The Controlled Compound Layer of Ni-Coated Nitrided Pure Iron

Abstract

:1. Introduction

2. Materials and Methods

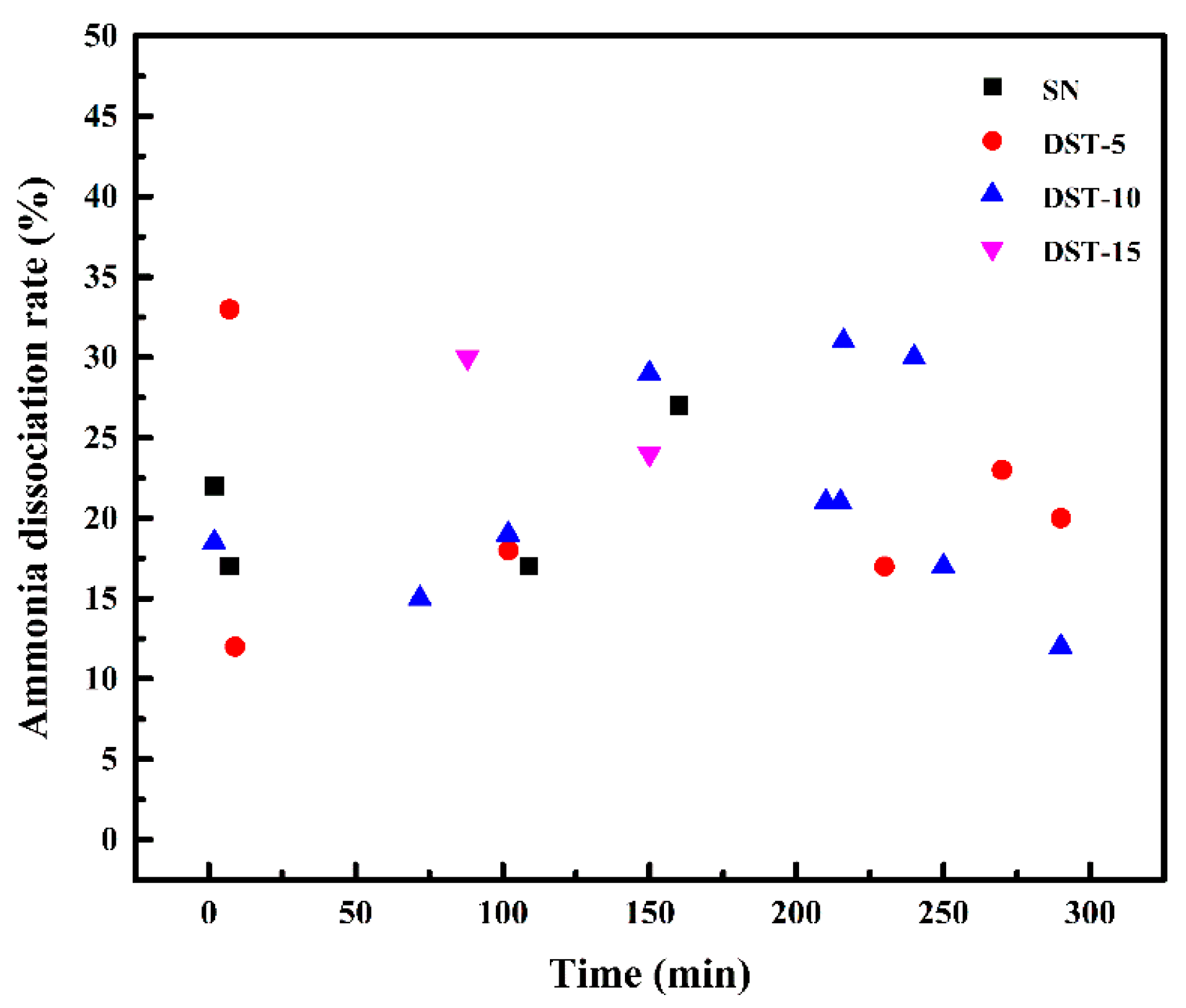

3. Results and Discussion

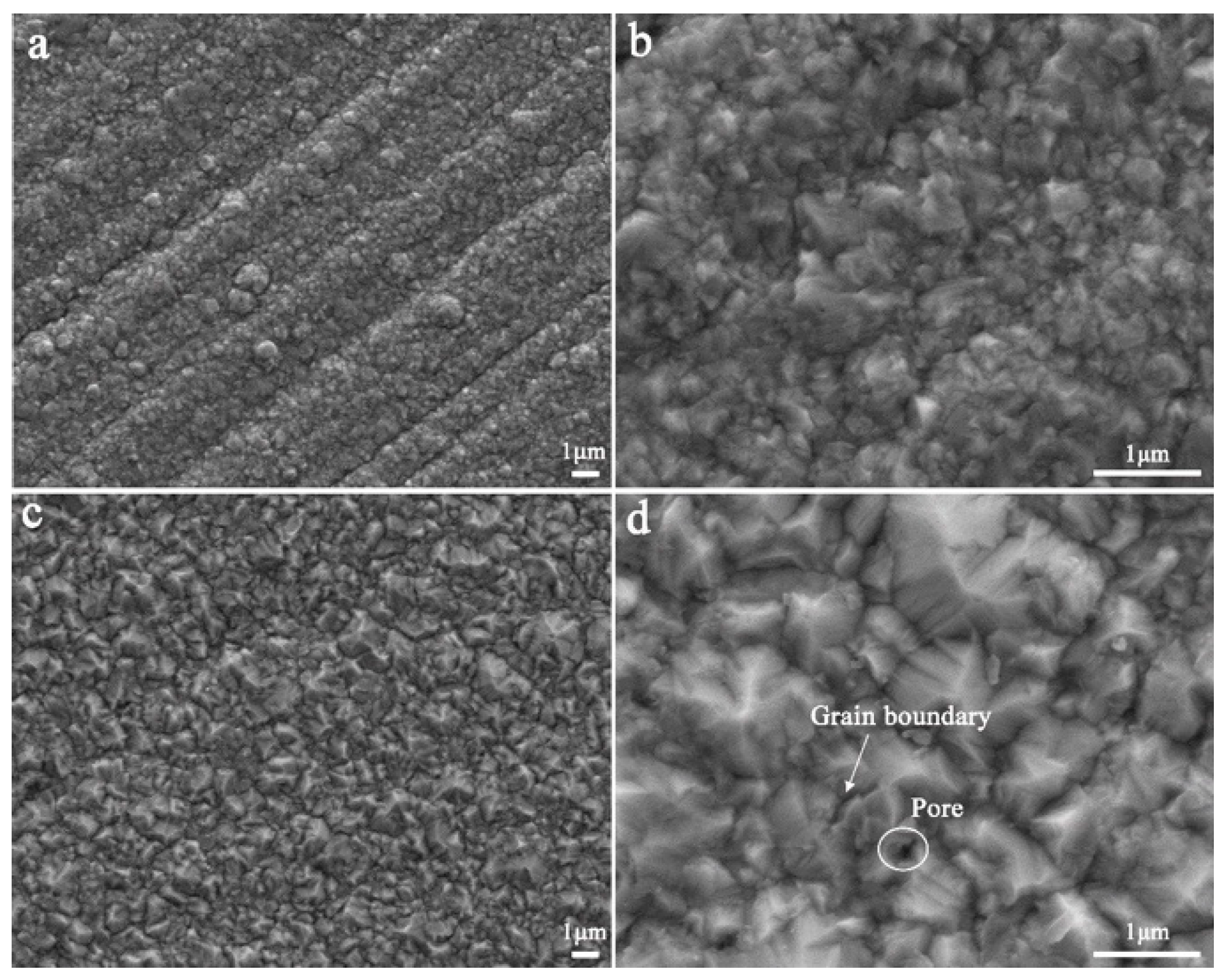

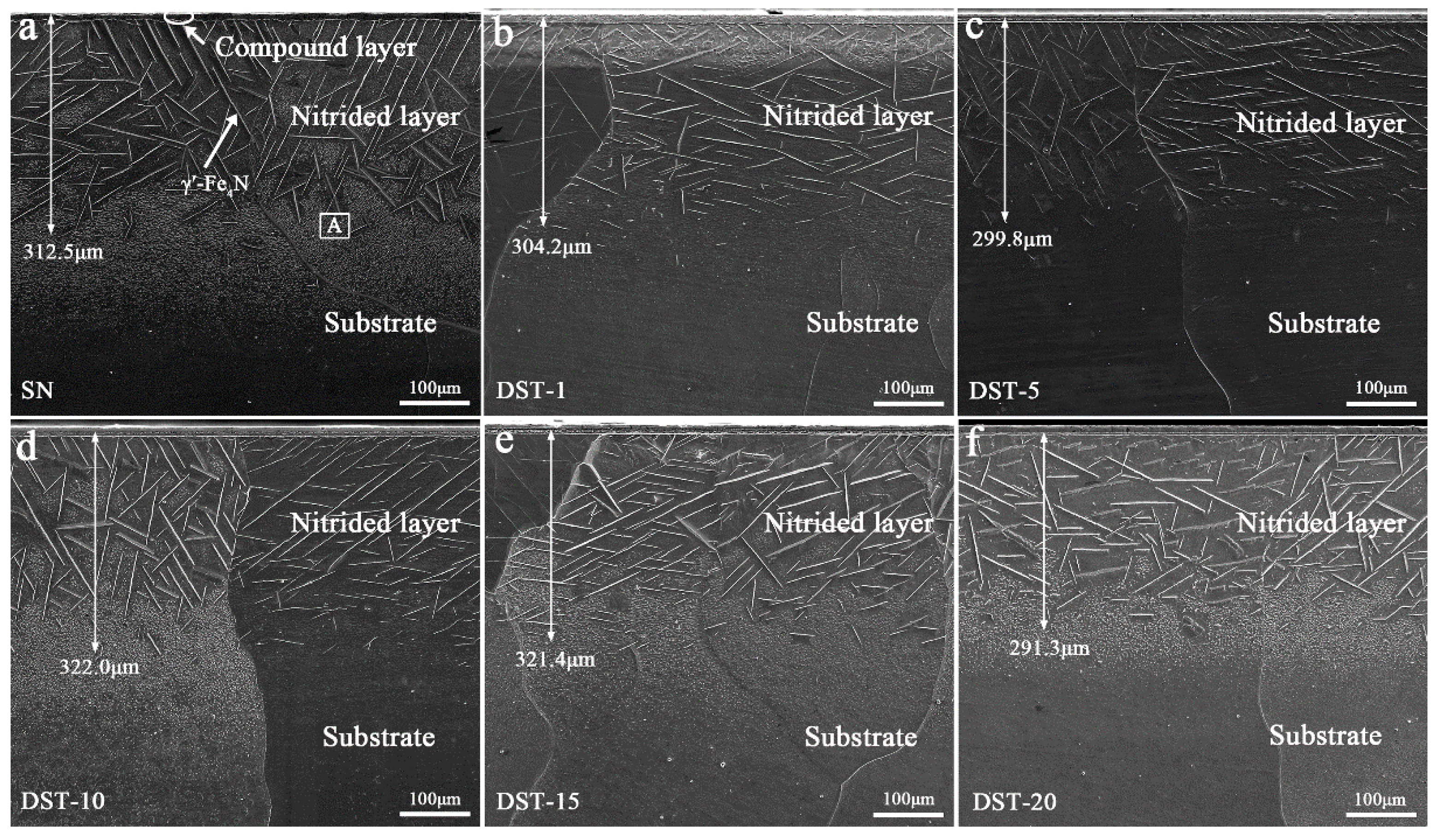

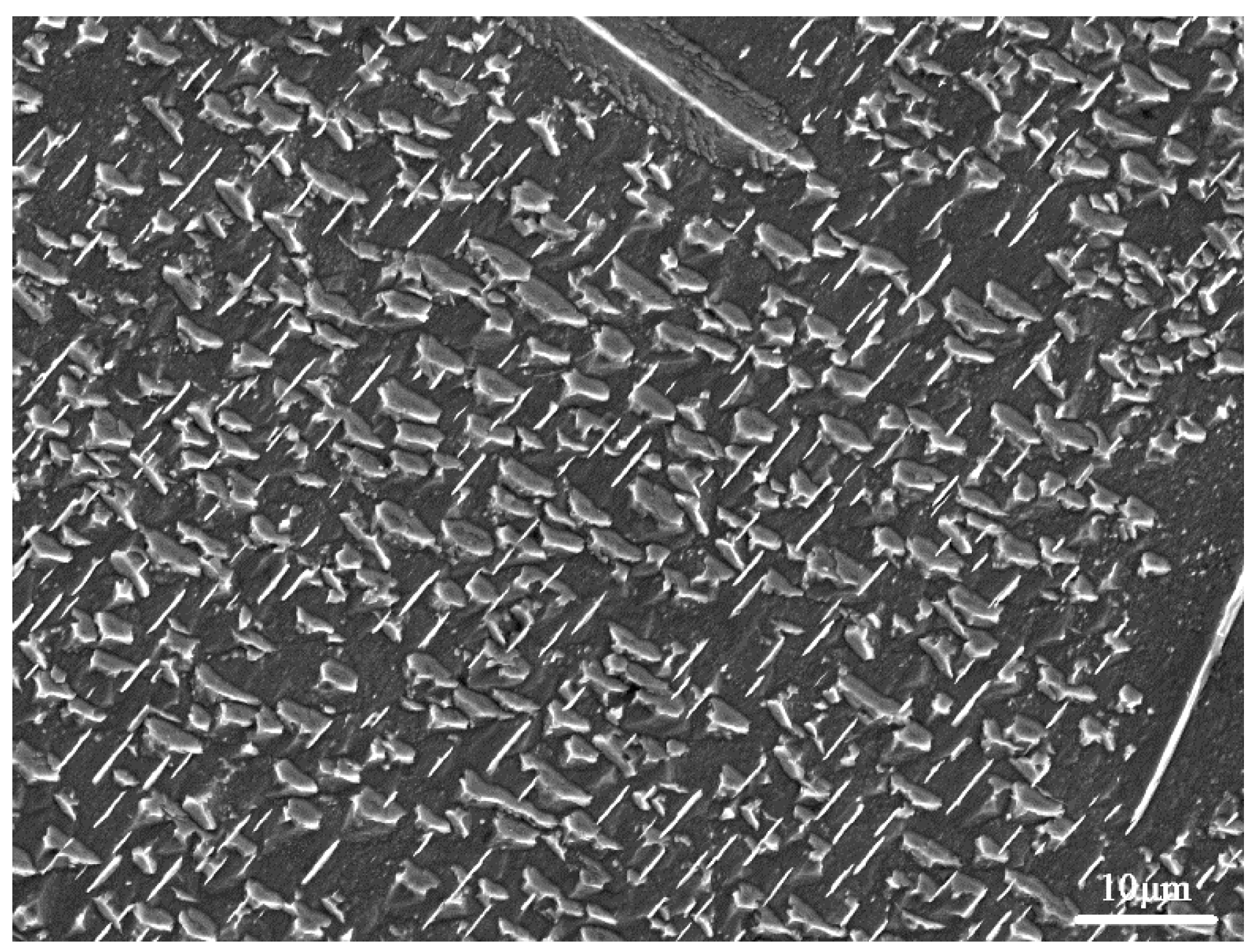

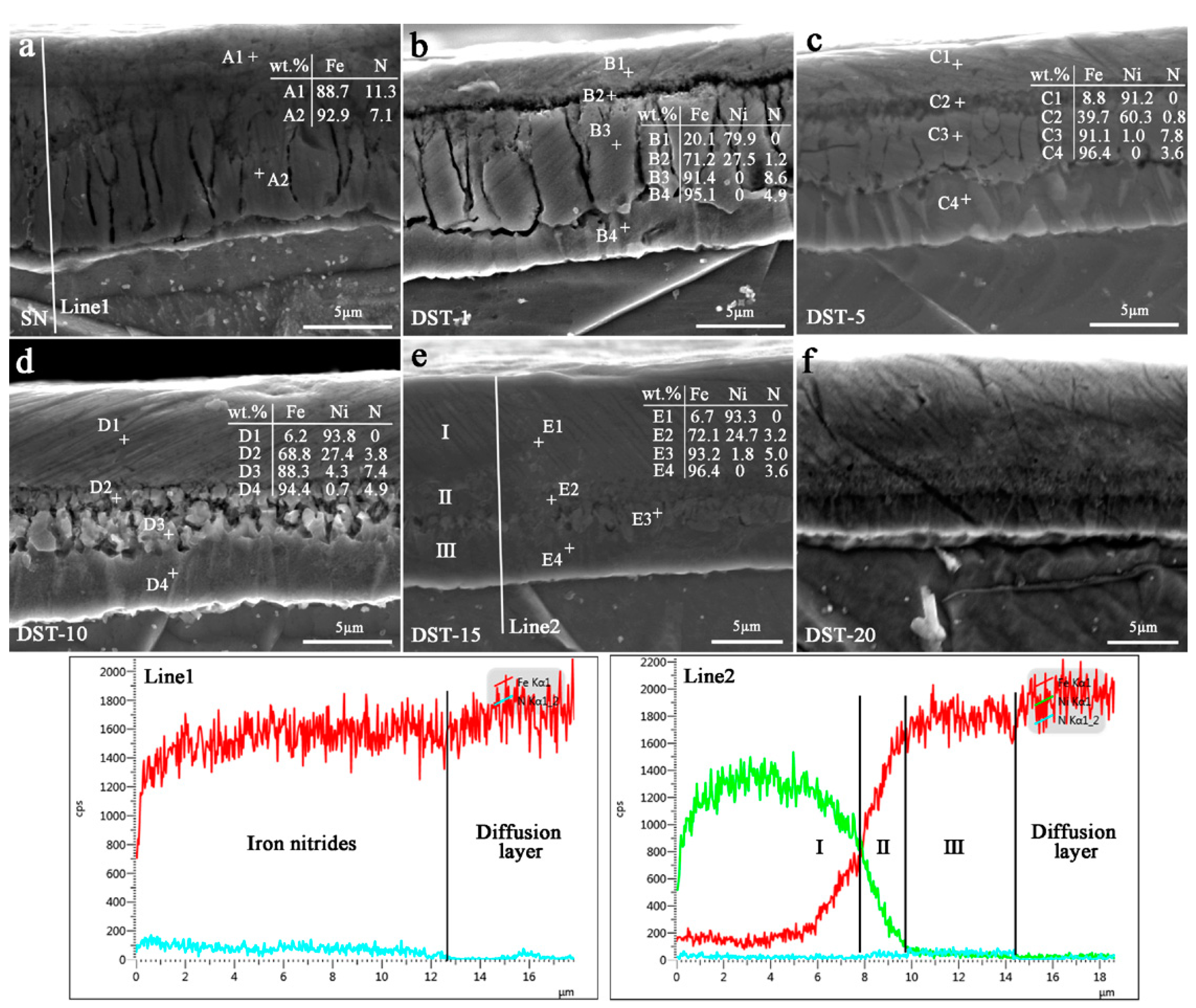

3.1. Microscopic Morphology

3.2. Phase Analysis

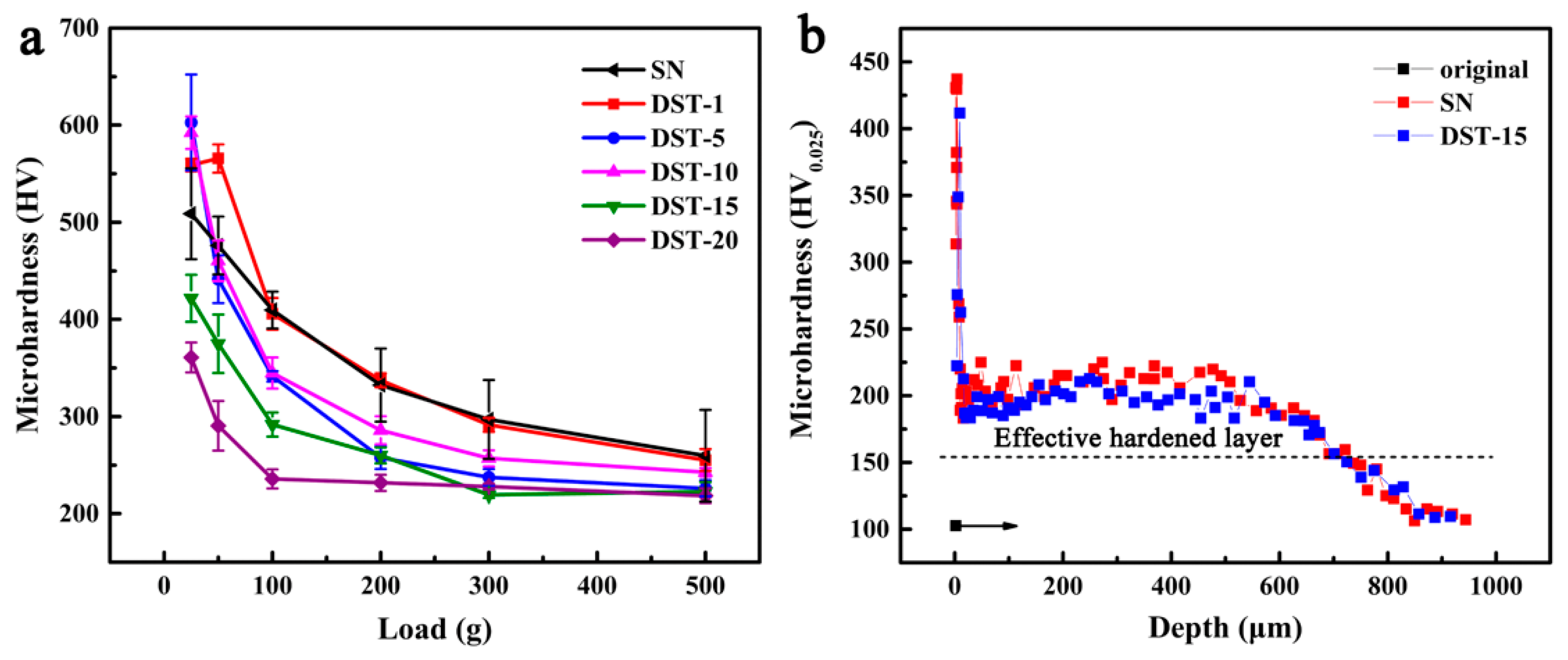

3.3. Microhardness

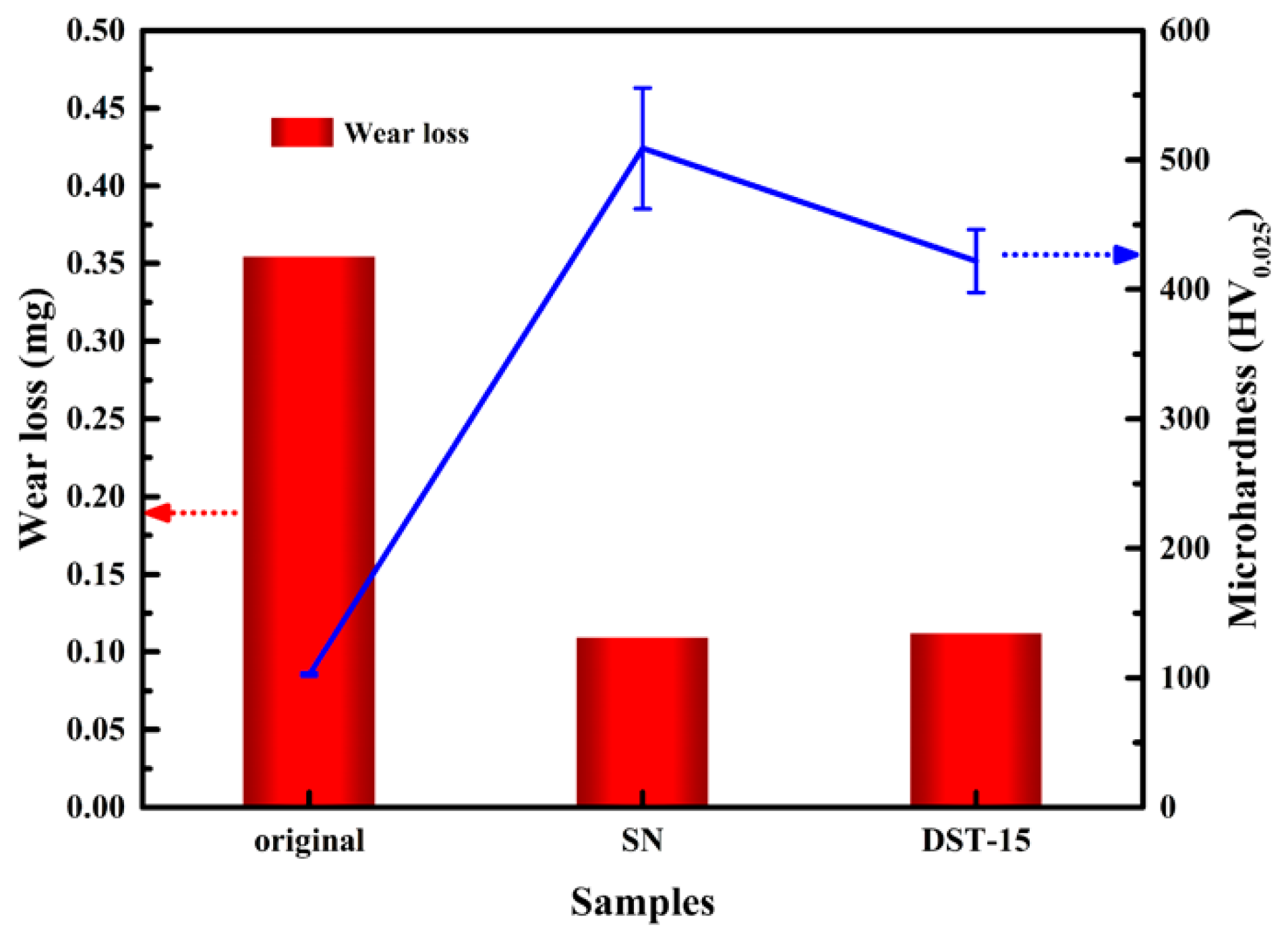

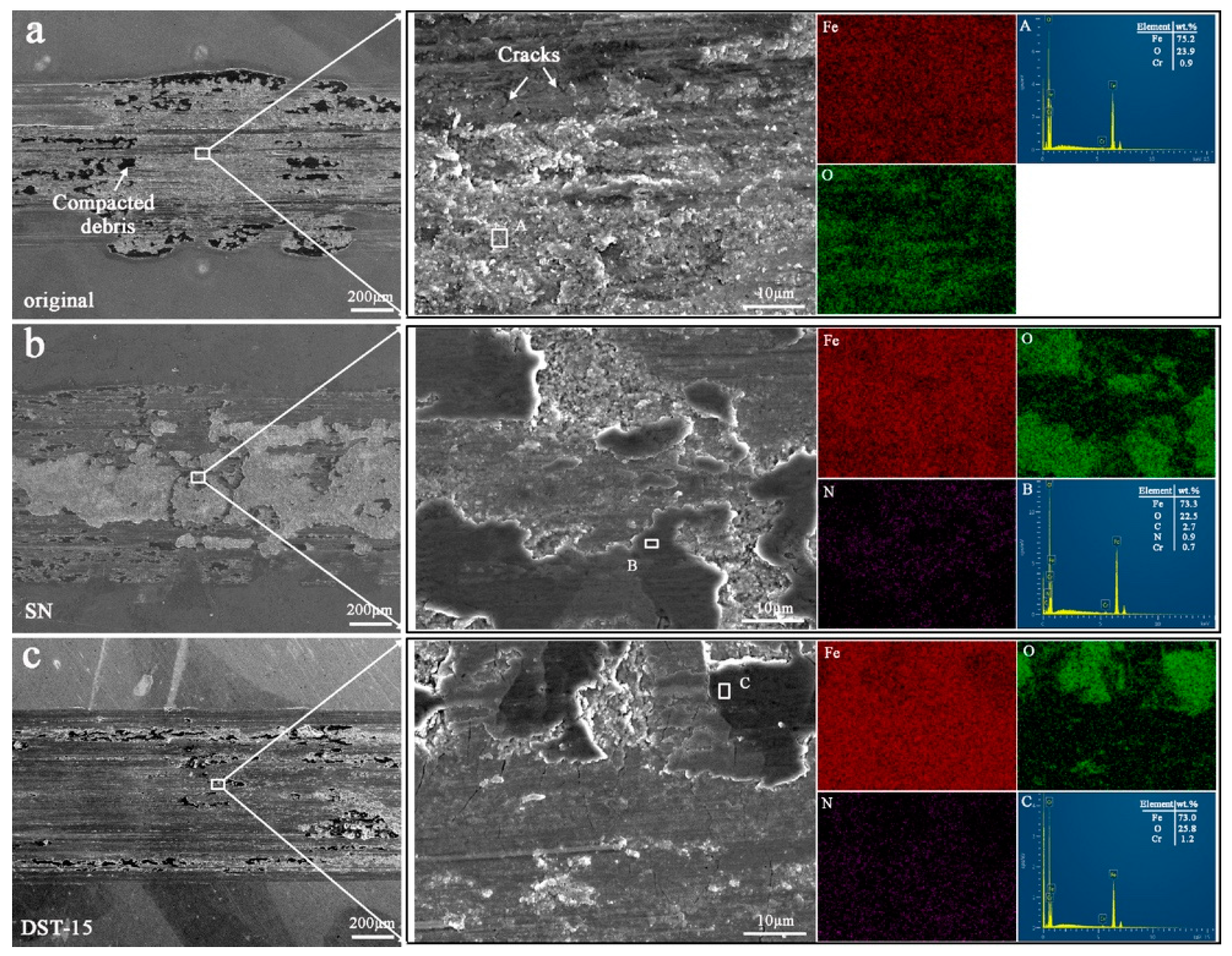

3.4. Wear Resistance

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Christiansen, T.; Somers, M.A.J. Low temperature gaseous nitriding and carburising of stainless steel. Surf. Eng. 2005, 21, 445–455. [Google Scholar] [CrossRef]

- Baranowska, J.; Arnold, B. Corrosion resistance of nitrided layers on austenitic steel. Surf. Coat. Technol. 2006, 200, 6623–6628. [Google Scholar] [CrossRef]

- Kundalkar, D.; Mavalankar, M.; Tewari, A. Effect of gas nitriding on the thermal fatigue behavior of martensitic chromium hot-work tool steel. Mater. Sci. Eng. A 2016, 651, 391–398. [Google Scholar] [CrossRef]

- Farè, S.; Lecis, N.; Brescia, E.; Mazzola, M. Role of grain boundaries in diffusional phenomena during gas nitriding of pure iron. Procedia Eng. 2011, 10, 2943–2948. [Google Scholar] [CrossRef] [Green Version]

- Panfil, D.; Kulka, M.; Wach, P.; Michalski, J.; Przestacki, D. Nanomechanical properties of iron nitrides produced on 42CrMo4 steel by controlled gas nitriding and laser heat treatment. J. Alloys Compd. 2017, 706, 63–75. [Google Scholar] [CrossRef]

- Sun, J.; Tong, W.P.; Zhang, H.; Du, X.D.; Wu, Y.C. Enhanced strength and plasticity of gas nitrided iron by surface mechanical attrition pretreatment. Surf. Coat. Technol. 2016, 286, 279–284. [Google Scholar] [CrossRef]

- Tong, W.P.; Tao, N.R.; Wang, Z.B.; Lu, J.; Lu, K. Nitriding iron at lower temperatures. Science 2003, 299, 686–688. [Google Scholar] [CrossRef] [Green Version]

- Tong, W.P.; Liu, C.Z.; Wang, W.; Tao, N.R.; Wang, Z.B.; Zuo, L.; He, J.C. Gaseous nitriding of iron with a nanostructured surface layer. Scr. Mater. 2007, 57, 533–536. [Google Scholar] [CrossRef]

- Wang, B.; Fu, W.T.; Dong, F.; Jin, G.F.; Feng, W.W.; Wang, Z.H.; Sun, S.H. Significant acceleration of nitriding kinetics in pure iron by pressurized gas treatment. Mater. Des. 2015, 85, 91–96. [Google Scholar] [CrossRef]

- Chen, X.; Bao, X.Y.; Xiao, Y.; Zhang, C.S.; Tang, L.N.; Yao, L.; Cui, G.D.; Yang, Y. Low-temperature gas nitriding of AISI 4140 steel accelerated by LaFeO3 perovskite oxide. Appl. Surf. Sci. 2019, 466, 989–999. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, H.Y.; Jin, X.L.; Ge, Q.J.; Li, W.Z. Characterizations and activities of the nano-sized Ni/Al2O3 and Ni/La-Al2O3 catalysts for NH3 decomposition. Appl. Catal. A Gen. 2005, 290, 87–96. [Google Scholar] [CrossRef]

- Deng, Q.F.; Zhang, H.; Hou, X.X.; Ren, T.Z.; Yuan, Z.Y. High-surface-area Ce0.8Zr0.2O2 solid solutions supported Ni catalysts for ammonia decomposition to hydrogen. Int. J. Hydrogen Energy 2012, 37, 15901–15907. [Google Scholar] [CrossRef]

- Meng, T.; Xu, Q.Q.; Li, Y.T.; Chang, J.L.; Ren, T.Z.; Yuan, Z.Y. Nickle nanoparticles highly dispersed on reduced graphene oxide for ammonia decomposition to hydrogen. J. Ind. Eng. Chem. 2015, 32, 373–379. [Google Scholar] [CrossRef]

- García-Bordejé, E.; Armenise, S.; Roldán, L. Toward practical application of H2 generation from ammonia decomposition guided by rational catalyst design. Catal. Rev.Sci. Eng. 2014, 56, 220–237. [Google Scholar] [CrossRef]

- Su, Q.; Gu, L.L.; Yao, Y.; Zhao, J.; Ji, W.J.; Ding, W.P.; Au, C.-T. Layered double hydroxides derived Nix(MgyAlzOn) catalysts: Enhanced ammonia decomposition by hydrogen spillover effect. Appl. Catal. B Environ. 2017, 201, 451–460. [Google Scholar] [CrossRef]

- Inia, D.K.; Arnoldbik, W.M.; Vredenberg, A.M.; Boerma, D.O. New method for low temperature gaseous nitriding of iron. Surf. Eng. 1996, 12, 326–330. [Google Scholar] [CrossRef]

- Inia, D.K.; Pröpper, M.H.; Arnoldbik, W.M.; Vredenberg, A.M.; Boerma, D.O. Low-temperature nitriding of iron through a thin nickel layer. Appl. Phys. Lett. 1997, 70, 1245–1247. [Google Scholar] [CrossRef] [Green Version]

- Van Voorthuysen, E.H.D.M.; Chechenin, N.C.; Boerma, D.O. Low-temperature extension of the Lehrer diagram and the iron-nitrogen phase diagram. Metall. Mater. Trans. A 2002, 33, 2593–2598. [Google Scholar] [CrossRef]

- Somers, M.A.J.; Christiansen, T.; Moller, P. Case-hardening of stainless steel. U.S. Patent 20060090817A1, 5 April 2006. [Google Scholar]

- Brink, B.K.; Ståhl, K.; Christiansen, T.L.; Frandsen, C.; Hansen, M.F.; Somers, M.A.J. Composition-dependent variation of magnetic properties and interstitial ordering in homogeneous expanded austenite. Acta Mater. 2016, 106, 32–39. [Google Scholar] [CrossRef] [Green Version]

- Li, H.S.; Gao, Y.F.; Ge, P.Q.; Bi, W.B.; Zhang, L. Study on process parameters of fabrication fine diameter electroplated diamond wire for slicing crystalline silicon solar cell. Int. J. Adv. Manuf. Technol. 2020, 106, 3153–3175. [Google Scholar] [CrossRef]

- Sun, D.C.; Jiang, E.Y.; Sun, D.Q. Study on the structure of Fe16N2 single-crystal films by transmission electron microscopy. Thin. Solid Films 1997, 298, 116–121. [Google Scholar] [CrossRef]

- Liu, Z.Q.; Chen, Y.X.; Hei, Z.K.; Li, D.X.; Hashimoto, H. Microstructural investigation on the precipitation of α″ Nitrides and α″→γ′ nitride transformation in ion-nitrided pure iron. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2001, 32, 2681–2688. [Google Scholar] [CrossRef]

- Sakamoto, M. Cycle Precipitation of Fe16N2 in Nitrided Iron Alloys; Chandra, T., Torralba, J., Sakai, T., Eds.; Trans Tech Publications Ltd.: Zurich-Uetikon, Switzerland, 2003; Volume 426–432. [Google Scholar]

- Dirks, A.G.; Meijering, J.L. Rapid Fe-Ni surface diffusion and rapid diffusion of N and C along an austenite/ferrite phase boundary. Acta Metall. 1972, 20, 1101–1107. [Google Scholar] [CrossRef]

- Djellal, R.; Saker, A.; Bouzabata, B.; Mekki, D.E. Thermal stability and phase decomposition of nitrided layers on 316L and 310 austenitic stainless steels. Surf. Coat. Technol. 2017, 325, 533–538. [Google Scholar] [CrossRef]

- Keddam, M.; Djeghlal, M.E.; Barrallier, L. A diffusion model for simulation of bilayer growth (ε/γ′) of nitrided pure iron. Mater. Sci. Eng. A 2004, 378, 475–478. [Google Scholar] [CrossRef]

- Somers, M.A.J. 12.13—Development of Compound Layer and Diffusion Zone during Nitriding and Nitrocarburizing of Iron and Steels; Hashmi, S., Batalha, G.F., Van Tyne, C.J., Yilbas, B.B.T.-C.M.P., Eds.; Elsevier: Oxford, UK, 2014; pp. 413–437. ISBN 978-0-08-096533-8. [Google Scholar]

- Lacaille, V.; Peres, V.; Langlade, C.; Morel, C.; Feulvarch, E.; Bergheau, J.M.; Kermouche, G. Combination of mechanical and chemical pre-treatments to improve nitriding efficiency on pure iron. Appl. Surf. Sci. 2017, 414, 73–81. [Google Scholar] [CrossRef] [Green Version]

- Yin, S.F.; Zhang, Q.H.; Xu, B.Q.; Zhu, W.X.; Ng, C.F.; Au, C.T. Investigation on the catalysis of COx-free hydrogen generation from ammonia. J. Catal. 2004, 224, 384–396. [Google Scholar] [CrossRef]

- Wolowiec-Korecka, E.; Michalski, J.; Kucharska, B. Kinetic aspects of low-pressure nitriding process. Vacuum 2018, 155, 292–299. [Google Scholar] [CrossRef]

- Wang, B.; Sun, S.H.; Guo, M.W.; Jin, G.F.; Zhou, Z.A.; Fu, W.T. Study on pressurized gas nitriding characteristics for steel 38CrMoAlA. Surf. Coat. Technol. 2015, 279, 60–64. [Google Scholar] [CrossRef]

- Chen, W.L.; Wu, C.L.; Liu, Z.R.; Ni, S.; Hong, Y.; Zhang, Y.; Chen, J.H. Phase transformations in the nitrocarburizing surface of carbon steels revisited by microstructure and property characterizations. Acta Mater. 2013, 61, 3963–3972. [Google Scholar] [CrossRef]

- Tjong, S.C.; Lau, K.C. Properties and abrasive wear of TiB2/Al-4%Cu composites produced by hot isostatic pressing. Compos. Sci. Technol. 1999, 59, 2005–2013. [Google Scholar] [CrossRef]

| Samples | DST-1 | DST-5 | DST-10 | DST-15 | DST-20 | |

|---|---|---|---|---|---|---|

| ε(111) | d′ (nm) | 2.0760 | 2.0787 | 2.0878 | 2.0787 | -- |

| (d′ − d)/d (%) | 0.2850 | 0.4154 | 0.8550 | 0.4154 | -- | |

| γ′(111) | d′ (nm) | 2.1934 | 2.1944 | 2.1954 | 2.1933 | 2.1933 |

| (d′ − d)/d (%) | 0.1095 | 0.1552 | 0.2008 | 0.1050 | 0.1050 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, Q.; Zhang, Y.; Li, X.; Xiang, L.; Nie, C. The Controlled Compound Layer of Ni-Coated Nitrided Pure Iron. Nanomaterials 2021, 11, 31. https://doi.org/10.3390/nano11010031

Shen Q, Zhang Y, Li X, Xiang L, Nie C. The Controlled Compound Layer of Ni-Coated Nitrided Pure Iron. Nanomaterials. 2021; 11(1):31. https://doi.org/10.3390/nano11010031

Chicago/Turabian StyleShen, Qianqian, Yu Zhang, Xuesha Li, Li Xiang, and Chaoyin Nie. 2021. "The Controlled Compound Layer of Ni-Coated Nitrided Pure Iron" Nanomaterials 11, no. 1: 31. https://doi.org/10.3390/nano11010031

APA StyleShen, Q., Zhang, Y., Li, X., Xiang, L., & Nie, C. (2021). The Controlled Compound Layer of Ni-Coated Nitrided Pure Iron. Nanomaterials, 11(1), 31. https://doi.org/10.3390/nano11010031