Failure Analysis of Ultra High-Performance Fiber-Reinforced Concrete Structures Enhanced with Nanomaterials by Using a Diffuse Cohesive Interface Approach

Abstract

1. Introduction

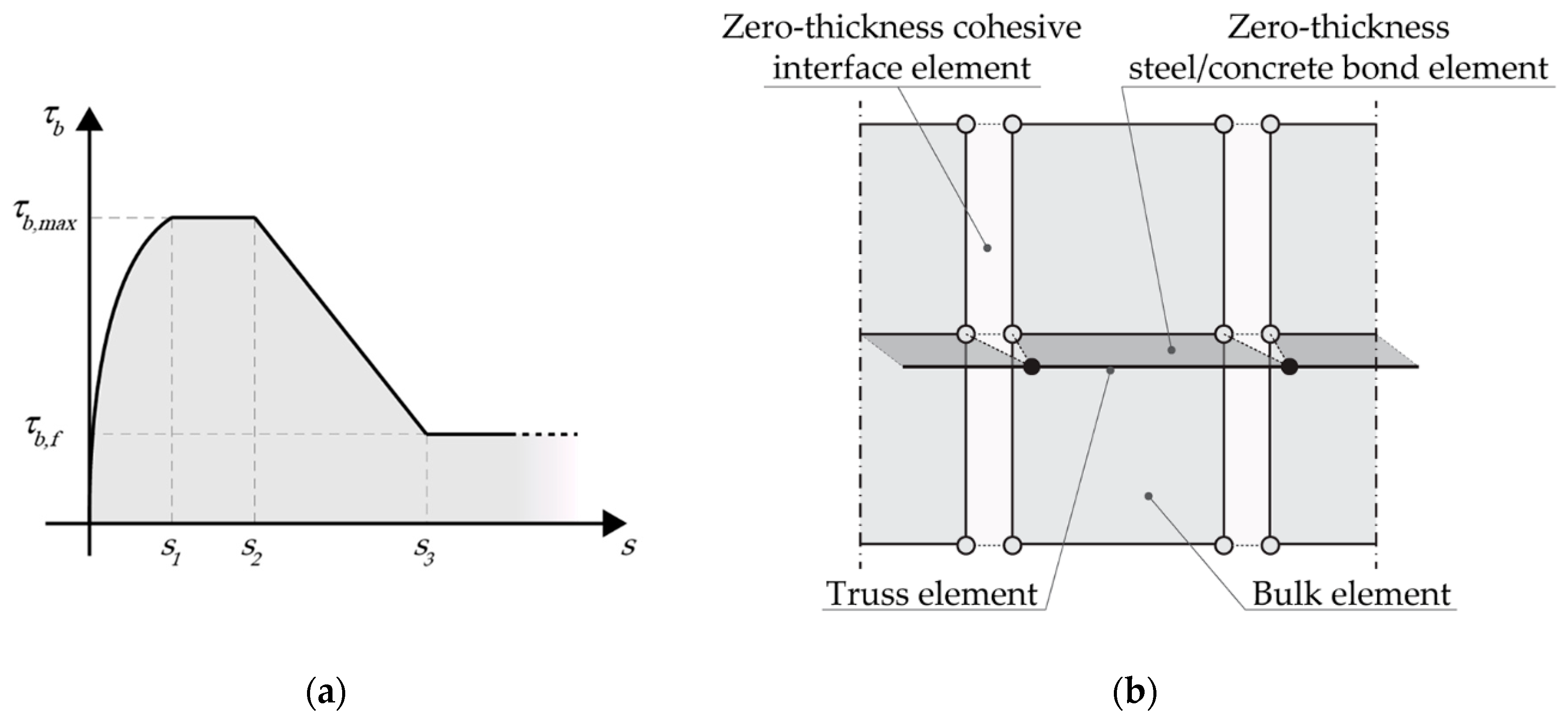

- a diffuse interface modeling (DIM) approach, based on a cohesive finite element methodology, introduced by some of the authors in [51] for conventional concrete and here adapted to the case of nano-enhanced UHPFRC. This approach, whose theoretical background is briefly recalled in Section 2, considers all the internal mesh boundaries as potential crack segments, modeled as cohesive interfaces equipped with a suitably calibrated mixed-mode traction-separation law. The desired feature of this approach consists in the possibility to simulate multiple crack onset and propagation without requiring externally introduced crack initiation criteria or computationally costly remeshing operations;

2. Diffuse Cohesive Interface Modeling Approach for Nano-Enhanced UHPFRC Structures

2.1. General Cohesive Finite Element Formulation

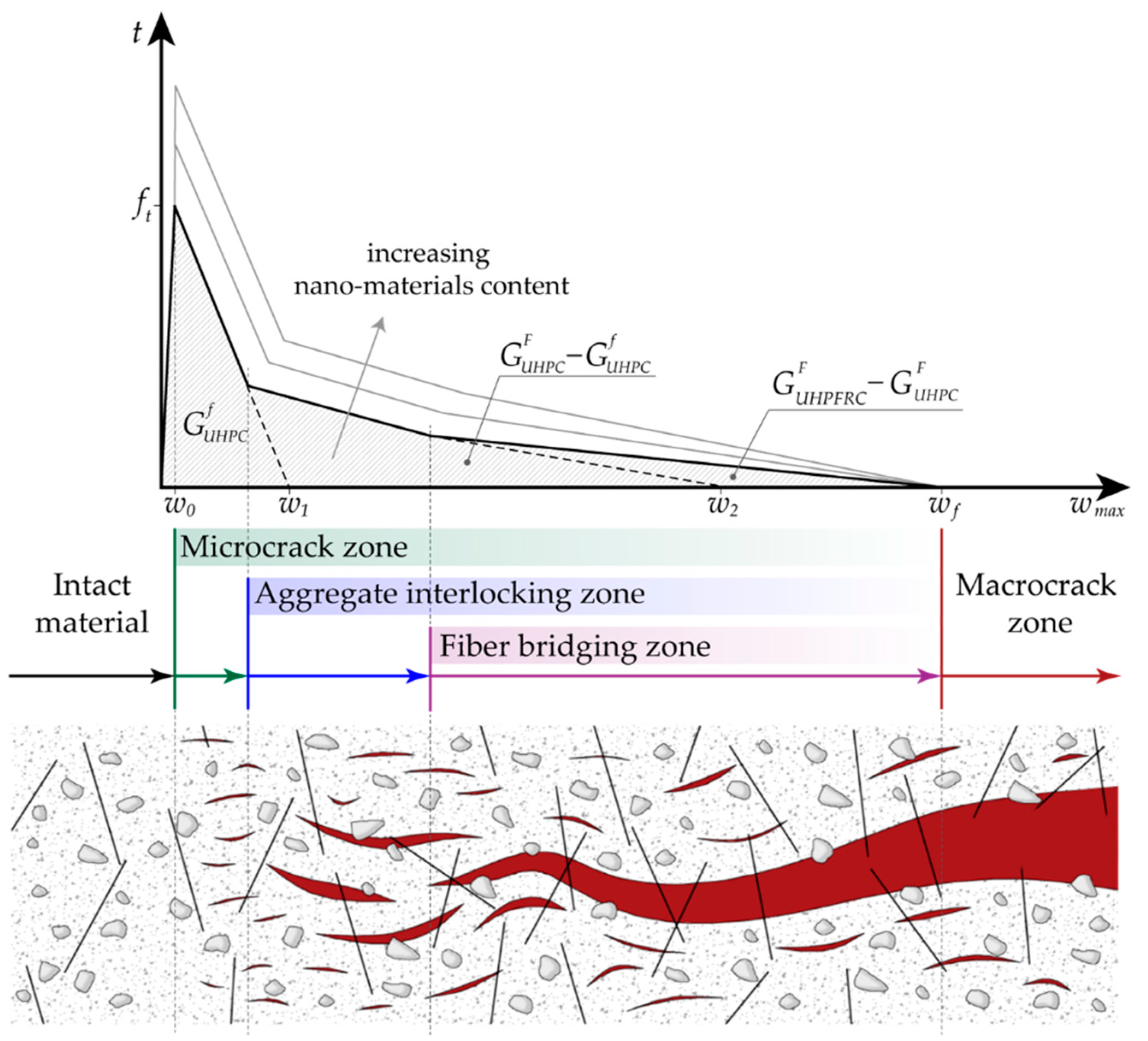

2.2. Traction–Separation Law for Nano-Enhanced UHPFRC Structures

3. An Integrated Numerical Model for UHPFRC Structures Enhanced with Nanomaterials

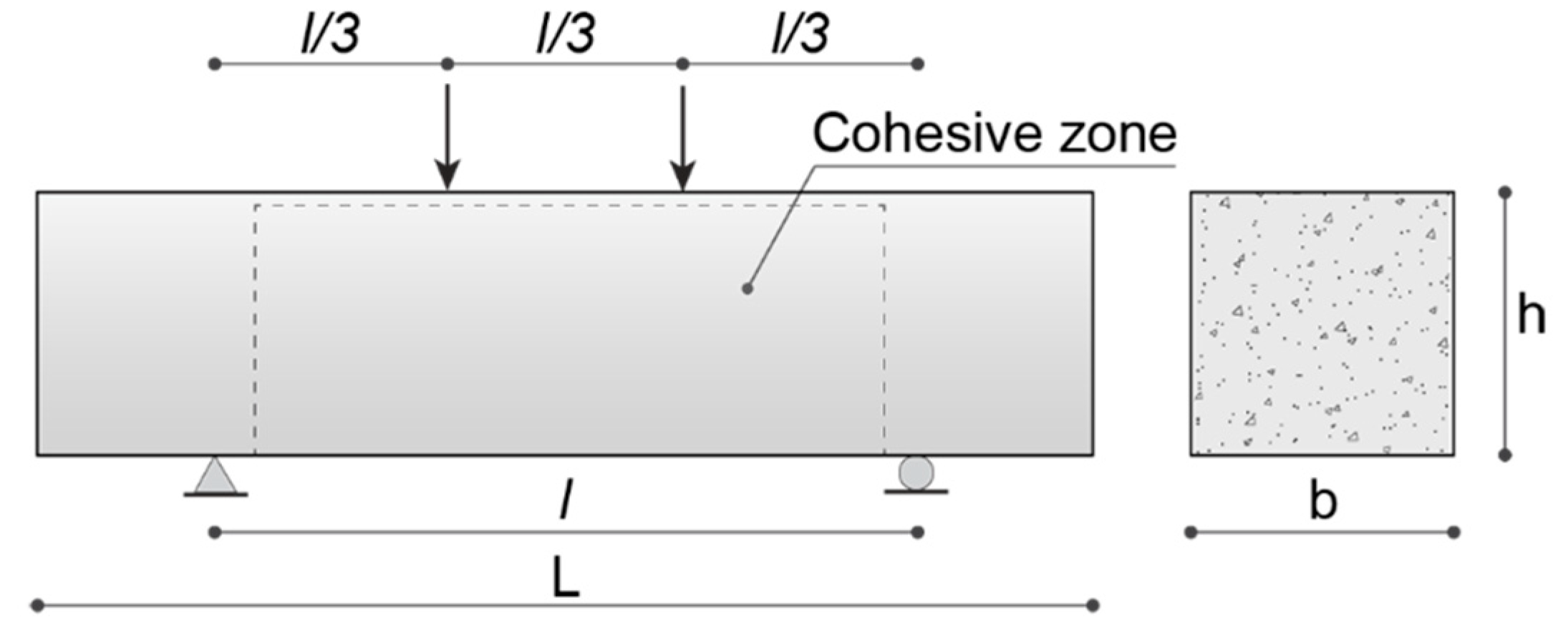

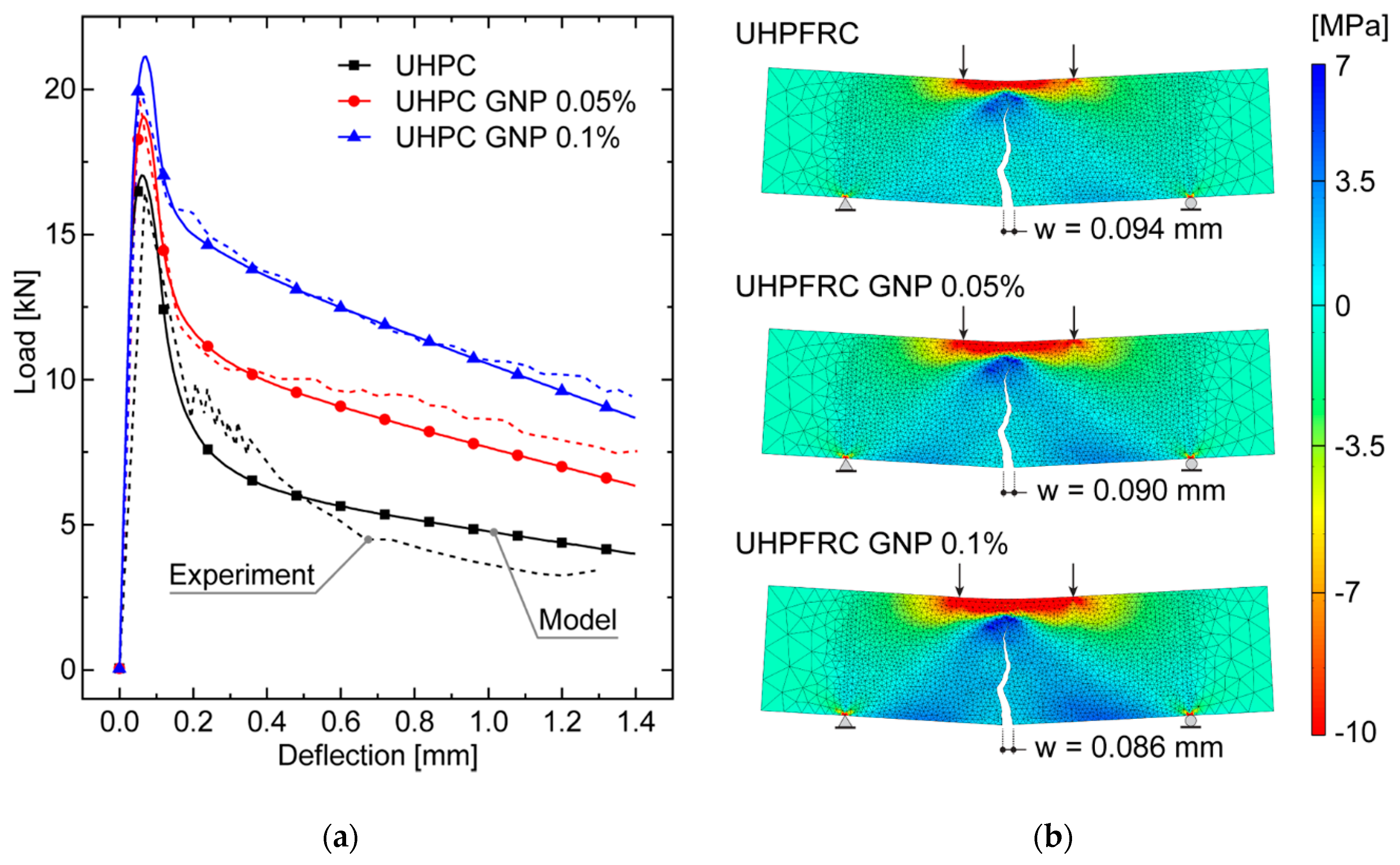

4. Numerical Application to Plain Nano-Enhanced UHPFRC

4.1. Model Calibration and Comparison with Experiments

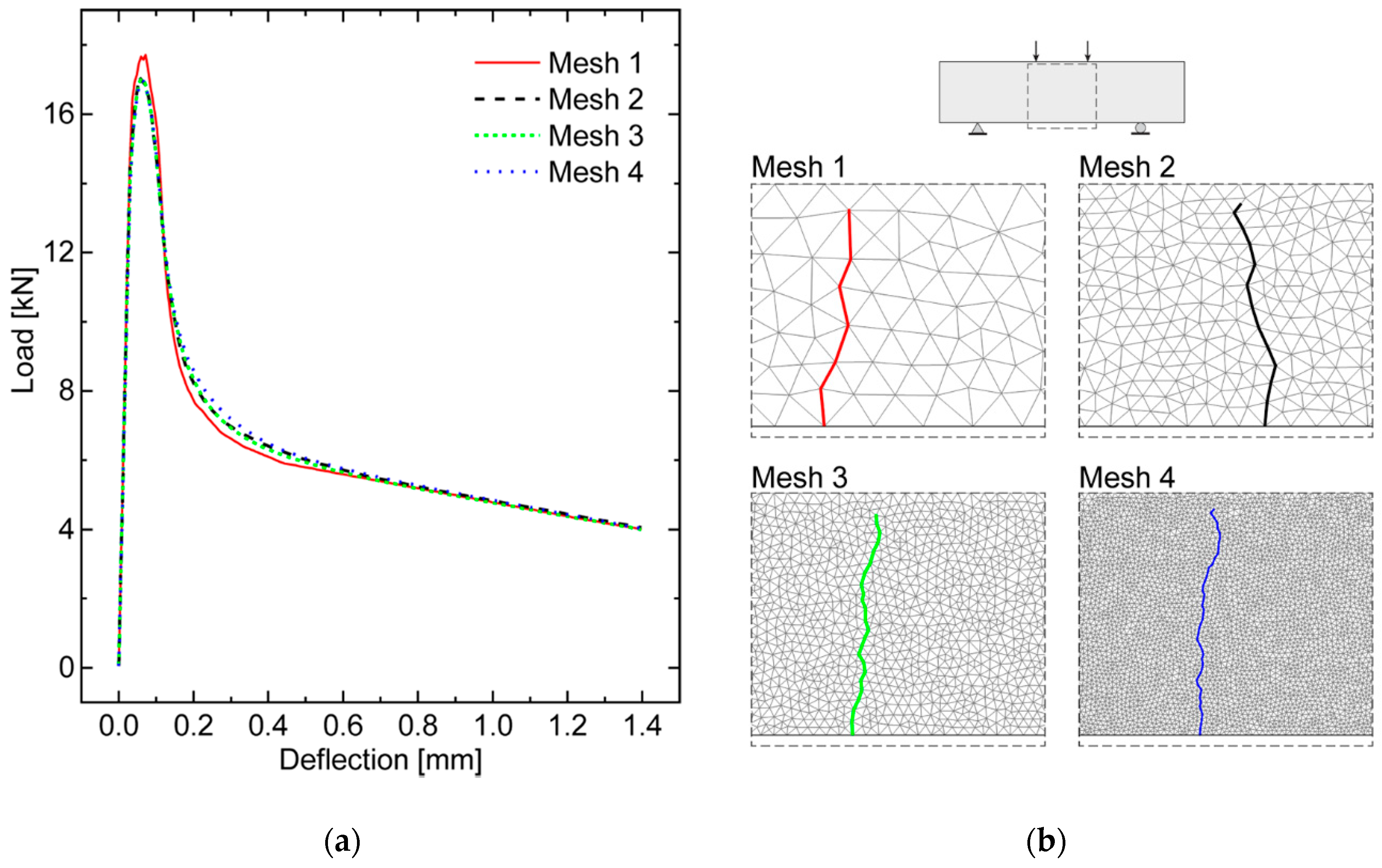

4.2. Mesh Size Sensitivity Analysis

5. Numerical Application to Steel Bar-Reinforced Nano-Enhanced UHPFRC

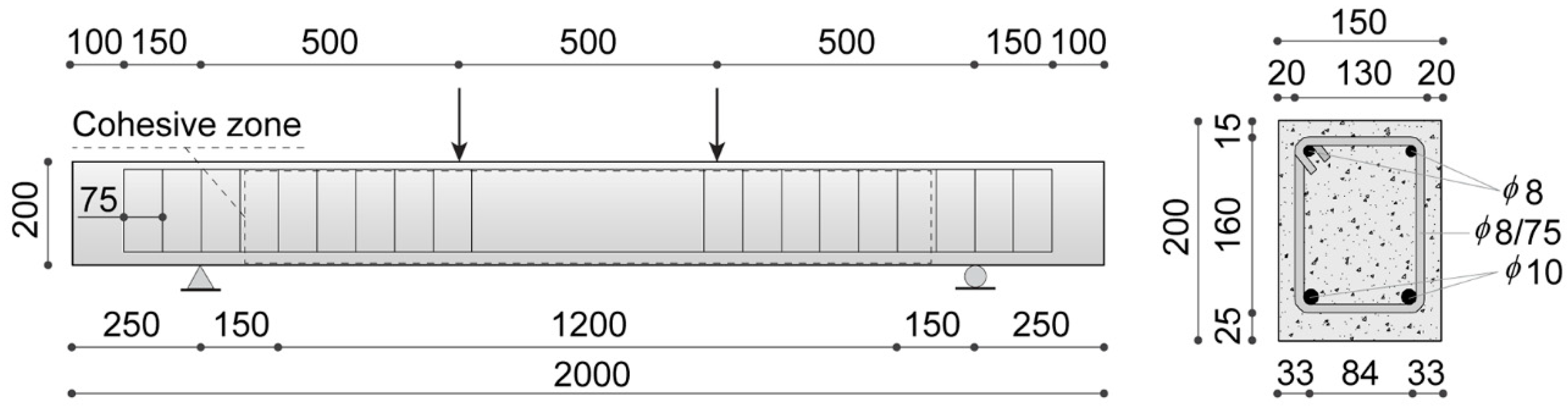

5.1. Geometric and Material Properties

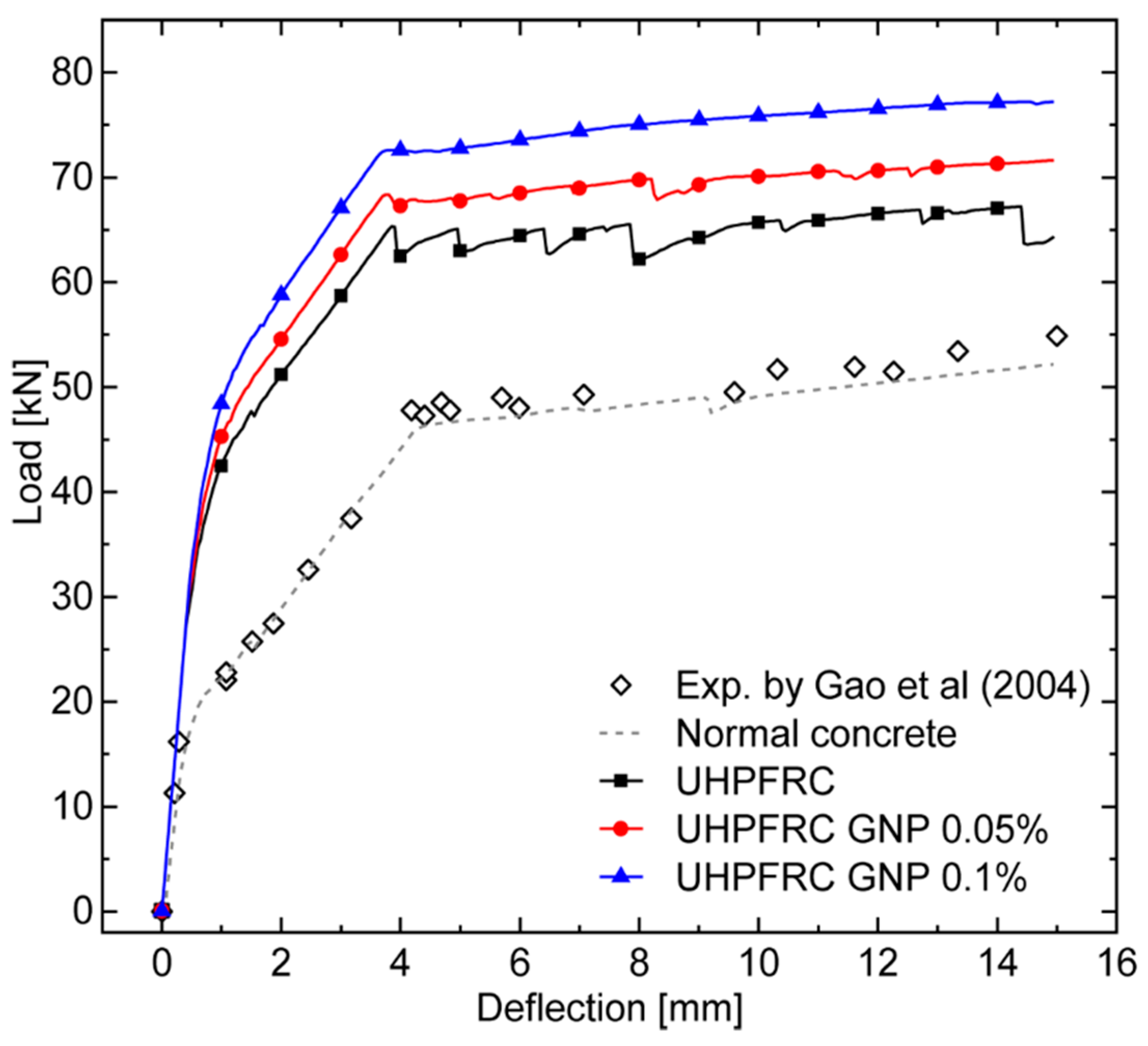

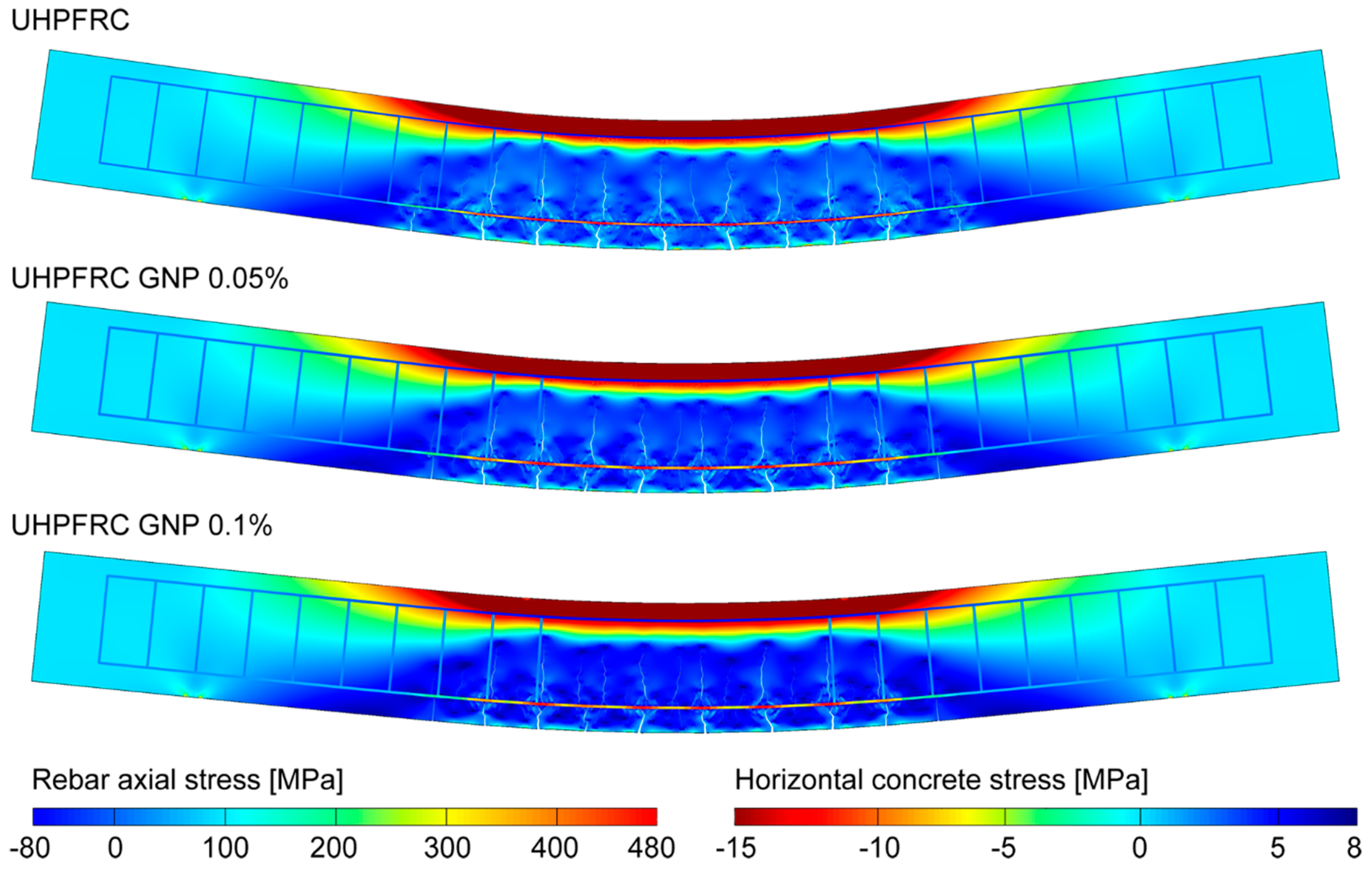

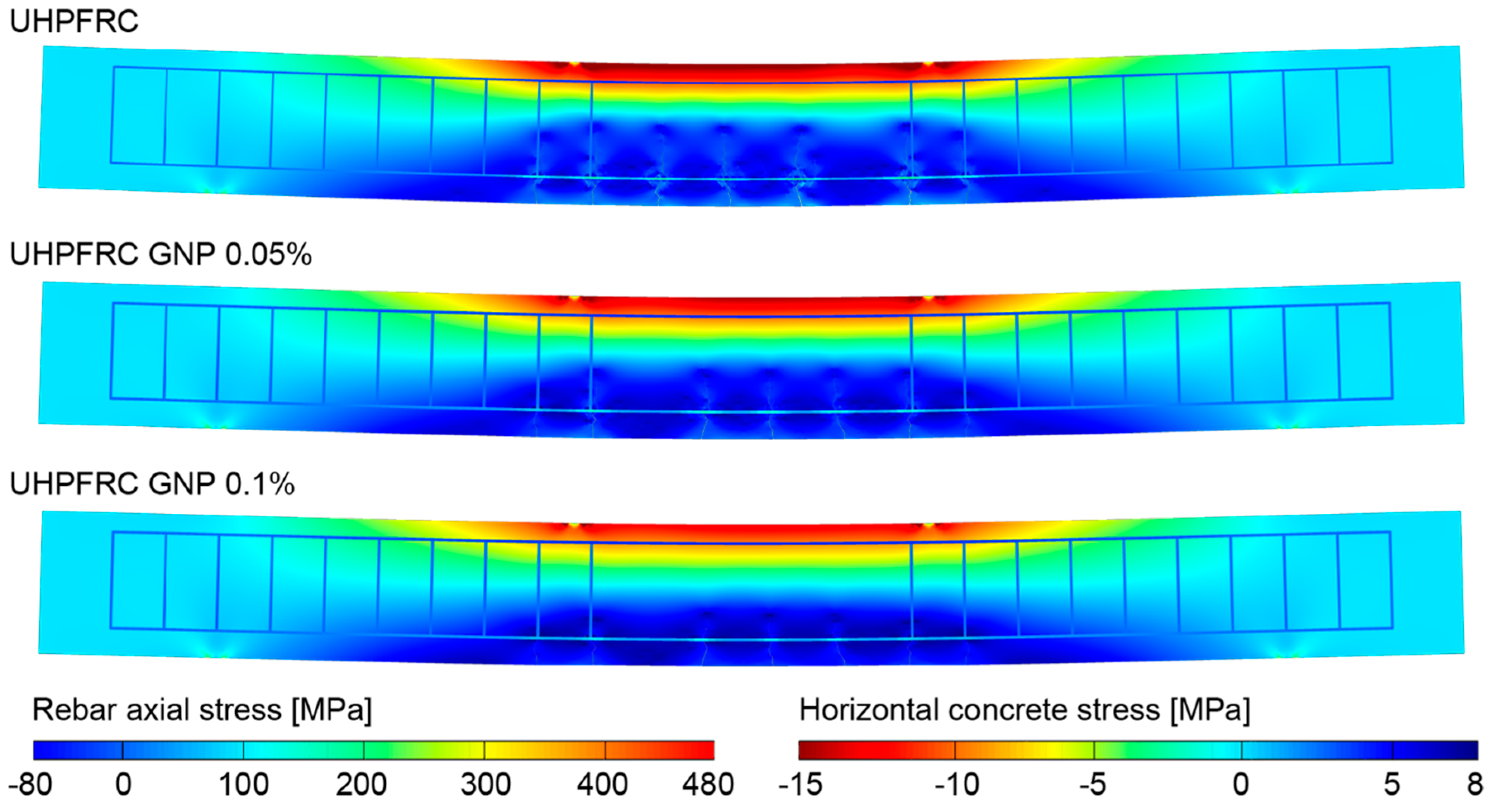

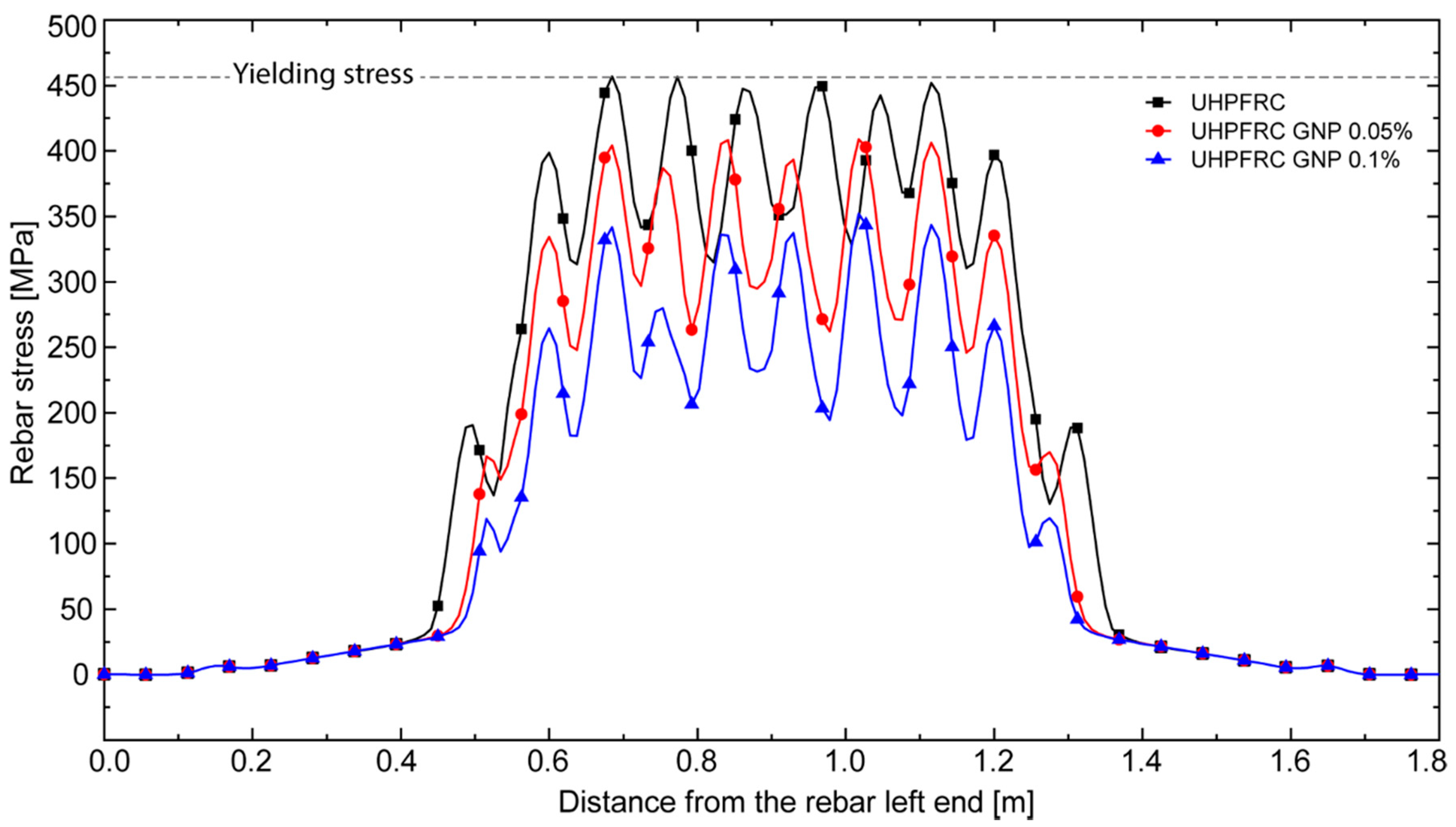

5.2. Numerical Results and Discussion

6. Conclusions

- possibility to accurately predict multiple crack initiation and propagation phenomena within a rather standard and readily implementable displacement-type finite element setting;

- capability to preserve the discrete nature of fracture processes, and, therefore, to capture the real complex crack patterns, in terms of both crack spacing and crack widths, whose knowledge is of fundamental importance for the safety and serviceability assessment of UHPFRC structures, as well as for their fiber content optimization within the design process.

Author Contributions

Funding

Conflicts of Interest

References

- Biernacki, J.J.; Bullard, J.W.; Sant, G.; Brown, K.; Glasser, F.P.; Jones, S.; Ley, T.; Livingston, R.; Nicoleau, L.; Olek, J.; et al. Cements in the 21st Century: Challenges, Perspectives, and Opportunities. J. Am. Ceram. Soc. 2017, 100, 2746–2773. [Google Scholar] [CrossRef] [PubMed]

- Azmee, N.M.; Shafiq, N. Ultra-High Performance Concrete: From Fundamental to Applications. Case Stud. Constr. Mater. 2018, 9, e00197. [Google Scholar] [CrossRef]

- Reda, M.M.; Shrive, N.G.; Gillott, J.E. Microstructural Investigation of Innovative UHPC. Cem. Concr. Res. 1999, 29, 323–329. [Google Scholar] [CrossRef]

- Fehling, E.; Schmidt, M.; Walraven, J.C.; Leutbecher, T.; Fröhlich, S. Ultra-High Performance Concrete UHPC: Fundamentals—Design—Examples; Ernst & Sohn: Berlin, Germany, 2014. [Google Scholar]

- Wille, K.; Kim, D.J.; Naaman, A.E. Strain-Hardening UHP-FRC with Low Fiber Contents. Mater. Struct. 2011, 44, 583–598. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Shin, H.-O.; Yang, J.-M.; Yoon, Y.-S. Material and Bond Properties of Ultra High Performance Fiber Reinforced Concrete with Micro Steel Fibers. Compos. Part B Eng. 2014, 58, 122–133. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Mix Design and Properties Assessment of Ultra-High Performance Fibre Reinforced Concrete (UHPFRC). Cem. Concr. Res. 2014, 56, 29–39. [Google Scholar] [CrossRef]

- Naaman, A.E.; Reinhardt, H.W. Proposed Classification of HPFRC Composites Based on Their Tensile Response. Mater. Struct. 2007, 39, 547–555. [Google Scholar] [CrossRef]

- Wille, K.; El-Tawil, S.; Naaman, A.E. Properties of Strain Hardening Ultra High Performance Fiber Reinforced Concrete (UHP-FRC) under Direct Tensile Loading. Cem. Concr. Compos. 2014, 48, 53–66. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Kang, S.-T.; Yoon, Y.-S. Effect of Fiber Length and Placement Method on Flexural Behavior, Tension-Softening Curve, and Fiber Distribution Characteristics of UHPFRC. Constr. Build. Mater. 2014, 64, 67–81. [Google Scholar] [CrossRef]

- Hassan, A.M.T.; Jones, S.W.; Mahmud, G.H. Experimental Test Methods to Determine the Uniaxial Tensile and Compressive Behaviour of Ultra High Performance Fibre Reinforced Concrete (UHPFRC). Constr. Build. Mater. 2012, 37, 874–882. [Google Scholar] [CrossRef]

- Kang, S.-T.; Lee, Y.; Park, Y.-D.; Kim, J.-K. Tensile Fracture Properties of an Ultra High Performance Fiber Reinforced Concrete (UHPFRC) with Steel Fiber. Compos. Struct. 2010, 92, 61–71. [Google Scholar] [CrossRef]

- Gesoglu, M.; Güneyisi, E.; Muhyaddin, G.F.; Asaad, D.S. Strain Hardening Ultra-High Performance Fiber Reinforced Cementitious Composites: Effect of Fiber Type and Concentration. Compos. Part B Eng. 2016, 103, 74–83. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; He, W.; Wu, L. Effects of Steel Fiber Content and Shape on Mechanical Properties of Ultra High Performance Concrete. Constr. Build. Mater. 2016, 103, 8–14. [Google Scholar] [CrossRef]

- Wille, K.; Naaman, A.E.; El-Tawil, S.; Parra-Montesinos, G.J. Ultra-High Performance Concrete and Fiber Reinforced Concrete: Achieving Strength and Ductility without Heat Curing. Mater. Struct. 2012, 45, 309–324. [Google Scholar] [CrossRef]

- Zhang, P.; Huang, Y.; Li, Y.; Zhao, J.; Dong, H.; Chen, T. Influence Factors on the Properties of Ultrahigh-Performance Fiber-Reinforced Concrete Cured under the Condition of Room Temperature. Adv. Civ. Eng. 2018, 2018, 1–9. [Google Scholar] [CrossRef]

- Nguyen Amanjean, E.; Mouret, M.; Vidal, T. Effect of Design Parameters on the Properties of Ultra-High Performance Fibre-Reinforced Concrete in the Fresh State. Constr. Build. Mater. 2019, 224, 1007–1017. [Google Scholar] [CrossRef]

- Park, S.H.; Kim, D.J.; Ryu, G.S.; Koh, K.T. Tensile Behavior of Ultra High Performance Hybrid Fiber Reinforced Concrete. Cem. Concr. Compos. 2012, 34, 172–184. [Google Scholar] [CrossRef]

- Yu, R.; Tang, P.; Spiesz, P.; Brouwers, H.J.H. A Study of Multiple Effects of Nano-Silica and Hybrid Fibres on the Properties of Ultra-High Performance Fibre Reinforced Concrete (UHPFRC) Incorporating Waste Bottom Ash (WBA). Constr. Build. Mater. 2014, 60, 98–110. [Google Scholar] [CrossRef]

- Kim, D.J.; Park, S.H.; Ryu, G.S.; Koh, K.T. Comparative Flexural Behavior of Hybrid Ultra High Performance Fiber Reinforced Concrete with Different Macro Fibers. Constr. Build. Mater. 2011, 25, 4144–4155. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; He, W.; Wang, D. Static and Dynamic Compressive Properties of Ultra-High Performance Concrete (UHPC) with Hybrid Steel Fiber Reinforcements. Cem. Concr. Compos. 2017, 79, 148–157. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Metaxa, Z.S.; Shah, S.P. Highly Dispersed Carbon Nanotube Reinforced Cement Based Materials. Cem. Concr. Res. 2010, 40, 1052–1059. [Google Scholar] [CrossRef]

- Chuah, S.; Pan, Z.; Sanjayan, J.G.; Wang, C.M.; Duan, W.H. Nano Reinforced Cement and Concrete Composites and New Perspective from Graphene Oxide. Constr. Build. Mater. 2014, 73, 113–124. [Google Scholar] [CrossRef]

- Gdoutos, E.E.; Konsta-Gdoutos, M.S.; Danoglidis, P.A. Portland Cement Mortar Nanocomposites at Low Carbon Nanotube and Carbon Nanofiber Content: A Fracture Mechanics Experimental Study. Cem. Concr. Compos. 2016, 70, 110–118. [Google Scholar] [CrossRef]

- Li, G.Y.; Wang, P.M.; Zhao, X. Mechanical Behavior and Microstructure of Cement Composites Incorporating Surface-Treated Multi-Walled Carbon Nanotubes. Carbon 2005, 43, 1239–1245. [Google Scholar] [CrossRef]

- Sun, H.; Ling, L.; Ren, Z.; Memon, S.A.; Xing, F. Effect of Graphene Oxide/Graphene Hybrid on Mechanical Properties of Cement Mortar and Mechanism Investigation. Nanomaterials 2020, 10, 113. [Google Scholar] [CrossRef]

- Lu, L.; Ouyang, D. Properties of Cement Mortar and Ultra-High Strength Concrete Incorporating Graphene Oxide Nanosheets. Nanomaterials 2017, 7, 187. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Jiang, R.; Wu, Z. Investigation of the Mechanical Properties and Microstructure of Graphene Nanoplatelet-Cement Composite. Nanomaterials 2016, 6, 200. [Google Scholar] [CrossRef]

- Stankovich, S.; Dikin, D.A.; Dommett, G.H.B.; Kohlhaas, K.M.; Zimney, E.J.; Stach, E.A.; Piner, R.D.; Nguyen, S.T.; Ruoff, R.S. Graphene-Based Composite Materials. Nature 2006, 442, 282–286. [Google Scholar] [CrossRef]

- Yu, M.-F.; Lourie, O.; Dyer, M.J.; Moloni, K.; Kelly, T.F.; Ruoff, R.S. Strength and Breaking Mechanism of Multiwalled Carbon Nanotubes under Tensile Load. Science 2000, 287, 637–640. [Google Scholar] [CrossRef]

- Tornabene, F.; Fantuzzi, N.; Bacciocchi, M. Linear Static Response of Nanocomposite Plates and Shells Reinforced by Agglomerated Carbon Nanotubes. Compos. Part B Eng. 2017, 115, 449–476. [Google Scholar] [CrossRef]

- Tornabene, F.; Bacciocchi, M.; Fantuzzi, N.; Reddy, J.N. Multiscale Approach for Three-Phase CNT/Polymer/Fiber Laminated Nanocomposite Structures. Polym. Compos. 2019, 40, E102–E126. [Google Scholar] [CrossRef]

- Meng, W.; Khayat, K.H. Mechanical Properties of Ultra-High-Performance Concrete Enhanced with Graphite Nanoplatelets and Carbon Nanofibers. Compos. Part B Eng. 2016, 107, 113–122. [Google Scholar] [CrossRef]

- Wille, K.; Loh, K.J. Nanoengineering Ultra-High-Performance Concrete with Multiwalled Carbon Nanotubes. Transp. Res. Rec. 2010, 2142, 119–126. [Google Scholar] [CrossRef]

- Ahmed Sbia, L.; Peyvandi, A.; Soroushian, P.; Lu, J.; Balachandra, A.M. Enhancement of Ultrahigh Performance Concrete Material Properties with Carbon Nanofiber. Adv. Civ. Eng. 2014, 2014, 1–10. [Google Scholar] [CrossRef]

- Kononova, O.; Krasnikovs, A.; Stonys, R.; Sahmenko, G.; Vitols, R. Investigation of influence of nano-reinforcement on the mechanical properties of composite materials. J. Civ. Eng. Manag. 2016, 22, 425–433. [Google Scholar] [CrossRef]

- Eftekhari, M.; Hatefi Ardakani, S.; Mohammadi, S. An XFEM Multiscale Approach for Fracture Analysis of Carbon Nanotube Reinforced Concrete. Theor. Appl. Fract. Mech. 2014, 72, 64–75. [Google Scholar] [CrossRef]

- Peerlings, R.H.J.; de Borst, R.; Brekelmans, W.A.M.; Geers, M.G.D. Gradient-Enhanced Damage Modelling of Concrete Fracture. Mech. Cohesive-Frict. Mater. 1998, 3, 323–342. [Google Scholar] [CrossRef]

- Leonetti, L.; Fantuzzi, N.; Trovalusci, P.; Tornabene, F. Scale Effects in Orthotropic Composite Assemblies as Micropolar Continua: A Comparison between Weak- and Strong-Form Finite Element Solutions. Materials 2019, 12, 758. [Google Scholar] [CrossRef]

- Chi, Y.; Yu, M.; Huang, L.; Xu, L. Finite Element Modeling of Steel-Polypropylene Hybrid Fiber Reinforced Concrete Using Modified Concrete Damaged Plasticity. Eng. Struct. 2017, 148, 23–35. [Google Scholar] [CrossRef]

- Othman, H.; Marzouk, H. Applicability of Damage Plasticity Constitutive Model for Ultra-High Performance Fibre-Reinforced Concrete under Impact Loads. Int. J. Impact Eng. 2018, 114, 20–31. [Google Scholar] [CrossRef]

- Hameed, R.; Sellier, A.; Turatsinze, A.; Duprat, F. Metallic Fiber-Reinforced Concrete Behaviour: Experiments and Constitutive Law for Finite Element Modeling. Eng. Fract. Mech. 2013, 103, 124–131. [Google Scholar] [CrossRef]

- Bruno, D.; Greco, F. Delamination in Composite Plates: Influence of Shear Deformability on Interfacial Debonding. Cem. Concr. Compos. 2001, 23, 33–45. [Google Scholar] [CrossRef]

- Greco, F.; Lonetti, P.; Zinno, R. An Analytical Delamination Model for Laminated Plates Including Bridging Effects. Int. J. Solids Struct. 2002, 39, 2435–2463. [Google Scholar] [CrossRef]

- Greco, F. Homogenized Mechanical Behavior of Composite Micro-Structures Including Micro-Cracking and Contact Evolution. Eng. Fract. Mech. 2009, 76, 182–208. [Google Scholar] [CrossRef]

- Pascuzzo, A.; Yudhanto, A.; Alfano, M.; Lubineau, G. On the Effect of Interfacial Patterns on Energy Dissipation in Plastically Deforming Adhesive Bonded Ductile Sheets. Int. J. Solids Struct. 2020, 198, 31–40. [Google Scholar] [CrossRef]

- Kazemi, M.T.; Fazileh, F.; Ebrahiminezhad, M.A. Cohesive Crack Model and Fracture Energy of Steel-Fiber-Reinforced-Concrete Notched Cylindrical Specimens. J. Mater. Civ. Eng. 2007, 19, 884–890. [Google Scholar] [CrossRef]

- Park, K.; Paulino, G.H.; Roesler, J. Cohesive Fracture Model for Functionally Graded Fiber Reinforced Concrete. Cem. Concr. Res. 2010, 40, 956–965. [Google Scholar] [CrossRef]

- Suárez, F.; Gálvez, J.C.; Enfedaque, A.; Alberti, M.G. Modelling Fracture on Polyolefin Fibre Reinforced Concrete Specimens Subjected to Mixed-Mode Loading. Eng. Fract. Mech. 2019, 211, 244–253. [Google Scholar] [CrossRef]

- Zhan, Y.; Meschke, G. Multilevel Computational Model for Failure Analysis of Steel-Fiber–Reinforced Concrete Structures. J. Eng. Mech. 2016, 142, 04016090. [Google Scholar] [CrossRef]

- De Maio, U.; Greco, F.; Leonetti, L.; Luciano, R.; Nevone Blasi, P.; Vantadori, S. A Refined Diffuse Cohesive Approach for the Failure Analysis in Quasibrittle Materials—Part I: Theoretical Formulation and Numerical Calibration. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 221–241. [Google Scholar] [CrossRef]

- De Maio, U.; Fabbrocino, F.; Greco, F.; Leonetti, L.; Lonetti, P. A Study of Concrete Cover Separation Failure in FRP-Plated RC Beams via an Inter-Element Fracture Approach. Compos. Struct. 2019, 212, 625–636. [Google Scholar] [CrossRef]

- De Maio, U.; Greco, F.; Leonetti, L.; Luciano, R.; Nevone Blasi, P.; Vantadori, S. A Refined Diffuse Cohesive Approach for the Failure Analysis in Quasibrittle Materials—Part II: Application to Plain and Reinforced Concrete Structures. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 2764–2781. [Google Scholar] [CrossRef]

- Klein, P.A.; Foulk, J.W.; Chen, E.P.; Wimmer, S.A.; Gao, H.J. Physics-Based Modeling of Brittle Fracture: Cohesive Formulations and the Application of Meshfree Methods. Theor. Appl. Fract. Mech. 2001, 37, 99–166. [Google Scholar] [CrossRef]

- Espinosa, H.D.; Zavattieri, P.D. A Grain Level Model for the Study of Failure Initiation and Evolution in Polycrystalline Brittle Materials. Part I: Theory and Numerical Implementation. Mech. Mater. 2003, 35, 333–364. [Google Scholar] [CrossRef]

- Tomar, V.; Zhai, J.; Zhou, M. Bounds for Element Size in a Variable Stiffness Cohesive Finite Element Model. Int. J. Numer. Methods Eng. 2004, 61, 1894–1920. [Google Scholar] [CrossRef]

- Blal, N.; Daridon, L.; Monerie, Y.; Pagano, S. Artificial Compliance Inherent to the Intrinsic Cohesive Zone Models: Criteria and Application to Planar Meshes. Int. J. Fract. 2012, 178, 71–83. [Google Scholar] [CrossRef]

- Park, K.; Paulino, G.H.; Roesler, J.R. Determination of the Kink Point in the Bilinear Softening Model for Concrete. Eng. Fract. Mech. 2008, 75, 3806–3818. [Google Scholar] [CrossRef]

- Fantilli, A.P.; Mihashi, H.; Vallini, P. Multiple Cracking and Strain Hardening in Fiber-Reinforced Concrete under Uniaxial Tension. Cem. Concr. Res. 2009, 39, 1217–1229. [Google Scholar] [CrossRef]

- Marchand, P.; Baby, F.; Khadour, A.; Battesti, T.; Rivillon, P.; Quiertant, M.; Nguyen, H.-H.; Généreux, G.; Deveaud, J.-P.; Simon, A.; et al. Bond Behaviour of Reinforcing Bars in UHPFRC. Mater. Struct. 2016, 49, 1979–1995. [Google Scholar] [CrossRef]

- New Model Code Fib Special Activity Group; Taerwe, L.; Matthys, S. Fib Model Code for Concrete Structures 2010; Ernst & Sohn: Berlin, Germany, 2013. [Google Scholar]

- COMSOL AB. COMSOL Multiphysics Reference Manual; COMSOL AB: Stockholm, Sweden, 2020. [Google Scholar]

- Gao, B.; Kim, J.-K.; Leung, C.K.Y. Experimental Study on RC Beams with FRP Strips Bonded with Rubber Modified Resins. Compos. Sci. Technol. 2004, 64, 2557–2564. [Google Scholar] [CrossRef]

- Petersson, P.-E. Crack Growth and Development of Fracture Zones in Plain Concrete and Similar Materials. Ph.D. Thesis, Lund Institute of Technology, Lund, Sweden, December 1981. [Google Scholar]

- Qasem, A.; Sallam, Y.S.; Hossam Eldien, H.; Ahangarn, B.H. Bond-Slip Behavior between Ultra-High-Performance Concrete and Carbon Fiber Reinforced Polymer Bars Using a Pull-out Test and Numerical Modelling. Constr. Build. Mater. 2020, 260, 119857. [Google Scholar] [CrossRef]

- Greco, F.; Leonetti, L.; Luciano, R. A Multiscale Model for the Numerical Simulation of the Anchor Bolt Pull-out Test in Lightweight Aggregate Concrete. Constr. Build. Mater. 2015, 95, 860–874. [Google Scholar] [CrossRef]

- Greco, F.; Leonetti, L.; Medaglia, C.M.; Penna, R.; Pranno, A. Nonlinear Compressive Failure Analysis of Biaxially Loaded Fiber Reinforced Materials. Compos. Part B Eng. 2018, 147, 240–251. [Google Scholar] [CrossRef]

- Greco, F.; Leonetti, L.; Pranno, A.; Rudykh, S. Mechanical Behavior of Bio-Inspired Nacre-like Composites: A Hybrid Multiscale Modeling Approach. Compos. Struct. 2020, 233, 111625. [Google Scholar] [CrossRef]

- Greco, F.; Leonetti, L.; Lonetti, P.; Luciano, R.; Pranno, A. A Multiscale Analysis of Instability-Induced Failure Mechanisms in Fiber-Reinforced Composite Structures via Alternative Modeling Approaches. Compos. Struct. 2020, 251, 112529. [Google Scholar] [CrossRef]

- Greco, F.; Leonetti, L.; Luciano, R.; Trovalusci, P. Multiscale Failure Analysis of Periodic Masonry Structures with Traditional and Fiber-Reinforced Mortar Joints. Compos. Part B Eng. 2017, 118, 75–95. [Google Scholar] [CrossRef]

| Specific Gravity [g/cm3] | Elastic Modulus [GPa] | Tensile Strength [MPa] | Dimensions | |

|---|---|---|---|---|

| GNP | 1.95 | 1000 | 5000 |  |

| Straight steel fiber | 7.85 | 203 | 1900 |  |

| [MPa] | [N/m] | [mm] | ||||

|---|---|---|---|---|---|---|

| UHPFRC | 5.71 1 | 40 | 350 | 1800 | 0.005 | 3.25 |

| UHPFRC GNP 0.05% | 6.14 1 | 50 | 375 | 2800 | 0.005 | 3.25 |

| UHPFRC GNP 0.1% | 6.81 1 | 60 | 400 | 3800 | 0.005 | 3.25 |

| Young’s Modulus [GPa] | Poisson’s Ratio [-] | Yield Strength [MPa] | Tangent Modulus [GPa] | Compressive Strength [MPa] | |

|---|---|---|---|---|---|

| Steel | 200 | 0.3 | 460 | 2.0 | - |

| UHPRFC | 40 | 0.2 | - | - | 174 |

| UHPRFC GNP 0.05% | 40 | 0.2 | - | - | 176 |

| UHPRFC GNP 0.1% | 40 | 0.2 | - | - | 178 |

| Average Crack Width [mm] | Crack Spacing [mm] | Beam Deflection [mm] | |

|---|---|---|---|

| UHPFRC | 0.093 | 91 | 3.80 |

| UHPFRC GNP 0.05% | 0.080 | 84 | 3.30 |

| UHPFRC GNP 0.1% | 0.064 | 84 | 2.75 |

| Average Crack Width [mm] | Crack Spacing [mm] | Beam Deflection [mm] | |

|---|---|---|---|

| UHPFRC | 0.027 | 100 | 1.20 |

| UHPFRC GNP 0.05% | 0.019 | 100 | 1.00 |

| UHPFRC GNP 0.1% | 0.012 | 100 | 0.85 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Maio, U.; Fantuzzi, N.; Greco, F.; Leonetti, L.; Pranno, A. Failure Analysis of Ultra High-Performance Fiber-Reinforced Concrete Structures Enhanced with Nanomaterials by Using a Diffuse Cohesive Interface Approach. Nanomaterials 2020, 10, 1792. https://doi.org/10.3390/nano10091792

De Maio U, Fantuzzi N, Greco F, Leonetti L, Pranno A. Failure Analysis of Ultra High-Performance Fiber-Reinforced Concrete Structures Enhanced with Nanomaterials by Using a Diffuse Cohesive Interface Approach. Nanomaterials. 2020; 10(9):1792. https://doi.org/10.3390/nano10091792

Chicago/Turabian StyleDe Maio, Umberto, Nicholas Fantuzzi, Fabrizio Greco, Lorenzo Leonetti, and Andrea Pranno. 2020. "Failure Analysis of Ultra High-Performance Fiber-Reinforced Concrete Structures Enhanced with Nanomaterials by Using a Diffuse Cohesive Interface Approach" Nanomaterials 10, no. 9: 1792. https://doi.org/10.3390/nano10091792

APA StyleDe Maio, U., Fantuzzi, N., Greco, F., Leonetti, L., & Pranno, A. (2020). Failure Analysis of Ultra High-Performance Fiber-Reinforced Concrete Structures Enhanced with Nanomaterials by Using a Diffuse Cohesive Interface Approach. Nanomaterials, 10(9), 1792. https://doi.org/10.3390/nano10091792