Molecular Dynamics Simulation of Laser Induced Heating of Silicon Dioxide Thin Films

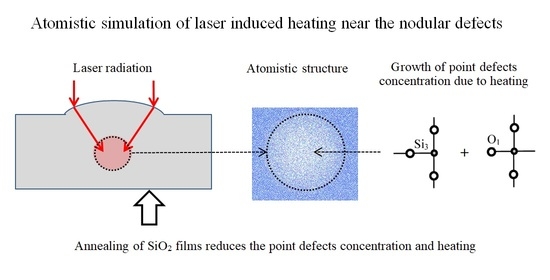

Abstract

:1. Introduction

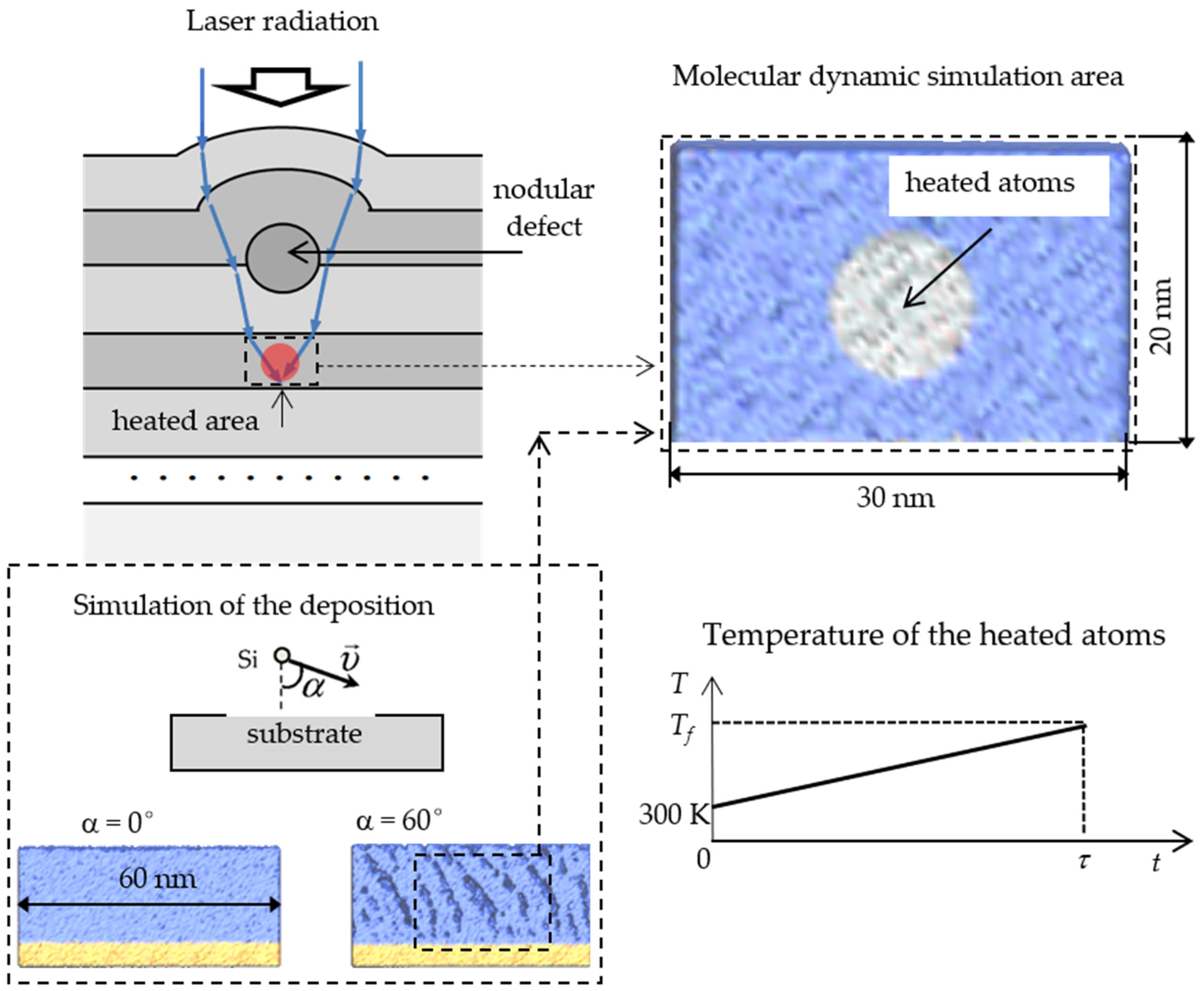

2. Simulation Method

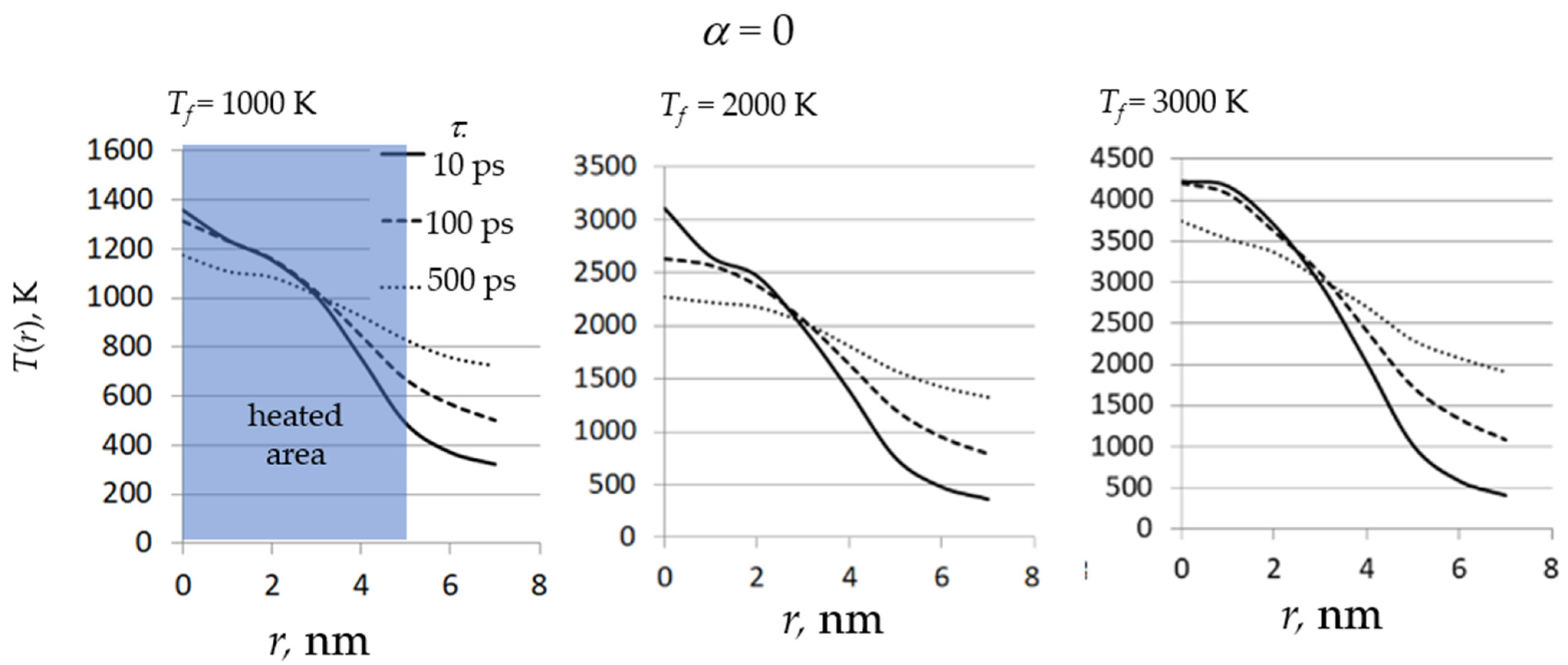

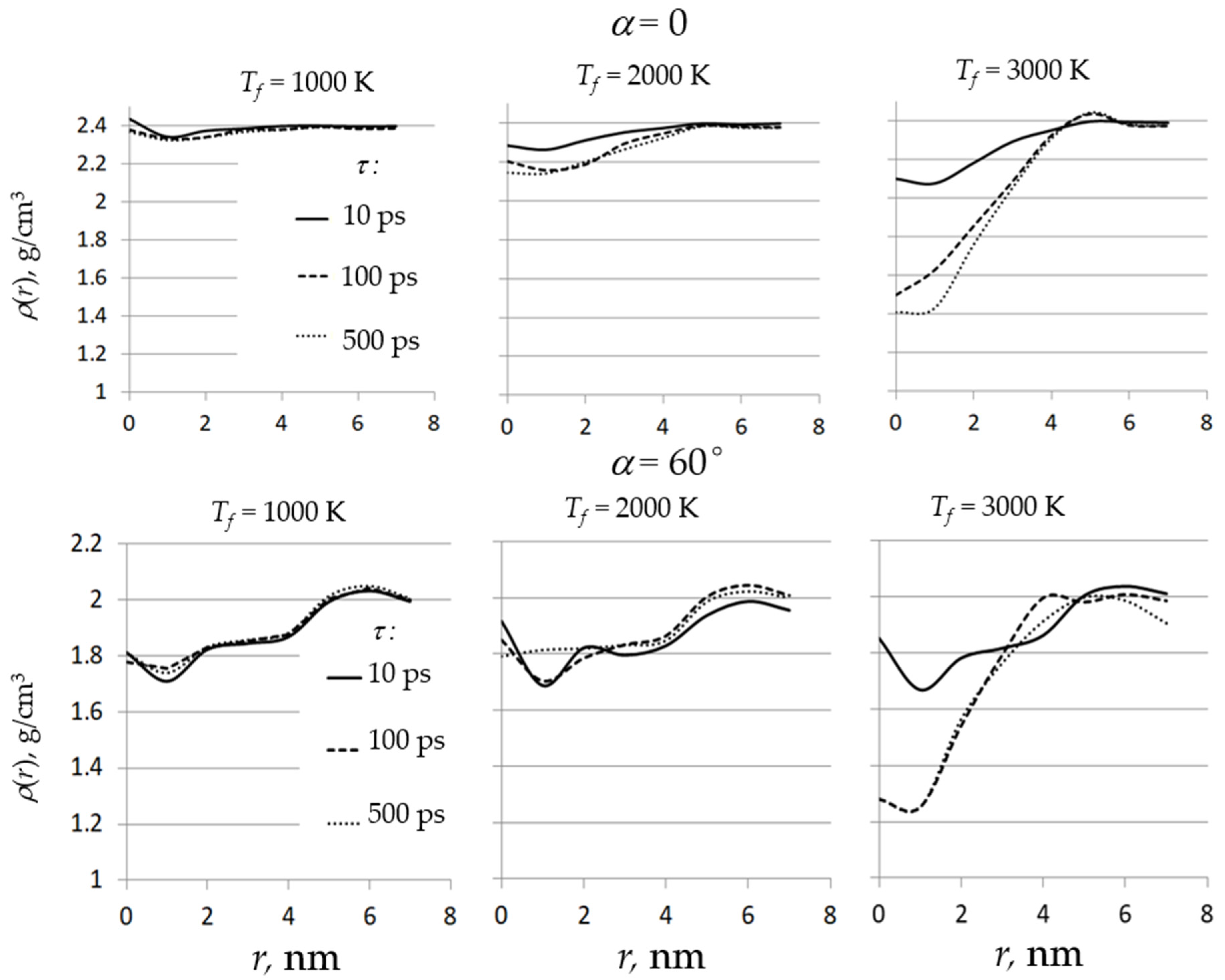

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Manenkov, A.A. Fundamental mechanisms of laser-induced damage in optical materials: Today’s state of understanding and problems. Opt. Eng. 2014, 53, 010901. [Google Scholar] [CrossRef]

- Gallais, L.; Douti, D.-B.; Commandré, M.; Batavičiūtė, G.; Pupka, E.; Ščiuka, M.; Smalakys, L.; Sirutkaitis, V.; Melninkaitis, A. Wavelength dependence of femtosecond laser-induced damage threshold of optical materials. J. Appl. Phys. 2015, 117, 223103. [Google Scholar] [CrossRef] [Green Version]

- Velpula, P.K.; Kramer, D.; Rus, B. Femtosecond Laser-Induced Damage Characterization of Multilayer Dielectric Coatings. Coatings 2020, 10, 603. [Google Scholar] [CrossRef]

- Chorel, M. Study of High Damage Threshold Optical Coatings Used in Environment with Very Low Hygrometry for Fusion Class Laser System. Optics/Photonic. Ph.D. Thesis, Université de Bordeaux, Bordeaux, France, 2019. (In English). [Google Scholar]

- Kozlowski, M.R.; Chow, R. Role of defects in laser damage of multilayer coatings. In Proceedings of the Volume 2114, Laser-Induced Damage in Optical Materials: 1993, Boulder, CO, USA, 28 July 1994. [Google Scholar] [CrossRef] [Green Version]

- Papernov, S. Laser-Induced Damage in Optical Materials, Chapter Defect-Induced Damage; CRC Press: Boca Raton, FL, USA, 2015; pp. 25–75. [Google Scholar]

- Yang, H.; Cheng, J.; Liu, Z.; Liu, Q.; Zhao, L.; Wang, J.; Chen, M. Dynamic behavior modeling of laser-induced damage initiated by surface defects on KDP crystals under nanosecond laser irradiation. Sci. Rep. 2020, 10, 500. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, M.; Ding, W.; Cheng, J.; Yang, H.; Liu, Q. Recent Advances in Laser-Induced Surface Damage of KH2PO4 Crystal. Appl. Sci. 2020, 10, 6642. [Google Scholar] [CrossRef]

- Rouquette, P.; Amra, C.; Zerrad, M.; Grèzes-Besset, C. Photo-induced thermal radiation within multilayers optics. In Proceedings of the SPIE 11872, Advances in Optical Thin Films VII, Online, 12 September 2021. [Google Scholar] [CrossRef]

- Klein, D.; Eisfeld, E.; Roth, J. Molecular dynamics simulations of the laser ablation of silicon with the thermal spike model. J. Phys. D Appl. Phys. 2021, 54, 015103. [Google Scholar] [CrossRef]

- Wang, X.; Xu, X. Molecular Dynamics Simulation of Heat Transfer and Phase Change During Laser Material Interaction. J. Heat Transf. 2002, 124, 265–274. [Google Scholar] [CrossRef]

- Huang, C.; Cheng, Y.; Yin, H.; Wei, F. Molecular dynamics simulation of laser-induced interconnections of silver nanowires. Ferroelectrics 2020, 564, 91–101. [Google Scholar] [CrossRef]

- Dubost, L.; Rhallabi, A.; Perrin, J.; Schmitt, J. Growth of nodular defects during film deposition. J. Appl. Phys. 1995, 78, 3784. [Google Scholar] [CrossRef]

- Panjan, P.; Drnovšek, A.; Gselman, P.; Cekada, M.; Panjan, M. Review of Growth Defects in Thin Films Prepared by PVD Techniques. Coatings 2020, 10, 447. [Google Scholar] [CrossRef]

- Liu, X.; Li, D.; Zhao, Y.; Li, X. Further investigation of the characteristics of nodular defects. Appl. Opt. 2010, 49, 1774–1779. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ma, H.; Cheng, X.; Zhang, J.; Jiao, H.; Ma, B.; Tang, Y.; Wu, Z.; Wang, Z. Effect of boundary continuity on nanosecond laser damage of nodular defects in high-reflection coatings. Opt. Lett. 2017, 42, 478–481. [Google Scholar] [CrossRef] [PubMed]

- Stolz, C.J.; Feigenbaum, E. Impact of high refractive coating material on the nodular-induced electric field enhancement for near infrared multilayer mirrors. Appl. Opt. 2020, 59, A20–A25. [Google Scholar] [CrossRef]

- Stolz, C.J.; Negres, R.A. Ten-year summary of the Boulder Damage Symposium annual thin film laser damage competition. Opt. Eng. 2018, 57, 121910. [Google Scholar] [CrossRef]

- Milward, J.R.; Lewis, K.L.; Pitt, A.M.; Kirton, J.; Overend, R.B.; Gibson, D.R.; Leonard, J.; Hendry, A. Laser damage issues for mid-IR optical parametric oscillator mirrors. In Proceedings of the SPIE 2114, Laser-Induced Damage in Optical Materials: 1993, Boulder, CO, USA, 28 July 1994. [Google Scholar] [CrossRef]

- Leko, V.K.; Mazurin, O.V. Properties of Quartz Glass; Nauka: Leningrad, Russian, 1985. (In Russian) [Google Scholar]

- Grigoriev, F.V.; Sulimov, A.V.; Kochikov, I.V.; Kondakova, O.A.; Sulimov, V.B.; Tikhonravov, A.V. Supercomputer modeling of the ion beam sputtering process: Full-atomistic level. In Proceedings of the SPIE—The International Society for Optical Engineering, Jena, Germany, 23 September 2015; Volume 9627. [Google Scholar] [CrossRef]

- Berendsen, H.J.C.; Postma, J.P.M.; van Gunsteren, W.F.; DiNola, A.; Haak, J.R. Molecular-Dynamics with Coupling to an External Bath. J. Chem. Phys. 1984, 81, 3684–3690. [Google Scholar] [CrossRef] [Green Version]

- Grigoriev, F.V.; Sulimov, V.B.; Tikhonravov, A.V. Atomistic simulation of the glancing angle deposition of SiO2 thin films. J. Non-Cryst. Solids 2019, 512, 98–102. [Google Scholar] [CrossRef]

- Grigoriev, F.V.; Sulimov, V.B.; Tikhonravov, A.V. Structure of Highly Porous Silicon Dioxide Thin Film: Results of Atomistic Simulation. Coatings 2019, 9, 568–576. [Google Scholar] [CrossRef] [Green Version]

- Grigoriev, F.V.; Sulimov, V.B.; Tikhonravov, A.V. Laser-Induced Thermal Stresses in Dense and Porous Silicon Dioxide Films. Coatings 2020, 11, 394. [Google Scholar] [CrossRef]

- Robbie, K.; Brett, M.J.; Lakhtakia, A. Chiral sculptured thin films. Nature 1996, 384, 616. [Google Scholar] [CrossRef]

- Abraham, M.J.; Murtola, T.; Schulz, R.; Páll, S.; Smith, J.C.; Hess, B.; Lindahl, E. GROMACS: High performance molecular simulations through multi-level parallelism from laptops to supercomputers. SoftwareX 2015, 1–2, 19–25. [Google Scholar] [CrossRef] [Green Version]

- Voevodin, V.L.; Antonov, A.; Nikitenko, D.; Shvets, P.; Sobolev, S.; Sidorov, I.; Stefanov, K.; Voevodin, V.; Zhumatiy, S. Supercomputer Lomonosov-2: Large Scale, Deep Monitoring and Fine Analytics for the User Community. Supercomput. Front. Innov. 2019, 6, 4–11. [Google Scholar] [CrossRef] [Green Version]

- Taniguchi, K.; Tanaka, M.; Hamaguchi, C.; Imai, K. Density relaxation of silicon dioxide on (100) silicon during thermal annealing. J. Appl. Phys. 1990, 67, 2195–2198. [Google Scholar] [CrossRef]

- Perry, D.L. Handbook of Inorganic Compounds; CRC Press: Boca Raton, FL, USA, 2016; 581p. [Google Scholar]

- Bakos, T.; Rashkeev, S.N.; Pantelides, S.T. Optically active defects in SiO2: The nonbridging oxygen center and the interstitial OH molecule. Phys. Rev. B 2004, 70, 075203. [Google Scholar] [CrossRef]

- Skuja, L. Optically active oxygen-deficiency-related centers in amorphous silicon dioxide. J. Non-Cryst. Solids 1998, 239, 16–48. [Google Scholar] [CrossRef]

- Grigoriev, F.V.; Sulimov, A.V.; Katkova, E.V.; Kochikov, I.V.; Kondakova, O.A.; Sulimov, V.B.; Tikhonravov, A.V. Annealing of deposited SiO2 thin films: Full-atomistic simulation results. Opt. Mater. Express 2016, 6, 3960–3966. [Google Scholar] [CrossRef]

- Melninkaitis, A.; Grinevičiūtė, L.; Abromavičius, G.; Mažulė, L.; Smalakys, L.; Pupka, E.; Ščiuka, M.; Buzelis, R.; Kičas, S.; Tolenis, T. Next-generation allsilica coatings for UV applications. In Proceedings of the SPIE 10447, Laser-Induced Damage in Optical Materials, Boulder, CO, USA, 13 November 2017. [Google Scholar] [CrossRef]

- Ramalis, L.; Norkutė, U.; Buzelis, R.; Selskis, A.; Tolenis, T. Sculptured thin film based all-silica mirrors for high power lasers. In Proceedings of the SPIE 11872, Advances in Optical Thin Films VII, Online, 12 September 2021. [Google Scholar] [CrossRef]

| “As Deposited” Films | ||||||

| α | τ, ps | Defect | T0 = 300 K (before Heating) | Tf, K | ||

| 1000 | 2000 | 3000 | ||||

| 0 | 10 | c(O1) | 1.13 | 1.17 | 1.43 | 2.26 |

| c(Si3) | 0.35 | 0.32 | 0.87 | 2.50 | ||

| 100 | c(O1) | 1.16 | 1.44 | 2.70 | ||

| c(Si3) | 0.30 | 0.91 | 3.54 | |||

| 500 | c(O1) | 1.12 | 1.61 | 4.69 | ||

| c(Si3) | 0.36 | 1.62 | 7.52 | |||

| 60 | 10 | c(O1) | 2.17 | 2.20 | 3.25 | 6.35 |

| c(Si3) | 0.75 | 0.86 | 3.03 | 8.20 | ||

| 100 | c(O1) | 2.19 | 3.53 | 8.40 | ||

| c(Si3) | 0.90 | 3.82 | 12.05 | |||

| 500 | c(O1) | 2.12 | 3.32 | 11.08 | ||

| c(Si3) | 0.92 | 4.35 | 18.11 | |||

| Annealed Films | ||||||

| α | τ, ps | Defect | T0 = 300 K (before heating) | Tf, K | ||

| 1000 | 2000 | 3000 | ||||

| 0 | 10 | c(O1) | 1.04 | 1.03 | 1.88 | 4.90 |

| c(Si3) | 0.47 | 0.50 | 2.07 | 7.17 | ||

| 100 | c(O1) | 1.05 | 2.29 | 7.40 | ||

| c(Si3) | 0.50 | 2.87 | 11.38 | |||

| 500 | c(O1) | 1.04 | 2.46 | 10.48 | ||

| c(Si3) | 0.51 | 3.44 | 17.50 | |||

| 60 | 10 | c(O1) | 1.42 | 1.45 | 2.39 | 5.24 |

| c(Si3) | 0.67 | 0.92 | 2.83 | 7.57 | ||

| 100 | c(O1) | 1.36 | 2.58 | 6.99 | ||

| c(Si3) | 0.89 | 3.46 | 10.63 | |||

| 500 | c(O1) | 1.36 | 2.55 | 9.95 | ||

| c(Si3) | 0.89 | 3.72 | 16.76 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grigoriev, F.V.; Sulimov, V.B.; Tikhonravov, A.V. Molecular Dynamics Simulation of Laser Induced Heating of Silicon Dioxide Thin Films. Nanomaterials 2021, 11, 2986. https://doi.org/10.3390/nano11112986

Grigoriev FV, Sulimov VB, Tikhonravov AV. Molecular Dynamics Simulation of Laser Induced Heating of Silicon Dioxide Thin Films. Nanomaterials. 2021; 11(11):2986. https://doi.org/10.3390/nano11112986

Chicago/Turabian StyleGrigoriev, Fedor Vasilievich, Vladimir Borisovich Sulimov, and Alexander Vladimirovich Tikhonravov. 2021. "Molecular Dynamics Simulation of Laser Induced Heating of Silicon Dioxide Thin Films" Nanomaterials 11, no. 11: 2986. https://doi.org/10.3390/nano11112986

APA StyleGrigoriev, F. V., Sulimov, V. B., & Tikhonravov, A. V. (2021). Molecular Dynamics Simulation of Laser Induced Heating of Silicon Dioxide Thin Films. Nanomaterials, 11(11), 2986. https://doi.org/10.3390/nano11112986