In Vivo Evaluation of the Effects of Sintering Temperature on the Optical Properties of Dental Glass-Ceramics

Abstract

:1. Introduction

2. Materials and Methods

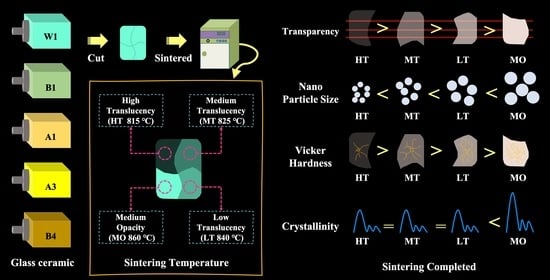

2.1. Preparation of Glass-Ceramics

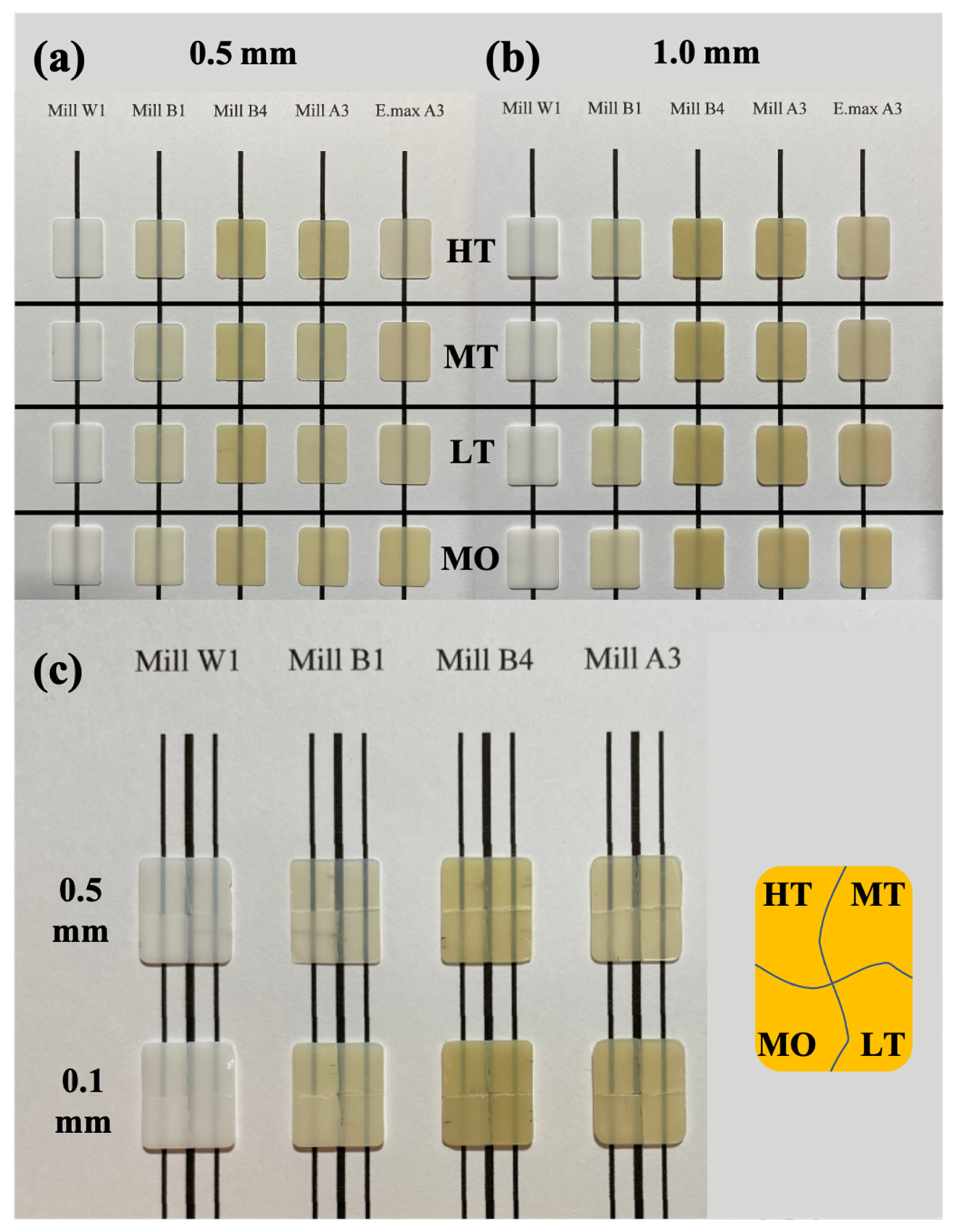

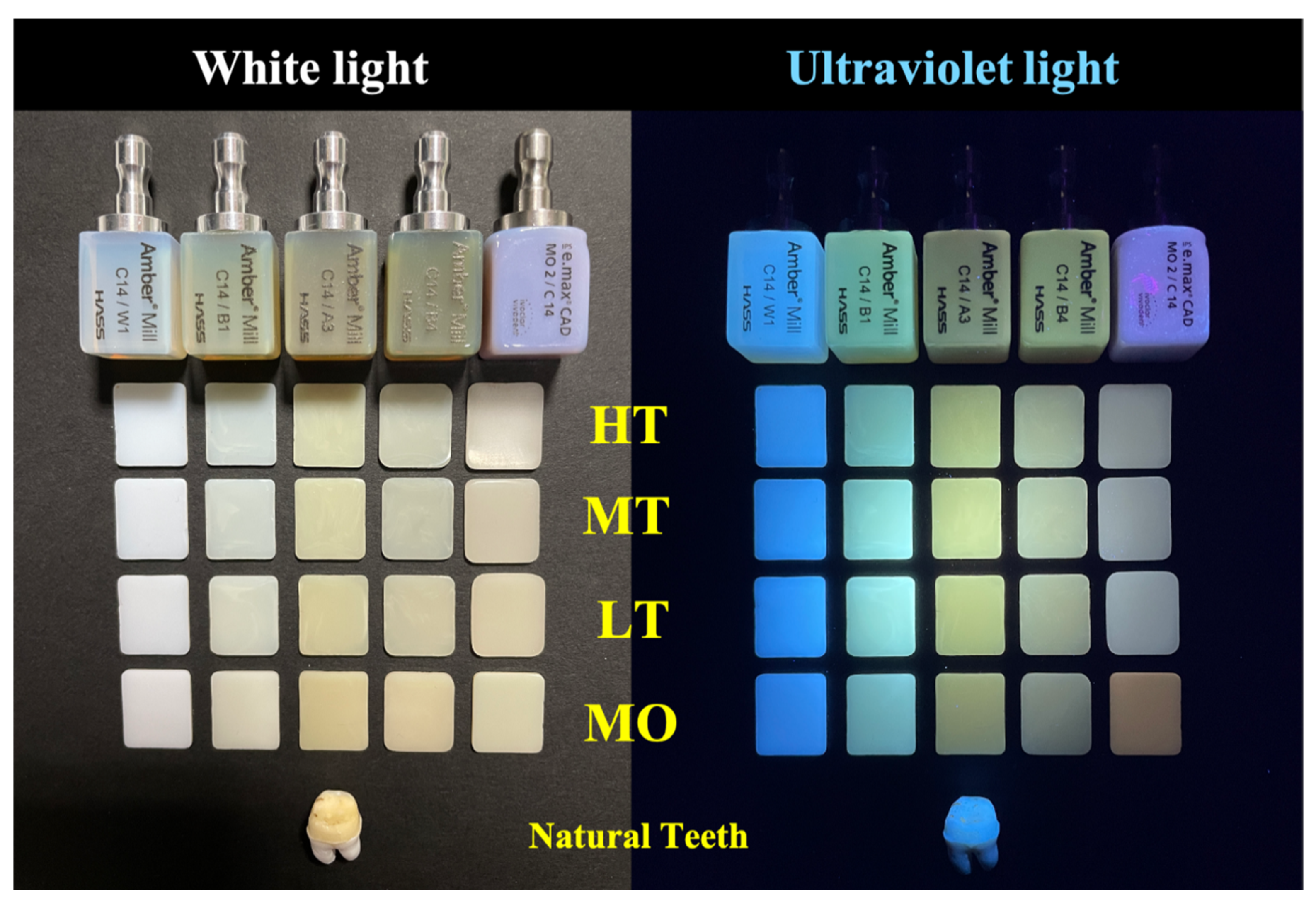

2.2. Optical Image Comparison of Glass-Ceramics

2.3. Evaluation of the Optical Properties

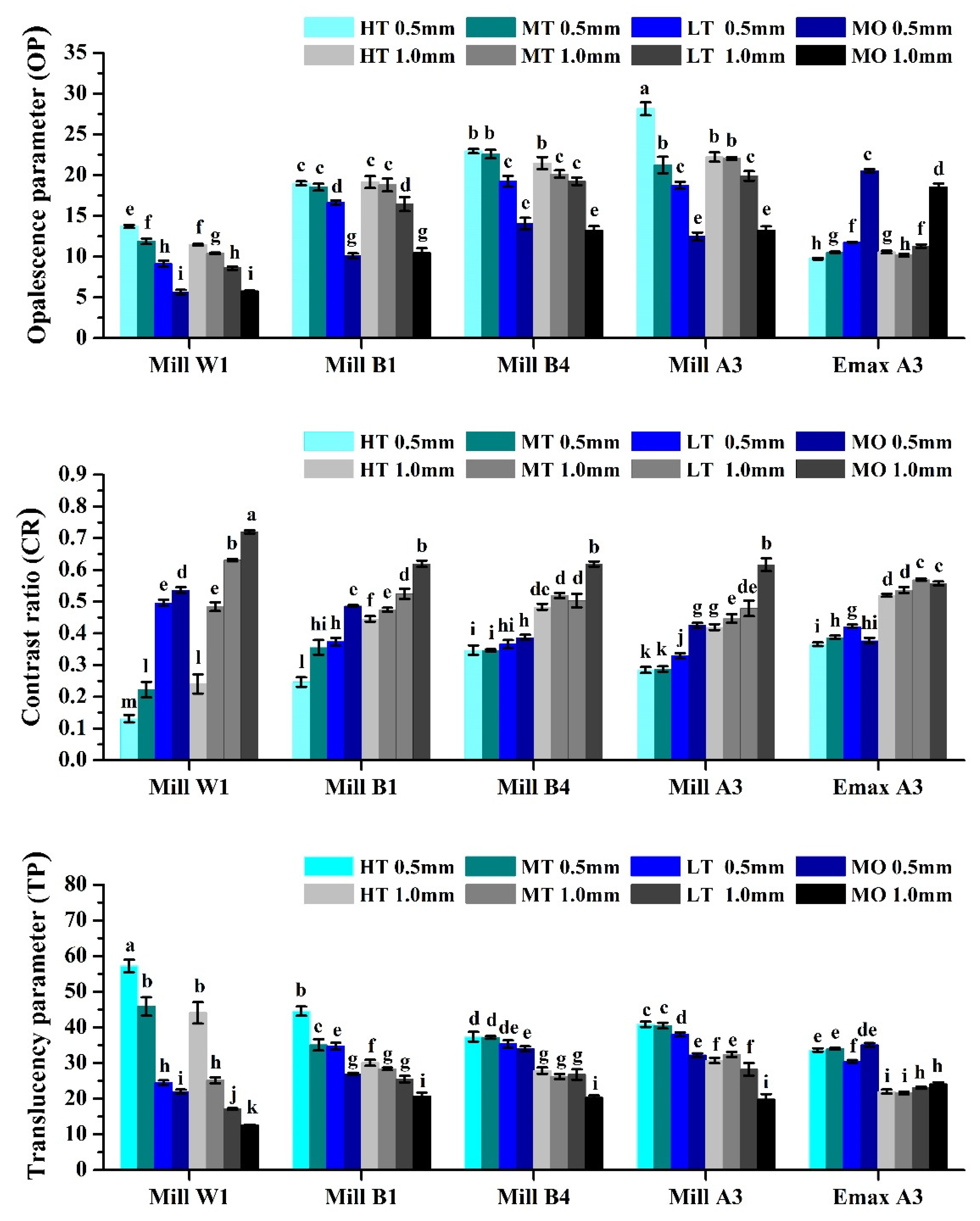

2.3.1. Opalescence Parameter (OP)

2.3.2. Contrast Ratio (CR)

2.3.3. Translucency Parameter (TP)

2.4. Surface Modification of Glass-Ceramics

2.5. X-ray Diffraction (XRD) Analysis

2.6. Surface Microhardness Test

2.7. In Vivo Evaluation of Prosthodontic Applications

Color Difference (ΔE)

2.8. Statistical Analysis

3. Results and Discussion

3.1. Optical Image Comparisons of Glass-Ceramics

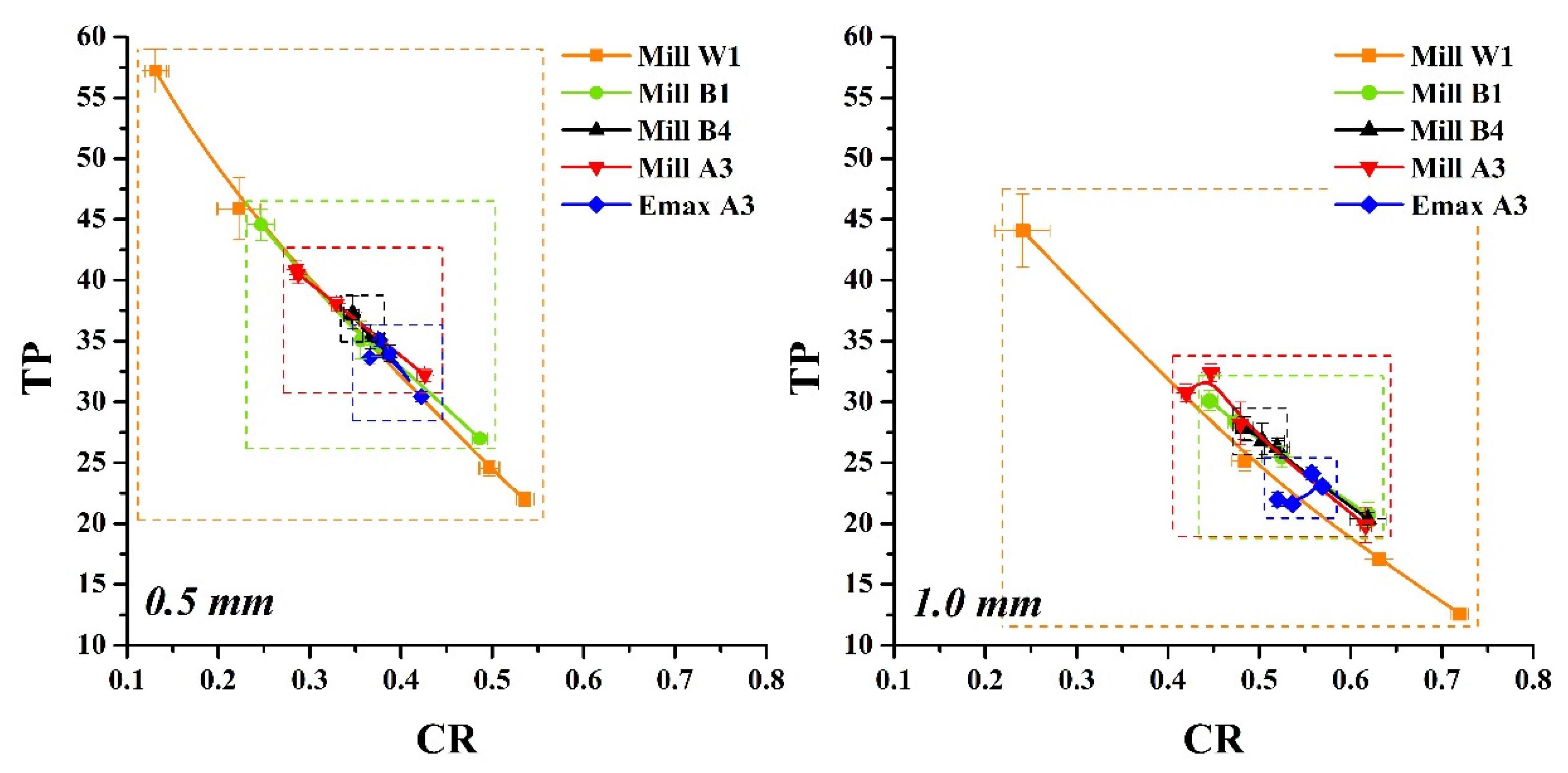

3.2. Evaluation of Optical Properties

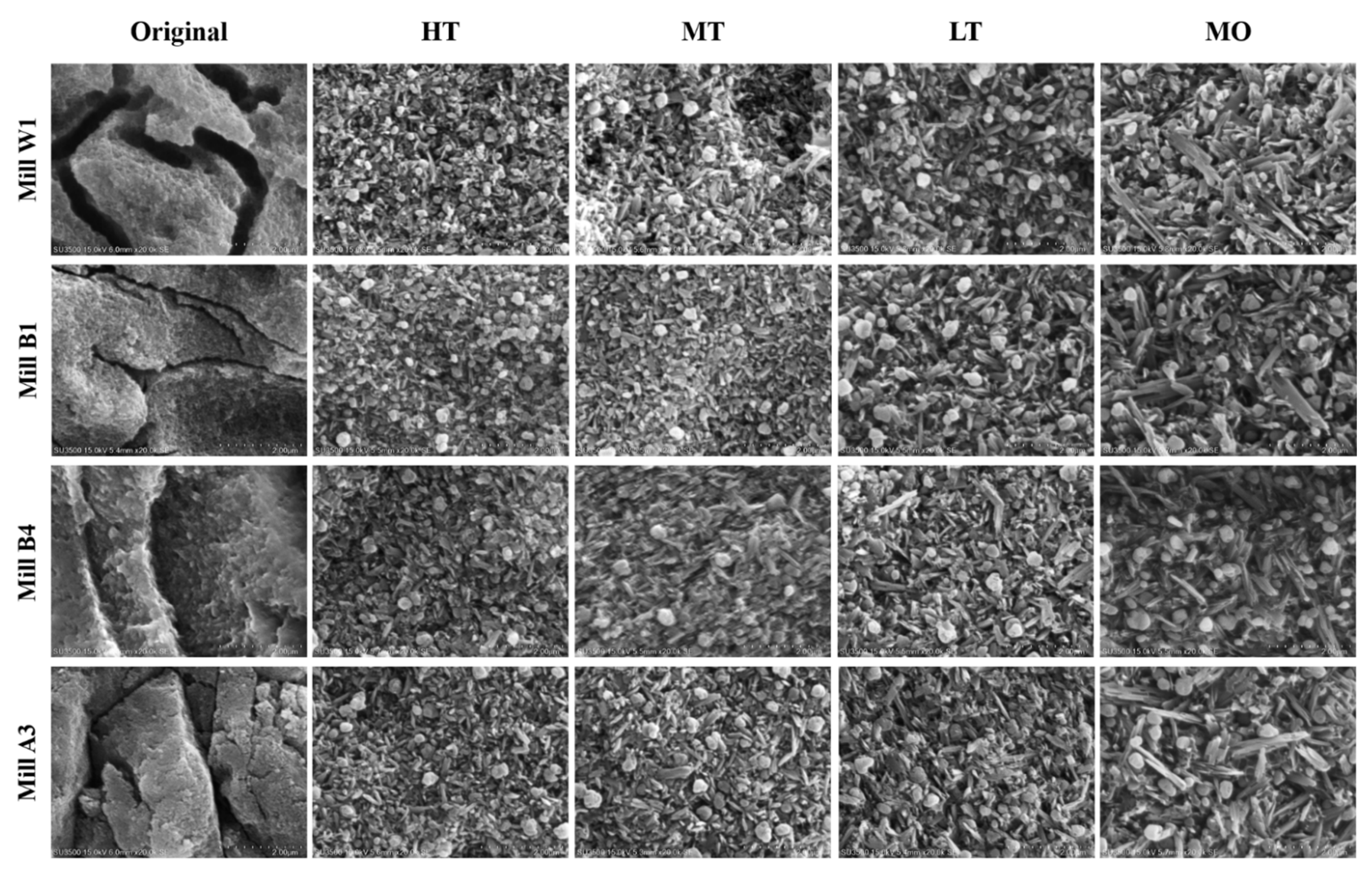

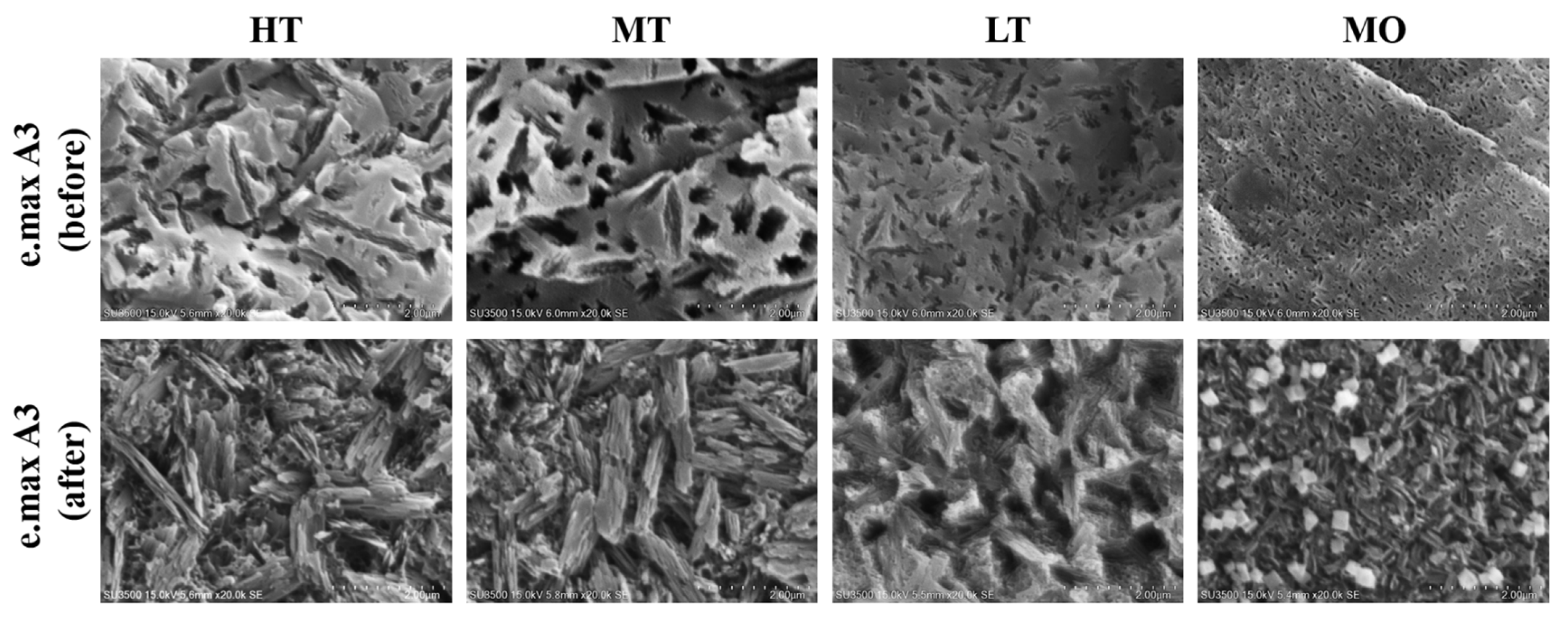

3.3. Surface Modification of Glass-Ceramics

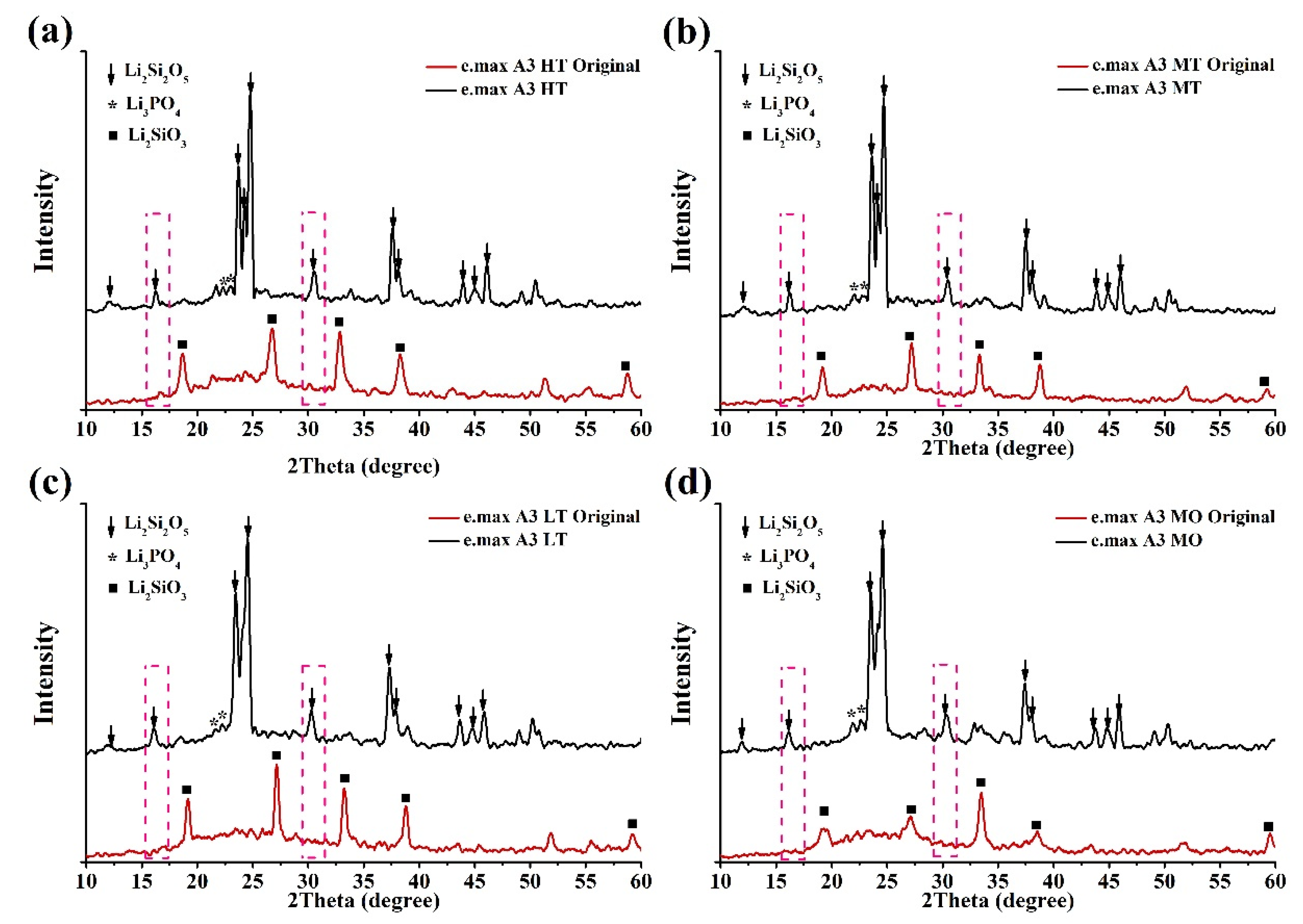

3.4. XRD Analysis

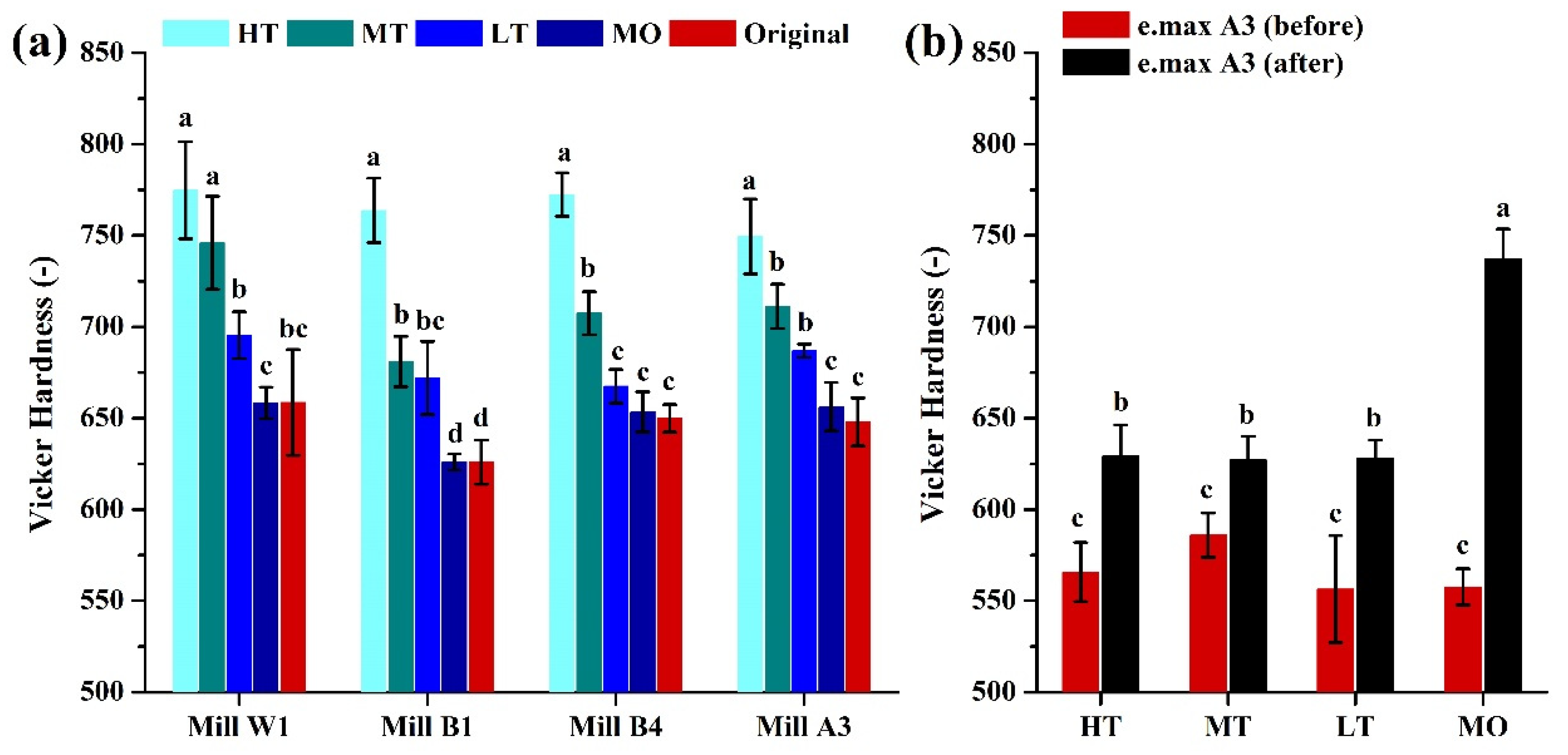

3.5. Surface Microhardness Test

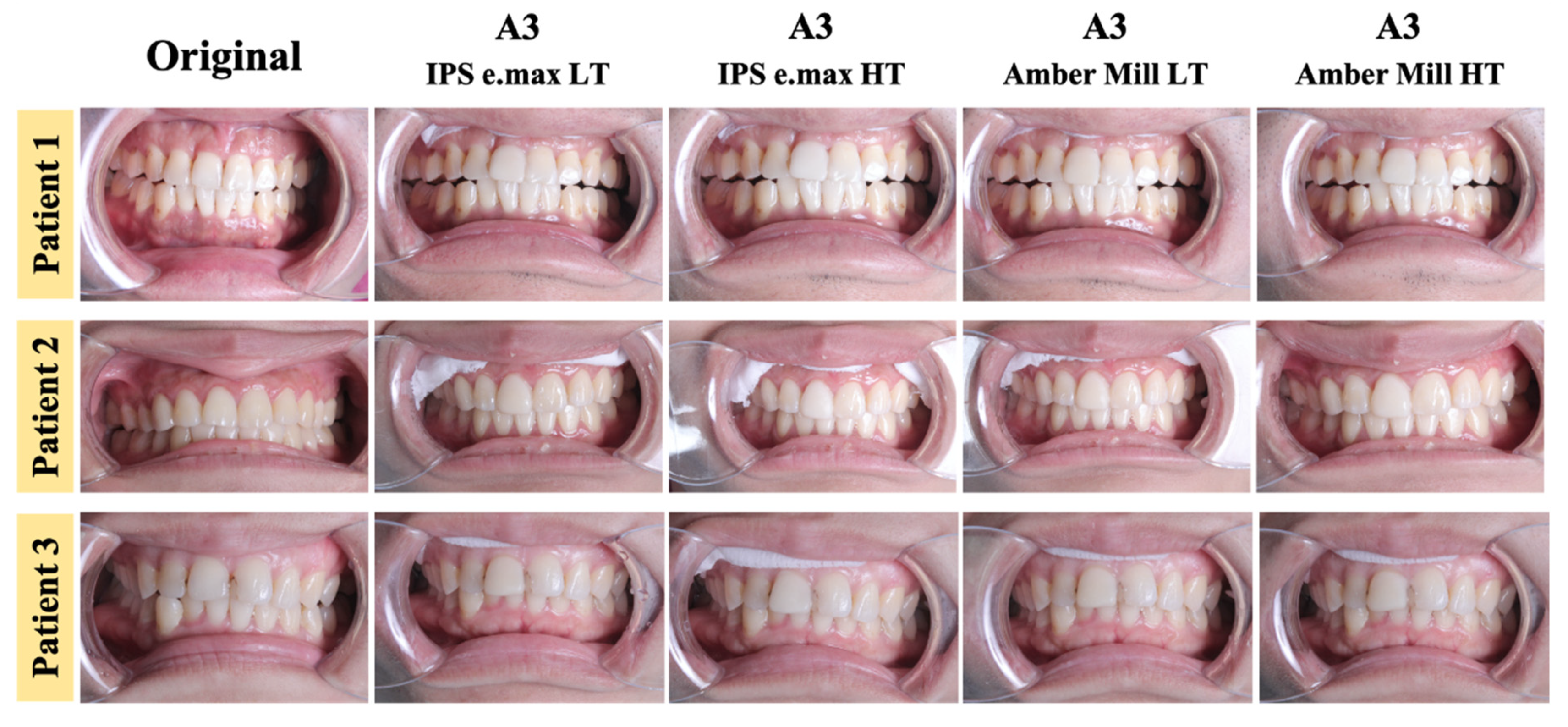

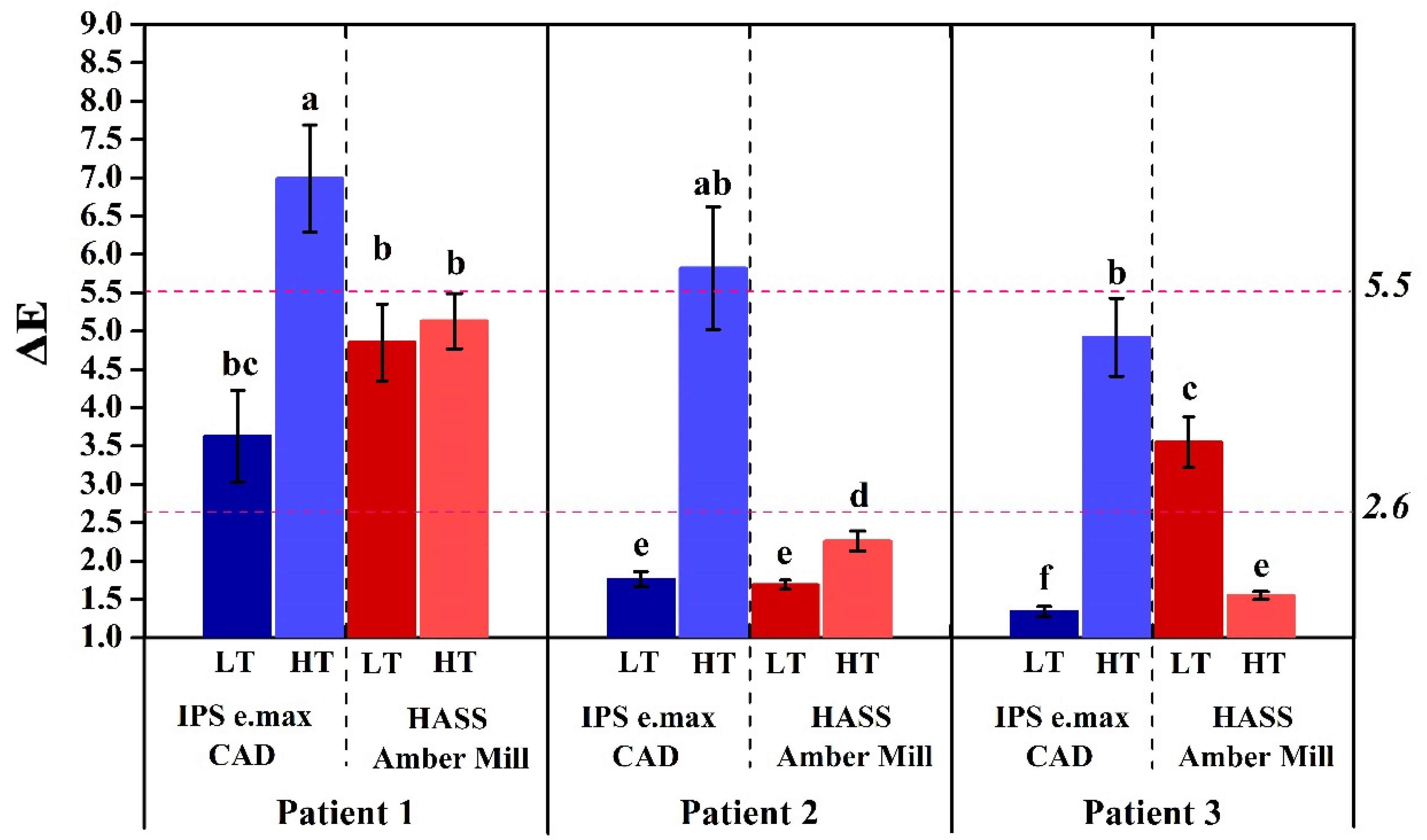

3.6. In Vivo Evaluation of Prosthodontic Applications

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Carlsson, G.E.; Omar, R. Trends in prosthodontics. Med. Princ. Pract. 2006, 15, 167–179. [Google Scholar] [CrossRef]

- Saeed, F.; Muhammad, N.; Khan, A.S.; Sharif, F.; Rahim, A.; Ahmad, P.; Irfan, M. Prosthodontics dental materials: From conventional to unconventional. Mater. Sci. Eng. C Mater. Biol. Appl. 2020, 106, 110167. [Google Scholar] [CrossRef]

- John, C.W. Alloys for prosthodontic restorations. J. Prosthet. Dent. 2002, 87, 351–363. [Google Scholar]

- Wataha, J.C.; Messer, R.L. Casting alloys. Dent. Clin. N. Am. 2004, 48, 499–512. [Google Scholar] [CrossRef]

- Kedici, S.P.; Aksüt, A.A.; Kílíçarslan, M.A.; Bayramoğlu, G.; Gökdemir, K. Corrosion behaviour of dental metals and alloys in different media. J. Oral Rehabil. 1998, 25, 800–808. [Google Scholar] [CrossRef]

- Poggio, C.E.; Ercoli, C.; Rispoli, L.; Maiorana, C.; Esposito, M. Metal-free materials for fixed prosthodontic restorations. Cochrane Database Syst. Rev. 2017, 12, CD009606. [Google Scholar] [CrossRef]

- Rekow, E.D.; Silva, N.R.; Coelho, P.G.; Zhang, Y.; Guess, P.; Thompson, V.P. Performance of dental ceramics: Challenges for improvements. J. Dent. Res. 2011, 90, 937–952. [Google Scholar] [CrossRef] [Green Version]

- Zarone, F.; Russo, S.; Sorrentino, R. From porcelain-fused-to-metal to zirconia: Clinical and experimental considerations. Dent. Mater. 2011, 27, 83–96. [Google Scholar] [CrossRef]

- Hsieh, Y.L.; Lai, Y.L.; Chen, H.L.; Hung, C.Y.; Chen, X.L.; Lee, S.Y. Photoconductive method for measuring light transmission to the root of metal-ceramic and all-ceramic restorations. Dent. Mater. 2008, 24, 1230–1235. [Google Scholar] [CrossRef]

- Nicolas, V.; Raptis, D.; Konstantinos, X.; Michalakis, D.; Hiroshi Hirayama, D. Optical behavior of current ceramic system. Int. J. Periodontics Restor. Dent. 2006, 26, 31–41. [Google Scholar]

- Greta, D.C.; Gasparik, C.; Colosi, H.A.; Dudea, D. Color matching of full ceramic versus metal-ceramic crowns—A spectrophotometric study. Med. Pharm. Rep. 2020, 93, 89–96. [Google Scholar]

- Jorn, D.; Waddell, J.N.; Swain, M.V. The influence of opaque application methods on the bond strength and final shade of pfm restorations. J. Dent. 2010, 38 (Suppl. S2), e143–e149. [Google Scholar] [CrossRef]

- Ramos Nde, C.; Campos, T.M.; Paz, I.S.; Machado, J.P.; Bottino, M.A.; Cesar, P.F.; Melo, R.M. Microstructure characterization and scg of newly engineered dental ceramics. Dent. Mater. 2016, 32, 870–878. [Google Scholar] [CrossRef] [Green Version]

- Blackburn, J.; Jackson, T.; Cook, R.; Sulaiman, T.A. Optical properties of a novel glass-ceramic restorative material. J. Esthet. Restor. Dent. 2021, 33, 1160–1165. [Google Scholar] [CrossRef]

- Rekow, E.D. Digital dentistry: The new state of the art—Is it disruptive or destructive? Dent. Mater. 2020, 36, 9–24. [Google Scholar] [CrossRef]

- Beuer, F.; Schweiger, J.; Edelhoff, D. Digital dentistry: An overview of recent developments for cad/cam generated restorations. Br. Dent. J. 2008, 204, 505–511. [Google Scholar] [CrossRef]

- Kelly, J.R.; Benetti, P. Ceramic materials in dentistry: Historical evolution and current practice. Aust. Dent. J. 2011, 56 (Suppl. S1), 84–96. [Google Scholar] [CrossRef]

- Rodrigues, C.D.S.; Aurelio, I.L.; Fraga, S.; Kaizer, M.D.R.; Zhang, Y.; May, L.G. Extended glaze firings for porcelain-veneered zirconia: Effects on the mechanical and optical behavior. Dent. Mater. 2021, 37, 1096–1106. [Google Scholar] [CrossRef]

- Wildgoose, D.G.; Johnson, A.; Winstanley, R.B. Glass/ceramic/refractory techniques, their development and introduction into dentistry: A historical literature review. J. Prosthet. Dent. 2004, 91, 136–143. [Google Scholar] [CrossRef]

- Montazerian, M.; Zanotto, E.D. Bioactive and inert dental glass-ceramics. J. Biomed. Mater. Res. A 2017, 105, 619–639. [Google Scholar] [CrossRef]

- Fu, L.; Engqvist, H.; Xia, W. Glass-ceramics in dentistry: A review. Materials 2020, 13, 1049. [Google Scholar] [CrossRef] [Green Version]

- Lee, Y.K.; Yu, B. Measurement of opalescence of tooth enamel. J. Dent. 2007, 35, 690–694. [Google Scholar] [CrossRef]

- Valizadeh, S.; Mahmoudi Nahavandi, A.; Daryadar, M.; Ozcan, M.; Hashemikamangar, S.S. The effect of ceramic thickness on opalescence. Clin. Exp. Dent. Res. 2020, 6, 693–699. [Google Scholar] [CrossRef]

- Heffernan, M.J.; Aquilino, S.A.; Diaz-Arnold, A.M.; Haselton, D.R.; Stanford, C.M.; Vargas, M.A. Relative translucency of six all-ceramic systems. Part I: Core materials. J. Prosthet. Dent. 2002, 88, 4–9. [Google Scholar] [CrossRef]

- Kandil, B.S.M.; Hamdy, A.M.; Aboelfadl, A.K.; El-Anwar, M.I. Effect of ceramic translucency and luting cement shade on the color masking ability of laminate veneers. Dent. Res. J. 2019, 16, 193–199. [Google Scholar]

- Nogueira, A.D.; Della Bona, A. The effect of a coupling medium on color and translucency of cad-cam ceramics. J. Dent. 2013, 41 (Suppl. S3), e18–e23. [Google Scholar] [CrossRef] [Green Version]

- Gunal, B.; Ulusoy, M.M. Optical properties of contemporary monolithic cad-cam restorative materials at different thicknesses. J. Esthet. Restor. Dent. 2018, 30, 434–441. [Google Scholar] [CrossRef]

- Salas, M.; Lucena, C.; Herrera, L.J.; Yebra, A.; Della Bona, A.; Perez, M.M. Translucency thresholds for dental materials. Dent. Mater. 2018, 34, 1168–1174. [Google Scholar] [CrossRef]

- Dozić, A.; Kleverlaan, C.J.; Meegdes, M.; van der Zel, J.; Feilzer, A.J. The influence of porcelain layer thickness on the final shade of ceramic restorations. J. Prosthet. Dent. 2003, 90, 563–570. [Google Scholar] [CrossRef]

- Tang, X.; Nakamura, T.; Usami, H.; Wakabayashi, K.; Yatani, H. Effects of multiple firings on the mechanical properties and microstructure of veneering ceramics for zirconia frameworks. J. Dent. 2012, 40, 372–380. [Google Scholar] [CrossRef]

- Ozturk, O.; Uludag, B.; Usumez, A.; Sahin, V.; Celik, G. The effect of ceramic thickness and number of firings on the color of two all-ceramic systems. J. Prosthet. Dent. 2008, 100, 99–106. [Google Scholar] [CrossRef]

- Haak, R.; Siegner, J.; Ziebolz, D.; Blunck, U.; Fischer, S.; Hajto, J.; Frankenberger, R.; Krause, F.; Schneider, H. Oct evaluation of the internal adaptation of ceramic veneers depending on preparation design and ceramic thickness. Dent. Mater. 2021, 37, 423–431. [Google Scholar] [CrossRef]

- Albelasy, E.; Hamama, H.H.; Tsoi, J.K.H.; Mahmoud, S.H. Influence of material type, thickness and storage on fracture resistance of cad/cam occlusal veneers. J. Mech. Behav. Biomed. Mater. 2021, 119, 104485. [Google Scholar] [CrossRef]

- Schmeling, M.; Maia, H.P.; Baratieri, L.N. Opalescence of bleached teeth. J. Dent. 2012, 40 (Suppl. S1), e35–e39. [Google Scholar] [CrossRef]

- Barizon, K.T.; Bergeron, C.; Vargas, M.A.; Qian, F.; Cobb, D.S.; Gratton, D.G.; Geraldeli, S. Ceramic materials for porcelain veneers. Part i: Correlation between translucency parameters and contrast ratio. J. Prosthet. Dent. 2013, 110, 397–401. [Google Scholar] [CrossRef]

- Johnston, W.M.; Ma, T.; Kienle, B.H. Translucency parameter of colorants for maxillofacial prostheses. Int. J. Prosthodont. 1995, 8, 79–86. [Google Scholar]

- Al Mansour, F.; Karpukhina, N.; Grasso, S.; Wilson, R.M.; Reece, M.J.; Cattell, M.J. The effect of spark plasma sintering on lithium disilicate glass-ceramics. Dent. Mater. 2015, 31, e226–e235. [Google Scholar] [CrossRef]

- Karlsen, C.A.; Schriwer, C.; Oilo, M. Damage tolerance of six dental zirconias with different translucencies. Biomater. Investig. Dent. 2020, 7, 126–133. [Google Scholar] [CrossRef]

- Douglas, R.D.; Steinhauer, T.J.; Wee, A.G. Intraoral determination of the tolerance of dentists for perceptibility and acceptability of shade mismatch. J. Prosthet. Dent. 2007, 97, 200–208. [Google Scholar] [CrossRef]

- Joiner, A. Tooth colour: A review of the literature. J. Dent. 2004, 32, 3–12. [Google Scholar] [CrossRef]

- Oh, S.-H.; Kim, S.-G. Effect of abutment shade, ceramic thickness, and coping type on the final shade of zirconia all-ceramic restorations:In vitrostudy of color masking ability. J. Adv. Prosthodont. 2015, 7, 368. [Google Scholar] [CrossRef] [Green Version]

- Farzin, M.; Ansarifard, E.; Taghva, M.; Imanpour, R. Effect of external staining on the optical properties and surface roughness of monolithic zirconia of different thicknesses. J. Prosthet. Dent. 2021, 126, 687.e1–687.e8. [Google Scholar] [CrossRef]

- Della Bona, A.; Nogueira, A.D.; Pecho, O.E. Optical properties of cad-cam ceramic systems. J. Dent. 2014, 42, 1202–1209. [Google Scholar] [CrossRef] [Green Version]

- Jung, S.-K.; Kim, D.W.; Lee, J.; Ramasamy, S.; Kim, H.S.; Ryu, J.J.; Shim, J.S. Modulation of lithium disilicate translucency through heat treatment. Materials 2021, 14, 2094. [Google Scholar] [CrossRef]

- Lee, Y.K. Criteria for clinical translucency evaluation of direct esthetic restorative materials. Restor. Dent. Endod. 2016, 41, 159–166. [Google Scholar] [CrossRef] [Green Version]

- Kang, S.H.; Chang, J.; Son, H.H. Flexural strength and microstructure of two lithium disilicate glass ceramics for cad/cam restoration in the dental clinic. Restor. Dent. Endod. 2013, 38, 134–140. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y. Making yttria-stabilized tetragonal zirconia translucent. Dent. Mater. 2014, 30, 1195–1203. [Google Scholar] [CrossRef] [Green Version]

- Apetz, R.; Van Bruggen, M.P. Transparent alumina: A light-scattering model. J. Am. Ceram. Soc. 2003, 86, 480–486. [Google Scholar] [CrossRef]

- Tavares, L.d.N.; ZancopÉ, K.; Silva, A.C.A.; Raposo, L.H.A.; Soares, C.J.; Neves, F.D.d. Microstructural and mechanical analysis of two cad-cam lithium disilicate glass-reinforced ceramics. Braz. Oral Res. 2020, 34, e004. [Google Scholar] [CrossRef]

- Gracis, S.; Fradeani, M.; Celletti, R.; Bracchetti, G. Biological integration of aesthetic restorations: Factors influencing appearance and long-term success. Periodontology 2000 2001, 27, 29–44. [Google Scholar] [CrossRef]

- Blatz, M.; Chiche, G.; Bahat, O.; Roblee, R.; Coachman, C.; Heymann, H. Evolution of aesthetic dentistry. J. Dent. Res. 2019, 98, 1294–1304. [Google Scholar] [CrossRef] [PubMed]

- Spear, F.; Holloway, J. Which all-ceramic system is optimal for anterior esthetics? J. Am. Dent. Assoc. 2008, 139, S19–S24. [Google Scholar] [CrossRef] [PubMed]

- Bahadır, H.S.; Karadağ, G.; Bayraktar, Y. Minimally invasive approach for improving anterior dental aesthetics: Case report with 1-year follow-up. Case Rep. Dent. 2018, 2018, 4601795. [Google Scholar] [CrossRef] [Green Version]

| Sample | Translucency and Color | Size | Size | |||

|---|---|---|---|---|---|---|

| High-Translucency Temperature (°C) | Medium-Translucency Temperature (°C) | Low-Translucency Temperature (°C) | Medium-Opacity Temperature (°C) | A | B | |

| Amber Mill | W1 | W1 | W1 | W1 | 0.5 mm | 1.0 mm |

| (815 °C) | (825 °C) | (840 °C) | (860 °C) | |||

| B1 | B1 | B1 | B1 | |||

| (815 °C) | (825 °C) | (840 °C) | (860 °C) | |||

| A3 | A3 | A3 | A3 | |||

| (815 °C) | (825 °C) | (840 °C) | (860 °C) | |||

| B4 | B4 | B4 | B4 | |||

| (815 °C) | (825 °C) | (840 °C) | (860 °C) | |||

| IPS e.max CAD | A3 | A3 | A3 | A3 | 0.5 mm | 1.0 mm |

| (850 °C) | (850 °C) | (850 °C) | (850 °C) | |||

| Brand | Color | TP | Patient 1 | Patient 2 | Patient 3 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | a | b | # | L | a | b | # | L | a | b | # | |||

| Original tooth color | 77.2 | 0.5 | 21.4 | A3 | 75.3 | 0.8 | 22.6 | A3 | 78.7 | −0.1 | 19.7 | A2 | ||

| IPS e.max CAD | A3 | LT | 80.2 | 0.1 | 23.4 | A3 | 76 | 1 | 24.2 | A3 | 79 | 0.6 | 20.8 | A3 |

| A3 | HT | 81.3 | −0.3 | 15.8 | B2 | 76.3 | 0.2 | 16.9 | A2 | 80.1 | −1.5 | 15.2 | A1 | |

| HASS Amber Mill | A3 | LT | 74.3 | −0.7 | 25.1 | A3 | 75.7 | −0.2 | 23.9 | A3 | 76.9 | 0.5 | 22.7 | A3 |

| A3 | HT | 75.6 | −0.8 | 26.1 | A3 | 76 | −0.2 | 24.5 | A3 | 77.2 | −0.1 | 20.1 | A3 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, K.-C.; Lin, Y.-L.; Tsao, H.-W.; Chen, H.; Lee, S.-Y.; Cheng, Y.-C.; Huang, H.-P.; Lin, W.-C. In Vivo Evaluation of the Effects of Sintering Temperature on the Optical Properties of Dental Glass-Ceramics. Nanomaterials 2022, 12, 2187. https://doi.org/10.3390/nano12132187

Fan K-C, Lin Y-L, Tsao H-W, Chen H, Lee S-Y, Cheng Y-C, Huang H-P, Lin W-C. In Vivo Evaluation of the Effects of Sintering Temperature on the Optical Properties of Dental Glass-Ceramics. Nanomaterials. 2022; 12(13):2187. https://doi.org/10.3390/nano12132187

Chicago/Turabian StyleFan, Kuo-Cheng, Yu-Ling Lin, Hao-Wei Tsao, Hsuan Chen, Sheng-Yang Lee, Yu-Chen Cheng, Hsiao-Ping Huang, and Wei-Chun Lin. 2022. "In Vivo Evaluation of the Effects of Sintering Temperature on the Optical Properties of Dental Glass-Ceramics" Nanomaterials 12, no. 13: 2187. https://doi.org/10.3390/nano12132187

APA StyleFan, K.-C., Lin, Y.-L., Tsao, H.-W., Chen, H., Lee, S.-Y., Cheng, Y.-C., Huang, H.-P., & Lin, W.-C. (2022). In Vivo Evaluation of the Effects of Sintering Temperature on the Optical Properties of Dental Glass-Ceramics. Nanomaterials, 12(13), 2187. https://doi.org/10.3390/nano12132187