Lubrication Performances of Polyalkylene Glycols at Steel Interface under External Electric Fields

Abstract

:1. Introduction

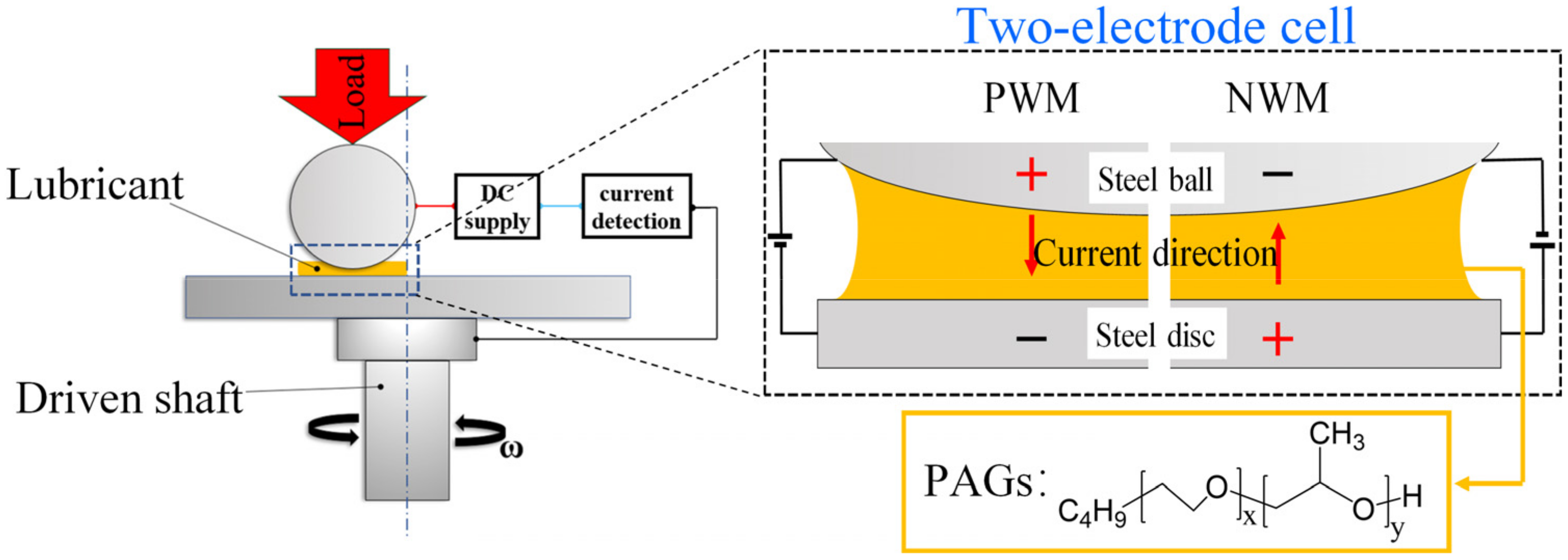

2. Materials and Methods

2.1. Materials and Experimental Methods

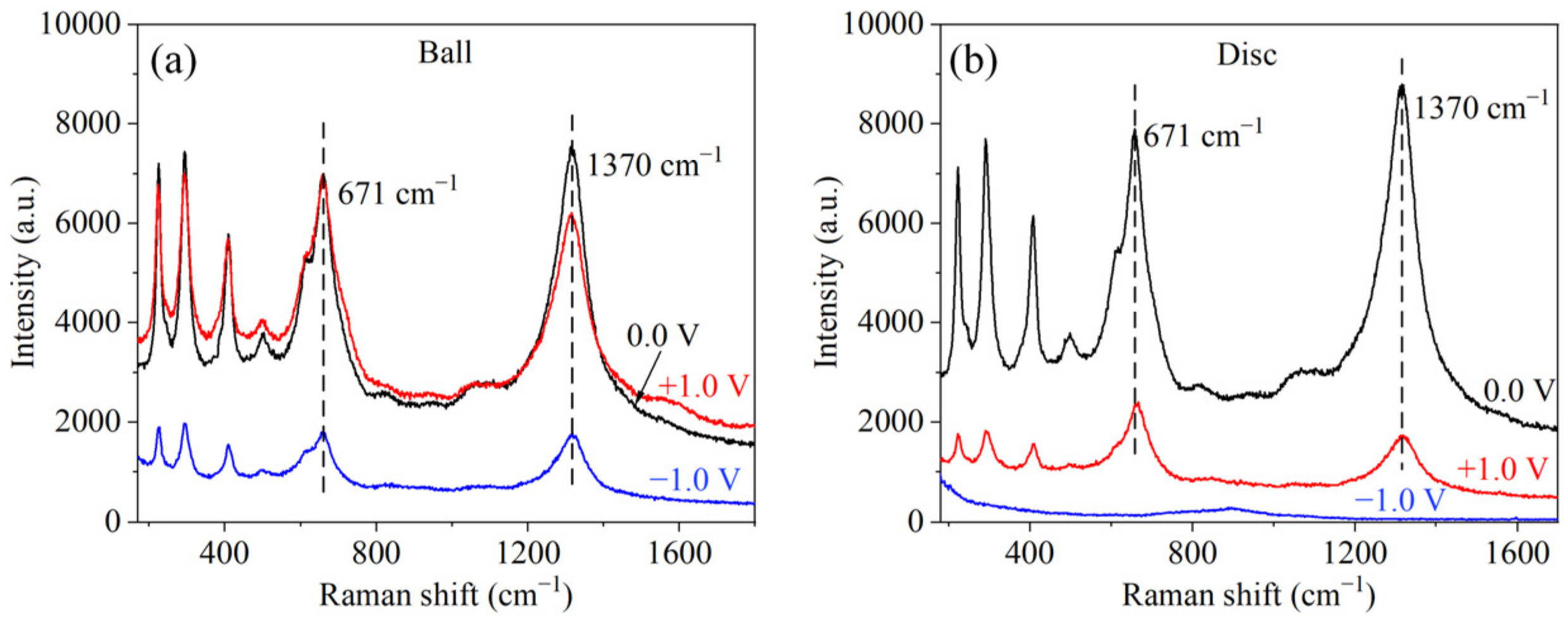

2.2. Surface Analysis

3. Results and Discussion

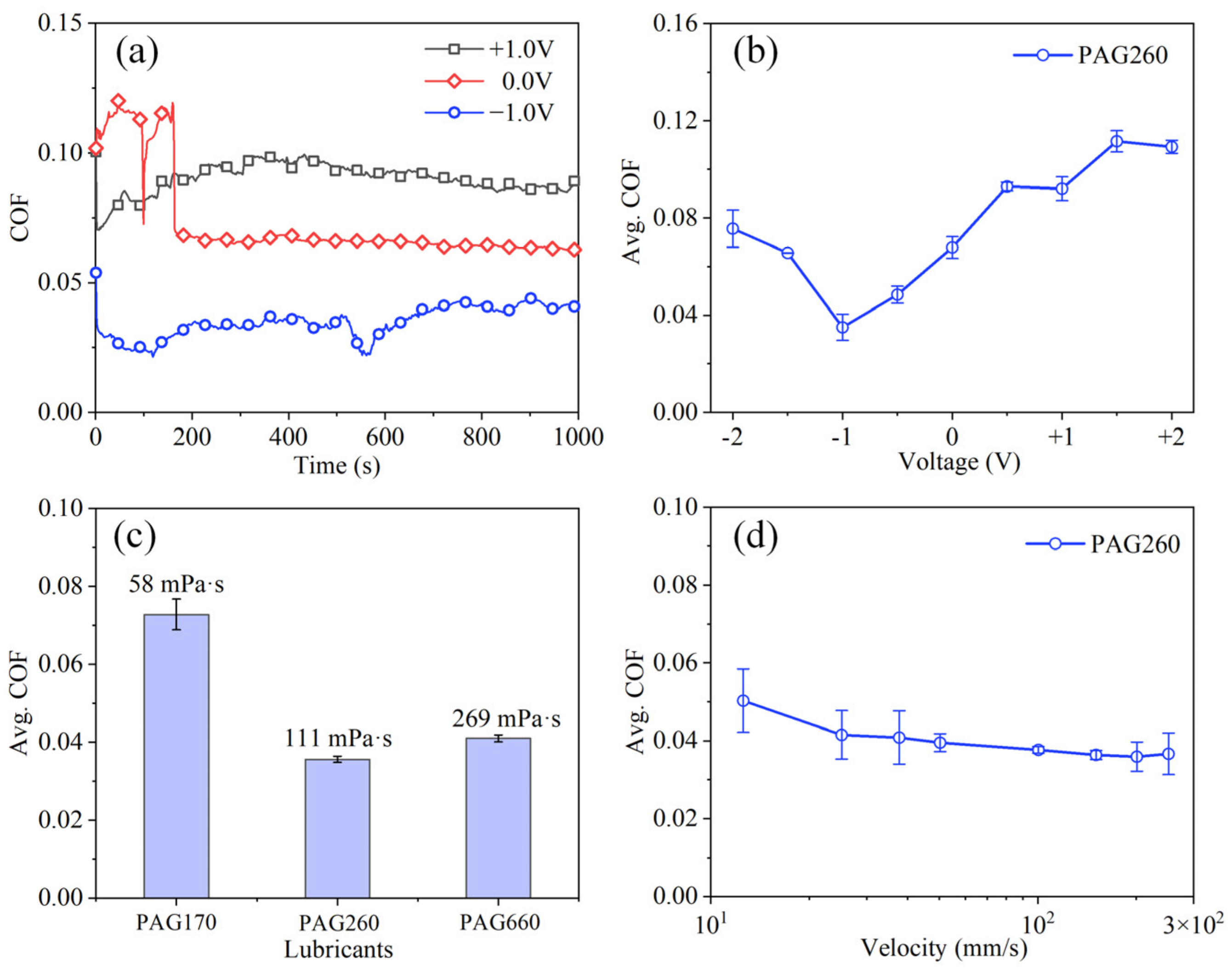

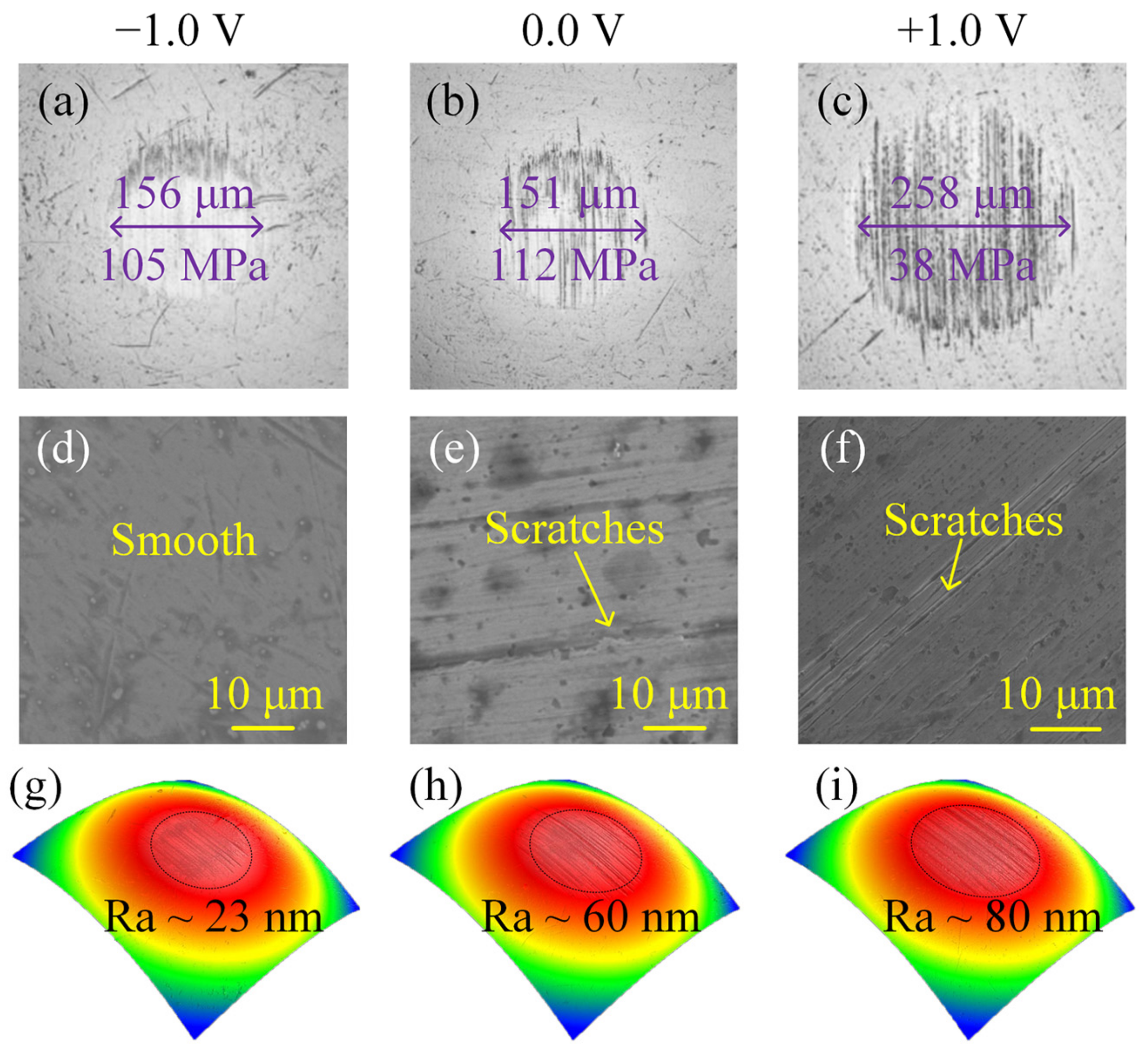

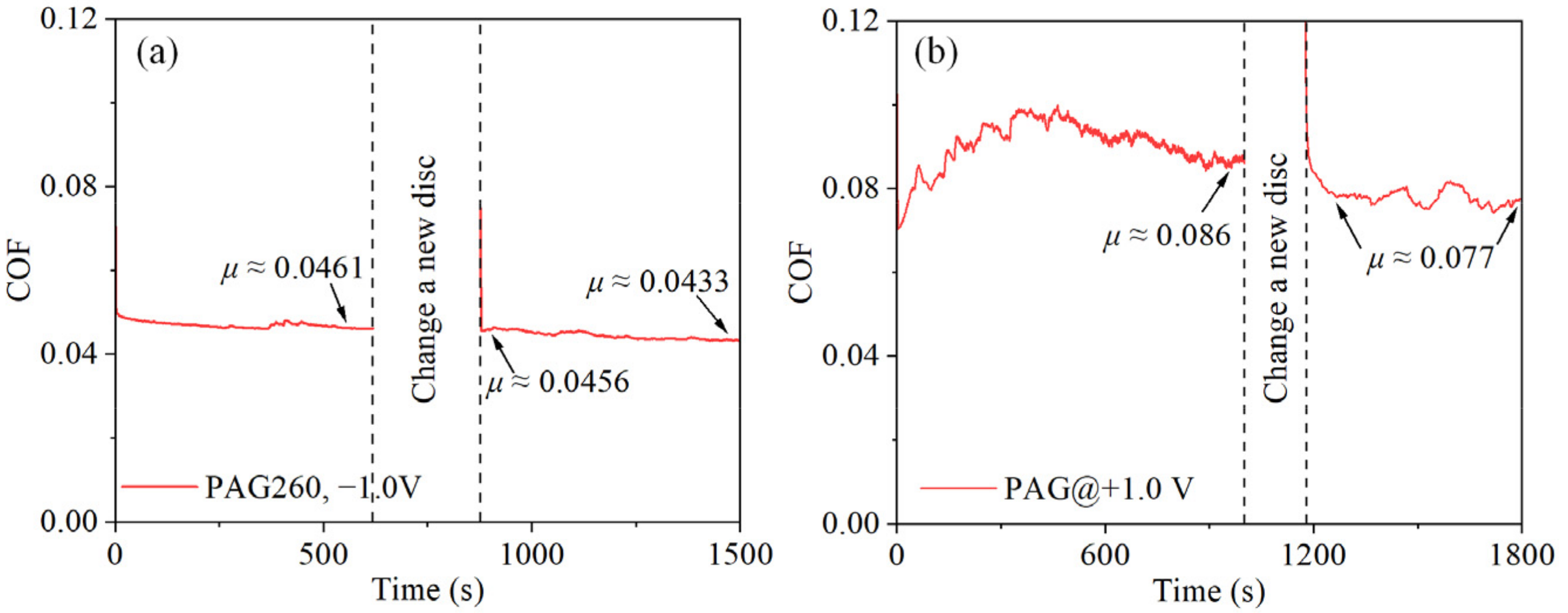

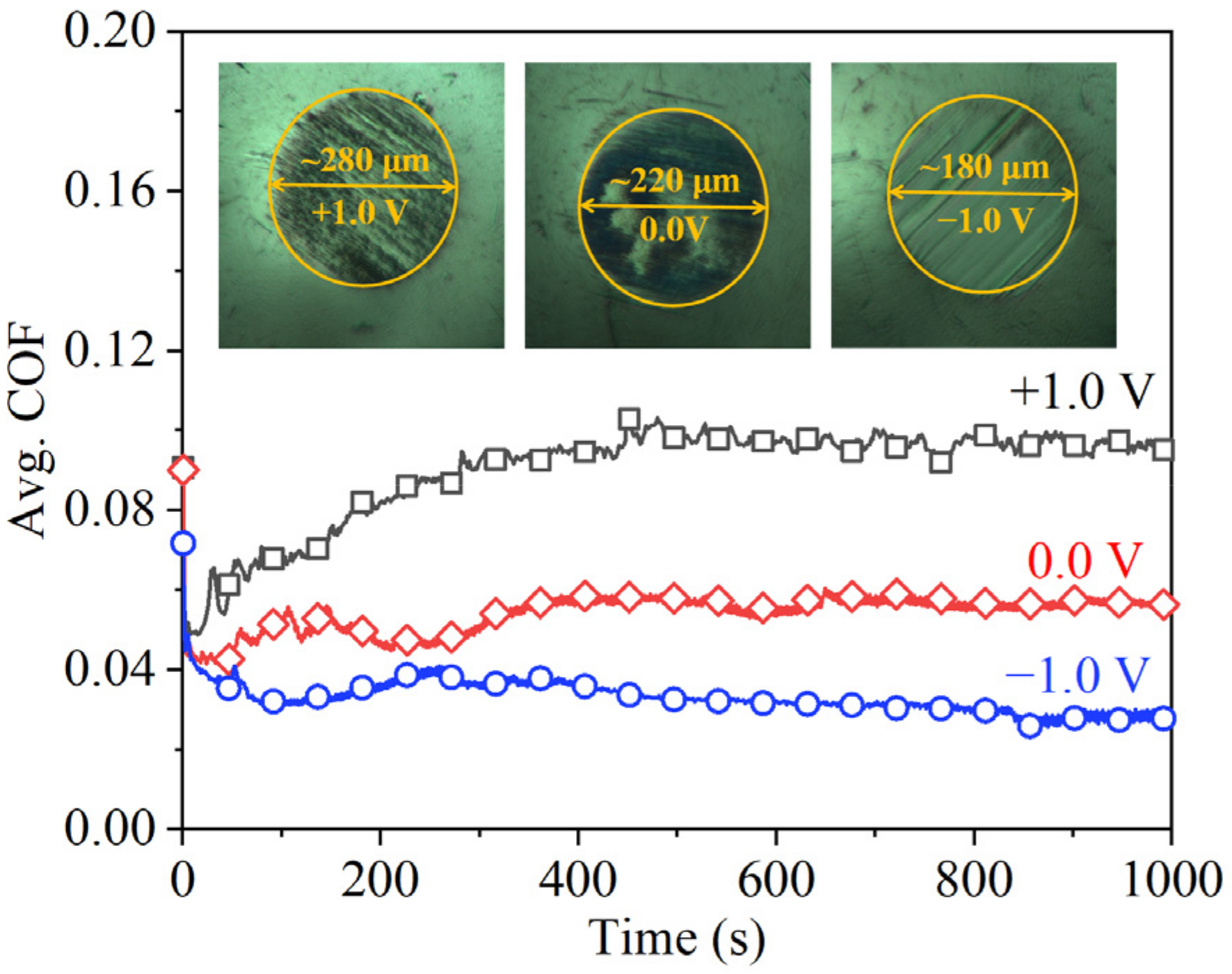

3.1. Lubrication Performances

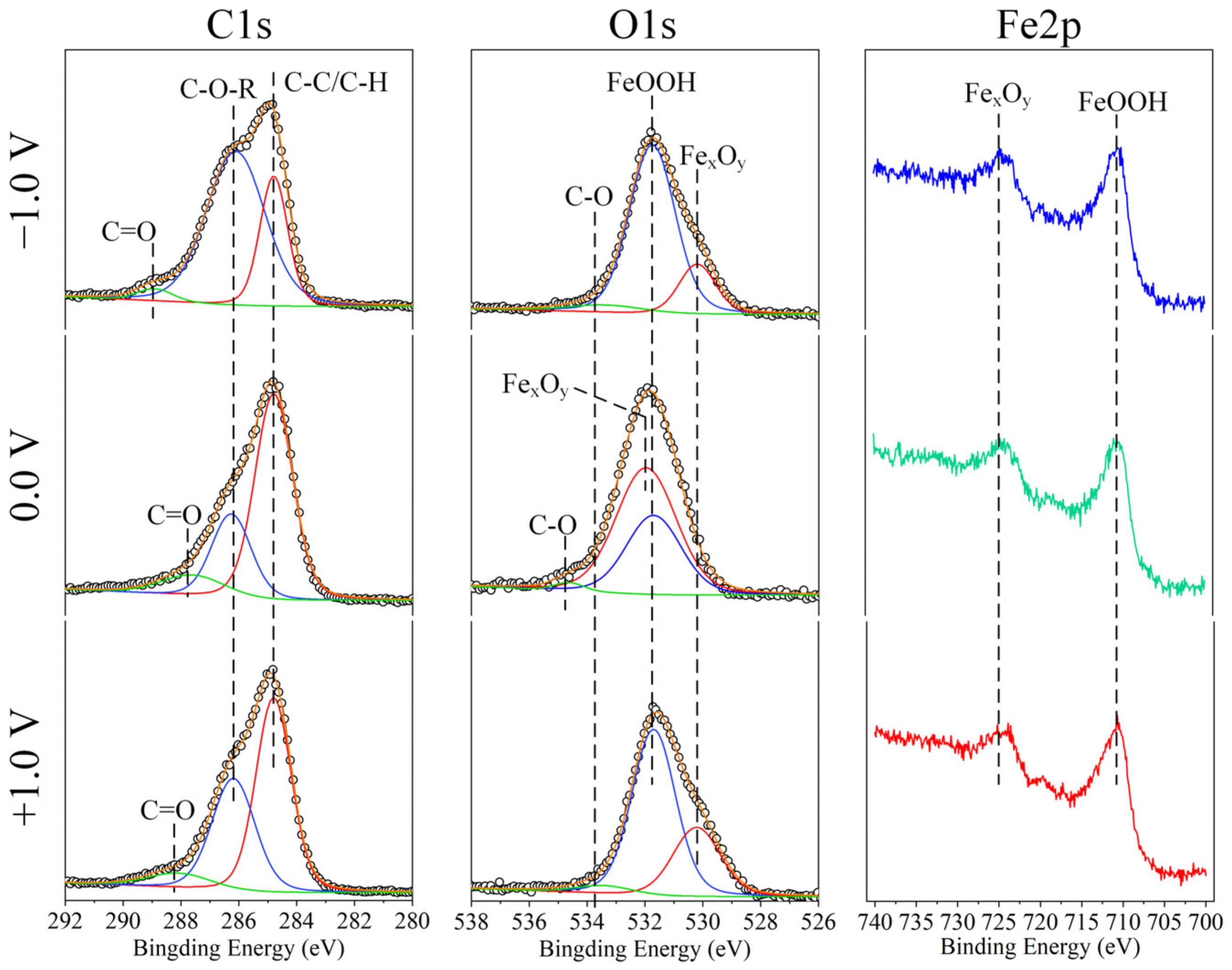

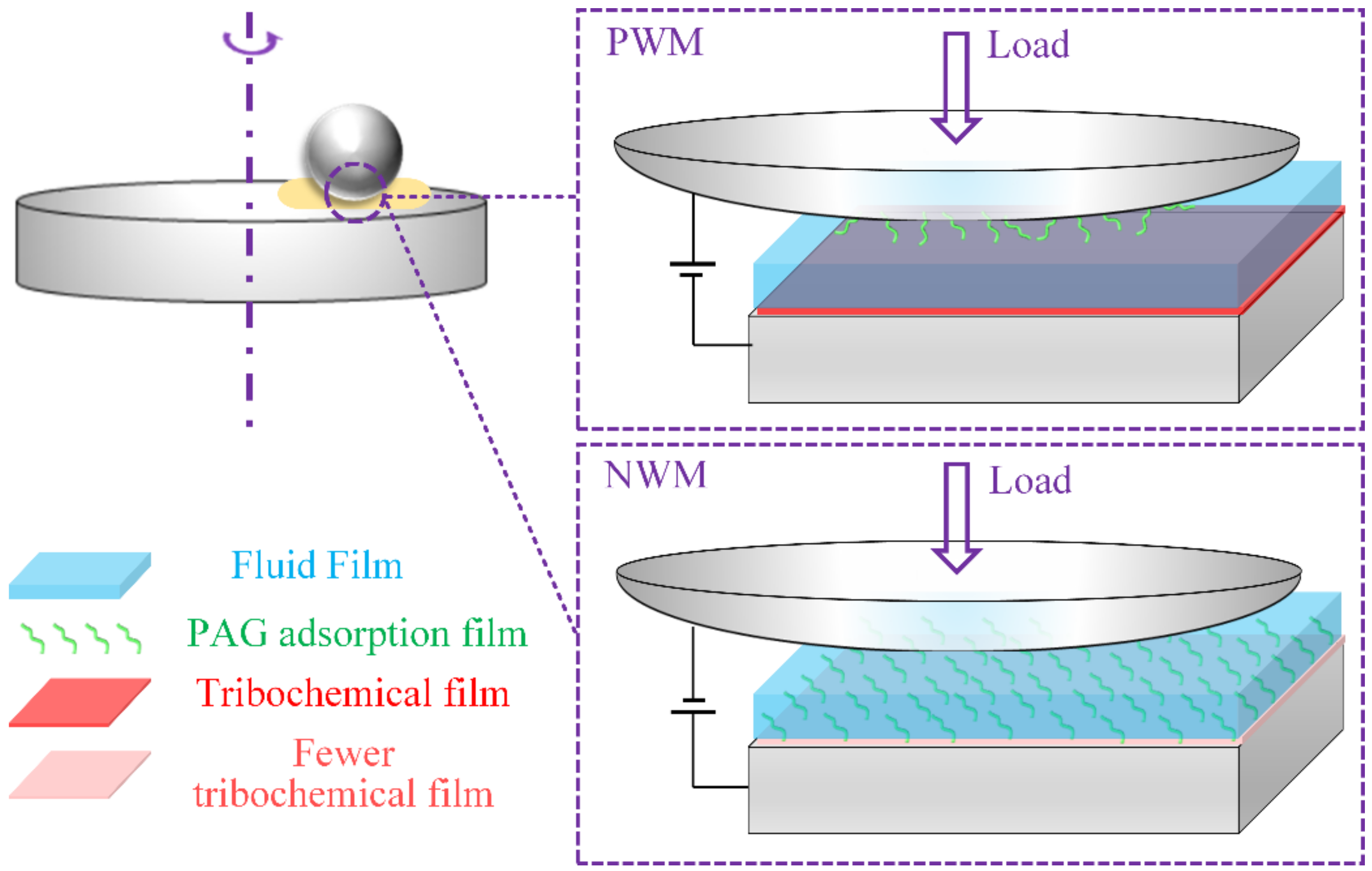

3.2. Discussions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xie, G.X.; Guo, D.; Luo, J.B. Lubrication under charged conditions. Tribol. Int. 2015, 84, 22–35. [Google Scholar] [CrossRef]

- Whittle, M.; Trevelyan, J.; Tavner, P.J. Bearing currents in wind turbine generators. J. Renew. Sustain. Ener. 2013, 5, 053128. [Google Scholar] [CrossRef]

- Becker, A.; Abanteriba, S. Electric discharge damage in aircraft propulsion bearings. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2014, 228, 104–113. [Google Scholar] [CrossRef]

- Sjöholm, M.; Mäusli, P.; Bonner, F.; Gass, V. Development and qualification of the international space station centrifuge slip ring assembly. In 11th European Space Mechanisms and Tribology Symposium, Lucerne, Switzerland, 21–23 September 2005; ESA Publications Division: Noordwijk, The Netherlands, 2005; Volume 591, pp. 133–140. [Google Scholar]

- Spikes, H.A. Triboelectrochemistry: Influence of applied electrical potentials on friction and wear of lubricated contacts. Tribol. Lett. 2020, 68, 90. [Google Scholar] [CrossRef]

- He, F.; Xie, G.X.; Luo, J.B. Electrical bearing failures in electric vehicles. Friction 2020, 8, 4–28. [Google Scholar] [CrossRef] [Green Version]

- Guruswamy, V.; Bockris, J.O. Triboelectrochemistry. In Electrochemical Materials Science; Bockris, J.O., Conway, B.E., Yeager, E., White, R.E., Eds.; Springer: Berlin/Heidelberg, Germany, 1981; pp. 463–471. [Google Scholar]

- Salmeron, G.C.; Leckner, J.; Schwack, F.; Westbroek, R.; Glavatskih, S. Greases for electric vehicle motors: Thickener effect and energy saving potential. Tribol. Int. 2022, 167, 107400. [Google Scholar] [CrossRef]

- Cao, Z.F.; Xia, Y.Q.; Chen, C.; Zheng, K.; Zhang, Y. A synergetic strategy based on laser surface texturing and lubricating grease for improving the tribological and electrical properties of Ag coating under current-carrying friction. Friction 2020, 9, 978–989. [Google Scholar] [CrossRef]

- Cai, M.; Yan, H.; Li, Y.T.; Li, W.; Li, H.; Fan, X.; Zhu, M. Ti3C2Tx/PANI composites with tunable conductivity towards anticorrosion application. Chem. Eng. J. 2021, 410, 128310. [Google Scholar] [CrossRef]

- Kimura, Y.; Nakano, K.; Kato, T.; Morishita, S. Control of friction coefficient by applying electric fields across liquid crystal boundary films. Wear 1994, 175, 143–149. [Google Scholar] [CrossRef]

- Luo, J.B.; Shen, M.; Wen, S.Z. Tribological properties of nanoliquid film under an external electric field. J. Appl. Phys. 2004, 96, 6733–6738. [Google Scholar] [CrossRef]

- Xie, G.; Luo, J.; Liu, S.; Guo, D.; Zhang, C. Nanoconfined liquid aliphatic compounds under external electric fields: Roles of headgroup and alkyl chain length. Soft Matter 2011, 7, 4453–4460. [Google Scholar] [CrossRef]

- Cao, Z.F.; Xia, Y.Q.; Liu, L.H.; Feng, X. Study on the conductive and tribological properties of copper sliding electrical contacts lubricated by ionic liquids. Tribol. Int. 2019, 130, 27–35. [Google Scholar] [CrossRef]

- Fan, X.Q.; Wang, L.P. Highly conductive ionic liquids towards high–performance space lubricating greases. ACS Appl. Mater. Interfaces 2014, 6, 14660–14671. [Google Scholar] [CrossRef]

- Michalec, M.; Svoboda, P.; Krupka, I.; Hartl, M.; Vencl, A. Investigation of the tribological performance of ionic liquids in non-conformal EHL contacts under electric field activation. Friction 2020, 8, 982–994. [Google Scholar] [CrossRef] [Green Version]

- Chen, Q.; Shyu, S.; Li, W. An overlapped electrical double layer model for aqueous electrolyte lubrication with asymmetric surface electric potentials. Tribol. Int. 2020, 147, 106283. [Google Scholar] [CrossRef]

- Zuo, Q.; Huang, P.; Su, F. Theory analysis of asymmetrical electric double layer effects on thin film lubrication. Tribol. Int. 2012, 49, 67–74. [Google Scholar] [CrossRef]

- Cai, M.; Liang, Y.; Zhou, F.; Liu, W. Anticorrosion imidazolium ionic liquids as the additive in poly (ethylene glycol) for steel/Cu-Sn alloy contacts. Faraday Discuss. 2012, 156, 147–157. [Google Scholar] [CrossRef]

- Ge, X.Y.; Li, J.J.; Luo, R.; Zhang, C.; Luo, J. Macroscale superlubricity enabled by synergy effect of graphene-oxide nanoflakes and ethanediol. ACS Appl. Mater. Interfaces 2018, 10, 40863–40870. [Google Scholar] [CrossRef]

- Zhang, C.H.; Zhao, Y.C.; Bjrling, M.; Wang, Y.; Luo, J.B.; Prakash, B. EHL properties of polyalkylene glycols and their aqueous solutions. Tribol. Lett. 2012, 45, 379–385. [Google Scholar] [CrossRef]

- Cai, M.; Liang, Y.; Zhou, F.; Liu, W. Tribological properties of novel imidazolium ionic liquids bearing benzotriazole group as the antiwear/anticorrosion additive in poly (ethylene glycol) and polyurea grease for steel/steel contacts. ACS Appl. Mater. Interfaces 2011, 3, 4580–4592. [Google Scholar] [CrossRef]

- National Institute of Standards and Technology (NIST). NIST X-ray Photoelectron Spectroscopy Database. 2012; Version 4.1. Available online: http://srdata.nist.gov/xps/ (accessed on 5 January 2020).

- Zhao, G.; Wu, X.; Li, W.; Wang, X. Hydroquinone bis (diphenyl phosphate) as an antiwear/extreme pressure additive in polyalkylene glycol for steel/steel contacts at elevated temperature. Ind. Eng. Chem. Res. 2013, 52, 7419–7424. [Google Scholar] [CrossRef]

- White, S.N. Qualitative and quantitative analysis of CO2 and CH4 dissolved in water and seawater using laser Raman spectroscopy. Appl. Spectrosc. 2010, 64, 819–827. [Google Scholar] [CrossRef] [PubMed]

- Espinosa, T.; Sanes, J.; Bermúdez, M.D. New alkylether-thiazolium room-temperature ionic liquid lubricants: Surface interactions and tribological performance. ACS Appl. Mater. Interfaces 2016, 8, 18631–18639. [Google Scholar] [CrossRef] [PubMed]

- Amann, T.; Gatti, F.; Oberle, N.; Kailer, A.; Rühe, J. Galvanically induced potentials to enable minimal tribochemical wear of stainless steel lubricated with sodium chloride and ionic liquid aqueous solution. Friction 2018, 6, 230–242. [Google Scholar] [CrossRef] [Green Version]

| Voltage (V) | Formula (C) | Proportion (%) | Formula (O) | Proportion (%) |

|---|---|---|---|---|

| +1.0 V | C−O/C−H | 54.22 | FeOOH | 66.07 |

| C−O−R | 38.12 | FexOy | 29.66 | |

| C=O | 7.66 | C−O | 4.27 | |

| 0.0 V | C−O/C−H | 62.29 | FeOOH | 35.67 |

| C−O−R | 26.8 | FexOy | 62.34 | |

| C=O | 10.91 | C−O/C=O | 1.99 | |

| −1.0 V | C−O/C−H | 30.71 | FeOOH | 76.41 |

| C−O−R | 65.60 | FexOy | 18.01 | |

| C=O | 3.69 | C−O | 5.58 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ge, X.; Wu, X.; Shi, Q.; Wang, W. Lubrication Performances of Polyalkylene Glycols at Steel Interface under External Electric Fields. Nanomaterials 2022, 12, 2067. https://doi.org/10.3390/nano12122067

Ge X, Wu X, Shi Q, Wang W. Lubrication Performances of Polyalkylene Glycols at Steel Interface under External Electric Fields. Nanomaterials. 2022; 12(12):2067. https://doi.org/10.3390/nano12122067

Chicago/Turabian StyleGe, Xiangyu, Xiaodong Wu, Qiuyu Shi, and Wenzhong Wang. 2022. "Lubrication Performances of Polyalkylene Glycols at Steel Interface under External Electric Fields" Nanomaterials 12, no. 12: 2067. https://doi.org/10.3390/nano12122067

APA StyleGe, X., Wu, X., Shi, Q., & Wang, W. (2022). Lubrication Performances of Polyalkylene Glycols at Steel Interface under External Electric Fields. Nanomaterials, 12(12), 2067. https://doi.org/10.3390/nano12122067