Design, Development and Evaluation of Thermal Properties of Polysulphone–CNT/GNP Nanocomposites

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

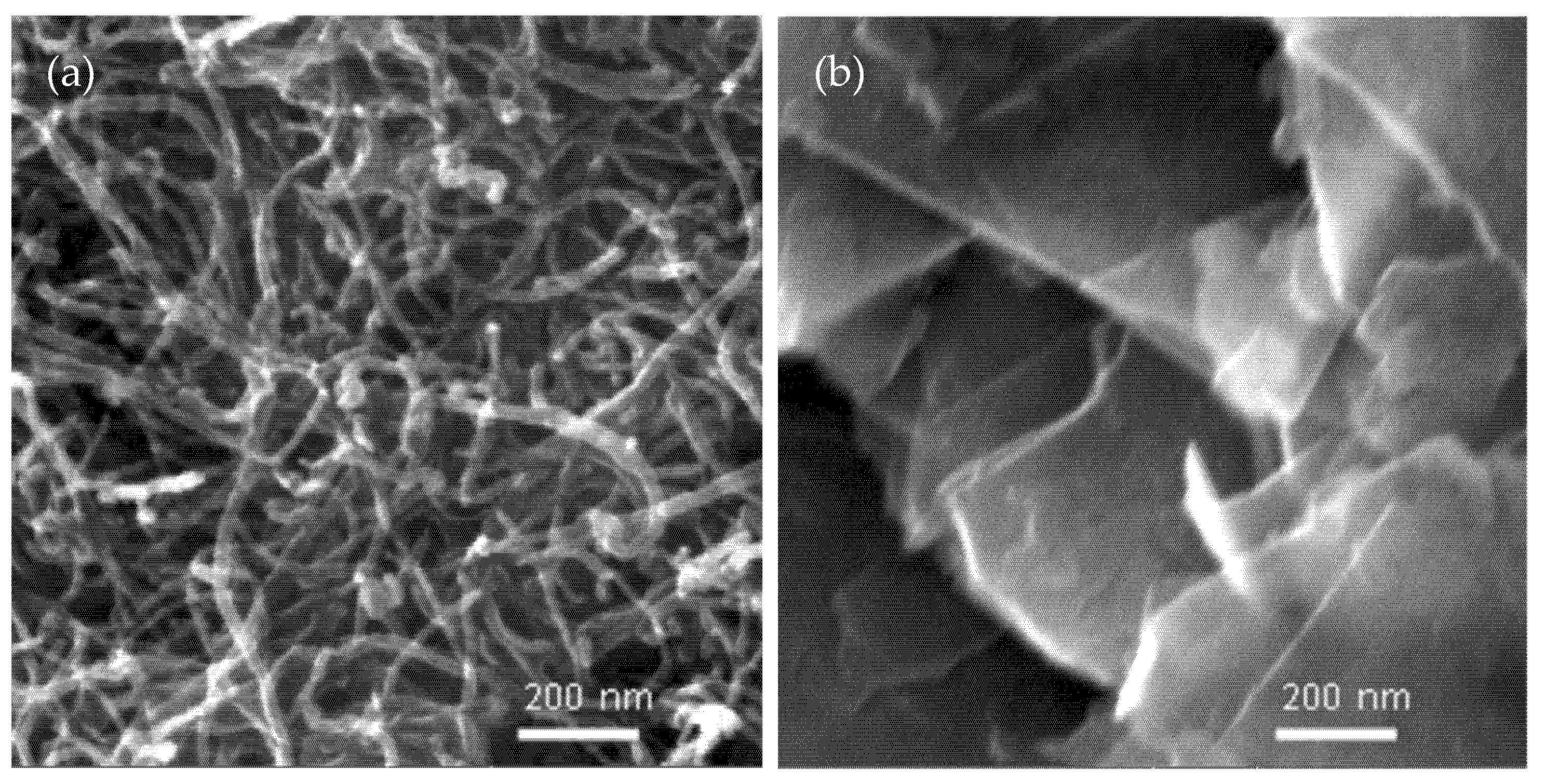

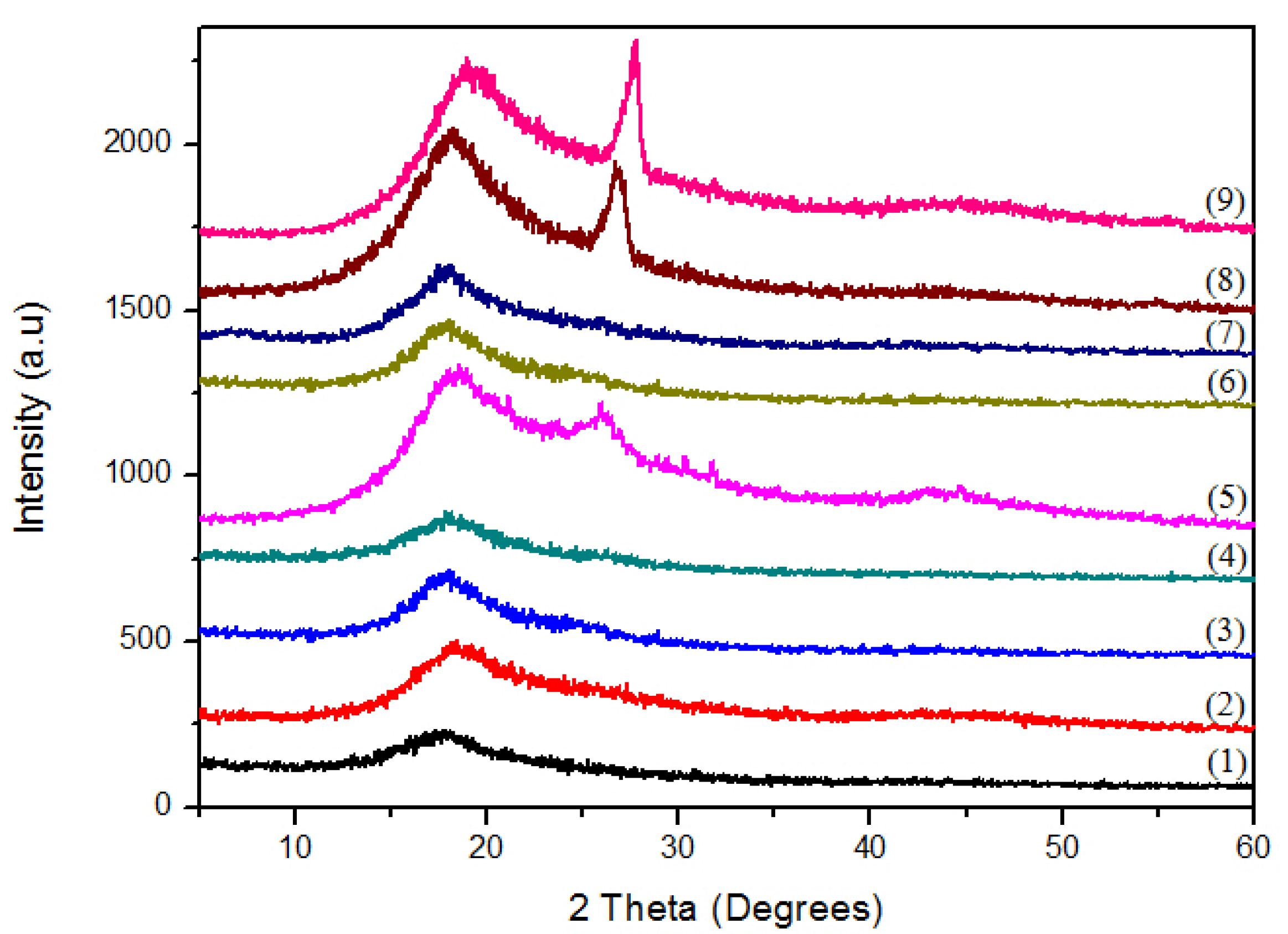

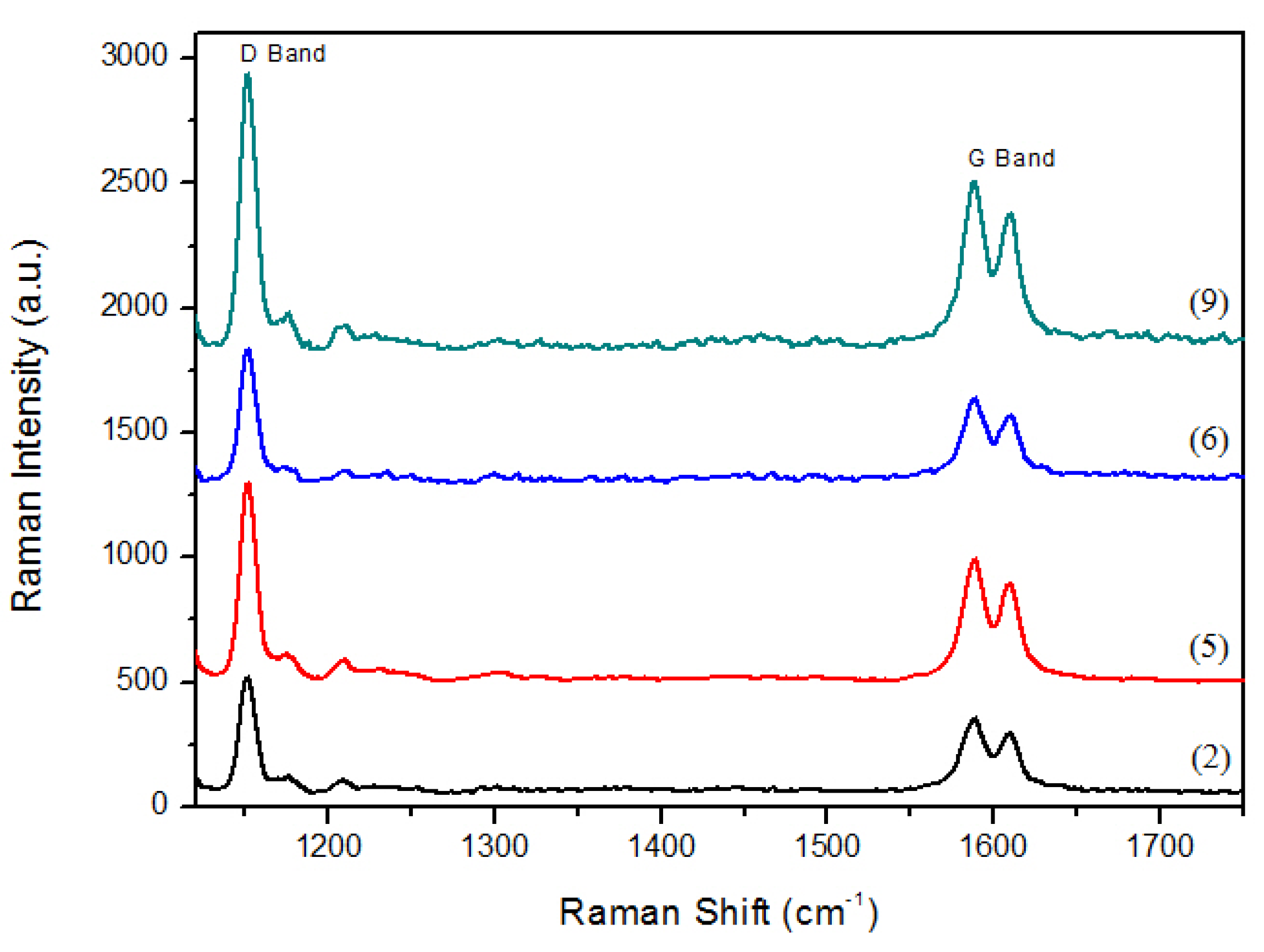

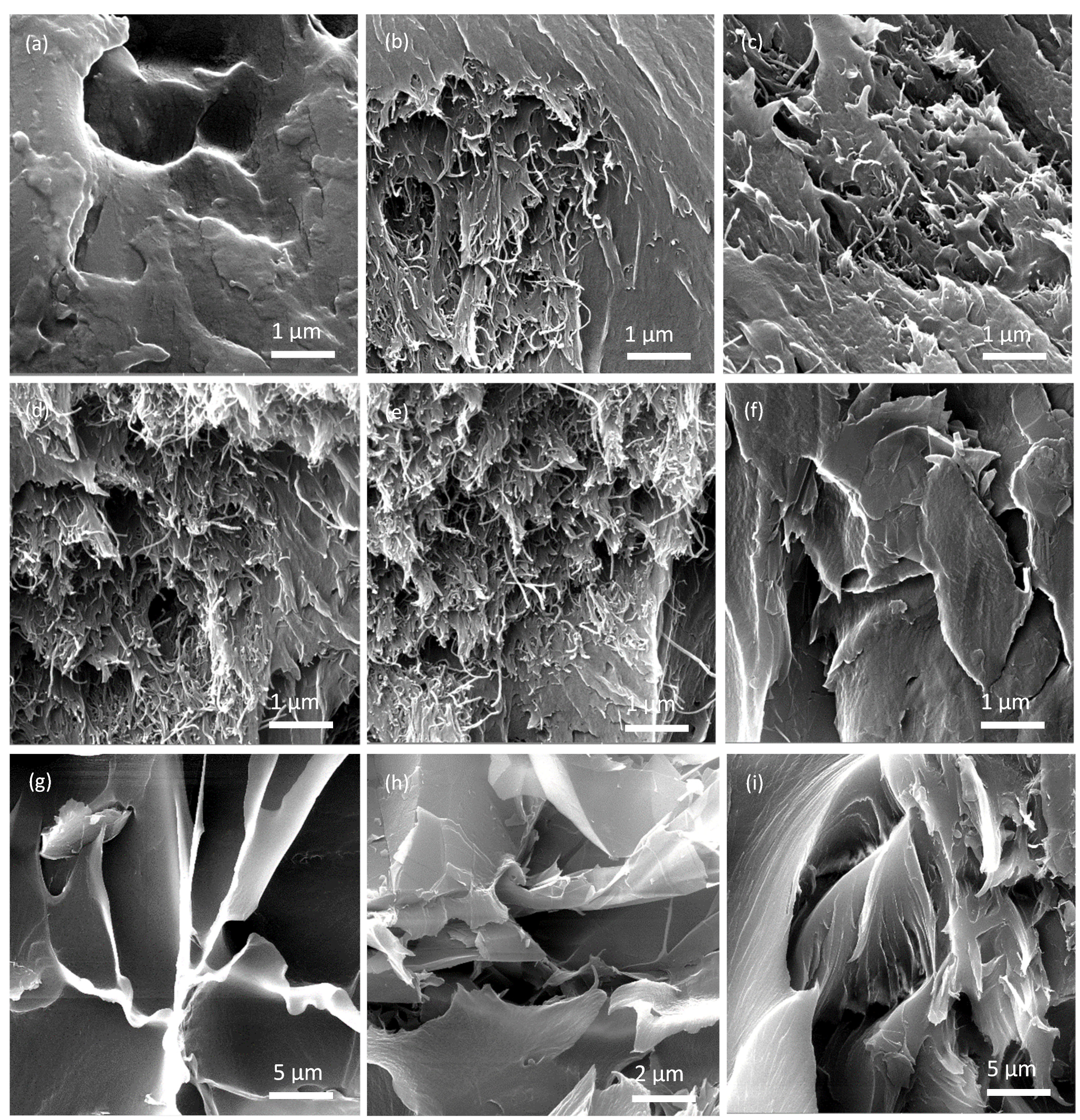

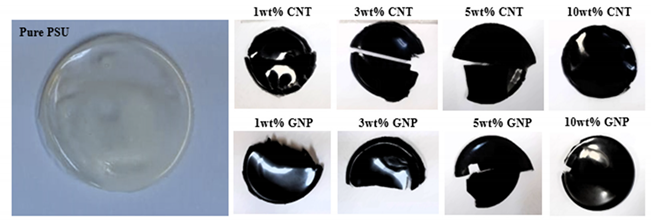

3.1. Microstructural Characterisation

3.2. Thermal Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, H.; Ginzburg, V.V.; Yang, J.; Yang, Y.; Liu, W.; Huang, Y.; Du, L.; Chen, B. Thermal conductivity of polymer-based composites: Fundamentals and applications. Prog. Polym. Sci. 2016, 59, 41–85. [Google Scholar] [CrossRef]

- Camargo, P.H.C.; Satyanarayana, K.G.; Wypych, F. Nanocomposites: Synthesis, structure, properties and new application opportunities. Mater. Res. 2009, 12, 1–39. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y. Thermal conductivity. In Physical Properties of Polymers Handbook, 2nd ed.; Mark, J.E., Ed.; Springer: New York, NY, USA, 2007; pp. 155–163. [Google Scholar]

- Hussain, A.R.J.; Alahyari, A.A.; Eastman, S.A.; Thibaud-Erkey, C.; Johnston, S.; Sobkowicz, M.J. Review of polymers for heat exchanger applications: Factors concerning thermal conductivity. Appl. Therm. Eng. 2017, 113, 1118–1127. [Google Scholar] [CrossRef] [Green Version]

- Saba, N.; Jawaid, M. A review on thermomechanical properties of polymers and fibers reinforced polymer composites. J. Ind. Eng. Chem. 2018, 67, 1–11. [Google Scholar] [CrossRef]

- Davis, A. Thermal stability of polysulphone. Die Makromol. Chem. Macromol. Chem. Phys. 1969, 128, 242–251. [Google Scholar] [CrossRef]

- Bose, S.; Kuila, T.; Nguyen, T.X.H.; Kim, N.H.; Lau, K.-T.; Lee, J.H. Polymer membranes for high temperature proton exchange membrane fuel cell: Recent advances and challenges. Prog. Polym. Sci. 2011, 36, 813–843. [Google Scholar] [CrossRef]

- Sur, G.; Sun, H.; Lyu, S.; Mark, J. Synthesis, structure, mechanical properties, and thermal stability of some polysulfone/organoclay nanocomposites. Polymer 2001, 42, 9783–9789. [Google Scholar] [CrossRef]

- Chlopek, J.; Rosol, P.; Morawska-Chochol, A. Durability of polymer-ceramics composite implants determined in creep tests. Compos. Sci. Technol. 2006, 66, 1615–1622. [Google Scholar] [CrossRef]

- Sohail, O.B.; Sreekumar, P.; De, S.; Jabarullah Khan, M.; Hakeem, A.; Alshaiban, A.A.; Al-Harthi, M.A. Thermal effect of ceramic nanofiller aluminium nitride on polyethylene properties. J. Nanomater. 2012, 2012, 87. [Google Scholar] [CrossRef]

- Lu, X.; Xu, G. Thermally conductive polymer composites for electronic packaging. J. Appl. Polym. Sci. 1997, 65, 2733–2738. [Google Scholar] [CrossRef]

- Raza, K.; Akhtar, S.S.; Arif, A.F.M.; Hakeem, A.S. Design of a Composite Encapsulation for Concentrated Photovoltaic Systems With Improved Performance. ASME Int. Mech. Eng. Congr. Expo. 2019. [Google Scholar] [CrossRef]

- Raza, K.; Akhtar, S.S.; Arif, A.F.M.; Hakeem, A.S. Computational design and development of high-performance polymer-composites as new encapsulant material for concentrated PV modules. Sci. Rep. 2020, 10, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Schelling, P.K.; Shi, L.; Goodson, E. Managing heat for electronics. Mater. Today 2005, 8, 30–35. [Google Scholar] [CrossRef]

- Tyagi, M.; Tyagi, D. Polymer nanocomposites and their applications in electronics industry. Int. J. Electron. Electr. Eng. 2014, 7, 603–608. [Google Scholar]

- Wong, C.; Bollampally, R.S. Thermal conductivity, elastic modulus, and coefficient of thermal expansion of polymer composites filled with ceramic particles for electronic packaging. J. Appl. Polym. Sci. 1999, 74, 3396–3403. [Google Scholar] [CrossRef]

- Khan, M.Y.; Khan, A.; Elsharif, A.M.; Helal, A.; Yamani, Z.; Hakeem, A.S. Mixed dimensional nanostructure (UiO66 decorated MWCNT) as nanofiller in MMMs for enhanced CO2/CH4 separation. Chem. A Eur. J. 2021, 27, 11132–11140. [Google Scholar] [CrossRef] [PubMed]

- Yu, J.; Cennini, G. Improving thermal conductivity of polymer composites in embedded LEDs systems. Microelectron. J. 2014, 45, 1829–1833. [Google Scholar] [CrossRef]

- Zahir, M.H.; Helal, A.; Hakeem, A.S. Hybrid polyMOF materials prepared by combining an organic polymer with a MOF and their application for solar thermal energy storage. Energy Fuels 2021, 35, 10199–10209. [Google Scholar] [CrossRef]

- Tessema, A.; Zhao, D.; Moll, J.; Xu, S.; Yang, R.; Li, C.; Kumar, S.K.; Kidane, A. Effect of filler loading, geometry, dispersion and temperature on thermal conductivity of polymer nanocomposites. Polym. Test. 2017, 57, 101–106. [Google Scholar] [CrossRef] [Green Version]

- Gu, J.; Meng, X.; Tang, Y.; Li, Y.; Zhuang, Q.; Kong, J. Hexagonal boron nitride/polymethyl-vinyl siloxane rubber dielectric thermally conductive composites with ideal thermal stabilities. Compos. Part A Appl. Sci. Manuf. 2017, 92, 27–32. [Google Scholar] [CrossRef]

- Weidenfeller, B.; Höfer, M.; Schilling, F.R. Thermal conductivity, thermal diffusivity, and specific heat capacity of particle filled polypropylene. Compos. Part A Appl. Sci. Manuf. 2004, 35, 423–429. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, P.; Zheng, Q. Preparation and properties of polysulfone/TiO2 composite ultrafiltration membranes. J. Polym. Sci. Part B Polym. Phys. 2006, 44, 879–887. [Google Scholar] [CrossRef]

- Weidenfeller, B.; Höfer, M.; Schilling, F. Thermal and electrical properties of magnetite filled polymers. Compos. Part A Appl. Sci. Manuf. 2002, 33, 1041–1053. [Google Scholar] [CrossRef]

- Zhao, Y.-H.; Zhang, Y.-F.; Bai, S.-L.; Yuan, X.-W. Carbon fibre/graphene foam/polymer composites with enhanced mechanical and thermal properties. Compos. Part B Eng. 2016, 94, 102–108. [Google Scholar] [CrossRef]

- Yang, S.-Y.; Lin, W.-N.; Huang, Y.-L.; Tien, H.-W.; Wang, J.-Y.; Ma, C.-C.M.; Li, S.-M.; Wang, Y.-S. Synergetic effects of graphene platelets and carbon nanotubes on the mechanical and thermal properties of epoxy composites. Carbon 2011, 49, 793–803. [Google Scholar] [CrossRef]

- Hong, J.; Lee, J.; Jung, D.; Shim, S.E. Thermal and electrical conduction behavior of alumina and multiwalled carbon nanotube incorporated poly (dimethyl siloxane). Thermochim. Acta 2011, 512, 34–39. [Google Scholar] [CrossRef]

- Takenaka, K.; Ichigo, M. Thermal expansion adjustable polymer matrix composites with giant negative thermal expansion filler. Compos. Sci. Technol. 2014, 104, 47–51. [Google Scholar] [CrossRef]

- Takenaka, K. Negative thermal expansion materials: Technological key for control of thermal expansion. Sci. Technol. Adv. Mater. 2012, 13, 013001. [Google Scholar] [CrossRef]

- Hu, N.; Jia, B.; Arai, M.; Yan, C.; Li, J.; Liu, Y.; Atobe, S.; Fukunaga, H. Prediction of thermal expansion properties of carbon nanotubes using molecular dynamics simulations. Comput. Mater. Sci. 2012, 54, 249–254. [Google Scholar]

- Hu, C.; Li, Z.; Wang, Y.; Gao, J.; Dai, K.; Zheng, G.; Liu, C.; Shen, C.; Song, H.; Guo, Z. Comparative assessment of the strain-sensing behaviors of polylactic acid nanocomposites: Reduced graphene oxide or carbon nanotubes. J. Mater. Chem. C 2017, 5, 2318–2328. [Google Scholar] [CrossRef]

- Balandin, A.A.; Ghosh, S.; Bao, W.; Calizo, I.; Teweldebrhan, D.; Miao, F.; Lau, C.N. Superior thermal conductivity of single-layer graphene. Nano Lett. 2008, 8, 902–907. [Google Scholar] [CrossRef]

- Han, Z.; Fina, A. Thermal conductivity of carbon nanotubes and their polymer nanocomposites: A review. Prog. Polym. Sci. 2011, 36, 914–944. [Google Scholar] [CrossRef] [Green Version]

- Martin-Gallego, M.; Bernal, M.; Hernandez, M.; Verdejo, R.; López-Manchado, M.A. Comparison of filler percolation and mechanical properties in graphene and carbon nanotubes filled epoxy nanocomposites. Eur. Polym. J. 2013, 49, 1347–1353. [Google Scholar] [CrossRef] [Green Version]

- Díez-Pascual, A.M.; Ashrafi, B.; Naffakh, M.; González-Domínguez, J.M.; Johnston, A.; Simard, B.; Martinez, M.T.; Gómez-Fatou, M.A. Influence of carbon nanotubes on the thermal, electrical and mechanical properties of poly (ether ether ketone)/glass fiber laminates. Carbon 2011, 49, 2817–2833. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.S.; Jang, J.-U.; Yu, J.; Kim, S.Y. Thermal conductivity of polymer composites based on the length of multi-walled carbon nanotubes. Compos. Part B Eng. 2015, 79, 505–512. [Google Scholar] [CrossRef]

- Ma, P.-C.; Siddiqui, N.A.; Marom, G.; Kim, J.-K. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1345–1367. [Google Scholar] [CrossRef]

- Kotov, N.A. Materials science: Carbon sheet solutions. Nature 2006, 442, 254. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.-F.; Zhao, Y.-H.; Bai, S.-L.; Yuan, X. Numerical simulation of thermal conductivity of graphene filled polymer composites. Compos. Part B Eng. 2016, 106, 324–331. [Google Scholar] [CrossRef]

- Kuilla, T.; Bhadra, S.; Yao, D.; Kim, N.H.; Bose, S.; Lee, J.H. Recent advances in graphene based polymer composites. Prog. Polym. Sci. 2010, 35, 1350–1375. [Google Scholar] [CrossRef]

- Liao, Q.; Liu, Z.; Liu, W.; Deng, C.; Yang, N. Extremely high thermal conductivity of aligned carbon nanotube-polyethylene composites. Sci. Rep. 2015, 5, 16543. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Du, J.; Bai, J.; Cheng, H. The present status and key problems of carbon nanotube based polymer composites. Express Polym. Lett. 2007, 1, 253–273. [Google Scholar] [CrossRef]

- Ionita, M.; Pandele, A.M.; Crica, L.; Pilan, L. Improving the thermal and mechanical properties of polysulfone by incorporation of graphene oxide. Compos. Part B Eng. 2014, 59, 133–139. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Tzounis, L.; Velidakis, E.; Mountakis, N.; Grammatikos, S.A. Polyamide 12/multiwalled carbon nanotube and carbon black nanocomposites manufactured by 3D printing fused filament fabrication: A comparison of the electrical, thermoelectric, and mechanical properties. C 2021, 7, 38. [Google Scholar]

- Tzounis, L.; Pegel, S.; Zafeiropoulos, N.E.; Avgeropoulos, A.; Paipetis, A.S.; Stamm, M. Shear alignment of a poly (styrene-butadiene-styrene) triblock copolymer/MWCNT nanocomposite. Polymer 2017, 131, 1–9. [Google Scholar] [CrossRef]

- Raza, K.; Siddiqui, M.U.; Arif, A.F.M.; Akhtar, S.S.; Hakeem, A.S. Design and development of thermally conductive hybrid nano-composites in polysulfone matrix. Polym. Compos. 2019, 40, 1419–1432. [Google Scholar] [CrossRef]

- Balandin, A.A. Thermal properties of graphene and nanostructured carbon materials. Nat. Mater. 2011, 10, 569. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zabihi, Z.; Araghi, H. Effect of functional groups on thermal conductivity of graphene/paraffin nanocomposite. Phys. Lett. A 2016, 380, 3828–3831. [Google Scholar] [CrossRef]

- Nan, C.-W.; Liu, G.; Lin, Y.; Li, M. Interface effect on thermal conductivity of carbon nanotube composites. Appl. Phys. Lett. 2004, 85, 3549–3551. [Google Scholar] [CrossRef]

- Shenogin, S.; Xue, L.; Ozisik, R.; Keblinski, P.; Cahill, D.G. Role of thermal boundary resistance on the heat flow in carbon-nanotube composites. J. Appl. Phys. 2004, 95, 8136–8144. [Google Scholar] [CrossRef]

- Kemaloglu, S.; Ozkoc, G.; Aytac, A. Properties of thermally conductive micro and nano size boron nitride reinforced silicon rubber composites. Thermochim. Acta 2010, 499, 40–47. [Google Scholar] [CrossRef]

- Verdejo, R.; Bernal, M.M.; Romasanta, L.J.; Lopez-Manchado, M.A. Graphene filled polymer nanocomposites. J. Mater. Chem. 2011, 21, 3301–3310. [Google Scholar] [CrossRef] [Green Version]

- Nayak, L.; Rahaman, M.; Khastgir, D.; Chaki, T. Thermal and electrical properties of carbon nanotubes based polysulfone nanocomposites. Polym. Bull. 2011, 67, 1029. [Google Scholar] [CrossRef]

| Composition | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Sample IDs | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| Composition (%) | Pure PSU | 1% CNT | 3% CNT | 5% CNT | 10% CNT | 1% GNP | 3% GNP | 5% GNP | 10% GNP |

| PSU (gm) | 10 | 9.9 | 9.7 | 9.6 | 9 | 9.9 | 9.7 | 9.6 | 9 |

| CNTs/GNPs (gm) | 0 | 0.1 | 0.3 | 0.4 | 1 | 0.1 | 0.3 | 0.4 | 1 |

| Composition | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Sample ID | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| Composition | Pure PSU | 1% CNT | 3% CNT | 5% CNT | 10% CNT | 1% GNP | 3% GNP | 5% GNP | 10% GNP |

| Thermal Conductivity (W/m·K) | 0.43(3) | 0.69(3) | 0.92(5) | 1.09(1) | 1.13(7) | 0.58(6) | 0.67(3) | 0.82(2) | 0.92(3) |

| % Increase in Thermal Conductivity | 0 | 60 | 114 | 153 | 163 | 35 | 56 | 91 | 114 |

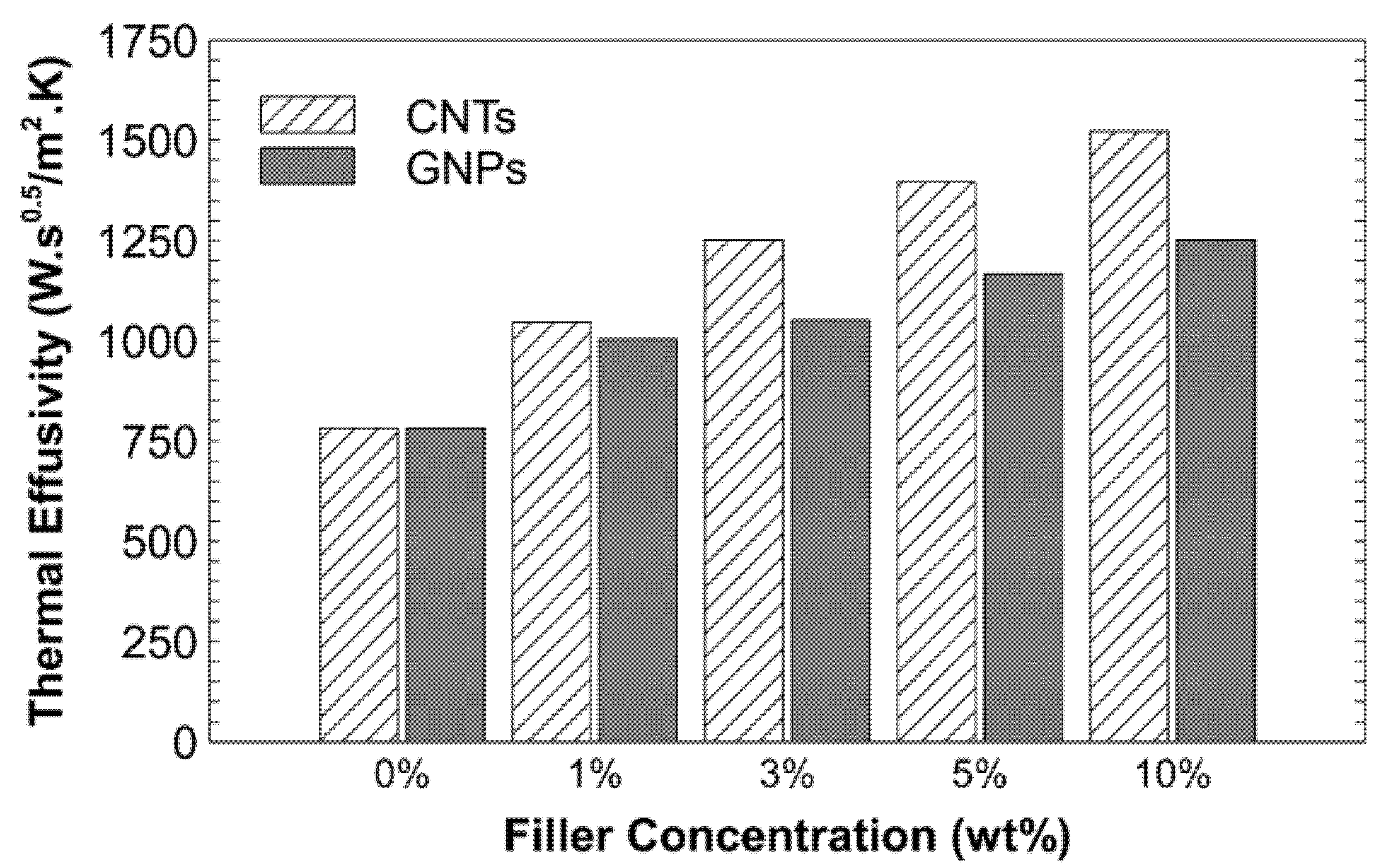

| Thermal Effusivity | 782(3) | 1047(7) | 1252(6) | 1397(3) | 1522(2) | 1005(3) | 1052(5) | 1167(6) | 1252(8) |

| Thermal Expansion (ppm/K) | 60(4) | 57.6(6) | 49.8(3) | 45(5) | 38.4(1) | 58.2(2) | 54.6(3) | 50.4(1) | 45.6(5) |

| % Reduction of Thermal Expansion | 0 | 4 | 17 | 25 | 36 | 3 | 9 | 16 | 24 |

| Tg (°C) | 190(2) | 210(2) | 230(6) | 245(8) | 250(7) | 205(4) | 220(3) | 235(4) | 240(2) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Irshad, H.M.; Hakeem, A.S.; Raza, K.; Baroud, T.N.; Ehsan, M.A.; Ali, S.; Tahir, M.S. Design, Development and Evaluation of Thermal Properties of Polysulphone–CNT/GNP Nanocomposites. Nanomaterials 2021, 11, 2080. https://doi.org/10.3390/nano11082080

Irshad HM, Hakeem AS, Raza K, Baroud TN, Ehsan MA, Ali S, Tahir MS. Design, Development and Evaluation of Thermal Properties of Polysulphone–CNT/GNP Nanocomposites. Nanomaterials. 2021; 11(8):2080. https://doi.org/10.3390/nano11082080

Chicago/Turabian StyleIrshad, Hafiz Muzammil, Abbas Saeed Hakeem, Kabeer Raza, Turki Nabieh Baroud, Muhammad Ali Ehsan, Sameer Ali, and Muhammad Suleman Tahir. 2021. "Design, Development and Evaluation of Thermal Properties of Polysulphone–CNT/GNP Nanocomposites" Nanomaterials 11, no. 8: 2080. https://doi.org/10.3390/nano11082080

APA StyleIrshad, H. M., Hakeem, A. S., Raza, K., Baroud, T. N., Ehsan, M. A., Ali, S., & Tahir, M. S. (2021). Design, Development and Evaluation of Thermal Properties of Polysulphone–CNT/GNP Nanocomposites. Nanomaterials, 11(8), 2080. https://doi.org/10.3390/nano11082080