Properties of SS304 Modified by Nickel–Cobalt Alloy Coating with Cauliflower-Shaped Micro/Nano Structures in Simulated PEMFC Cathode Environment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Electrodeposited Hydrophobic Ni–Co/SS304

2.3. Surface Analyses

2.4. PEMFC Simulated Solutions

2.5. Electrochemical Tests

3. Results and Discussion

3.1. Morphology and Composition

3.2. Surface Wettability of Electrodeposited Ni–Co Alloy Coatings

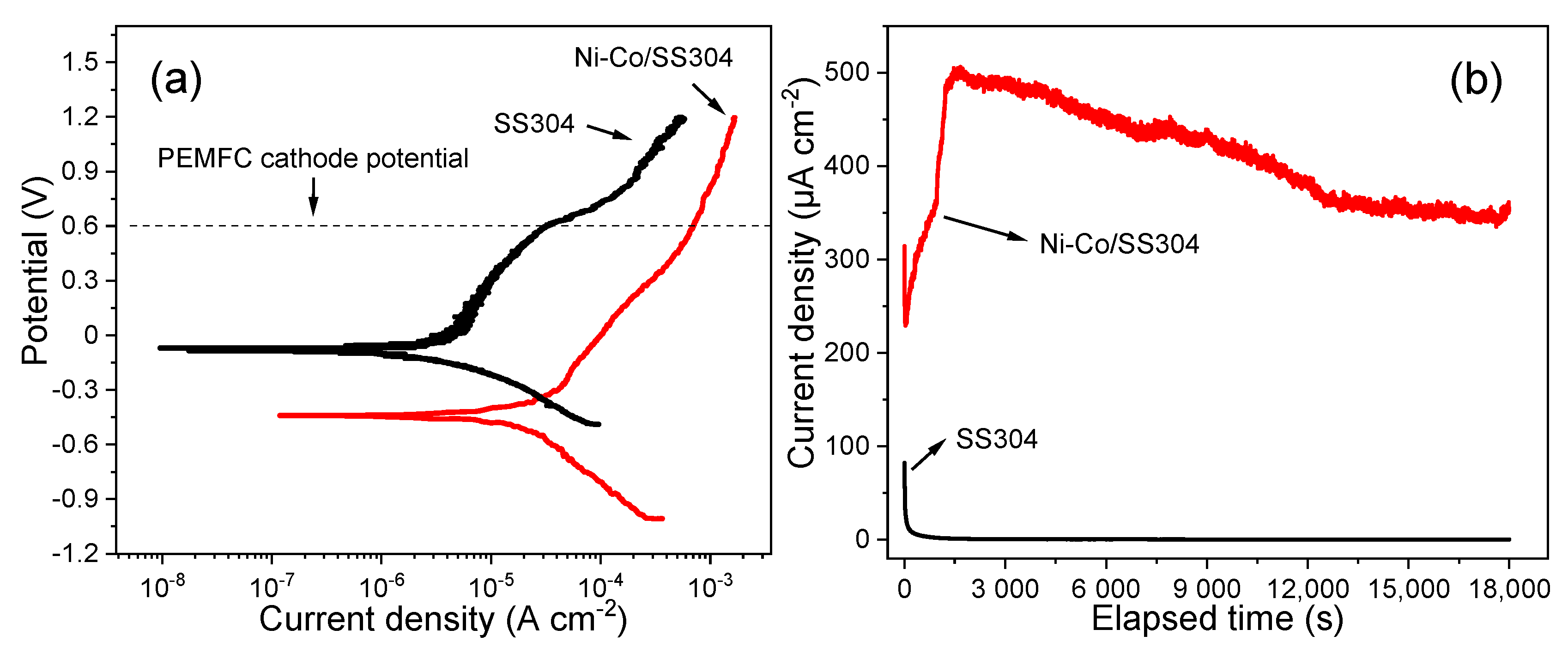

3.3. Corrosion Behavior of Ni–Co/SS304 in the Simulated PEMFC Cathodic Environment

3.4. Surface Properties of Ni–Co/SS304 in the Simulated PEMFC Cathodic Environment

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dunn, S. Hydrogen futures: Toward a sustainable energy system. Int. J. Hydrogen Energy 2002, 27, 235–264. [Google Scholar] [CrossRef]

- Momirlan, M.; Veziroglu, T. Current status of hydrogen energy. Renew. Sustain. Energy Rev. 2002, 6, 141–179. [Google Scholar] [CrossRef]

- Mehta, V.; Cooper, J.S. Review and analysis of PEM fuel cell design and manufacturing. J. Power Sources 2003, 114, 32–53. [Google Scholar] [CrossRef]

- Yang, Y.; Guo, L.J.; Liu, H.T. Corrosion characteristics of SS316L as bipolar plate material in PEMFC cathode environments with different acidities. Int. J. Hydrogen Energy 2011, 36, 1654–1663. [Google Scholar] [CrossRef]

- Kandlikar, S.G.; Lu, Z.J. Thermal management issues in a PEMFC stack-A brief review of current status. Appl. Therm. Eng. 2009, 29, 1276–1280. [Google Scholar] [CrossRef]

- Weil, K.S.; Xia, G.; Yang, Z.G.; Kim, J.Y. Development of a niobium clad PEM fuel cell bipolar plate material. Int. J. Hydrogen Energy 2007, 32, 3724–3733. [Google Scholar] [CrossRef]

- Yoon, W.; Huang, X.Y.; Fazzino, P.; Reifsnider, K.L.; Akkaoui, M.A. Evaluation of coated metallic bipolar plates for polymer electrolyte membrane fuel cells. J. Power Sources 2008, 179, 265–273. [Google Scholar] [CrossRef]

- Feng, K.; Wu, G.S.; Li, Z.G.; Cai, X.; Chu, P.K. Corrosion behavior of SS316L in simulated and accelerated PEMFC environments. Int. J. Hydrogen Energy 2011, 36, 13032–13042. [Google Scholar] [CrossRef]

- Davies, D.P.; Adcock, P.L.; Turpin, M.; Rowen, S.J. Stainless steel as a bipolar plate material for solid polymer fuel cells. J. Power Sources 2000, 86, 237–242. [Google Scholar] [CrossRef]

- Makkus, R.C.; Janssen, A.H.H.; de Bruijn, F.A.; Mallant, R.K.A.M. Use of stainless steel for cost competitive bipolar plates in the SPFC. J. Power Sources 2000, 86, 274–282. [Google Scholar] [CrossRef]

- Li, X.G.; Sabir, M. Review of bipolar plates in PEM fuel cells: Flow-field designs. Int. J. Hydrogen Energy 2005, 30, 359–371. [Google Scholar] [CrossRef]

- Nowak, A.P.; Salguero, T.T.; Kirby, K.W.; Zhong, F.; Blunk, R.H.J. A conductive and hydrophilic bipolar plate coating for enhanced proton exchange membrane fuel cell performance and water management. J. Power Sources 2012, 210, 138–145. [Google Scholar] [CrossRef]

- Cunningham, B.D.; Huang, J.; Baird, D.G. Review of materials and processing methods used in the production of bipolar plates for fuel cells. Int. Mater. Rev. 2007, 52, 1–13. [Google Scholar] [CrossRef]

- Hermann, A.; Chaudhuri, T.; Spagnol, P. Bipolar plates for PEM fuel cells: A review. Int. J. Hydrogen Energy 2005, 30, 1297–1302. [Google Scholar] [CrossRef]

- Wang, H.; Turner, J.A. Reviewing metallic PEMFC bipolar plates. Fuel Cells 2010, 10, 510–519. [Google Scholar] [CrossRef]

- Tawfik, H.; Hung, Y.; Mahajan, D. Metal bipolar plates for PEM fuel cell-A review. J. Power Sources 2007, 163, 755–767. [Google Scholar] [CrossRef]

- Karimi, S.; Fraser, N.; Roberts, B.; Foulkes, F.R. A review of metallic bipolar plates for proton exchange membrane fuel cells: Materials and fabrication methods. Adv. Mater. Sci. Eng. 2012, 2012, 828070. [Google Scholar] [CrossRef] [Green Version]

- Olayinka, A.; Emblom, W.J. Surface roughness of AISI 1010 and AISI 304 of PEMFC bipolar plates with microscale hydroformed capillary channels. Proc. Inst. Mech. Eng. Part B 2022, 09544054221077772. [Google Scholar] [CrossRef]

- Jin, C.K.; Lee, K.H.; Kang, C.G. Performance and characteristics of titanium nitride, chromium nitride, multi-coated stainless steel 304 bipolar plates fabricated through a rubber forming process. Int. J. Hydrogen Energy 2015, 40, 6681–6688. [Google Scholar] [CrossRef]

- Chen, M.; Ding, J.C.; Kwon, S.-H.; Wang, Q.; Zhang, S. Corrosion resistance and conductivity of NbN-coated 316L stainless steel bipolar plates for proton exchange membrane fuel cells. Corros. Sci. 2022, 196, 110042. [Google Scholar] [CrossRef]

- Forouzanmehr, M.; Kashyzadeh, K.R.; Borjali, A.; Ivanov, A.; Jafarnode, M.; Gan, T.H.; Wang, B.; Chizari, M. Detection and analysis of corrosion and contact resistance faults of TiN and CrN coatings on 410 stainless steel as bipolar plates in PEM fuel cells. Sensors 2022, 22, 750. [Google Scholar] [CrossRef] [PubMed]

- Maistro, G.; Kante, S.; Nyborg, L.; Cao, Y. Low-temperature carburized high-alloyed austenitic stainless steels in PEMFC cathodic environment. Surf. Interfaces 2021, 24, 101093. [Google Scholar] [CrossRef]

- Myung, S.T.; Kumagai, M.; Asaishi, R.; Sun, Y.K.; Yashiro, H. Nanoparticle TiN-coated type 310S stainless steel as bipolar plates for polymer electrolyte membrane fuel cell. Electrochem. Commun. 2008, 10, 480–484. [Google Scholar] [CrossRef]

- Lv, J.L.; Wang, Z.Q.; Liang, T.X.; Ken, S.; Hideo, M. Enhancing the corrosion resistance of the 2205 duplex stainless steel bipolar plates in PEMFCs environment by surface enriched molybdenum. Results Phys. 2017, 7, 3459–3464. [Google Scholar]

- Wang, L.; Li, L.; Liu, H.; Wang, S.; Fang, H.; Gao, H.; Gao, K.; Zhang, Y.; Sun, J.; Yan, J. Polylaminate TaN/Ta coating modified ferritic stainless steel bipolar plate for high temperature proton exchange membrane fuel cell. J. Power Sources 2018, 399, 343–349. [Google Scholar] [CrossRef]

- Fukutsuka, T.; Yamaguchi, T.; Miyano, S.I.; Matsuo, Y.; Sugie, Y.; Ogumi, Z. Carbon-coated stainless steel as PEFC bipolar plate material. J. Power Sources 2007, 174, 199–205. [Google Scholar] [CrossRef]

- Wang, L.X.; Sun, J.C.; Li, P.B.; Jing, B.; Li, S.; Wen, Z.S.; Ji, S.J. Niobized AISI 304 stainless steel bipolar plate for proton exchange membrane fuel cell. J. Power Sources 2012, 208, 397–403. [Google Scholar] [CrossRef]

- Kim, K.M.; Kim, J.H.; Lee, Y.Y.; Kim, K.Y. Electrodeposition of ruthenium oxide on ferritic stainless steel bipolar plate for polymer electrolyte membrane fuel cells. Int. J. Hydrogen Energy 2012, 37, 1653–1660. [Google Scholar] [CrossRef]

- Garcia, M.A.L.; Smit, M.A. Study of electrodeposited polypyrrole coatings for the corrosion protection of stainless steel bipolar plates for the PEM fuel cell. J. Power Sources 2006, 158, 397–402. [Google Scholar] [CrossRef]

- Feng, K.; Shen, Y.; Mai, J.M.; Liu, D.A.; Cai, X. An investigation into nickel implanted 316L stainless steel as a bipolar plate for PEM fuel cell. J. Power Sources 2008, 182, 145–152. [Google Scholar] [CrossRef]

- Feng, K.; Shen, Y.; Liu, D.A.; Chu, P.K.; Cai, X. Ni-Cr Co-implanted 316L stainless steel as bipolar plate in polymer electrolyte membrane fuel cells. Int. J. Hydrogen Energy 2010, 35, 690–700. [Google Scholar] [CrossRef]

- Loto, C.A. Electroless nickel plating-A review. Silicon 2016, 8, 177–186. [Google Scholar] [CrossRef]

- Kim, S.; Yamaura, S.; Makino, A.; Inoue, A. Production of Ni-P amorphous alloy-coated bipolar plate for PEM fuel cell by electro-less plating. Mater. Trans. 2011, 52, 709–713. [Google Scholar] [CrossRef] [Green Version]

- Fetohi, A.E.; Hameed, R.M.A.; El-Khatib, K.M. Ni-P and Ni-Mo-P modified aluminium alloy 6061 as bipolar plate material for proton exchange membrane fuel cells. J. Power Sources 2013, 240, 589–597. [Google Scholar] [CrossRef]

- Fetohi, A.E.; Hameed, R.M.A.; El-Khatib, K.M.; Souaya, E.R. Ni-P and Ni-Co-P coated aluminum alloy 5251 substrates as metallic bipolar plates for PEM fuel cell applications. Int. J. Hydrogen Energy 2012, 37, 7677–7688. [Google Scholar] [CrossRef]

- Fetohi, A.E.; Hameed, R.M.A.; El-Khatib, K.M.; Souaya, E.R. Study of different aluminum alloy substrates coated with Ni-Co-P as metallic bipolar plates for PEM fuel cell applications. Int. J. Hydrogen Energy 2012, 37, 10807–10817. [Google Scholar] [CrossRef]

- Tsai, S.Y.; Bai, C.Y.; Lin, C.H.; Shi, G.N.; Hou, K.H.; Liu, Y.M.; Ger, M.D. The characteristics and performance of electroless nickel and immersion Au plated aluminum alloy bipolar plates in polymer electrolyte membrane fuel cells. J. Power Sources 2012, 214, 51–58. [Google Scholar] [CrossRef]

- Tsai, S.Y.; Lin, C.H.; Jian, Y.J.; Hou, K.H.; Ger, M.D. The fabrication and characteristics of electroless nickel and immersion Au-polytetrafluoroethylene composite coating on aluminum alloy 5052 as bipolar plate. Surf. Coat. Technol. 2017, 313, 151–157. [Google Scholar] [CrossRef]

- Darband, G.B.; Aliofkhazraei, M.; Rouhaghdam, A.S.; Kiani, M.A. Three-dimensional Ni-Co alloy hierarchical nanostructure as efficient non-noble-metal electrocatalyst for hydrogen evolution reaction. Appl. Surf. Sci. 2019, 465, 846–862. [Google Scholar] [CrossRef]

- Khorsand, S.; Raeissi, K.; Ashrafizadeh, F.; Arenas, M.A. Relationship between the structure and water repellency of nickel-cobalt alloy coatings prepared by electrodeposition process. Surf. Coat. Technol. 2015, 276, 296–304. [Google Scholar] [CrossRef]

- Bakhit, B.; Akbari, A. Nanocrystalline Ni-Co alloy coatings: Electrodeposition using horizontal electrodes and corrosion resistance. J. Coat. Technol. Res. 2013, 10, 285–295. [Google Scholar] [CrossRef]

- Rashtchi, H.; Raeissi, K.; Shamanian, M.; Gomez, Y.A.; Lagergren, C.; Lindstrom, R.W.; Rajaei, V. Evaluation of Ni-Mo and Ni-Mo-P electroplated coatings on stainless steel for PEM fuel cells bipolar plates. Fuel Cells 2016, 16, 784–800. [Google Scholar] [CrossRef]

- Khorsand, S.; Raeissi, K.; Ashrafizadeh, F.; Arenas, M.A. Super-hydrophobic nickel-cobalt alloy coating with micro-nano flower-like structure. Chem. Eng. J. 2015, 273, 638–646. [Google Scholar] [CrossRef] [Green Version]

- Li, X.M.; Reinhoudt, D.; Crego-Calama, M. What do we need for a superhydrophobic surface? A review on the recent progress in the preparation of superhydrophobic surfaces. Chem. Soc. Rev. 2007, 36, 1350–1368. [Google Scholar] [CrossRef] [PubMed]

- Liu, P.; Cao, L.; Zhao, W.; Xia, Y.; Huang, W.; Li, Z. Insights into the superhydrophobicity of metallic surfaces prepared by electrodeposition involving spontaneous adsorption of airborne hydrocarbons. Appl. Surf. Sci. 2015, 324, 576–583. [Google Scholar] [CrossRef]

- Zhang, W. Research on the Preparation and Corrosion Resistance of Ni-Co Based Composite Coating on Carbon Steel Surface. Master’s Thesis, Ocean University of China, Qingdao, China, 2019. [Google Scholar]

- Lin, Z.F.; Zhang, W.; Xu, L.K.; Xue, Y.P.; Li, W.H. Fabrication of Ni-Co/Cu super-hydrophobic coating with improved corrosion resistance. Mater. Chem. Phys. 2022, 277, 125503. [Google Scholar] [CrossRef]

- Kumar, A.; Ricketts, M.; Hirano, S. Ex situ evaluation of nanometer range gold coating on stainless steel substrate for automotive polymer electrolyte membrane fuel cell bipolar plate. J. Power Sources 2010, 195, 1401–1407. [Google Scholar] [CrossRef]

- Wang, H.L.; Sweikart, M.A.; Turner, J.A. Stainless steel as bipolar plate material for polymer electrolyte membrane fuel cells. J. Power Sources 2003, 115, 243–251. [Google Scholar] [CrossRef]

- Xuan, J.J.; Xu, L.K.; Bai, S.F.; Zhao, T.; Xin, Y.L.; Zhang, G.D.; Xue, L.L.; Li, L. Influence of temperature on corrosion behavior, wettability, and surface conductivity of 304 stainless steel in simulated cathode environment of proton exchange membrane fuel cells. Int. J. Hydrogen Energy 2021, 46, 22920–22931. [Google Scholar] [CrossRef]

- Yang, Y.; Guo, L.J.; Liu, H.T. The effect of temperature on corrosion behavior of SS316L in the cathode environment of proton exchange membrane fuel cells. J. Power Sources 2011, 196, 5503–5510. [Google Scholar] [CrossRef]

- Yang, Y.; Guo, L.J.; Liu, H.T. Factors affecting corrosion behavior of SS316L as bipolar plate material in PEMFC cathode environments. Int. J. Hydrogen Energy 2012, 37, 13822–13828. [Google Scholar] [CrossRef]

- Li, D.G.; Wang, J.D.; Chen, D.R.; Liang, P. Influences of pH value, temperature, chloride ions and sulfide ions on the corrosion behaviors of 316L stainless steel in the simulated cathodic environment of proton exchange membrane fuel cell. J. Power Sources 2014, 272, 448–456. [Google Scholar] [CrossRef]

- Xu, P.; Wang, F.; Yang, C.; Ou, J.; Li, W.; Amirfazli, A. Reversible transition between superhydrophobicity and superhydrophilicity of a silver surface. Surf. Coat. Technol. 2016, 294, 47–53. [Google Scholar] [CrossRef]

- Dadfar, M.; Salehi, M.; Golozar, M.A.; Trasatti, S. Surface modification of 304 stainless steels to improve corrosion behavior and interfacial contact resistance of bipolar plates. Int. J. Hydrogen Energy 2016, 41, 21375–21384. [Google Scholar] [CrossRef]

- Rahimi, E.; Rafsanjani-Abbasi, A.; Kiani-Rashid, A.; Jafari, H.; Davoodi, A. Morphology modification of electrodeposited superhydrophobic nickel coating for enhanced corrosion performance studied by AFM, SEM-EDS and electrochemical measurements. Colloids Surf. A 2018, 547, 81–94. [Google Scholar] [CrossRef]

- Shen, L.; Fan, M.; Qiu, M.; Jiang, W.; Wang, Z. Superhydrophobic nickel coating fabricated by scanning electrodeposition. Appl. Surf. Sci. 2019, 483, 706–712. [Google Scholar] [CrossRef]

- Wang, Z.; Feng, Z.; Fan, X.H.; Zhang, L. Pseudo-passivation mechanism of CoCrFeNiMo0.01 high-entropy alloy in H2S-containing acid solutions. Corros. Sci. 2021, 179, 109146. [Google Scholar] [CrossRef]

| Samples | Ni | Co | C | O |

|---|---|---|---|---|

| Unannealed Ni–Co/SS304 | 50.32 | 43.87 | 2.96 | 2.85 |

| Annealed Ni–Co/SS304 | 49.39 | 42.85 | 3.71 | 4.05 |

| Samples | Ecorr (V vs. SCE) | Eb (V vs. SCE) | icorr (μA/cm2) | i0.6 V vs. SCE (μA/cm2) |

|---|---|---|---|---|

| SS304 | −0.0702 | 0.6008 | 4.395 | 32.27 |

| Ni–Co/SS304 | −0.4413 | - | 13.81 | 703.3 |

| Polarized Ni–Co/SS304 | Ni | Co | C | O |

|---|---|---|---|---|

| Area 1 | 51.27 | 42.15 | 2.60 | 3.97 |

| Area 2 | 34.12 | 28.25 | 1.38 | 33.64 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xuan, J.; Liu, Y.; Xu, L.; Xin, Y.; Xue, L.; Li, L. Properties of SS304 Modified by Nickel–Cobalt Alloy Coating with Cauliflower-Shaped Micro/Nano Structures in Simulated PEMFC Cathode Environment. Nanomaterials 2022, 12, 1976. https://doi.org/10.3390/nano12121976

Xuan J, Liu Y, Xu L, Xin Y, Xue L, Li L. Properties of SS304 Modified by Nickel–Cobalt Alloy Coating with Cauliflower-Shaped Micro/Nano Structures in Simulated PEMFC Cathode Environment. Nanomaterials. 2022; 12(12):1976. https://doi.org/10.3390/nano12121976

Chicago/Turabian StyleXuan, Junji, Yueren Liu, Likun Xu, Yonglei Xin, Lili Xue, and Li Li. 2022. "Properties of SS304 Modified by Nickel–Cobalt Alloy Coating with Cauliflower-Shaped Micro/Nano Structures in Simulated PEMFC Cathode Environment" Nanomaterials 12, no. 12: 1976. https://doi.org/10.3390/nano12121976

APA StyleXuan, J., Liu, Y., Xu, L., Xin, Y., Xue, L., & Li, L. (2022). Properties of SS304 Modified by Nickel–Cobalt Alloy Coating with Cauliflower-Shaped Micro/Nano Structures in Simulated PEMFC Cathode Environment. Nanomaterials, 12(12), 1976. https://doi.org/10.3390/nano12121976