Interfacing MXene Flakes on a Magnetic Fiber Network as a Stretchable, Flexible, Electromagnetic Shielding Fabric

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. MXene Solution Preparation

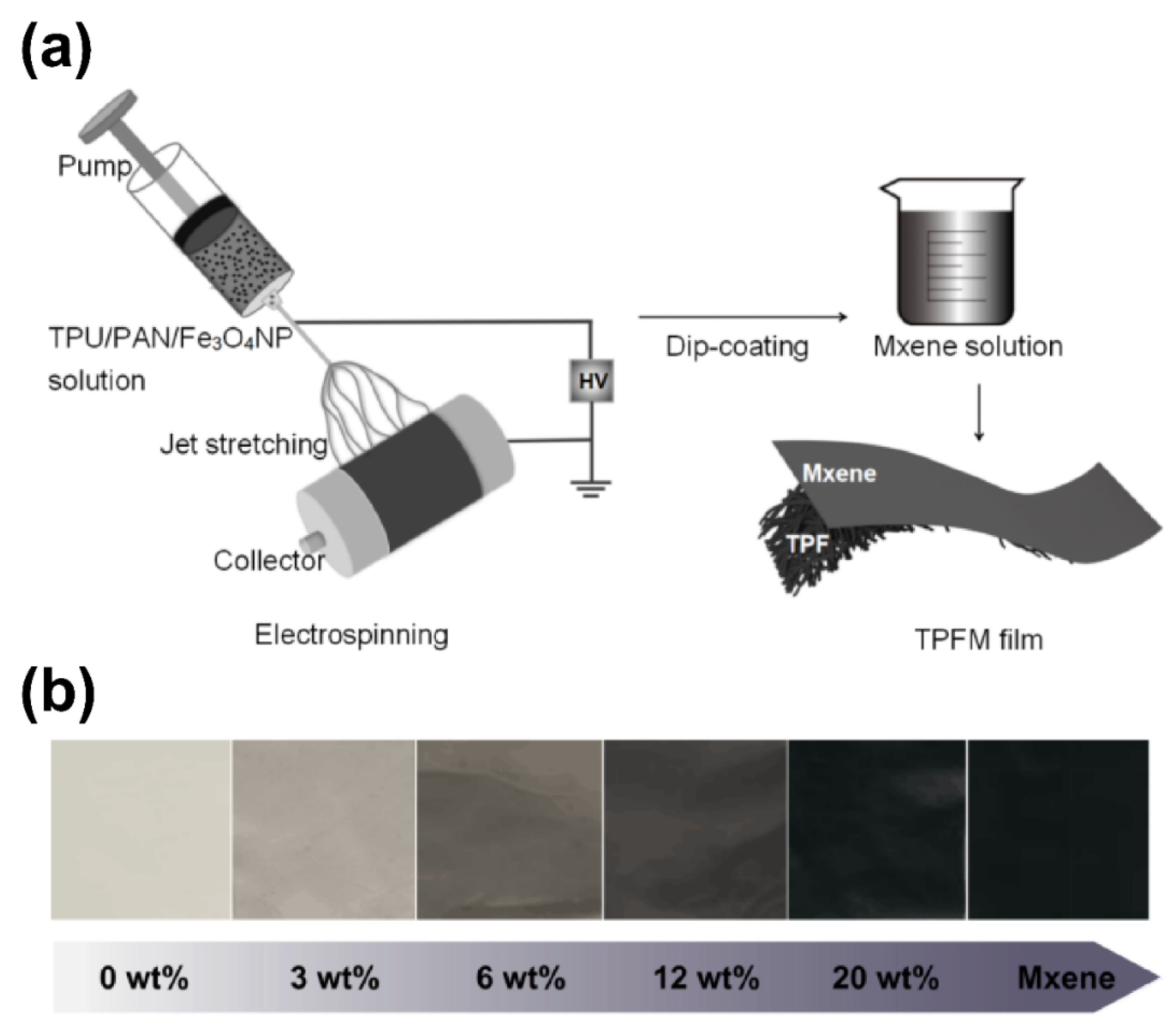

2.3. Preparation of TPU/PAN/Fe3O4/MXene Films

2.4. Characterization

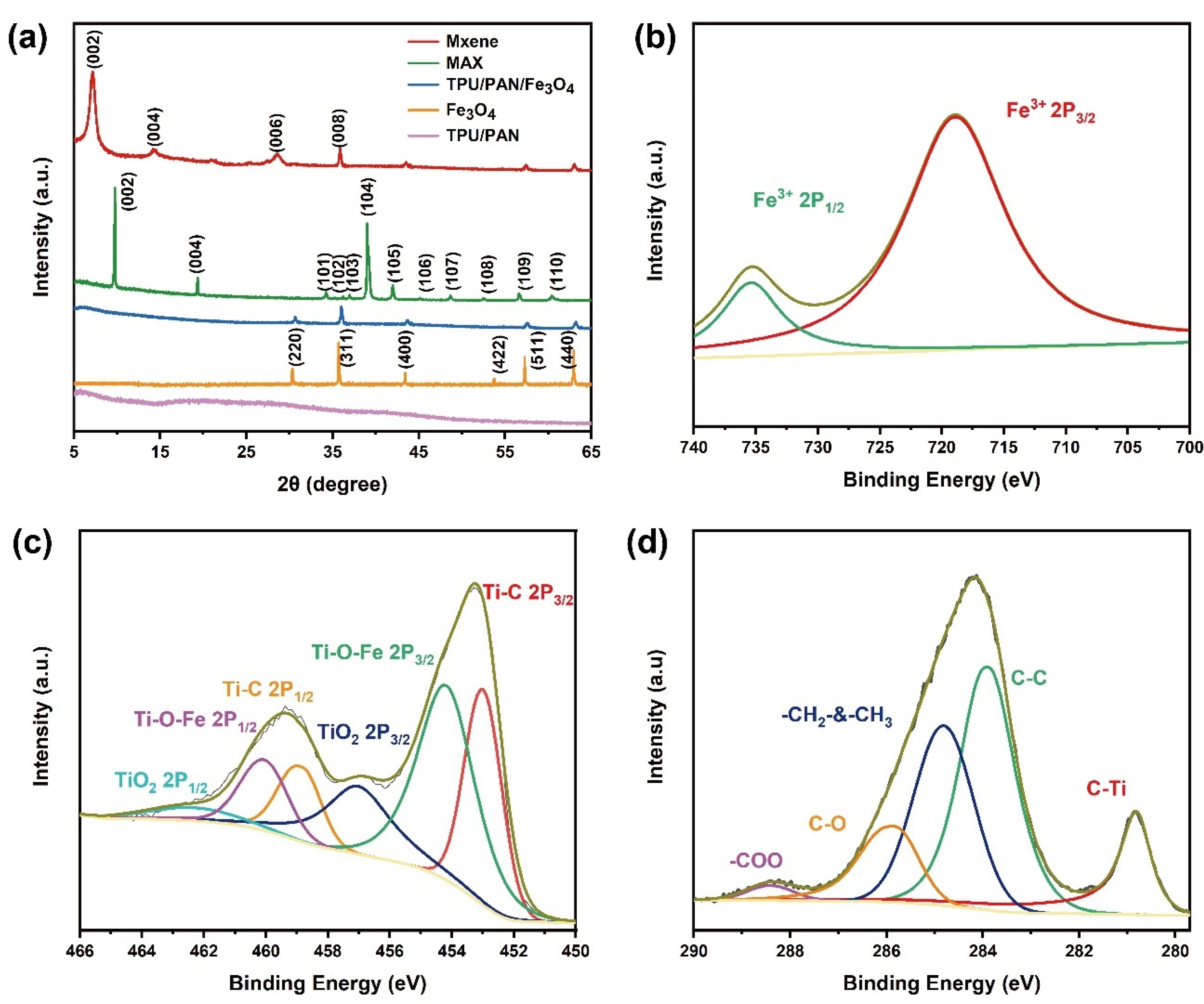

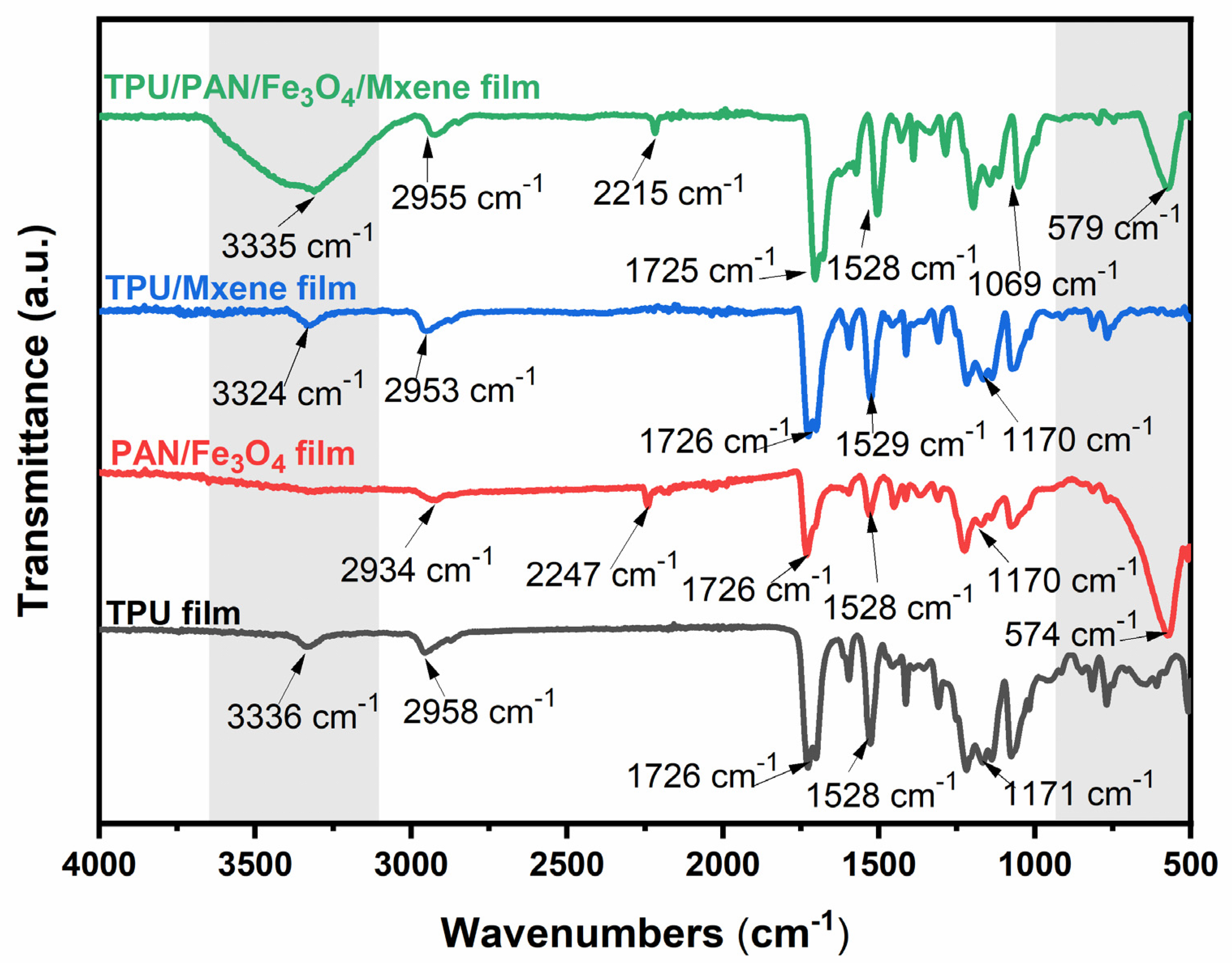

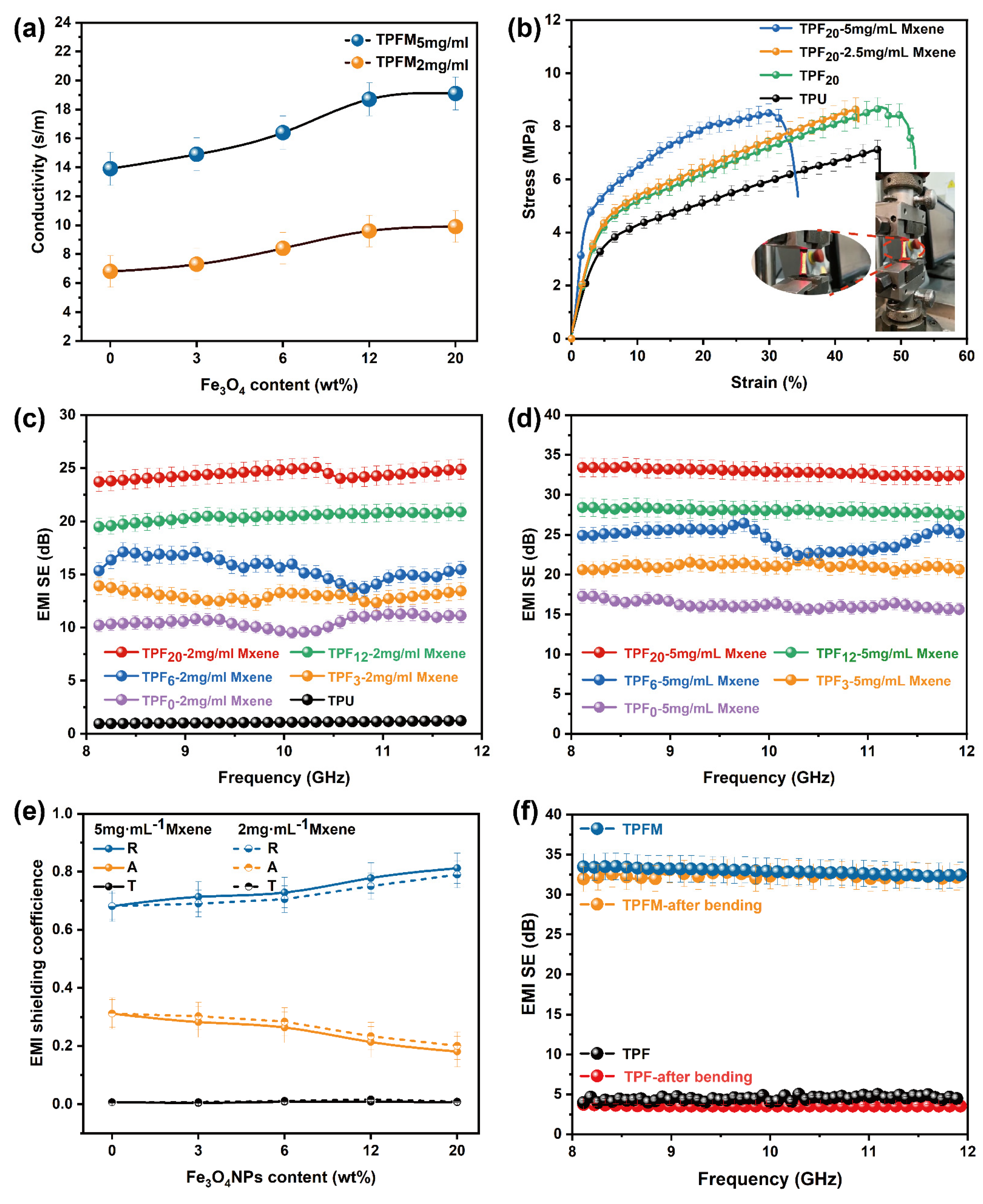

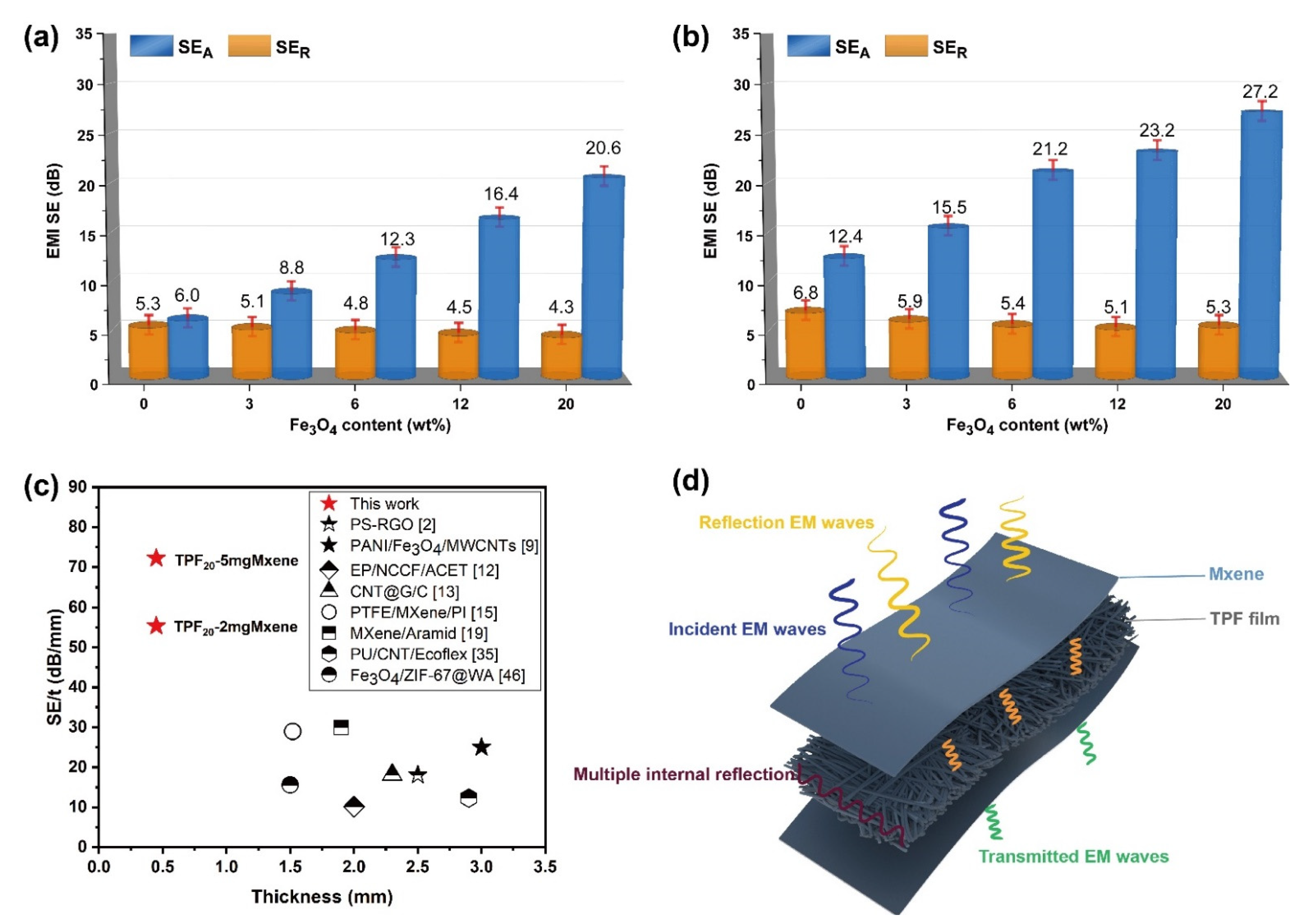

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shahzad, F.; Alhabeb, M.; Hatter, C.B.; Anasori, B.; Man Hong, S.; Koo, C.M.; Gogotsi, Y. Electromagnetic interference shielding with 2D transition metal carbides (MXenes). Science 2016, 353, 1137–1140. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yan, D.-X.; Pang, H.; Li, B.; Vajtai, R.; Xu, L.; Ren, P.-G.; Wang, J.-H.; Li, Z.-M. Structured Reduced Graphene Oxide/Polymer Composites for Ultra-Efficient Electromagnetic Interference Shielding. Adv. Funct. Mater. 2015, 25, 559–566. [Google Scholar] [CrossRef]

- Elmas, O. Effects of electromagnetic field exposure on the heart: A systematic review. Toxicol. Ind. Health 2016, 32, 76–82. [Google Scholar] [CrossRef] [PubMed]

- Driessen, S.; Napp, A.; Schmiedchen, K.; Kraus, T.; Stunder, D. Electromagnetic interference in cardiac electronic implants caused by novel electrical appliances emitting electromagnetic fields in the intermediate frequency range: A systematic review. Europace 2019, 21, 219–229. [Google Scholar] [CrossRef]

- Mathur, P.; Raman, S. Electromagnetic Interference (EMI): Measurement and Reduction Techniques. J. Electron. Mater. 2020, 49, 2975–2998. [Google Scholar] [CrossRef] [Green Version]

- Kim, K.; Huh, J.Y.; Hong, Y.C. Direct coating of copper nanoparticles on flexible substrates from copper precursors using underwater plasma and their EMI performance. Mater. Sci. Eng. B 2021, 265, 114995. [Google Scholar] [CrossRef]

- Xing, D.; Lu, L.; Xie, Y.; Tang, Y.; Teh, K.S. Highly flexible and ultra-thin carbon-fabric/Ag/waterborne polyurethane film for ultra-efficient EMI shielding. Mater. Des. 2020, 185, 108227. [Google Scholar] [CrossRef]

- Ghiyasvand, M.; Naser-Moghadasi, M.; Lotfi-Neyestanak, A.A.; Nikfarjam, A. Improving the Performance of Transparent Enclosure Using Heterogeneous Deposition of a Gold Nanolayer. IEEE Antennas Wirel. Propag. Lett. 2018, 17, 567–570. [Google Scholar] [CrossRef]

- Cao, M.S.; Yang, J.; Song, W.L.; Zhang, D.Q.; Wen, B.; Jin, H.B.; Hou, Z.L.; Yuan, J. Ferroferric oxide/multiwalled carbon nanotube vs polyaniline/ferroferric oxide/multiwalled carbon nanotube multiheterostructures for highly effective microwave absorption. ACS Appl. Mater. Interfaces 2012, 4, 6949–6956. [Google Scholar] [CrossRef]

- Im, J.S.; Park, I.K. Mechanically Robust Magnetic Fe3O4 Nanoparticle/Polyvinylidene Fluoride Composite Nanofiber and Its Application in a Triboelectric Nanogenerator. ACS Appl. Mater. Interfaces 2018, 10, 25660–25665. [Google Scholar] [CrossRef]

- Wan, Y.-J.; Zhu, P.-L.; Yu, S.-H.; Sun, R.; Wong, C.-P.; Liao, W.-H. Graphene paper for exceptional EMI shielding performance using large-sized graphene oxide sheets and doping strategy. Carbon 2017, 122, 74–81. [Google Scholar] [CrossRef]

- Duan, H.; Zhu, H.; Yang, J.; Gao, J.; Yang, Y.; Xu, L.; Zhao, G.; Liu, Y. Effect of carbon nanofiller dimension on synergistic EMI shielding network of epoxy/metal conductive foams. Compos. Part A Appl. Sci. Manuf. 2019, 118, 41–48. [Google Scholar] [CrossRef]

- Feng, L.; Zuo, Y.; He, X.; Hou, X.; Fu, Q.; Li, H.; Song, Q. Development of light cellular carbon nanotube@graphene/carbon nanocomposites with effective mechanical and EMI shielding performance. Carbon 2020, 168, 719–731. [Google Scholar] [CrossRef]

- Pothupitiya Gamage, S.; Yang, K.; Braveenth, R.; Raagulan, K.; Kim, H.; Lee, Y.; Yang, C.-M.; Moon, J.; Chai, K. MWCNT Coated Free-Standing Carbon Fiber Fabric for Enhanced Performance in EMI Shielding with a Higher Absolute EMI SE. Materials 2017, 10, 1350. [Google Scholar] [CrossRef] [Green Version]

- Sang, M.; Liu, G.; Liu, S.; Wu, Y.; Xuan, S.; Wang, S.; Xuan, S.; Jiang, W.; Gong, X. Flexible PTFE/MXene/PI soft electrothermal actuator with electromagnetic-interference shielding property. Chem. Eng. J. 2021, 414, 128883. [Google Scholar] [CrossRef]

- Liu, F.; Li, Y.; Hao, S.; Cheng, Y.; Zhan, Y.; Zhang, C.; Meng, Y.; Xie, Q.; Xia, H. Well-aligned MXene/chitosan films with humidity response for high-performance electromagnetic interference shielding. Carbohydr. Polym. 2020, 243, 116467. [Google Scholar] [CrossRef]

- He, P.; Cao, M.-S.; Cai, Y.-Z.; Shu, J.-C.; Cao, W.-Q.; Yuan, J. Self-assembling flexible 2D carbide MXene film with tunable integrated electron migration and group relaxation toward energy storage and green EMI shielding. Carbon 2020, 157, 80–89. [Google Scholar] [CrossRef]

- Li, R.; Ding, L.; Gao, Q.; Zhang, H.; Zeng, D.; Zhao, B.; Fan, B.; Zhang, R. Tuning of anisotropic electrical conductivity and enhancement of EMI shielding of polymer composite foam via CO2-assisted delamination and orientation of MXene. Chem. Eng. J. 2021, 415, 128930. [Google Scholar] [CrossRef]

- Lu, Z.; Jia, F.; Zhuo, L.; Ning, D.; Gao, K.; Xie, F. Micro-porous MXene/Aramid nanofibers hybrid aerogel with reversible compression and efficient EMI shielding performance. Compos. Part B Eng. 2021, 217, 108853. [Google Scholar] [CrossRef]

- Wan, Y.; Xiong, P.; Liu, J.; Feng, F.; Xun, X.; Gama, F.M.; Zhang, Q.; Yao, F.; Yang, Z.; Luo, H.; et al. Ultrathin, Strong, and Highly Flexible Ti3C2Tx MXene/Bacterial Cellulose Composite Films for High-Performance Electromagnetic Interference Shielding. ACS Nano 2021, 15, 8439–8449. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Tian, X.; Gao, S.P.; Jing, L.; Li, K.; Yang, H.; Fu, F.; Lee, J.Y.; Guo, Y.X.; Ho, J.S.; et al. Reversible Crumpling of 2D Titanium Carbide (MXene) Nanocoatings for Stretchable Electromagnetic Shielding and Wearable Wireless Communication. Adv. Funct. Mater. 2019, 30, 1907451. [Google Scholar] [CrossRef]

- Long, Q.; Zhao, S.; Chen, J.; Zhang, Z.; Qi, G.; Liu, Z.-Q. Self-assembly enabled nano-intercalation for stable high-performance MXene membranes. J. Membr. Sci. 2021, 635, 119464. [Google Scholar] [CrossRef]

- Kong, F.; He, X.; Liu, Q.; Qi, X.; Zheng, Y.; Wang, R.; Bai, Y. Improving the electrochemical properties of MXene Ti3C2 multilayer for Li-ion batteries by vacuum calcination. Electrochim. Acta 2018, 265, 140–150. [Google Scholar] [CrossRef]

- Salles, P.; Pinto, D.; Hantanasirisakul, K.; Maleski, K.; Shuck, C.E.; Gogotsi, Y. Electrochromic Effect in Titanium Carbide MXene Thin Films Produced by Dip-Coating. Adv. Funct. Mater. 2019, 29, 1809223. [Google Scholar] [CrossRef]

- Kurra, N.; Ahmed, B.; Gogotsi, Y.; Alshareef, H.N. MXene-on-Paper Coplanar Microsupercapacitors. Adv. Energy Mater. 2016, 6, 1601372. [Google Scholar] [CrossRef]

- Zhou, B.; Li, Y.; Li, Z.; Ma, J.; Zhou, K.; Liu, C.; Shen, C.; Feng, Y. Fire/heat-resistant, anti-corrosion and folding Ti2C3Tx MXene/single-walled carbon nanotube films for extreme-environmental EMI shielding and solar-thermal conversion applications. J. Mater. Chem. C 2021, 9, 10425–10434. [Google Scholar] [CrossRef]

- Vu, M.C.; Mani, D.; Kim, J.-B.; Jeong, T.-H.; Park, S.; Murali, G.; In, I.; Won, J.-C.; Losic, D.; Lim, C.-S.; et al. Hybrid shell of MXene and reduced graphene oxide assembled on PMMA bead core towards tunable thermoconductive and EMI shielding nanocomposites. Compos. Part A Appl. Sci. Manuf. 2021, 149, 106574. [Google Scholar] [CrossRef]

- Qing, Y.; Zhou, W.; Luo, F.; Zhu, D. Titanium carbide (MXene) nanosheets as promising microwave absorbers. Ceram. Int. 2016, 42, 16412–16416. [Google Scholar] [CrossRef]

- Wang, Q.-W.; Zhang, H.-B.; Liu, J.; Zhao, S.; Xie, X.; Liu, L.; Yang, R.; Koratkar, N.; Yu, Z.-Z. Multifunctional and Water-Resistant MXene-Decorated Polyester Textiles with Outstanding Electromagnetic Interference Shielding and Joule Heating Performances. Adv. Funct. Mater. 2019, 29, 1806819. [Google Scholar] [CrossRef]

- Liu, H.; Fu, R.; Su, X.; Wu, B.; Wang, H.; Xu, Y.; Liu, X. MXene confined in shape-stabilized phase change material combining enhanced electromagnetic interference shielding and thermal management capability. Compos. Sci. Technol. 2021, 210, 108835. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, Y.; Zhang, H.-B.; Dai, Y.; Liu, J.; Li, X.; Yu, Z.-Z. Electrically conductive aluminum ion-reinforced MXene films for efficient electromagnetic interference shielding. J. Mater. Chem. C 2020, 8, 1673–1678. [Google Scholar] [CrossRef]

- Yun, T.; Kim, H.; Iqbal, A.; Cho, Y.S.; Lee, G.S.; Kim, M.K.; Kim, S.J.; Kim, D.; Gogotsi, Y.; Kim, S.O.; et al. Electromagnetic Shielding of Monolayer MXene Assemblies. Adv. Mater. 2020, 32, e1906769. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Han, B.; Zhang, H.-B.; Xie, X.; Tu, T.; Zhang, Y.; Dai, Y.; Yang, R.; Yu, Z.-Z. Compressible, durable and conductive polydimethylsiloxane-coated MXene foams for high-performance electromagnetic interference shielding. Chem. Eng. J. 2020, 381, 122622. [Google Scholar] [CrossRef]

- Kumar, P.; Shahzad, F.; Yu, S.; Hong, S.M.; Kim, Y.-H.; Koo, C.M. Large-area reduced graphene oxide thin film with excellent thermal conductivity and electromagnetic interference shielding effectiveness. Carbon 2015, 94, 494–500. [Google Scholar] [CrossRef]

- Huang, K.; Chen, M.; He, G.; Hu, X.; He, W.; Zhou, X.; Huang, Y.; Liu, Z. Stretchable microwave absorbing and electromagnetic interference shielding foam with hierarchical buckling induced by solvent swelling. Carbon 2020, 157, 466–477. [Google Scholar] [CrossRef]

- Ibrahim Takai, Z.; Kamarulzaki Mustafa, M.; Ahmad Sekak, K.; AbdulKadir, H.K.; Asman, S.; Idris, A.; Mohammad, J. Fabrication, characterization and X-band microwave absorption properties of PANI/Fe3O4/PVA nanofiber composites materials. Arab. J. Chem. 2020, 13, 7978–7989. [Google Scholar] [CrossRef]

- Halim, J.; Cook, K.M.; Naguib, M.; Eklund, P.; Gogotsi, Y.; Rosen, J.; Barsoum, M.W. X-ray photoelectron spectroscopy of select multi-layered transition metal carbides (MXenes). Appl. Surf. Sci. 2016, 362, 406–417. [Google Scholar] [CrossRef] [Green Version]

- Shi, Z.; Zhang, Q.; Zhao, L.; Wang, H.; Zhou, W. Inner-Stress-Optimized High-Density Fe3O4 Dots Embedded in Graphitic Carbon Layers with Enhanced Lithium Storage. ACS Appl. Mater. Interfaces 2020, 12, 15043–15052. [Google Scholar] [CrossRef]

- Kim, S.J.; Koh, H.J.; Ren, C.E.; Kwon, O.; Maleski, K.; Cho, S.Y.; Anasori, B.; Kim, C.K.; Choi, Y.K.; Kim, J.; et al. Metallic Ti3C2Tx MXene Gas Sensors with Ultrahigh Signal-to-Noise Ratio. ACS Nano 2018, 12, 986–993. [Google Scholar] [CrossRef] [Green Version]

- Yan, P.; Zhang, R.; Jia, J.; Wu, C.; Zhou, A.; Xu, J.; Zhang, X. Enhanced supercapacitive performance of delaminated two-dimensional titanium carbide/carbon nanotube composites in alkaline electrolyte. J. Power Sources 2015, 284, 38–43. [Google Scholar] [CrossRef]

- Xue, Q.; Zhang, H.; Zhu, M.; Pei, Z.; Li, H.; Wang, Z.; Huang, Y.; Huang, Y.; Deng, Q.; Zhou, J.; et al. Photoluminescent Ti3C2 MXene Quantum Dots for Multicolor Cellular Imaging. Adv. Mater. 2017, 29, 1604847. [Google Scholar] [CrossRef]

- Li, Z.; Wang, L.; Sun, D.; Zhang, Y.; Liu, B.; Hu, Q.; Zhou, A. Synthesis and thermal stability of two-dimensional carbide MXene Ti3C2. Mater. Sci. Eng. B 2015, 191, 33–40. [Google Scholar] [CrossRef]

- Salavati-Niasari, M. Synthesis and Characterization of Host (Nanodimensional Pores of Zeolite-Y)–Guest [Unsaturated 16-Membered Octaaza–macrocycle Manganese(II), Cobalt(II), Nickel(II), Copper(II), and Zinc(II) Complexes] Nanocomposite Materials. Chem. Lett. 2005, 34, 1444–1445. [Google Scholar] [CrossRef]

- Zhang, D.; Karki, A.B.; Rutman, D.; Young, D.P.; Wang, A.; Cocke, D.; Ho, T.H.; Guo, Z. Electrospun polyacrylonitrile nanocomposite fibers reinforced with Fe3O4 nanoparticles: Fabrication and property analysis. Polymer 2009, 50, 4189–4198. [Google Scholar] [CrossRef]

- Deng, L.J.; Zhou, P.H.; Xie, J.L.; Zhang, L. Characterization and microwave resonance in nanocrystalline FeCoNi flake composite. J. Appl. Phys. 2007, 101, 103916. [Google Scholar] [CrossRef]

- Xu, L.; Xiong, Y.; Dang, B.; Ye, Z.; Jin, C.; Sun, Q.; Yu, X. In-situ anchoring of Fe3O4/ZIF-67 dodecahedrons in highly compressible wood aerogel with excellent microwave absorption properties. Mater. Des. 2019, 182, 108006. [Google Scholar] [CrossRef]

- Liu, Y.; Li, Y.; Jiang, K.; Tong, G.; Lv, T.; Wu, W. Controllable synthesis of elliptical Fe3O4@C and Fe3O4/Fe@C nanorings for plasmon resonance-enhanced microwave absorption. J. Mater. Chem. C 2016, 4, 7316–7323. [Google Scholar] [CrossRef]

- Ma, L.; Lu, Z.; Tan, J.; Liu, J.; Ding, X.; Black, N.; Li, T.; Gallop, J.; Hao, L. Transparent Conducting Graphene Hybrid Films To Improve Electromagnetic Interference (EMI) Shielding Performance of Graphene. ACS Appl. Mater. Interfaces 2017, 9, 34221–34229. [Google Scholar] [CrossRef] [PubMed]

- Shang, W.; Liu, Y.; Wan, W.; Hu, C.; Liu, Z.; Wong, C.T.; Fukuda, T.; Shen, Y. Hybrid 3D printing and electrodeposition approach for controllable 3D alginate hydrogel formation. Biofabrication 2017, 9, 025032. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miao, Z.; Chen, X.; Zhou, H.; Liu, P.; Fu, S.; Yang, J.; Gao, Y.; Ren, Y.; Rong, D. Interfacing MXene Flakes on a Magnetic Fiber Network as a Stretchable, Flexible, Electromagnetic Shielding Fabric. Nanomaterials 2022, 12, 20. https://doi.org/10.3390/nano12010020

Miao Z, Chen X, Zhou H, Liu P, Fu S, Yang J, Gao Y, Ren Y, Rong D. Interfacing MXene Flakes on a Magnetic Fiber Network as a Stretchable, Flexible, Electromagnetic Shielding Fabric. Nanomaterials. 2022; 12(1):20. https://doi.org/10.3390/nano12010020

Chicago/Turabian StyleMiao, Zhen, Xiaohong Chen, Honglei Zhou, Ping Liu, Shaoli Fu, Jiajie Yang, Yuhang Gao, Yupeng Ren, and Dong Rong. 2022. "Interfacing MXene Flakes on a Magnetic Fiber Network as a Stretchable, Flexible, Electromagnetic Shielding Fabric" Nanomaterials 12, no. 1: 20. https://doi.org/10.3390/nano12010020

APA StyleMiao, Z., Chen, X., Zhou, H., Liu, P., Fu, S., Yang, J., Gao, Y., Ren, Y., & Rong, D. (2022). Interfacing MXene Flakes on a Magnetic Fiber Network as a Stretchable, Flexible, Electromagnetic Shielding Fabric. Nanomaterials, 12(1), 20. https://doi.org/10.3390/nano12010020