A Rational Fabrication Method for Low Switching-Temperature VO2

Abstract

1. Introduction

2. Materials and Methods

3. Results And Discussion

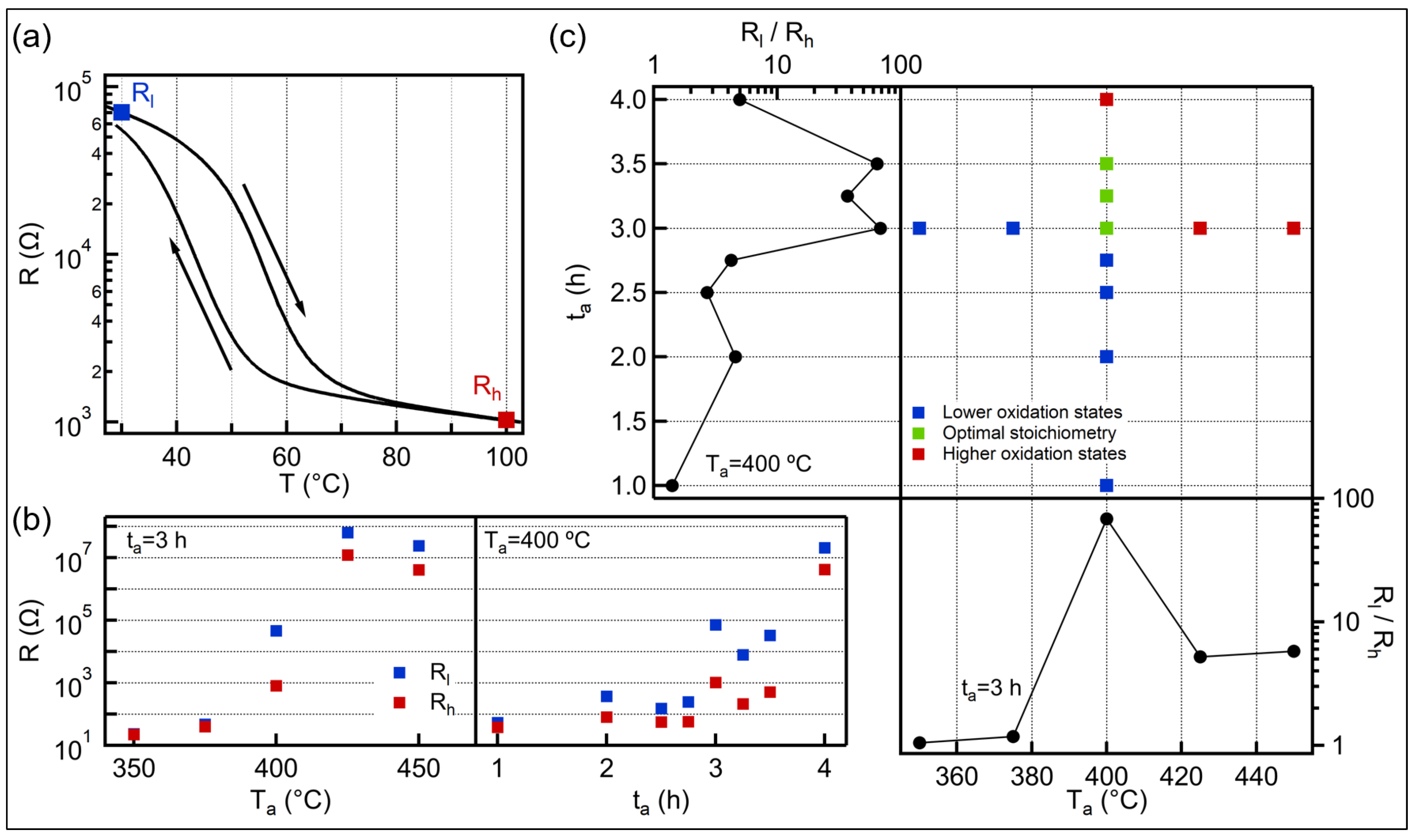

3.1. Electrical Properties

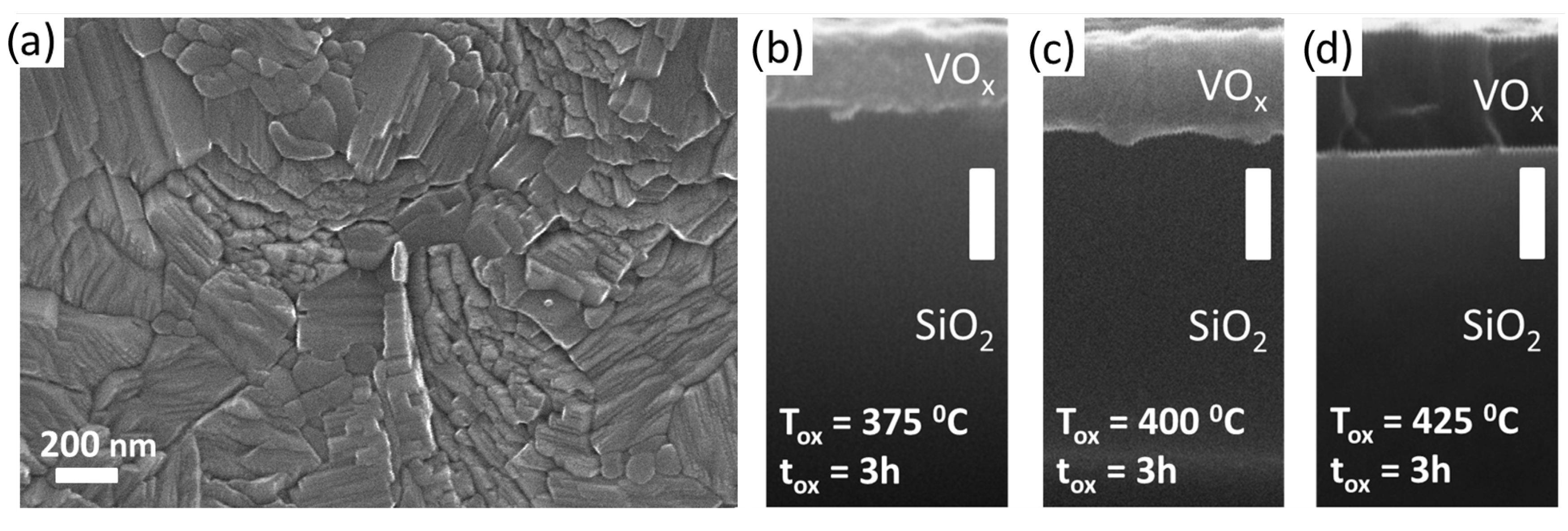

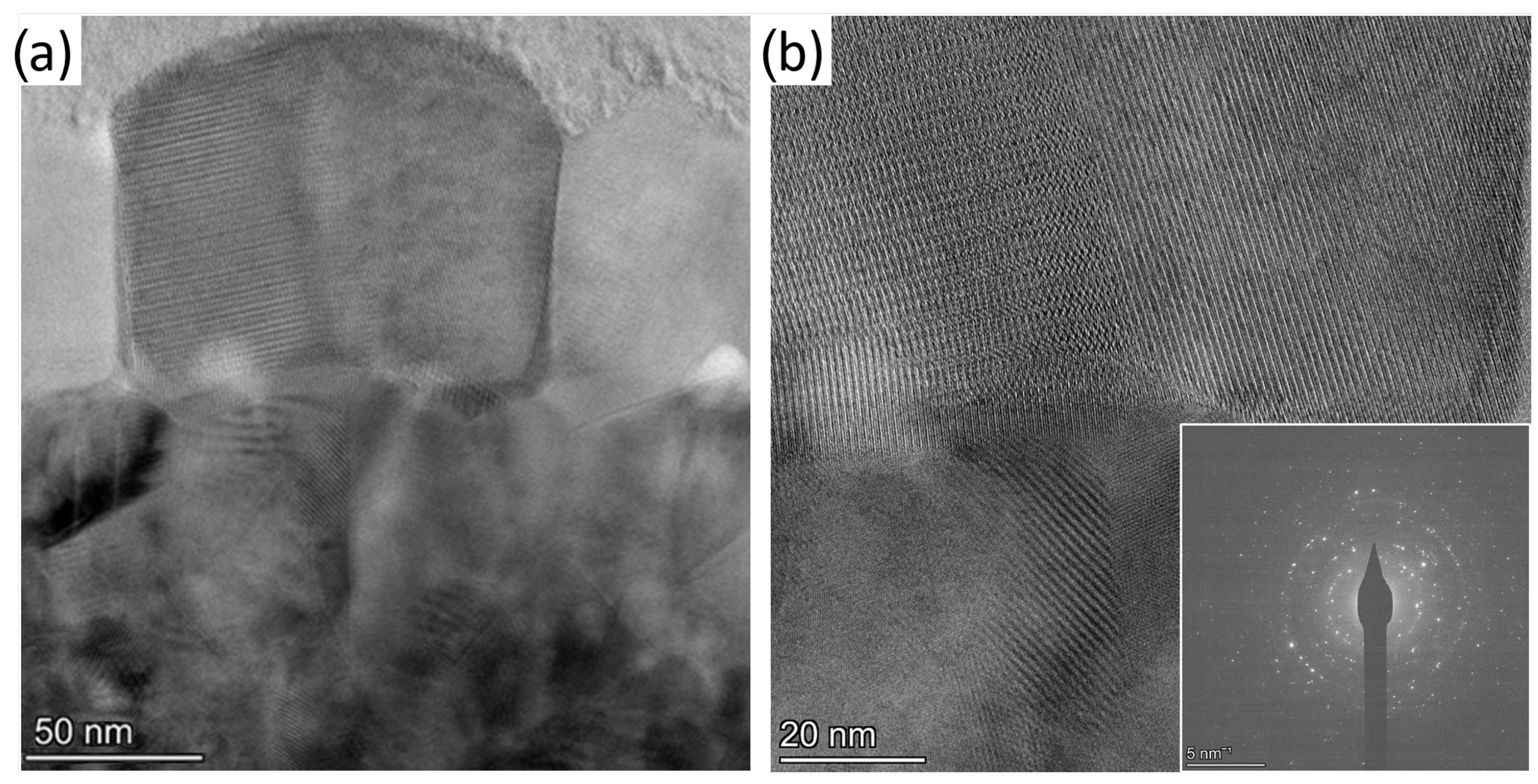

3.2. Structural Analysis

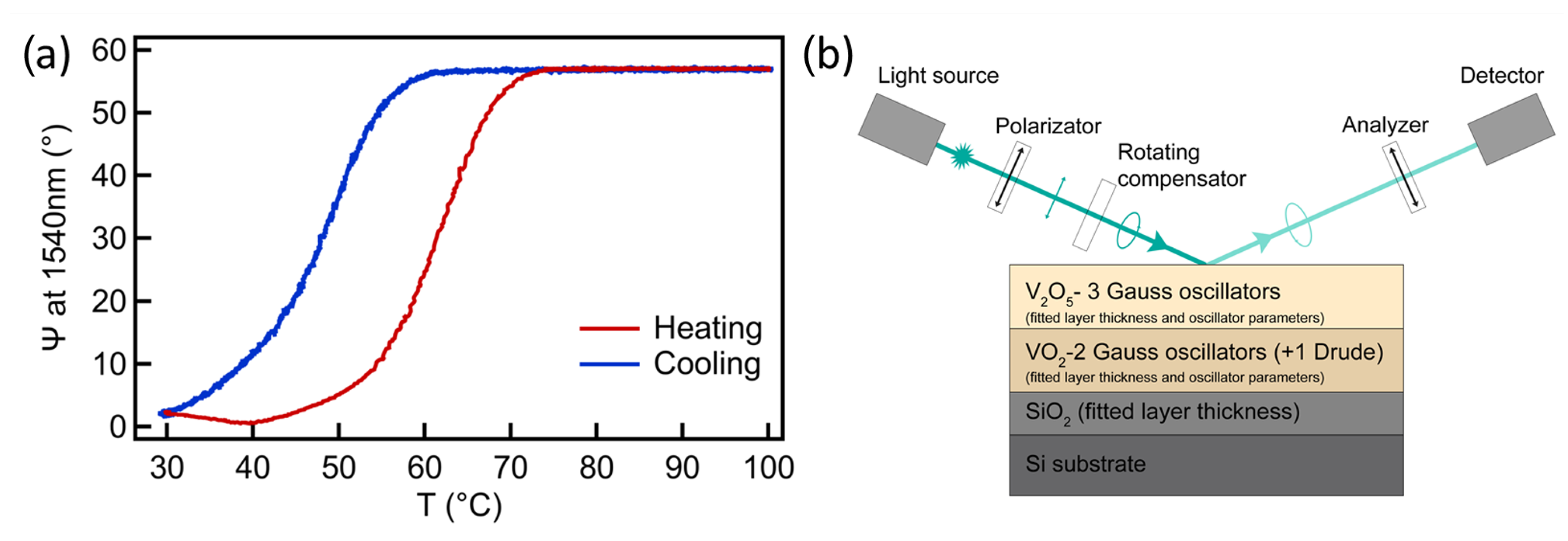

3.3. Optical Properties

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shao, Z.; Cao, X.; Luo, H.; Jin, P. Recent progress in the phase-transition mechanism and modulation of vanadium dioxide materials. NPG Asia Mater. 2018, 10, 581–605. [Google Scholar] [CrossRef]

- Kamila, S.; Chakraborty, B.; Basu, S.; Jena, B.K. Combined Experimental and Theoretical Insights into Energy Storage Applications of a VO2(D)–Graphene Hybrid. J. Phys. Chem. C 2019, 123, 24280–24288. [Google Scholar] [CrossRef]

- Wang, S.; Owusu, K.A.; Mai, L.; Ke, Y.; Zhou, Y.; Hu, P.; Magdassi, S.; Long, Y. Vanadium dioxide for energy conservation and energy storage applications: Synthesis and performance improvement. Appl. Energy 2018, 211, 200–217. [Google Scholar] [CrossRef]

- del Valle, J.; Salev, P.; Tesler, F.; Vargas, N.M.; Kalcheim, Y.; Wang, P.; Trastoy, J.; Lee, M.H.; Kassabian, G.; Ramírez, J.G.; et al. Subthreshold firing in Mott nanodevices. Nature 2019, 569, 388–392. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, C.; Pan, X.; Zhu, Y.; Holtz, M.; Bernussi, A.; Fan, Z. Tuning the properties of VO2 thin films through growth temperature for infrared and terahertz modulation applications. J. Appl. Phys. 2013, 114, 113509. [Google Scholar] [CrossRef]

- Émond, N.; Hendaoui, A.; Ibrahim, A.; Al-Naib, I.; Ozaki, T.; Chaker, M. Transmission of reactive pulsed laser deposited VO2 films in the THz domain. Appl. Surf. Sci. 2016, 379, 377–383. [Google Scholar] [CrossRef]

- Strelcov, E.; Lilach, Y.; Kolmakov, A. Gas Sensor Based on Metal-Insulator Transition in VO2 Nanowire Thermistor. Nano Lett. 2009, 9, 2322–2326. [Google Scholar] [CrossRef]

- Kocer, H.; Butun, S.; Banar, B.; Wang, K.; Tongay, S.; Wu, J.; Aydin, K. Thermal tuning of infrared resonant absorbers based on hybrid gold-VO2 nanostructures. Appl. Phys. Lett. 2015, 106, 161104. [Google Scholar] [CrossRef]

- Ko, C.; Ramanathan, S. Observation of electric field-assisted phase transition in thin film vanadium oxide in a metal-oxide-semiconductor device geometry. Appl. Phys. Lett. 2008, 93, 252101. [Google Scholar] [CrossRef]

- Chang, T.C.; Cao, X.; Bao, S.H.; Ji, S.D.; Luo, H.J.; Jin, P. Review on thermochromic vanadium dioxide based smart coatings: From lab to commercial application. Adv. Manuf. 2018, 6, 1–19. [Google Scholar] [CrossRef]

- Brassard, D.; Fourmaux, S.; Jean-Jacques, M.; Kieffer, J.C.; El Khakani, M.A. Grain size effect on the semiconductor-metal phase transition characteristics of magnetron-sputtered VO2 thin films. Appl. Phys. Lett. 2005, 87, 051910. [Google Scholar] [CrossRef]

- Liang, J.; Li, J.; Hou, L.; Liu, X. Tunable Metal-Insulator Properties of Vanadium Oxide Thin Films Fabricated by Rapid Thermal Annealing. ECS J. Solid State Sci. Technol. 2016, 5, P293–P298. [Google Scholar] [CrossRef]

- Cui, Y.; Ramanathan, S. Substrate effects on metal-insulator transition characteristics of rf-sputtered epitaxial VO2 thin films. J. Vac. Sci. Technol. A 2011, 29, 041502. [Google Scholar] [CrossRef]

- Théry, V.; Boulle, A.; Crunteanu, A.; Orlianges, J.C.; Beaumont, A.; Mayet, R.; Mennai, A.; Cosset, F.; Bessaudou, A.; Fabert, M. Structural and electrical properties of large area epitaxial VO2 films grown by electron beam evaporation. J. Appl. Phys. 2017, 121, 055303. [Google Scholar] [CrossRef]

- Soltani, M.; Chaker, M.; Haddad, E.; Kruzelecky, R.V.; Nikanpour, D. Optical switching of vanadium dioxide thin films deposited by reactive pulsed laser deposition. J. Vac. Sci. Technol. A 2004, 22, 859–864. [Google Scholar] [CrossRef]

- Vernardou, D.; Pemble, M.E.; Sheel, D.W. Vanadium oxides prepared by liquid injection MOCVD using vanadyl acetylacetonate. Surf. Coat. Technol. 2004, 188–189, 250–254. [Google Scholar] [CrossRef]

- Prasadam, V.P.; Bahlawane, N.; Mattelaer, F.; Rampelberg, G.; Detavernier, C.; Fang, L.; Jiang, Y.; Martens, K.; Parkin, I.P.; Papakonstantinou, I. Atomic layer deposition of vanadium oxides: Process and application review. Mater. Today Chem. 2019, 12, 396–423. [Google Scholar] [CrossRef]

- Vlček, J.; Kolenatý, D.; Houška, J.; Kozák, T.; Čerstvý, R. Controlled reactive HiPIMS—Effective technique for low-temperature (300 °C) synthesis of VO2 films with semiconductor-to-metal transition. J. Phys. D Appl. Phys. 2017, 50, 38LT01. [Google Scholar] [CrossRef]

- Houska, J.; Kolenaty, D.; Rezek, J.; Vlcek, J. Characterization of thermochromic VO2 (prepared at 250 °C) in a wide temperature range by spectroscopic ellipsometry. Appl. Surf. Sci. 2017, 421, 529–534. [Google Scholar] [CrossRef]

- Houska, J.; Kolenaty, D.; Vlcek, J.; Cerstvy, R. Properties of thermochromic VO2 films prepared by HiPIMS onto unbiased amorphous glass substrates at a low temperature of 300 °C. Thin Solid Film. 2018, 660, 463–470. [Google Scholar] [CrossRef]

- Ruzmetov, D.; Zawilski, K.T.; Senanayake, S.D.; Narayanamurti, V.; Ramanathan, S. Infrared reflectance and photoemission spectroscopy studies across the phase transition boundary in thin film vanadium dioxide. J. Phys. Condens. Matter 2008, 20, 465204. [Google Scholar] [CrossRef]

- Cueff, S.; Li, D.; Zhou, Y.; Wong, F.J.; Kurvits, J.A.; Ramanathan, S.; Zia, R. Dynamic control of light emission faster than the lifetime limit using VO2 phase-change. Nat. Commun. 2015, 6, 8636. [Google Scholar] [CrossRef]

- Xu, X.; He, X.; Wang, G.; Yuan, X.; Liu, X.; Huang, H.; Yao, S.; Xing, H.; Chen, X.; Chu, J. The study of optimal oxidation time and different temperatures for high quality VO2 thin film based on the sputtering oxidation coupling method. Appl. Surf. Sci. 2011, 257, 8824–8827. [Google Scholar] [CrossRef]

- Kang, Y.B. Critical evaluation and thermodynamic optimization of the VO–VO2.5 system. J. Eur. Ceram. Soc. 2012, 32, 3187–3198. [Google Scholar] [CrossRef]

- Guo, P.; Biegler, Z.; Back, T.; Sarangan, A. Vanadium dioxide phase change thin films produced by thermal oxidation of metallic vanadium. Thin Solid Film. 2020, 707, 138117. [Google Scholar] [CrossRef]

- Liu, X.; Wang, S.W.; Chen, F.; Yu, L.; Chen, X. Tuning phase transition temperature of VO2 thin films by annealing atmosphere. J. Phys. D Appl. Phys. 2015, 48, 265104. [Google Scholar] [CrossRef]

- Liu, X.; Ji, R.; Zhang, Y.; Li, H.; Wang, S.W. Annealing process and mechanism of glass based VO2 film from V oxidation in pure oxygen atmosphere. Opt. Quantum Electron. 2016, 48, 453. [Google Scholar] [CrossRef]

- Liang, J.; Zhao, Y.; Guo, J.; Yang, Z.; Su, T. Rapid Thermal Oxidation of Sputtering Power Dependent Vanadium Thin Films for VO2 Thin Films Preparation. ECS J. Solid State Sci. Technol. 2018, 7, P429–P434. [Google Scholar] [CrossRef]

- Rampelberg, G.; De Schutter, B.; Devulder, W.; Martens, K.; Radu, I.; Detavernier, C. In situ X-ray diffraction study of the controlled oxidation and reduction in the V–O system for the synthesis of VO2 and V2O3 thin films. J. Mater. Chem. C 2015, 3, 11357–11365. [Google Scholar] [CrossRef]

- Griffiths, C.H.; Eastwood, H.K. Influence of stoichiometry on the metal-semiconductor transition in vanadium dioxide. J. Appl. Phys. 1974, 45, 2201–2206. [Google Scholar] [CrossRef]

- Ba, C.O.F.; Fortin, V.; Bah, S.T.; Vallée, R.; Pandurang, A. Formation of VO2 by rapid thermal annealing and cooling of sputtered vanadium thin films. J. Vac. Sci. Technol. A 2016, 34, 031505. [Google Scholar] [CrossRef]

- Mukherjee, A.; Wach, S. Kinetics of the oxidation of vanadium in the temperature range 350–950 °C. J. Less Common Met. 1983, 92, 289–300. [Google Scholar] [CrossRef]

- Ji, Y.X.; Niklasson, G.A.; Granqvist, C.G.; Boman, M. Thermochromic VO2 films by thermal oxidation of vanadium in SO2. Sol. Energy Mater. Sol. Cells 2016, 144, 713–716. [Google Scholar] [CrossRef]

- Jiang, S.J.; Ye, C.B.; Khan, M.S.R.; Granqvist, C.G. Evolution of thermochromism during oxidation of evaporated vanadium films. Appl. Opt. 1991, 30, 847–851. [Google Scholar] [CrossRef] [PubMed]

- Kana, J.K.; Ndjaka, J.; Vignaud, G.; Gibaud, A.; Maaza, M. Thermally tunable optical constants of vanadium dioxide thin films measured by spectroscopic ellipsometry. Opt. Commun. 2011, 284, 807–812. [Google Scholar] [CrossRef]

- Mokerov, V.G.; Makarov, L.V.; Tulvinskii, B.V.; Begishev, A.R. Optical properties of vanadium pentoxide in the region of photon energies from 2 eV to 14 eV. Opt. Spectrosc. 1976, 40, 58–61. [Google Scholar]

- Parker, J.C.; Lam, D.J.; Xu, Y.N.; Ching, W.Y. Optical properties of vanadium pentoxide determined from ellipsometry and band-structure calculations. Phys. Rev. B 1990, 42, 5289–5293. [Google Scholar] [CrossRef]

- Landry, A.; Vinh Son, T.; Haché, A. Optical modulation at the interface between silicon and a phase change material. Optik 2020, 209, 164585. [Google Scholar] [CrossRef]

- Shibuya, K.; Sawa, A. Optimization of conditions for growth of vanadium dioxide thin films on silicon by pulsed-laser deposition. AIP Adv. 2015, 5, 107118. [Google Scholar] [CrossRef]

- Wan, C.; Zhang, Z.; Woolf, D.; Hessel, C.M.; Rensberg, J.; Hensley, J.M.; Xiao, Y.; Shahsafi, A.; Salman, J.; Richter, S.; et al. On the Optical Properties of Thin-Film Vanadium Dioxide from the Visible to the Far Infrared. Ann. Phys. 2019, 1900188. [Google Scholar] [CrossRef]

- Deal, B.E.; Grove, A.S. General Relationship for the Thermal Oxidation of Silicon. J. Appl. Phys. 1965, 36, 3770–3778. [Google Scholar] [CrossRef]

- Bárta, T.; Vlček, J.; Houška, J.; Haviar, S.; Čerstvý, R.; Szelwicka, J.; Fahland, M.; Fahlteich, J. Pulsed Magnetron Sputtering of Strongly Thermochromic VO2-Based Coatings with a Transition Temperature of 22 °C onto Ultrathin Flexible Glass. Coatings 2020, 10, 1258. [Google Scholar] [CrossRef]

- Xu, F.; Cao, X.; Luo, H.; Jin, P. Recent advances in VO2-based thermochromic composites for smart windows. J. Mater. Chem. C 2018, 6, 1903–1919. [Google Scholar] [CrossRef]

- Mukherjee, A.; Wach, S. An investigation of the kinetics and stability of VO2. J. Less Common Met. 1987, 132, 107–113. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pósa, L.; Molnár, G.; Kalas, B.; Baji, Z.; Czigány, Z.; Petrik, P.; Volk, J. A Rational Fabrication Method for Low Switching-Temperature VO2. Nanomaterials 2021, 11, 212. https://doi.org/10.3390/nano11010212

Pósa L, Molnár G, Kalas B, Baji Z, Czigány Z, Petrik P, Volk J. A Rational Fabrication Method for Low Switching-Temperature VO2. Nanomaterials. 2021; 11(1):212. https://doi.org/10.3390/nano11010212

Chicago/Turabian StylePósa, László, György Molnár, Benjamin Kalas, Zsófia Baji, Zsolt Czigány, Péter Petrik, and János Volk. 2021. "A Rational Fabrication Method for Low Switching-Temperature VO2" Nanomaterials 11, no. 1: 212. https://doi.org/10.3390/nano11010212

APA StylePósa, L., Molnár, G., Kalas, B., Baji, Z., Czigány, Z., Petrik, P., & Volk, J. (2021). A Rational Fabrication Method for Low Switching-Temperature VO2. Nanomaterials, 11(1), 212. https://doi.org/10.3390/nano11010212