Probing the Mechanical Properties of Porous Nanoshells by Nanoindentation

Abstract

:1. Introduction

2. Methods

3. Results

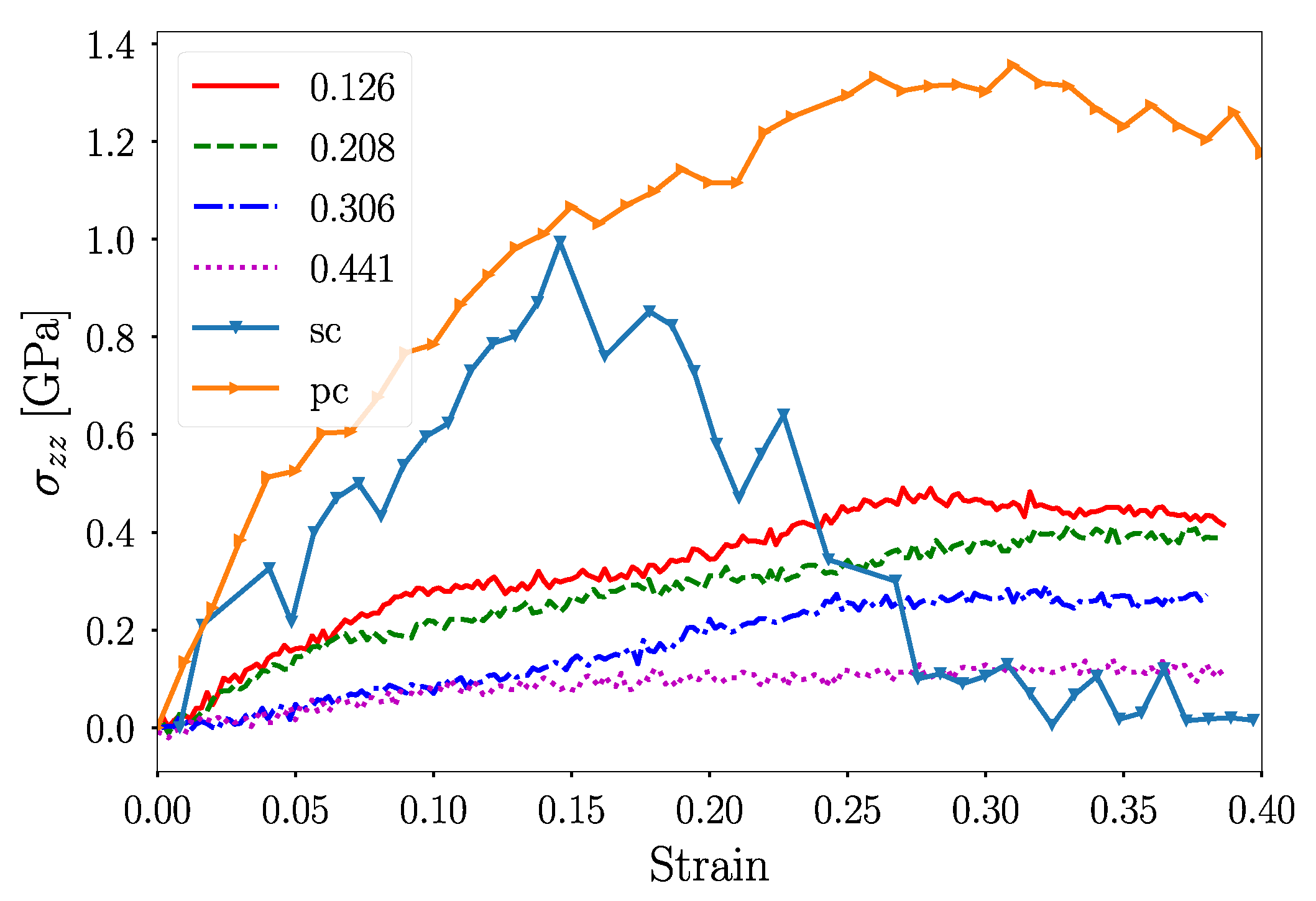

3.1. Elastic Regimen Calculations

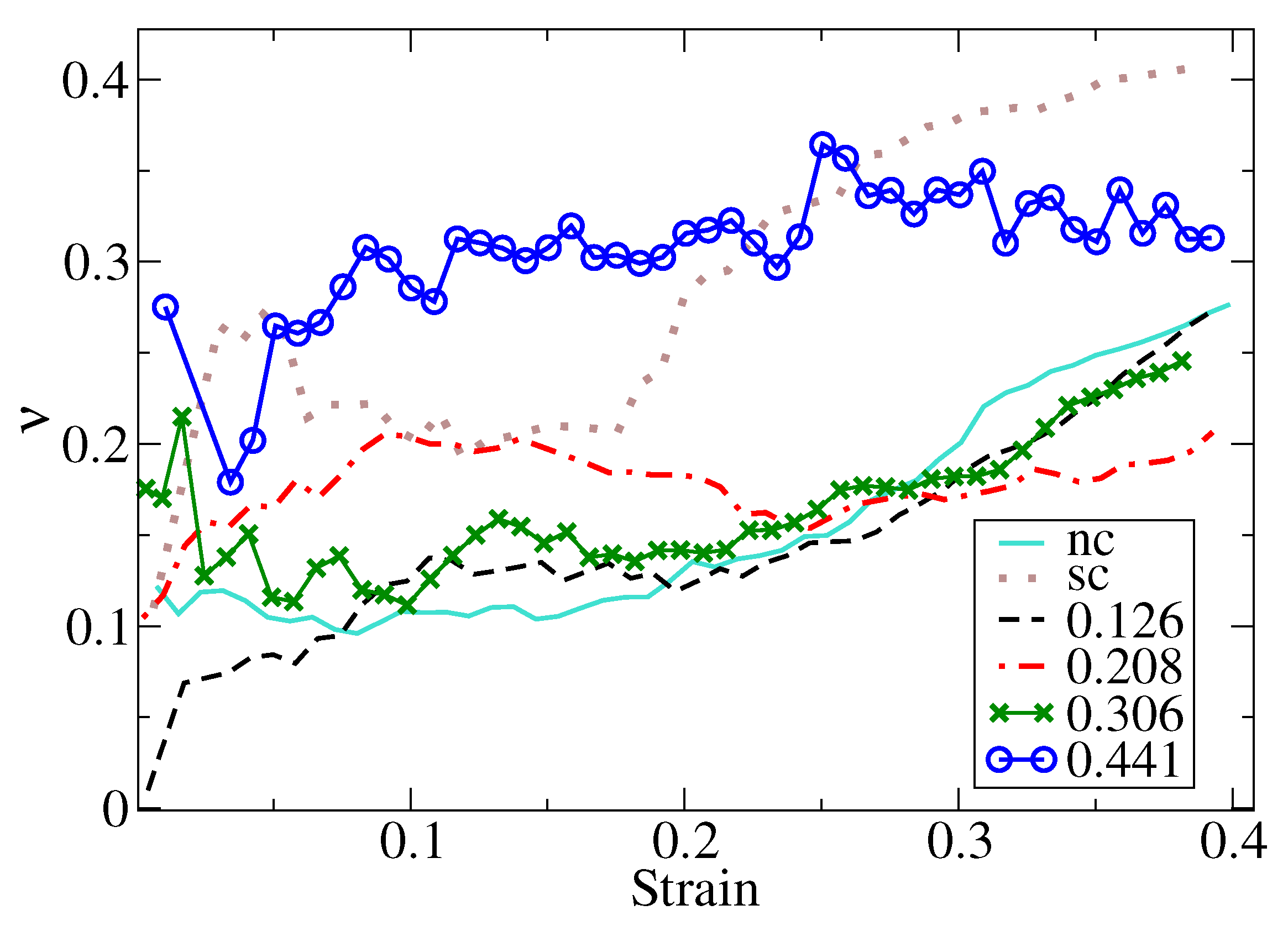

3.2. Poisson’s Ratio Calculations

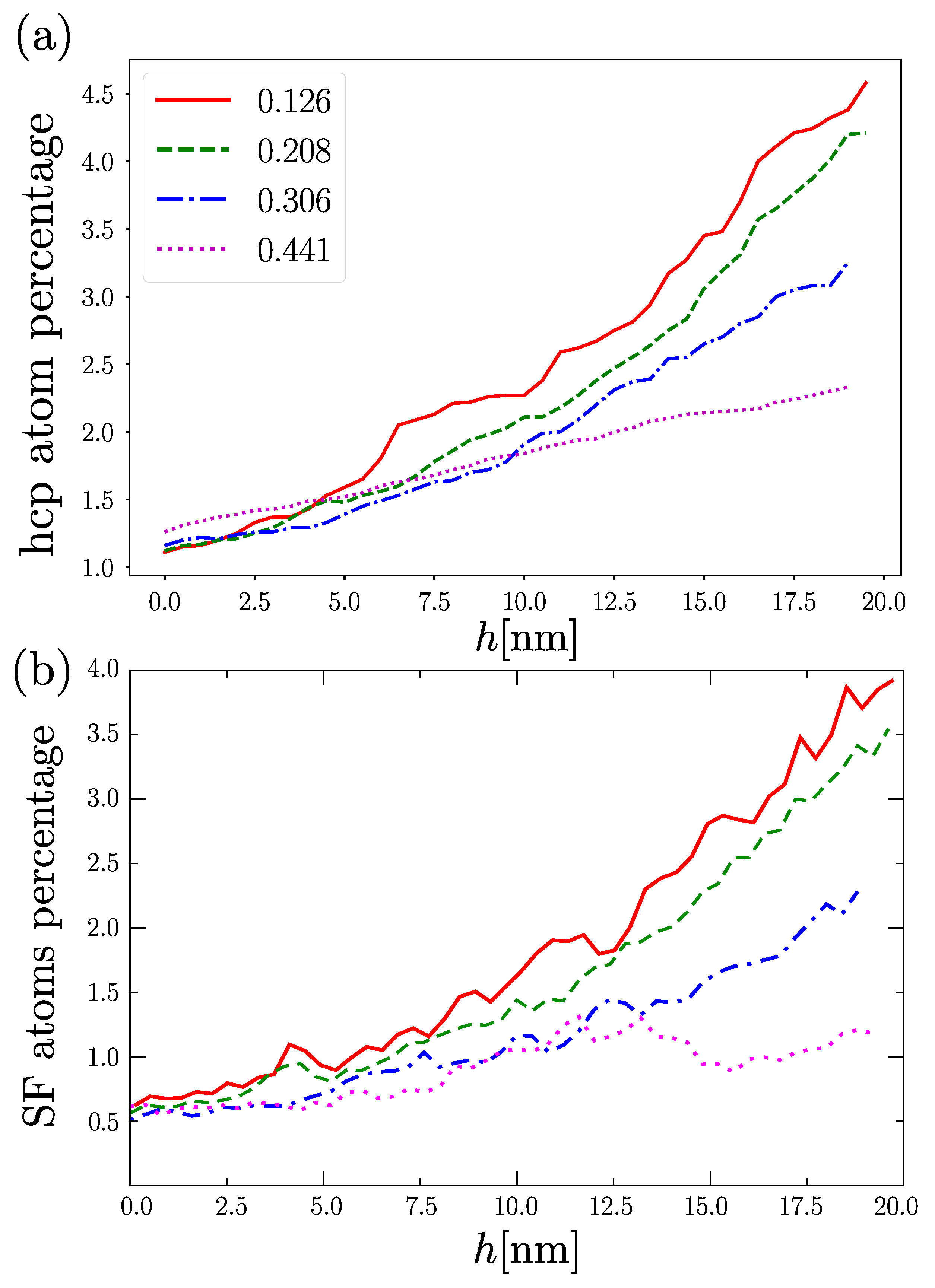

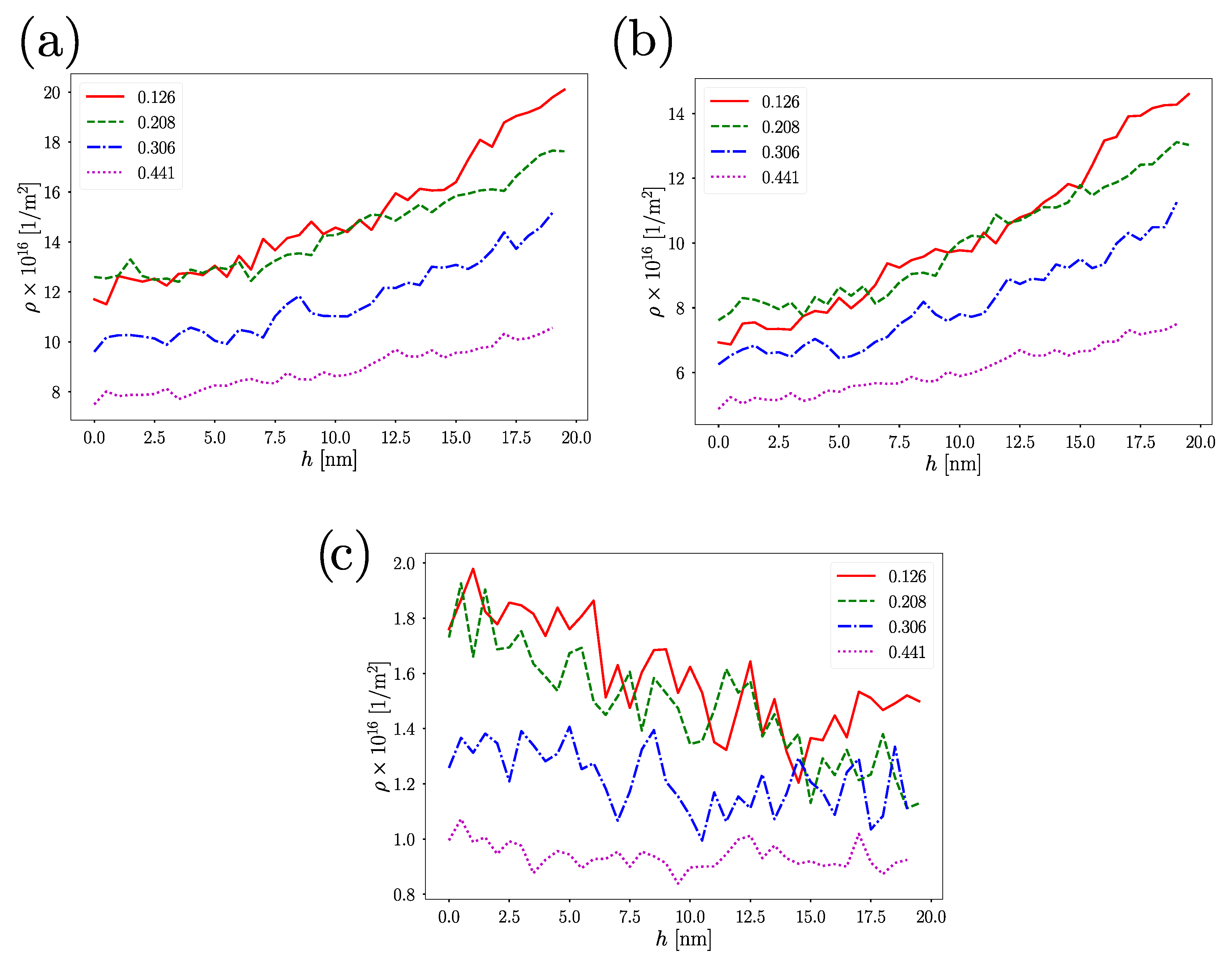

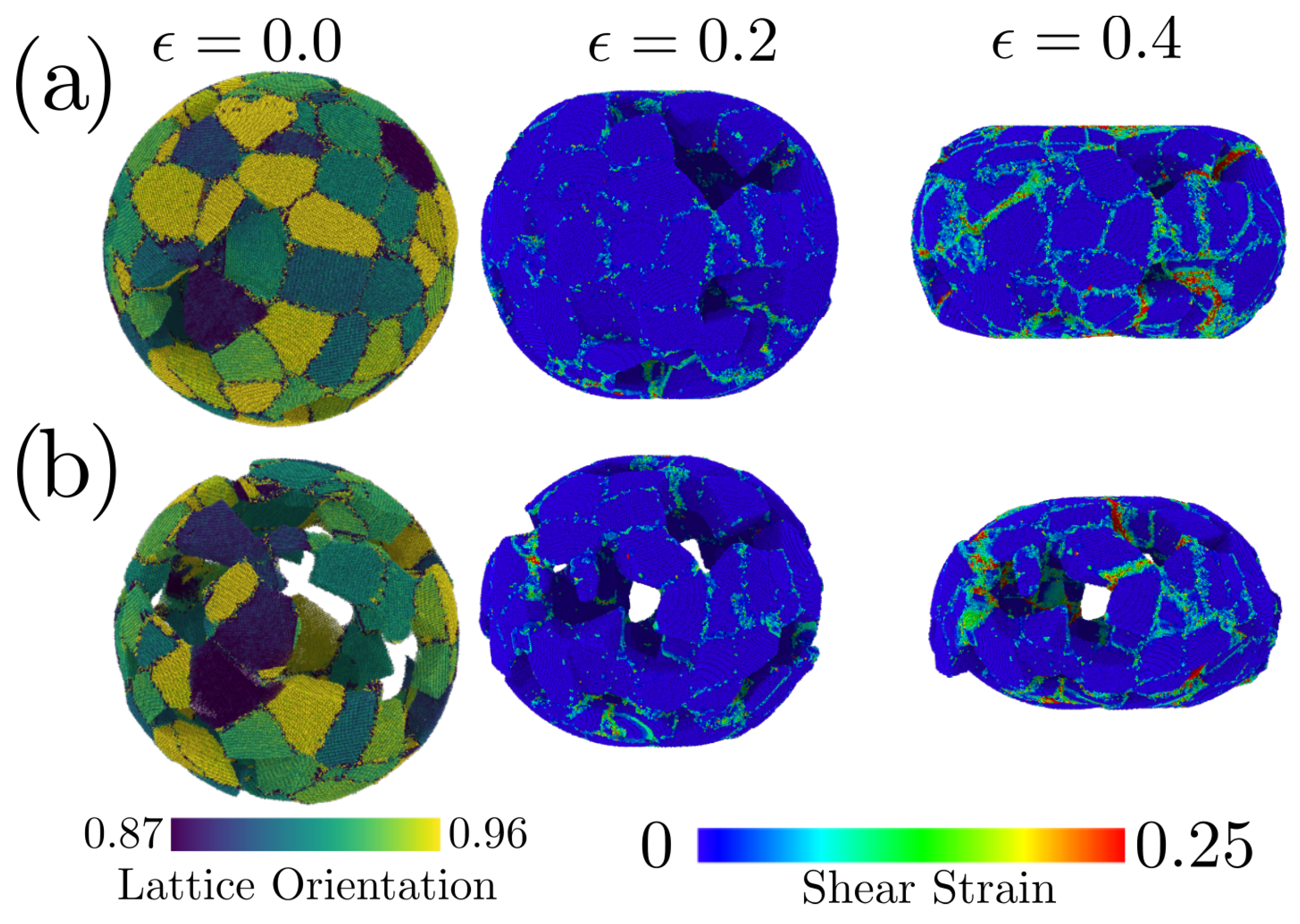

3.3. Plastic Deformation Mechanism

4. Conclusions

- Porous NS displayed mechanical properties that were dependent on the porosity of the shell. For smaller values, a deformation dominated that was closely related to that observed for polycrystalline or single-crystalline NS; larger porosities render plastic deformation that is mediated by grain boundary sliding instead of dislocation activity.

- Young’s modulus decreased with the increase in the porosity of the nanoshell, as expected from the theories of porous materials. The Reissner model for thin shells provided the best fit for Young’s modulus determination. However, there was no quantitative agreement between the models to obtain the Young’s modulus of porous NS.

- Contact pressure was independent of nanoshell porosity, not revealing evidence of Hall–Petch hardening due to the grain boundaries or the filament structure, as is reported for nanoporous materials. Instead, the difference in load for the indented specimens increase inversely with the atomic contact area leading a constant contact pressure, which held for strains as high as 0.4.

- For low porosities, plastic deformation is mainly attributed to Shockley partial dislocations, with a minor contribution of sessile dislocations as stair-rods and Hirth locks. Dislocation densities values for were smaller than those of other fcc nanoporous materials [32,55]. Nanoshells with high values of porosities (up to 0.441), show lower dislocation densities of almost an order of magnitude and a significant contribution of grain boundary sliding to deformation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| NS | Nanoshell |

| sc | Single crystalline |

| pc | Polycrystalline |

References

- Mahmoud, M.; Saira, F.; El-Sayed, M. Experimental evidence for the nanocage effect in catalysis with hollow nanoparticles. Nano Lett. 2010, 10, 3764–3769. [Google Scholar] [CrossRef]

- Amali, A.J.; Sun, J.K.; Xu, Q. From assembled metal–organic framework nanoparticles to hierarchically porous carbon for electrochemical energy storage. Chem. Commun. 2014, 50, 1519–1522. [Google Scholar] [CrossRef] [Green Version]

- Quy, C.T.; Hung, C.M.; Van Duy, N.; Hoa, N.D.; Jiao, M.; Nguyen, H. Ethanol-sensing characteristics of nanostructured ZnO: Nanorods, nanowires, and porous nanoparticles. J. Electron. Mater. 2017, 46, 3406–3411. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, J.; Guo, X.; Wu, S.; Wang, S. Porous α-Fe2O3 decorated by Au nanoparticles and their enhanced sensor performance. Nanotechnology 2010, 21, 095501. [Google Scholar] [CrossRef] [PubMed]

- Shan, Z.; Adesso, G.; Cabot, A.; Sherburne, M.; Asif, S.S.; Warren, O.; Chrzan, D.; Minor, A.; Alivisatos, A. Ultrahigh stress and strain in hierarchically structured hollow nanoparticles. Nat. Mater. 2008, 7, 947–952. [Google Scholar] [CrossRef]

- Yang, L.; Bian, J.; Zhang, H.; Niu, X.; Wang, G. Size-dependent deformation mechanisms in hollow silicon nanoparticles. AIP Adv. 2015, 5, 077162. [Google Scholar] [CrossRef] [Green Version]

- Guo, D.; Xie, G.; Luo, J. Mechanical properties of nanoparticles: Basics and applications. J. Phys. Appl. Phys. 2013, 47, 013001. [Google Scholar] [CrossRef] [Green Version]

- Zou, M.; Yang, D. Nanoindentation of silica nanoparticles attached to a silicon substrate. In Proceedings of the International Joint Tribology Conference, San Antonio, TX, USA, 23–25 October 2006; Volume 42592, pp. 767–774. [Google Scholar]

- Roy, S.; Gatti, R.; Devincre, B.; Mordehai, D. A multiscale study of the size-effect in nanoindentation of Au nanoparticles. Comput. Mater. Sci. 2019, 162, 47–59. [Google Scholar] [CrossRef]

- Sharma, A.; Hickman, J.; Gazit, N.; Rabkin, E.; Mishin, Y. Nickel nanoparticles set a new record of strength. Nat. Commun. 2018, 9, 4102. [Google Scholar] [CrossRef]

- An, L.; Zhang, D.; Zhang, L.; Feng, G. Effect of nanoparticle size on the mechanical properties of nanoparticle assemblies. Nanoscale 2019, 11, 9563–9573. [Google Scholar] [CrossRef] [PubMed]

- Valencia, F.J.; Amigo, N.; Bringa, E.M. Tension–compression behavior in gold nanoparticle arrays: A molecular dynamics study. Nanotechnology 2021, 32, 145715. [Google Scholar] [CrossRef]

- Bian, J.; Yang, L.; Niu, X.; Wang, G. Orientation-dependent deformation mechanisms of bcc niobium nanoparticles. Philos. Mag. 2018, 98, 1848–1864. [Google Scholar] [CrossRef] [Green Version]

- Amodeo, J.; Pizzagalli, L. Modeling the mechanical properties of nanoparticles: A review. Comptes Rendus Phys. 2021, 22, 35–66. [Google Scholar] [CrossRef]

- Kilymis, D.; Gérard, C.; Amodeo, J.; Waghmare, U.; Pizzagalli, L. Uniaxial compression of silicon nanoparticles: An atomistic study on the shape and size effects. Acta Mater. 2018, 158, 155–166. [Google Scholar] [CrossRef] [Green Version]

- Kilymis, D.; Gérard, C.; Pizzagalli, L. Ductile deformation of core-shell Si-SiC nanoparticles controlled by shell thickness. Acta Mater. 2019, 164, 560–567. [Google Scholar] [CrossRef] [Green Version]

- Bian, J.; Yang, L.; Yuan, W.; Wang, G. Influence of hydrogenation on the mechanical properties of Pd nanoparticles. RSC Adv. 2021, 11, 3115–3124. [Google Scholar] [CrossRef]

- Yang, W.; Mao, S.; Yang, J.; Shang, T.; Song, H.; Mabon, J.; Swiech, W.; Vance, J.R.; Yue, Z.; Dillon, S.J.; et al. Large-deformation and high-strength amorphous porous carbon nanospheres. Sci. Rep. 2016, 6, 24187. [Google Scholar] [CrossRef]

- Yang, W.; Yang, J.; Dong, Y.; Mao, S.; Gao, Z.; Yue, Z.; Dillon, S.J.; Xu, H.; Xu, B. Probing buckling and post-buckling deformation of hollow amorphous carbon nanospheres: In-situ experiment and theoretical analysis. Carbon 2018, 137, 411–418. [Google Scholar] [CrossRef]

- Valencia, F.J.; González, R.I.; Vega, H.; Ruestes, C.; Rogan, J.; Valdivia, J.A.; Bringa, E.M.; Kiwi, M. Mechanical Properties Obtained by Indentation of Hollow Pd Nanoparticles. J. Phys. Chem. C 2018, 122, 25035–25042. [Google Scholar] [CrossRef]

- Yin, Y.; Rioux, R.M.; Erdonmez, C.K.; Hughes, S.; Somorjai, G.A.; Alivisatos, A.P. Formation of hollow nanocrystals through the nanoscale Kirkendall effect. Science 2004, 304, 711–714. [Google Scholar] [CrossRef] [Green Version]

- El Mel, A.A.; Nakamura, R.; Bittencourt, C. The Kirkendall effect and nanoscience: Hollow nanospheres and nanotubes. Beilstein J. Nanotechnol. 2015, 6, 1348–1361. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yu, L.; Yu, X.Y.; Lou, X.W. The Design and Synthesis of Hollow Micro-/Nanostructures: Present and Future Trends. Adv. Mater. 2018, 30, 1800939. [Google Scholar] [CrossRef]

- Valencia, F.J.; Pinto, B.; Kiwi, M.; Ruestes, C.J.; Bringa, E.M.; Rogan, J. Nanoindentation of polycrystalline pd hollow nanoparticles: Grain size role. Comput. Mater. Sci. 2020, 179, 109642. [Google Scholar] [CrossRef]

- Fan, H.J.; Gösele, U.; Zacharias, M. Formation of nanotubes and hollow nanoparticles based on Kirkendall and diffusion processes: A review. Small 2007, 3, 1660–1671. [Google Scholar] [CrossRef] [PubMed]

- Teng, Z.; Li, W.; Tang, Y.; Elzatahry, A.; Lu, G.; Zhao, D. Mesoporous organosilica hollow nanoparticles: Synthesis and applications. Adv. Mater. 2019, 31, 1707612. [Google Scholar] [CrossRef] [PubMed]

- Cheng, K.; Sun, S. Recent advances in syntheses and therapeutic applications of multifunctional porous hollow nanoparticles. Nano Today 2010, 5, 183–196. [Google Scholar] [CrossRef]

- Zhao, L.; Rong, X.; Niu, Y.; Xu, R.; Zhang, T.; Li, T.; Yu, Y.; Hou, Y. Ostwald Ripening Tailoring Hierarchically Porous Na3V2 (PO4) 2O2F Hollow Nanospheres for Superior High-Rate and Ultrastable Sodium Ion Storage. Small 2020, 16, 2004925. [Google Scholar] [CrossRef]

- Liang, J.; Kou, H.; Ding, S. Complex Hollow Bowl-Like Nanostructures: Synthesis, Application, and Perspective. Adv. Funct. Mater. 2021, 31, 2007801. [Google Scholar] [CrossRef]

- Xu, Y.; Bian, W.; Wu, J.; Tian, J.H.; Yang, R. Preparation and electrocatalytic activity of 3D hierarchical porous spinel CoFe2O4 hollow nanospheres as efficient catalyst for oxygen reduction reaction and oxygen evolution reaction. Electrochim. Acta 2015, 151, 276–283. [Google Scholar] [CrossRef]

- Rodriguez-Nieva, J.; Ruestes, C.; Tang, Y.; Bringa, E. Atomistic simulation of the mechanical properties of nanoporous gold. Acta Mater. 2014, 80, 67–76. [Google Scholar] [CrossRef]

- Ruestes, C.J.; Schwen, D.; Millán, E.N.; Aparicio, E.; Bringa, E.M. Mechanical properties of Au foams under nanoindentation. Comput. Mater. Sci. 2018, 147, 154–167. [Google Scholar] [CrossRef]

- Gunkelmann, N.; Bringa, E.M.; Rosandi, Y. Molecular dynamics simulations of aluminum foams under tension: Influence of oxidation. J. Phys. Chem. C 2018, 122, 26243–26250. [Google Scholar] [CrossRef]

- Zhong, Y.; Kou, R.; Wang, M.; Qiao, Y. Synthesis of centimeter-scale monolithic SiC nanofoams and pore size effect on mechanical properties. J. Eur. Ceram. Soc. 2019, 39, 2566–2573. [Google Scholar] [CrossRef]

- Zhao, M.; Schlueter, K.; Wurmshuber, M.; Reitgruber, M.; Kiener, D. Open-cell tungsten nanofoams: Scaling behavior and structural disorder dependence of Young’s modulus and flow strength. Mater. Des. 2021, 197, 109187. [Google Scholar] [CrossRef]

- Shukla, S.; Priscilla, A.; Banerjee, M.; Bhonde, R.R.; Ghatak, J.; Satyam, P.; Sastry, M. Porous gold nanospheres by controlled transmetalation reaction: A novel material for application in cell imaging. Chem. Mater. 2005, 17, 5000–5005. [Google Scholar] [CrossRef]

- Ihsan, A.; Katsiev, H.; Alyami, N.; Anjum, D.H.; Khan, W.S.; Hussain, I. From porous gold nanocups to porous nanospheres and solid particles—A new synthetic approach. J. Colloid Interface Sci. 2015, 446, 59–66. [Google Scholar] [CrossRef] [PubMed]

- Ruestes, C.J.; Anders, C.; Bringa, E.M.; Urbassek, H.M. Nanoindentation tests of heavy-ion-irradiated Au foams—Molecular dynamics simulation. J. Appl. Phys. 2018, 123, 225903. [Google Scholar] [CrossRef]

- Bringa, E.M.; Monk, J.; Caro, A.; Misra, A.; Zepeda-Ruiz, L.; Duchaineau, M.; Abraham, F.; Nastasi, M.; Picraux, S.; Wang, Y.; et al. Are nanoporous materials radiation resistant? Nano Lett. 2012, 12, 3351–3355. [Google Scholar] [CrossRef]

- Farkas, D.; Caro, A.; Bringa, E.; Crowson, D. Mechanical response of nanoporous gold. Acta Mater. 2013, 61, 3249–3256. [Google Scholar] [CrossRef]

- Olsson, P.A. Transverse resonant properties of strained gold nanowires. J. Appl. Phys. 2010, 108, 034318. [Google Scholar] [CrossRef]

- Ma, X.; Sun, H.; Wang, Y.; Wu, X.; Zhang, J. Electronic and optical properties of strained noble metals: Implications for applications based on LSPR. Nano Energy 2018, 53, 932–939. [Google Scholar] [CrossRef]

- Plimpton, S. Fast Parallel Algorithms for Short-Range Molecular Dynamics. J. Comp. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Valencia, F.J.; González, R.I.; Tramontina, D.; Rogan, J.; Valdivia, J.A.; Kiwi, M.; Bringa, E.M. Hydrogen Storage in Palladium Hollow Nanoparticles. J. Phys. Chem. C 2016, 41, 23836–23841. [Google Scholar] [CrossRef]

- Idrissi, H.; Wang, B.; Colla, M.S.; Raskin, J.P.; Schryvers, D.; Pardoen, T. Ultrahigh strain hardening in thin palladium films with nanoscale twins. Adv. Mater. 2011, 23, 2119–2122. [Google Scholar] [CrossRef] [PubMed]

- Mehrizi, M.Z.; Abdi, J.; Rezakazemi, M.; Salehi, E. A review on recent advances in hollow spheres for hydrogen storage. Int. J. Hydrogen Energy 2020, 45, 17583–17604. [Google Scholar] [CrossRef]

- Zhou, R.; Wu, Z.; Sun, Z.; Su, X. Sensitive Surface Enhanced Raman Scattering Substrates Based on Filter Paper Loaded with Au Porous Nanospheres. Nanosci. Nanotechnol. Lett. 2015, 7, 801–805. [Google Scholar] [CrossRef]

- Valencia, F.J.; Ramírez, M.; Varas, A.; Rogan, J.; Kiwi, M. Thermal stability of hollow porous gold nanoparticles: A molecular dynamics study. J. Chem. Inf. Model. 2020, 60, 6204–6210. [Google Scholar] [CrossRef]

- Valencia, F.J.; González, R.I.; Bringa, E.M.; Kiwi, M. Hillock formation on nanocrystalline diamond. Carbon 2017, 119, 219–224. [Google Scholar] [CrossRef]

- Valencia, F.; Mella, J.D.; Gonzalez, R.I.; Kiwi, M.; Bringa, E.M. Confinement effects in irradiation of nanocrystalline diamond. Carbon 2015, 93, 458–464. [Google Scholar] [CrossRef]

- Bringa, E.M.; Caro, A.; Wang, Y.; Victoria, M.; McNaney, J.M.; Remington, B.A.; Smith, R.F.; Torralva, B.R.; Van Swygenhoven, H. Ultrahigh strength in nanocrystalline materials under shock loading. Science 2005, 309, 1838–1841. [Google Scholar] [CrossRef] [Green Version]

- Jiang, L.; Yin, X.; Zhao, J.; Liu, H.; Liu, Y.; Wang, F.; Zhu, J.; Boey, F.; Zhang, H. Theoretical investigation on the thermal stability of hollow gold nanoparticles. J. Phys. Chem. C 2009, 113, 20193–20197. [Google Scholar] [CrossRef]

- Jiang, L.; Sun, W.; Gao, Y.; Zhao, J. Geometric thermal phase diagrams for studying the thermal dynamic stability of hollow gold nanoballs at different temperatures. Phys. Chem. Chem. Phys. 2014, 16, 6623–6629. [Google Scholar] [CrossRef]

- Reyes, P.N.; Valencia, F.J.; Vega, H.; Ruestes, C.; Rogan, J.; Valdivia, J.; Kiwi, M. The stability of hollow nanoparticles and the simulation temperature ramp. Inorg. Chem. Front. 2018, 5, 1139–1144. [Google Scholar] [CrossRef]

- Ruestes, C.J.; Farkas, D.; Caro, A.; Bringa, E.M. Hardening under compression in Au foams. Acta Mater. 2016, 108, 1–7. [Google Scholar] [CrossRef]

- Daw, M.S.; Baskes, M.I. Embedded-atom method: Derivation and application to impurities, surfaces, and other defects in metals. Phys. Rev. B 1984, 29, 6443. [Google Scholar] [CrossRef] [Green Version]

- Johnson, R. Phase stability of fcc alloys with the embedded-atom method. Phys. Rev. B 1990, 41, 9717. [Google Scholar] [CrossRef] [PubMed]

- Ziegenhain, G.; Urbassek, H.M.; Hartmaier, A. Influence of crystal anisotropy on elastic deformation and onset of plasticity in nanoindentation: A simulational study. J. Appl. Phys. 2010, 107, 061807. [Google Scholar] [CrossRef] [Green Version]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO–the Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2010, 18, 015012. [Google Scholar] [CrossRef]

- Larsen, P.M.; Schmidt, S.; Schiøtz, J. Robust structural identification via polyhedral template matching. Model. Simul. Mater. Sci. Eng. 2016, 24, 055007. [Google Scholar] [CrossRef]

- Stukowski, A. Structure identification methods for atomistic simulations of crystalline materials. Model. Simul. Mater. Sci. Eng. 2012, 20, 045021. [Google Scholar] [CrossRef]

- Bazilchuk, M.; Sumigawa, T.; Kitamura, T.; Zhang, Z.; Kristiansen, H.; He, J. Contact area measurement of micron-sized metal-coated polymer particles under compression. Int. J. Mech. Sci. 2020, 165, 105214. [Google Scholar] [CrossRef]

- Wu, B.; Heidelberg, A.; Boland, J.J. Mechanical properties of ultrahigh-strength gold nanowires. Nat. Mater. 2005, 4, 525–529. [Google Scholar] [CrossRef]

- Reissner, E. Stresses and small displacements of shallow spherical shells. II. J. Math. Phys. 1946, 25, 279–300. [Google Scholar] [CrossRef]

- Reissner, E. Stresses and small displacements of shallow spherical shells. I. J. Math. Phys. 1946, 25, 80–85. [Google Scholar] [CrossRef]

- Lee, B.J.; Shim, J.H.; Baskes, M. Semiempirical atomic potentials for the fcc metals Cu, Ag, Au, Ni, Pd, Pt, Al, and Pb based on first and second nearest-neighbor modified embedded atom method. Phys. Rev. B 2003, 68, 144112. [Google Scholar] [CrossRef]

- Sheng, H.; Kramer, M.; Cadien, A.; Fujita, T.; Chen, M. Highly optimized embedded-atom-method potentials for fourteen fcc metals. Phys. Rev. B 2011, 83, 134118. [Google Scholar] [CrossRef] [Green Version]

- Yang, Z.; Yang, Q.; Zhang, G. Poisson’s ratio and Young’s modulus in single-crystal copper nanorods under uniaxial tensile loading by molecular dynamics. Phys. Lett. A 2017, 381, 280–283. [Google Scholar] [CrossRef]

- Vidable, G.G.; Gonzalez, R.; Valencia, F.; Amigo, N.; Tramontina, D.; Bringa, E. Simulations of plasticity in diamond nanoparticles showing ultrahigh strength. Diam. Relat. Mater. 2022, 126, 109109. [Google Scholar]

- Valencia, F.J.; Ortega, R.; González, R.I.; Bringa, E.M.; Kiwi, M.; Ruestes, C.J. Nanoindentation of nanoporous tungsten: A molecular dynamics approach. Comput. Mater. Sci. 2022, 209, 111336. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valencia, F.J.; Aurora, V.; Ramírez, M.; Ruestes, C.J.; Prada, A.; Varas, A.; Rogan, J. Probing the Mechanical Properties of Porous Nanoshells by Nanoindentation. Nanomaterials 2022, 12, 2000. https://doi.org/10.3390/nano12122000

Valencia FJ, Aurora V, Ramírez M, Ruestes CJ, Prada A, Varas A, Rogan J. Probing the Mechanical Properties of Porous Nanoshells by Nanoindentation. Nanomaterials. 2022; 12(12):2000. https://doi.org/10.3390/nano12122000

Chicago/Turabian StyleValencia, Felipe J., Viviana Aurora, Max Ramírez, Carlos J. Ruestes, Alejandro Prada, Alejandro Varas, and José Rogan. 2022. "Probing the Mechanical Properties of Porous Nanoshells by Nanoindentation" Nanomaterials 12, no. 12: 2000. https://doi.org/10.3390/nano12122000

APA StyleValencia, F. J., Aurora, V., Ramírez, M., Ruestes, C. J., Prada, A., Varas, A., & Rogan, J. (2022). Probing the Mechanical Properties of Porous Nanoshells by Nanoindentation. Nanomaterials, 12(12), 2000. https://doi.org/10.3390/nano12122000