Screen-Printable Silver Paste Material for Semitransparent and Flexible Metal–Semiconductor–Metal Photodetectors with Liquid-Phase Procedure

Abstract

:1. Introduction

2. Materials and Methods

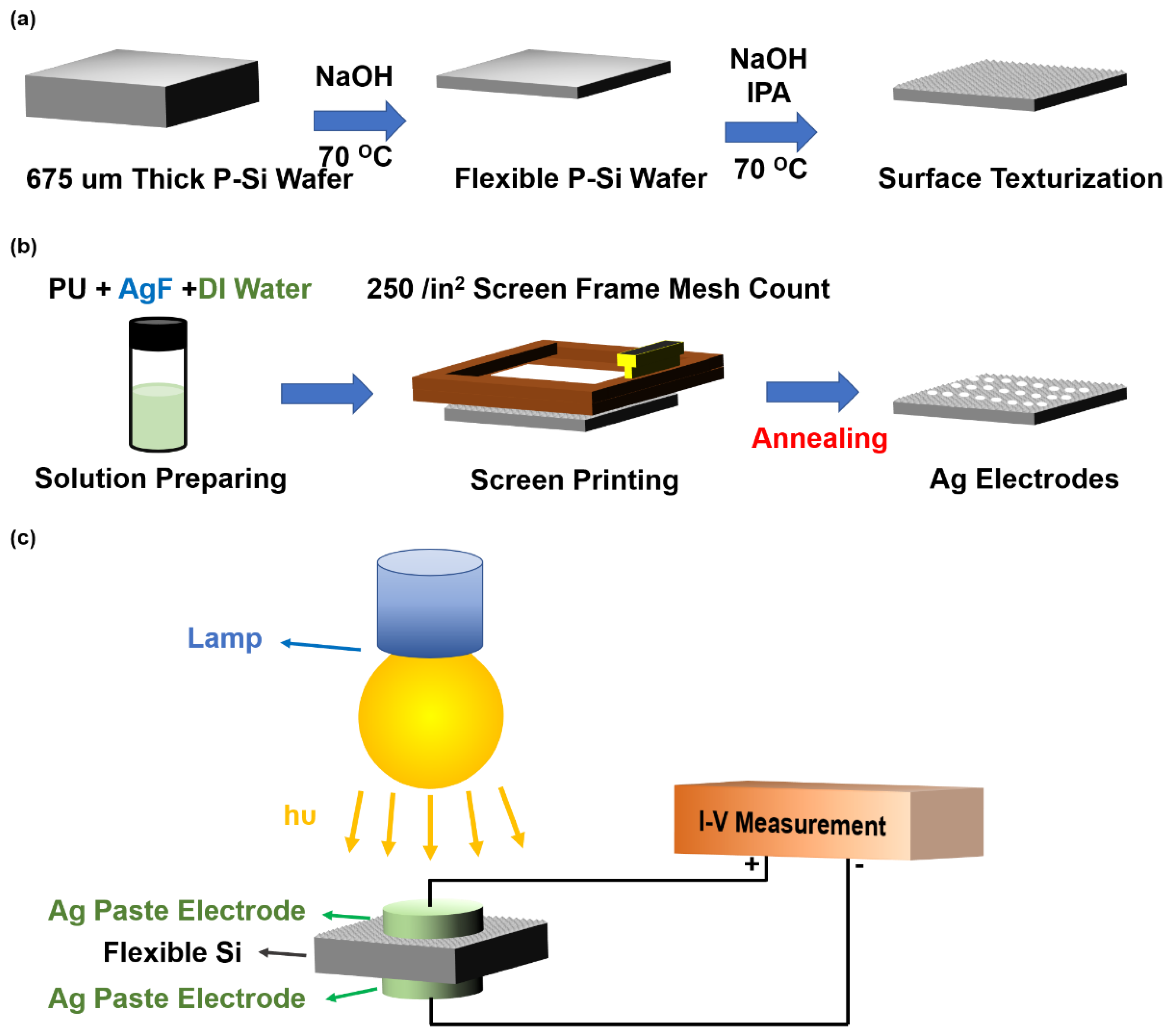

2.1. Flexible and Surface Texturization of Si Substrate Fabrication

2.2. Silver Paste MSM Broadband Visible Light Photodetector Fabrication

2.3. Characteristics

3. Results and Discussion

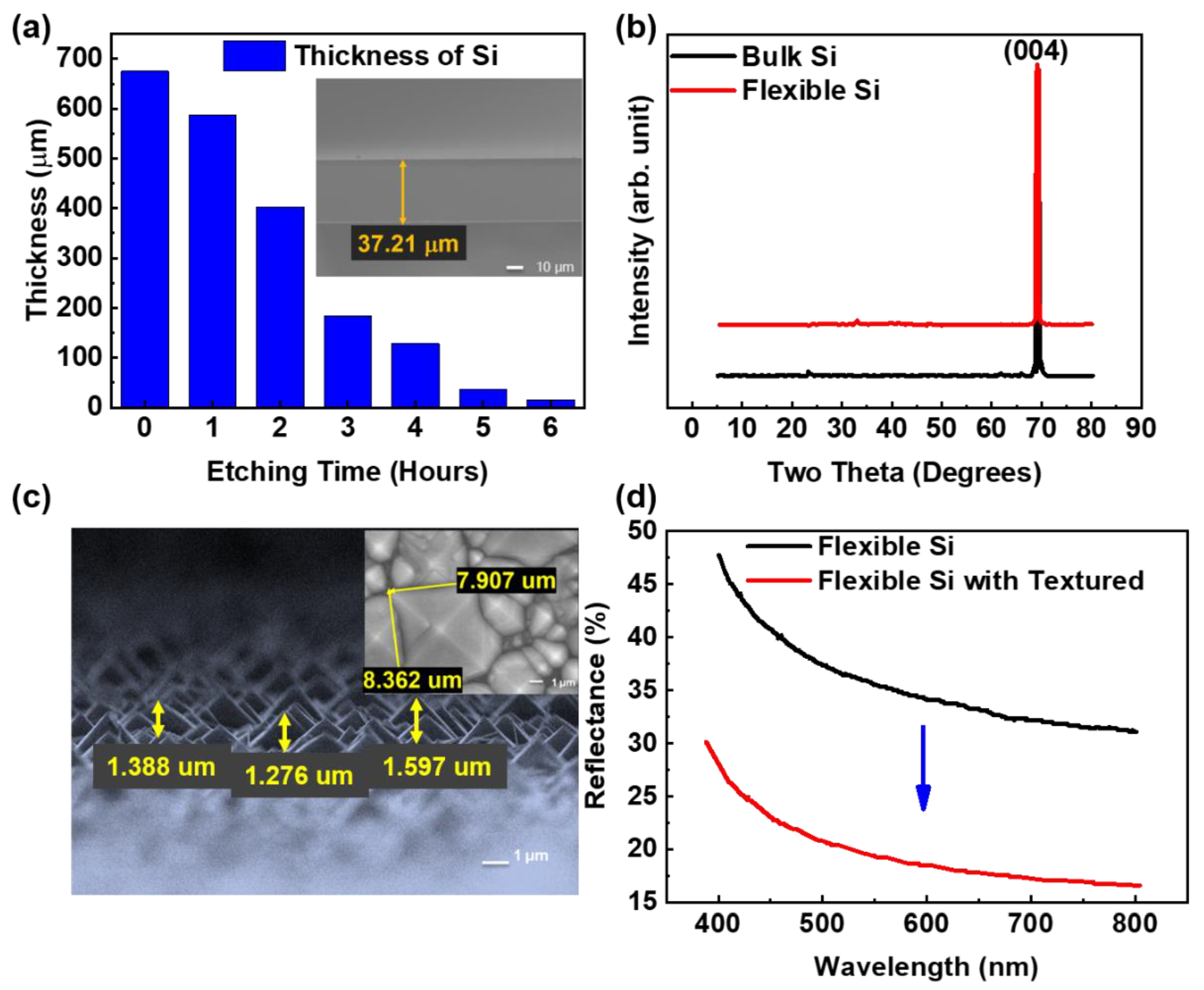

3.1. Flexibility and Surface Texturization of Si

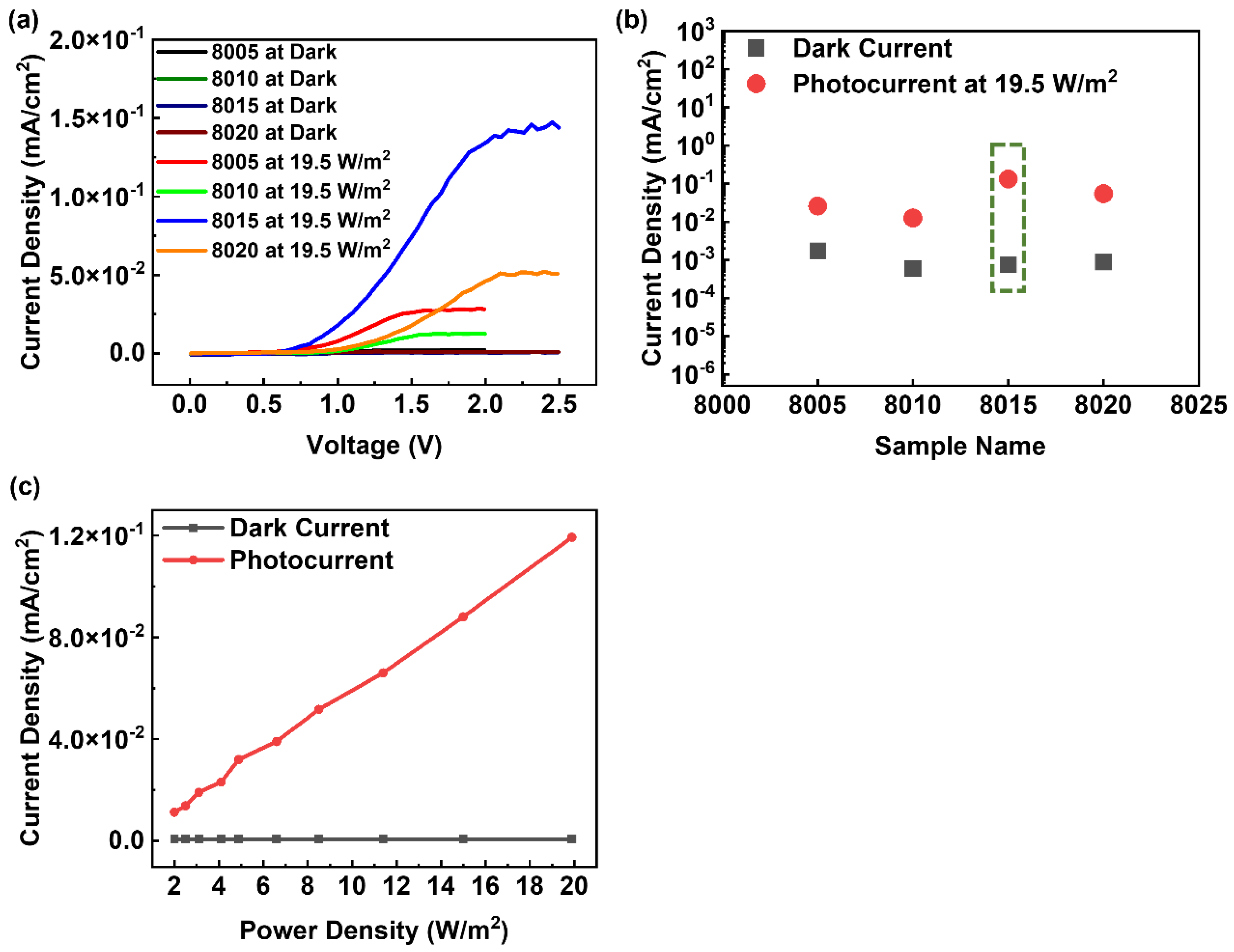

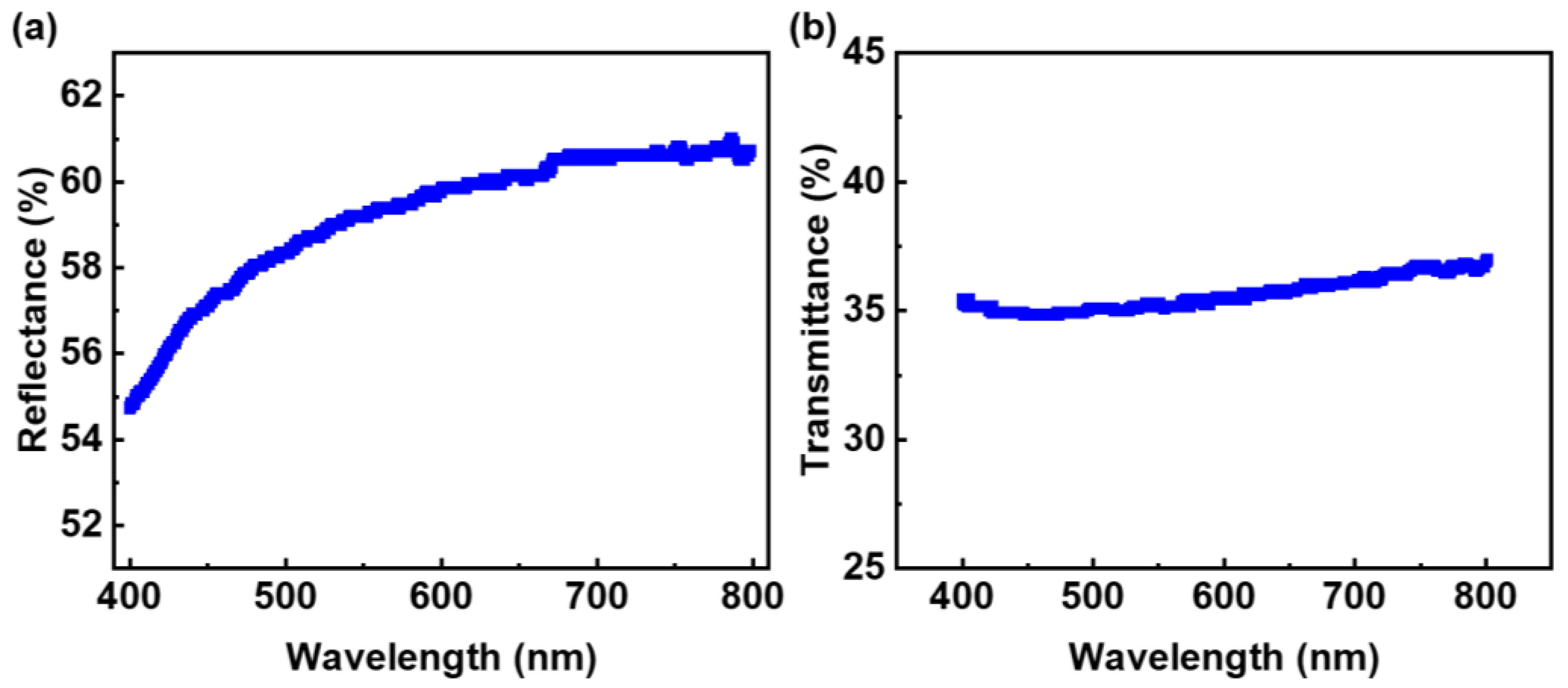

3.2. Electrical and Optical Properties of Conductive Silver Paste

3.3. Flexibility Characteristics of Flexible MSM Broadband Visible Light Photodetectors

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jin, X.; Sun, Y.; Wu, Q.; Jia, Z.; Huang, S.; Yao, J.; Huang, H.; Xu, J. High-Performance Free-Standing Flexible Photodetectors Based on Sulfur-Hyperdoped Ultrathin Silicon. ACS Appl. Mater. Interfaces 2019, 11, 42385–42391. [Google Scholar] [CrossRef] [PubMed]

- Zheng, S.; Lu, J.; Duan, X. Novel Visible-Light Photodetector Based on Two-Dimensional Confined Electron Donor-Acceptor Co-Assembled Layered Double Hydroxide Ultrathin Films. ACS Omega 2016, 1, 1239–1246. [Google Scholar] [CrossRef] [PubMed]

- Jeon, C.W.; Lee, S.S.; Park, I.K. Flexible Visible-Blind Ultraviolet Photodetectors Based on ZnAl-Layered Double Hydroxide Nanosheet Scroll. ACS Appl. Mater. Interfaces 2019, 11, 35138–35145. [Google Scholar] [CrossRef] [PubMed]

- Cao, F.; Meng, L.; Wang, M.; Tian, W.; Li, L. Gradient Energy Band Driven High-Performance Self-Powered Perovskite/CdS Photodetector. Adv. Mater. 2019, 31, e1806725. [Google Scholar] [CrossRef] [PubMed]

- Kim, W.; Kim, H.; Yoo, T.J.; Lee, J.Y.; Jo, J.Y.; Lee, B.H.; Sasikala, A.A.; Jung, G.Y.; Pak, Y. Perovskite multifunctional logic gates via bipolar photoresponse of single photodetector. Nat. Commun. 2022, 13, 720. [Google Scholar] [CrossRef]

- Guo, F.; Yang, B.; Yuan, Y.; Xiao, Z.; Dong, Q.; Bi, Y.; Huang, J. A nanocomposite ultraviolet photodetector based on interfacial trap-controlled charge injection. Nat. Nanotechnol. 2012, 7, 798–802. [Google Scholar] [CrossRef]

- Zhou, G.; Zhao, H.; Li, X.; Sun, Z.; Wu, H.; Li, L.; An, H.; Ruan, S.; Peng, Z. Highly-Responsive Broadband Photodetector Based on Graphene-PTAA-SnS2 Hybrid. Nanomaterials 2022, 12, 475. [Google Scholar] [CrossRef]

- Sun, Y.; Xie, L.; Ma, Z.; Qian, Z.; Liao, J.; Hussain, S.; Liu, H.; Qiu, H.; Wu, J.; Hu, Z. High-Performance Photodetectors Based on the 2D SiAs/SnS2 Heterojunction. Nanomaterials 2022, 12, 371. [Google Scholar] [CrossRef]

- Shao, D.; Zhu, W.; Liu, X.; Li, M.; Chen, J.; Sun, Y.Y.; Xin, G.; Lian, J.; Sawyer, S. Ultrasensitive UV Photodetector Based on Interfacial Charge-Controlled Inorganic Perovskite-Polymer Hybrid Structure. ACS Appl. Mater. Interfaces 2020, 12, 43106–43114. [Google Scholar] [CrossRef]

- Luchechko, A.; Vasyltsiv, V.; Kostyk, L.; Pavlyk, B. Dual-Channel Solar-Blind UV Photodetector Based on β-Ga2O3. Physica Status Solidi 2019, 216, 1900444. [Google Scholar] [CrossRef]

- Ramiro, I.; Marti, A.; Antolin, E.; Lopez, E.; Datas, A.; Luque, A.; Ripalda, J.M.; Gonzalez, Y. Optically triggered infrared photodetector. Nano Lett. 2015, 15, 224–228. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Das, B.; Das, N.S.; Sarkar, S.; Chatterjee, B.K.; Chattopadhyay, K.K. Topological Insulator Bi2Se3/Si-Nanowire-Based p-n Junction Diode for High-Performance Near-Infrared Photodetector. ACS Appl. Mater. Interfaces 2017, 9, 22788–22798. [Google Scholar] [CrossRef] [PubMed]

- Mallows, J.; Planells, M.; Thakare, V.; Bhosale, R.; Ogale, S.; Robertson, N. p-Type NiO Hybrid Visible Photodetector. ACS Appl. Mater. Interfaces 2015, 7, 27597–27601. [Google Scholar] [CrossRef]

- Xia, W.; Qian, H.; Zeng, X.; Dong, J.; Wang, J.; Xu, Q. Visible-Light Self-Powered Photodetector and Recoverable Photocatalyst Fabricated from Vertically Aligned Sn3O4 Nanoflakes on Carbon Paper. J. Phys. Chem. C 2017, 121, 19036–19043. [Google Scholar] [CrossRef]

- Michel, J.; Liu, J.; Kimerling, L.C. High-performance Ge-on-Si photodetectors. Nat. Photonics 2010, 4, 527–534. [Google Scholar] [CrossRef]

- Bigas, M.; Cabruja, E.; Forest, J.; Salvi, J. Review of CMOS image sensors. Microelectron. J. 2006, 37, 433–451. [Google Scholar] [CrossRef] [Green Version]

- Cai, Y.; Shen, S.; Zhu, C.; Zhao, X.; Bai, J.; Wang, T. Nonpolar (1120) GaN Metal-Semiconductor-Metal Photodetectors with Superior Performance on Silicon. ACS Appl. Mater. Interfaces 2020, 12, 25031–25036. [Google Scholar] [CrossRef]

- Chen, X.; Wang, D.; Wang, T.; Yang, Z.; Zou, X.; Wang, P.; Luo, W.; Li, Q.; Liao, L.; Hu, W.; et al. Enhanced Photoresponsivity of a GaAs Nanowire Metal-Semiconductor-Metal Photodetector by Adjusting the Fermi Level. ACS Appl. Mater. Interfaces 2019, 11, 33188–33193. [Google Scholar] [CrossRef]

- Nau, S.; Wolf, C.; Sax, S.; List-Kratochvil, E.J. Organic non-volatile resistive photo-switches for flexible image detector arrays. Adv. Mater. 2015, 27, 1048–1052. [Google Scholar] [CrossRef]

- Hu, W.; Huang, W.; Yang, S.; Wang, X.; Jiang, Z.; Zhu, X.; Zhou, H.; Liu, H.; Zhang, Q.; Zhuang, X.; et al. High-Performance Flexible Photodetectors based on High-Quality Perovskite Thin Films by a Vapor-Solution Method. Adv. Mater. 2017, 29, 1703256. [Google Scholar] [CrossRef]

- Ko, H.C.; Stoykovich, M.P.; Song, J.; Malyarchuk, V.; Choi, W.M.; Yu, C.J.; Geddes, J.B., 3rd; Xiao, J.; Wang, S.; Huang, Y.; et al. A hemispherical electronic eye camera based on compressible silicon optoelectronics. Nature 2008, 454, 748–753. [Google Scholar] [CrossRef] [PubMed]

- Lochner, C.M.; Khan, Y.; Pierre, A.; Arias, A.C. All-organic optoelectronic sensor for pulse oximetry. Nat. Commun. 2014, 5, 5745. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sun, B.; Shao, M.; Lee, S. Nanostructured Silicon Used for Flexible and Mobile Electricity Generation. Adv. Mater. 2016, 28, 10539–10547. [Google Scholar] [CrossRef]

- Xie, C.; Yan, F. Flexible Photodetectors Based on Novel Functional Materials. Small 2017, 13, 1701822. [Google Scholar] [CrossRef] [PubMed]

- Mulazimoglu, E.; Coskun, S.; Gunoven, M.; Butun, B.; Ozbay, E.; Turan, R.; Unalan, H.E. Silicon nanowire network metal-semiconductor-metal photodetectors. Appl. Phys. Lett. 2013, 103, 083114. [Google Scholar] [CrossRef]

- Hossain, M.; Kumar, G.S.; Barimar Prabhava, S.N.; Sheerin, E.D.; McCloskey, D.; Acharya, S.; Rao, K.D.M.; Boland, J.J. Transparent, Flexible Silicon Nanostructured Wire Networks with Seamless Junctions for High-Performance Photodetector Applications. ACS Nano 2018, 12, 4727–4735. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, D.H.; Lee, W.; Myoung, J.M. Flexible multi-wavelength photodetector based on porous silicon nanowires. Nanoscale 2018, 10, 17705–17711. [Google Scholar] [CrossRef]

- Lim, S.; Um, D.-S.; Ha, M.; Zhang, Q.; Lee, Y.; Lin, Y.; Fan, Z.; Ko, H. Broadband omnidirectional light detection in flexible and hierarchical ZnO/Si heterojunction photodiodes. Nano Res. 2016, 10, 22–36. [Google Scholar] [CrossRef]

- Dai, Y.; Wang, X.; Peng, W.; Xu, C.; Wu, C.; Dong, K.; Liu, R.; Wang, Z.L. Self-Powered Si/CdS Flexible Photodetector with Broadband Response from 325 to 1550 nm Based on Pyro-phototronic Effect: An Approach for Photosensing below Bandgap Energy. Adv. Mater. 2018, 30, 1705893. [Google Scholar] [CrossRef]

- Faddoul, R.; Reverdy-Bruas, N.; Blayo, A. Formulation and screen printing of water based conductive flake silver pastes onto green ceramic tapes for electronic applications. Mater. Sci. Eng. B 2012, 177, 1053–1066. [Google Scholar] [CrossRef]

- Berggren, M.; Nilsson, D.; Robinson, N.D. Organic materials for printed electronics. Nat. Mater. 2007, 6, 3. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Liu, N.; Yang, C.; Liu, W.; Su, J.; Li, L.; Yang, C.; Gao, Y. Fully screen printed highly conductive electrodes on various flexible substrates for asymmetric supercapacitors. RSC Adv. 2015, 5, 85799–85805. [Google Scholar] [CrossRef]

- Li, M.; Li, Y.T.; Li, D.W.; Long, Y.T. Recent developments and applications of screen-printed electrodes in environmental assays--a review. Anal. Chim. Acta 2012, 734, 31–44. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Lei, W.; Zhang, X.; Zhou, X.; Wang, Q.; Zhang, Y.; Wang, B. Field emission characteristic of screen-printed carbon nanotube cathode. Appl. Surf. Sci. 2003, 220, 96–104. [Google Scholar] [CrossRef]

- Sanchez, S.; Pumera, M.; Fabregas, E. Carbon nanotube/polysulfone screen-printed electrochemical immunosensor. Biosens. Bioelectron. 2007, 23, 332–340. [Google Scholar] [CrossRef]

- Trojanowicz, M.; Mulchandani, A.; Mascini, M. Carbon Nanotubes-Modified Screen-Printed Electrodes for Chemical Sensors and Biosensors. Anal. Lett. 2004, 37, 3185–3204. [Google Scholar] [CrossRef]

- Guo, G.; Gan, W.; Xiang, F.; Zhang, J.; Zhou, H.; Liu, H.; Luo, J. Effect of dispersibility of silver powders in conductive paste on microstructure of screen-printed front contacts and electrical performance of crystalline silicon solar cells. J. Mater. Sci. Mater. Electron. 2010, 22, 527–530. [Google Scholar] [CrossRef]

- Lee, H.-H.; Chou, K.-S.; Shih, Z.-W. Effect of nano-sized silver particles on the resistivity of polymeric conductive adhesives. Int. J. Adhes. Adhes. 2005, 25, 437–441. [Google Scholar] [CrossRef]

- Lim, J.E.; Lee, S.M.; Kim, S.S.; Kim, T.W.; Koo, H.W.; Kim, H.K. Brush-paintable and highly stretchable Ag nanowire and PEDOT:PSS hybrid electrodes. Sci. Rep. 2017, 7, 14685. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Zhu, X.; Li, Z.; Yang, J.; Lan, H. Preparation of Nano Silver Paste and Applications in Transparent Electrodes via Electric-Field Driven Micro-Scale 3D Printing. Nanomaterials 2020, 10, 107. [Google Scholar] [CrossRef] [Green Version]

- Lin, C.C.; Sun, D.S.; Lin, Y.L.; Tsai, T.T.; Cheng, C.; Sun, W.H.; Ko, F.H. A flexible and miniaturized hair dye based photodetector via chemiluminescence pathway. Biosens. Bioelectron. 2017, 90, 349–355. [Google Scholar] [CrossRef] [PubMed]

- An, Q.; Meng, X.; Xiong, K.; Qiu, Y. Self-powered ZnS Nanotubes/Ag Nanowires MSM UV Photodetector with High On/Off Ratio and Fast Response Speed. Sci. Rep. 2017, 7, 4885. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhou, J.; Chen, L.; Wang, Y.; He, Y.; Pan, X.; Xie, E. An overview on emerging photoelectrochemical self-powered ultraviolet photodetectors. Nanoscale 2016, 8, 50–73. [Google Scholar] [CrossRef] [PubMed]

- Pawbake, A.S.; Waykar, R.G.; Late, D.J.; Jadkar, S.R. Highly Transparent Wafer-Scale Synthesis of Crystalline WS2 Nanoparticle Thin Film for Photodetector and Humidity-Sensing Applications. ACS Appl. Mater. Interfaces 2016, 8, 3359–3365. [Google Scholar] [CrossRef] [PubMed]

- Jo, M.S.; Song, H.J.; Kim, B.J.; Shin, Y.K.; Kim, S.H.; Tian, X.; Kim, S.M.; Seo, M.H.; Yoon, J.B. Aligned CuO nanowire array for a high performance visible light photodetector. Sci. Rep. 2022, 12, 2284. [Google Scholar] [CrossRef]

- Chung, P.H.; Kuo, C.T.; Wang, T.H.; Lu, Y.Y.; Liu, C.I.; Yew, T.R. A Sensitive Visible Light Photodetector Using Cobalt-Doped Zinc Ferrite Oxide Thin Films. ACS Appl. Mater. Interfaces 2021, 13, 6411–6420. [Google Scholar] [CrossRef]

| Sample Name | 8005 | 8010 | 8015 | 8020 |

|---|---|---|---|---|

| PU:AgF:H2O | 1.0:4.0:0.5 | 1.0:4.0:1.0 | 1.0:4.0:1.5 | 1.0:4.0:2.0 |

| PU:AgF:H2O (wt %) | 18:73:9 | 16: 67:16 | 15:62:23 | 14:57:29 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsai, S.Y.; Lin, C.-C.; Yu, C.-T.; Chen, Y.-S.; Wu, W.-L.; Chang, Y.-C.; Chen, C.C.; Ko, F.-H. Screen-Printable Silver Paste Material for Semitransparent and Flexible Metal–Semiconductor–Metal Photodetectors with Liquid-Phase Procedure. Nanomaterials 2022, 12, 2428. https://doi.org/10.3390/nano12142428

Tsai SY, Lin C-C, Yu C-T, Chen Y-S, Wu W-L, Chang Y-C, Chen CC, Ko F-H. Screen-Printable Silver Paste Material for Semitransparent and Flexible Metal–Semiconductor–Metal Photodetectors with Liquid-Phase Procedure. Nanomaterials. 2022; 12(14):2428. https://doi.org/10.3390/nano12142428

Chicago/Turabian StyleTsai, Shang Yu, Ching-Chang Lin, Cheng-Tang Yu, Yen-Shuo Chen, Wei-Lin Wu, Yu-Cheng Chang, Chun Chi Chen, and Fu-Hsiang Ko. 2022. "Screen-Printable Silver Paste Material for Semitransparent and Flexible Metal–Semiconductor–Metal Photodetectors with Liquid-Phase Procedure" Nanomaterials 12, no. 14: 2428. https://doi.org/10.3390/nano12142428

APA StyleTsai, S. Y., Lin, C.-C., Yu, C.-T., Chen, Y.-S., Wu, W.-L., Chang, Y.-C., Chen, C. C., & Ko, F.-H. (2022). Screen-Printable Silver Paste Material for Semitransparent and Flexible Metal–Semiconductor–Metal Photodetectors with Liquid-Phase Procedure. Nanomaterials, 12(14), 2428. https://doi.org/10.3390/nano12142428