Three Dimensional Printing of Multiscale Carbon Fiber-Reinforced Polymer Composites Containing Graphene or Carbon Nanotubes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Materials Processing and Sample Preparation

2.2.1. Compounding

2.2.2. Compression Molding (CM)

2.2.3. Filament Extrusion

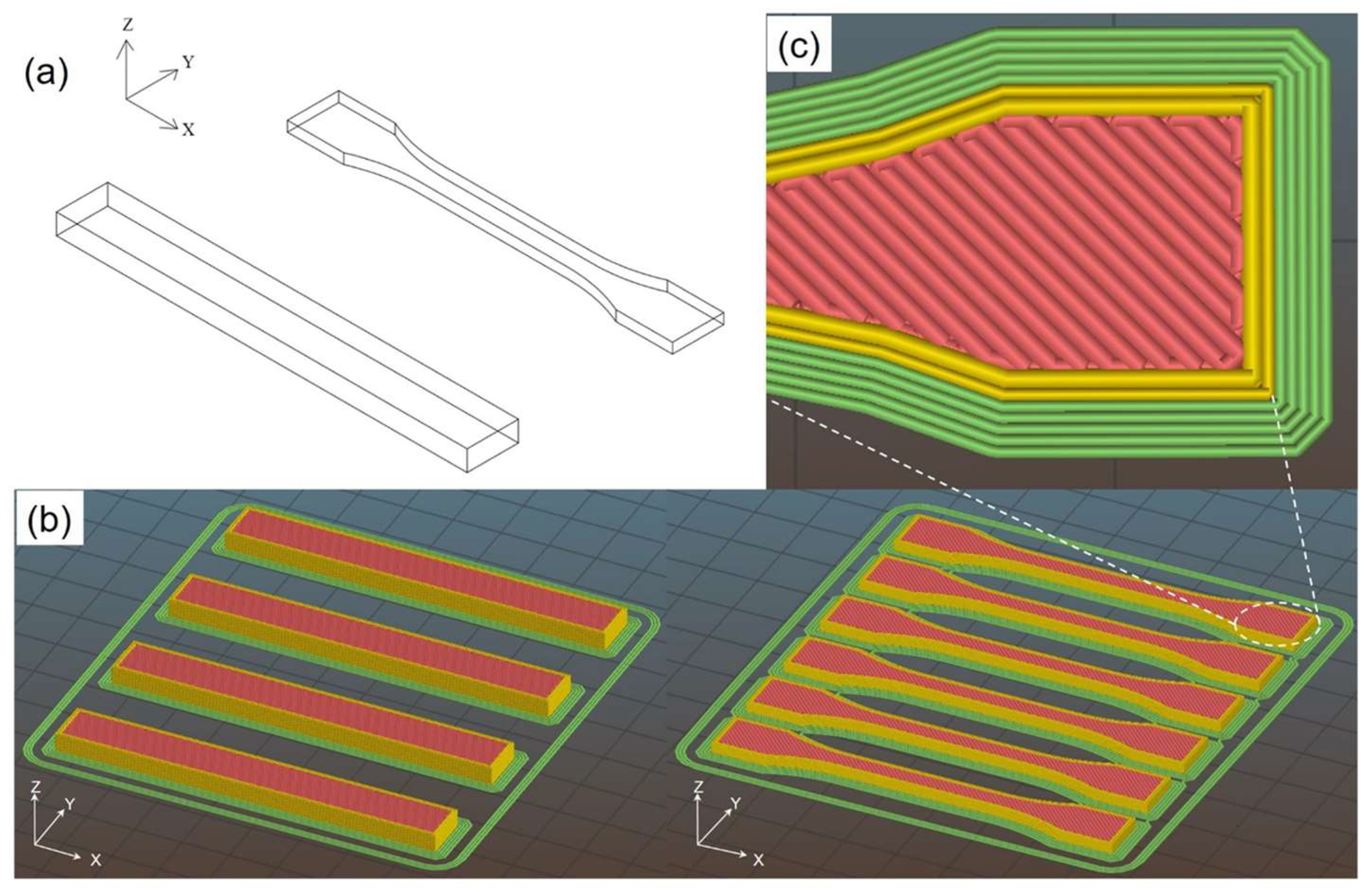

2.2.4. FFF Printed Samples Preparation

2.3. Testing Techniques

2.3.1. Melt Flow Index

2.3.2. Density Measurements

2.3.3. Scanning Electron Microscopy (SEM)

2.3.4. Quasi-Static Tensile Test

2.3.5. Nanoindentation Tests

2.3.6. Electrical Resistivity Test

2.3.7. Thermogravimetric Analysis (TGA)

2.3.8. Vicat Softening Temperature (VST)

2.3.9. Heat Deflection Temperature (HDT)

3. Results and Discussion

3.1. Compression Molding

3.1.1. Melt Flow Index

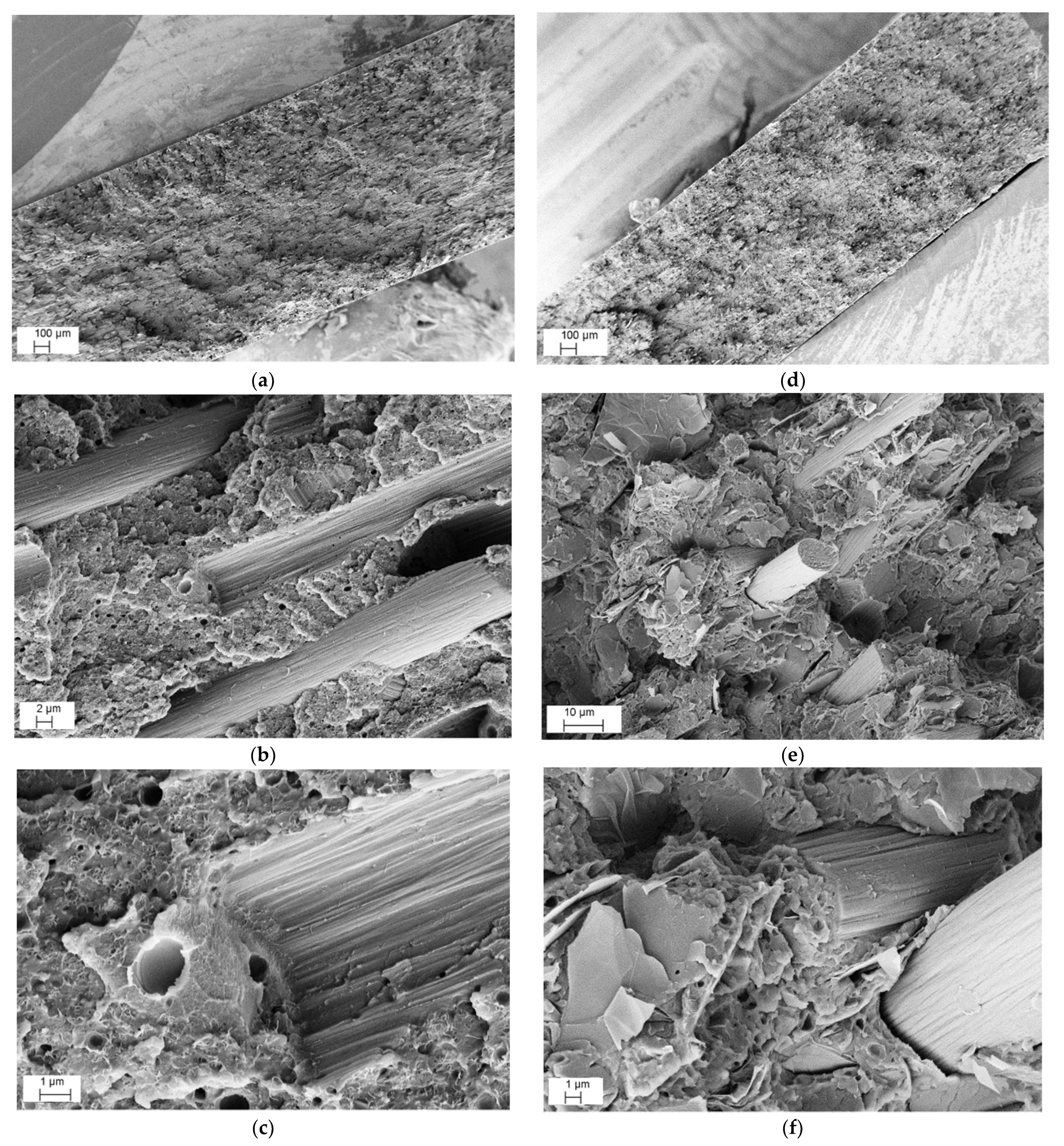

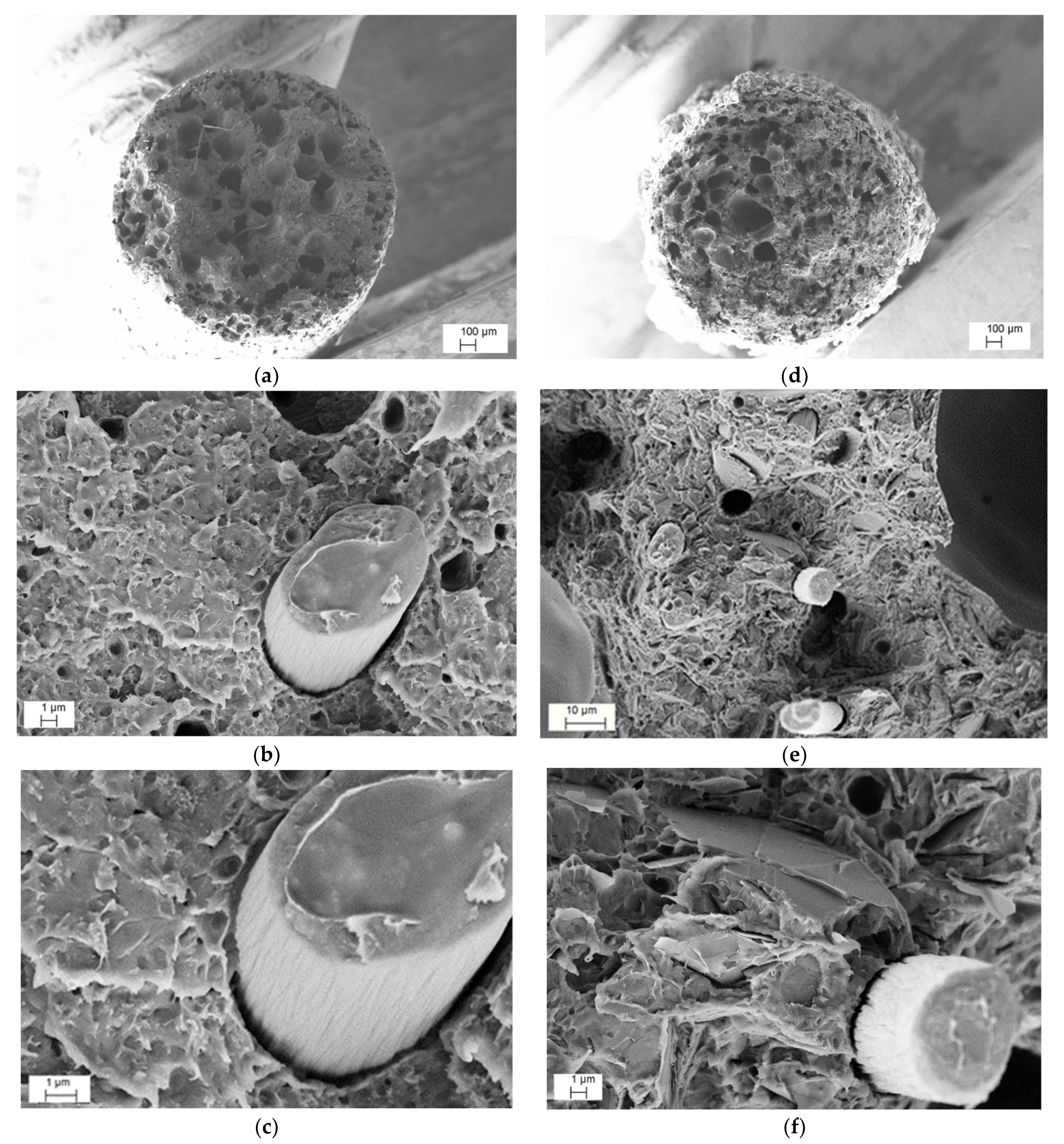

3.1.2. Density and Morphological Analyses

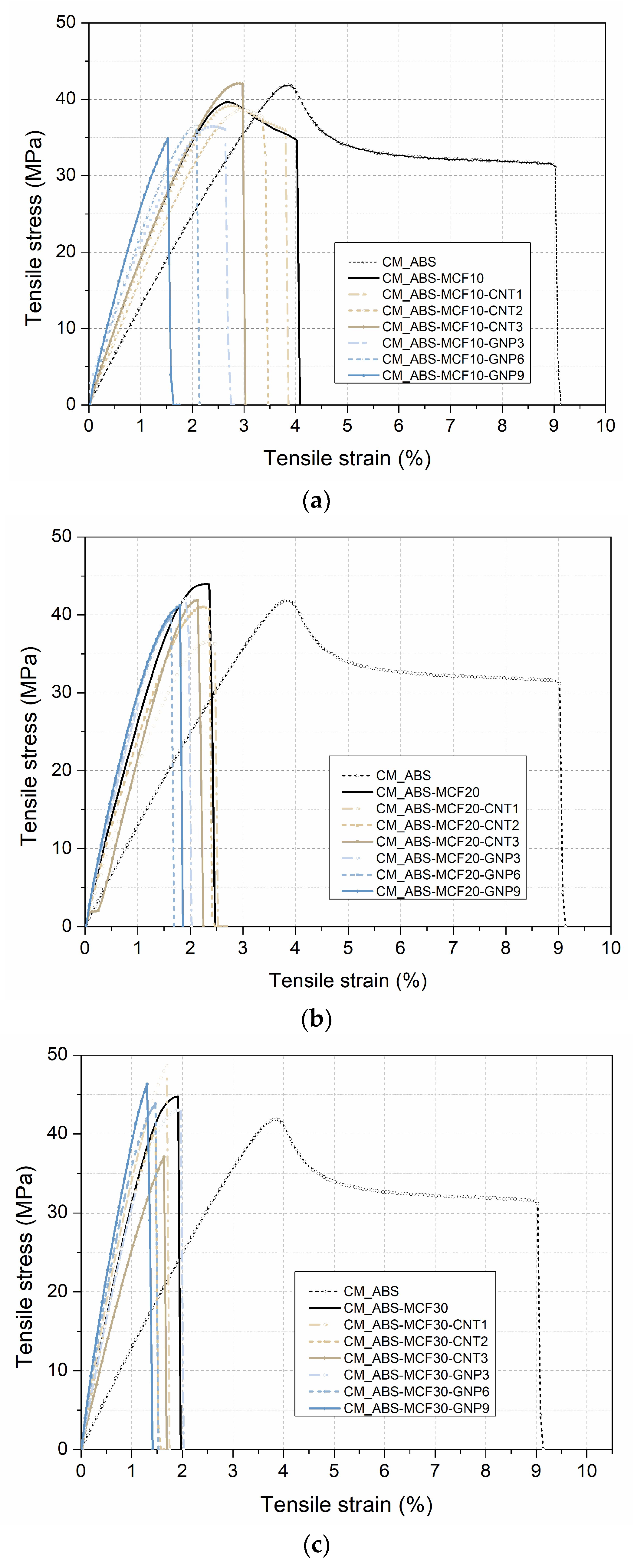

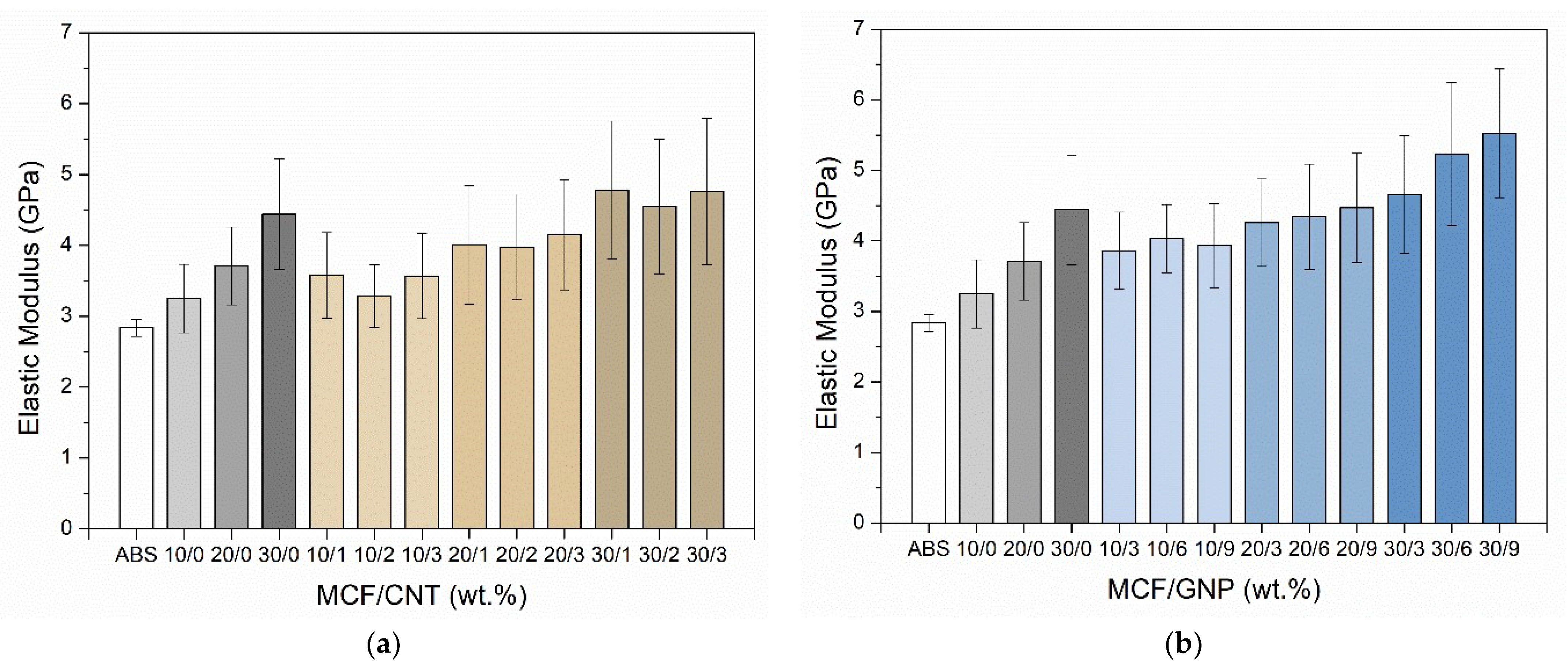

3.1.3. Mechanical Properties

3.1.4. Nanoindentation Test

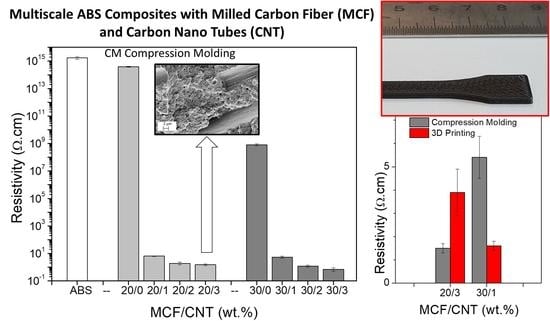

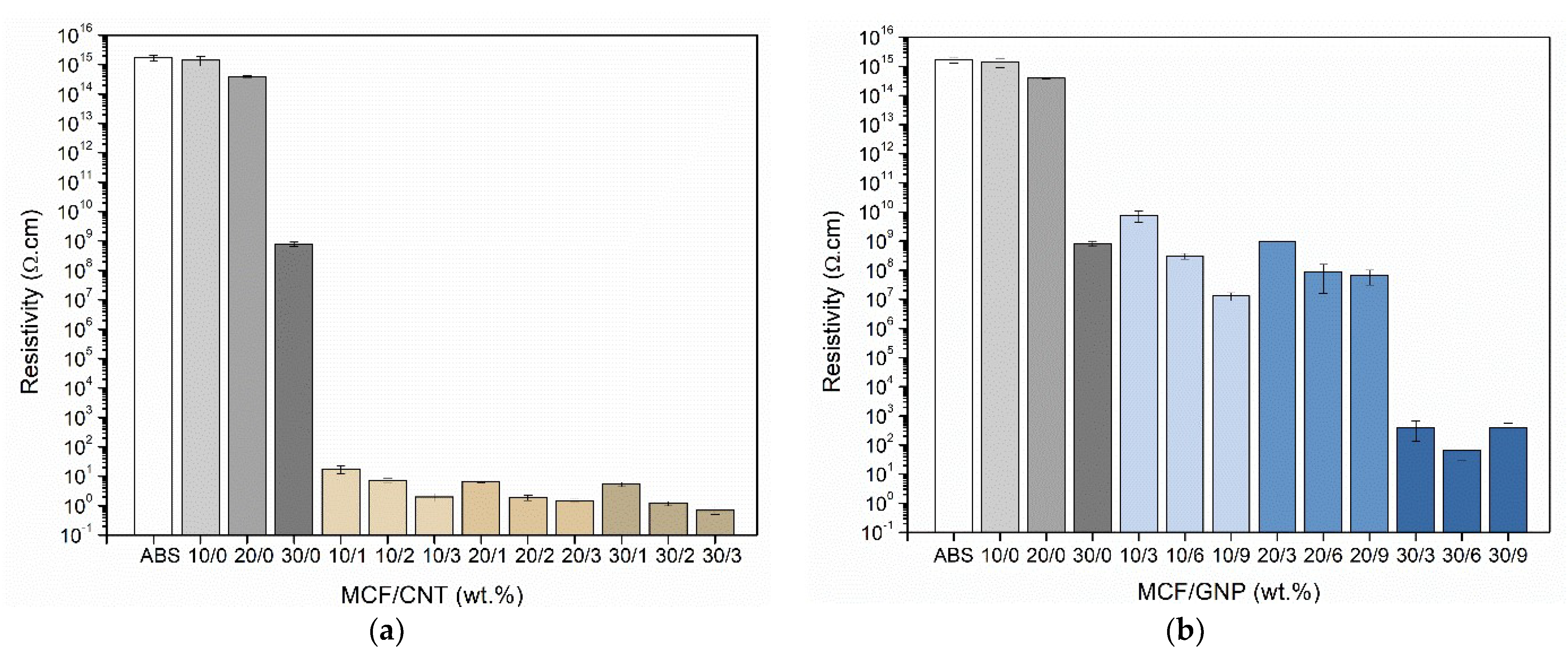

3.1.5. Electrical Resistivity

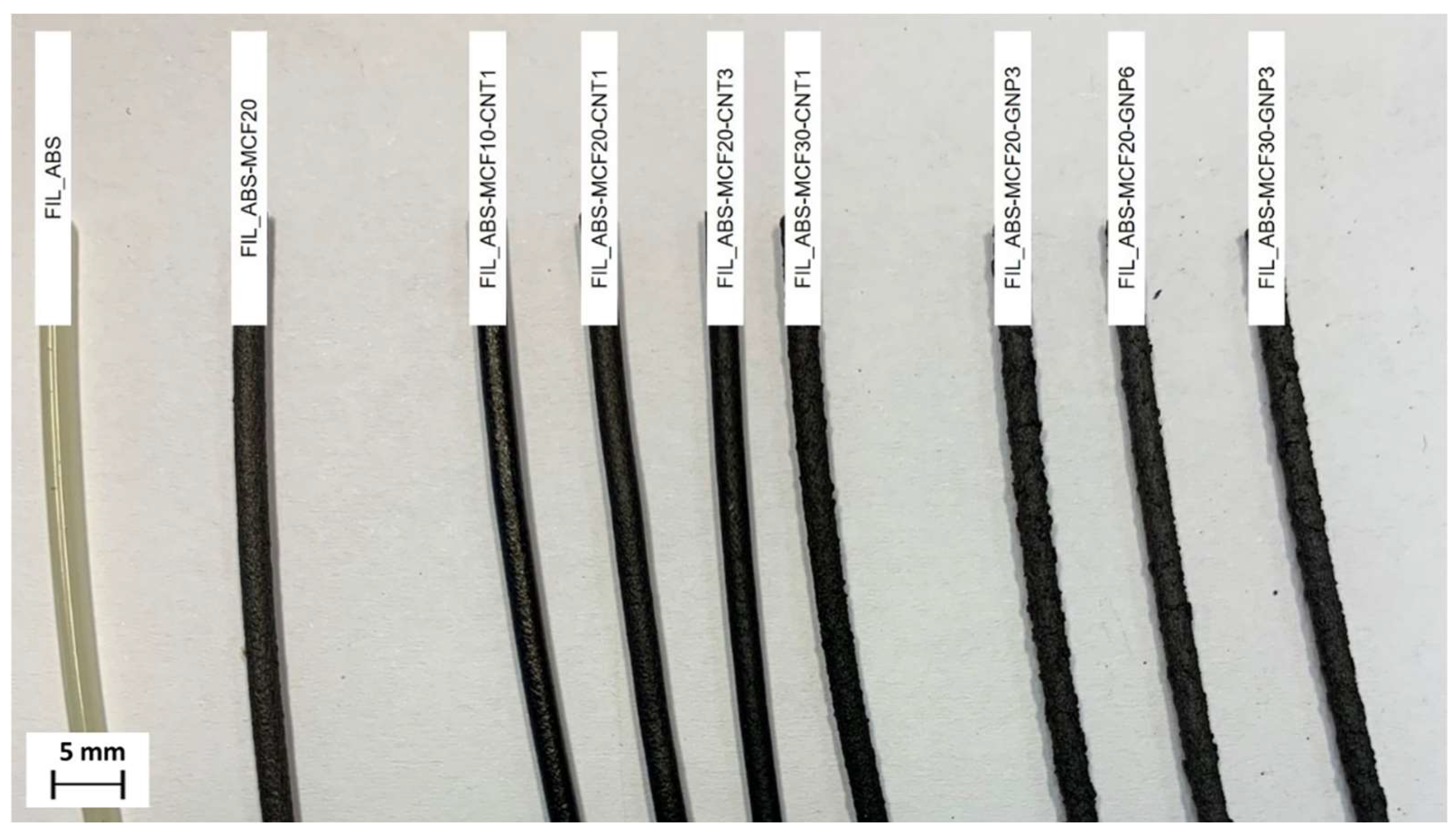

3.2. Filaments and 3D Printing Samples

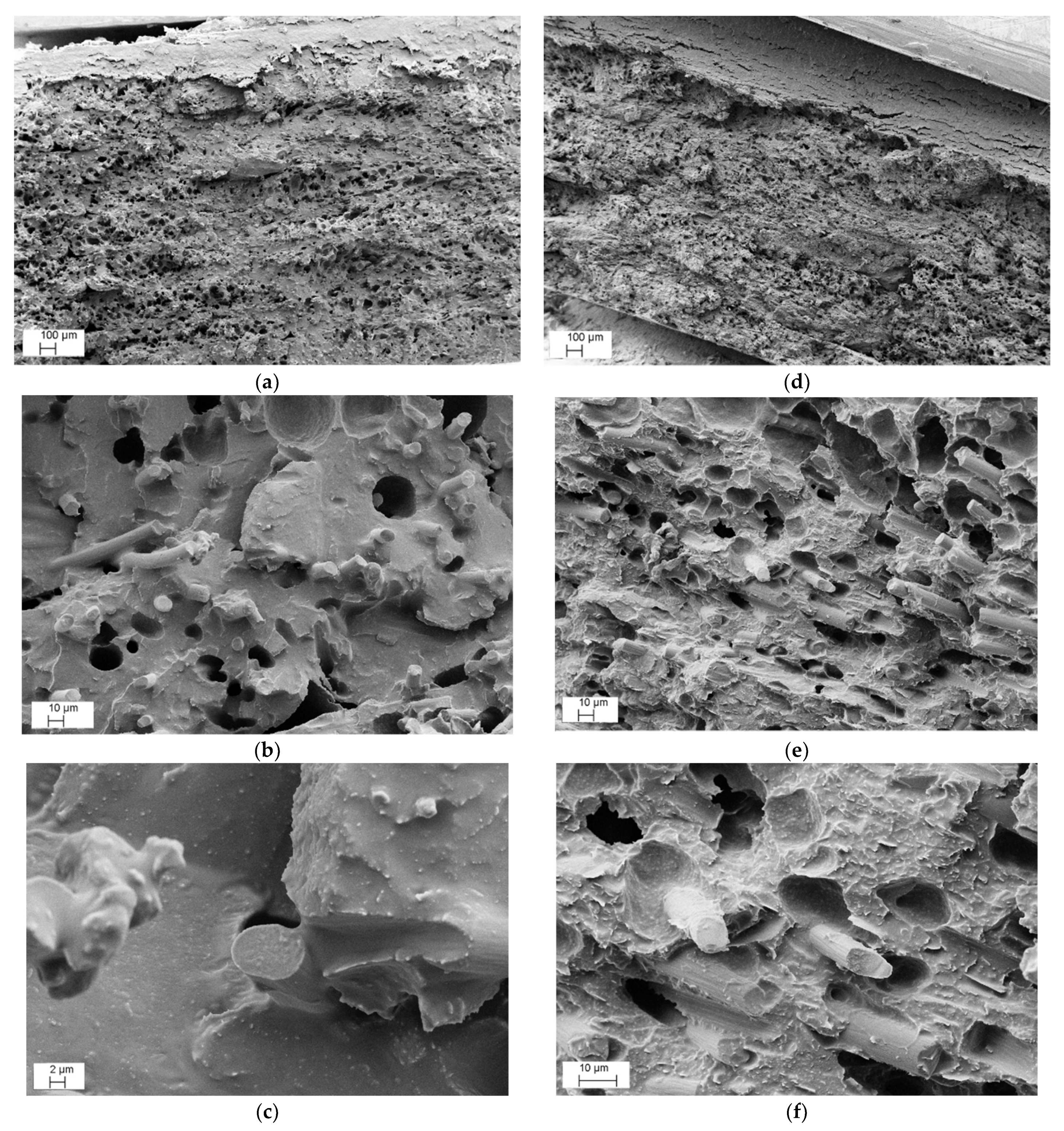

3.2.1. Density and Morphological Analysis

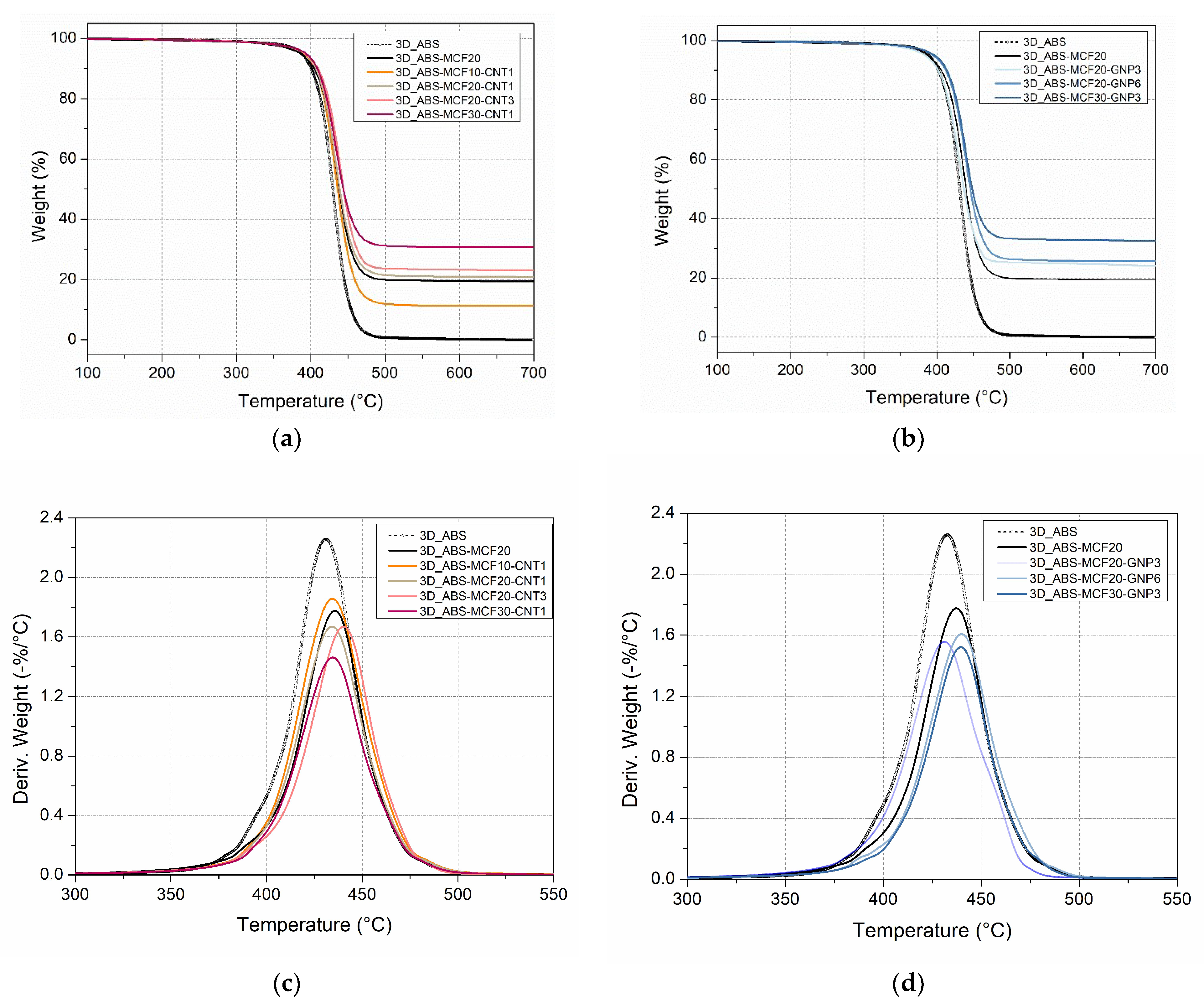

3.2.2. Thermal Degradation Behavior

3.2.3. Vicat Softening Temperature (VST) and Heat Deflection Temperature (HDT)

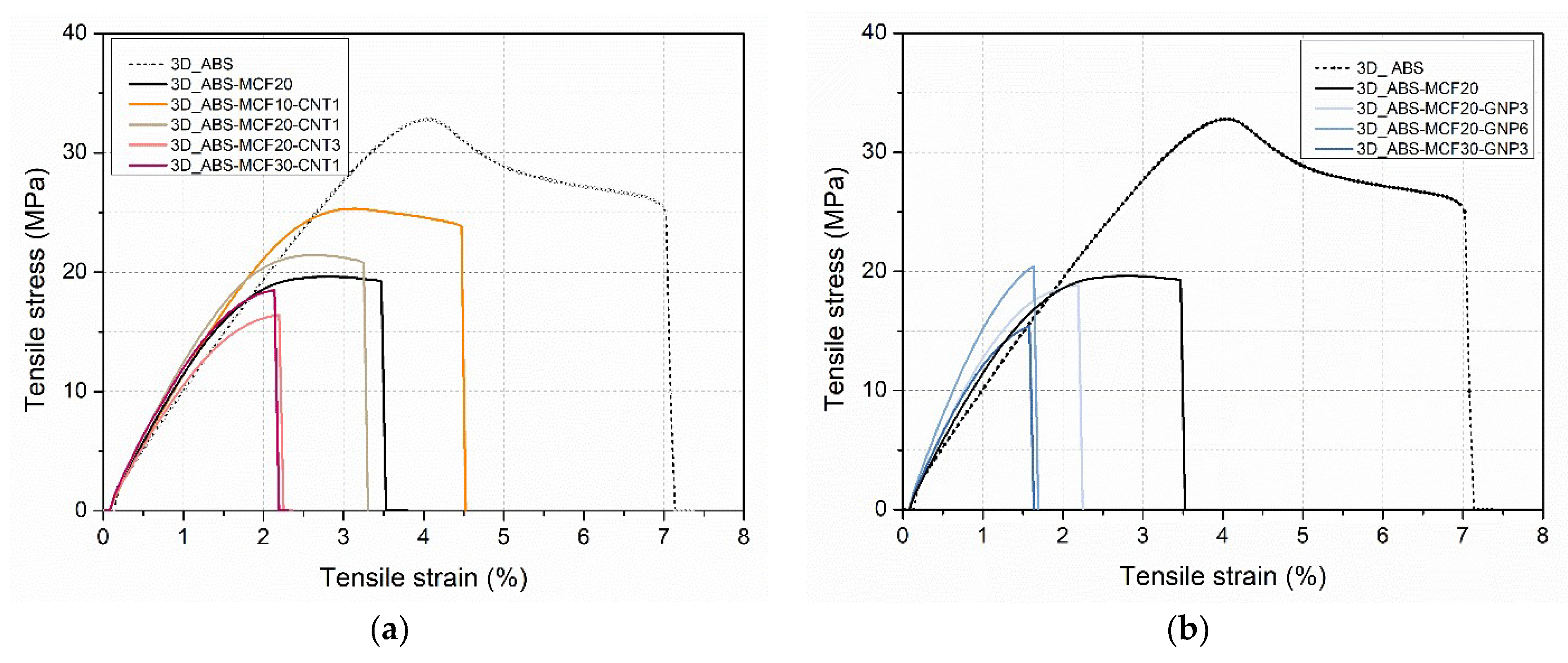

3.2.4. Mechanical Properties

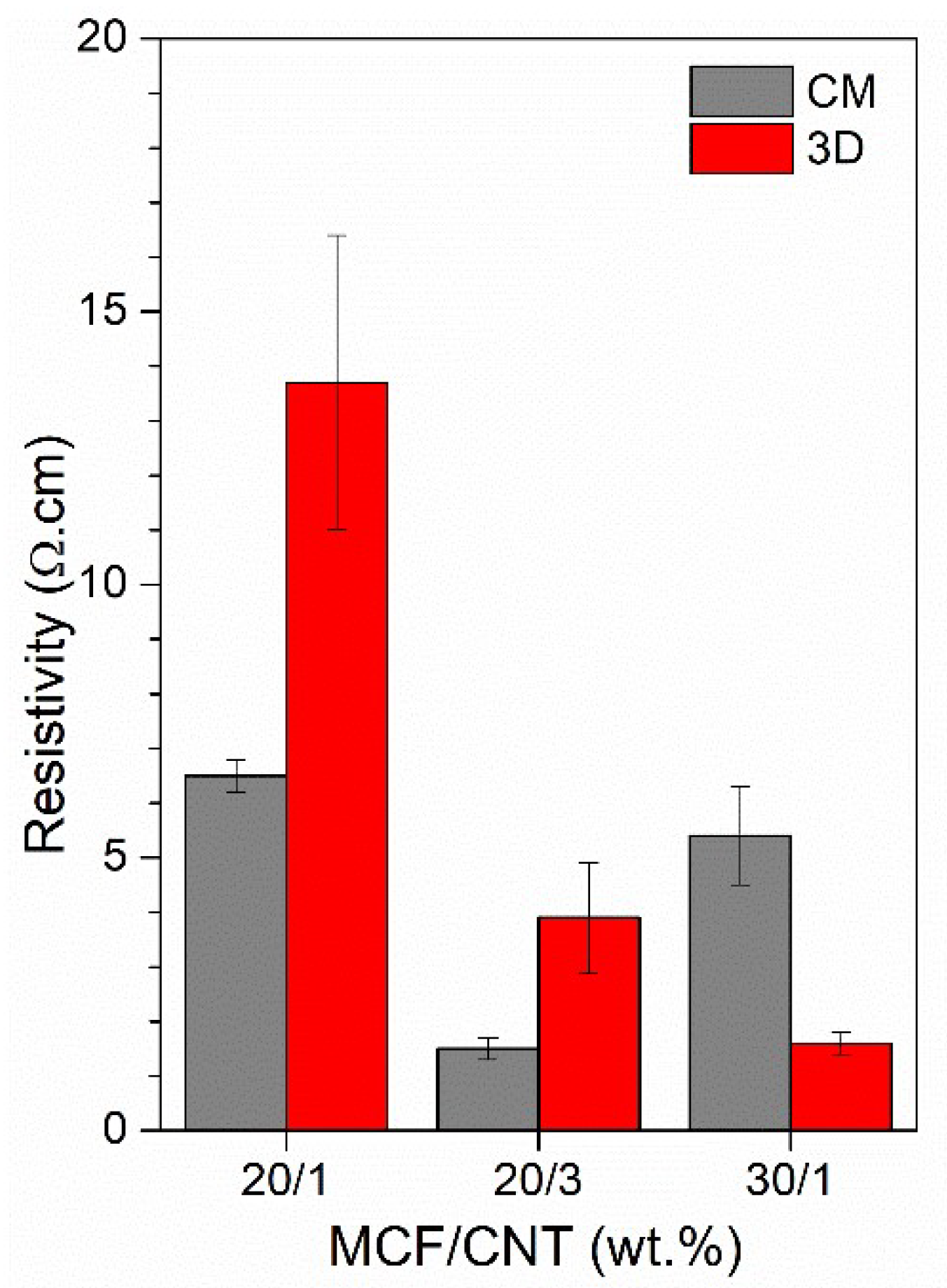

3.2.5. Electrical Resistivity Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lee, J.; An, J.; Chua, C.K. Fundamentals and applications of 3D printing for novel materials. Appl. Mater. Today 2017, 7, 120–133. [Google Scholar] [CrossRef]

- Ghoshal, S. Polymer/Carbon Nanotubes (CNT) Nanocomposites Processing Using Additive Manufacturing (Three-Dimensional Printing) Technique: An Overview. Fibers 2017, 5, 40. [Google Scholar] [CrossRef]

- Campbell, T.A.; Ivanova, O.S. 3D printing of multifunctional nanocomposites. Nano Today 2013, 8, 119–120. [Google Scholar] [CrossRef]

- Agag, T.; Koga, T.; Takeichi, T. Studies on thermal and mechanical properties of polyimide-clay nanocomposites. Polymer 2001, 42, 3399–3408. [Google Scholar] [CrossRef]

- Dul, S.; Fambri, L.; Pegoretti, A. High-Performance Polyamide/Carbon Fiber Composites for Fused Filament Fabrication: Mechanical and Functional Performances. J. Mater. Eng. Perform. 2021, 30, 5066–5085. [Google Scholar] [CrossRef]

- Shelley, S.; Mather, P.T.; Devries, K.L. Reinforcement and environmental degradation of nylon-6/clay nanocomposites. Polymer 2021, 42, 5849–5858. [Google Scholar] [CrossRef] [Green Version]

- Alonso-Gutierrez, B.J.; Dul, S.; Pegoretti, A.; Alvarez-Quintana, J.; Fambri, L. Investigation of the Effects of Multi-Wall and Single-Wall Carbon Nanotubes Concentration on the Properties of ABS Nanocomposites. J. Carbon Res. 2021, 7, 33. [Google Scholar] [CrossRef]

- Pourzahedi, L.; Zhai, P.; Isaacs, J.A.; Eckelman, M.J. Life cycle energy benefits of carbon nanotubes for electromagnetic interference (EMI) shielding applications. J. Clean. Prod. 2017, 142, 1971–1978. [Google Scholar] [CrossRef]

- Gonçalves, J.; Lima, P.; Krause, B.; Pötschke, P.; Lafont, U.; Gomes, J.R.; Abreu, C.S.; Paiva, M.C.; Covas, J.A. Electrically Conductive Polyetheretherketone Nanocomposite Filaments: From Production to Fused Deposition Modeling. Polymers 2018, 10, 925. [Google Scholar] [CrossRef] [Green Version]

- Dudek, P. FDM 3D printing technology in manufacturing composite elements. Arch. Metall. Mater. 2013, 58, 1415–1418. [Google Scholar] [CrossRef]

- Yang, Y.; Gupta, M.C.; Dudley, K.L. Towards cost-efficient EMI shielding materials using carbon nanostructure-based nanocomposites. Nanotechnology 2007, 18, 345701. [Google Scholar] [CrossRef]

- Zaldivar, R.J.; Mclouth, T.D.; Patel, D.N.; Severino, J.V.; Kim, H.I. Strengthening of plasma treated 3D printed ABS through epoxy infiltration. Prog. Addit. Manuf. 2017, 2, 193–200. [Google Scholar] [CrossRef] [Green Version]

- Çant, E.; Ayd, M. Effects of micro particle reinforcement on mechanical properties of 3D printed parts. Rapid Prototyp. J. 2018, 24, 171–176. [Google Scholar] [CrossRef]

- Zhang, W.; Cotton, C.; Sun, J.; Heider, D.; Gu, B.; Sun, B.; Chou, T.-W. Interfacial bonding strength of short carbon fiber/acrylonitrile-butadiene-styrene composites fabricated by fused deposition modeling. Compos. Part B Eng. 2018, 137, 51–59. [Google Scholar] [CrossRef]

- Tekinalp, H.L.; Kunc, V.; Velez-Garcia, G.M.; Duty, C.E.; Love, L.J.; Naskar, A.K.; Blue, C.A.; Ozcan, S. Highly oriented carbon fiber-polymer composites via additive manufacturing. Comp. Sci. Tech. 2014, 105, 144–150. [Google Scholar] [CrossRef] [Green Version]

- Ning, F.; Cong, W.; Qiu, J.; Wei, J.; Wang, S. Additive Manufacturing of Carbon Fiber Reinforced Thermoplastic Composites Using Fused Deposition Modeling. Compos. Part B Eng. 2015, 80, 369–378. [Google Scholar] [CrossRef]

- Adeniran, O.; Cong, W.; Bediako, E.; Aladesanmi, V. Additive Manufacturing of Carbon Fiber Reinforced Plastic Composites: The Effect of Fiber Content on Compressive Properties. J. Compos. Sci. 2021, 5, 325. [Google Scholar] [CrossRef]

- Leigh, S.J.; Bradley, R.J.; Purssell, C.P.; Billson, D.R.; Hutchins, D.A. A Simple, Low-Cost Conductive Composite Material for 3D Printing of Electronic Sensors. PLoS ONE 2012, 7, e49365. [Google Scholar] [CrossRef] [PubMed]

- Farahani, R.D.; Dalir, H.; Le Borgne, V.; Therriault, D. Direct-write fabrication of freestanding nanocomposite strain sensors. Nanotechnology 2012, 23, 085502. [Google Scholar] [CrossRef] [PubMed]

- Muth, J.T.; Vogt, D.M.; Truby, R.L.; Kolesky, D.B.; Wood, R.J.; Lewis, J.A. Embedded 3D Printing of Strain Sensors within Highly Stretchable Elastomers. Adv. Mater. 2014, 26, 6307–6312. [Google Scholar] [CrossRef]

- Zhang, D.; Chi, B.; Li, B.; Gao, Z.; Du, Y.; Guo, J.; Wei, J. Fabrication of highly conductive graphene flexible circuits by 3D printing. Synth. Met. 2016, 217, 79–86. [Google Scholar] [CrossRef]

- Sun, K.; Wei, T.; Ahn, B.Y.; Seo, J.Y.; Dillon, S.J.; Lewis, J.A. 3D Printing of Interdigitated Li-Ion Microbattery Architectures. Adv. Mater. 2013, 25, 4539–4543. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kennedy, Z.C.; Christ, J.F.; Evans, K.A.; Arey, B.W.; Sweet, L.E.; Warner, M.G.; Eriksonb, R.L.; Barrett, C.A. 3D-printed poly(vinylidene fluoride)/carbon nanotube composites a tunable, low-cost chemical vapour sensing platform. Nanoscale 2017, 9, 5458–5466. [Google Scholar] [CrossRef] [PubMed]

- Mora, A.; Verma, P.; Kumar, S. Electrical conductivity of CNT / polymer composites: 3D printing, measurements and modeling. Compos. Part B 2019, 183, 107600. [Google Scholar] [CrossRef]

- Dorigato, A.; Moretti, V.; Dul, S.; Unterberger, S.H.; Pegoretti, A. Electrically conductive nanocomposites for fused deposition modelling. Synth. Met. 2017, 226, 7–14. [Google Scholar] [CrossRef]

- Dul, S.; Fambri, L.; Pegoretti, A. Fused deposition modelling with ABS—graphene nanocomposites. Compos. Part A 2016, 85, 181–191. [Google Scholar] [CrossRef]

- Pedrazzoli, D.; Pegoretti, A. Expanded graphite nanoplatelets as coupling agents in glass fiber reinforced polypropylene composites. Compos. Part A 2014, 66, 25–34. [Google Scholar] [CrossRef]

- Dul, S.; Ecco, L.G.; Pegoretti, A.; Fambri, L. Graphene/Carbon Nanotube Hybrid Nanocomposites: Effect of Compression Molding and Fused Filament Fabrication on Properties. Polymers 2020, 12, 101. [Google Scholar] [CrossRef] [Green Version]

- Sinkral® F 322-ABS-Versalis S.p.A Material Data. Available online: https://www.materialdatacenter.com/ms/en/Sinkral/Versalis+S%252Ep%252EA/SINKRAL%C2%AE+F+332/c6da6726/1895 (accessed on 27 December 2021).

- PX30 Milled Carbon Fibers. Available online: https://zoltek.com/products/px30/ (accessed on 13 January 2022).

- TDS Sheet; Nanocyl SA. Nanocyl® NC7000TM Technical Data Sheet. NC7000™-Technical Data Sheet-Nanocyl. Available online: https://www.nanocyl.com/download/tds-nc7000/ (accessed on 27 December 2021).

- xGnP® Graphene Nanoplatelets–Grade M. p. 48911. Available online: https://xgsciences.com/wp-content/uploads/2017/11/xGnP-M.-MD00003.-2018-1.pdf (accessed on 27 December 2021).

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Reasearch 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Cheng, Y.T.; Cheng, C.M. Relationships between hardness, elastic modulus, and the work of indentation. Appl. Phys. Lett. 1998, 73, 614–616. [Google Scholar] [CrossRef]

- Fischer-Cripps, A.C. Nanoindentation. Mechanical Engineering Series 1, 3rd ed.; Springer: Heidelberg, Germany, 2011. [Google Scholar] [CrossRef]

- Dul, S.; Pegoretti, A.; Fambri, L. Effects of the Nanofillers on Physical Properties of Acrylonitrile-Butadiene-Styrene Nanocomposites: Comparison of Graphene Nanoplatelets and Multiwall Carbon Nanotubes. J. Mater. Eng. Perform. 2018, 8, 674. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pedrazzoli, D.; Dorigato, A.; Conti, T.; Vanzetti, L.; Bersani, M.; Pegoretti, A. Liquid crystalline polymer nanocomposites reinforced with in-situ reduced graphene oxide. Express Polym. Lett. 2015, 9, 709–720. [Google Scholar] [CrossRef]

- Dul, S.; Fambri, L.; Merlini, C.; Barra, G.M.O.; Bersani, M.; Vanzetti, L.; Pegoretti, A. Effect of graphene nanoplatelets structure on the properties of acrylonitrile–butadiene–styrene composites. Polym. Comp. 2019, 40, E285–E300. [Google Scholar] [CrossRef]

- Singh, B.K.; Kar, P.; Shrivastava, N.K.; Banerjee, S.; Khatua, B.B. Electrical and Mechanical Properties of Acrylonitrile-Butadiene-Styrene/Multiwall Carbon Nanotube Nanocomposites Prepared by Melt-Blending. J. Appl. Polym. Sci. 2011, 124, 3165–3174. [Google Scholar] [CrossRef]

- Vidakis, N.; Maniadi, A.; Petousis, M. Mechanical and Electrical Properties Investigation of 3D-Printed Acrylonitrile–Butadiene–Styrene Graphene and Carbon Nanocomposites. J. Mater. Eng. Perform. 2020, 29, 1909–1918. [Google Scholar] [CrossRef]

- Dul, S.; Gutierrez, B.J.A.; Pegoretti, A.; Alvarez-Quintana, J.; Fambri, L. 3D printing of ABS Nanocomposites. Comparison of processing and effects of Multi-Wall and Single-Wall Carbon Nanotubes on thermal, mechanical and electrical properties. J. Mater. Sci. Technol. 2022, 121, 52–56. [Google Scholar] [CrossRef]

| Filler Code | Filler Type | Manufacturer | Density (g/cm3) | Length/Width(μm) | Diameter/ Thickness (nm) | Aspect Ratio | Surface Area (m2/g) | Carbon Purity (%) |

|---|---|---|---|---|---|---|---|---|

| MCF | PX30 | Zoltek, St. Louis, MO, USA | 1.75 a | 100–150 | 7200 | 14–21 | - | >99 |

| CNT | MWCNT-NC7000 b | Nanocyl, Belgium | 2.15 ± 0.03 b | 1.5 | 9.5 | 158 | 250–300 | >90 |

| GNP | xGnP-M5 c | XG Sciences, Lansing, MI, USA | 2.06 ± 0.03 c | 5 | 6–8 | 625–833 | 120–150 | >99.5 |

| Sample | Material Composition | Processing Technique | ||||||

|---|---|---|---|---|---|---|---|---|

| ABS (wt.%) | MCF (wt.%) | CNT (wt.%) | GNP (wt.%) | Nanofiller/MCF Ratio | CM | Filament | 3D Printing | |

| ABS | 100 | - | - | - | - | X | X | X |

| ABS-MCF10 | 90 | 10 | - | - | 0 | X | - | - |

| ABS-MCF20 | 80 | 20 | - | - | 0 | X | X | X |

| ABS-MCF30 | 70 | 30 | - | - | 0 | X | - | - |

| ABS-MCF10-CNT1 | 89 | 10 | 1 | - | 0.1 | X | X | X |

| ABS-MCF10-CNT2 | 88 | 10 | 2 | - | 0.2 | X | - | - |

| ABS-MCF10-CNT3 | 87 | 10 | 3 | - | 0.3 | X | - | - |

| ABS-MCF20-CNT1 | 79 | 20 | 1 | - | 0.05 | X | X | X |

| ABS-MCF20-CNT2 | 78 | 20 | 2 | - | 0.1 | X | - | - |

| ABS-MCF20-CNT3 | 77 | 20 | 3 | - | 0.15 | X | X | X |

| ABS-MCF30-CNT1 | 69 | 30 | 1 | - | 0.03 | X | X | X |

| ABS-MCF30-CNT2 | 68 | 30 | 2 | - | 0.07 | X | - | - |

| ABS-MCF30-CNT3 | 67 | 30 | 3 | - | 0.1 | X | - | - |

| ABS-MCF10-GNP3 | 87 | 10 | - | 3 | 0.3 | X | - | - |

| ABS-MCF10-GNP6 | 84 | 10 | - | 6 | 0.6 | X | - | - |

| ABS-MCF10-GNP9 | 81 | 10 | - | 9 | 0.9 | X | - | - |

| ABS-MCF20-GNP3 | 77 | 20 | - | 3 | 0.15 | X | X | X |

| ABS-MCF20-GNP6 | 74 | 20 | - | 6 | 0.3 | X | X | X |

| ABS-MCF20-GNP9 | 71 | 20 | - | 9 | 0.45 | X | - | - |

| ABS-MCF30-GNP3 | 67 | 30 | - | 3 | 0.1 | X | X | X |

| ABS-MCF30-GNP6 | 64 | 30 | - | 6 | 0.2 | X | - | - |

| ABS-MCF30-GNP9 | 61 | 30 | - | 9 | 0.3 | X | - | - |

| Sample | X (mm) | Y (mm) | Z (mm) | Deposition Time of a Single Layer (s) | Number of Layers | Total Time (min) | Testing |

|---|---|---|---|---|---|---|---|

| Dumbbell | 75.0 | 5–10 | 2.0 | 123 | 10 | 20.5 | Density, tensile test, resistivity |

| Parallelepiped | 80.0 | 10.0 | 3.8 | 123 | 19 | 39.0 | TGA, VST, and HDT |

| Sample | ρc (g/cm3) | ρm (g/cm3) | Vv (%) | CAR |

|---|---|---|---|---|

| CM_ABS | 1.040 | 1.040 ± 0.000 | 0.00 | // |

| CM_ABS-MCF10 | 1.083 | 1.081 ± 0.000 | 0.16 | 1.1 |

| CM_ABS-MCF20 | 1.130 | 1.130 ± 0.002 | 0.01 | 2.3 |

| CM_ABS-MCF30 | 1.180 | 1.177 ± 0.001 | 0.30 | 3.6 |

| CM_ABS-MCF10-CNT1 | 1.089 | 1.086 ± 0.001 | 0.30 | 2.7 |

| CM_ABS-MCF10-CNT2 | 1.095 | 1.092 ± 0.000 | 0.31 | 3.9 |

| CM_ABS-MCF10-CNT3 | 1.101 | 1.098 ± 0.001 | 0.26 | 5.1 |

| CM_ABS-MCF20-CNT1 | 1.136 | 1.133 ± 0.001 | 0.24 | 5.1 |

| CM_ABS-MCF20-CNT2 | 1.143 | 1.140 ± 0.001 | 0.25 | 6.7 |

| CM_ABS-MCF20-CNT3 | 1.149 | 1.147 ± 0.000 | 0.18 | 8.2 |

| CM_ABS-MCF30-CNT1 | 1.187 | 1.183 ± 0.001 | 0.37 | 6.8 |

| CM_ABS-MCF30-CNT2 | 1.194 | 1.193 ± 0.001 | 0.14 | 8.4 |

| CM_ABS-MCF30-CNT3 | 1.202 | 1.200 ± 0.002 | 0.15 | 10.0 |

| CM_ABS-MCF10-GNP3 | 1.100 | 1.089 ± 0.001 | 1.00 | 23.6 |

| CM_ABS-MCF10-GNP6 | 1.118 | 1.105 ± 0.001 | 1.10 | 45.5 |

| CM_ABS-MCF10-GNP9 | 1.136 | 1.124 ± 0.001 | 1.04 | 67.4 |

| CM_ABS-MCF20-GNP3 | 1.148 | 1.138 ± 0.001 | 0.88 | 25.4 |

| CM_ABS-MCF20-GNP6 | 1.167 | 1.158 ± 0.001 | 0.77 | 47.2 |

| CM_ABS-MCF20-GNP9 | 1.187 | 1.172 ± 0.002 | 1.27 | 69.1 |

| CM_ABS-MCF30-GNP3 | 1.201 | 1.191 ± 0.000 | 0.77 | 27.1 |

| CM_ABS-MCF30-GNP6 | 1.222 | 1.210 ± 0.001 | 0.98 | 49.0 |

| CM_ABS-MCF30-GNP9 | 1.243 | 1.228 ± 0.001 | 1.24 | 70.9 |

| Sample | ET (MPa) | σy (MPa) | σb (MPa) | εb (%) | PE,MFI ×10−3 * (GPa g/10 min) |

|---|---|---|---|---|---|

| CM_ABS | 2313 ± 38 | 41.4 ± 0.8 | 31.2 ± 0.5 | 10.1 ± 5.6 | 76.6 |

| CM_ABS-MCF10 | 3752 ± 324 | 39.8 ± 0.6 | 34.8 ± 1.2 | 4.2 ± 0.5 | 96.1 |

| CM_ABS-MCF20 | 6000 ± 499 | n.d. ** | 44.2 ± 1.5 | 2.1 ± 0.3 | 124.8 |

| CM_ABS-MCF30 | 6586 ± 1614 | n.d. ** | 42.9 ± 3.0 | 1.8 ± 0.1 | 114.6 |

| CM_ABS-MCF10-CNT1 | 3609 ± 455 | 38.8 ± 1.2 | 36.5 ± 0.9 | 3.7 ± 1.1 | 55.2 |

| CM_ABS-MCF10-CNT2 | 3858 ± 396 | 39.0 ± 0.6 | 36.3 ± 2.2 | 3.5 ± 0.2 | 31.3 |

| CM_ABS-MCF10-CNT3 | 3912 ± 508 | n.d. ** | 42.2 ± 1.0 | 2.9 ± 0.2 | 10.6 |

| CM_ABS-MCF20-CNT1 | 5165 ± 621 | n.d. ** | 38.7 ± 3.3 | 2.2 ± 0.5 | 56.3 |

| CM_ABS-MCF20-CNT2 | 5305 ± 1077 | n.d. ** | 41.6 ± 2.8 | 2.3 ± 0.2 | 23.8 |

| CM_ABS-MCF20-CNT3 | 5336 ± 848 | n.d. ** | 41.7 ± 1.6 | 2.0 ± 0.2 | 6.4 |

| CM_ABS-MCF30-CNT1 | 6388 ± 1369 | n.d. ** | 46.2 ± 5.2 | 1.9 ± 0.1 | 41.5 |

| CM_ABS-MCF30-CNT2 | 6367 ± 533 | n.d. ** | 41.3 ± 1.7 | 1.6 ± 0.1 | 20.4 |

| CM_ABS-MCF30-CNT3 | 5739 ± 560 | n.d. ** | 36.5 ± 1.7 | 1.6 ± 0.2 | 2.9 |

| CM_ABS-MCF10-GNP3 | 3658 ± 212 | 36.3 ± 1.3 | 34.3 ± 3.1 | 2.8 ± 0.1 | 74.3 |

| CM_ABS-MCF10-GNP6 | 4025 ± 313 | n.d. ** | 33.2 ± 4.7 | 2.2 ± 0.2 | 60.8 |

| CM_ABS-MCF10-GNP9 | 4760 ± 560 | n.d. ** | 35.7 ± 2.3 | 1.7 ± 0.2 | 55.7 |

| CM_ABS-MCF20-GNP3 | 6101 ± 187 | n.d. ** | 42.6 ± 1.8 | 2.0 ± 0.2 | 93.3 |

| CM_ABS-MCF20-GNP6 | 6104 ± 127 | n.d. ** | 39.8 ± 2.0 | 1.7 ± 0.1 | 56.8 |

| CM_ABS-MCF20-GNP9 | 6406 ± 675 | n.d. ** | 41.8 ± 2.0 | 1.7 ± 0.1 | 47.4 |

| CM_ABS-MCF30-GNP3 | 7208 ± 1390 | n.d. ** | 42.8 ± 2.9 | 1.8 ± 0.1 | 70.6 |

| CM_ABS-MCF30-GNP6 | 8239 ± 937 | n.d. ** | 45.1 ± 2.7 | 1.5 ± 0.1 | 51.9 |

| CM_ABS-MCF30-GNP9 | 9193 ± 1030 | n.d. ** | 47.7 ± 3.0 | 1.4 ± 0.1 | 48.7 |

| Sample | Filament | 3D-Printed Sample | ||

|---|---|---|---|---|

| ρc (g/cm3) | Vv (%) | ρc (g/cm3) | Vv (%) | |

| ABS | 1.045 ± 0.002 | 0.0 | 1.044 ± 0.002 | 0.0 |

| ABS-MCF20 | 0.919 ± 0.025 | 18.9 | 0.930 ± 0.006 | 17.9 |

| ABS-MCF10-CNT1 | 1.015 ± 0.003 | 7.2 | 1.024 ± 0.005 | 6.2 |

| ABS-MCF20-CNT1 | 1.021 ± 0.025 | 10.5 | 0.968 ± 0.003 | 15.0 |

| ABS-MCF20-CNT3 | 0.851 ± 0.008 | 26.2 | 0.937 ± 0.013 | 18.0 |

| ABS-MCF30-CNT1 | 1.001 ± 0.041 | 15.9 | 0.992 ± 0.038 | 16.7 |

| ABS-MCF20-GNP3 | 0.883 ± 0.015 | 23.4 | 0.938 ± 0.014 | 19.9 |

| ABS-MCF20-GNP6 | 0.875 ± 0.023 | 25.3 | 0.938 ± 0.012 | 19.1 |

| ABS-MCF30-GNP3 | 0.873 ± 0.003 | 27.5 | 0.973 ± 0.007 | 18.5 |

| Sample | Residual Mass at 250 °C (wt.%) | Td,max 1 (°C) | Residual Mass at Peak (wt.%) | MMLR (%/°C) | Residual Mass at 700 °C (wt.%) |

|---|---|---|---|---|---|

| 3D_ABS | 99.3 | 431.1 | 47.6 | −2.26 | 0.0 |

| 3D_ABS-MCF20 | 99.4 | 434.6 | 55.2 | −1.78 | 19.4 |

| 3D_ABS-MCF10-CNT1 | 99.4 | 433.3 | 53.4 | −1.86 | 11.2 |

| 3D_ABS-MCF20-CNT1 | 99.4 | 432.5 | 58.0 | −1.67 | 20.9 |

| 3D_ABS-MCF20-CNT3 | 99.4 | 437.8 | 56.6 | −1.67 | 22.9 |

| 3D_ABS-MCF30-CNT1 | 99.4 | 433.4 | 62.8 | −1.46 | 30.7 |

| 3D_ABS-MCF20-GNP3 | 99.5 | 429.8 | 59.2 | −1.56 | 23.2 |

| 3D_ABS-MCF20-GNP6 | 99.4 | 437.4 | 59.6 | −1.61 | 25.5 |

| 3D_ABS-MCF30-GNP3 | 99.5 | 437.9 | 63.0 | −1.52 | 32.1 |

| Sample | VST (10 N) (°C) | HDT (1.8 MPa) (°C) |

|---|---|---|

| 3D_ABS | 107.2 ± 1.4 | 90.3 ± 3.6 |

| 3D_ABS-MCF20 | 104.5 ± 1.0 | 88.7 ± 4.0 |

| 3D_ABS-MCF10-CNT1 | 106.3 ± 1.2 | 92.0 ± 3.6 |

| 3D_ABS-MCF20-CNT1 | 107.0 ± 0.7 | 90.3 ± 4.5 |

| 3D_ABS-MCF20-CNT3 | 111.0 ± 1.2 | 87.0 ± 0.2 |

| 3D_ABS-MCF30-CNT1 | 110.0 ± 1.4 | 91.0 ± 2.7 |

| 3D_ABS-MCF20-GNP3 | 105.3 ± 1.1 | 85.3 ± 1.0 |

| 3D_ABS-MCF20-GNP6 | 107.5 ± 1.4 | 87.3 ± 1.7 |

| 3D_ABS-MCF30-GNP3 | 108.8 ± 1.1 | 91.7 ± 0.8 |

| Sample | ET (MPa) | σy (MPa) | σb (MPa) | εb (%) | E ratio 3D/CM | σb ratio 3D/CM |

|---|---|---|---|---|---|---|

| 3D_ABS | 2345 ± 149 | 32.3 ± 0.5 | 24.9 ± 2.2 | 8.2 ± 2.9 | 1.01 | 0.80 |

| 3D_ABS-MCF20 | 3131 ± 280 | 19.7 ± 0.5 | 19.4 ± 0.6 | 3.4 ± 0.2 | 0.52 | 0.44 |

| 3D_ABS-MCF10-CNT1 | 3072 ± 77 | 25.5 ± 0.6 | 24.2 ± 0.7 | 4.3 ± 0.3 | 0.85 | 0.66 |

| 3D_ABS-MCF20-CNT1 | 3353 ± 193 | 21.1 ± 0.9 | 20.4 ± 1.1 | 2.9 ± 0.2 | 0.65 | 0.53 |

| 3D_ABS-MCF20-CNT3 | 4019 ± 340 | n.d. * | 18.4 ± 5.2 | 1.8 ± 0.3 | 0.75 | 0.44 |

| 3D_ABS-MCF30-CNT1 | 2882 ± 355 | n.d. * | 17.4 ± 1.6 | 2.1 ± 0.1 | 0.45 | 0.38 |

| 3D_ABS-MCF20-GNP3 | 3053 ± 389 | n.d. * | 19.7 ± 1.9 | 1.8 ± 0.1 | 0.50 | 0.46 |

| 3D_ABS-MCF20-GNP6 | 3509 ± 515 | n.d. * | 20.5 ± 1.8 | 1.5 ± 0.1 | 0.57 | 0.52 |

| 3D_ABS-MCF30-GNP3 | 3091 ± 707 | n.d. * | 14.9 ± 3.1 | 1.3 ± 0.1 | 0.43 | 0.35 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Residori, S.; Dul, S.; Pegoretti, A.; Fambri, L.; Pugno, N.M. Three Dimensional Printing of Multiscale Carbon Fiber-Reinforced Polymer Composites Containing Graphene or Carbon Nanotubes. Nanomaterials 2022, 12, 2064. https://doi.org/10.3390/nano12122064

Residori S, Dul S, Pegoretti A, Fambri L, Pugno NM. Three Dimensional Printing of Multiscale Carbon Fiber-Reinforced Polymer Composites Containing Graphene or Carbon Nanotubes. Nanomaterials. 2022; 12(12):2064. https://doi.org/10.3390/nano12122064

Chicago/Turabian StyleResidori, Sara, Sithiprumnea Dul, Alessandro Pegoretti, Luca Fambri, and Nicola M. Pugno. 2022. "Three Dimensional Printing of Multiscale Carbon Fiber-Reinforced Polymer Composites Containing Graphene or Carbon Nanotubes" Nanomaterials 12, no. 12: 2064. https://doi.org/10.3390/nano12122064

APA StyleResidori, S., Dul, S., Pegoretti, A., Fambri, L., & Pugno, N. M. (2022). Three Dimensional Printing of Multiscale Carbon Fiber-Reinforced Polymer Composites Containing Graphene or Carbon Nanotubes. Nanomaterials, 12(12), 2064. https://doi.org/10.3390/nano12122064