Abstract

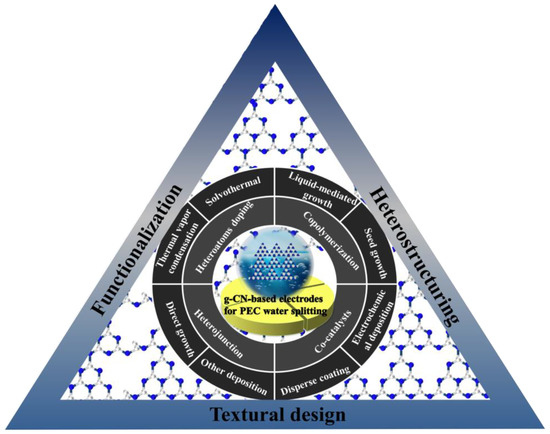

Graphitic carbon nitride (g−CN), a promising visible-light-responsive semiconductor material, is regarded as a fascinating photocatalyst and heterogeneous catalyst for various reactions due to its non-toxicity, high thermal durability and chemical durability, and “earth-abundant” nature. However, practical applications of g−CN in photoelectrochemical (PEC) and photoelectronic devices are still in the early stages of development due to the difficulties in fabricating high-quality g−CN layers on substrates, wide band gaps, high charge-recombination rates, and low electronic conductivity. Various fabrication and modification strategies of g−CN-based films have been reported. This review summarizes the latest progress related to the growth and modification of high-quality g−CN-based films. Furthermore, (1) the classification of synthetic pathways for the preparation of g−CN films, (2) functionalization of g−CN films at an atomic level (elemental doping) and molecular level (copolymerization), (3) modification of g−CN films with a co-catalyst, and (4) composite films fabricating, will be discussed in detail. Last but not least, this review will conclude with a summary and some invigorating viewpoints on the key challenges and future developments.

1. Introduction

Energy shortage and environmental pollution issues are receiving increasing attention due to the rapid industrialization and excessive consumption of resources by mankind [1,2]. At present, energy supply is mainly dependent on fossil fuels, such as coal, petroleum, and natural gas [3]. The utilization of these fossil fuels is inevitably accompanied by the release of various harmful gases, including carbon dioxide, nitrogen oxides and sulfur oxides etc. [4]. Therefore, developing environmentally friendly and renewable energies to replace conventional fossil fuels is considered a perfect solution to remove these issues, and hydrogen energy is one of the most promising candidates. However, over 90% of hydrogen gas is produced from steam reforming of methane in industry, which limits the development of hydrogen energy because methane is non-renewable energy [5]. In 1972, Fujishima and Honda discovered photoelectrochemical (PEC) H2 production from water splitting via using a TiO2 cell under ultraviolet (UV) light radiation [6]. Photoelectrochemical (PEC) water splitting by solar energy is generally considered a promising strategy to generate hydrogen gas because both water and solar energy are inexhaustible on the earth.

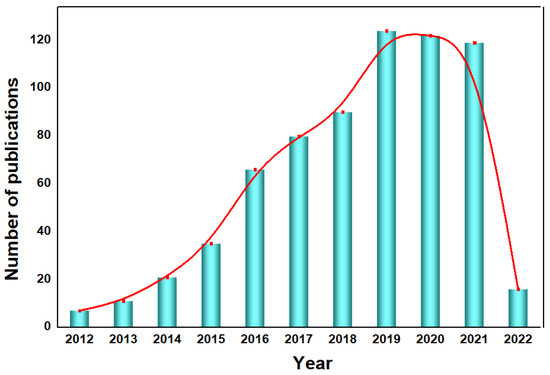

Carbon nitride-based polymers have attracted widespread attention thanks to their outstanding electronic properties, which have been exploited in numerous applications such as photocatalysis [7,8,9], CO2 reduction [10], fuel cells [11], bioimaging [12], and so on. Modified graphitic carbon nitride (g−CN-based films), the focus of this review, can be synthesized and applied for PEC water splitting. Graphitic carbon nitride (g−CN), a metal-free semiconductor, is one of the emerging two-dimensional (2D) materials for PEC. g−CN is widely investigated thanks to its medium band gap structure (ca. 2.7 eV), an appropriate optical wavelength (ca. 460 nm), non-toxicity, high thermal durability (600 °C in air) and chemical durability (against acid, alkali, and organic solvents), and “earth-abundant” nature [13,14,15,16]. Figure 1 illustrate that PEC device applications of g−CN-based films have been soaring since 2016. Nevertheless, it still remains a crucial issue about how to sufficiently probe the unusual features of g−CN for the setout of highly efficient g−CN-based films. The practical application for PEC water splitting is still impeded because it is still difficult to construct a homogenous g−CN film with good crystalline quality on conductive substrates to form photoelectrodes in PEC devices from the viewpoint of the intrinsic layer properties. Furthermore, several key factors still restrict its efficiencies, such as insufficient visible-light absorption, the high recombination rate of charge carriers, short electron diffusion length due to its poor electronic conductivity, and the existence of defects, which act as recombination centers and form a barrier for conductivity. To overcome these issues, various fabrication and modification strategies are applied to improve the PEC performance of g−CN-based films. Enhanced absorption of g−CN-based films is acquired via the construction of π-conjugated polymers, by doping with heteroatoms, or by copolymerizing with different organic monomers [17,18,19]. The conductivity of electrons can be improved by replacing some C=N with C=C bonds, and forming a heterojunction with other semiconductors is utilized to decrease the recombination of photo-excited charges for g−CN materials in PEC applications. In water-splitting PECs, water oxidation (produces oxygen molecules, OER) and water reduction (produces hydrogen molecules, HER) are performed simultaneously but are spatially separated. The oxidation reaction at the photoanode decides the speed of water splitting on account of the sluggish kinetics containing O-H bond dissociation and O-O bond formation [20,21]. Therefore, water oxidation on the semiconductor surface is still considered the bottleneck. To solve this issue, the introduction of a co-catalyst at the g−CN/electrolyte interface is an efficient strategy.

Figure 1.

Year-by-year publications of g−CN research on PEC devices, the keywords were set to [“graphitic carbon nitride” and “photoelectrochemical”] (The red line is the trend line). Data are obtained from the ISI Web of Science, dated 17 April 2022.

Up to now, several insightful reviews have already focused on the fabrication and modification of the bulk or powder g−CN and their applications in dealing with the energy crisis and environmental problems [3,22]. However, only a handful of reviews can be traced that focused on the synthesis and applications of g−CN films for PEC water splitting. This scenario thus makes it very urgent to offer a critical and relatively comprehensive review of the state-of-the-art advances of g−CN films for PEC water splitting. In the present review, we initially focus on the latest advances in the fabrication, versatile properties, rational modification, and applications of g−CN-based films for PEC water splitting. Firstly, this review will conclude the different types of g−CN photoelectrodes according to their preparation pathways and then the rational modification methods to promote the PEC performance. Last but not least, the major challenges and some invigorating perspectives for future research on g−CN-based film materials are also concluded. We hope that this review will not only offer valuable insight into new g−CN-based film materials but also therefore promote the further developments of g−CN-based films in green and sustainable energy production and storage.

2. Water-Splitting Reaction Mechanisms

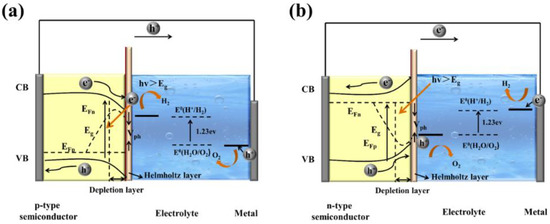

Gaining an elementary understanding of photoelectrochemical, charge-separation, and transfer mechanisms is the crucial step in designing photoelectrodes. Figure 2 show structural diagrams of the general photoelectrocatalytic processes for PEC water splitting. There are three primary components of a typical PEC device: (1) a working electrode consists of semiconductor material, a p-type semiconductor as a photocathode (Figure 2a), and an n-type semiconductor as a photoanode (Figure 2b), (2) a counter electrode, and (3) an electrolyte system. It will facilitate the transport of electrons and holes and ensure the separation of hydrogen and oxygen produced on different electrode surfaces. Before contact with the electrolyte, the energy level in the semiconductor is flat. Once in contact with the electrolyte, the different chemical potentials will drive the charge in the semiconductor to the electrolyte until the formation of the built-in electric field. Then, a depletion layer (WD) and a Helmholtz layer (WHL) present at the semiconductor interface and the electrolyte interface, respectively, to form a semiconductor–liquid junction (SCLJ). This charge transfer also gives rise to band bending at the semiconductor interface. For the n-type semiconductors, electrons flow from the semiconductor conduction band to the electrolyte, and the semiconductor surface forms a positively charged depletion layer, resulting in the upward band bending. In contrast, holes flow from the semiconductor to the electrolyte for the p-type semiconductors, which leads to the downward band bending.

Figure 2.

General scheme of a PEC system using semiconductors as (a) photocathode and (b) photoanode.

In this section, the transport of excitons is discussed. Under a steady illumination, the semiconductor photoelectrode absorbs the photons whose energy is higher than the band gap energy. Then, the electrons become excited from the valence band (VB) to the conduction band (CB), leaving empty states that constitute positive holes in VB. The built-in electric field at the semiconductor/electrolyte interface and the band bending inside the semiconductor separate the electron–hole pairs and consequently generate the photovoltage (Vph) and photocurrent. For the semiconductor photocatalysts with a flat band potential above the H+/H2 energy level, the separation and transport of excitons (electron–hole pairs) do not require external bias to produce H2 and O2 (self-powered mode). However, the transport of excitons usually suffers from an over-potential across the semiconductor, potential drops at contacts, the resistance of the electrodes, and so on. Therefore, the photovoltage generated by the photoelectrode material is not enough to overcome these losses and provides the energy required for PEC water splitting, and an external bias is needed [23]. Once the charged carriers are spatially separated, they are migrated to the semiconductor photoelectrode surface and initiate the redox reaction for PEC water splitting. In a photoanode, holes are injected into the electrolyte, where they react with OH− to produce oxygen, and the electrons migrate to the counter electrode by a conducting wire that leads to hydrogen generation. In contrast, for photocathodes, the electrons injection electrolyte undergoes a reduction reaction (react with H+) to produce hydrogen, while oxygen is produced at the counter electrode. The hydrogen and oxygen evolution reactions of water splitting in different electrolyte environments can be described as follows:

Acidic conditions:

HER: 4H+ + 4e− → 2H2, E0 = 0 V vs. NHE

OER: 2H2O + 4h+→4H+ + O2 E0 = 1.23 V vs. NHE

Alkaline conditions:

HER: 4H2O + 4e− →2H2 + 4OH− E0 = −0.83 V vs. NHE

OER: 4OH− + 4h+ → O2 + 2H2O E0 = 0.4 V vs. NHE

In simple words, the PEC water splitting process can be divided into (1) light absorption by semiconductor, (2) the separation and transportation of electron–hole pairs, and (3) surface redox reactions. Water splitting is an uphill reaction that demands a minimum Gibbs free energy of +237.2 kJ/mol. Theoretically, the minimum band-gap of a semiconductor appropriate for water splitting is 1.23 eV, but a band-gap of approximately 2.0 eV is required due to both thermodynamic energy losses and the over potential required to surmount surface reaction kinetics, which can achieve a theoretical photocurrent density of 14.5 mA cm−2 and a maximum solar-to-hydrogen (STH) efficiency of 17.9% under AM 1.5G (100 mW cm−2) [24,25,26,27]. To date, n-type semiconductor photoanodes usually exhibit lower photocurrent densities (several mA cm−2) under AM 1.5G, which is still much lower than the theoretical values. The semiconductor materials used in overall PEC water splitting must also satisfy specific requirements, which the potential of the conduction band must be more negative than the reduction edge of hydrogen, and the valence band potential must be positive enough to actuate water oxidation (more than +1.23 eV) [28,29,30]. Based on the above discussion, we can infer that a moderate band gap (that is, a sufficient light absorption property), suitable energy level positions, efficient electron–hole excitation and separation, minimal overpotential, long-term stability, and cost-effective are the main requirements for a photoelectrode in PEC water splitting device.

3. Electronic Structure of g−CN

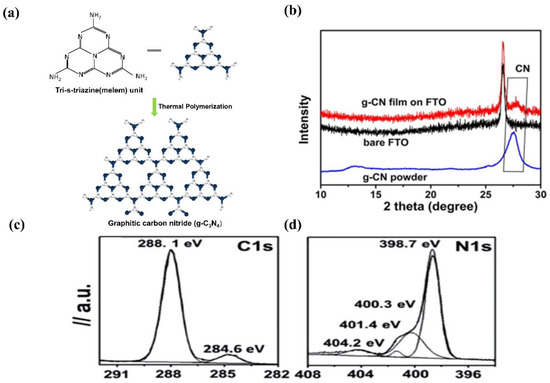

Commonly, g−CN films and g−CN powders possess identically graphitic structures. Ideal g−CN is composed of only C and N elements (C/N ratio is 0.75), showing a band-gap of 2.1 eV. While the synthetic g−CN universally displays a band-gap of 2.7 eV due to incomplete condensation [31]. For the most stable allotrope, the graphitic planes are constituted by triazine C3N3 (melam) or tri-s-triazine C6N7 (melem) units connected by planar amino groups (Figure 3a) [32]. However, Tri-s-triazine was regarded as the building block of g−CN because it is a more stable phase at ambient temperature [33]. For pure g−CN, two typical X-ray diffraction peaks observed at 13.04° and 27.251° are attributed to (100) and (002) planes, respectively. The strong peak corresponds to inter-layer diffraction of conjugated aromatic system (002) facet similar to graphite materials; meanwhile, the small peak at (100) is pertinent to the in-plane repeating pattern of tri-s-triazine units formed by hydrogen bonding (Figure 3b) [34]. However, X-ray diffraction (XRD) patterns only offer deficient information due to the low crystallinity of g−CN films. The C1s and N1s X-ray photoelectron spectroscopy (XPS)spectra of g−CN films are exhibited in Figure 3c,d. The C1s spectrum consists of two distinct peaks, the peaks at 284.6 and 288.1 eV correspond to sp2 carbon–carbon bonding (C–C) or (C=C), and sp2 carbon atoms bonded to nitrogen (C–N=C), respectively. The N1s consist of four peaks. The peaks at 398.7, 400.3, 401.4, and 404.2 eV correspond to sp2 hybridized carbon–nitrogen bonding (C–N=C), sp3 tertiary nitrogen bonding N–(C)3, weak amino hydrogen-bonded functional groups (C–N–H), andπ-excitations (π/π* transition), respectively [35,36].

Figure 3.

(a) Schematic structure of a g−CN constructed from tri-s-triazine units. (b) XRD pattern of g−CN film. Reprinted with permission from ref. [34] Copyright 2015 Wiley-VCH. (c,d) XPS high-resolution spectra of the C1s and N1s core energy spectra of g−CN film. Reprinted with permission from ref. [36] Copyright 2012 Elsevier.

The band-gap of the laboratory fabricated g−CN is identified to be about 2.7 eV, corresponding to the absorption from the highest occupied molecular orbitals (HOMOs) to the lowest unoccupied molecular orbitals (LUMOs). The HOMO and LUMO levels originated from nitrogen pz and carbon pz orbitals, respectively [37]. This band-gap is large enough to surmount the thermodynamic barrier of the water-splitting, which requires 1.23 eV theoretically. Furthermore, the HOMO/LUMO levels of g−CN straddle the energy levels of water reduction and oxidation, which manifests that g−CN can thermodynamically function as a candidate semiconductor material for PEC [38,39].

Until now, thermal pyrolysis of nitrogen-rich precursors such as cyanamide, dicyanamide, urea, melamine, thiourea, guanidine hydrochloride, trithiocyanuric acid, etc. has been employed to synthesize g−CN. This type of nitrogen-rich precursor has a slight effect on the band-gap structure of g−CN [40]. The flat band potential generated by different precursors was measured using the Mott–Schottky plot, which is −0.6 V vs. RHE for urea [35], −0.8 V for cyanamide and dicyandiamide [41,42], and −0.7 V for melamine [43,44]. The valence band X-ray photoelectron spectroscopy plot, which calculates the energy level difference between the valence band and the Fermi level [45], produced a value of 1.56 V for urea, thiourea and melamine [35,40], and 1.74 V for dicyandiamide [46]. Ragupathi et al. [47] reported a band-gap of 2.89 eV, 2.78 eV, and 2.35 eV for thiourea, urea, and urea with glycine precursor to synthesize g−CN, respectively.

4. g−CN Thin-Film Preparation Methods

Numerous synthesis strategies have been developed to prepare g−CN films on substrates, which are classified as thermal vapor condensation (TVC), solvothermal route, liquid-mediated growth, seed growth, electrophoretic deposition, disperse coating, and other deposition methods. Detailed descriptions of the various types of synthesis methods for the construction of g−CN films are provided below. The main advantages and disadvantages of the different synthetic methods are summarized in Table 1.

Table 1.

The main advantages and disadvantages comparison of different methods.

4.1. Thermal Vapor Condensation (TVC)

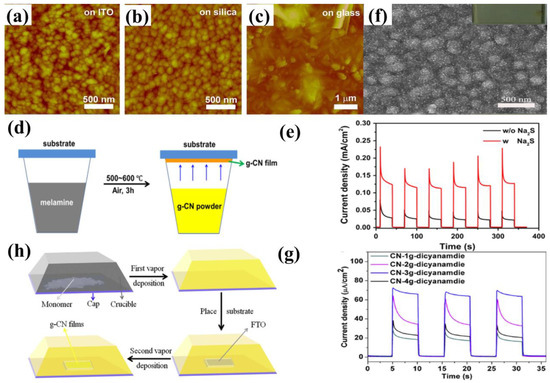

The TVC setups for the deposition of g−CN thin film are shown in Figure 4d,h. Owing to the different deposition sequences, TVC can be categorized into two forms: the one-step process and the two-step process. In a one-step TVC procedure (Figure 4d), the substrate is placed on top of a reactor. Taking nitrogen-rich precursor for an example, the precursor vapor generates if the temperature is higher than its sublimation point (above 300 °C). Then, the vapor inside the container will deposit on the substrate surface when the temperature reaches the condensation temperature (500–600 °C) of the precursor, resulting in the nucleation and growth of g−CN thin film [48]. While for the two-step TVC procedure, g−CN is condensed and deposited on the inner wall of the container upon the first vapor deposition. Subsequently, the substrate is placed on top of a reactor. The g−CN attached to the container is vaporized again and grown on the g−CN thin film on the substrate surface [49]. To date, g−CN thin film has mainly been prepared by TVC with different precursors, such as melamine [50], dicyanamide [49], thiourea [51], urea [52], and cyanamide [53], and the bulky g−CN is always utilized. Bian et al. discovered that melamine, compared with dicyandiamide, thiourea, and urea, shows the highest photocurrent density for the PEC system in a one-step TVC procedure [48]. The g−CN film fabricated with dicyanamide shows a photocurrent density of up to 63 μA cm−2 at the bias of 1.23 V versus RHE without a sacrificial reagent in a two-step TVC procedure (Figure 4f–g) [49].

Figure 4.

TVC via melamine, illustrating AFM surface morphologies grown on (a) ITO glass, (b) silica and (c) glass, (d) TVC growth mechanism, and (e) transient photocurrent density of the thin film tested with and without adding Na2S at 1.55 V vs. RHE. Reprinted with permission from ref. [48] Copyright 2015 Elsevier. Two-step TVD procedure utilizing dicyanamide: (f) SEM images of the g−CN electrodes (the inset is the digital image), (g) the corresponding transient photocurrent density in 0.1 M Na2SO4 at 1.23 V vs. RHE, and (h) two-step TVC growth mechanism. Reprinted with permission from ref. [49] Copyright 2017 Elsevier.

The dependency of the properties of g−CN films on the influence factors, including deposition temperature, altering the substrate, precursor amount, and sacrificial reagent, will be compared and discussed. The vapor deposition method has been widely explored for depositing uniform and dense g−CN films on various substrates, such as indium-doped tin oxide (ITO) glass, fluorine-doped tin oxide (FTO) glass, silicon slice, quartz glass, and glass. Bian et al. discovered that the morphology of the g−CN film is substrate-dependent, grown on ITO glass and silica are similar to that of on FTO glass; they are continuous films with many nanoparticles on the surface. However, inhomogeneous particles and nanorods formed on glass (Figure 4a–c) [48]. The sacrificial reagent is able to not only facilitate hole consumption, which can decrease the recombination of electron-hole pairs but also is significantly affected by the holes in the energy levels where they cannot react with OH−. The g−CN film prepared with melamine shows a photocurrent density up to 30 μA cm−2 versus RHE without sacrificial reagent under one sun illumination at 1.55 V. When sacrificial reagent was added to electrolytes, the highest photocurrent density reached up to 120 μA cm−2 (Figure 4e) [48]. Both the thickness and the optical light absorption of the films increase with the increasing mass precursor. The increased film thickness reduces the transfer resistance of electron-hole pairs between film and electrolyte interfaces, but a high mass precursor makes the films partly peel off [49]. Based on the experiment analysis, an increased deposition temperature is beneficial to enhance the optical light absorption and increase the thickness of the films. This indicates that the light absorption alongside the films shifts towards red-shift as the deposition temperature increases, which is very consistent with the absorption alongside the change of the bulk g−CN [54,55]. However, the high process temperature (above 650 °C) makes substrates largely deform [48], decreasing the uniformity and the PEC performance.

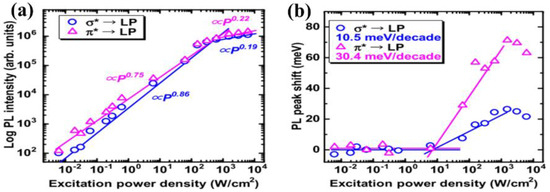

The luminescence mechanism of the g−CN thin film was reported by Urakami et al. [56], who successfully realized high-quality g−CN films on different types of substrates, such as SiO2, HfO2, and c-plane sapphire through TVC at 600 °C. A crystalline g−CN thin film can be deposited on both non-crystalline and crystalline surfaces by employing an amorphous-like buffer layer. The bonding states and stoichiometric chemical composition (N/C ratio was 1.36–1.39) are close to those of ideal g−CN. From the dependence of the photoluminescence (PL) intensity and peak shift on the excitation–power–density, electron injection from the sp3 C–N σ to the sp2 C–N π conduction band was strengthened under the above excitation condition (Eex > Eg σ) (Figure 5a,b).

Figure 5.

Excitation-power dependence of (a) the integrated PL intensities and (b) PL peak shift for σ*-LP and π*-LP transition paths of the thin film. Reprinted with permission from ref. [56] Copyright 2019 Japan Society of Applied Physics.

Based on the above analysis, TVC is considered a very simple, convenient, and effective method to prepare g−CN films. In addition to morphology, the thickness and structure of the g−CN film can easily be controlled. However, the number of precursors that can be utilized is restricted. Other frequently reported precursors fail to form g−CN films on solid substrates [48]. As is well known, NH2 groups play an essential role in nucleation. However, a lack of one NH2 group in each precursor molecule is proven to fail to realize high-quality g−CN thin film [53].

4.2. Solvothermal Route

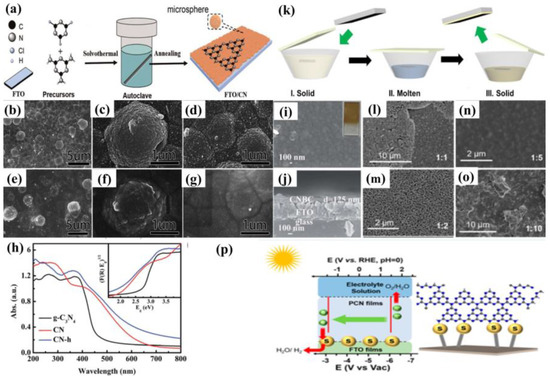

The solvothermal route is a procedure to arrange the covalent bond between the molecular precursors and the substrate surface [57,58]. It includes two essential steps (Figure 6a): Firstly, the substrate is placed in an organic solvent that is filled with nitrogen-rich precursor solutions. Subsequently, the g−CN films were annealed for the purpose of further polymerization and enhancing the contact between film and substrate.

Figure 6.

(a) Schematic illustration of the solvothermal synthesis route. Solvothermal approach utilizing melamine and cyanuric chloride: SEM images of (b–d) g−CN sample before annealing and (e–g) g−CN sample after annealing and (h) UV-vis absorption spectra (the inset shows the Tauc plots). Reprinted with permission from ref. [57] Copyright 2016 Royal Society of Chemistry. Solvothermal approach using cyanuric chloride and cyanuric acid: SEM images of the top view (i) and cross-section (j) of annealed g−CN thin film (the inset is the digital image). Reprinted with permission from ref. [58] Copyright 2017 Royal Society of Chemistry. (k) Liquid mediated growth mechanism, (l–o) SEM images of the structured PCN films with different molar ratios (the mixture of melamine and trithiocyanuric acid) after condensation at 500 °C for 4 h, and (p) the growth mechanism of the PCN films by combination of sulfur and non-sulfur mixtures and mechanism for water splitting. Reprinted with permission from ref. [59] Copyright 2014 American Chemical Society.

Using the solvothermal method with post-annealing, g−CN films can be grown on different substrates, such as FTO [57,58], glass [58], and TiO2/FTO [58]. Xie et al. fabricated g−CN films on FTO via simply dissolving cyanuric chloride and melamine in acetonitrile, as described in Figure 6a. The solutions were maintained at 180 °C for 24 h, and the g−CN film followed the Stranski–Krastanov growth mode. A transition from the two-dimensional layer-by-layer mode (shorter than 12 h) to three-dimensional micro-spheres stacking mode was observed owing to the changes in the surface energy of substrates and the properties of solutions. However, this process can hardly form a complete tri-s-triazine structure g−CN film because of insufficient kinetic energy. An annealing process, annealed in N2 at 520 °C for 1 h, for example, plays a key role in forming a tri-s-triazine structure. The interfaces of microspheres and nanoparticles become vague after a post-annealing treatment, manifesting the thermal cross-linking and condensation sequentially (Figure 6b–g). The obtained g−CN films showed higher activity in PEC performance of this technique, with photocurrent densities of 3.5 μA cm−2 at 1.23 V vs. NHE produced, compared with traditional paste-prepared g−CN. The improvement was mainly attributed to the following two factors. Firstly, the presence of covalent linkage between g−CN and the substrate generates synergistic effects. Secondly, a red shift from approximately 460 nm to 620 nm is accompanied by the diminished band gap of 2.0 eV, narrower than the 2.7 eV of the conventional g−CN (Figure 6h) [57].

Recently, a significant improvement was achieved by Gu et al. with a facile solvothermal method. Using cyanuric chloride and cyanuric acid as precursors, highly crystalline g−CN thin films were obtained on different substrates with post-annealing at 450 °C. In consequence, the photocurrent densities of 10 μA cm−2 at 1.23 V vs. RHE are produced. The resulting g−CN film exhibits enlarged conjugating structures of tri-s-triazines and s-triazines, allowing uniform and continuous interfacial contact (Figure 6i,j). Moreover, when the film was grown on the surface of anatase TiO2, the photocurrent densities were further enhanced owing to vectorial charge transfer induced by the layer-by-layer configuration [58]. This work manifests the vital effects of morphology and structure on the properties of carbon nitride films for PEC water splitting.

In addition, an effective tactic for controlling the thickness and density of g−CN films can be achieved by changing the growth time, precursor concentration, and post-heating temperature. The improvement of PEC performance was attributed to the presence of covalent linkage due to introducing either cyanuric acid or cyanuric chloride, which enhances the charge carrier transportation. Furthermore, both studies reported a diminished band gap due to improved π-electron delocalization of the conjugated structure, widening the light absorption range [57,58]. However, the obtained g−CN films for PEC water splitting were not as good as we expected, seemingly aroused by the rich surface defects of carbon nitride films. Developing new solvents and combining multiple precursors to tailor g−CN is particularly important.

4.3. Liquid-Mediated Growth

To obtain uniform, transparent, and reproducible g−CN solid thin films, the precursor in the liquid reaction system should be granted priority because liquid-mediated growth provides more intimate contact with the substrate than its common solid-phase counterpart.

The process of liquid-mediated growth is shown in Figure 6k [59]. Firstly, the substrate is fixed to the bottom of a crucible that is filled with nitrogen-rich solid precursors. Upon heating, this solid precursor melts into the liquid phase, obtaining a chummy contact with the surface of the substrate. Finally, post-annealing condensates the liquid phase and eventually turns it into a solid film. The obtained film is continuous, stable, and hand-in-glove adhered to the surface of various substrates, including FTO, ITO, glass, metal foil, and TiO2, providing great potential for the fabrication of high-performance devices. The supramolecular pre-assembly strategy has attracted extensive attention because its precursors show an identical chemical structure to g−CN and effectuate liquid-mediated growth [60]. Shalom et al. [61] utilized this strategy to form ordered structures of g−CN via hydrogen-bonded cyanuric acid-melamine supramolecular complex. The solid complex locals between two desired substrates were post-annealed to form homogeneous and comparatively organized g−CN rods. Besides its hydrogen bonds, the complex appears to possess free hydroxyl and amine groups which can be grown on varying substrates (glass, FTO, TiO2, ZnO, etc.) with diverse morphologies of g−CN. The electrode demonstrated current densities could reach up to 0.8 mA cm−2 at 0.6 V (vs. RHE) in neutral media.

In another similar work by Xu and co-workers, [59] the obtained g−CN film exhibited continuous porous network morphology on various substrates since no template was utilized during the fabrication. The mechanical robustness of the g−CN films fabricated utilizing a liquid-mediated pathway was very high, obtaining thin films that were not peeled off via sonication in water for 1 h. Moreover, g−CN films fabricated through supramolecular aggregates improve the optical and electronic properties because of their enhanced structure intactness. Inspired by these facts, Xu and co-workers [62] presented a liquid-mediated approach to preparing continuous phenyl-modified carbon nitride films via combining molten sulfur and 2,4-diamino-6-phenyl-1,3,5-triazine–cyanuric acid complexes. The photocurrent density of the prepared phenyl-substituted g−CN photoelectrode was up to 60 μA cm−2, which was 20-fold higher than that of non-sulfur-processed. The high-temperature molten sulfur integrates phenyl groups into the thin film effectively to enhance the conductivity and charge transfer, which is beneficial to improving the PEC efficiency. The intermediate state plays a crucial role in the monomer’s preorganization for the liquid-phase thin-film growth, owing to its influence on the supramolecular interactions [63]. Aside from film quality and intermediate state, the insufficient binding between the functional films and conductive substrate is also considered a major issue that hinders Polymeric carbon nitride (PCN) films for solar water splitting. To overcome this challenge, Fang et al. proposed a combination precursor of sulfur and non-sulfur complexes for the preparation of polymeric carbon nitride films [64]. It is found that sulfur exists on the PCN/FTO glass interface, which not only initializes the formation of the PCN films but also assists the charge migration between films and the substrate (Figure 6l–p). A preeminent photocurrent density of 100 μA cm−2 was achieved at 1.23 V (vs. RHE) under AM 1.5 illumination without sacrificial reagents. Inspired by the aforementioned method, the Ni chloride salt molecules were also introduced into the cyanuric acid and 2,4-diamino-6-phenyl-1,3,5-triazine supramolecular aggregates. The band gap and catalytic properties of the obtained g−CN films could be regulated via altering the Ni amount, and the PEC properties were prominently improved. The Ni atoms within the carbon nitride layers significantly extend the light absorption range and enhance the charge transfer properties [65].

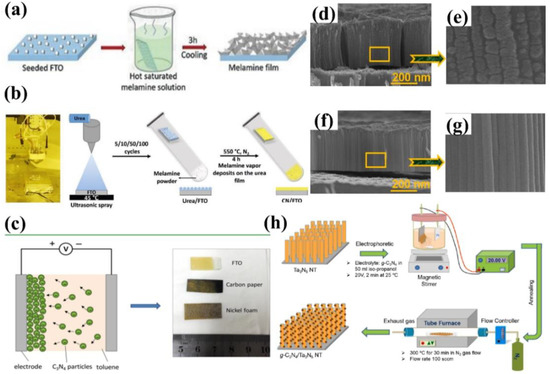

4.4. Seed Growth

Seed growth has been developed to fabricate g−CN films, and it includes three main steps: seeding the substrate, soaking the seeded layer into a hot supersaturated precursor solution, and calcination. The seeds are protected by the supersaturated precursor solution to prevent dissolution, which acts as nucleation sites for the crystallization of precursor from the solution. Upon cooling, precursor crystals spontaneously grew on the seeded substrate surface to form a well-covered film. Upon calcination of the as-prepared film, a g−CN layer was synthesized on the substrate. Shalom et al. [66] grew highly ordered carbon–nitrogen films via the seeded crystallization of carbon–nitrogen monomers, leading to a photocurrent density of 116 μA cm−2 at 1.23 V versus RHE (Figure 7a). A similar approach was used for the fabrication of g−CN-based films on conductive carbon paper [67]. Recently, Shalom et al. [68] developed a new approach to growing thick g−CN layer films via a spray-coated seeding layer composed of CN monomers, leading to an impressive photocurrent density of 300 μA cm−2 at 1.23 V versus RHE in the presence of a hole scavenger (Figure 7b), implying the high scalability potential of this method for the flexible material and device applications.

4.5. Electrochemical Deposition

To date, there are two representative routers of electrochemical deposition, including (1) electrodeposition (ED) in the involvement of ionic precipitation [35,69,70] and (2) electrophoretic deposition (EPD) based on the adsorption of charged granules onto externally biased electrodes [45,71]. In the last few years, there has been growing research interest in the fabrication of g−CN-based photoelectrodes by utilizing electrochemical deposition methods. Xu et al. [71] presented a mild pathway to construct a uniform g−CN film through the EPD approach under an anodic bias of 200 V, which can be successfully grown on different substrates such as FTO and carbon paper as well as nickel foam with complex 3D geometries. Toluene was used as a solvent owing to its large electrochemical window. The films deposited on carbon paper proved a higher photocurrent response of 12 μA cm−2 compared with 1 μA cm−2 on FTO under zero bias. The photocurrent was further improved significantly to 65 μA cm−2 by doping with barbituric acid. Therefore, tailored construction of these modified carbon nitride layers led to efficient contact with electrolytes due to the high surface area of 3D carbon paper and enhanced light-harvesting and conductivity via heteroatom doping (Figure 7c). Recently, Kang et al. designed the g−CN grown on Ta3N5 nanotube/Si substrate by electrophoretic deposition to enhance PEC performance (Figure 7d–h) [72].

Figure 7.

(a) Schematic illustration of the synthesis of melamine film, reprinted with permission from ref. [66] Copyright 2018 John Wiley and Sons Ltd. (b) Digital photo of the spray coater system, Reprinted with permission from ref. [68] Copyright 2021 Wiley-Blackwell. (c) A diagram illustrating the process of electrophoretic deposition, digital image of the deposited g−CN on FTO glass, carbon paper, and nickel foam, Reprinted with permission from ref. [71] Copyright 2016 American Chemical Society. (d–g) Cross-sectional views of FE-SEM and Magnified view of the Ta3N5NT/Si and g−CN/Ta3N5NT/Si films. (h) Representative schematic diagrams to represent the experimental procedures and methods of the g−CN. Reprinted with permission from ref. [72] Copyright 2021 Elsevier.

4.6. Disperse Coating

In spite of the fact that g−CN powder has been extensively and deeply researched, the preparation knowledge of g−CN film is still in its infancy. Recently, disperse coating strategy from colloid sources has also been reported extensively owing to its extraordinary features, including facile and cost-effectiveness. It has been applied to the deposition of carbon nitride thin film on various substrates via conventional filming technologies, such as spin coating [73], silk-screen printing [74], drop-casting [75], dip casting [76], doctor blade coating (DBC) [77], and Sol-gel process [42]. The uniformity and performance of the g−CN films mainly depend on the influenced various parameters of g−CN colloids in terms of chemical bonding and size of particles [42].

In order to fabricate the uniform g−CN thin films, the principal requirement is to obtain a stable dispersion in appropriate solvents such as alcohol, water, and methanol. Several researchers gained g−CN dispersions in water [78,79] or the combination of alcohol and water [80,81]. Nevertheless, the existence of water has always been restricted to obtain uniform thin films due to its high boiling point and surface tension. Furthermore, due to the poor solubility of g−CN powder in most solvents, the fabricated g−CN films usually present poor physical contact with the substrate as well as boundary defects, which results in a weak photocurrent response of less than 1 μA cm−2 [41,82,83].

As we know, exfoliation of two-dimensional structures shows abundant surface active sites and effectively captures the visible light compared to bulk g−CN [79,84,85]. From the practical application viewpoint, the alteration of bulk g−CN by two-dimensional g−CN nanosheets with a unilamellar structure via adopting a physical modification process (ultrasound-assisted or hydrolysis), chemical exfoliation with different solvents (acids, salts, bases, etc.), and physicochemical methods (heating and hot water) are widely used. Zhang et al. [77] demonstrated that the protonation of g−CN using strong acid (HNO3) results in a sol, which allows the fabrication of films through facile dip coating. The melon units stack together through hydrogen bonds between the nitrogen atom and NH/NH2 group, which in principle can be used as proton acceptors. To the best of our knowledge, a stable g−CN thin film with high photocurrent density not only benefits from the post-annealing process but, more importantly, should preserve its unique physicochemical features after robust HNO3 etching. As a result, there is great potential for applying the sol-gel technique for carbon–nitrogen PEC application, which shows enhanced PEC response compared to powder-based thin films.

Despite significant advances in the exfoliation of g−CN powders, the finding of ultrathin or monolayer g−CN nanosheets through strong acid treatment or chemical exfoliation undergo slight defects due to the fact that the preparation process is not environmentally friendly. Therefore, scientists suggested an urgent demand to obtain a stable and environmentally friendly dispersion for the preparation of g−CN films, which are solvents. Safaei et al. [86] demonstrated that methanol is preferable for layered g−CN due to the short drying time and significantly low surface tension. Inspired by this idea, a very promising work was reported by Mohamed and co-workers [87], who showed a simple synthetic method for the fabrication of a thinner layer by layer from bulk g−CN by employing a slow direct low thermal treatment (40 °C, 24 h) with ultrasonication, which was obtained as the highly stable g−CN suspension in a methanol solution. The exfoliation of nanosheets from bulk g−CN can form a uniform layer of g−CN thin films via using a spin-coating method followed by an appropriate post-annealing temperature at 350 °C. The obtained g−CN thin film presents a more negative conduction and valence band potentials as well as a much rougher surface (Sa roughness: 14.58 nm), which are generally helpful to PEC performance. Moreover, the photocurrent responses of the prepared g−CN films reached up to 10.21 μA cm −2 at 1.23 vs. (Ag/AgCl), which was two times higher than that of bulk g−CN.

The post-annealing temperatures also play an important role in the morphology and the chemical bonding of the g−CN thin film that ultimately influences the PEC efficiency. Zheng and co-workers [88] investigated that post-annealing transforms the hollow carbon nitride nanospheres into the triazine unit. Mohamed et al. [52] found that post-annealing improves the chemical bond structure and morphology of g−CN fabricated by the spin-coating method. In addition, there is a direct relationship between post-annealing temperature and band gap. The band gap reduces from 2.79 eV to 2.71 eV by increasing the post-annealing temperature from 150 ℃ to 350 °C, while it increases from 2.71 eV to 2.85 eV at higher temperatures (350 °C to 500 °C), the energy band gap of the g−CN thin film was enlarged. This phenomenon is ascribed to the quantum confinement effect and the shift of the CB and VB in opposite directions [88].

Whereas using the supramolecular assembly affords thin dense layers, applying a paste made up of supramolecular precursors in dispersant (such as ethylene glycol) enabling hydrogen bonds leads to porous layers of controllable thickness. It is noteworthy that the carbon–nitrogen monomers can connect with triazine derivatives (e.g., barbituric acid and cyanuric acid) to form supramolecular paste via hydrogen bond interactions [22]. Changing the supramolecular precursors can control the elemental ingredient as well. Therefore, this method enables the application of the knowledge to progress from powder-based g−CN synthesis to g−CN-based electrodes. Based on the supramolecular pre-assembly approach, an ameliorative work based on g−CN films was reported by Shalom and co-workers, who presented a general and simple pathway for the construction of highly porous and large-scale g−CN films through forming a supramolecular paste, which can be successfully grown on different substrates using the doctor blade technique [89]. g−CN has a 2D layered structure connected by van der Waals forces. When it is stripped into multilayer or single-layer nanosheets, unique chemical and physical properties are produced to further improve PEC efficiency, including (1) larger specific surface area to increase the density of the reactive center, (2) reduced thickness to reduce the carrier migration distance and effectively inhibit carrier recombination, and (3) unique two-dimensional flexible planar structure to enhance compatibility with heterojunction construction, cocatalyst modification, vacancy, and other modification strategies.

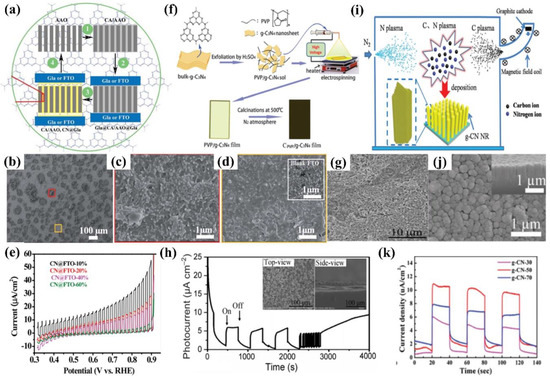

4.7. Other Deposition Methods

Some other ex situ methods have also been developed to fabricate g−CN electrodes successfully, including anodic aluminum oxide (AAO) membrane deposition [90], direct growth [61], vacuum filtration deposition [91,92], electrospinning (ESP) [77], vacuum magnetic filtered arc ion plating (VMFAIP) [93], ionothermal (molten salt) deposition [94], radio frequency magnetron (RFM)−based sputtering [95], and so on. A microcontact-printing process was reported by Liu et al., who fabricated g−CN nanostructures by injecting cyanamide into an anodized aluminum oxide (AAO) membrane sandwiched between two substrates and subsequently calcinating at 550 °C for 4 h (Figure 8a). The AAO is not a versatile template but a guide for gas-phase precursors to reach and react with the sandwiching substrates. The film thicknesses can be simply modulated by varying the concentration of cyanamide. The photocurrent density can reach about 30 μA cm−2 at 1.23 V vs. RHE (Figure 8a–e) [90].

Figure 8.

(a) Schematic illustration of printing g−CN thin films on “sandwiching” substrates (AAO template growth mechanism), (b) the surface morphology, (c) magnified image of the selected box area (red) in (b) displaying that the nano−islands, (d) magnified image of the selected box area (yellow) in (b) displaying the detailed microstructures (the inset is the bare FTO image), and (e) LSV photocurrent density in 0.2 M Na2SO4 at 0.86 VRHE. Reprinted with permission from ref. [90] Copyright 2015 Wiley-Blackwell. (f) A diagram illustrating the process of electrospinning mechanism, (g) top−view SEM image of the CPVP/g−CN film on ITO glass, (h) time dependence of the photocurrent density of CPVP/g−CN in 0.05 M Na2SO4 at a 0.5 V vs. SCE (the insets are top-view and cross-section SEM images of the film after testing). Reprinted with permission from ref. [77] Copyright 2017 Wiley-VCH. (i) Schematic illustration of VMFAIP system used for fabrication of g−CN NRs on FTO glass, (j) SEM images of the top-view and cross-sectional (inset), (k) transient photocurrent response under different target currents in 0.5 M Na2SO4 at 1.23 V vs. RHE. Reprinted with permission from ref. [93] Copyright 2018 Royal Society of Chemistry.

Electrospinning as a practicably proven method is also used to fabricate the PEC photoanode, in which the ITO substrate is coated with prepared polyvinylpyrrolidone (PVP)/g−CN sol and annealed at 500 °C. The thickness of the films can be modulated by varying the electrospinning time and actually controlling the PEC performance. Furthermore, the photoelectrode demonstrates a stable photocurrent performance (6.64 μA cm−2) for 4000 s with no degradation (Figure 8f–h) [77]. Wang et al. developed a vacuum magnetic filtered arc ion plating (VMFAIP) approach, in which the carbon plasma emitted from a graphite cathode was deflected by a magnetic field and combined with N2 to generate C–N compound on the FTO substrate. The resulting g−CN nanorod (NR) arrays eliminated the intralayer hydrogen bonds owing to the utilization of carbon and nitrogen sources alone. The change of the graphite target current allowed different lengths of the g−CN nanorod arrays from 550 nm to 1.1 µm. The gas-based approach via the VMFAIP system enabled the g−CN to form heterostructures easily with, including but not limited to, TiO2 nanorod arrays (Figure 8i–k) [93]. Ladva et al. [94] synthesized g−CN thin films with a bandgap of approximately 1.73 eV by an ionothermal (molten salt) approach using dicyandiamide, KBr, and LiBr mixture precursors. Lou et al. [96] demonstrated a g−CN layer on the substrate by embedding g−CN in a matrix conductive polymer binder (PEDOT-PSS [96,97,98], Nafion [57,99,100], and others) [101]. Compared with Nafion, the g−CN film blended by PEDOT-PSS showed superior PEC activities because the PEDOT-PSS binder is a wonderful conducting polymer and can act as a hole-transport layer. Recently, Tejasvi et al. [95] synthesized stoichiometric g−CN thin films by radio frequency magnetron sputtering using a g−CN pellet as a target. Thin-film samples can be deposited on the borosilicate glass and TiO2 nanotube array in Ar and N2 plasma media. The PEC studies summarized that the g−CN/TiO2 formed under Ar plasma (~290 μA/cm2 at 0.9 V) obtained a higher current density as compared to that under N2 plasma (~160 μA/cm2 at 0.9 V).

Although various techniques have been employed to prepare g−CN electrodes, g−CN films prepared by ex situ methods mostly show poor photocurrent density (several μA cm−2), which can be ascribed to the uneven coverage and the weak adhesion of g−CN on the substrates [83]. In contrast, the g−CN films in situ synthesized on various conductive substrates by a bottom-up route generally exhibit good photocurrent density (10–120 μA cm−2) [66]. Shalom et al. [66] grew highly ordered g−CN films via the seeded crystallization of melamine monomers, leading to a photocurrent density of 116 μA cm−2 at 1.23 V versus RHE under AM 1.5G in 0.1 M KOH aqueous solution. This is the best value reported for pure g−CN electrodes without a sacrificial agent. Enormous space still exists for achieving a theoretical photocurrent density of 14.5 mA cm−2 and a maximum solar-to−hydrogen (STH) efficiency of 17.9% under AM 1.5G (100 mW cm−2) [24,25,26]. The various types of synthesis methods for the construction of g−CN films with the corresponding photocurrent comparison are summarized in Table 2. In addition, in order to produce g−CN with a uniform texture, casting g−CN embedded in a conductive polymer matrix tactics is highly worth considering. The method has two-fold advantages: it improves the charge transfer in the film and enhances the casting homogeneity. Despite this, enormous space still exists for devising efficient tactics to fabricate homogenous electrodes.

Table 2.

Photocurrent response comparison of different methods.

5. Functionalization of g−CN Photoelectrode

5.1. Heteroatoms Doping

When pure g−CN films are employed as photocatalysts, their practical applications are still hindered by limited theoretical photocurrents. The p–p* transitions in the conjugated aromatic system of g−CN result in a band gap of 2.7 eV, suppressing the absorption above 460 nm [75]. Doping of additional atoms and impurities into the g−CN matrix is considered an effective strategy to ameliorate structural defects and distinctly tune its physicochemical properties, including extending visible-light absorption scope and regulating redox potentials to further promote the PEC properties. There are two main types of elemental doping that will be explored in this section, namely nonmetallic elements doping and metallic elements doping.

Qi and co-workers [102] prepared Ag-doped g−CN films (Ag/g−CN) via a liquid-based reaction process employing AgNO3 as the Ag dopant. The AgNO3 strongly affects the PEC efficiency of the Ag/g−CN films. The optimized photocurrent density was as high as 6.40 μA mm−2 for the Ag/g−CN films (molar ratio of 1: 10), which was approximately 6.8−fold higher than that of a pristine g−CN film electrode. This is due to the efficient charge transfer and improved light-harvesting property of Ag-doped g−CN film. Apart from Ag, Karimi-Nazarabad and co-workers [103] developed a new type of Pd-doped g−CN photoanode via an electrophoretic deposition (EPD) strategy. A Pd-doping amount of 2 at% into g−CN exhibits a transient photocurrent density of 79.2 μA cm−2, which is notably higher than those of Ag/g−CN and pristine g−CN films. Additionally, the photoelectrocatalytic oxygen evolution performance is improved due to the facilitated transfer efficiency of photo-generated charge carriers, which can be ascribed to the deeper band bending and the remarkable trapping capability for electrons. Recently, doping engineering with Thorium Nitrate (ThO2) during g−CN polymerization altered the chemical bonding, with the improved PEC activity (Figure 9a) [104]. The Sr-doped g−CN showed enhanced PEC activity [105].

In addition to the metallic atom-doping mentioned above, the incorporation of non-metallic atoms such as B, C, and S into the g−CN framework was also studied. Compared with metal doping, the superiority of nonmetal doping is distinct due to its capability of reserving the nonmetallic properties of g−CN.

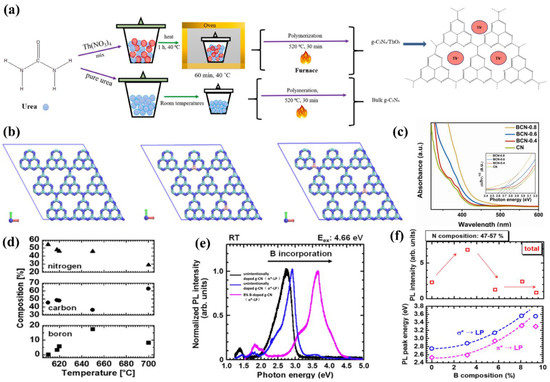

Huang and co-workers [106] presented a facile TVC method to prepare B-doped g−CN films using boric acid as the B source. The XPS analysis clearly confirmed that the B atoms were successfully incorporated into the g−CN framework and replaced the C composition partially (Figure 9b). The B doping effectively reduced the band-gap by raising the valence band and prolonging the charge carrier lifetime by altering spatially orbital distributions. Optical band-gap energies decreased from 2.77 to 2.60 eV with the increasing boric acid content in the precursor (0 to 0.8 g), extending the photon absorption edge (Figure 9c). The photocurrent density of the optimized B-doped g−CN films was as high as 55 μ Acm−2 at 1.23 V vs. RHE, which was four-fold higher than that of pristine g−CN films. The type of species supplied from the precursors and the pyrolysis temperature has a slight effect on the chemical compositions of compound semiconductor alloys [107,108,109]. Therefore, to control additional atoms composition and band-gap energy, the influence of pyrolysis conditions on additional atoms incorporation into the C–N network should be expounded. Inspired by these facts, Urakami and co-workers [110] reported a simple thermal chemical vapor deposition (CVD) route to prepare the B-incorporated g−CN film by employing ammonia borane (H3N–BH3) as the B source. It was also noted that the pyrolysis temperature had an intimate connection with the compositional ratios, and the preferable temperature for B doping ranged from 618 °C to 650 °C (Figure 9d). Importantly, a shift of the PL peak from 2.7 eV to 3.60 eV was manifested by B-incorporation with a composition of 8.0%. The PL peak energies for σ*−LP and π*−LP shift routes were in accordance with the quadratic function, manifesting that the band-gap bowing appeared as in orthodox compound semiconductor alloys (Figure 9e,f).

Figure 9.

(a) Schematic illustration of the formation process. Reprinted with permission from ref. [104] Copyright 2021 Elsevier. (b) Top-views of super-cell 3 × 3 pure g−CN (left) and B-doped g−CN with two C substituted by B at corner (middle) and bay (right) sites in a lattice with constants of a = b = 21.04 Å, c = 20.0 Å, and α = β = 90°, γ = 120° by DFT optimizations. The green, blue, and pink colors represent C, N, and B atoms, respectively, and (c) the UV–vis absorption spectra (the inset shows the Tauc plots). Reprinted with permission from ref. [106] Copyright 2018 Elsevier. (d) Substrate temperature dependence of compositions, (e) typical RT-PL spectra for B-doped g−CN films with various compositions, the black line is the a peak energy corresponds to unintentionally doped g−CN films (π*-LP), the blue line is the a peak energy corresponds to unintentionally doped g−CN films (σ*-LP), and the pink line is the a peak energy corresponds to B-incorporated g−CN with a composition of 8.0% (σ*-LP) and (f) room temperature integrated PL intensity and PL peak energy depended on B composition. Reprinted with permission from ref. [110] Copyright 2020 Wiley-VCH.

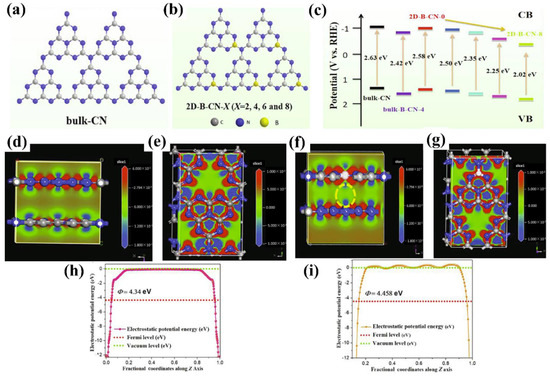

In addition, a novel two-step surface boron decoration of g−CN is currently gaining attention as this approach shows active influences on the structural and optical properties [111]. The strong van der Waals force attractions between sp2 carbon atoms make g−CN poorly dispersible in an aqueous solution, and the strong hydrophilicity is key to ensuring the full development of g−CN-based materials in an aqueous medium. A structure of hydrophilic and high surface area assembled by two-dimensional B-doped g−CN has been successfully prepared to effectively control the band gap and charge separation (Figure 10a–c). The electron density difference (EDD) map and work function results show that B-doped g−CN has a higher distribution of electron density (Figure 10d–g), and a larger work function makes a higher degree of band bending, leading to the rapid transfer of electrons, and thus improving the PEC capability (Figure 10h,i) [112].

Figure 10.

(a,b) The detailed structures of bulk-CN and 2D B doped g−CN (2D-B-CN) samples. (c) schematic energy level diagrams. (d,e) Electron density difference (EDD) plots and (h) work function of bulk-CN. (f,g) EDD plots and (i) Work function of 2D-B-CN (C, N and B atoms are labelled in gray, blue, and white, respectively). Reprinted with permission from ref. [112] Copyright 2022 Elsevier.

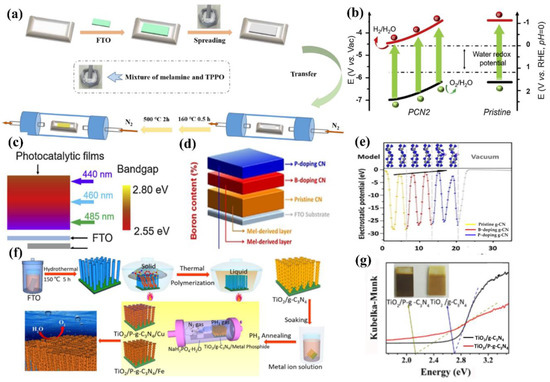

Similarly to B, other non-metallic atoms such as C, P, and S were also examined. Bian and co-workers [53] fabricated a series of C-doped g−CN films by altering the weight percentage of 2, 6−Diaminopyridine and melamine precursors. The embedded gaseous sp2 C groups influenced the energy band structure (absorption edge) and improved the diffusion length, resulting in the enhancement of PEC activity. The photocurrent density of C-doped g−CN film (5 wt %) was 0.1 mA cm−2 at 1.23 V versus RHE, which was over four-fold higher than that of pure g−CN. Dang et al. [113] prepared P-doped g−CN by utilizing melamine as the g−CN precursor and triphenylphosphine oxide as the P source through a facile solid thermal melting method (Figure 11a). The optimum efficiency was achieved as 127.4 μA cm−2, which was five-fold higher than that of pure g−CN. Similar methods were also prepared for the p-doped g−CN with enhanced PEC activity [114].

Other non-metallic atom-doped g−CN photoelectrodes have also attracted extensive attention in PEC applications. Ye et al., 2016 [115], grew a uniform and reproducible g−CN thin film on indium-tin oxide (ITO) substrates by incorporating quantitative thiourea into melamine through a CVD method with a slow heating rate. The S-doped g−CN films displayed a photocurrent of approximately 30 μA cm −2, which was mainly ascribed to the S-doping and particularly the modification of surface morphology, crystalline, and band structure by the polymerization of the precursors.

In addition, Fang et al. [116] modified the g−CN by the incorporation of gradient sulfur doping along the films through molten mediated polymerization of melamine and ammonium thiocyanate. As we know, the band edges have an important role in the thermodynamics of the redox reactions. An ideal design of the photoanodic film and the corresponding charge separation and transfer after the visible absorption are shown in Figure 11b. The valence band maximum of the film should gradually increase from the bottom (close to the substrate) to the top (away from the substrate) versus vacuum potential (vs. Vac), while the conduction band minimum of the film should progressively decrease from the top to bottom (vs. Vac). Therefore, the photo-excited electron will transfer to the counter electrode for hydrogen evolution on the other side. Furthermore, the band-gap of the film should increase from bottom to top. Under illumination, the top of the photoanode will absorb the solar light with a low wavelength. Subsequently, the incident illumination with a higher wavelength will be captured by the bottom active film. As expected, the S-doped g−CN narrowed the band gap from 2.8 to 2.55 eV with a forceful absorption tail in the visible light region. In the depth study, charge separation and migration are enhanced via virtue of the inch-by−inch varied band structures, which makes an agreement with the theoretical example as shown in Figure 11c. As a result, the optimal photocurrent density is ca. 110 μA/cm2 at 1.23 V vs. reversible hydrogen electrode. This manifestation acts as a platform to form the gradual variation of the band-gap employing metal-free films to enhance the performance of PEC for other extended applications [117,118,119,120].

Lately, g−CN film via co-doping of nonmetal and metal atoms has gained wide attention because this strategy shows a positive impact on the structural and optical properties. Jing et al. [121] reported the preparation of K and I co-doped g−CN with the use of dicyandiamide, KI, and I2 as the starting materials. It was found that the K&I co-doping transforms the from amphoteric to n-type semiconductor property. The photocurrent density of K&I co-doped g−CN is approximately 50.3 μA cm−2 at 0.5 V versus Ag/AgCl. Luan et al. [122] reported a unique multi-layer doped non-metal g−CN photoanode using a one-pot TVC. In this structure, a P-doped top layer, B-doped middle layer, and pure g−CN bottom layer were designed to enhance the photocurrent density by nearly nine times that of the pure g−CN. This approach effectively forms dual junctions composed of ternary layers to optimize the charge carrier behavior. The calculated electrostatic potential along the c-axis clearly exhibits that the work function gradually decreases from pure g−CN to B-doped g−CN and P-doped g−CN layers, which is conducive to transfer carrier from bulk to surface (Figure 11d,e).

Based on the discussion above, doping additional atoms and impurities into the g−CN matrix was mainly focused on solid or liquid state reactions. A gas-phase reaction using phosphide as a P source was also achieved by Qin et al. [123]. Clearly, a gas reagent can diffuse into the interlayer and produce a more homogeneous modification. Moreover, a simple phosphide gas treatment of TiO2 nanorod/g−CN not only narrows the band gap into a visible-light range from 2.70 to 2.13 eV but also forms a metal (Cu and Fe) phosphide water oxidation cocatalyst via one-step phosphide annealing process. As a result, the metal phosphide-modified sample yields an outstanding visible light (>420 nm) photocurrent response of approximately 0.3 mA cm−2 at 1.23 V versus RHE (Figure 11f,g). This strategy will provide new insight into other correlative and highly applicable 2D semiconducting materials.

In fact, heteroatom doping is deemed to introduce impurities into g−CN films, with the doping atoms either substituting lattice atoms or dwelling in the in-planar cave of g−CN. In addition, the incorporation of dopant orbitals into the g−CN molecular orbitals enables us to modulate the light absorption and redox band potentials. The above-discussed investigations on the novel doping approach can be further applied to other modified g−CN-based films, which hold immense potential for other applications such as organic pollutants degradation and CO2 reduction. However, excessive doping of heteroatom is detrimental to PEC efficiency because the appearance of more defects reorganizes the light-generated electron/hole pairs due to the doping asymmetry [119,124,125].

Figure 11.

Illustration of (a) preparation process of P−doped g−CN photoelectrodes. Reprinted with permission from ref. [113] Copyright 2022 Elsevier. (b) A schematic illustration of band structures of gradient S−doped g−CN and pristine g−CN for solar water oxidation, and (c) the requirements of the band gap from the top to the bottom of photocatalytic films to allow fully absorbing of solar energy. Reprinted with permission from ref. [116] Copyright 2020 Elsevier. (d) Schematic illustration of layer−doped g−CN photoanode composed of ternary layers (P−doped top layer, B−doped middle layer, and pure g−CN bottom layer) and (e) electrostatic potential along the c-axis in different doping layers and related models. Reprinted with permission from ref. [122] Copyright 2020 Wiley−VCH. (f) A diagram illustrating the fabrication of FTO/TiO2−nanorod/P−g−CN/metal phosphide electrodes for the PEC water splitting and (g) the Tauc plots. Reprinted with permission from ref. [123] Copyright 2019 Wiley−VCH.

5.2. Copolymerization of g−CN

The π−conjugated structure of g−CN is another factor that influences the PEC activity owing to the sp2−hybridization of carbon and nitrogen elements. The copolymerization approach allows the integration of structure-matching aromatic groups or organic additives into the g−CN framework to adjust its intrinsic properties [126,127,128]. It was found that molecular doping can modulate the conventional π systems, band structure, electronic properties, optical absorption, and, importantly, PEC performance [129]. Bian et al. [53] copolymerized melamine and 2,6−diaminopyridine (26D) to synthesize g−CN film by the TVC method. The XPS demonstrates that the 26D generates gaseous sp2 C groups under high temperatures and increases the C/N ratio of g−CN film to promote electron transport. The resulting film shows strong light response properties as well as an extended light absorption region, resulting in the improved photocurrent density from approximately 0.024 to 0.1 mA cm−2 at 1.23 V versus RHE (nearly four times).

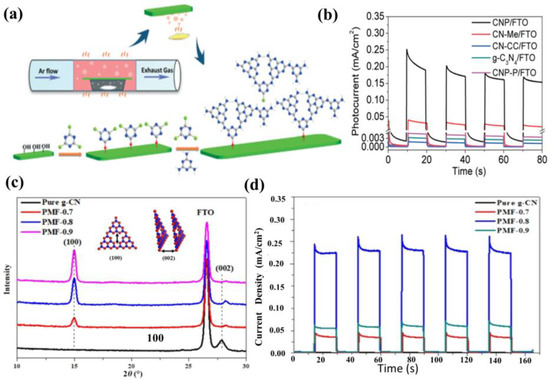

In another work, Jia et al. [130] prepared a compact 2D carbon nitride polymer film (CNP) on FTO through an evaporation polymerization strategy, utilizing melamine and cyanuric chloride as raw materials. The photocurrent density of the CNP film is 230 μA cm−2 at 1.23 V (vs. RHE) under visible light irradiation without sacrificial reagents and cocatalysts, which is 7.5, 176.9 and 67.6 times higher than that of the CN-Me (melamine as a precursor), CN-CC (cyanuric chloride as a precursor), and bulk g−CN powders, respectively. The improved PEC performance is ascribed to the enhanced charge transport, increased number of terminal amino groups, and the efficient visible light harvesting caused by the intimate contact (Figure 12a,b). According to the report by Xiong et al. [131], a synergistic protocol is employed to combine the formaldehyde modification and sulfur doping methods to tune (100) and (001) crystal facets of g−CN. This strategy yielded tremendous enhancement in photocurrent response, reaching nearly 228.2 μA cm−2 at 1.23 V vs. RHE (Figure 12c,d).

Figure 12.

(a) Schematic illustration of the synthesis of the g−CN film with a triazine–heptazine network, and (b) photocurrent (i–t curve) of g−CN film chopping in 0.5 M Na2SO4 under simulated solar irradiation. Reprinted with permission from ref. [130] Copyright 2019 Royal Society of Chemistry. (c) XRD patterns of pure g−CN and tailored films, and (d) transient photocurrent response in 0.2 M Na2SO4 at 1.23 V vs. RHE. Reprinted with permission from ref. [131] Copyright 2018 Wiley-VCH.

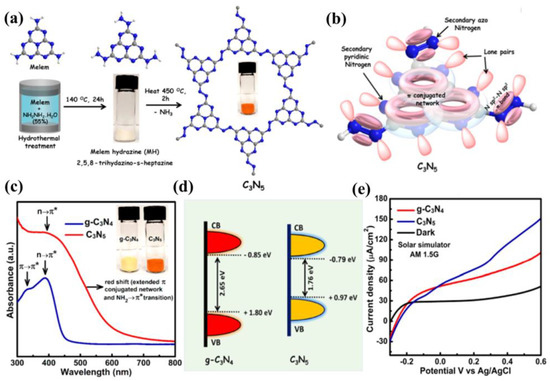

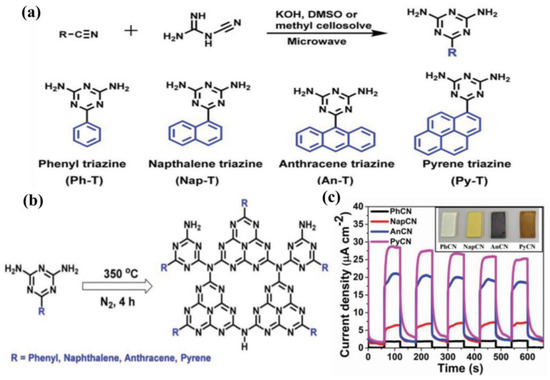

In view of the advantages of chemical structure modification and copolymerization, Kumar et al. [132] synthesized C3N5 polymer by applying melamine-derived melem (2,5,8−triamino-s−heptazine) and inorganic monomer (hydrazine hydrate) to generate intermediate melem hydrazine (MH) through hydrothermal reaction, following annealing at 450 °C for 2 h. In the C3N5 framework, two s-heptazine units are bridged together by azo linkage (−N≡N−), which is a completely different bonding mode compared to C3N4, where three heptazine units are connected with tertiary nitrogen. Owing to overlap between the π orbitals of azo-bridged units and the π system of heptazine motif, the band-gap of C3N5 was markedly reduced to 1.76 eV, which enables the optical light absorption to expand up to 670 nm. The photocurrent response for the C3N5 and g−C3N4 blended TiO2 electrode was proved to be 152 and 100 μA cm−2 at 1.23 V vs. NHE (Figure 13a–e). Recently, a high dispersible carbon nitride material functionalized with polycyclic aromatic hydrocarbons (PAH-CNs) was first introduced by Karjule et al. [133]. New starting monomers with substituted triazines were fabricated through a microwave (MW) irradiation strategy using dicyandiamide and aryl-nitrile as raw materials, which forms PAH-CNs by thermal condensation at 350 °C. Furthermore, changing the PAH group within the g−CN scaffold enables the modulation of their optical and electronic properties. The photocurrent density is improved from approximately 2 to 27 µA cm−2 (nearly 13 times) owing to the more extended conjugation to promote electron transport and expand light-harvesting range (Figure 14a–c). This breakthrough work can permit researchers to fabricate well-dispersed g−CN materials with tunable electronic and improved light-harvesting properties for PEC or other applications.

Figure 13.

(a) Synthesis strategy of C3N5 from melem by melem hydrazine. Gray, blue, and white balls denote C, N, and H, respectively. (b) Plausible molecular orbital overlap schematic diagram of C3N5. (c) DR−UV-vis absorption spectra (the inset shows the photographs of g−C3N4 and C3N5 samples). (d) Density of state (DOS) revealing band-gap structure of g−C3N4 and C3N5. (e) LSV photocurrent response of C3N5 and g−C3N4 blended TiO2 sample measured in 0.1 M Na2SO4 solution AM1.5G light irradiation and under dark conditions. Reprinted with permission from ref. [132] Copyright 2019 American Chemical Society.

Figure 14.

(a) Synthesis diagram of polycyclic aromatic triazines and their different molecular structures. (b) Self-condensation of the corresponding monomers. (c) The photocurrent measurements of polycyclic aromatic hydrocarbons modified CNs (PAH-CN) drop-casted electrodes at 1.23 V vs. RHE (the inset shows the photographs of g−CN dissolved in tetrahydrofuran (THF) and drop-casted on FTO). Reprinted with permission from ref. [133] Copyright 2019 Wiley-Blackwell.

To sum up, doping is used to modulate the π conjugated system including light absorption, electron band structure-properties, and PEC activity by introducing heteroatoms, aromatic groups, or organic additives. It can be divided into atomic doping and molecular doping according to the doping levels. In general, atomic doping involves the insertion of non-metallic atoms into the g−CN lattice, partially replacing C or N atoms. On the other hand, the metal atoms can be inserted into the triangular gap cavity of the g−CN lattice. Compared with metal doping, non-metallic doping has obvious advantages because it can retain the non-metallic properties of g−CN. Co-doping and gradient doping have also attracted extensive attention. However, excessive heteroatomic doping will lead to doping asymmetry and a large number of defects, which will lead to the recombination of photo-generated carriers, which will hinder the improvement of PEC efficiency. Copolymerization is a molecular doping method in which the addition of structure-matching organic reagents (such as organic comonomers containing cyanide and benzene rings) in the copolymerization of nitrogen-rich precursors is an effective method to adjust their band structure at the molecular level of g−CN.

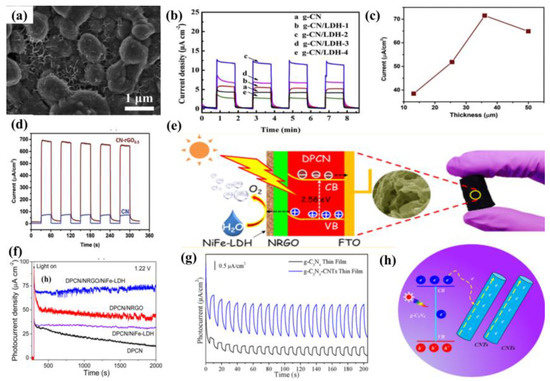

5.3. Cocatalysts

The modification of semiconductors with a cocatalyst is also a fascinating endeavor to enhance PEC performance. Cocatalysts mainly play two important roles, namely, acting as a reactive site and facilitating the separation of photo-induced charge. The typical reduction cocatalysts employed in the g−CN photoelectrodes are noble metals such as Pt, Rh, Ru, and Au. Nevertheless, it is not practical for commercial g−CN-based PEC applications owing to their high cost and rarity. In terms of economic and practical production, much research has been conducted on the use of transition metals (such as Ni [13] and Cu [134]) or alloying Pt with less expensive and abundant metals as co-catalysts. For example, nickel-decorated sulfur-doped graphitic carbon nitride with bismuth oxybromide (Ni/S-g−CN/BiOBr) shows a photocurrent density of 177.2 uA/cm2 at 1.23 V vs. RHE, which is nearly three-fold higher than that of S-g−CN/BiOBr [13]. In addition, bimetallic co-catalysts have a great advantage in promoting the PEC reaction in comparison with monometallic analogues. The excited electrons from semiconductors can be injected into bimetallic alloys more easily. The bimetallic Pt-Ni incorporated g−CN nanotubes exhibit an excellent and stable photocatalytic performance, which is higher than that of Pt/g−CN nanotubes [135]. This result shows that bimetallic is expected to replace noble metal with better performance and lower cost. Furthermore, hydroxides [136] and oxyhydroxides [137,138] are effective cocatalysts for the g−CN modification to improve the redox reactions activity [139,140]. The photocurrent density could be availably improved from 89 μA cm−2 to 0.12 mA cm−2 after loading FeOOH on the g−CN film surface [51]. In another work, Fan et al. [141] modified g−CN film with NiCo-layered double hydroxide (NiCo-LDH) co-catalysts via cathodic electrochemical deposition. The resulting photoelectrode after incorporation of the NiCo-LDH decreases the charge migration resistance at the interfaces, which helps to promote the reaction kinetics and charge separation. The optimized g−CN/NiCo-LDH photoelectrode shows a photocurrent up to 11.8 μA cm−2 at 0.6 V vs. SCE, which was 2.8−fold higher than that of pristine g−CN (Figure 15a,b).

Because of the superior electrical conductivity of sp2−bonded carbon atom, carbon-based materials, e.g., carbon dots, carbon nanotubes (CNT), and graphene oxide, etc., are promising substrates and excellent reductive cocatalyst to integrate with g−CN, inhibiting the recombination of charge carriers [142,143,144]. Graphene, a honeycomb nanostructured 2D macromolecular structure of carbon atoms, has received tremendous attention because of its excellent optical and electrical features, large surface area, and good chemical stability. There are growing numbers of research on the fabrication of graphene/g−CN hybrid photoelectrodes for PEC applications by considering 2D/2D face-to−face interaction. In one of the pioneer studies [145], a hybrid material with the carbon nitride layer on the reduced graphene oxide layer (CN-rGO) was synthesized by a doctor-blade technique using a supramolecular precursor followed by thermal calcination. The incorporated graphene behaves as the electron-conducting channel to improve both photo-generated charge separation and electron diffusion length. With increasing graphene contents, the hybrid material exhibited a higher photocurrent response of 72 µA cm−2 at 1.23 V versus RHE (electrode thickness up to 36 µm) and subsequently decreased for a thicker photoelectrode. Photocurrent measurements with holes scavenger (TEOA) display a photocurrent response of 660 µA cm−2 at 1.23 V versus RHE and the external quantum yield of 60% at 400 nm (Figure 15c,d).

Figure 15.

(a) SEM images of g−CN/LDH with 10 mC electric quantity. (b) i–t curves of g−CN and g−CN/LDH composites with different LDH amount under chopped light. Reprinted with permission from ref. [141] Copyright 2019 Elsevier. (c) The photocurrent-thickness relationship. (d) Photocurrent response in 0.1M KOH and10% TEOA aqueous solution at 1.23 V vs. RHE upon illumination of one sun. Reprinted with permission from ref. [145] Copyright 2018 Wiley-VCH. (e) The photographs, FESEM image and charge transfer mechanism. (f) Transient photocurrent responses under AM 1.5G irradiation at 1.22 V vs. RHE. Reprinted with permission from ref. [142] Copyright 2016 American Chemical Society. (g) Photocurrent response of g−CN−CNTs compared with pure g−CN thin film in 0.5M Na2SO4 at 0 V vs. RHE. (h) Schematic illustration of charge transfer mechanism. Reprinted with permission from ref. [91] Copyright 2017 Elsevier.

Recently, graphene derivatives (e.g., chemically doped graphene) have been integrated with g−CN to form a heterojunction photoelectrode. In particular, various types of dopants have triggered keen interest in the preparation of N-doped graphene as it can ameliorate the optical, electronic, and chemical reactivity of graphene by making use of the lone-pair electrons of nitrogen atoms and the π−conjugated electrons of 2D graphene. Hou and coworkers [142] employed a facile hydrothermal method with urea to integrate N-deficient porous g−CN nanosheets (DPCN) and Nickel-iron−layered double hydroxide (NiFe-LDH) into 3D N-doped graphene (NRGO) framework. A record-high photocurrent density of 162.3 μA cm−2 at 1.4 V and remarkable photostability (>10 h) are realized (Figure 15e,f). The enhancement in the efficiency of this novel aerogel photoanode is based on: (i) the optimized energy band structure and improved light absorption derived from the 2D DPCN with deficient structures, (ii) 3D NRGO-based aerogel provides a hierarchical porous structure to improve the charge transport property, and (iii) a close-contacting NiFe-LDH contributes to the effective kinetic transportation of photo-generated electron–hole pairs via introducing the spatially separated interfaces.

In addition, 1D CNT is another carbon allotrope with extraordinary electronic properties. Hitherto, there have been several investigations to integrate g−CN with CNT as the composite films for promising PEC applications. Miao et al. [91] employed a vacuum filtration self-assembled process and subsequent annealing treatment to synthesize g−CN−CNTs thin film by incorporating g−CN nanosheets supernatant with CNTs aqueous solution. The photocurrent density could be availably improved from approximately 0.5 to 1.8 μA/cm2 (nearly 3.7 times) via the recombination of CNTs to promote electron transport. The enhanced PEC performance was accredited to the excellent electrons transport capability by CNTs, fundamentally resolves the poor electronic conductivity of the conglomerated g−CN nanosheets structure and allows valid electrons separation and collection (Figure 15g,h).

Among the surface modification methods to improve the PEC performance of g−CN, the supported co-catalyst is an effective one to improve the separation efficiency of photo-generated carriers. The co-catalyst can not only promote the activity of the substrate semiconductor but also inhibit the photo-corrosion that may occur during the PEC process. However, non-noble metal-based co-catalysts still encounter low activity and low stability. In addition, the energy level structure, electronic structure and interface structure also require reasonable construction for the g−CN/co-catalyst system. There are many factors affecting the PEC performance of the g−CN/cocatalyst system, including load, particle size, interface binding force, etc. Only after reasonable consideration and design can the photo-generated carriers be efficiently generated from g−CN and across the contact interface to the cocatalyst surface in the right direction. In addition, a photocurrent density comparison of the functionalization of g−CN-based photoelectrodes by heteroatoms doping and textural design is shown in Table 3.

Table 3.

Representative summary of the PEC activity enhancement of g−CN-based photoelectrodes.

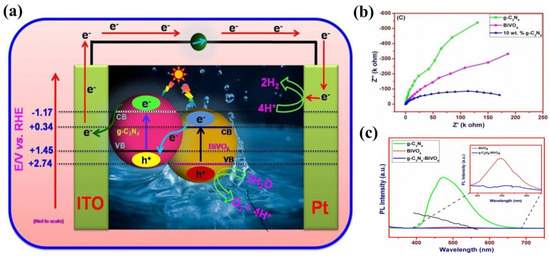

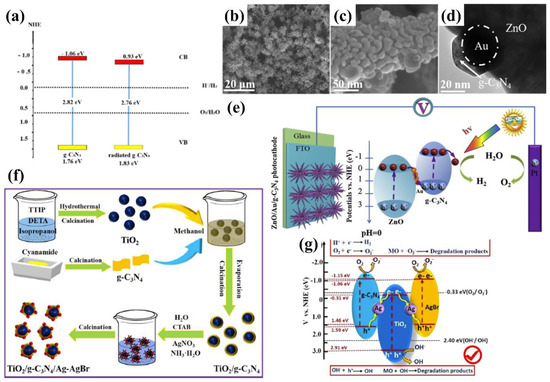

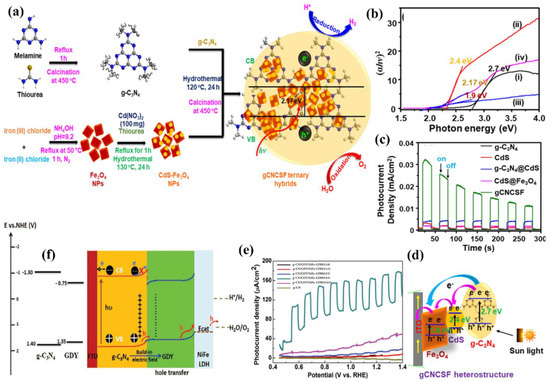

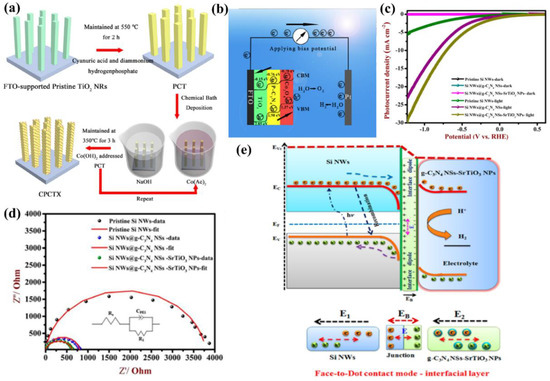

6. Composite Films of g−CN as Highly Valid Photoelectrodes for PEC Application

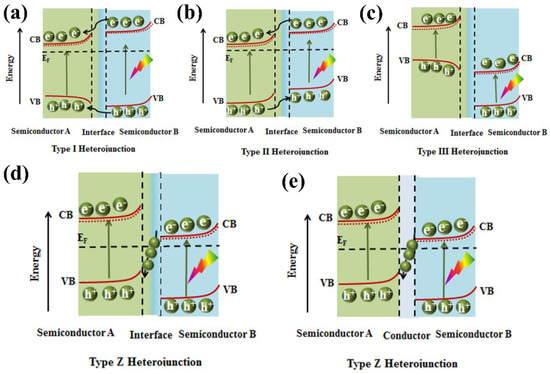

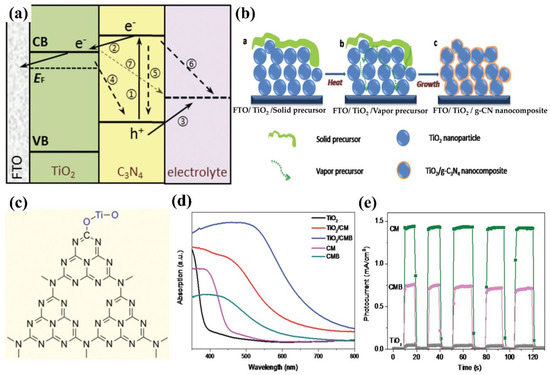

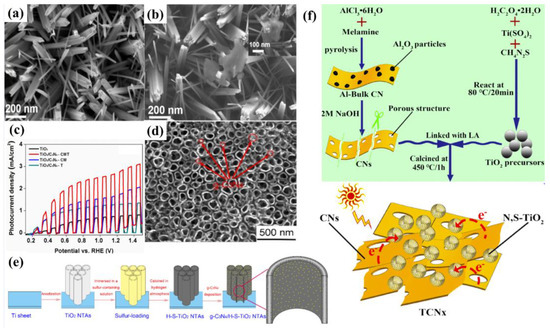

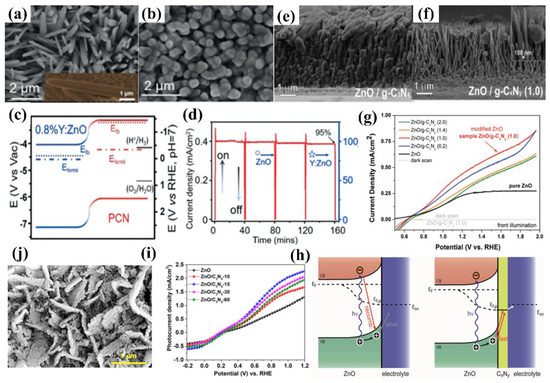

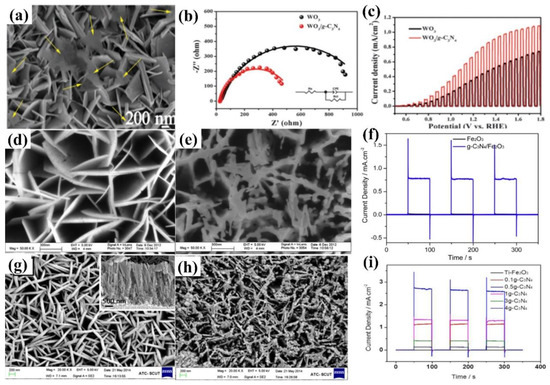

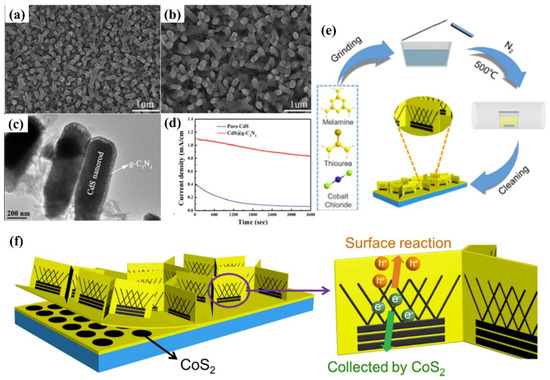

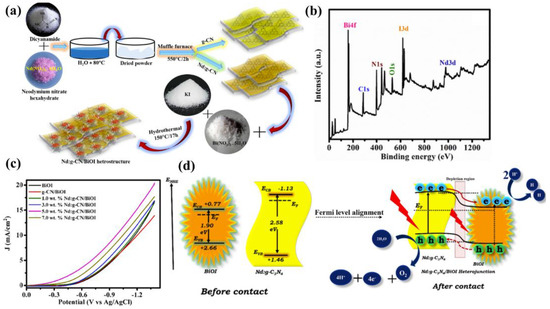

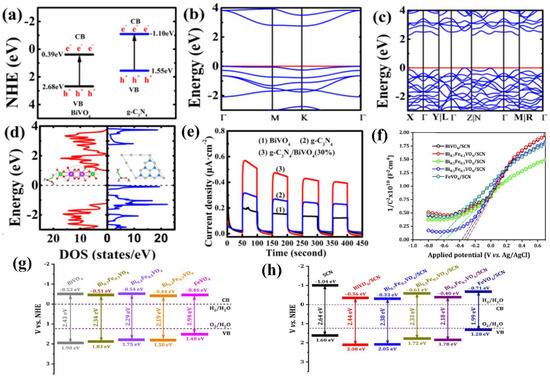

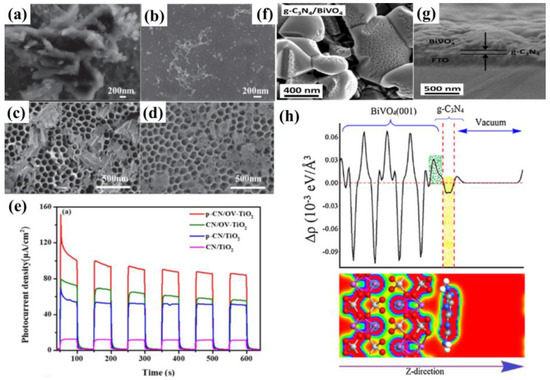

As aforementioned, similar to the conventional inorganic semiconductor photocatalysts, the pristine g−CN films usually suffer from several intrinsic shortcomings, such as insufficient visible-light absorption, the rapid recombination rate of charge carriers, and low electrical conductivity [105,146,147]. Therefore, various strategies are employed to restrain the recombination of charge carriers in g−CN films to enhance the PEC performance. In addition to the heteroatoms doping and textural design, as discussed in Section 5, the construction of g−CN-based heterojunction composite films for PEC application has elicited a great deal of attention, which will be across-the−board reviewed in the following subsections.