Magnetic Configurations in Modulated Cylindrical Nanowires

Abstract

1. Introduction

2. Materials and Methods

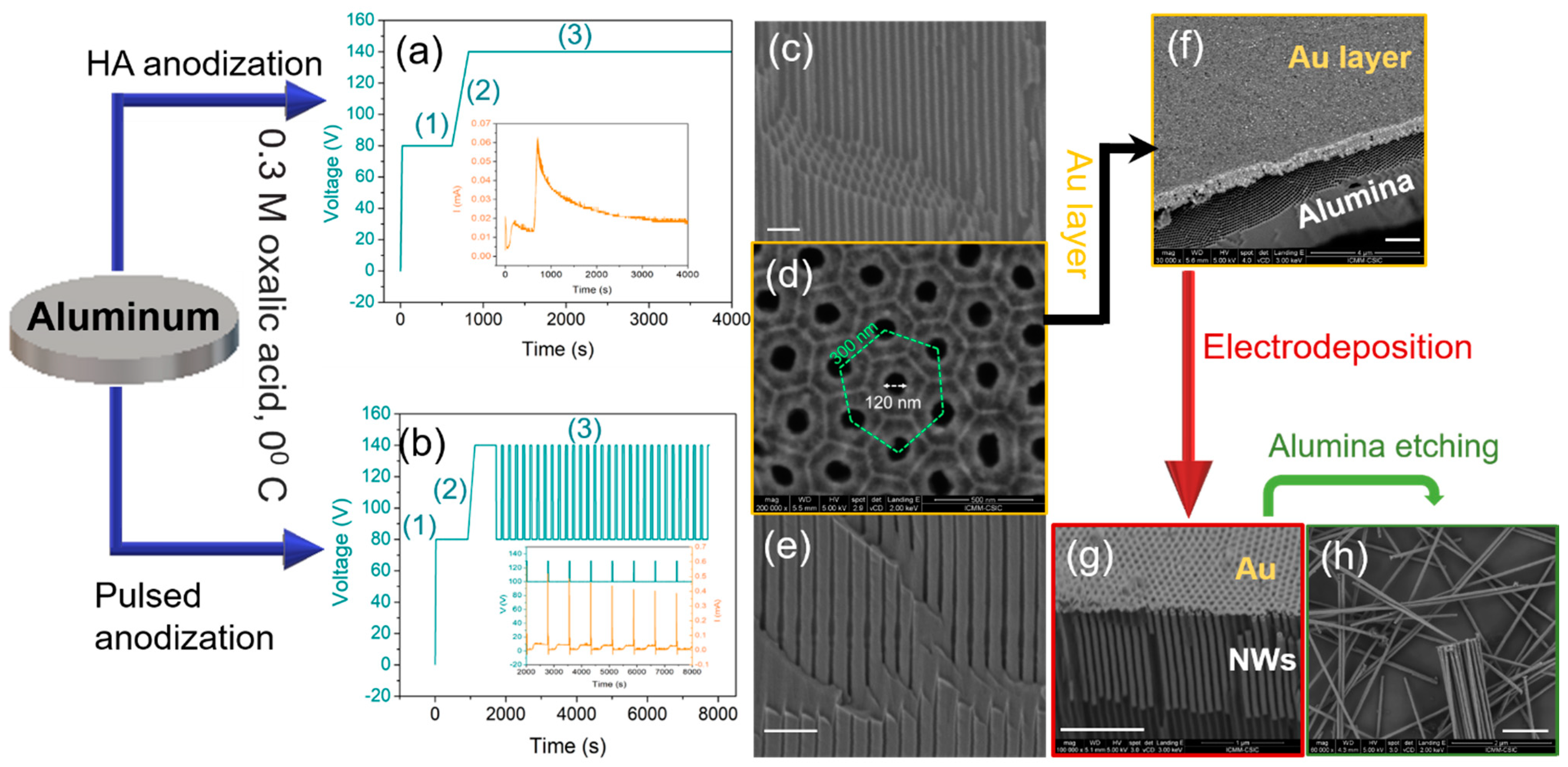

2.1. Alumina Substrates

2.2. Samples Deposition

2.3. Characterization Methods

2.4. Micromagnetic Simulations

3. Magnetic Configurations of Cylindrical Nanowires with Large Shape Anisotropy

3.1. Magnetic Domain Configuration in Nanowires with Uniform Diameter

3.2. Magnetic Configurations in Nanowires with Tailored Geometry

3.3. Micromagnetic Simulations of Nanowires with Tailored Geometry

3.4. Magnetic Configuration of Individual Nanowires with Chemical Notches

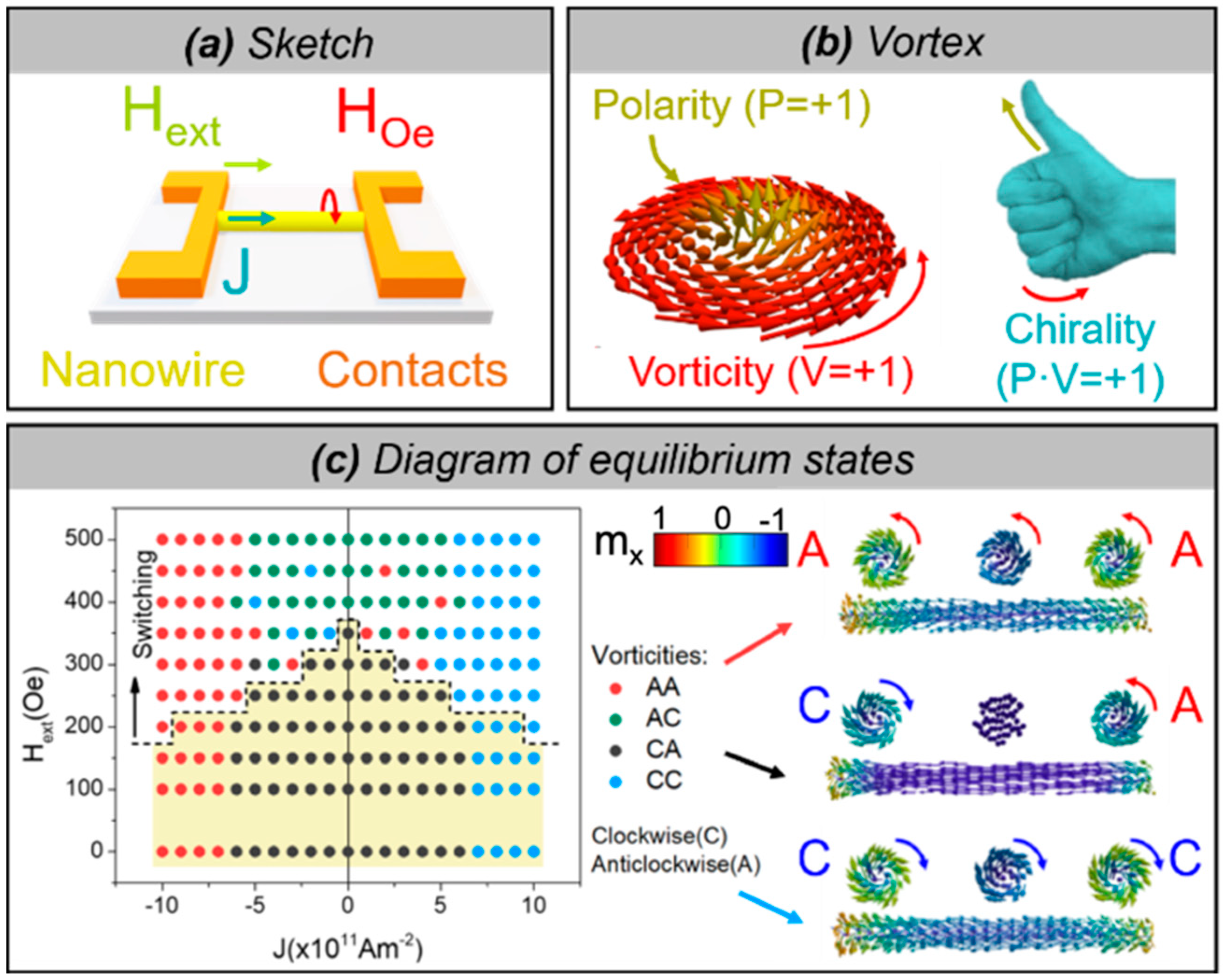

3.5. Manipulation of Magnetization Reversal by Magnetic and Electric Fields

4. Magnetic Configurations of Cylindrical Nanowires with Large Magnetocrystalline Anisotropy

Magnetic Nanowires with Modulated Anisotropy

5. Discussion and Summary

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Streubel, R.; Fischer, P.; Kronast, F.; Kravchuk, V.P.; Sheka, D.D.; Gaididei, Y.; Schmidt, O.G.; Makarov, D. Magnetism in curved geometries. J. Phys. D Appl. Phys. 2016, 49, 363001. [Google Scholar] [CrossRef]

- Braun, H.-B.; Charilaou, M.; Löffler, J.F. Skyrmion lines, monopoles, and emergent electromagnetism in nanowires. In Magnetic Nano- and Microwires, 2nd ed.; Vázquez, M., Ed.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 381–401. ISBN 978-0-08-102832-2. [Google Scholar]

- Fischer, P.; Sanz-Hernández, D.; Streubel, R.; Fernández-Pacheco, A. Launching a new dimension with 3D magnetic nanostructures. APL Mater. 2020, 8, 010701. [Google Scholar] [CrossRef]

- Donnelly, C.; Scagnoli, V. Imaging three-dimensional magnetic systems with X-rays. J. Phys. Condens. Matter 2020, 32, 213001. [Google Scholar] [CrossRef]

- da Câmara Santa Clara Gomes, T.; Marchal, N.; Abreu Araujo, F.; Piraux, L. Spin Caloritronics in 3D Interconnected Nanowire Networks. Nanomaterials 2020, 10, 2092. [Google Scholar] [CrossRef]

- Guzmán-Mínguez, J.C.; Ruiz-Gómez, S.; Vicente-Arche, L.M.; Granados-Miralles, C.; Fernández-González, C.; Mompeán, F.; García-Hernández, M.; Erohkin, S.; Berkov, D.; Mishra, D.; et al. FeCo Nanowire–Strontium Ferrite Powder Composites for Permanent Magnets with High-Energy Products. ACS Appl. Nano Mater. 2020, 3, 9842–9851. [Google Scholar] [CrossRef]

- Pierrot, A.; Béron, F.; Blon, T. FORC signatures and switching-field distributions of dipolar coupled nanowire-based hysterons. J. Appl. Phys. 2020, 128, 093903. [Google Scholar] [CrossRef]

- Zamani Kouhpanji, M.R.; Ghoreyshi, A.; Visscher, P.B.; Stadler, B.J.H. Facile decoding of quantitative signatures from magnetic nanowire arrays. Sci. Rep. 2020, 10, 15482. [Google Scholar] [CrossRef] [PubMed]

- Alsharif, N.A.; Aleisa, F.A.; Liu, G.; Ooi, B.S.; Patel, N.; Ravasi, T.; Merzaban, J.S.; Kosel, J. Functionalization of Magnetic Nanowires for Active Targeting and Enhanced Cell-Killing Efficacy. ACS Appl. Bio Mater. 2020, 3, 4789–4797. [Google Scholar] [CrossRef]

- Sharma, A.; Zhu, Y.; Thor, S.; Zhou, F.; Stadler, B.; Hubel, A. Magnetic Barcode Nanowires for Osteosarcoma Cell Control, Detection and Separation. IEEE Trans. Magn. 2013, 49, 453–456. [Google Scholar] [CrossRef]

- Wolf, D.; Rodriguez, L.A.; Béché, A.; Javon, E.; Serrano, L.; Magen, C.; Gatel, C.; Lubk, A.; Lichte, H.; Bals, S.; et al. 3D Magnetic Induction Maps of Nanoscale Materials Revealed by Electron Holographic Tomography. Chem. Mater. 2015, 27, 6771–6778. [Google Scholar] [CrossRef] [PubMed]

- Schöbitz, M.; De Riz, A.; Martin, S.; Bochmann, S.; Thirion, C.; Vogel, J.; Foerster, M.; Aballe, L.; Menteş, T.O.; Locatelli, A.; et al. Fast Domain Wall Motion Governed by Topology and Œrsted Fields in Cylindrical Magnetic Nanowires. Phys. Rev. Lett. 2019, 123, 217201. [Google Scholar] [CrossRef]

- Chu, S.-Z.; Wada, K.; Inoue, S.; Isogai, M.; Yasumori, A. Fabrication of Ideally Ordered Nanoporous Alumina Films and Integrated Alumina Nanotubule Arrays by High-Field Anodization. Adv. Mater. 2005, 17, 2115–2119. [Google Scholar] [CrossRef]

- Lee, W.; Ji, R.; Gösele, U.; Nielsch, K. Fast fabrication of long-range ordered porous alumina membranes by hard anodization. Nat. Mater. 2006, 5, 741–747. [Google Scholar] [CrossRef]

- Lee, W.; Kim, J.-C.; Gösele, U. Spontaneous Current Oscillations during Hard Anodization of Aluminum under Potentiostatic Conditions. Adv. Funct. Mater. 2010, 20, 21–27. [Google Scholar] [CrossRef]

- Vega, V.; García, J.; Montero-Moreno, J.M.; Hernando, B.; Bachmann, J.; Prida, V.M.; Nielsch, K. Unveiling the Hard Anodization Regime of Aluminum: Insight into Nanopores Self-Organization and Growth Mechanism. ACS Appl. Mater. Interfaces 2015, 7, 28682–28692. [Google Scholar] [CrossRef] [PubMed]

- Alraddadi, S.; Hines, W.; Yilmaz, T.; Gu, G.D.; Sinkovic, B. Structural phase diagram for ultra-thin epitaxial Fe3O4/MgO(0 0 1) films: Thickness and oxygen pressure dependence. J. Phys. Condens. Matter 2016, 28, 115402. [Google Scholar] [CrossRef]

- Lee, W.; Park, S.-J.J. Porous Anodic Aluminum Oxide: Anodization and Templated Synthesis of Functional Nanostructures. Chem. Rev. 2014, 114, 7487–7556. [Google Scholar] [CrossRef]

- Palmero, E.M.; Bran, C.; Del Real, R.P.; Vázquez, M. Vortex domain wall propagation in periodically modulated diameter FeCoCu nanowire as determined by the magneto-optical Kerr effect. Nanotechnology 2015, 26. [Google Scholar] [CrossRef]

- Bran, C.; Fernandez-Roldan, J.A.; Palmero, E.M.; Berganza, E.; Guzman, J.; Del Real, R.P.; Asenjo, A.; Fraile Rodríguez, A.; Foerster, M.; Aballe, L.; et al. Direct observation of transverse and vortex metastable magnetic domains in cylindrical nanowires. Phys. Rev. B 2017, 96, 125415. [Google Scholar] [CrossRef]

- Bran, C.; Berganza, E.; Palmero, E.M.; Fernandez-Roldan, J.A.; Del Real, R.P.; Aballe, L.; Foerster, M.; Asenjo, A.; Fraile Rodríguez, A.; Vazquez, M. Spin configuration of cylindrical bamboo-like magnetic nanowires. J. Mater. Chem. C 2016, 4, 978–984. [Google Scholar] [CrossRef]

- Rodríguez, L.A.; Bran, C.; Reyes, D.; Berganza, E.; Vázquez, M.; Gatel, C.; Snoeck, E.; Asenjo, A. Quantitative Nanoscale Magnetic Study of Isolated Diameter-Modulated FeCoCu Nanowires. ACS Nano 2016, 10, 9669–9678. [Google Scholar] [CrossRef]

- Minguez-Bacho, I.; Rodriguez-López, S.; Vázquez, M.; Hernández-Vélez, M.; Nielsch, K. Electrochemical synthesis and magnetic characterization of periodically modulated Co nanowires. Nanotechnology 2014, 25, 145301. [Google Scholar] [CrossRef]

- Iglesias-Freire, Ó.; Bran, C.; Berganza, E.; Mínguez-Bacho, I.; Magén, C.; Vázquez, M.; Asenjo, A. Spin configuration in isolated FeCoCu nanowires modulated in diameter. Nanotechnology 2015, 26, 395702. [Google Scholar] [CrossRef] [PubMed]

- Bran, C.; Palmero, E.M.; Li, Z.-A.; Del Real, R.P.; Spasova, M.; Farle, M.; Vázquez, M. Correlation between structure and magnetic properties in CoxFe100−x nanowires: The roles of composition and wire diameter. J. Phys. D Appl. Phys. 2015, 48. [Google Scholar] [CrossRef]

- Moraes, S.; Navas, D.; Béron, F.; Proenca, M.; Pirota, K.; Sousa, C.; Araújo, J. The Role of Cu Length on the Magnetic Behaviour of Fe/Cu Multi-Segmented Nanowires. Nanomaterials 2018, 8, 490. [Google Scholar] [CrossRef]

- García, J.; Vega, V.; Iglesias, L.; Prida, V.M.; Hernando, B.; Barriga-Castro, E.D.; Mendoza-Reséndez, R.; Luna, C.; Görlitz, D.; Nielsch, K. Template-assisted Co-Ni alloys and multisegmented nanowires with tuned magnetic anisotropy. Phys. Status Solidi 2014, 211, 1041–1047. [Google Scholar] [CrossRef]

- Abreu Araujo, F.; Piraux, L. Spin-Transfer-Torque Driven Vortex Dynamics in Electrodeposited Nanowire Spin-Valves. SPIN 2017, 7, 1740007. [Google Scholar] [CrossRef]

- Staňo, M.; Fruchart, O. Magnetic Nanowires and Nanotubes. Handb. Magn. Mater. 2018, 27, 155–267. [Google Scholar] [CrossRef]

- Aballe, L.; Foerster, M.; Pellegrin, E.; Nicolas, J.; Ferrer, S. The ALBA spectroscopic LEEM-PEEM experimental station: Layout and performance. J. Synchrotron Radiat. 2015, 22, 745–752. [Google Scholar] [CrossRef]

- Kimling, J.; Kronast, F.; Martens, S.; Böhnert, T.; Martens, M.; Herrero-Albillos, J.; Tati-Bismaths, L.; Merkt, U.; Nielsch, K.; Meier, G. Photoemission electron microscopy of three-dimensional magnetization configurations in core-shell nanostructures. Phys. Rev. B Condens. Matter Mater. Phys. 2011, 84. [Google Scholar] [CrossRef]

- Scholl, A.; Ohldag, H.; Nolting, F.; Stöhr, J.; Padmore, H.A. X-ray photoemission electron microscopy, a tool for the investigation of complex magnetic structures (invited). Rev. Sci. Instrum. 2002, 73, 1362–1366. [Google Scholar] [CrossRef]

- Vansteenkiste, A.; Van de Wiele, B. MuMax: A new high-performance micromagnetic simulation tool. J. Magn. Magn. Mater. 2011, 323, 2585–2591. [Google Scholar] [CrossRef]

- Ivanov, Y.P.; Vázquez, M.; Chubykalo-Fesenko, O. Magnetic reversal modes in cylindrical nanowires. J. Phys. D Appl. Phys. 2013, 46, 485001. [Google Scholar] [CrossRef]

- Moreno, R.; Evans, R.F.L.; Khmelevskyi, S.; Muñoz, M.C.; Chantrell, R.W.; Chubykalo-Fesenko, O. Temperature-dependent exchange stiffness and domain wall width in Co. Phys. Rev. B 2016, 94, 104433. [Google Scholar] [CrossRef]

- Bran, C.; Ivanov, Y.P.; García, J.; Del Real, R.P.; Prida, V.M.; Chubykalo-Fesenko, O.; Vazquez, M. Tuning the magnetization reversal process of FeCoCu nanowire arrays by thermal annealing. J. Appl. Phys. 2013, 114, 043908. [Google Scholar] [CrossRef]

- Kronmüller, H.; Fischer, R.; Hertel, R.; Leineweber, T. Micromagnetism and the microstructure in nanocrystalline materials. J. Magn. Magn. Mater. 1997, 175, 177–192. [Google Scholar] [CrossRef]

- Vega, V.; Böhnert, T.; Martens, S.; Waleczek, M.; Montero-Moreno, J.M.; Görlitz, D.; Prida, V.M.; Nielsch, K. Tuning the magnetic anisotropy of Co–Ni nanowires: Comparison between single nanowires and nanowire arrays in hard-anodic aluminum oxide membranes. Nanotechnology 2012, 23, 465709. [Google Scholar] [CrossRef] [PubMed]

- Fernandez-Roldan, J.A.; Perez del Real, R.; Bran, C.; Vazquez, M.; Chubykalo-Fesenko, O. Magnetization pinning in modulated nanowires: From topological protection to the “corkscrew” mechanism. Nanoscale 2018, 10, 5923–5927. [Google Scholar] [CrossRef] [PubMed]

- Sellmyer, D.J.; Zheng, M.; Skomski, R. Magnetism of Fe, Co and Ni nanowires in self-assembled arrays. J. Phys. Condens. Matter 2001, 13, R433–R460. [Google Scholar] [CrossRef]

- Fernandez-Roldan, J.A.; Ivanov, Y.P.; Chubykalo-Fesenko, O. Micromagnetic modeling of magnetic domain walls and domains in cylindrical nanowires. In Magnetic Nano- and Microwires; Woodhead Publishing: Amsterdam, The Netherlands, 2020; pp. 403–426. [Google Scholar] [CrossRef]

- Hertel, R. Computational micromagnetism of magnetization processes in nickel nanowires. J. Magn. Magn. Mater. 2002, 249, 251–256. [Google Scholar] [CrossRef]

- Forster, H.; Schrefl, T.; Suess, D.; Scholz, W.; Tsiantos, V.; Dittrich, R.; Fidler, J. Domain wall motion in nanowires using moving grids (invited). J. Appl. Phys. 2002, 91, 6914. [Google Scholar] [CrossRef]

- Ferguson, C.A.; Maclaren, D.A.; McVitie, S. Metastable magnetic domain walls in cylindrical nanowires. J. Magn. Magn. Mater. 2015. [Google Scholar] [CrossRef]

- Ivanov, Y.P.; Trabada, D.G.; Chuvilin, A.; Kosel, J.; Chubykalo-Fesenko, O.; Vázquez, M. Crystallographically driven magnetic behaviour of arrays of monocrystalline Co nanowires. Nanotechnology 2014, 25, 475702. [Google Scholar] [CrossRef]

- Talapatra, S.; Tang, X.; Padi, M.; Kim, T.; Vajtai, R.; Sastry, G.V.S.; Shima, M.; Deevi, S.C.; Ajayan, P.M. Synthesis and characterization of cobalt-nickel alloy nanowires. J. Mater. Sci. 2009, 44, 2271–2275. [Google Scholar] [CrossRef]

- Pereira, A.; Palma, J.L.; Vázquez, M.; Denardin, J.C.; Escrig, J. A soft/hard magnetic nanostructure based on multisegmented CoNi nanowires. Phys. Chem. Chem. Phys. 2015. [Google Scholar] [CrossRef]

- Liébana Viñas, S.; Salikhov, R.; Bran, C.; Palmero, E.M.; Vazquez, M.; Arvan, B.; Yao, X.; Toson, P.; Fidler, J.; Spasova, M.; et al. Magnetic hardening of Fe30Co70 nanowires. Nanotechnology 2015, 26. [Google Scholar] [CrossRef]

- Escrig, J.; Altbir, D.; Jaafar, M.; Navas, D.; Asenjo, A.; Vázquez, M. Remanence of Ni nanowire arrays: Influence of size and labyrinth magnetic structure. Phys. Rev. B 2007, 75, 184429. [Google Scholar] [CrossRef]

- Fernández-Pacheco, A.; Streubel, R.; Fruchart, O.; Hertel, R.; Fischer, P.; Cowburn, R.P. Three-dimensional nanomagnetism. Nat. Commun. 2017, 8, 15756. [Google Scholar] [CrossRef] [PubMed]

- Torrejon, J.; Raposo, V.; Martinez, E.; del Real, R.P.; Hayashi, M. Current-induced dynamics of chiral domain walls in magnetic heterostructures. In Magnetic Nano- and Microwires, 2nd ed.; Vázquez, M., Ed.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 297–324. ISBN 978-0-08-102832-2. [Google Scholar]

- Méndez, M.; Vega, V.; González, S.; Caballero-Flores, R.; García, J.; Prida, V. Effect of Sharp Diameter Geometrical Modulation on the Magnetization Reversal of Bi-Segmented FeNi Nanowires. Nanomaterials 2018, 8, 595. [Google Scholar] [CrossRef] [PubMed]

- Biziere, N.; Gatel, C.; Lassalle-Balier, R.; Clochard, M.C.; Wegrowe, J.E.; Snoeck, E. Imaging the Fine Structure of a Magnetic Domain Wall in a Ni Nanocylinder. Nano Lett. 2013, 13, 2053–2057. [Google Scholar] [CrossRef] [PubMed]

- Andersen, I.M.; Rodríguez, L.A.; Bran, C.; Marcelot, C.; Joulie, S.; Hungria, T.; Vazquez, M.; Gatel, C.; Snoeck, E. Exotic Transverse-Vortex Magnetic Configurations in CoNi Nanowires. ACS Nano 2019. [Google Scholar] [CrossRef]

- Berganza, E.; Bran, C.; Jaafar, M.; Vazquez, M.; Asenjo, A. Domain wall pinning in FeCoCu bamboo-like nanowires. Sci. Rep. 2016, 6. [Google Scholar] [CrossRef]

- Nasirpouri, F.; Peighambari-Sattari, S.-M.; Bran, C.; Palmero, E.M.; Berganza Eguiarte, E.; Vazquez, M.; Patsopoulos, A.; Kechrakos, D. Geometrically designed domain wall trap in tri-segmented nickel magnetic nanowires for spintronics devices. Sci. Rep. 2019, 9. [Google Scholar] [CrossRef]

- Palmero, E.M.; Méndez, M.; González, S.; Bran, C.; Vega, V.; Vázquez, M.; Prida, V.M. Stepwise magnetization reversal of geometrically tuned in diameter Ni and FeCo bi-segmented nanowire arrays. Nano Res. 2019, 12, 1547–1553. [Google Scholar] [CrossRef]

- Pitzschel, K.; Montero Moreno, J.M.; Escrig, J.; Albrecht, O.; Nielsch, K.; Bachmann, J. Controlled Introduction of Diameter Modulations in Arrayed Magnetic Iron Oxide Nanotubes. ACS Nano 2009, 3, 3463–3468. [Google Scholar] [CrossRef] [PubMed]

- Rotaru, A.; Lim, J.-H.; Lenormand, D.; Diaconu, A.; Wiley, J.B.; Postolache, P.; Stancu, A.; Spinu, L. Interactions and reversal-field memory in complex magnetic nanowire arrays. Phys. Rev. B 2011, 84, 13443. [Google Scholar] [CrossRef]

- Arrott, A.S. Visualization and Interpretation of Magnetic Configurations Using Magnetic Charge. IEEE Magn. Lett. 2016, 7, 1–5. [Google Scholar] [CrossRef]

- Ruiz-Gómez, S.; Foerster, M.; Aballe, L.; Proenca, M.P.; Lucas, I.; Prieto, J.L.; Mascaraque, A.; de la Figuera, J.; Quesada, A.; Pérez, L. Observation of a topologically protected state in a magnetic domain wall stabilized by a ferromagnetic chemical barrier. Sci. Rep. 2018, 8. [Google Scholar] [CrossRef]

- Ruiz-Gómez, S.; Fernández-González, C.; Martínez, E.; Raposo, V.; Sorrentino, A.; Foerster, M.; Aballe, L.; Mascaraque, A.; Ferrer, S.; Pérez, L. Helical surface magnetization in nanowires: The role of chirality. Nanoscale 2020, 12, 17880–17885. [Google Scholar] [CrossRef]

- Chizhik, A.; Zhukov, A.; Gonzalez, J.; Gawroński, P.; Kułakowski, K.; Stupakiewicz, A. Spiral magnetic domain structure in cylindrically-shaped microwires. Sci. Rep. 2018, 8, 15090. [Google Scholar] [CrossRef]

- Méndez, M.; González, S.; Vega, V.; Teixeira, J.; Hernando, B.; Luna, C.; Prida, V. Ni-Co Alloy and Multisegmented Ni/Co Nanowire Arrays Modulated in Composition: Structural Characterization and Magnetic Properties. Crystals 2017, 7, 66. [Google Scholar] [CrossRef]

- Bran, C.; Berganza, E.; Fernandez-Roldan, J.A.; Palmero, E.M.; Meier, J.; Calle, E.; Jaafar, M.; Foerster, M.; Aballe, L.; Fraile Rodriguez, A.; et al. Magnetization Ratchet in Cylindrical Nanowires. ACS Nano 2018, 12, 5932–5939. [Google Scholar] [CrossRef] [PubMed]

- Palmero, E.M.; Bran, C.; Del Real, R.P.; Magén, C.; Vázquez, M. Structural and magnetic characterization of FeCoCu/Cu multilayer nanowire arrays. IEEE Magn. Lett. 2014, 5, 14–17. [Google Scholar] [CrossRef]

- Proenca, M.P.; Muñoz, M.; Villaverde, I.; Migliorini, A.; Raposo, V.; Lopez-Diaz, L.; Martinez, E.; Prieto, J.L. Deterministic and time resolved thermo-magnetic switching in a nickel nanowire. Sci. Rep. 2019, 9. [Google Scholar] [CrossRef]

- Fernandez-Roldan, J.A.; Del Real, R.P.; Bran, C.; Vazquez, M.; Chubykalo-Fesenko, O. Electric current and field control of vortex structures in cylindrical magnetic nanowires. Phys. Rev. B 2020, 102, 1–6. [Google Scholar] [CrossRef]

- Sánchez-Barriga, J.; Lucas, M.; Radu, F.; Martin, E.; Multigner, M.; Marin, P.; Hernando, A.; Rivero, G. Interplay between the magnetic anisotropy contributions of cobalt nanowires. Phys. Rev. B 2009, 80, 184424. [Google Scholar] [CrossRef]

- Vivas, L.G.; Escrig, J.; Trabada, D.G.; Badini-Confalonieri, G.A.; Vázquez, M. Magnetic anisotropy in ordered textured Co nanowires. Appl. Phys. Lett. 2012, 100, 252405. [Google Scholar] [CrossRef]

- Vivas, L.G.; Yanes, R.; Chubykalo-Fesenko, O.; Vazquez, M. Coercivity of ordered arrays of magnetic Co nanowires with controlled variable lengths. Appl. Phys. Lett. 2011, 98, 232507. [Google Scholar] [CrossRef]

- Ivanov, Y.P.; Chuvilin, A.; Lopatin, S.; Kosel, J. Modulated Magnetic Nanowires for Controlling Domain Wall Motion: Toward 3D Magnetic Memories. ACS Nano 2016. [Google Scholar] [CrossRef] [PubMed]

- Bran, C.; Fernandez-Roldan, J.A.; P Del Real, R.; Asenjo, A.; Chen, Y.-S.; Zhang, J.; Zhang, X.; Fraile Rodríguez, A.; Foerster, M.; Aballe, L.; et al. Unveiling the Origin of Multidomain Structures in Compositionally Modulated Cylindrical Magnetic Nanowires. ACS Nano 2020, 14. [Google Scholar] [CrossRef] [PubMed]

- Moreno, J.A.; Mohammed, H.; Kosel, J. Effect of Segment length on domain wall pinning in multisegmented Co/Ni nanowires for 3D memory applications. J. Magn. Magn. Mater. 2019, 484, 110–113. [Google Scholar] [CrossRef]

- Berganza, E.; Jaafar, M.; Bran, C.; Fernández-Roldán, J.A.; Chubykalo-Fesenko, O.; Vázquez, M.; Asenjo, A. Multisegmented Nanowires: A Step towards the Control of the Domain Wall Configuration. Sci. Rep. 2017, 7, 11576. [Google Scholar] [CrossRef] [PubMed]

| Material | Electrolyte | Voltage |

|---|---|---|

| (1) Fe30Co65Cu5 [24] | 0.05 M FeSO4·7H2O, 0.12 M CoSO4·7H2O, 0.16 M H3BO3, 0.01 M CuSO4·5H2O, 0.06 M C6H8O6 | −1.8 |

| (2) Fe50Co50 [24] | 0.08 M CoSO4∙7H2O, 0.08 M FeSO4∙7H2O, 0.16 M H3BO3, 0.06 M C6H8O6 | −1.8 |

| (3) Ni | 0.76 M NiSO4·6H2O, 0.17 M NiCl2·6H2O, 0.65 M H3BO3 | −1.0 |

| (4) Co65Ni35 [20] | 0.09 M CoSO4·7H2O + 0.063 M CoCl2·6H2O +0.095 M NiSO4·7H2O + 0.084 M NiCl2·6H2O + 0.32 M H3BO3 | −1.1 |

| (5) Co85Ni15 [20] | 0.12 M CoSO4·7H2O + 0.084 M CoCl2·6H2O + 0.064 M NiSO4·7H2O + 0.063 M NiCl2·6H2O + 0.32 M H3BO3 | −1.2 |

| Material | μoMs (T) | Aex (pJ/m) | lex (nm) | Crystal Symmetry | K1 (kJ m−3) | Magnetization Easy Axis (e.a.) |

|---|---|---|---|---|---|---|

| Fe20Ni80 [34] | 1.0 | 10.8 | 5.2 | - | 0 | - |

| Co(111) [34] | 1.76 | 13.0 | 3.3 | Cubic | −75 | parallel to nanowire axis |

| Co(100) [34] | 1.76 | 13.0 | 3.3 | Uniaxial | 450 | e.a. at 75°–88° with nanowire axis |

| Co-hcp [34,35] | 1.76 | 30.0 | 4.9 | Uniaxial | 450 | e.a. at 75°–88° with nanowire axis |

| Fe30Co70 [36] | 2.0 | 10.7 | 2.6 | Cubic | 10 | polycrystalline textured, e.a. at 45° vs. nanowire axis * |

| Ni(111) [34] | 0.61 | 3.4 | 4.8 | Cubic | −4.8 | parallel to nanowire axis |

| Co85Ni15 [20,35,37,38] | 1.60 | 26.0 | 5.1 | Uniaxial ** | 350 | e.a. at 65–88° with nanowire axis |

| Co65Ni35 [20,35,37,38] | 1.35 | 15.0 | 4.5 | Uniaxial ** | 260 | e.a. at 65° with nanowire axis |

| Co35Ni65 [20,35,37,38] | 1.01 | 10.0 | 5.0 | Cubic | 2 | parallel to nanowire axis |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bran, C.; Fernandez-Roldan, J.A.; del Real, R.P.; Asenjo, A.; Chubykalo-Fesenko, O.; Vazquez, M. Magnetic Configurations in Modulated Cylindrical Nanowires. Nanomaterials 2021, 11, 600. https://doi.org/10.3390/nano11030600

Bran C, Fernandez-Roldan JA, del Real RP, Asenjo A, Chubykalo-Fesenko O, Vazquez M. Magnetic Configurations in Modulated Cylindrical Nanowires. Nanomaterials. 2021; 11(3):600. https://doi.org/10.3390/nano11030600

Chicago/Turabian StyleBran, Cristina, Jose Angel Fernandez-Roldan, Rafael P. del Real, Agustina Asenjo, Oksana Chubykalo-Fesenko, and Manuel Vazquez. 2021. "Magnetic Configurations in Modulated Cylindrical Nanowires" Nanomaterials 11, no. 3: 600. https://doi.org/10.3390/nano11030600

APA StyleBran, C., Fernandez-Roldan, J. A., del Real, R. P., Asenjo, A., Chubykalo-Fesenko, O., & Vazquez, M. (2021). Magnetic Configurations in Modulated Cylindrical Nanowires. Nanomaterials, 11(3), 600. https://doi.org/10.3390/nano11030600