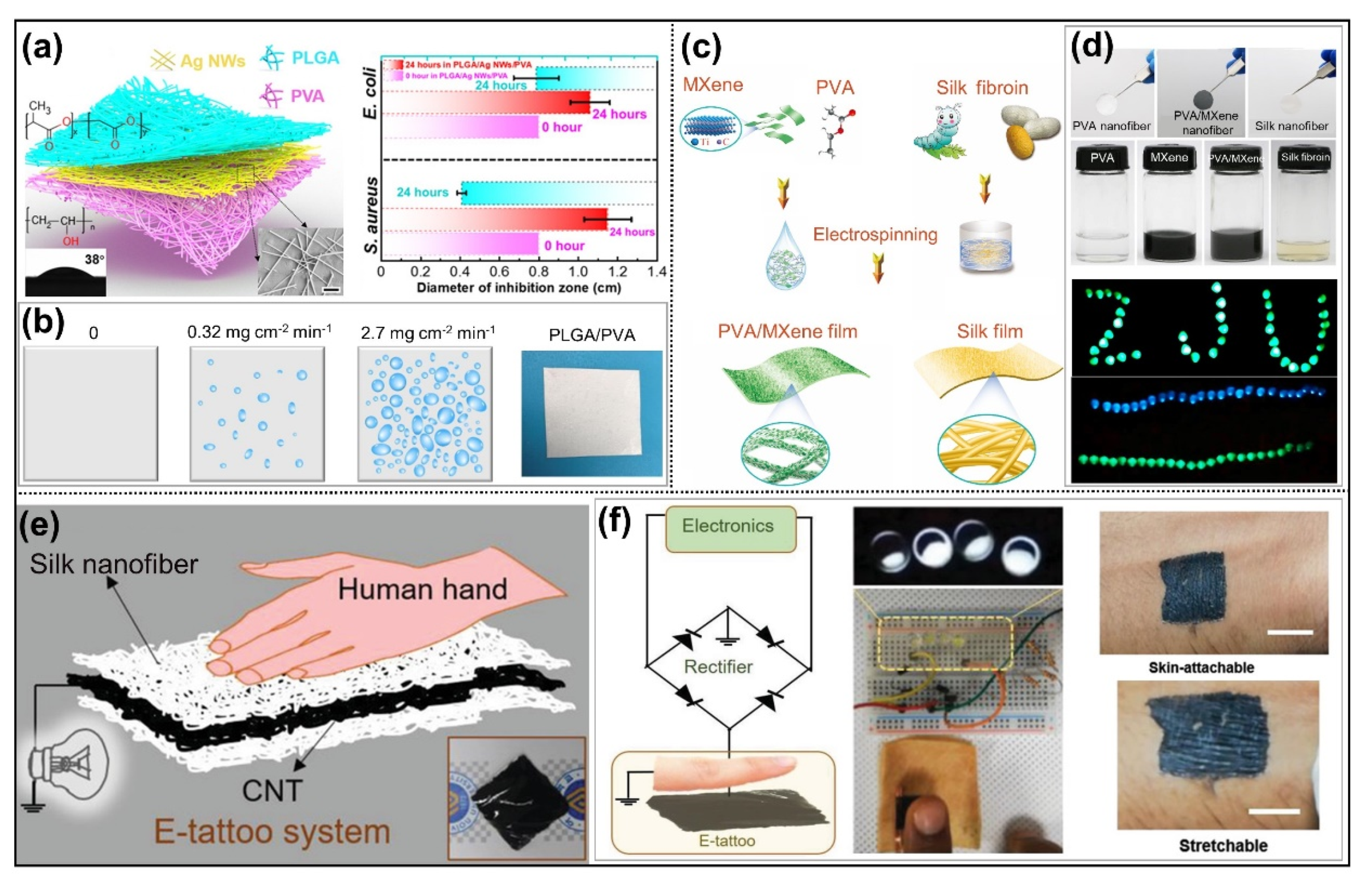

3.3. Nanofiber-Based TENG Prepared by Electrospinning

4. Summary and Outlook

4.1. Potential Applications

4.1.1. Health Care Monitoring

4.1.2. Smart Sports System

4.2. Future Challenges

- First, the preparation of TENG through spinning and weaving requires specific textiles. Not all fabrics can be used as triboelectric materials, because of their weak triboelectricity or wear resistance; besides, the spinnability also pose a great challenge to many triboelectric materials for their unsatisfied mechanical strength in twist and draw process. Moreover, the adding of electrodes to textiles may alter their wearability and contribute additional complexity to the weaving process, which requires more study on the spinning and weaving technics

- As for wet spinning, one of the primary drawbacks is that if a single fiber breaks during the spinning process, the continuity of the spinning process will be disrupted, meaning that the process requirements are quite stringent in comparison to other methods. More than that, the obtained fiber-shaped electrode still needs further coatings of triboelectric layers on the surface, which may cause interfacial adhesion problems. It is quite important to improve the continuity of spinning and enhance the interfacial adhesion between tribomaterial and fiber electrode for the future commercial application.

- Electrospinning is still adopted by researchers thanks to its simplicity, low cost, and extensive selection of triboelectric materials. However, large-scale production inevitably restricts other uses. The technological and process strategies are currently in the research phase.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wei, X.; Li, H.; Yue, W.; Gao, S.; Chen, Z.; Li, Y.; Shen, G. A high-accuracy, real-time, intelligent material perception system with a machine-learning-motivated pressure-sensitive electronic skin. Matter 2022, 5, 1481–1501. [Google Scholar] [CrossRef]

- Dong, J.; Wang, D.; Peng, Y.; Zhang, C.; Lai, F.; He, G.; Ma, P.; Dong, W.; Huang, Y.; Parkin, I.P.; et al. Ultra-stretchable and superhydrophobic textile-based bioelectrodes for robust self-cleaning and personal health monitoring. Nano Energy 2022, 97, 107160. [Google Scholar] [CrossRef]

- Zhao, Y.; Gao, W.; Dai, K.; Wang, S.; Yuan, Z.; Li, J.; Zhai, W.; Zheng, G.; Pan, C.; Liu, C.; et al. Bioinspired Multifunctional Photonic-Electronic Smart Skin for Ultrasensitive Health Monitoring, for Visual and Self-Powered Sensing. Adv. Mater. 2021, 33, 2102332. [Google Scholar] [CrossRef]

- Liu, Y.; Mauter, M.S. Marginal energy intensity of water supply. Energy Environ. Sci. 2021, 14, 4533–4540. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, T.; Tian, Z.; Bibi, K.; Zhang, Y.-Z.; Alshareef, H. MXenes for Energy Harvesting. Adv. Mater. 2022, 34, 2108560. [Google Scholar] [CrossRef]

- Long, Z.; Shi, C.; Wu, C.; Yuan, L.; Qiao, H.; Wang, K. Heterostructure Fe2O3 nanorods@imine-based covalent organic framework for long cycling and high-rate lithium storage. Nanoscale 2022, 14, 1906–1920. [Google Scholar] [CrossRef]

- Long, Z.; Li, R.; Dai, Z.; Shi, C.; Wu, C.; Wei, Q.; Qiao, H.; Wang, K.; Liu, K. Necklace-like NiCo2O4@carbon composite nanofibers derived from metal–organic framework compounds for high-rate lithium storage. Mater. Chem. Front. 2021, 5, 5726–5737. [Google Scholar] [CrossRef]

- Ao, K.; Daoud, W. Facile controlled formation of CoNi alloy and CoO embedded in N-doped carbon as advanced electrocatalysts for oxygen evolution and zinc-air battery. Electrochim. Acta 2021, 395, 139204. [Google Scholar] [CrossRef]

- Huang, L.; Lin, S.; Xu, Z.; Zhou, H.; Duan, J.; Hu, B.; Zhou, J. Fiber-Based Energy Conversion Devices for Human-Body Energy Harvesting. Adv. Mater. 2020, 32, 1902034. [Google Scholar] [CrossRef]

- Long, Z.; Yuan, L.; Shi, C.; Wu, C.; Qiao, H.; Wang, K. Porous Fe2O3 nanorod-decorated hollow carbon nanofibers for high-rate lithium storage. Adv. Compos. Hybrid. Mater. 2022, 5, 370–382. [Google Scholar] [CrossRef]

- Jia, C.; Xia, Y.; Zhu, Y.; Wu, M.; Zhu, S.; Wang, X. High-Brightness, High-Resolution, and Flexible Triboelectrification-Induced Electroluminescence Skin for Real-Time Imaging and Human–Machine Information Interaction. Adv. Funct. Mater. 2022, 32, 2201292. [Google Scholar] [CrossRef]

- Fan, C.; Wang, D.; Huang, J.; Ke, H.; Wei, Q. A highly sensitive epidermal sensor based on triple-bonded hydrogels for strain/pressure sensing. Compos. Commun. 2021, 28, 100951. [Google Scholar] [CrossRef]

- Huang, J.; Zhao, M.; Cai, Y.; Zimniewska, M.; Li, D.; Wei, Q. A Dual-Mode Wearable Sensor Based on Bacterial Cellulose Reinforced Hydrogels for Highly Sensitive Strain/Pressure Sensing. Adv. Electron. Mater. 2020, 6, 1900934. [Google Scholar] [CrossRef]

- Ao, K.; Shi, J.; Zhang, X.; Daoud, W.A. Tuning oxygen vacancies in spinel nanosheets for binder-free oxygen cathodes with superior catalytic activity in zinc-air batteries. J. Power Sources 2022, 521, 230918. [Google Scholar] [CrossRef]

- Sun, J.; Tu, K.; Büchele, S.; Koch, S.M.; Ding, Y.; Ramakrishna, S.N.; Stucki, S.; Guo, H.; Wu, C.; Keplinger, T.; et al. Functionalized wood with tunable tribopolarity for efficient triboelectric nanogenerators. Matter 2021, 4, 3049–3066. [Google Scholar] [CrossRef]

- Wu, C.; Wang, A.C.; Ding, W.; Guo, H.; Wang, Z. Triboelectric Nanogenerator: A Foundation of the Energy for the New Era. Adv. Energy Mater. 2019, 9, 1802906. [Google Scholar] [CrossRef]

- Wu, C.; Tetik, H.; Cheng, J.; Ding, W.; Guo, H.; Tao, X.; Zhou, N.; Zi, Y.; Wu, Z.; Wu, H.; et al. Electrohydrodynamic Jet Printing Driven by a Triboelectric Nanogenerator. Adv. Funct. Mater. 2019, 29, 1901102. [Google Scholar] [CrossRef]

- Sun, J.; Guo, H.; Schadli, G.N.; Tu, K.; Schar, S.; Schwarze, F.W.M.R.; Panzarasa, G.; Ribera, J.; Burgert, I. Enhanced mechanical energy conversion with selectively decayed wood. Sci. Adv. 2021, 7, eabd9138. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Guo, H.; Ribera, J.; Wu, C.; Tu, K.; Binelli, M.; Panzarasa, G.; Schwarze, F.W.M.R.; Wang, Z.L.; Burgert, I. Sustainable and Biodegradable Wood Sponge Piezoelectric Nanogenerator for Sensing and Energy Harvesting Applications. ACS Nano 2020, 14, 14665–14674. [Google Scholar] [CrossRef]

- Han, J.; Xu, C.; Zhang, J.; Xu, N.; Xiong, Y.; Cao, X.; Liang, Y.; Zheng, L.; Sun, J.; Zhai, J.; et al. Multifunctional Coaxial Energy Fiber toward Energy Harvesting, Storage, and Utilization. ACS Nano 2021, 15, 1597–1607. [Google Scholar] [CrossRef]

- Wu, C.; Jiang, P.; Li, W.; Guo, H.; Wang, J.; Chen, J.; Prausnitz, M.R.; Wang, Z.L. Self-Powered Iontophoretic Transdermal Drug Delivery System Driven and Regulated by Biomechanical Motions. Adv. Funct. Mater. 2020, 30, 1907378. [Google Scholar] [CrossRef]

- Liu, L.; Xu, W.; Ding, Y.; Agarwal, S.; Greiner, A.; Duan, G. A review of smart electrospun fibers toward textiles. Compos. Commun. 2020, 22, 100506. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, H.; Blanloeuil, P.; Li, G.; Sha, Z.; Wang, D.; Lei, W.; Boyer, C.; Yu, Y.; Tian, R.; et al. Enhancing the triboelectricity of stretchable electrospun piezoelectric polyvinylidene fluoride/boron nitride nanosheets composite nanofibers. Compos. Commun. 2020, 22, 100535. [Google Scholar] [CrossRef]

- Ma, L.; Wu, R.; Patil, A.; Yi, J.; Liu, D.; Fan, X.; Sheng, F.; Zhang, Y.; Liu, S.; Shen, S.; et al. Acid and Alkali-Resistant Textile Triboelectric Nanogenerator as a Smart Protective Suit for Liquid Energy Harvesting and Self-Powered Monitoring in High-Risk Environments. Adv. Funct. Mater. 2021, 31, 2102963. [Google Scholar] [CrossRef]

- Ma, L.; Zhou, M.; Wu, R.; Patil, A.; Gong, H.; Zhu, S.; Wang, T.; Zhang, Y.; Shen, S.; Dong, K.; et al. Continuous and Scalable Manufacture of Hybridized Nano-Micro Triboelectric Yarns for Energy Harvesting and Signal Sensing. ACS Nano 2020, 14, 4716–4726. [Google Scholar] [CrossRef]

- Gogurla, N.; Kim, Y.; Cho, S.; Kim, J.; Kim, S. Multifunctional and Ultrathin Electronic Tattoo for On-Skin Diagnostic and Therapeutic Applications. Adv. Mater. 2021, 33, 2008308. [Google Scholar] [CrossRef]

- Tang, P.; Deng, Z.; Zhang, Y.; Liu, L.-X.; Wang, Z.; Yu, Z.-Z.; Zhang, H.B. Tough, Strong, and Conductive Graphene Fibers by Optimizing Surface Chemistry of Graphene Oxide Precursor. Adv. Funct. Mater. 2022, 32, 2112156. [Google Scholar] [CrossRef]

- Shuai, L.; Guo, Z.H.; Zhang, P.; Wan, J.; Pu, X.; Wang, Z. Stretchable, self-healing, conductive hydrogel fibers for strain sensing and triboelectric energy-harvesting smart textiles. Nano Energy 2020, 78, 105389. [Google Scholar] [CrossRef]

- Luo, J.; Gao, W.; Wang, Z.L. The Triboelectric Nanogenerator as an Innovative Technology toward Intelligent Sports. Adv. Mater. 2021, 33, 2004178. [Google Scholar] [CrossRef]

- Liang, C.; Gu, H.; Xia, Y.; Wang, Z.; Liu, X.; Xia, J.; Zuo, S.; Hu, Y.; Gao, X.; Hui, W.; et al. Two-dimensional Ruddlesden-Popper layered perovskite solar cells based on phase-pure thin films. Nat. Energy 2021, 6, 38–45. [Google Scholar] [CrossRef]

- Wang, Z.L.; Wang, A.C. On the origin of contact-electrification. Mater. Today 2019, 30, 34–51. [Google Scholar] [CrossRef]

- Li, X.M.; Ning, X.Y.; Li, L.X.; Wang, X.; Li, B.W.; Li, J.D.; Yin, J.; Guo, W.L. Performance and power management of droplets-based electricity generators. Nano Energy 2022, 92, 106705. [Google Scholar] [CrossRef]

- Dudem, B.; Dharmasena, R.D.I.G.; Riaz, R.; Vivekananthan, V.; Wijayantha, K.G.U.; Lugli, P.; Petti, L.; Silva, S.R.P. Wearable Triboelectric Nanogenerator from Waste Materials for Autonomous Information Transmission via Morse Code. ACS. Appl. Mater. Inter. 2022, 14, 5328–5337. [Google Scholar] [CrossRef] [PubMed]

- Zou, H.; Zhang, Y.; Guo, L.; Wang, P.; He, X.; Dai, G.; Zheng, H.; Chen, C.; Wang, A.C.; Xu, C.; et al. Quantifying the triboelectric series. Nat. Commun. 2019, 10, 1427. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cheng, R.; Dong, K.; Liu, L.; Ning, C.; Chen, P.; Peng, X.; Liu, D.; Wang, Z. Flame-Retardant Textile-Based Triboelectric Nanogenerators for Fire Protection Applications. ACS Nano 2020, 14, 15853–15863. [Google Scholar] [CrossRef] [PubMed]

- Dong, K.; Peng, X.; Wang, Z. Fiber/Fabric-Based Piezoelectric and Triboelectric Nanogenerators for Flexible/Stretchable and Wearable Electronics and Artificial Intelligence. Adv. Mater. 2020, 32, 1902549. [Google Scholar] [CrossRef] [PubMed]

- Han, G.H.; Kim, S.W.; Kim, J.K.; Lee, S.H.; Jeong, M.H.; Song, H.C.; Choi, K.J.; Baik, J.M. 3D Multiple Triangular Prisms for Highly Sensitive Non-Contact Mode Triboelectric Bending Sensors. Nanomaterials 2022, 12, 1499. [Google Scholar] [CrossRef]

- Wu, H.; Wang, J.; Wu, Z.; Kang, S.; Wei, X.; Wang, H.; Luo, H.; Yang, L.; Liao, R.; Wang, Z. Multi-Parameter Optimized Triboelectric Nanogenerator Based Self-Powered Sensor Network for Broadband Aeolian Vibration Online-Monitoring of Transmission Lines. Adv. Energy Mater. 2022, 12, 2103654. [Google Scholar] [CrossRef]

- He, H.; Liu, J.; Wang, Y.; Zhao, Y.; Qin, Y.; Zhu, Z.; Yu, Z.; Wang, J. An Ultralight Self-Powered Fire Alarm e-Textile Based on Conductive Aerogel Fiber with Repeatable Temperature Monitoring Performance Used in Firefighting Clothing. ACS Nano 2022, 16, 2953–2967. [Google Scholar] [CrossRef]

- Zhao, Z.; Wei, B.; Wang, Y.; Huang, X.; Li, B.; Lin, F.; Ma, L.; Zhang, Q.; Zou, Y.; Yang, F.; et al. An Array of Flag-Type Triboelectric Nanogenerators for Harvesting Wind Energy. Nanomaterials 2022, 12, 721. [Google Scholar] [CrossRef]

- Wang, S.; Lin, L.; Xie, Y.; Jing, Q.; Niu, S.; Wang, Z. Sliding-Triboelectric Nanogenerators Based on In-Plane Charge-Separation Mechanism. Nano Lett. 2013, 13, 2226–2233. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, S.; Xie, Y.; Niu, S.; Lin, L.; Wang, Z. Freestanding Triboelectric-Layer-Based Nanogenerators for Harvesting Energy from a Moving Object or Human Motion in Contact and Non-contact Modes. Adv. Mater. 2014, 26, 2818–2824. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Cui, P.; Zhang, J.; Ge, Y.; Liu, X.; Xuan, N.; Gu, G.; Cheng, G.; Du, Z. A stretchable self-powered triboelectric tactile sensor with EGaIn alloy electrode for ultra-low-pressure detection. Nano Energy 2021, 89, 106320. [Google Scholar] [CrossRef]

- Lin, S.; Hao, J.; Sda, B.; Sh, A.; Hk, A.; Hx, A.; Jc, C.; Wxb, C.; Sz, D.; Sl, E. High-performance triboelectric nanogenerator based on electrospun PVDF-graphene nanosheet composite nanofibers for energy harvesting—ScienceDirect. Nano Energy 2020, 80, 105599. [Google Scholar]

- Ye, C.; Liu, D.; Peng, X.; Jiang, Y.; Cheng, R.; Ning, C.; Sheng, F.; Zhang, Y.; Dong, K.; Wang, Z. A Hydrophobic Self-Repairing Power Textile for Effective Water Droplet Energy Harvesting. ACS Nano 2021, 15, 18172–18181. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Zhang, Y.; Yi, J.; Peng, X.; Cheng, R.; Ning, C.; Sheng, F.; Wang, S.; Dong, K.; Wang, Z. Large-scale fabrication of core-shell triboelectric braided fibers and power textiles for energy harvesting and plantar pressure monitoring. EcoMat 2022, 4, e12191. [Google Scholar] [CrossRef]

- Ma, L.; Wu, R.; Liu, S.; Patil, A.; Gong, H.; Yi, J.; Sheng, F.; Zhang, Y.; Wang, J.; Wang, J.; et al. A Machine-Fabricated 3D Honeycomb-Structured Flame-Retardant Triboelectric Fabric for Fire Escape and Rescue. Adv. Mater. 2020, 32, 2003897. [Google Scholar] [CrossRef]

- Dong, K.; Peng, X.; An, J.; Wang, A.C.; Luo, J.; Sun, B.; Wang, J.; Wang, Z. Shape adaptable and highly resilient 3D braided triboelectric nanogenerators as e-textiles for power and sensing. Nat. Commun. 2020, 11, 2868. [Google Scholar] [CrossRef]

- Lan, L.; Jiang, C.; Yao, Y.; Ping, J.; Ying, Y. A stretchable and conductive fiber for multifunctional sensing and energy harvesting. Nano Energy 2021, 84, 105954. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Mandal, D. Synergistically enhanced piezoelectric output in highly aligned 1D polymer nanofibers integrated all-fiber nanogenerator for wearable nano-tactile sensor. Nano Energy 2018, 53, 245–257. [Google Scholar] [CrossRef]

- Bhatta, T.; Maharjan, P.; Cho, H.; Park, C.; Yoon, S.H.; Sharma, S.; Salauddin, M.; Rahman, M.T.; Rana, S.M.S.; Park, J.Y. High-performance triboelectric nanogenerator based on MXene functionalized polyvinylidene fluoride composite nanofibers. Nano Energy 2021, 81, 105670. [Google Scholar] [CrossRef]

- Li, Y.; Xiong, J.; Lv, J.; Chen, J.; Gao, D.; Zhang, X.; Lee, P. Mechanically interlocked stretchable nanofibers for multifunctional wearable triboelectric nanogenerator. Nano Energy 2020, 78, 105358. [Google Scholar] [CrossRef]

- Jiang, F.; Zhou, X.; Lv, J.; Chen, J.; Chen, J.; Kongcharoen, H.; Zhang, Y.; Lee, P. Stretchable, Breathable, and Stable Lead-Free Perovskite/Polymer Nanofiber Composite for Hybrid Triboelectric and Piezoelectric Energy Harvesting. Adv. Mater. 2022, 34, 2200042. [Google Scholar] [CrossRef] [PubMed]

- Lan, L.; Xiong, J.; Gao, D.; Li, Y.; Chen, J.; Lv, J.; Ping, J.; Ying, Y.; Lee, P. Breathable Nanogenerators for an On-Plant Self-Powered Sustainable Agriculture System. ACS Nano 2021, 15, 5307–5315. [Google Scholar] [CrossRef] [PubMed]

- Peng, X.; Dong, K.; Ye, C.; Jiang, Y.; Wang, Z. A breathable, biodegradable, antibacterial, and self-powered electronic skin based on all-nanofiber triboelectric nanogenerators. Sci. Adv. 2020, 6, eaba9624. [Google Scholar] [CrossRef] [PubMed]

- Jiang, C.; Wu, C.; Li, X.; Yao, Y.; Lan, L.; Zhao, F.; Ye, Z.; Ying, Y.; Ping, J. All-electrospun flexible triboelectric nanogenerator based on metallic MXene nanosheets. Nano Energy 2019, 59, 268–276. [Google Scholar] [CrossRef]

- Gogurla, N.; Kim, S. Self-Powered and Imperceptible Electronic Tattoos Based on Silk Protein Nanofiber and Carbon Nanotubes for Human-Machine Interfaces. Adv. Energy Mater. 2021, 11, 2100801. [Google Scholar] [CrossRef]

- Dong, K.; Peng, X.; Cheng, R.; Ning, C.; Jiang, Y.; Zhang, Y.; Wang, Z. Advances in High-Performance Autonomous Energy and Self-Powered Sensing Textiles with Novel 3D Fabric Structures. Adv. Mater. 2022, 34, 2109355. [Google Scholar] [CrossRef]

- Xie, L.; Chen, X.; Wen, Z.; Yang, Y.; Shi, J.; Chen, C.; Peng, M.; Liu, Y.; Sun, X. Spiral Steel Wire Based Fiber-Shaped Stretchable and Tailorable Triboelectric Nanogenerator for Wearable Power Source and Active Gesture Sensor. Nano-Micro Lett. 2019, 11, 39. [Google Scholar] [CrossRef] [Green Version]

- Xiang, S.; Zhang, N.; Fan, X. From Fiber to Fabric: Progress Towards Photovoltaic Energy Textile. Adv. Fiber Mater. 2021, 3, 76–106. [Google Scholar] [CrossRef]

- Zhou, J.; Xu, X.; Xin, Y.; Lubineau, G. Coaxial Thermoplastic Elastomer-Wrapped Carbon Nanotube Fibers for Deformable and Wearable Strain Sensors. Adv. Funct. Mater. 2018, 28, 1705591. [Google Scholar] [CrossRef]

- Liu, L.-X.; Chen, W.; Zhang, H.-B.; Ye, L.; Wang, Z.; Zhang, Y.; Min, P.; Yu, Z.-Z. Super-Tough and Environmentally Stable Aramid. Nanofiber@MXene Coaxial Fibers with Outstanding Electromagnetic Interference Shielding Efficiency. Nano-Micro Lett. 2022, 14, 111. [Google Scholar] [CrossRef] [PubMed]

- Seyedin, S.; Uzun, S.; Levitt, A.; Anasori, B.; Dion, G.; Gogotsi, Y.; Razal, J. MXene Composite and Coaxial Fibers with High Stretchability and Conductivity for Wearable Strain Sensing Textiles. Adv. Funct. Mater. 2020, 30, 1910504. [Google Scholar] [CrossRef]

- Liu, Q.; Zhao, A.; He, X.; Li, Q.; Sun, J.; Lei, Z.; Liu, Z. Full-Temperature All-Solid-State Ti3C2Tx/Aramid Fiber Supercapacitor with Optimal Balance of Capacitive Performance and Flexibility. Adv. Funct. Mater. 2021, 31, 2010944. [Google Scholar] [CrossRef]

- Xiang, S.; Liu, D.; Jiang, C.; Zhou, W.; Ling, D.; Zheng, W.; Sun, X.; Li, X.; Mao, Y.; Shan, C. Liquid-Metal-Based Dynamic Thermoregulating and Self-Powered Electronic Skin. Adv. Funct. Mater. 2021, 31, 2100940. [Google Scholar] [CrossRef]

- Zheng, L.; Zhu, M.; Wu, B.; Li, Z.; Sun, S.; Wu, P. Conductance-stable liquid metal sheath-core microfibers for stretchy smart fabrics and self-powered sensing. Sci. Adv. 2021, 7, eabg4041. [Google Scholar] [CrossRef]

- He, P.; Guo, R.; Hu, K.; Liu, K.; Ni, Y. Tough and Super-stretchable conductive double network hydrogels with multiple sensations and moisture-electric generation. Chem. Eng. J. 2021, 414, 128726. [Google Scholar] [CrossRef]

- Zhang, Y.-Z.; El-Demellawi, J.K.; Jiang, Q.; Ge, G.; Liang, H.; Lee, K.; Dong, X.; Alshareef, H. MXene hydrogels: Fundamentals and applications. Chem. Soc. Rev. 2020, 49, 7229–7251. [Google Scholar] [CrossRef]

- Gong, J.P.; Katsuyama, Y.; Kurokawa, T.; Osada, Y. Double-Network Hydrogels with Extremely High Mechanical Strength. Adv. Mater. 2003, 15, 1155–1158. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, W.; Deng, L.; Zhang, H. A triboelectric nanogenerator based on temperature-stable high dielectric BaTiO3-based ceramic powder for energy harvesting. Nano Energy 2021, 87, 106176. [Google Scholar] [CrossRef]

- Li, X.; Ji, D.; Yu, B.; Ghosh, R.; He, J.; Qin, X.; Ramakrishna, S. Boosting piezoelectric and triboelectric effects of PVDF nanofiber through carbon-coated piezoelectric nanoparticles for highly sensitive wearable sensors. Chem. Eng. J. 2021, 426, 130345. [Google Scholar] [CrossRef]

- Li, X.J.; Jiang, C.M.; Ying, Y.B.; Ping, J.F. Biotriboelectric Nanogenerators: Materials, Structures, and Applications. Adv. Energy Mater. 2020, 10, 2002001. [Google Scholar] [CrossRef]

- Chen, G.; Xu, L.; Zhang, P.; Chen, B.; Wang, G.; Ji, J.; Pu, X.; Wang, Z. Seawater Degradable Triboelectric Nanogenerators for Blue Energy. Adv. Mater. Technol. 2020, 5, 2000455. [Google Scholar] [CrossRef]

- Pan, R.; Xuan, W.; Chen, J.; Dong, S.; Jin, H.; Wang, X.; Li, H.; Luo, J. Fully biodegradable triboelectric nanogenerators based on electrospun polylactic acid and nanostructured gelatin films. Nano Energy 2018, 45, 193–202. [Google Scholar] [CrossRef]

- Wang, X.; Ronsin, O.; Gravez, B.; Farman, N.; Baumberger, T.; Jaisser, F.; Coradin, T.; Hélary, C. Nanostructured Dense Collagen-Polyester Composite Hydrogels as Amphiphilic Platforms for Drug Delivery. Adv. Sci. 2021, 8, 2004213. [Google Scholar] [CrossRef]

- Khandelwal, G.; Joseph Raj, N.P.M.; Alluri, N.R.; Kim, S.J. Enhancing Hydrophobicity of Starch for Biodegradable Material-Based Triboelectric Nanogenerators. ACS Sustain. Chem. Eng. 2021, 9, 9011–9017. [Google Scholar] [CrossRef]

- Dong, X.; Liu, Q.; Liu, S.; Wu, R.; Ma, L. Silk Fibroin Based Conductive Film for Multifunctional Sensing and Energy Harvesting. Adv. Fiber Mater. 2022, 4, 885–893. [Google Scholar] [CrossRef]

- Han, K.; Luo, J.; Feng, Y.; Xu, L.; Tang, W.; Wang, Z. Self-powered electrocatalytic ammonia synthesis directly from air as driven by dual triboelectric nanogenerators. Energy Environ. Sci. 2020, 13, 2450–2458. [Google Scholar] [CrossRef]

- Dong, F.; Pang, Z.; Yang, S.; Lin, Q.; Song, S.; Li, C.; Ma, X.; Nie, S. Improving Wastewater Treatment by Triboelectric-Photo/Electric Coupling Effect. ACS Nano 2022, 16, 3449–3475. [Google Scholar] [CrossRef]

- Cai, C.; Mo, J.; Lu, Y.; Zhang, N.; Wu, Z.; Wang, S.; Nie, S. Integration of a porous wood-based triboelectric nanogenerator and gas sensor for real-time wireless food-quality assessment. Nano Energy 2021, 83, 105833. [Google Scholar] [CrossRef]

- Lv, P.; Lu, X.; Wang, L.; Feng, W. Nanocellulose-Based Functional Materials: From Chiral Photonics to Soft Actuator and Energy Storage. Adv. Funct. Mater. 2021, 31, 2104991. [Google Scholar] [CrossRef]

| Electrodes | Triboelectric Materials | Structures and Substrates | Main Methods | Power Outputs | Ref. |

|---|---|---|---|---|---|

| Silver | PDMS | Core-shell type; carbon fiber | Coating | 2.5 μW | [20] |

| Conductive yarn | PTFE yarn | Core-shell type; yarns; fabric | Fancy twisting | 3.36 µA; 180.06 V. | [24] |

| Conductive fiber | PVDF/PAN | Core-shell structure; yarns; fabric | Electrospinning; woven | 40.8 V, 0.705 μA cm–2 | [25] |

| Silver paste coated cotton | PTFE | Textile fabric | Coating | 343.19 mW m−2 | [35] |

| Conductive fabric | FDTS, PVDF-HFP | Textile fabric | Dipping | 0.11 mW, 22 V | [45] |

| Silver-coated nylon yarns | PVDF | Core-shell type; woven fabric | Weaving | 1008 mW m−2 | [46] |

| Conductive yarn | PI | 3D honeycomb structure; woven fabric | Hollow spindle fancy twisting | 73.55 µW m−1 | [47] |

| Silver-plated nylon | PDMS | 3D braiding structure; Braided yarn, axial yarn | Multiaxial yarn winding | 26 W m−3 | [48] |

| CNT, MXene, Au | PDMS | Shell-core structure; PU fiber | Wet spinning; dipping | 6 V | [49] |

| Hydrogel electrode | PMA | Shell-core structure; woven hydrogel fabric | Wet spinning; coating | ~88 mW m−2 | [28] |

| Ni; Al | PVDF/G; PA 6 | Nanofiber film | Electrospinning; spin-coating | ~130.2 W m−2 | [44] |

| Conductive fabric | Pt-PVDF | Nanofiber film | Electrospinning | 22 µW cm−2 | [50] |

| Copper | PVDF/Mxene; PA 6/6 | Nanofiber film | Electrospinning | 11.213 Wm−2 | [51] |

| Liquid metal; Ag flakes | PVDF-HFP | Nanofiber film | Electrospinning; electrospraying | 219.66 mW m−2 | [52] |

| Silver | PVDF-HFP/ Cs3Bi2Br9 | Nanofiber film | Electrospinning; electrospraying | 2.34 Wm−2 | [53] |

| CNT electrode | PVDF-HFP; F-CNT | Nanofiber film | Electrospinning; electrospraying | 330.6 μW cm−2 | [54] |

| AgNWs | PLGA | Sandwich structure; nanofiber film | Electrospinning | 130 mW m−2 | [55] |

| Al | Silk fibroin; PVA/MXene | Nanofiber film | Electrospinning | 1087.6 mW m−2 | [56] |

| CNT | Silk fiber | Sandwich structure; nanofiber film | Electrospinning | 6 mW m−2 | [57] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, C.; Zhang, Y.; Liao, S.; Zhao, M.; Lv, P.; Wei, Q. Manufacturing Technics for Fabric/Fiber-Based Triboelectric Nanogenerators: From Yarns to Micro-Nanofibers. Nanomaterials 2022, 12, 2703. https://doi.org/10.3390/nano12152703

Fan C, Zhang Y, Liao S, Zhao M, Lv P, Wei Q. Manufacturing Technics for Fabric/Fiber-Based Triboelectric Nanogenerators: From Yarns to Micro-Nanofibers. Nanomaterials. 2022; 12(15):2703. https://doi.org/10.3390/nano12152703

Chicago/Turabian StyleFan, Chonghui, Yuxin Zhang, Shiqin Liao, Min Zhao, Pengfei Lv, and Qufu Wei. 2022. "Manufacturing Technics for Fabric/Fiber-Based Triboelectric Nanogenerators: From Yarns to Micro-Nanofibers" Nanomaterials 12, no. 15: 2703. https://doi.org/10.3390/nano12152703

APA StyleFan, C., Zhang, Y., Liao, S., Zhao, M., Lv, P., & Wei, Q. (2022). Manufacturing Technics for Fabric/Fiber-Based Triboelectric Nanogenerators: From Yarns to Micro-Nanofibers. Nanomaterials, 12(15), 2703. https://doi.org/10.3390/nano12152703